Submitted:

17 June 2024

Posted:

19 June 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

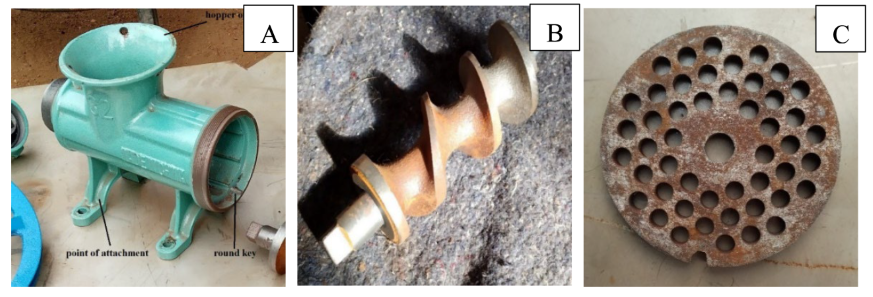

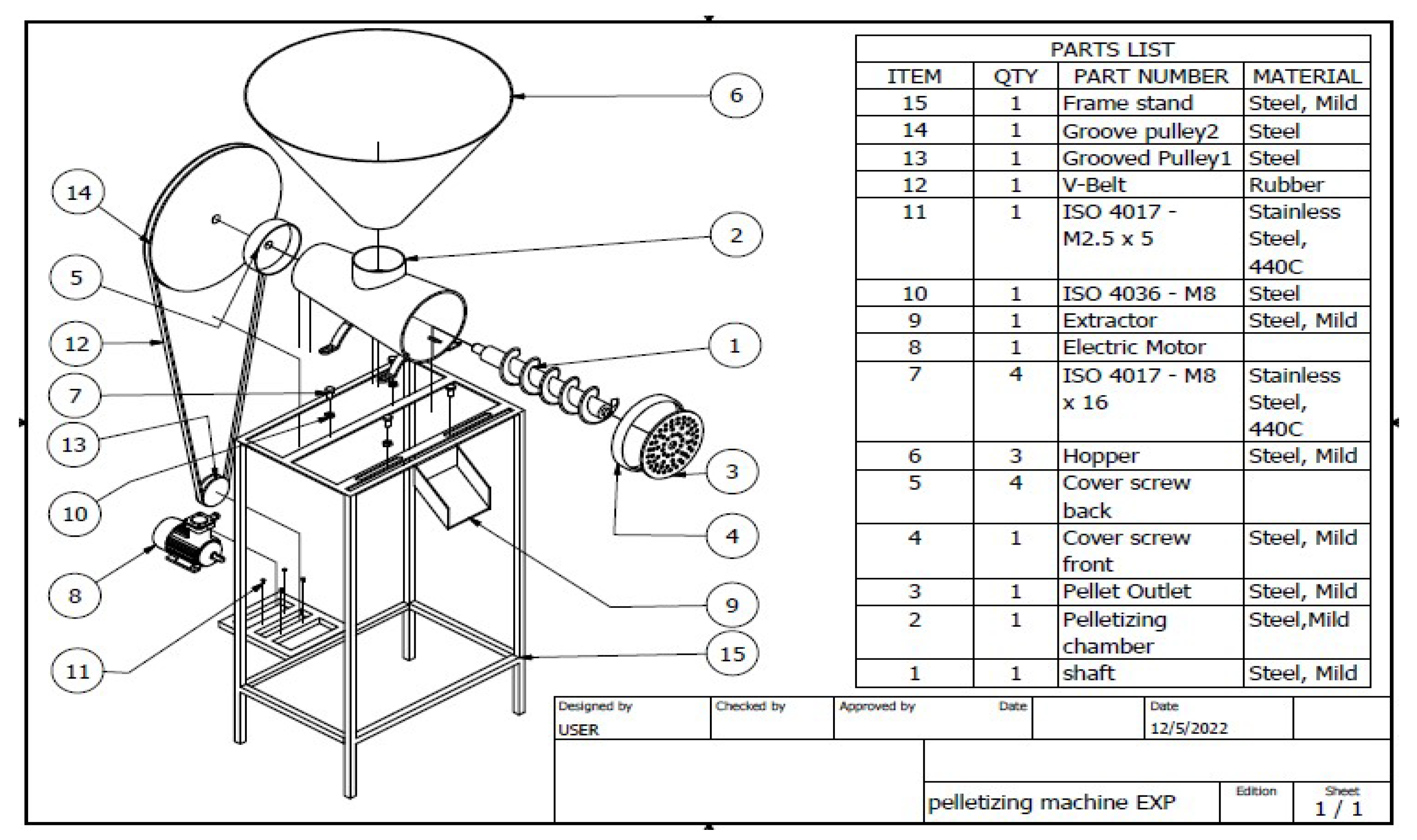

2.1. Description of the Existing Fish Feed Pelletizing Machines

- a.

- Compression Chamber

- b.

- Auger

- c.

- Die Plate

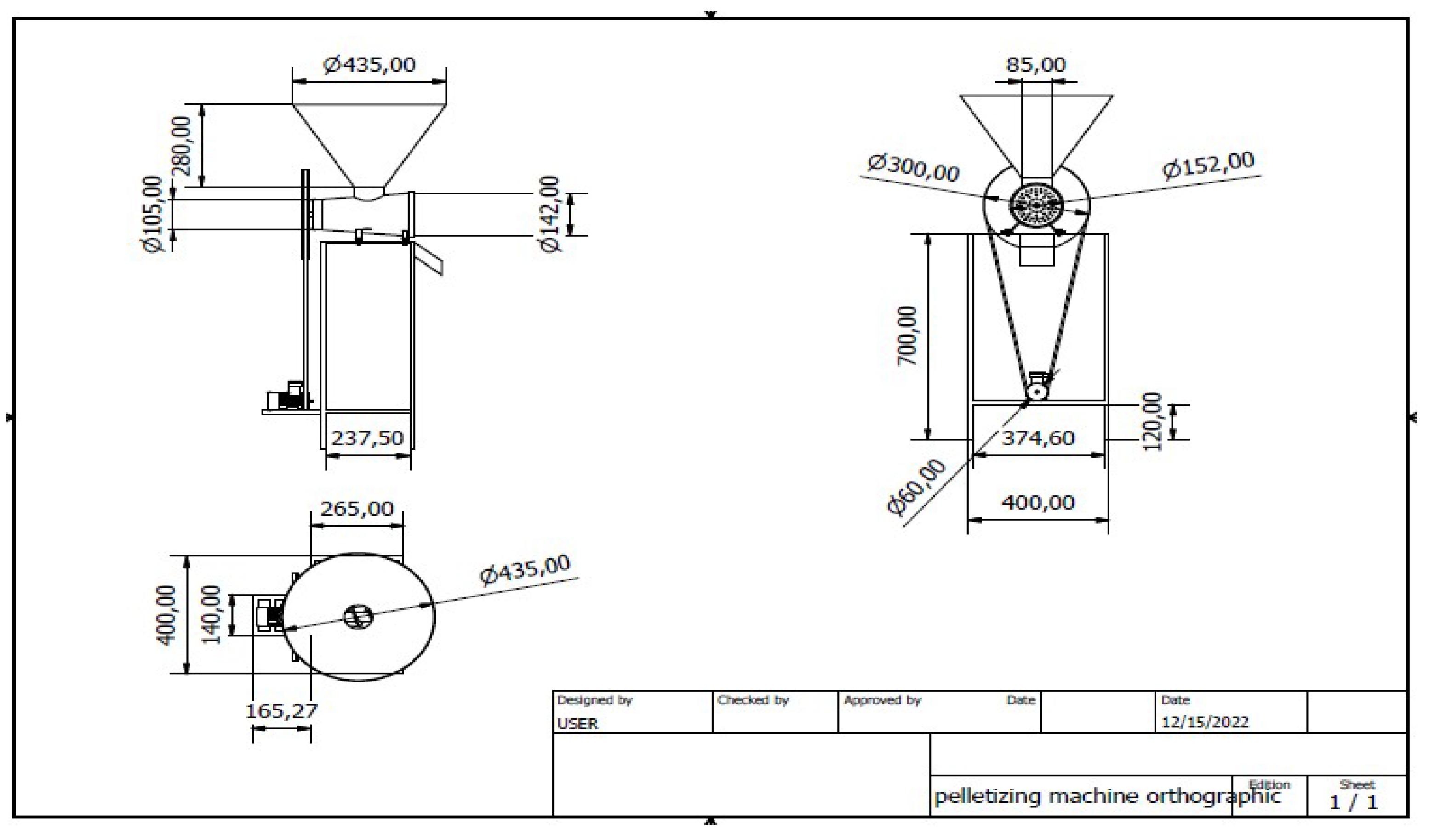

2.2. Design of Other Components

2.2.1. Design of Hopper Extension

| R = top radius = 217.5 mm |  |

| r = base radius = 45 mm | |

| h = height of frustum = 280 mm |

2.2.2. Power Required to Drive the Screw Conveyor

2.2.3. Design of Belt Drive System for Power Transmission

- (a)

- Speed of driven pulley

- Power range = 0.7-3.5 kW

- Top width (b) = 0.013 m

- Thickness (t) = 0.008 m

- Cross sectional area= b × t = 0.000104 m2

- Coefficient of friction = 0.25

- Density of rubber belt = 1000 kg/m3

- Permissible stress = 2.8 MPa

- (b)

- Belt velocity

- (c)

- Centrifugal tension of belt

- (d)

- Tension in belt

- (e)

- Power transmitted by belt

- (f)

- Torque transmitted by belt

2.3. Fabrication and Assemblage of the Pelleting Machine

2.4. Experimental Procedure

2.4.1. Feedstock Collection and Preparation

- a.

- Corncob

- b.

- Preparation of Binder (cassava starch)

- c.

- Mixing of corncobs with binder (Feedstock mixture)

2.4.2. Performance Evaluation Procedure

- (a)

- Machine efficiency

- (b).

- Machine throughput (MT)

2.4.3. Evaluation of Pellets Properties

- The length of pellets were measured using the method of Prulovic et al. [37]. Ten pellets were randomly selected from each experimental sample. The length (L) of each pellet was measured using a digital Vernier caliper and the average length was calculated as the mean of the lengths of the selected pellets.

- The bulk density of pellets were determined according to ASTM E873-82 [31] standard method. Sample weight of pellets was packed in a measuring cylinder. The weight of the sample (g) was divided by the volume (cm3) of the measuring cylinder. The bulk density was measured in triplicate and the average value recorded. The bulk density was calculated from the relationship in Equation 18 [39].

2.5. Experimental Design

3. Results and Discusssion

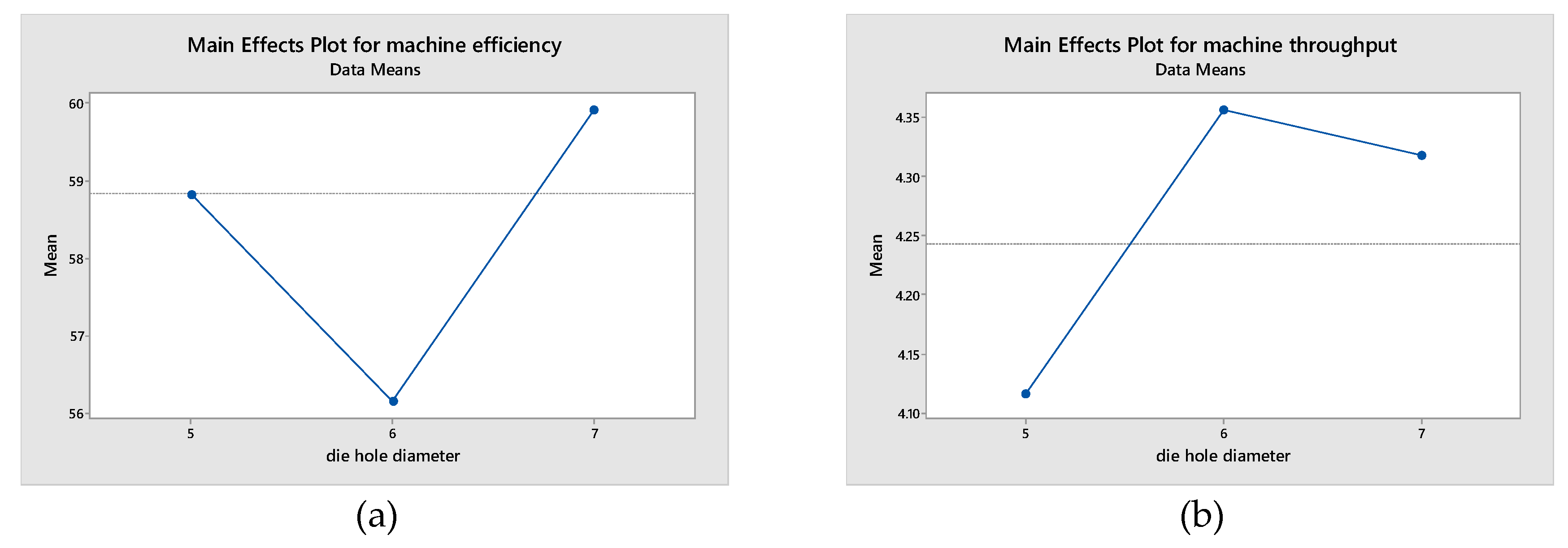

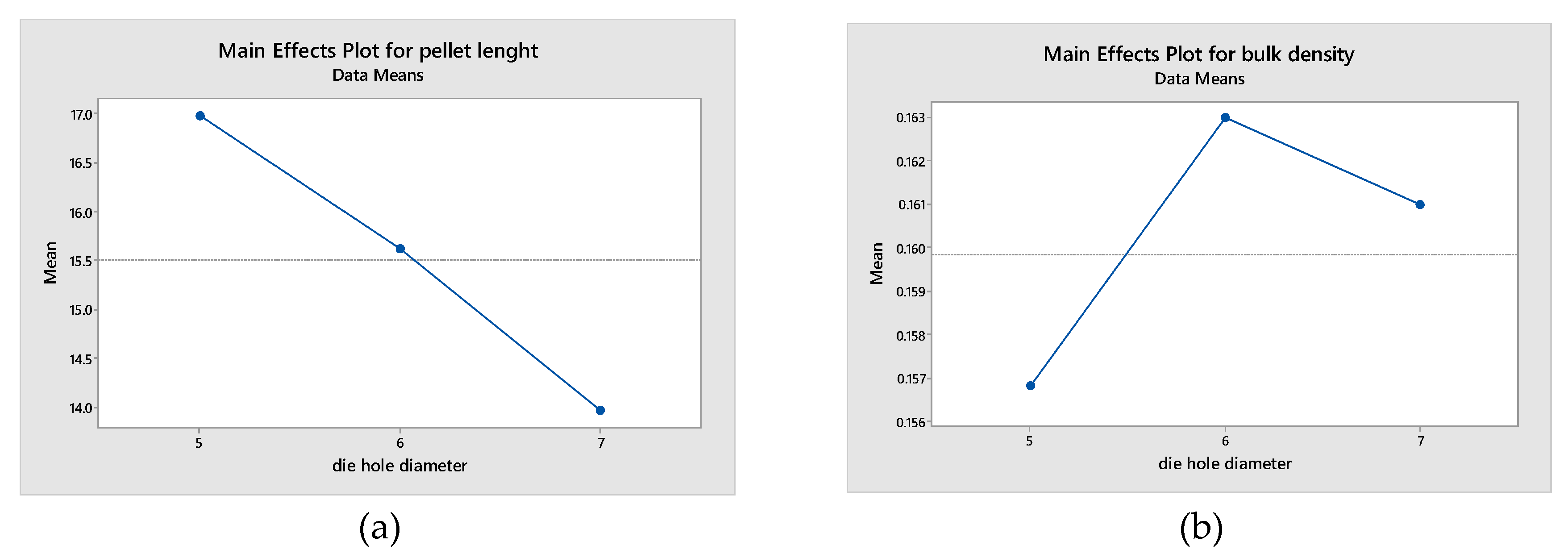

3.1. Effect of Die Hole Diameter on Machine Performance

3.2. Effect of Die Hole Diameter on Pellet Properties

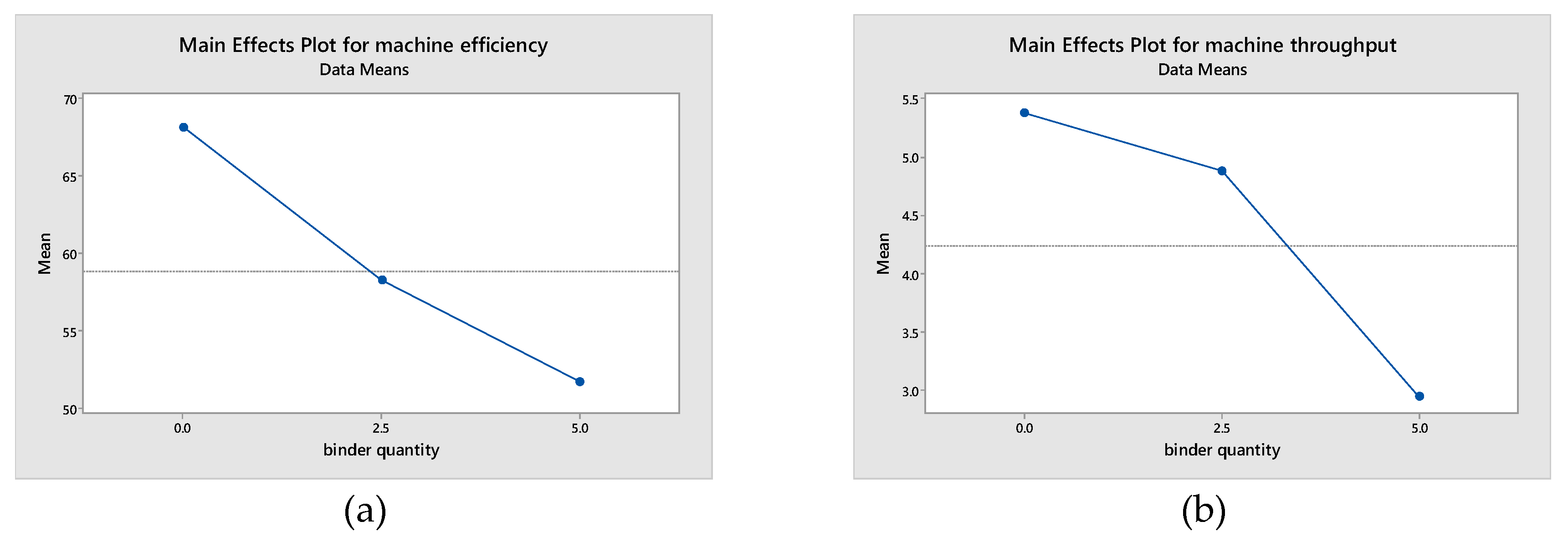

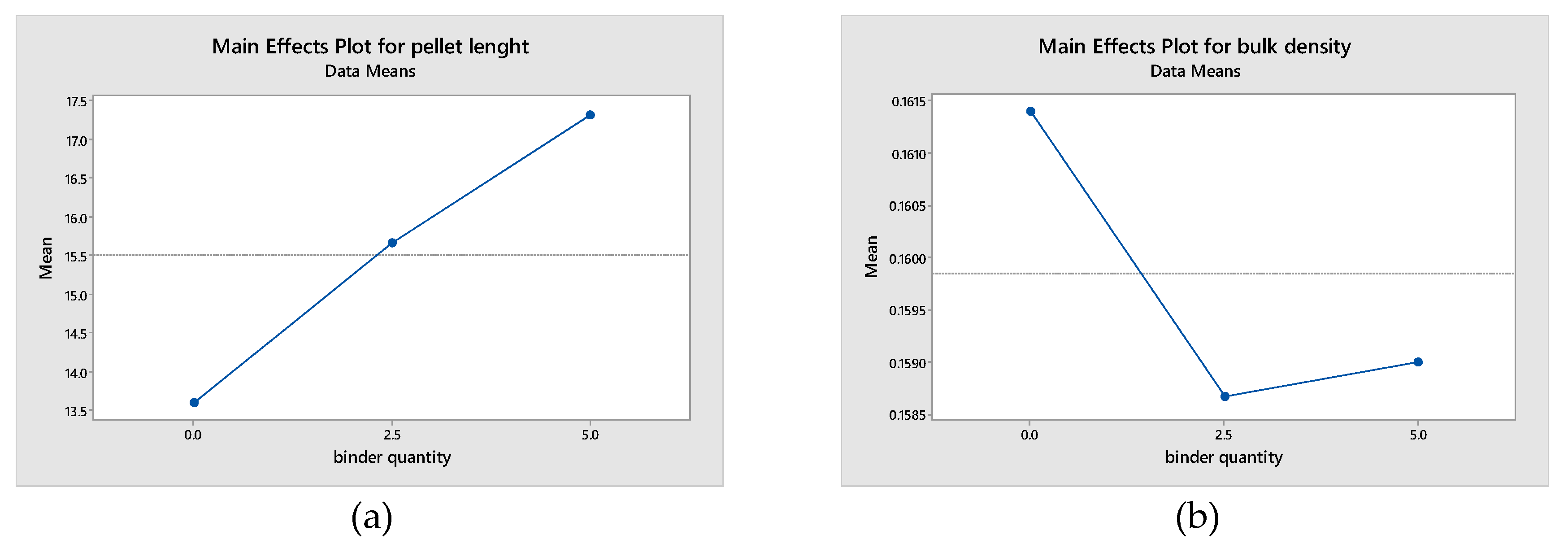

3.3. Effect of Binder Quantity on Machine Performance

3.4. Effect of Binder Quantity on Pellet Properties

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Japhet, J.A. , Tokan, A., and E. E. Kyauta. A Review of Pellet Production from Biomass Residues as Domestic Fuel. Int J Environ Agric Biotechnol. 2019, 4, 835–42. [Google Scholar]

- Mckendry, P. Energy production from biomass (part 1): overview of biomass. Bioresour Technol. 2002, 83, 37–64. [Google Scholar] [CrossRef] [PubMed]

- Markson, I.E. , Akpan, W.A., and Ufot, E. Determination of Combustion Characteristics of Compressed Pulverized Coal-Rice Husk Briquettes. Int J Appl Sci Technol 2013, 3, 61–4. [Google Scholar]

- Orisaleye, J.I. , Jekayinfa, S.O., Pecenka, R., and Onifade, T.B. Effect of densification variables on water resistance of corn cob briquettes. Agron Res. 2019, 17, 1722–34. [Google Scholar]

- Tumuluru, J.S. , Wright, C.T., Kenney, K.L., and Hess, J.R. A technical review on biomass processing: Densification, preprocessing, modeling and optimization. In: American Society of Agricultural and Biological Engineers Annual International Meeting 2010, ASABE 2010. American Society of Agricultural and Biological Engineers; 2010. p. 4594–625.

- Holm, J.K. , Henriksen, U.B., Hustad, J.E., and Sørensen, L.H. Toward an understanding of controlling parameters in softwood and hardwood pellets production. Energy and Fuels. 2006, 20, 2686–94. [Google Scholar]

- Miranda, T. , Arranz, J.I., Montero, I., Román, S., Rojas, C. V., and Nogales, S. Characterization and combustion of olive pomace and forest residue pellets. Fuel Process Technol. 2012, 103, 91–6. [Google Scholar] [CrossRef]

- Hu, Q. , Yang, H., Yao, D., Zhu, D., Wang, X., Shao, J., et al. The densification of bio-char: Effect of pyrolysis temperature on the qualities of pellets. Bioresour Technol. 2016, 200, 521–7. [Google Scholar] [CrossRef] [PubMed]

- Zainuddin, M. , Rosnah, S., Noriznan, M.M., and Dahlan, I. Effect of Moisture Content on Physical Properties of Animal Feed Pellets from Pineapple Plant Waste. Agric Agric Sci Procedia. 2014, 2, 224–30. [Google Scholar]

- Jackson, J. , Turner, A., Mark, T., and Montross, M. Densification of biomass using a pilot scale flat ring roller pellet mill. Fuel Process Technol. 2016, 148, 43–9. [Google Scholar] [CrossRef]

- Tondare, A. , Nadkar, A., Zope, V., and Khond, M.P. Design and Fabrication of Biomass Pelleting Machine. J Adv Mach. 2018, 3, 6–11. [Google Scholar]

- Anenberg, S.C. , Balakrishnan, K., Jetter, J., Masera, O., Mehta, S., Moss, J., et al. Cleaner cooking solutions to achieve health, climate, and economic cobenefits. ACS Publications; 2013.

- Carone, M.T. , Pantaleo, A., and Pellerano, A. Influence of process parameters and biomass characteristics on the durability of pellets from the pruning residues of Olea europaea L. Biomass and Bioenergy. 2011, 35, 402–10. [Google Scholar]

- Nunes, J. and Freitas, H. An indicator to assess the pellet production per forest area. A case-study from Portugal. For Policy Econ. 2016, 70, 99–105. [Google Scholar] [CrossRef]

- Pecenka, R. , Lenz, H., Jekayinfa, S.O., and Hoffmann, T. Influence of tree species, harvesting method and storage on energy demand and wood chip quality when chipping poplar, willow and black locust. Agriculture 2020, 10, 116. [Google Scholar] [CrossRef]

- Orisaleye, J.I. , Ogundare, A.A., Oloyede, C.T., Ojolo, S.J., and Jekayinfa, S.O. Effect of preconditioning and die thickness on pelleting of livestock feed. Aust J Multi-Disciplinary Eng 2024, 1–13. [Google Scholar] [CrossRef]

- Jekayinfa, S.O. , Abdulsalam, I.A., Ola, F.A., Akande, F.B., and Orisaleye, J.I. Effects of binders and die geometry on quality of densified rice bran using a screw-type laboratory scale pelleting machine. Energy Nexus 2024, 100275. [Google Scholar]

- Orisaleye, J.I. , Jekayinfa, S.O., Adebayo, A.O., Ahmed, N.A., and Pecenka, R. Effect of densification variables on density of corn cob briquettes produced using a uniaxial compaction biomass briquetting press. Energy Sources, Part A Recover Util Environ Eff 2018, 40, 3019–28. [Google Scholar]

- Orisaleye, J.I. , Jekayinfa, S.O., Dittrich, C., Obi, O.F., and Pecenka, R. Effects of feeding speed and temperature on properties of briquettes from poplar wood using a hydraulic briquetting press. Resources. 2023, 12, 12. [Google Scholar]

- Puig-Arnavat, M. , Shang, L., Sárossy, Z., Ahrenfeldt, J., and Henriksen, U.B. From a single pellet press to a bench scale pellet mill—Pelletizing six different biomass feedstocks. Fuel Process Technol. 2016, 142, 27–33. [Google Scholar] [CrossRef]

- Wang, T. , Li, Y., Zhang, J., Zhao, J., Liu, Y., Sun, L., et al. Evaluation of the potential of pelletized biomass from different municipal solid wastes for use as solid fuel. Waste Manag. 2018, 74, 260–6. [Google Scholar] [CrossRef] [PubMed]

- Stelte, W. , Clemons, C., Holm, J.K., Ahrenfeldt, J., Henriksen, U.B., and Sanadi, A.R. Fuel pellets from wheat straw: The effect of lignin glass transition and surface waxes on pelletizing properties. Bioenergy Res 2012, 5, 450–8. [Google Scholar] [CrossRef]

- Stelte, W. , Clemons, C., Holm, J.K., Sanadi, A.R., Ahrenfeldt, J., Shang, L., et al. Pelletizing properties of torrefied spruce. Biomass and Bioenergy. 2011, 35, 4690–8. [Google Scholar] [CrossRef]

- The American Society of Agricultural and Biological Engineers. Densified Products for Bulk Handling - Definitions and Method. Asae/Asabe S2695 2012, 1–8. [Google Scholar]

- Jekayinfa, S.O. , Adebayo, A.O., Oniya, O.O., and Olatunji, K.O. Comparative analysis of biogas and methane yields from different sizes of groundnut shell in a batch reactor at mesophilic temperature. J Energy Res Rev. 2020, 5, 34–44. [Google Scholar]

- Samuelsson, R. , Thyrel, M., Sjöström, M., and Lestander, T.A. Effect of biomaterial characteristics on pelletizing properties and biofuel pellet quality. Fuel Process Technol. 2009, 90, 1129–34. [Google Scholar]

- Crawford, N.C. , Ray, A.E., Yancey, N.A., and Nagle, N. Evaluating the pelletization of “pure” and blended lignocellulosic biomass feedstocks. Fuel Process Technol. 2015, 140, 46–56. [Google Scholar] [CrossRef]

- Fedler, C.B. Mathematical models describing the flow of granular material. Math Comput Model. 1988, 11, 510–3. [Google Scholar] [CrossRef]

- Huynh, T. and Dao, S. Highly efficient fruit mass and size estimation using only top view images. Multidiscip Digit Publ Inst Proc. 2019, 42, 57. [Google Scholar]

- Singh, S. Mechanical Engineer’s Handbook. Khanna; 2003.

- Laloon, K. , Junsiri, C., Sanchumpu, P., and Ansuree, P. Factors affecting the biomass pellet using industrial eucalyptus bark residue. Biomass Convers Biorefinery. 2022, 1–13. [Google Scholar]

- Mani, S. , Tabil, L.G., and Sokhansanj, S. Specific energy requirement for compacting corn stover. Bioresour Technol 2006, 97, 1420–1426. [Google Scholar] [CrossRef] [PubMed]

- Khurmi, R.S. and Gupta, J.K.K. A Textbook Of Machine Design. Handbook of Machinery Dynamics. S. Chand publishing; 2005. 800 p.

- EN 14961-2. Solid biofuels-Fuel specifications and classes-Part 2: Wood pellets for non-industrial use. European Union; 2011.

- EN 14961-6. Solid biofuels - Fuel specifications and classes - Part 6: Non-woody pellets for non-industrial use. British Standards Institution (BSI); 2016. p. 18.

- Orimaye, O.S. , Ajewole, P.O., and Oni, I.O. Design, Fabrication and Performance Evaluation of Indigenous Fish Feed Pelletizing Machine for Low Income Farmers in Nigeria. J Eng Res Reports 2019, 1–31. [Google Scholar] [CrossRef]

- Prvulovic, S. , Gluvakov, Z., Tolmac, J., Tolmac, D., Matic, M., and Brkic, M. Methods for determination of biomass energy pellet quality. Energy and fuels. 2014, 28, 2013–8. [Google Scholar]

- ASTM E873-82. Standard test method for bulk density of densified particulate biomass fuels. Am Soc Test Mater. 2014.

- Japhet, J.A. , Tokan, A., and Muhammad, M.H. Production and characterization of rice husk pellet. Am J Eng Res. 2015, 4, 112–9. [Google Scholar]

- Sunmonu, M.O. , Odewole, M.M., and Falua, K.J. Design of a Varying Die-plate Fish Feed Pelletizer and Performance Evaluation Using a Non-conventional Feed Sources. KMUTNB Int J Appl Sci Technol 2018, 11, 263–71. [Google Scholar] [CrossRef]

- Abdel Wahab, M.K. ., Tawfik, M.A., El Shal, A.M., and El Hussiny, Y.A. Factors Affecting the Performance of Aquatic Feeds Flat-die Pelleting Machine. Misr J Agric Eng 2011, 28, 129–48. [Google Scholar] [CrossRef]

- Orisaleye, J.I. , Ojolo, S.J., and Fashina A. B. Design and development of livestock feed pelleting machine. J Eng Res. 2009, 14. [Google Scholar]

- Birania, S. , Garg, M.K., Gupta, R., Kumar, R., Kumar, N., and others. Development and Performance Evaluation of Biomass Pellet Machine for On-Farm Sustainable Management and Valorization of Paddy Straw. Environ Eng Manag J 2021, 20. [Google Scholar]

- 44. ISO 17829. Solid Biofuels - Determination of Length and Diameter of Pellets. Br Stand Inst London, UK 2015.

- Liu, Z. , Fei, B., Jiang, Z., Cai, Z., Yu, Y., and others. The properties of pellets from mixing bamboo and rice straw. Renew Energy. 2013, 55, 1–5. [Google Scholar] [CrossRef]

- ISO 17225-3. Solid biofuels - Fuel specifications and classes - Part 3: Pellet quality Requirements. 2015.

- Ighodalo, O. , Amiebenomo, S.O., and Esabunor, T. Optimization of multiple performance responses of a fish feed pelletizer machine. J Adv Sci Eng. 2020, 3, 14–23. [Google Scholar]

- Tashiwa, Y.I. , Mojeed, K.A., Kabri, H.U., and Jilima, A.A. Development of a Motorized Fish Feed Pelletizing Machine. Niger J Eng Sci Technol Res. 2019, 5, 96–102. [Google Scholar]

- Ikubanni, P.P. , Agboola, O.O., Adeleke, A.A., Ogunsemi, B.T., and Ibikunle, R.A. Fabrication and Evaluation of Screw-like Fish Pelletizer. In: Journal of Physics: Conference Series. Institute of Physics Publishing; 2019.

- Olugboji, O. ., Abolarin, M.., Owolewa, M.., and Ajani, K.. Design, Construction and Testing of a Poultry Feed Pellet Machine. Int J Eng Trends Technol 2015, 22, 168–70. [Google Scholar] [CrossRef]

| S/N | Material | Description and sizes | Quantity | Unit cost (#) | Total cost (#) |

|---|---|---|---|---|---|

| 1 | Electric motor | 4 hp, 1400 rpm | 1 | 40,000 | 40,000 |

| 2 | Angle iron | 6 x 6 x 2 mm | 2 | 7,000 | 14,000 |

| 3 | Bolt and nut | M12 x 1.25 mm M14 x 2 mm |

7 4 |

100 120 |

700 480 |

| 4 | Rubber belt | Type A, 13 x 8 mm; 1255 mm | 1 | 750 | 750 |

| 5 | Iron plate | 435 x 280 x 2 mm mild steel 100 x 100 x 6 mm mild steel |

1 5 |

6000 7,000 |

6000 35,000 |

| 6 | Paint | Green, 2 litres | 5,250 | 10,500 | |

| 7 | Miscellaneous and Workmanship | 65,000 | 65,000 | ||

| Total | 161,930 |

| Run | Die hole diameter (mm) | Binder quantity (wt%) |

|---|---|---|

| 1 | 2.5 | 5 |

| 2 | 2.5 | 6 |

| 3 | 5.0 | 7 |

| 4 | 0.0 | 7 |

| 5 | 2.5 | 7 |

| 6 | 0.0 | 6 |

| 7 | 5.0 | 7 |

| 8 | 0.0 | 5 |

| 9 | 0.0 | 5 |

| 10 | 5.0 | 5 |

| 11 | 0.0 | 7 |

| 12 | 5.0 | 5 |

| 13 | 5.0 | 6 |

| Properties | Machine efficiency (%) | Machine throughput (kg/h) | Pellet length (mm) | bulk density (g/cm3) |

|---|---|---|---|---|

| Die hole diameter | ||||

| 5 mm | 58.82a | 4.12a | 16.98a | 0.156a |

| 6 mm | 56.16a | 4.36a | 15.62a | 0.163a |

| 7 mm | 59.92a | 4.32a | 13.97a | 0.161a |

| Binder Quantity | ||||

| 0.0 wt% | 68.16a | 5.39a | 17.32a | 0.161a |

| 2.5 wt% | 58.24ab | 4.88a | 15.67ab | 0.159a |

| 5.0 wt% | 51.73b | 2.95b | 13.60b | 0.159a |

| property | Source | DF | SS | MS | F-Value | P-Value | R2 |

|---|---|---|---|---|---|---|---|

| Machine efficiency | Die hole diameter | 2 | 20.21 | 10.10 | 0.08 | 0.926 | 1.70 |

| Binder quantity | 2 | 601.40 | 300.69 | 4.60 | 0.042 | 50.55 | |

| Machine throughput | Die hole diameter | 2 | 0.1416 | 0.0708 | 0.03 | 0.970 | 0.69 |

| Binder quantity | 2 | 14.819 | 7.4095 | 11.40 | 0.003 | 71.71 | |

| Pellet lenght | Die hole diameter | 2 | 22.79 | 11.395 | 2.45 | 0.136 | 32.88 |

| Binder quantity | 2 | 34.84 | 17.422 | 5.06 | 0.030 | 50.28 | |

| Bulk density | Die hole diameter | 2 | 8.3x10-5 | 4.1x10-5 | 2.15 | 0.167 | 30.07 |

| Binder quantity | 2 | 2x10-5 | 1x10-5 | 0.39 | 0.689 | 7.19 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).