1. Introduction

In the design of servo drive system controllers, in order to achieve a better response process or higher positioning accuracy, the controller parameter tuning usually needs to be substituted for mechanical parameter values. For example, in the design of a speed loop controller, the accurate rotational inertia is necessary. Otherwise, mismatched parameters will lead to slow dynamic response or poor steady-state performance of the system [

1]. Manufacturer’s production differences or variations in operating conditions may cause changes in the mechanical parameters of the system, resulting in a decline in control performance, so it is crucial to identify the mechanical parameters of the study.

In 1956, L.A. Zadeh first put forward the concept of "identification", and then gave its definition in 1962: system identification is to determine a mathematical model equivalent to the identification system from a set of model classes based on input and output observations of the identification system [

2]. Since then, domestic and foreign parameter identification technology has developed rapidly, and related algorithms have been applied to the field of motor drive by scholars.

Parameters in a servo drive system include internal electrical parameters (resistance, inductance, magnetic chain, etc.) and external mechanical parameters (rotational inertia, friction damping, drive shaft stiffness, etc.), where the internal parameters are used for the design of a current loop controller, and the external parameters are used for the design of a speed loop controller. The main difference between a single-inertia and a multi-inertia system parameter identification is the difference in external mechanical parameters, and the multi-inertia system adds the mechanical parameters of the transmission mechanism in addition to the parameters of the drive motor and load. The identification algorithms of each parameter in a single-inertia system have been more mature, including acceleration and deceleration methods, least squares and improvement algorithms [

3], model reference adaptive method [

4], observer-based method [

5], extended Kalman filtering method [

6], etc. Currently, this function is available in servo drives such as Mitsubishi MR-JE-40A and Panasonic A6 [

7] in Japan. The multi-inertia system parameter identification is represented by double inertia, due to the mechanical structure of the introduction of more parameters, complex working conditions and other issues appear more difficult. However, since the technology has not yet matured, the application of the method is not as rich as the single inertia system. At present, there are mainly two types of methods: parametric and non-parametric methods.

The parametric method recognizes the system parameters by assuming a system model such that the difference between its output and the actual output of the system satisfies a set performance index function. With the development of digitalization, the assumed system model has been transformed from a continuous data discrimination model to a discrete data discrimination model. Seppo E. Sarika’s team at Aalto University, Finland, used a discrete-time polynomial model with an Output Error (OE) structure in 2012 and a random binary sequence as the excitation signal. The comparisons of the identification accuracy under different test methods, such as open loop, indirect closed loop, and direct closed loop, pointed out that the identification results deviated greatly in the case of a closed loop at speed due to the influence of the controller [

8]. In order to overcome the difficulties of closed-loop identification, the team proposed an improved indirect method in 2013, which used a pseudo random binary sequence (PRBS) as the excitation signal for six external mechanical parameters (drive motor inertia and friction coefficient, load motor inertia and friction coefficient, driveshaft stiffness and friction coefficient), and a random binary sequence (PRBS) as the excitation signal. PRBS (Pseudo Random Binary Sequence) as the excitation signal, combined with the least squares method, to find out the parameters in the discrete domain, and then transformed to the frequency domain through the zero-pole matching method, to obtain the identification results. However, due to its cumbersome arithmetic process, it needs to be combined with dSPACE, which limits its application in industry [

9]. Literature [

10] considered the different identification settings and gave simulation and experimental results for two different mechanism signals, PRBS and Chirp, under ARX and OE identification models, respectively.

The non-parametric method achieves identification based on the system response curve, such as impulse response and frequency response characteristics. Literature [

11] superimposed PRBS on the stator current component

iq for system excitation without encoder, used an extended speed adaptive observer to obtain the motor rotational speed, performed signal processing, calculated the frequency response, plotted the Baud plot and obtained the resonance frequency by Welch's method. Literature [

12] proposed a send generation identification method using linearized weighted overall least squares, which derived the transfer function under the premise that the system resonance characteristics were unknown and there was a time delay, and completed the fixed order based on the coefficient map to obtain the transfer function reflecting the mechanical resonance characteristics and time lag, with a high identification accuracy. However, the nonparametric identification method cannot be used for systems with serious nonlinear features, because the nonlinear features will greatly change the system frequency response, resulting in poor identification accuracy [

13].

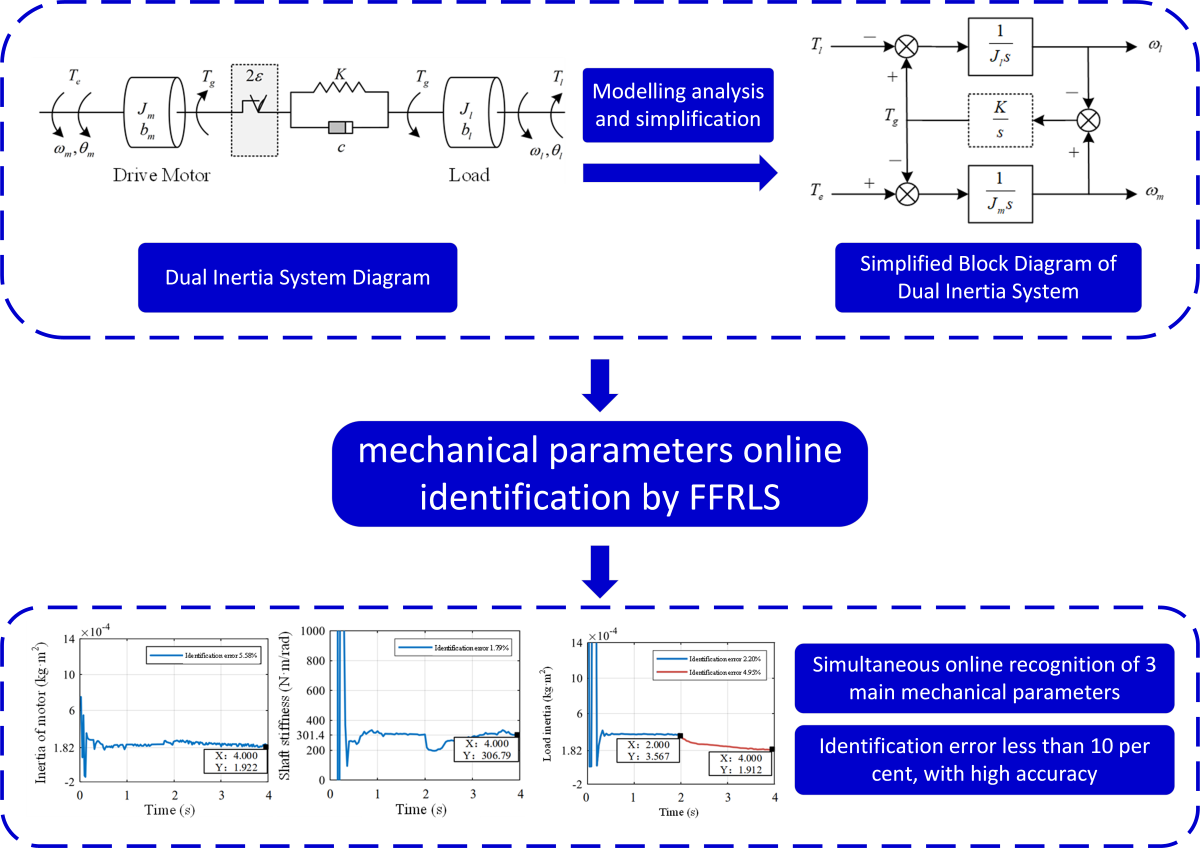

Inspired by the references, this paper firstly establishes the mathematical model of a dual-inertia servo system, secondly constructs the discrete identification function by the recursive least squares method with a forgetting factor, then realizes the on-line identification of the main mechanical parameters and at the same time analyses the influencing factors of the identification accuracy, and finally proves the validity of the identification algorithm by simulation and experiment.

2. Mathematical Modelling of Dual Inertia Systems

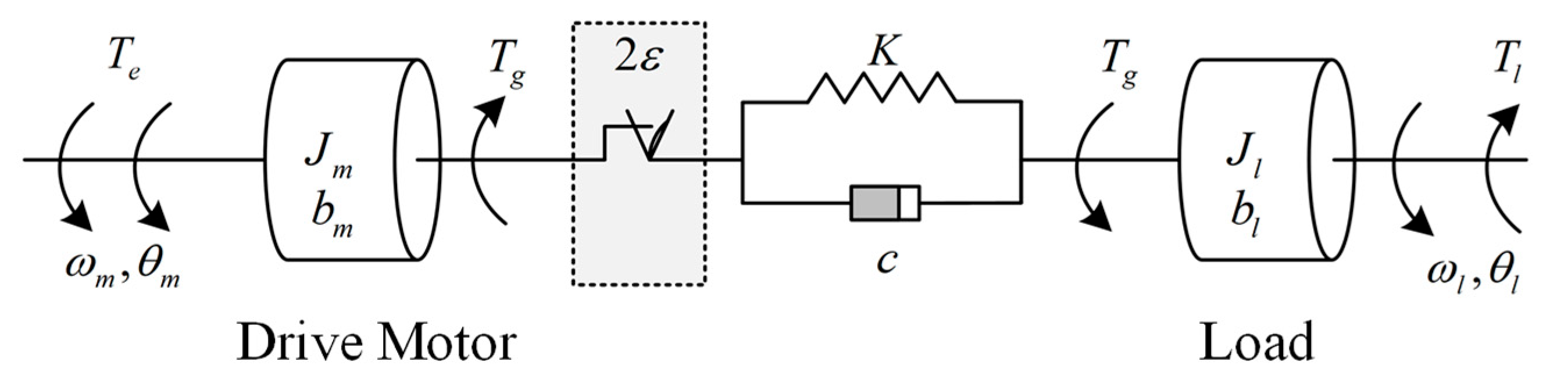

In a dual-inertia system, the drive motor and the load are connected via a driveshaft with a torsional stiffness of

K, a damping coefficient of

c, a clearance of 2

ε, and a simplified ratio of 1, as shown in

Figure 1.

Considering that the effect of the gap is mainly reflected in the initial position of non-engagement or changes in the direction of motion to produce positioning errors, while in the identification of mechanical parameters can be maintained in one direction of rotation, necessarily engaged. Therefore, the clearance only has an effect at the initial stage of identification and does not affect the final iteration results. Neglecting the gap, the coupling inertia, the damping coefficient of each part, that is, the mechanical parameters to be identified are simplified as the drive motor inertia

Jm, the coupling stiffness

K and load inertia

Jl, and analyze the motion process of each inertial body in the double inertia system to establish a mathematical model: when the drive is given a current to generate the electromagnetic torque

Te, which drives the drive motor with rotational inertia of

Jm to rotate, and the load side is static due to the inertia, and the existence of the angular difference that This causes the drive shaft to twist and deform, generating a transfer torque. This torque is both the load torque of the drive motor and the driving torque of the load, which acts together with the load-side torque

Tl to determine the load speed. The mathematical model of the above process is as follows:

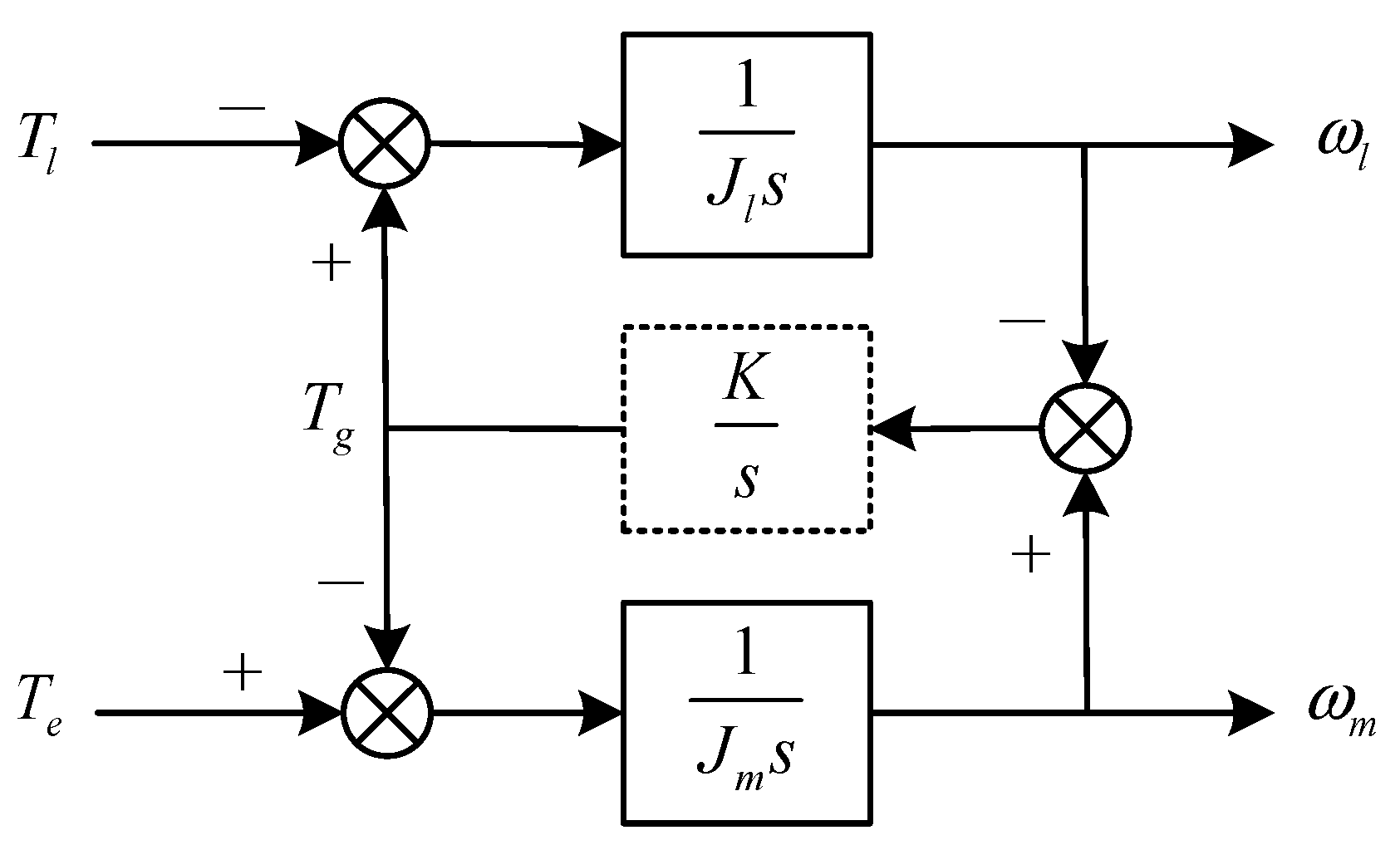

A simplified block diagram of the dual-inertia system is shown in

Figure 2.

The motor speed is determined by the electromagnetic torque and load torque together, and its transfer function is

where the transfer function from motor speed to electromagnetic torque is

From (3), the system exists a pair of conjugates zero poles, the conjugate zero point is the Anti-resonance Frequency (ARF), the conjugate poles are the Natural Torsional Frequency (NTF), the zero poles make the system produce a relatively strong response to the input of a specific frequency, i.e., trigger mechanical resonance. The zero pole causes the system to respond more strongly to a specific frequency input, i.e., triggering a mechanical resonance.

6. Experimental Verification

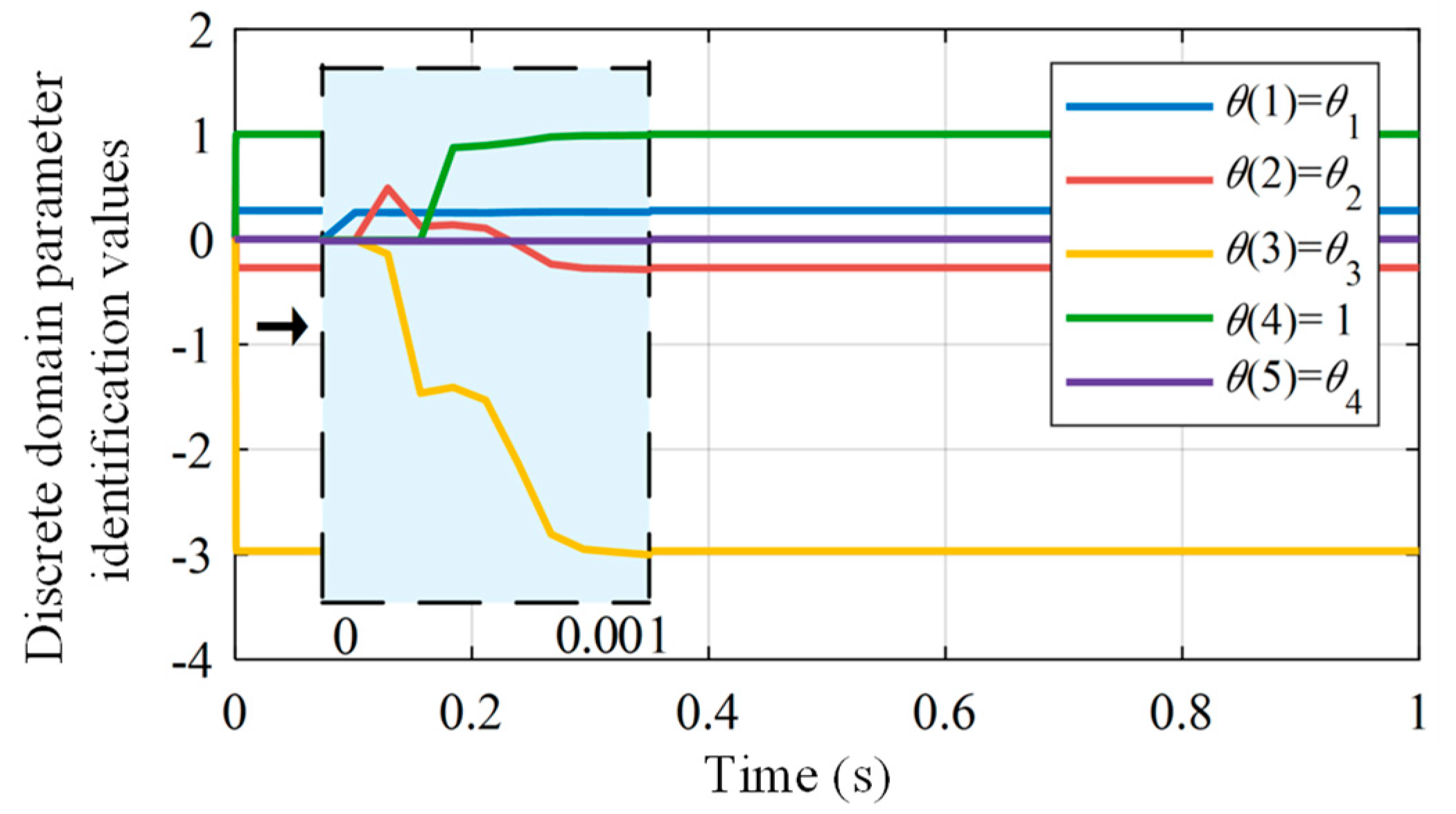

The iterative algorithm designed in section 3.3.2 is a fifth-order matrix operation, which takes more time, and FFRLS also has requirements for discrete time (i.e. sampling time), so it is necessary to test the algorithm time. The clock period of the controller used in the experiment is 0.67ns, and the running time of the test programmed using breakpoints is 4994 clock cycles (33μs) for the motor control programmed, and the time of the parameter recognition algorithm is shown in

Table 4, with a total running time of 84μs for no-load operation, and 121μs for with-load operation When the current loop control frequency is 10kHz and the speed loop control frequency is 1kHz, the recognition time in the loaded case the discrimination time exceeds one current loop cycle. In order to simplify the control and improve the recognition accuracy as much as possible, the sampling time is 0.0002s.

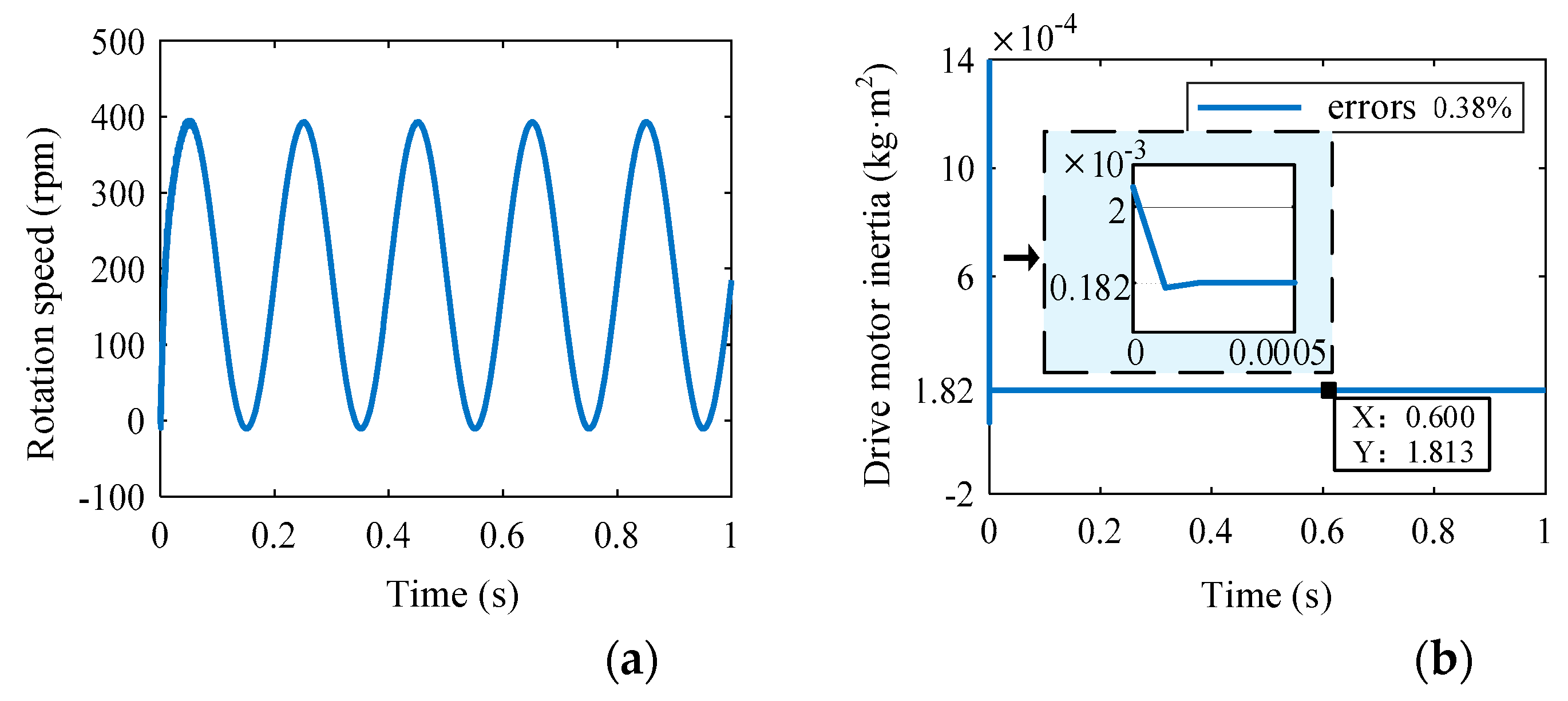

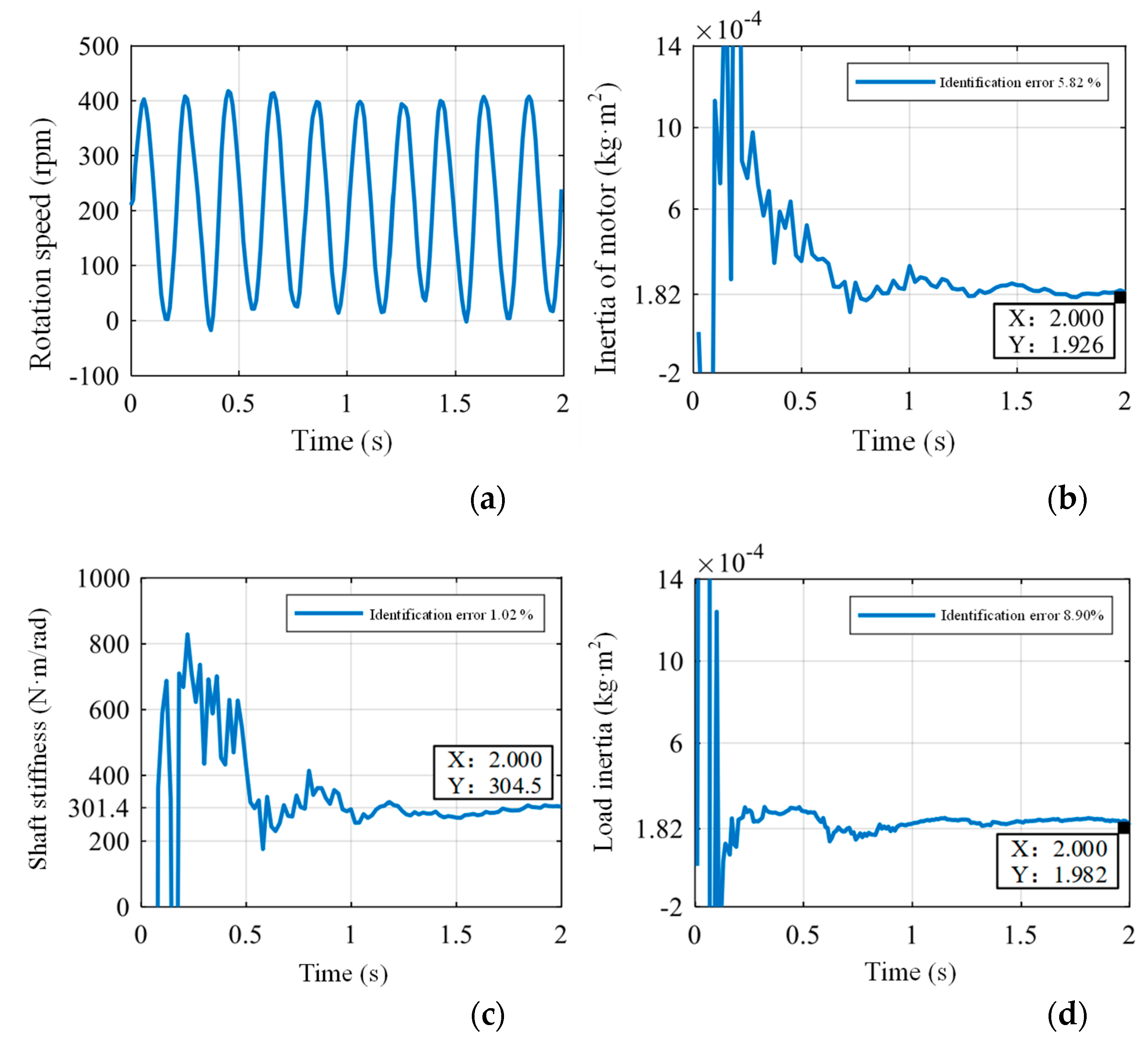

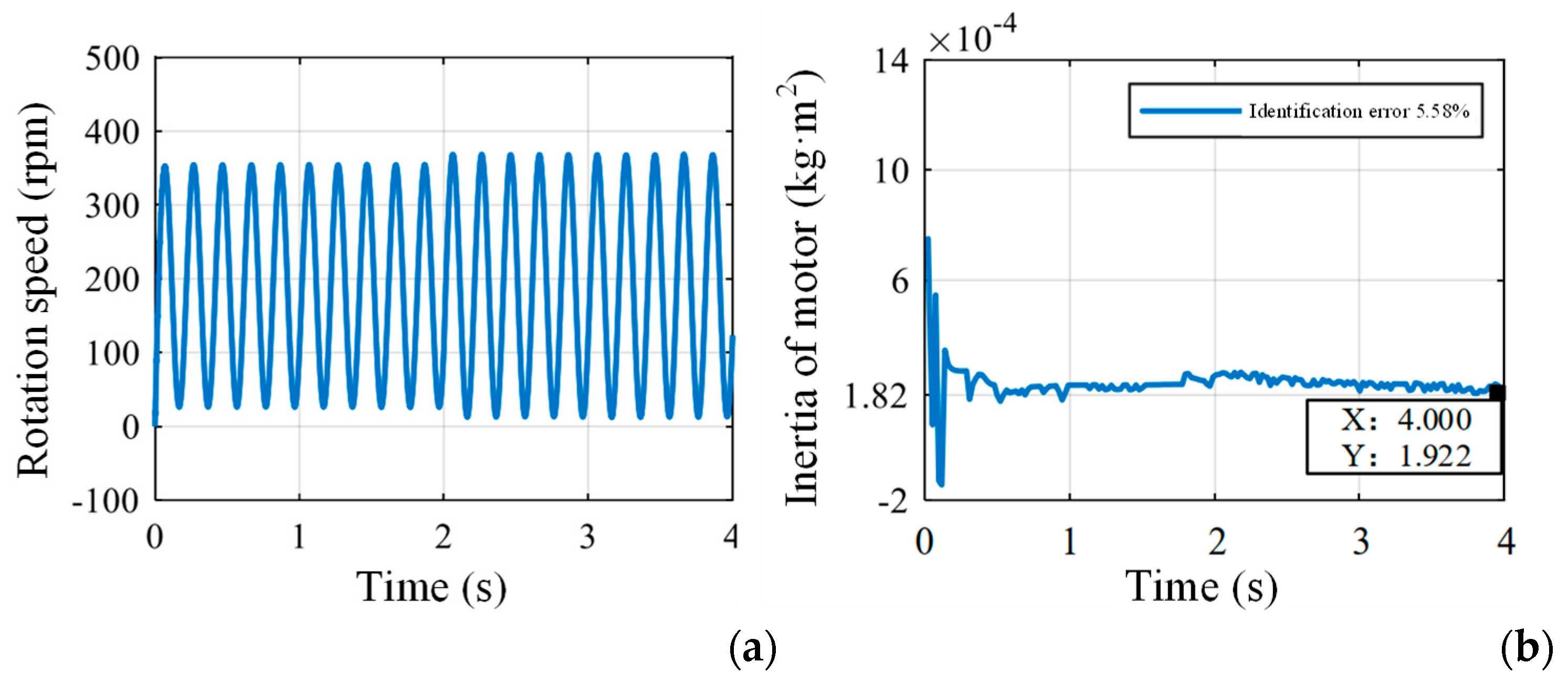

Given

nr*=200+200sin(5πt) rpm with sinusoidal speed, the system response waveform and the convergence waveform of the discriminated values of mechanical parameters are shown in

Figure 6. It is considered to be basically converged in 0.6s, and the discriminated values of the drive motor inertia, load inertia, and shaft stiffness in 2s are 1.93×10

-4kg·m2, 1.98×10

-4kg·m2, and 304.5 N·m/rad, with identification errors of 5.82%, 8.90%, and 1.02%, respectively.

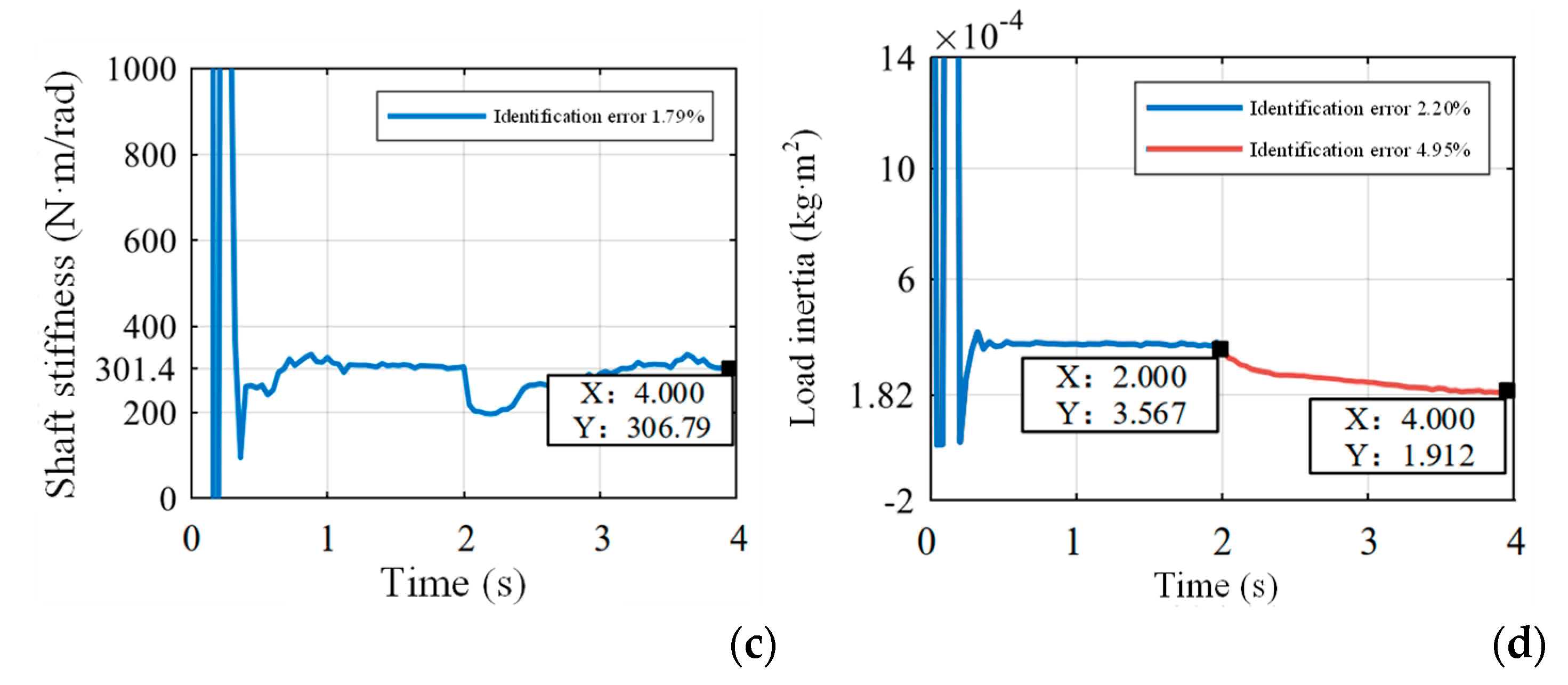

Figure 7 shows the system response and recognition waveforms when the load inertia changes suddenly. The load inertia decreases from 2

Jl to

Jl at 2s, the drive motor inertia and shaft stiffness converge to the real value after fluctuation, while the load inertia converges slower and the recognition accuracy decreases from 2.2% to 4.95%, which is due to the fact that the covariance matrix

P is not re-initialized.

7. Conclusions

In this paper, to address the problem of unknown or inaccurate mechanical parameters, especially load-side inertia, in non-direct-drive servo systems, firstly, the system is simplified into a dual-inertia system, its equations of motion are analyzed and mathematically modelled. Secondly, using the least recursive squares method with forgetting factor, an online identification algorithm of the main mechanical parameters of the dual-inertia system is constructed to accurately obtain the dual-side inertia of the system and the stiffness of the coupling. The algorithm chooses the bilinear transformation discretization method, which avoids the computational solution of nonlinear equations and shortens the parameter conversion time of the algorithm. Finally, the proposed algorithm is simulated and experimentally verified, and the influencing factors of the recognition accuracy are discussed. The total time of the recognition algorithm under unloaded and loaded conditions is 51μs and 88μs respectively. The experiment shows that the mechanical parameter recognition algorithm of the dual-inertia system can simultaneously recognize the three main mechanical parameters online, and the recognition accuracy is high and has certain robustness.