1. Introduction

During drilling operations, shale formations pose significant challenges, accounting for approximately 90% of wellbore instability issues [

1,

2]. Despite extensive research, shale instability remains a critical concern in the petroleum industry [

3,

4]. The emergence of shale gas has further complicated this issue, especially in horizontal drilling sections [

5,

6]. Traditional drilling fluids struggle to stabilize shale due to their large particle size, which cannot effectively bridge and seal nanopores within shale formations [

7]. While oil-based drilling fluids (OBM) perform well under these conditions, their high cost and environmental impact limit their use. Consequently, water-based drilling fluids (WBDF) are preferred, despite their tendency to interact adversely with shale clays [

8].

Nanoparticles (NPs) have recently been explored to enhance the performance of WBDFs. NPs, typically ranging from 1 to 100 nm, can physically block shale pores, reducing filtrate invasion and improving wellbore stability [

9,

10]. Their high surface area-to-volume ratio allows for effective use at low concentrations, minimizing fluid losses and filter cake thickness under both low-temperature low-pressure (LTLP) and high-temperature high-pressure (HTHP) conditions. NPs also improve the rheological properties of WBDFs, preventing excessive gel strength [

11].

Research has shown that polymer latex nanoparticles and nano-emulsions can bridge and seal nanopores and microfractures in shale, but these solutions often lack stability and resistance to high temperatures [

12,

13]. A promising alternative is the incorporation of nano-fillers into polymer matrices, combining the rigidity and thermal stability of inorganic nanomaterials with the resilience of polymers [

14,

15]. This study investigates the preparation and evaluation of a silica nanocomposite as a potential shale stabilizer in WBDFs. Silica nanocomposite was synthesized using styrene (St), butyl acrylate (BA), and nano-silica through emulsion polymerization. The effects of silica nanocomposite and graphene nanopowder on the rheological behavior of WBDFs were assessed, showing improved shale stability and reduced shale permeability.

2. Materials and Methods

2.1. Materials

The study utilized various materials: 1) Styrene (St); 2) n-butyl acrylate (BA); 3) SiO2 nanoparticles (7-40 nm); 4) octylphenol polyoxyethylene ether (OP-10); 5) ethanol, silane coupling agent KH570; 6) sodium dodecyl sulfate (SDS); 7) ethylic acid; 8) potassium persulfate (KPS); 9) sodium bicarbonate (NaHCO3); and graphene nanopowder were also incorporated. Deionized water was consistently used as the solvent throughout the experiments.

Silica oxide nanoparticles (SiO2-NPs) were obtained from the Scientific Center of Composite Materials in Almaty, Kazakhstan. These spherical SiO2-NPs ranged in size from 7 nm to 40 nm and were unmodified and non-porous. Graphene nanopowder, sourced from Sarsen Amanzholov East Kazakhstan University in Ust-Kamenogorsk, Kazakhstan, had a two-dimensional (2D) structure, with particles sized between 1.3 μm and 2.3 μm and a thickness of less than 3 nm.

Traditional additives were used in the drilling fluid formulation. Bentonite was the main viscosifier, while xanthan gum (XG) enhanced rheology. Polyanionic cellulose low-viscosity (PAC-LV) and pre-gelled starch controlled filtration, and graphite was used as a lost circulation material (LCM). Potassium hydroxide (KOH, 85%) adjusted the alkalinity. These additives were sourced from various suppliers and used without further modification.

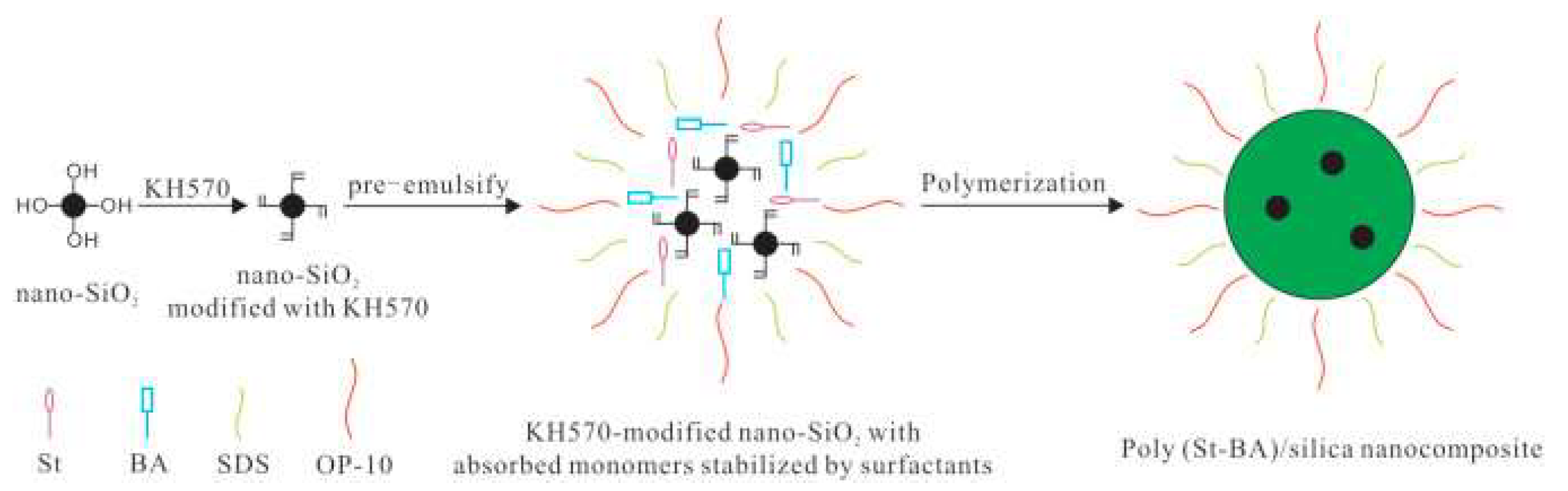

2.2. Preparation of silica nanocomposite

The preparation of silica nanocomposite involved several sequential steps. Initially, nanosilica was dispersed in 100 mL of ethanol using ultrasonic assistance for 1 hour. KH570 was then dissolved in the ethanol along with a small amount of water, maintaining a weight ratio of 1:1:18 for KH570/H2O/ethanol. Subsequently, 1 mL of ethylic acid was added to the dispersion and stirred magnetically for 30 minutes at room temperature. The resulting dispersion was transferred to a reaction flask and vigorously stirred for 4 hours at 75°C using a mechanical stirrer to yield KH570-modified nanosilica. Finally, the modified nanosilica was washed multiple times with absolute ethanol and dried at 60°C for subsequent use.

To prepare the silica nanocomposite as a potential shale stabilizer, emulsion polymerization was conducted using KH570-modified nanosilica, Styrene (St), Butyl acrylate (BA). The polymerization process occurred in a 250-mL four-necked flask equipped with a reflux condenser, mechanical stirrer, thermometer, and dropping funnel. Initially, modified nanosilica was dispersed in deionized water containing SDS and OP-10. Subsequently, 0.12 g of NaHCO3, 28 g of Styrene (St), and 12 g of Butyl acrylate (BA) were added to the dispersion and subjected to ultrasonic treatment for 1 hour. The mixture was then pre-emulsified under mechanical stirring and heated to 75°C for an additional hour. KPS (0.24 g) was added to initiate polymerization, which continued for 3 hours at 75°C before cooling to room temperature.

Figure 1 illustrates the mechanism of preparing the modified polymer-based silica nanocomposite.

2.3. Characterization and Measurement of Graphene Nanopowder and SiO2-NPs

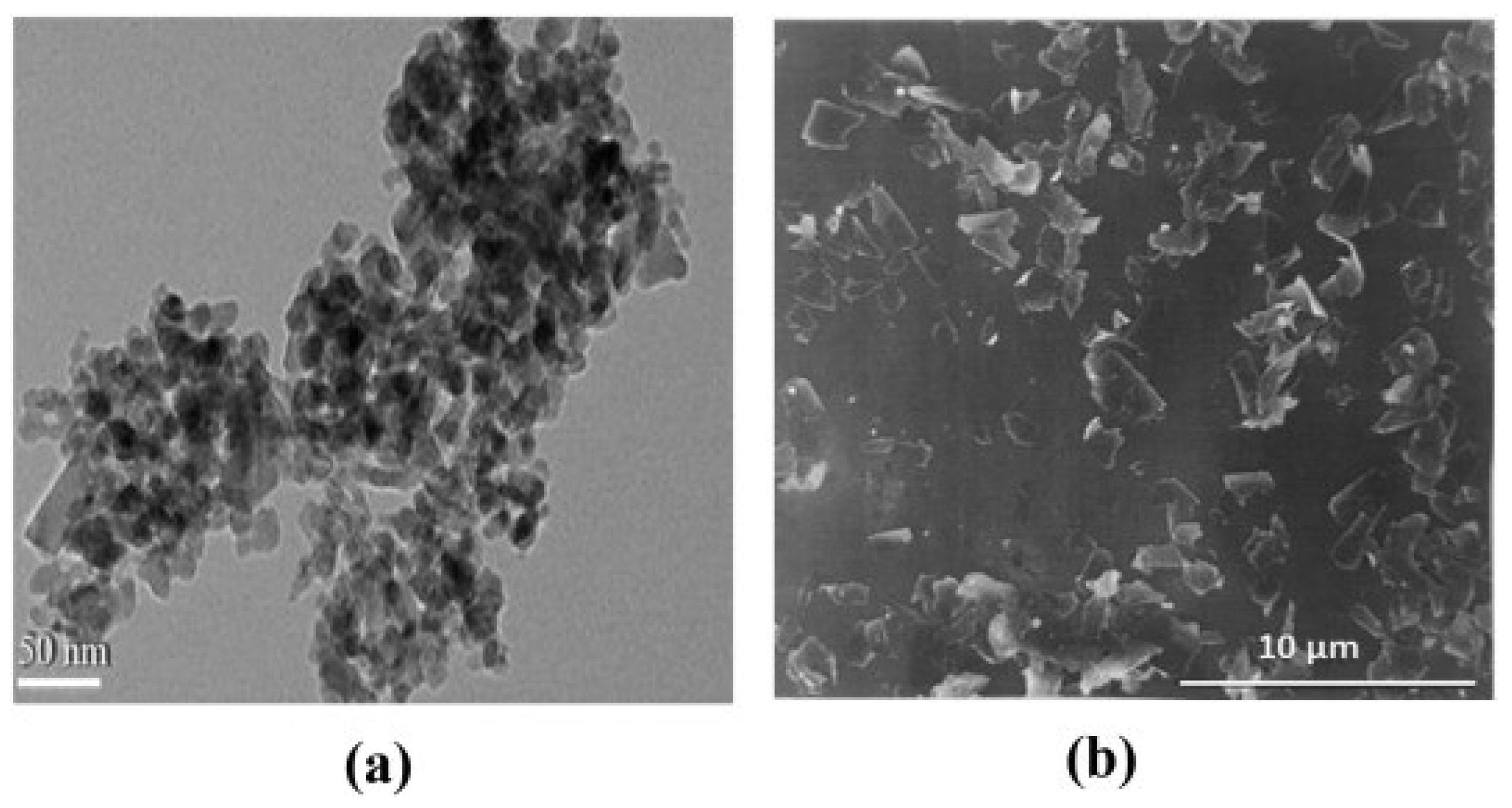

SEM was used to analyze the morphology of both graphene nanopowder and silica oxide nanoparticles (SiO2-NPs).

Figure 2 shows SEM images of (a) SiO2-NPs and (b) graphene nanopowder. The surface morphology was investigated using the SEM Quanta 200i 3D (FEI, Netherlands) under high vacuum conditions with a secondary electron detector at an accelerating voltage of 15 kV. To enhance electron transfer, an aluminum coating was applied to the surfaces of both materials. The specimens were then affixed to aluminum pins using carbon tape for examination.

2.4. Characterization of silica nanocomposite

The chemical composition of silica nanocomposite was analyzed using FTIR with a Simex FTIR FT-801 spectrometer, featuring a resolution of 1 cm⁻¹ and a wavelength range of 450-4700 cm⁻¹. The analysis employed standard procedures using single-use universal full internal reflection and mirror-diffuse reflection methods. Measurements were conducted at 25°C, with each sample undergoing 100 scans. The size of silica nanocomposite particles was assessed using dynamic light scattering with a particle size distribution analyzer (Zetasizer Nano ZS90, UK). The morphology of silica nanocomposite was examined through TEM analysis (TEM, JEOL JEM-2100UHR, Japan).

2.5. Preparation of WBDFs

The formulation in

Table 1 was used to prepare the base fluid (A). To prepare the base fluid, bentonite was added to 675 ml of deionized water and agitated at 11,000 rev/min for 30 minutes. The resulting slurry was allowed to hydrate undisturbed for 12 h at 25°C before introducing other additives. The remaining 300 ml of deionized water was used to prepare nanoparticle dispersions.

For graphene nanopowder dispersion, a high-precision balance with an accuracy of ±0.0001 g was used to measure the nanomaterial. Then, 250 ml of deionized water was poured into an the flask, then graphene nanopowder was added with magnetic stirring. An ultrasonication step was conducted for one hour at 40 kHz and 185W to ensure a uniform dispersion. In contrast, silica nanocomposite underwent polymerization and was added to the base fluid during its preparation.

2.6. Drilling Fluid Properties Measurements

Rheological Properties. A rotational viscometer (OFITE 800) was used to assess the rheological characteristics at varying shear rates and a temperature of 120°F.

Figure 3 shows the OFITE 800 rotational viscometer. The rheological parameters, Plastic Viscosity (PV) and Yield Point (YP), were determined following the guidelines in the American Petroleum Institute (API) document API RP 13B-1 (2003). Gel strength measurements were obtained by recording the maximum dial reading at 3 revolutions per minute (rev/min) after allowing the drilling fluid to remain undisturbed for specified intervals (i.e., Gel10sec, Gel10min, Gel30min). PV represents the fluid's resistance to flow, corresponding to the mud's viscosity due to friction between solids. YP indicates the initial stress required to initiate fluid movement. The computation method for PV and YP is as follows:

Here, PV represents the plastic viscosity, measured in cP, and YP denotes the yield point, measured in lb/100 ft2. These values are derived from the dial readings at 600 rpm (θ600) and 300 rpm (θ300).

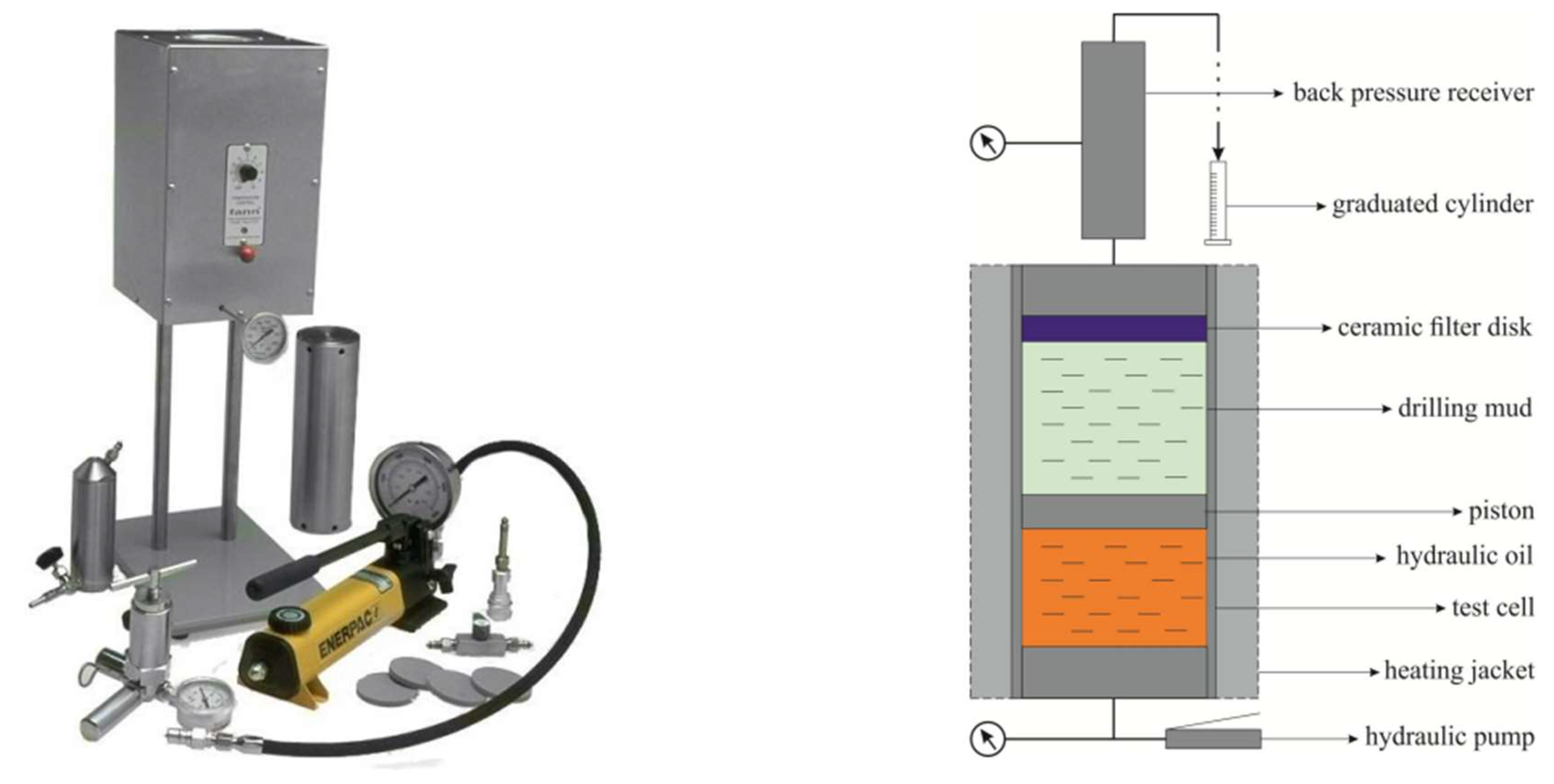

Filtration Properties. The API Low Temperature Low Pressure (LTLP) filtration test was carried out at 77°F and 100 psi, using standard filter paper with a pore size of 2.7 μm and air as the pressure source. The High Temperature High Pressure (HTHP) filtration test was conducted at 250°F and 500 psi, utilizing an OFITE HTHP filter press system with CO₂ as the pressure source and standard filter paper.

Figure 4 shows the OFITE HTHP filter press. Both tests involved monitoring the filtrate volume over 30 minutes, with the final volume reported to the nearest 0.1 ml. Due to the HTHP filter press area being half that of the LTLP test, the HTHP filtrate volume was doubled according to API guidelines. The same adjustment was made for the spurt volume. Additionally, the filter cake thickness was measured using a Vernier caliper.

Swelling Investigation Methodology and Artificial Sample Preparation. Standard certified Swellmeter OFITE, Fann instruments were used to assess the technological parameters of drilling fluids and their impact on the stability of clay formations.

Figure 5 shows the OFITE dynamic-linear swellmeter. The inhibition capabilities of the drilling fluids were studied using samples made from unmodified clay powder, primarily composed of montmorillonite, pressed at 6 MPa with a mass of 9.6 g each. The longitudinal swelling tester investigates the interaction between the circulating drilling fluid and rock samples. The tester is equipped with multiple measurement cells, and the sample is subjected to the drilling fluid circulating around it. A differential longitudinal expansion sensor measures the sample's vertical expansion at one-minute intervals with an accuracy of 0.1%.

The research methodology involved the following steps:

Preparation of the drilling fluids (A, B, C).

Placement of artificial samples in a container, which was then filled with the fluid.

Determination of the change in sample volume.

The experiment duration was limited to 24 hours. The linear swelling percentage is determined using the following equation:

where h

0 is the original thickness of the clay samle, and the h

t is the swelled height after exposure to the drilling fluids.

3. Results and discussion

3.1. Material Characterization

The choice of SiO2-NPs was driven by their size, which aligns with the pore size of shale samples, making them effective as pore-plugging agents [

16]. Additionally, their cost-effectiveness, due to established preparation methods, enhances their economic appeal [

17]. Graphene nanopowders were included because their pliable nature at downhole temperatures could seal shale fissures, potentially reducing the development of microfractures along the shale bedding planes. This could mitigate water influx into the shale matrix, thereby enhancing wellbore stability [

18,

19]. FESEM analysis revealed that both graphene nanopowder and SiO2-NPs had small dimensions. SiO2-NPs measured between 7 nm and 40 nm, while graphene nanopowder ranged from 1.3 μm to 2.3 μm in size, with a thickness of less than 3 nm, as shown in

Figure 2. These characteristics are advantageous for their adsorption onto the shale surface.

3.2. Characterization of NFC

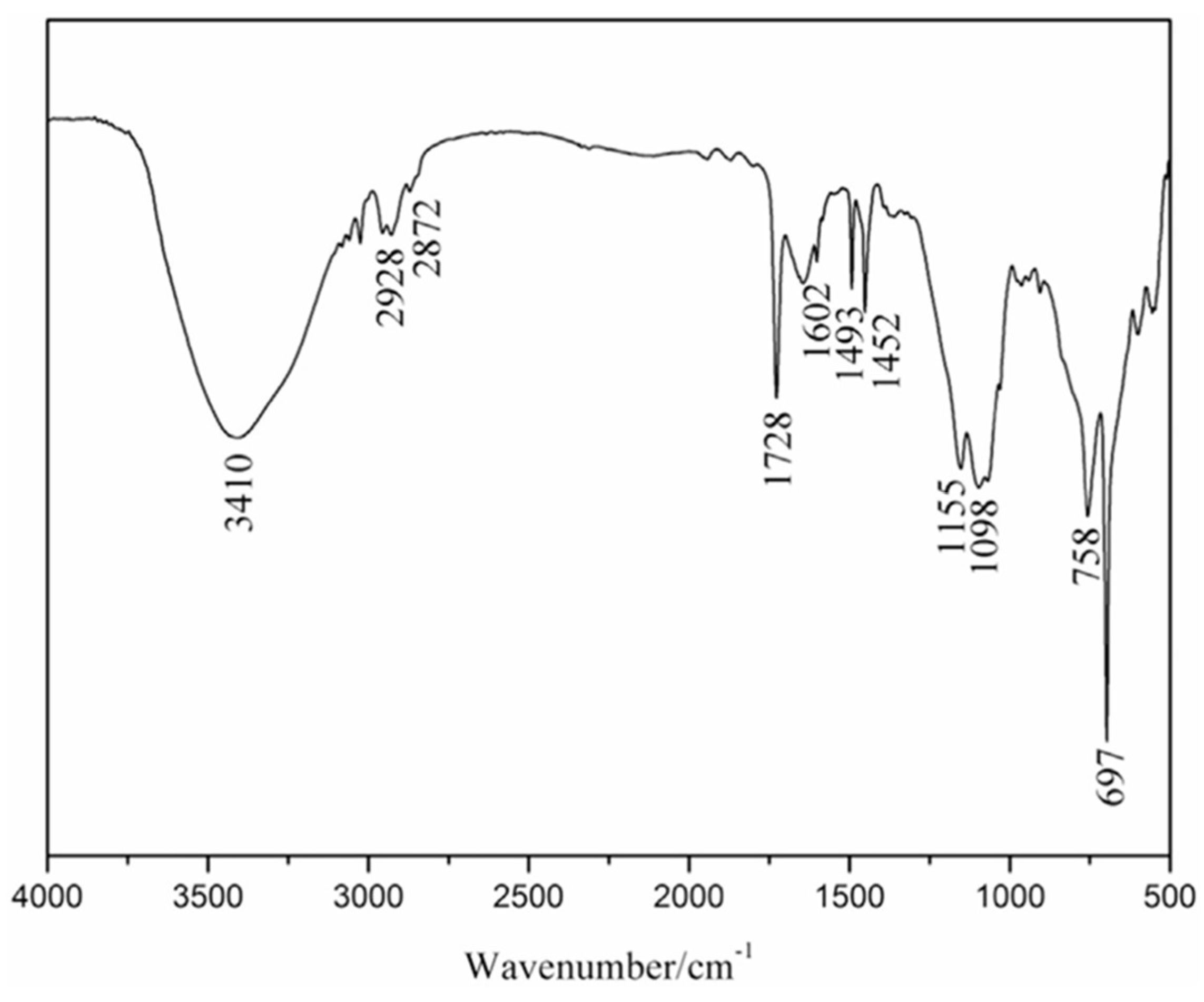

3.2.1. FT-IR Analysis

Figure 6 shows the FT-IR spectra of the Poly(St-BA)/silica nanocomposite. Peaks at 1602 cm⁻¹, 1493 cm⁻¹, and 1452 cm⁻¹ correspond to characteristic vibrations of the benzene skeleton. Peaks at 758 cm⁻¹ and 697 cm⁻¹ indicate a single substitution benzene ring, confirming the successful incorporation of styrene in the polymerization reaction. The peak at 1728 cm⁻¹ corresponds to the C=O bond, and the peak at 1155 cm⁻¹ corresponds to the C–O–C bond, indicating the involvement of butyl acrylate in the polymerization process. Additionally, the peak at 1098 cm⁻¹ corresponds to the Si–O–Si bond. Thus, the FT-IR spectra confirm the effective synthesis of the Poly(St-BA)/silica nanocomposite.

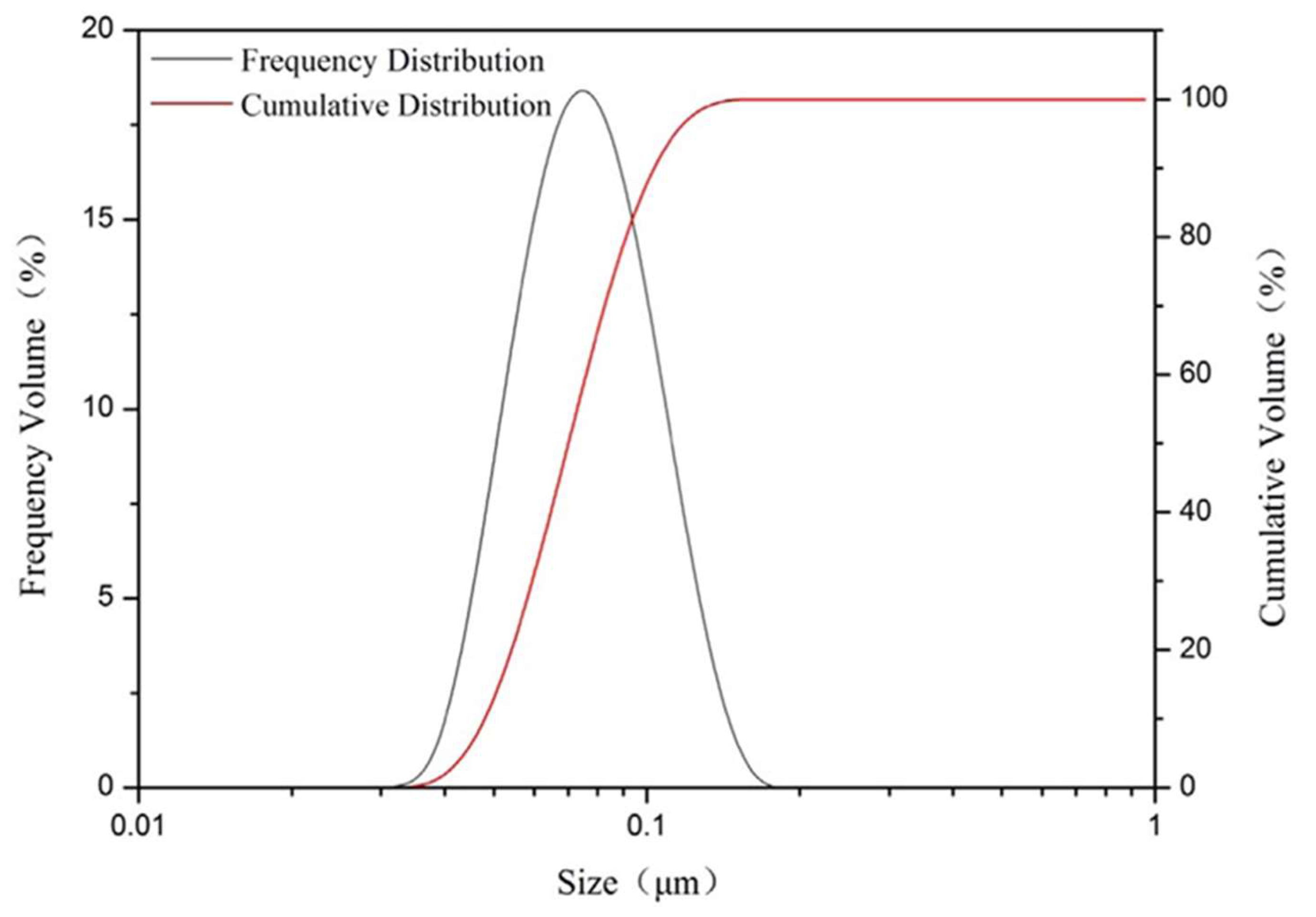

3.2.2. PSD analysis

Figure 7 illustrates the particle size distribution of the nanocomposite NFC in a diluted aqueous solution. It is evident from the graph that the distribution of particle sizes in the nanocomposite NFC was more focused, forming a parabolic curve. The particle sizes ranged from 38 to 164 nm, with a medium particle size D50 value of 72 nm. As a result, NFC demonstrates the ability to efficiently seal micro-nano scale pore throats and fractures within shale formations, thus contributing to borehole stability.

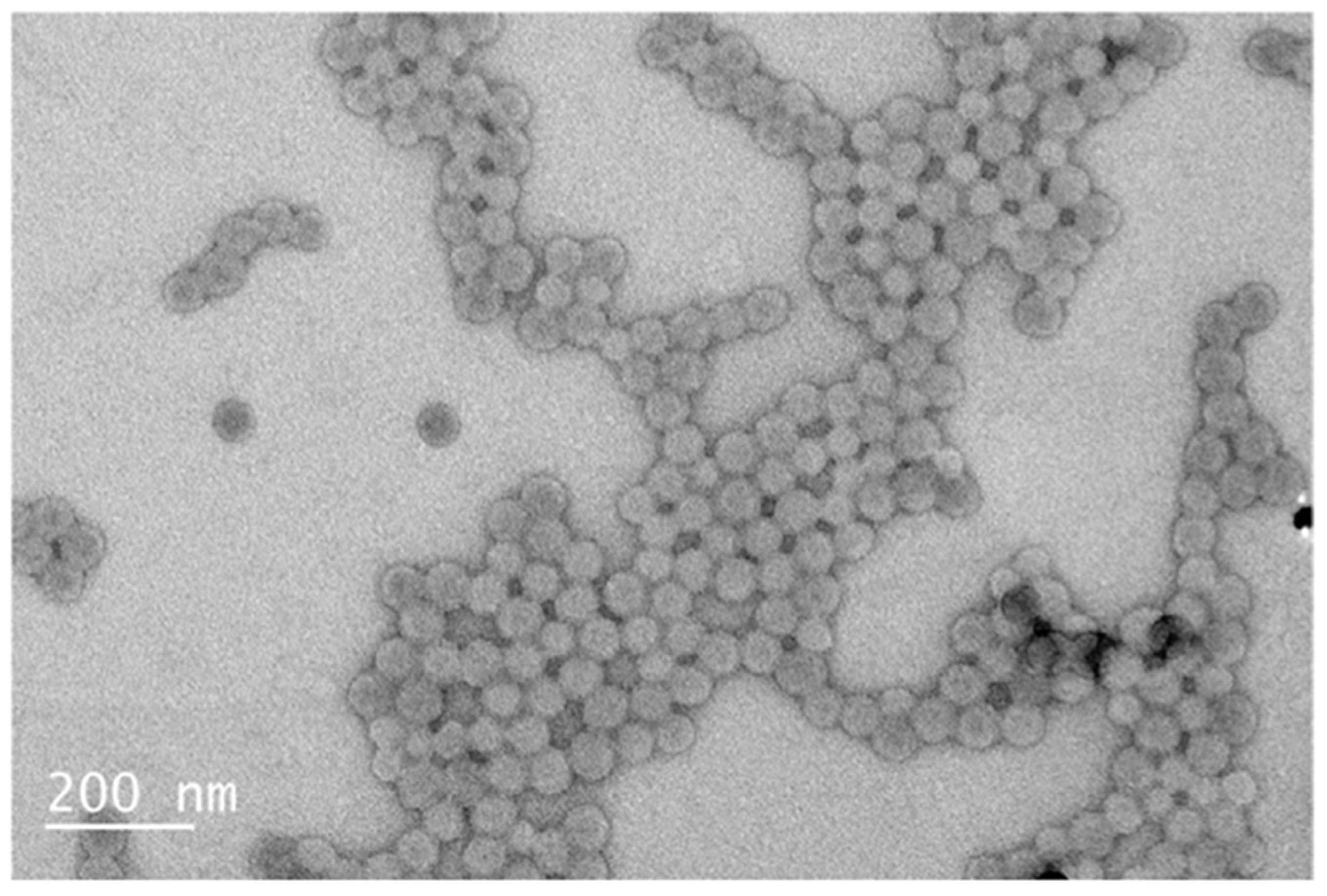

3.2.3. TEM Analysis

Figure 8 shows the TEM image of the nanocomposite NFC in a diluted aqueous solution. The image reveals uniformly dispersed particles with a consistent spherical shape. The average particle size was approximately 70 nm, closely aligning with the D50 value (72 nm) from the particle size distribution characterization. Additionally, the core-shell structure of the particles suggests successful grafting of the hydrophobic polymer Poly(St-BA) onto the surface of the nano-silica particles.

3.3. Rheological Properties

The rheological characteristics of Graphene nanopowder-WBDF and NFC-WBDF were compared with those of the base fluid (A).

Table 3 summarizes the properties of the base fluid and samples containing different concentrations of Graphene nanopowder and NFC modified nanocomposite at 120°F and 14.7 psi. The addition of Graphene nanopowder and NFC modified nanocomposite led to a decrease in PV compared to the base fluid. This reduction can be attributed to enhanced repulsive forces among particles in the drilling fluid, stemming from interactions between the negatively charged nanoparticles (NPs) and clay surfaces. Lower PV enhances drilling efficiency by enabling faster penetration rates and reducing total pressure losses and equivalent circulation densities (ECD) [

20]. Moreover, well-dispersed NPs promote a more uniform distribution of conventional additives in the drilling fluid, improving polymer hydration and enhancing the yield point (YP). NFC-WBDF exhibited superior performance, reducing filtrate volume by up to 16.28% and 25.74% in LTLP and HTHP filtration tests, respectively.

3.4. Filtration Properties

Adding Graphene nanopowder to fluid A reduced LTLP filtrate by 12.79%, while NFC showed superior performance with a 20.93% reduction. Under HTHP conditions, NFC-WBDF demonstrated a 27.21% reduction compared to 16.91% with Graphene nanopowder-WBDF, highlighting NFC's better filtration performance. Furthermore, NP WBM reduced filter cake thickness by over 10% in both tests, directly impacting filter cake permeability. Well-dispersed nanoparticles create denser and less permeable filter cakes, which limit fluid invasion into formations. This is particularly beneficial for NFC-WBDF and Graphene nanopowder-WBDF in unconventional shales, where they can form external filter cakes on nanopore structures, reducing fluid invasion and pore pressure impact to enhance wellbore stability. Previous research corroborates these findings with Graphene nanopowder, SiO2, and NFC [31–34].

Figure 9 illustrates SEM photos of shale samples before and after interaction with NFC and Graphene nanopowder, showing effective bridging and sealing of pore throats and microcracks, forming a dense plugging film on the shale surface to improve shale stability during drilling. NFC's inhibition mechanism against shale hydration is attributed to its small particle size, large specific surface area, and high surface energy, promoting strong surface activity and easy adsorption onto clay particles. Additionally, NFC's surface, when grafted with hydrophobic polymer Poly(St-BA), becomes more hydrophobic upon contact with NFC solution, inhibiting clay mineral hydration by restricting water molecule entry into clay particle clearances, thereby demonstrating effective shale inhibition performance.

3.5. Swelling and Hydration Research Results

The inhibitory capacity of the tested solutions was evaluated based on changes in sample swelling. Observations were recorded at 1h, 2h, 3h, 12h, and 24h after the start of the experiment.

Table 4 summarizes the swelling behavior of shale samples in different fluids. In the base solution, the clay sample initially swelled sharply, followed by nearly linear volume changes over time, without a damping phase observed. Visual inspection revealed the sample surface covered with large cracks, yet it remained intact, indicating preserved connections between individual aggregates. When NFC was introduced to the base solution, three distinct phases were observed: an initial period of intensive swelling in the first hour, followed by more stable behavior with minimal volume changes from 2h to 12h, and a damping phase from 12h to 24h. Throughout the observation period, the sample maintained stability without further swelling or fracturing, retaining its original shape. This underscores NFC's effective inhibitory capacity. Similarly, graphene nanopowder-treated solution exhibited effective inhibitory properties by hydrophobicizing the sample surface. At a concentration of 0.5 wt%, the sample showed approximately 10% increase in volume over the entire observation period, maintaining its shape even at lower concentrations of the product.

4. Conclusions

The hydrophobic modified polymer-based silica nanocomposite (NFC) was successfully synthesized as a potential shale stabilizer for water-based drilling fluids. With a particle size distribution ranging from 38 nm to 164 nm and a D50 value of approximately 72 nm, the newly developed NFC demonstrated excellent thermal stability. NFC effectively impeded pressure transmission and reduced shale permeability by bridging and sealing shale core pore throats and microcracks, leading to the formation of a dense plugging film on the shale surface and enhancing shale stability. In terms of shale inhibition performance, NFC exhibited outstanding results, achieving a 90.7% recovery rate at a 2% concentration, surpassing both the base fluid and Graphene nanopowder-WBDF. Additionally, NFC adsorption rendered the shale surface more hydrophobic, further contributing to enhanced shale stability. Overall, NFC shows promising potential as a superior shale stabilizer in water-based drilling fluids, particularly for challenging shale formations.

References

- Steiger, R., Leung, P.K., 1992. Quantitative determination of the mechanical properties of shales. SPE Paper 18024, SPE Drilling Engineering, 7(3), 181-185. [CrossRef]

- S. Zhang, Z. Qiu, W. Huang, J. Cao, X. Luo Characterization of a novel aluminum-based shale stabilizer J. Pet. Sci. Eng., 103 (2013), pp. 36-40. [CrossRef]

- E. Van Oort On the physical and chemical stability of shales J. Pet. Sci. Eng., 38 (3) (2003), pp. 213-235. [CrossRef]

- C. Liang, M. Chen, Y. Jin, Y. Lu Wellbore stability model for shale gas reservoir considering the coupling of multi-weakness planes and porous flow J. Nat. Gas. Sci. Eng., 21 (2014), pp. 364-378. [CrossRef]

- S. Zhou, H. Xue, W. Guo, X. Li A new nuclear magnetic resonance permeability model of shale of Longmaxi Formation in southern Sichuan Basin J. China Univ. Pet. (Ed. Nat. Sci.), 40 (1) (2016), pp. 56-61.

- S. Akhtarmanesh, M.A. Shahrabi, A. Atashnezhad Improvement of wellbore stability in shale using nanoparticles J. Pet. Sci. Eng., 112 (2013), pp. 290-295. [CrossRef]

- R.T. Ewy, E.K. Morton Wellbore stability performance of water base mud additives Soc. Pet. Eng. (2008).

- S. Ponmani, R. Nagarajan, J.S. Sangwai Effect of nanofluids of CuO and ZnO in polyethylene glycol and polyvinylpyrrolidone on the thermal, electrical, and filtration-loss properties of water-based drilling fluids SPE J., 21 (02) (2016), pp. 405-415. [CrossRef]

- K.P. Hoelscher, G. De Stefano, M. Riley, S. Young Application of nanotechnology in drilling fluids SPE International Oilfield Nanotechnology Conference and Exhibition, (June), 12–14 (2012).

- M.M. Sharma, R. Zhang, M.E. Chenevert A new family of nanoparticle-based drilling fluids SPE Annual Technical Conference and Exhibition (2012), pp. 1-13.

- A.I. El-Diasty, A.M.S. Ragab Applications of nanotechnology in the oil & gas industry: latest trends worldwide & future challenges in Egypt North Africa Technical Conference and Exhibition (2013), pp. 1-13.

- J.Y. Liu, Z.S. Qiu, W.A. Huang Novel latex particles and aluminum complexes as potential shale stabilizers in water-based drilling fluids J. Pet. Sci. Eng., 135 (2015), pp. 433-441. [CrossRef]

- J. Xu, Z. Qiu, W. Huang, X. Zhao Preparation and performance properties of polymer latex sdnl in water-based drilling fluids for drilling troublesome shale formations J. Nat. Gas. Sci. Eng., 37 (2017), pp. 462-470. [CrossRef]

- P.M. Ajayan, L.S. Schadler, P.V. Braun Nanocomposite science and technology John Wiley & Sons (2006).

- H. Zou, S. Wu, J. Shen Polymer/silica nanocomposites: preparation, characterization, properties, and applications Chem. Rev., 108 (9) (2008), pp. 3893-3957.

- L. Ji, Q. Guo, J. Friedheim, R. Zhang, M. Chenevert, M. Sharma Laboratory evaluation and analysis of physical shale inhibition of an innovative water-based drilling fluid with nanoparticles for drilling unconventional shales SPE Asia Pacific Oil and Gas Conference and Exhibition, (Sandrea 2006) (2012), pp. 1-12.

- M. Riley, S. Young, E. Stamatakis, Q. Guo, L. Ji, G. De Stefano, J. Friedheim Wellbore stability in unconventional shales - the design of a nano-particle fluid SPE Oil and Gas India Conference and Exhibition (2012).

- J.P. Deville, B. Fritz, M. Jarrett Development of water-based drilling fluids customized for shale reservoirs SPE Drill. Complet., 26 (04) (2011), pp. 484-491. [CrossRef]

- S.L. Gomez, W. He Fighting wellbore instability: customizing drilling fluids based on laboratory studies of shale-fluid interactions Soc. Petrol. Eng. (2012, January 1),.

- A.H. Salih, T.A. Elshehabi, H.I. Bilgesu Impact of nanomaterials on the rheological and filtration properties of water-based drilling fluids SPE Eastern Regional Meeting (2016).

- Jian-gen Xu, Zhengsong Qiu, Xin Zhao, Weian Huang Hydrophobic modified polymer based silica nanocomposite for improving shale stability in water-based drilling fluids Journal of Petroleum Science and Engineering, Volume 153, May 2017, Pages 325-330. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).