Submitted:

29 June 2024

Posted:

02 July 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Preparation of MRSs

2.1. Materials

- Lard, produced by Elit (Alba Iulia, Romania), supplied through commercial stores.

- Animal gelatin, from Dr. Oetker SRL (Curtea de Arges, Romania), supplied through grocery stores. The gelatin is in the form of white granules (GP) with equivalent diameters less than or equal to 1 mm (Figure A1 in Appendix A).

- CI microparticles, are produced by Sigma-Aldrich (St. Louis, USA). Their sizes are between 4.5 m and 5.4 m.

2.2. Method

- The volume of lard, of CI microparticles and of GP are measured. The corresponding values are listed in Table 2.

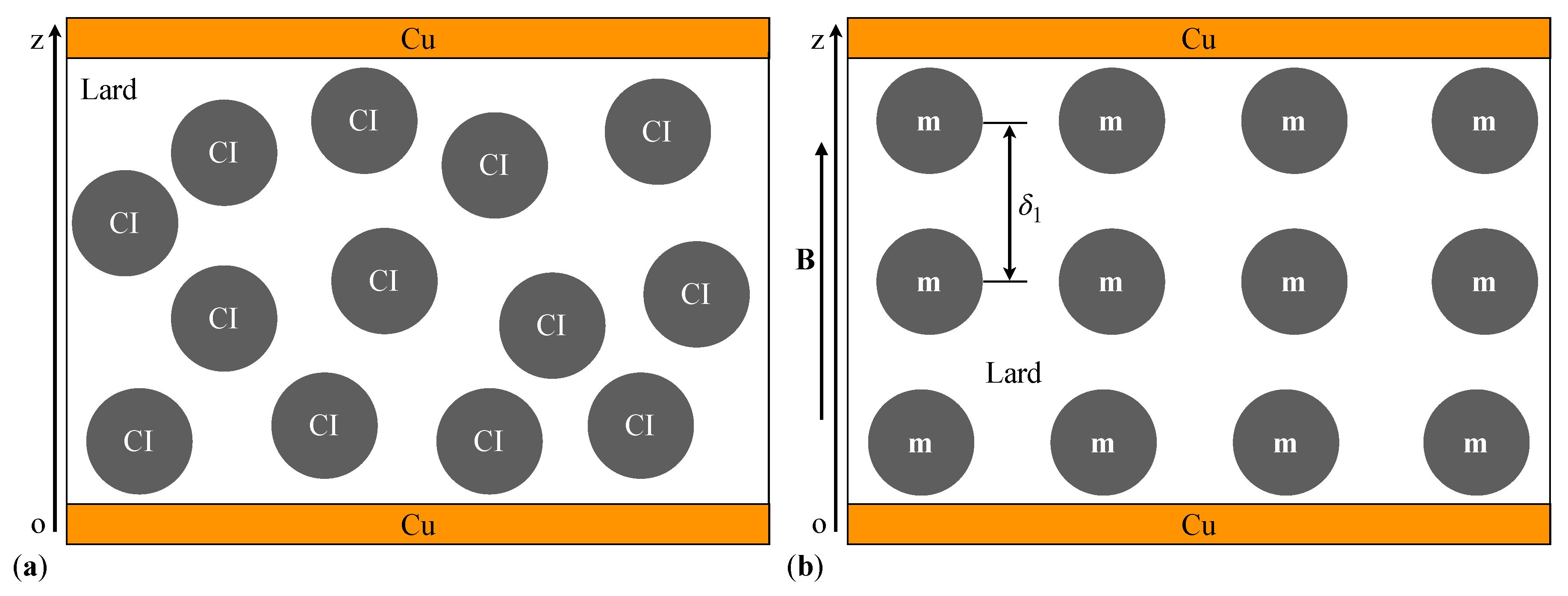

- In a Berzelius beaker, the volumes and corresponding to MRS from Table 2 are introduced. The components, consisting of lard and CI microparticles, are mixed while heating (approximately at 250C) for about five minutes. The mixing continues until the liquid mixture reaches ambient temperature (approximately 27C). At the end of this stage, a dark-colored mixture, hereafter referred to as MRS suspension, is obtained.

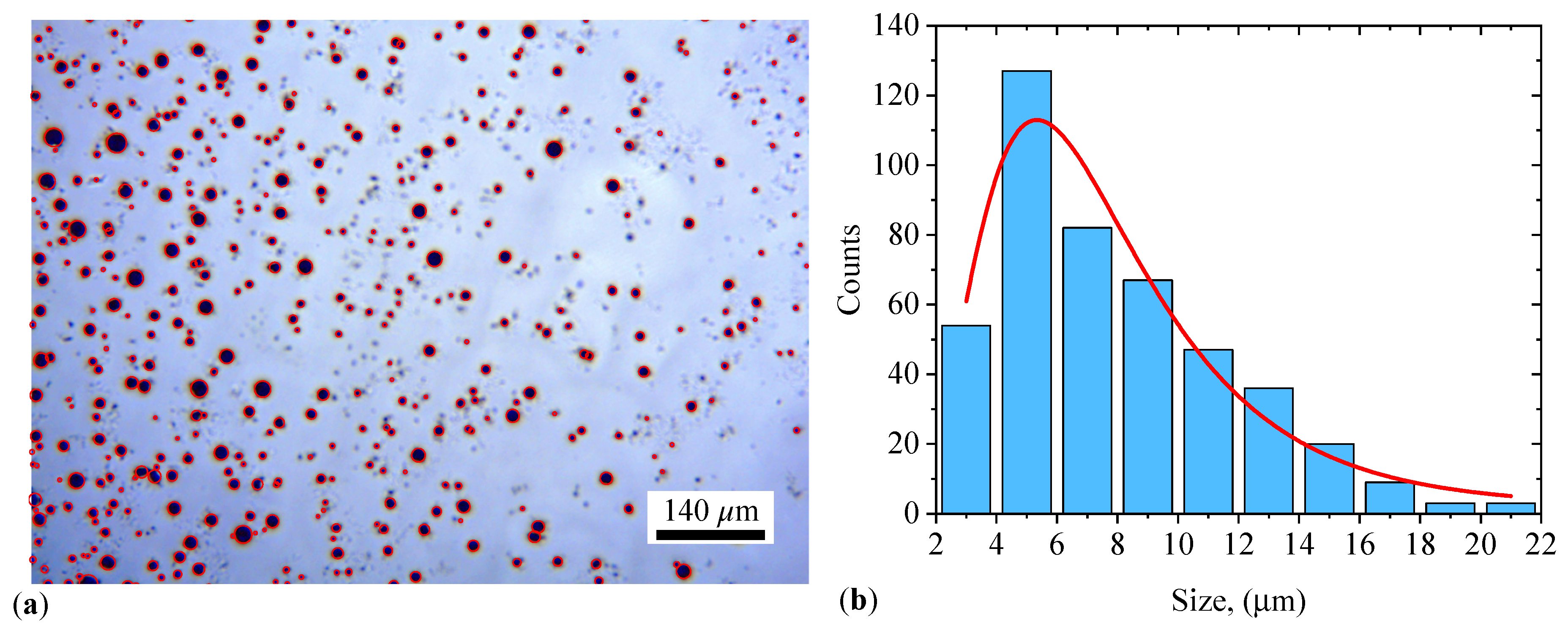

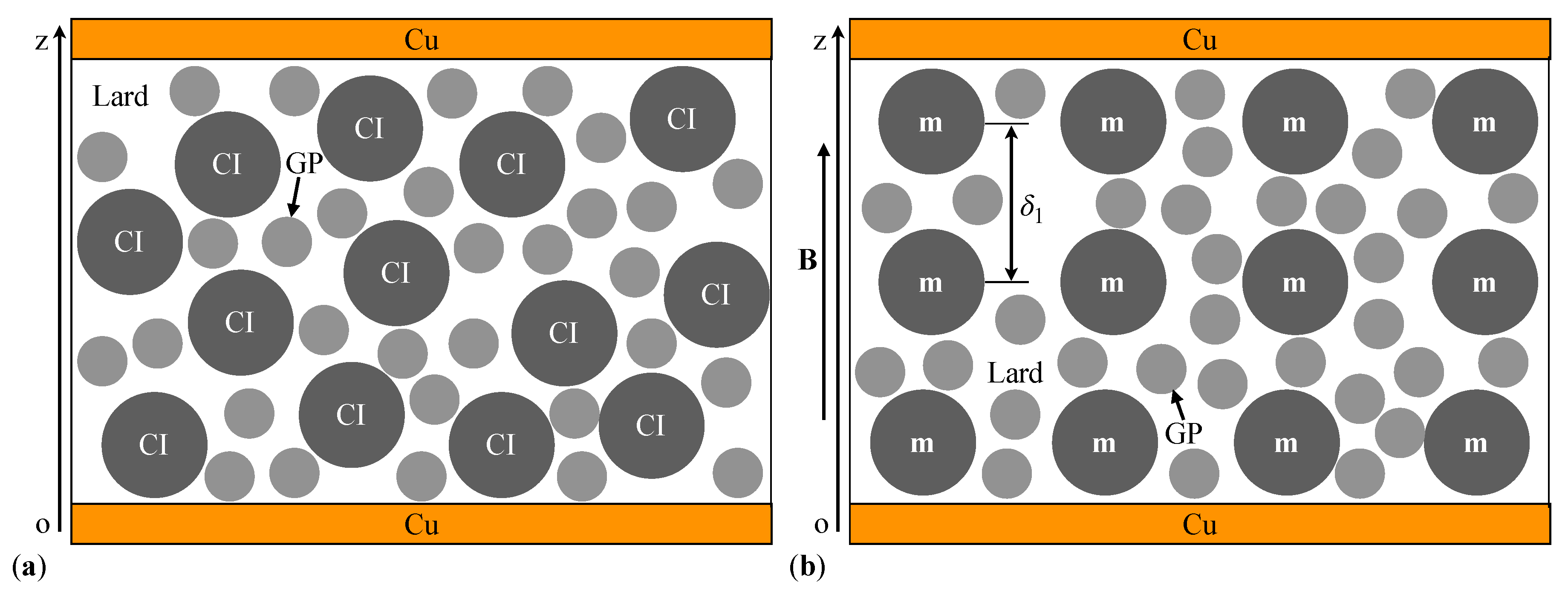

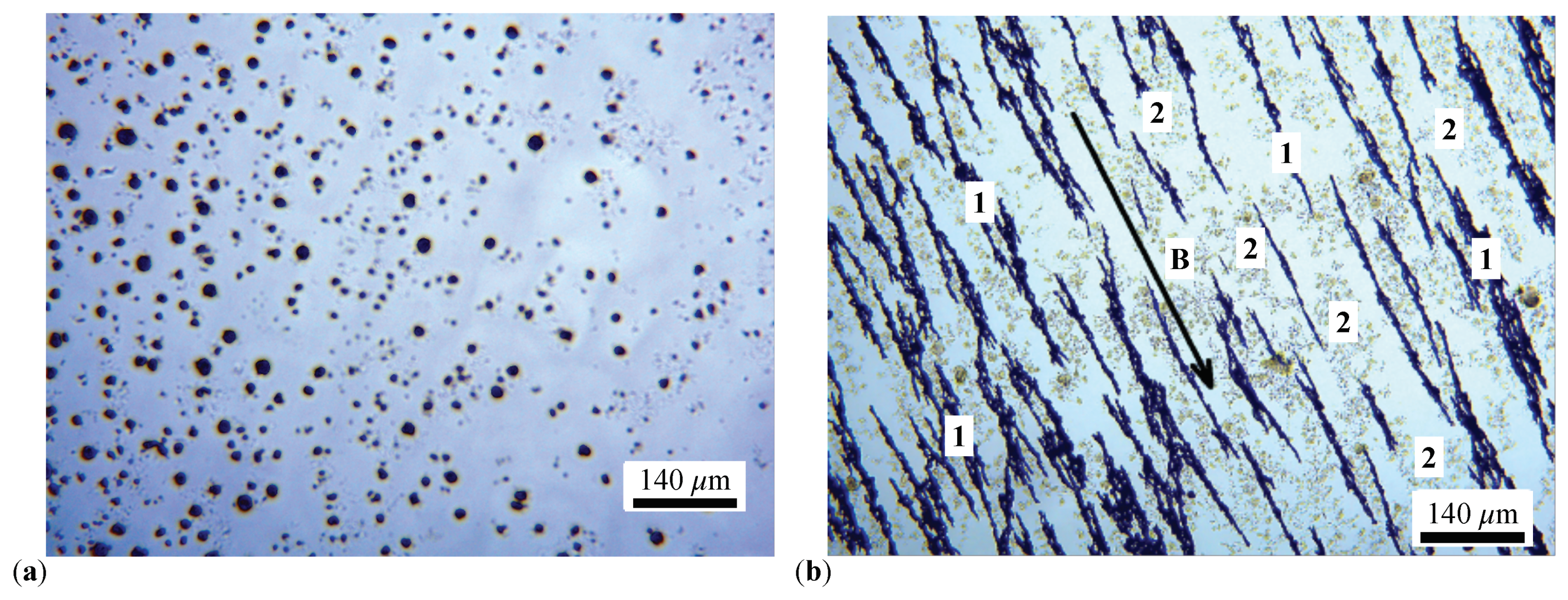

- Volumes of 3.2 cm of lard and 0.4 cm of GP are measured and introduced into a Berzelius beaker. In a second Berzelius beaker, are introduced 2.8 cm of lard and 0.8 cm of GP. The mixtures in the Berzelius beakers are homogenized by turn at a temperature of approximately 250C for about five minutes, after which the mixing continues until the liquid mixtures reach ambient temperature (approximately 27C). A film of the prepared mixture is deposited on a glass slide. The resulting image is shown in Figure 1(a). It can be observed from this figure that the formed microparticles have micrometric dimensions with an average diameter of 6.94 ± 0.55 m (see Appendix B for details), and have a spherical shape.

- In the Berzelius beaker with 3.2 cm of lard and 0.4 cm of GP, are introduced 0.4 cm of CI microparticles and the mixture is heated to approximately 150C for about five minutes. At the end of this period, the mixture is further homogenized until it reaches ambient temperature. At the end of this stage, the MRS suspension is formed.

- In the Berzelius beaker with 2.8 cm of lard and 0.8 cm of GP, is introduced 0.4 cm of CI microparticles and the mixture is heated to approximately 150C for about five minutes. At the end of this period, the mixture further homogenizing until it reaches ambient temperature. At the end of this stage, the MRS suspension is formed.

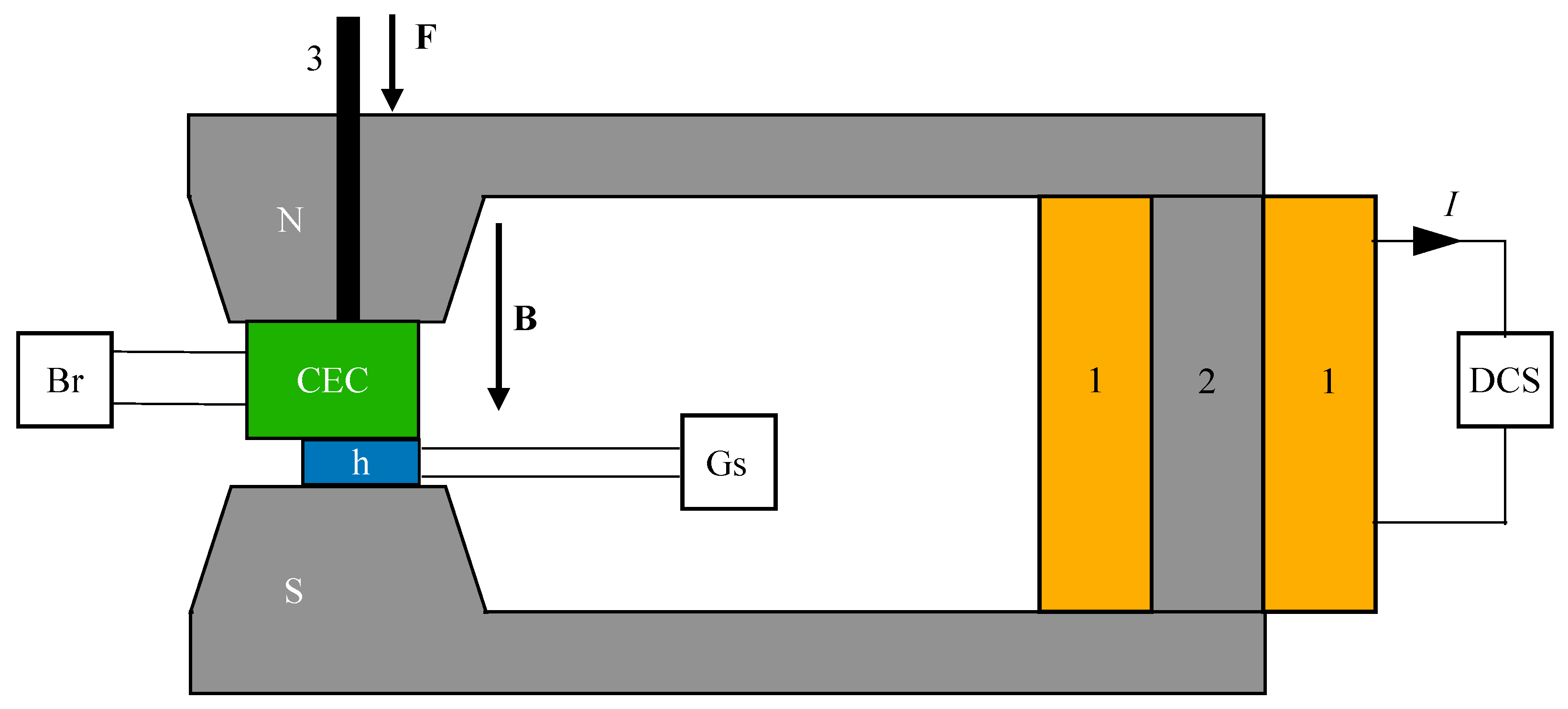

3. Fabrication of CECs

3.1. Materials

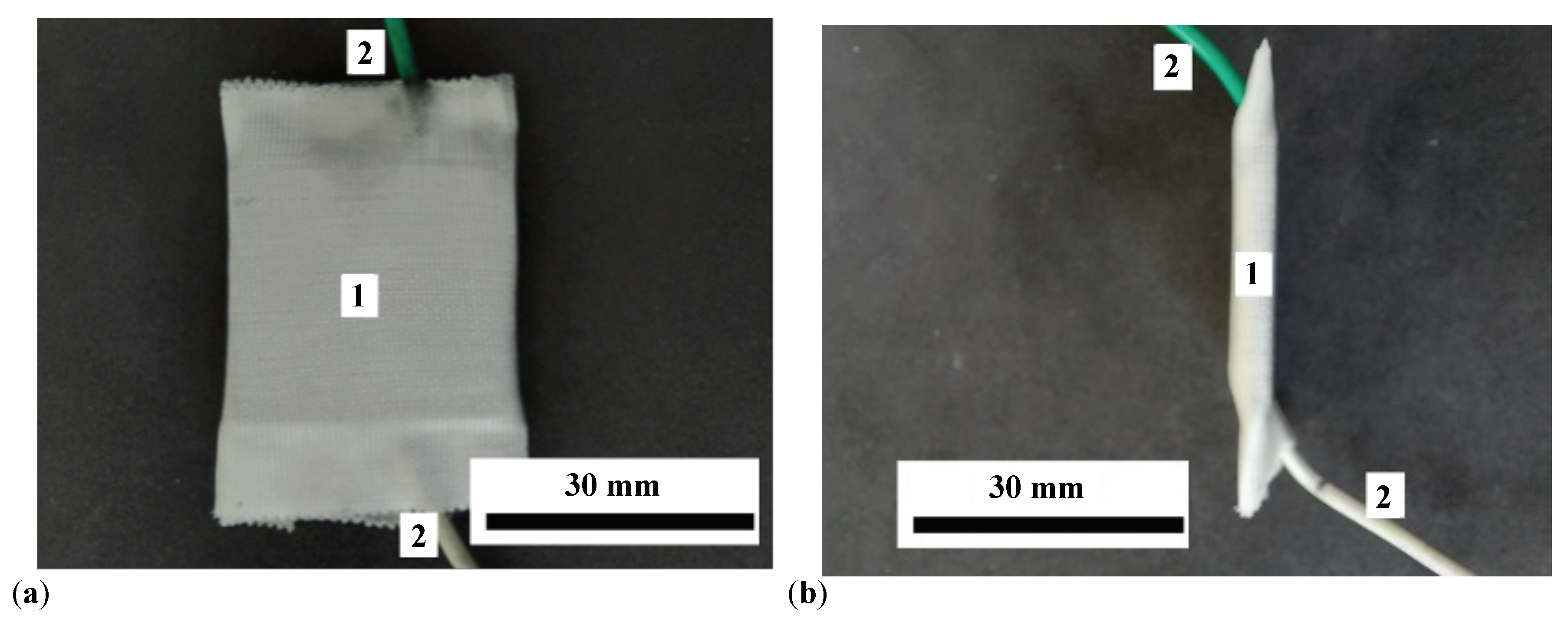

- Laminated board (LB) based on epoxy resin, reinforced with fiberglass, with one side plated with copper, having a thickness of 0.35 m. The LB is obtained from HobbyMarket (Romania) and is delivered in dimensions of 210 mm × 100 mm × 1.5 mm.

- Non-slip rubber pad (RP), type CAR-BOY (made in Japan) and supplied by Hornbach (Romania). The RP pad has a diameter of 40 mm and a thickness of 2 mm.

- Surgical adhesive tape Durapore (ST), manufactured by 3M EMEA GmbH (Switzerland), and supplied through Help Net (Romania). The tape is 5 cm wide and 9 m long.

3.2. Method

- LB is cut into six pieces. Each piece has dimensions of 30 mm× 30 mm× 1.5 mm.

- Three rings with an inner diameter of 20 mm are cut from the RP pad.

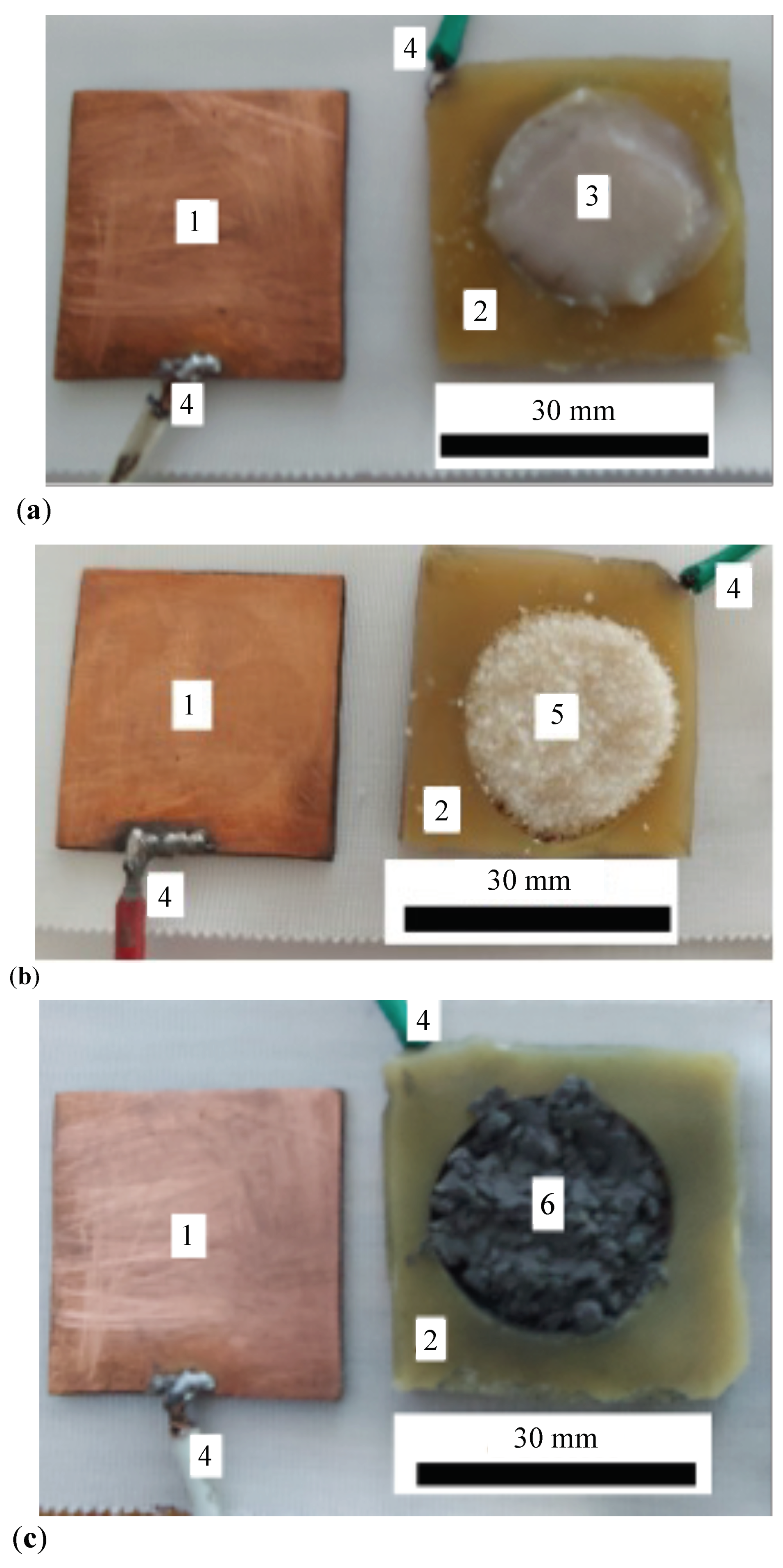

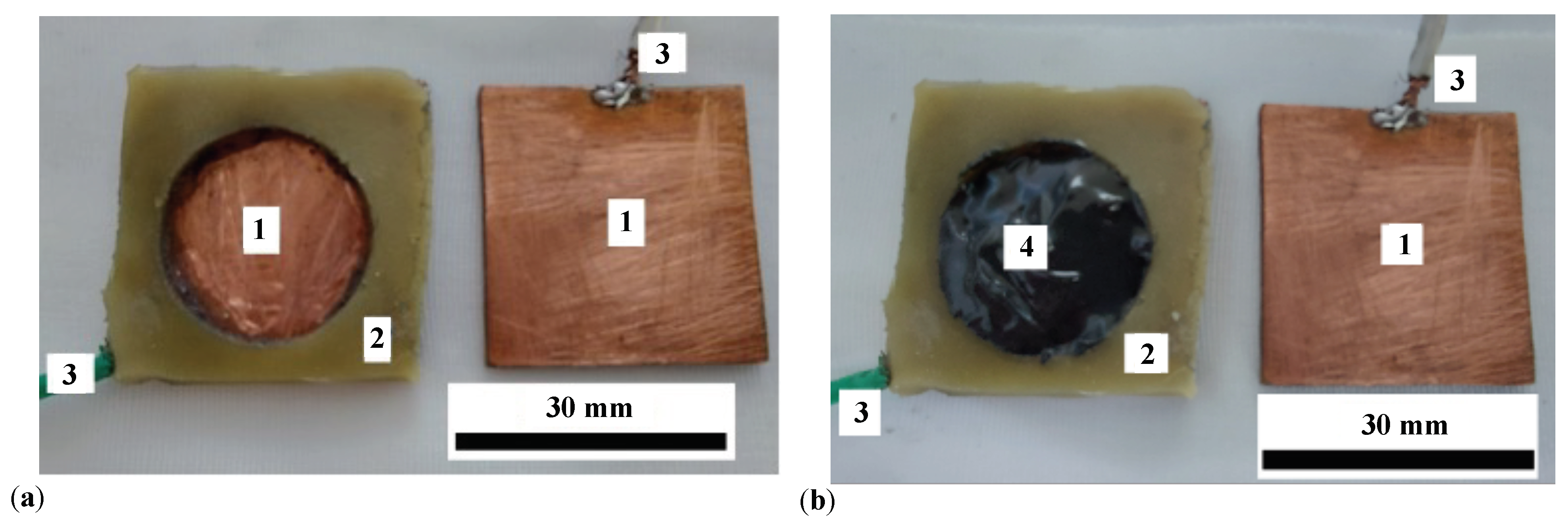

- On top of the MC filled with MRS (Figure 2b), the copper-coated side of the LB is fixed by pressing. The assembly thus realized is consolidated with ST tape. At the end of this stage, three capacitors denoted by CEC, CEC and CEC are obtained, as shown in Figure 3 (see details in Figure A3 in Appendix C).

4. Measurements of Electrical Properties

5. Results

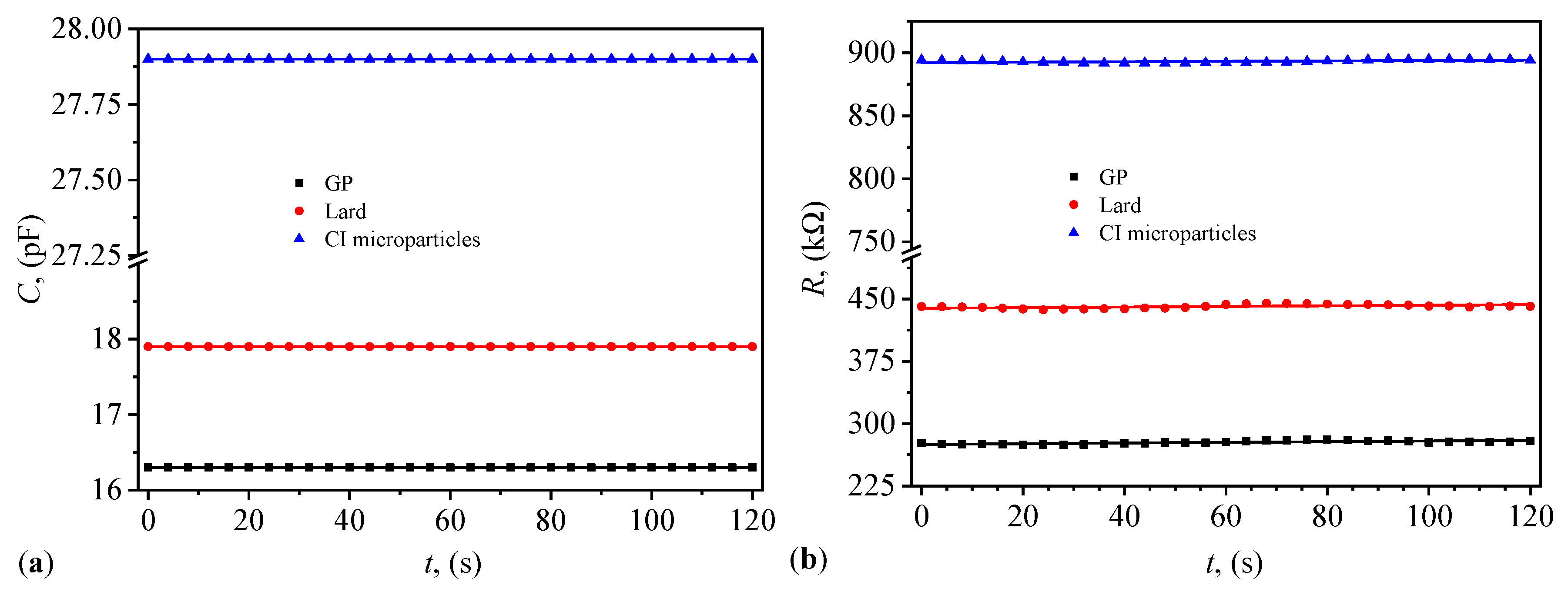

5.1. Stability of CECs with Lard, GP and Respectively CI Microparticles

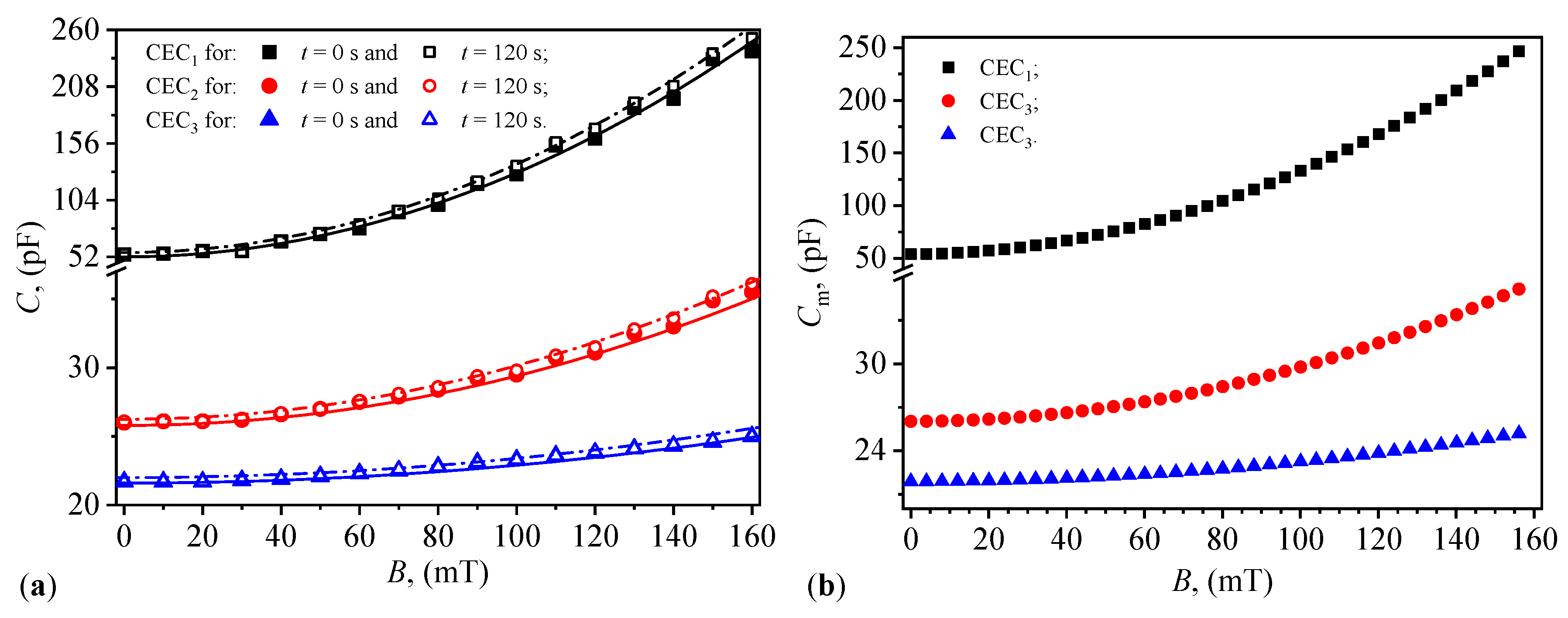

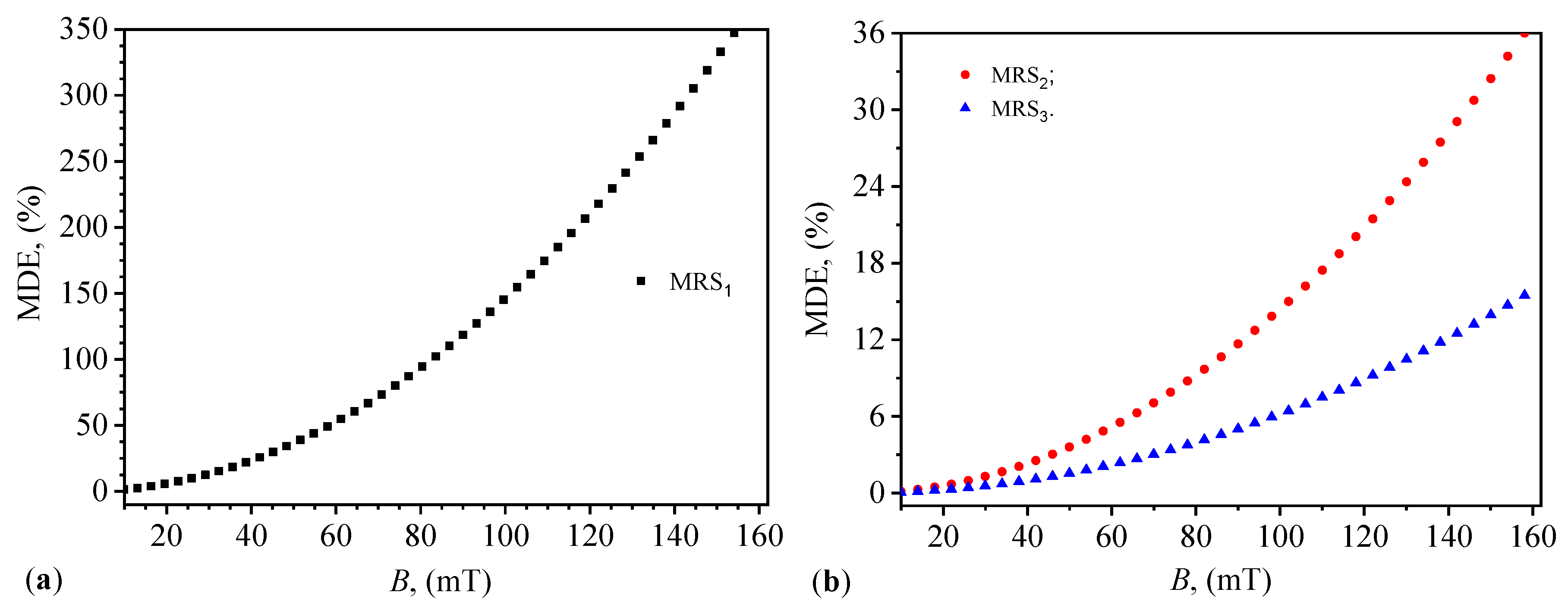

5.2. Electrical Properties of CECs

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Appendix A. Morphology of Gelatin Particles GP

Appendix B. Size Distribution of GP

Appendix C. CECs with Lard, CP and GP Microparticles

Appendix D. Fitting C and R Data for CECs with Lard, CP and GP Microparticles

| (pF) | (pF/s) | (k) | (k/s) | |

|---|---|---|---|---|

| Lard | 17.9 ± 1.91 × 10 | 4.762 × 10 ± 2.75 × 10 | 275 ± 0.238 | 0.0407 ± 0.0343 |

| GP | 16.3 ± 5.73 × 10 | 1.429 × 10 ± 8.25 × 10 | 438 ± 0.344 | 0.0361 ± 0.0496 |

| CI | 27.9 ± 5.73 × 10 | 1.429 × 10 ± 8.25 × 10 | 892 ± 0.168 | 0.0169 ± 0.0343 |

Appendix E. Fitting C and C m Data for CECs with MRSs

Appendix F. Derivation of the Relation for Calculating the Capacitance of CECs

References

- Wang, Y.; Xie, W.; Wu, D. Rheological properties of magnetorheological suspensions stabilized with nanocelluloses. Carbohydr. Polym. 2020, 231, 115776. [Google Scholar] [CrossRef]

- Zhao, P.; Du, T.; Ma, N.; Dong, X.; Qi, M. Effect of interfacial shear strength between magnetic particles and carrier liquid on rheological properties of magnetorheological fluids. J. Mol. Liq. 2023, 369, 120929. [Google Scholar] [CrossRef]

- Pei, P.; Peng, Y. Constitutive modeling of magnetorheological fluids: A review. J. Magn. Magn. Mater. 2022, 550, 169076. [Google Scholar] [CrossRef]

- Bica, I.; Anitas, E. Magnetodielectric effects in membranes based on magnetorheological bio-suspensions. Mater. & Des. 2018, 155, 317–324. [Google Scholar] [CrossRef]

- Saberi, H.; Esmaeilnezhad, E.; Choi, H.J. Application of artificial intelligence to magnetite-based magnetorheological fluids. J. Ind. Eng. Chem. 2021, 100, 399–409. [Google Scholar] [CrossRef]

- Jenis, F.; Kubik, M.; Michalek, T.; Strecker, Z.; Zacek, J.; Mazurek, I. Effect of the Magnetorheological Damper Dynamic Behaviour on the Rail Vehicle Comfort: Hardware-in-the-Loop Simulation. Actuators 2023, 12. [Google Scholar] [CrossRef]

- Bica, I. Electroconductive magnetorheological suspensions. Smart Mater. Struct. 2006, 15, N147. [Google Scholar] [CrossRef]

- Wang, S.; Ge, Y.; Chen, W.; Gao, F. A dynamic analytical model on electrical circuit response of magnetorheological clutch. Proc. Inst. Mech. Eng. C 2024, 238, 1968–1977. [Google Scholar] [CrossRef]

- Kumar, S.; Sehgal, R.; Wani, M.; Sharma, M.D. Stabilization and tribological properties of magnetorheological (MR) fluids: A review. J. Magn. Magn. Mater. 2021, 538, 168295. [Google Scholar] [CrossRef]

- Choi, S.B. Sedimentation Stability of Magnetorheological Fluids: The State of the Art and Challenging Issues. Micromachines 2022, 13. [Google Scholar] [CrossRef]

- Narwade, P.; Deshmukh, R.; Nagarkar, M.; Wagh, M. Experimental study and rheology of magneto-rheological fluid for a suspension system. Materials Today: Proceedings, 2023. [Google Scholar] [CrossRef]

- Bica, I.; Anitas, E. Magnetic field intensity effect on electrical conductivity of magnetorheological biosuspensions based on honey, turmeric and carbonyl iron. J. Ind. Eng. Chem. 2018, 64, 276–283. [Google Scholar] [CrossRef]

- Bica, I.; Anitas, E.M.; Averis, L.M.E.; Kwon, S.H.; Choi, H.J. Magnetostrictive and viscoelastic characteristics of polyurethane-based magnetorheological elastomer. J. Ind. Eng. Chem. 2019, 73, 128–133. [Google Scholar] [CrossRef]

- Shixu, L.; Jing, Z.; Jun, L.; Jie, F.; Miao, Y.; Song, Q. Enhancing Effect of Fe3O4/Nanolignocelluloses in Magnetorheological Fluid. Langmuir 2021, 37, 7176–7184. [Google Scholar] [CrossRef]

- Plachy, T.; Rohrer, P.; Holcapkova, P. Gelatine-Coated Carbonyl Iron Particles and Their Utilization in Magnetorheological Suspensions. Materials 2021, 14. [Google Scholar] [CrossRef]

- Sista, K.S.; Dwarapudi, S.; Kumar, D.; Sinha, G.R.; Moon, A.P. Carbonyl iron powders as absorption material for microwave interference shielding: A review. J. Alloys Compd. 2021, 853, 157251. [Google Scholar] [CrossRef]

- Eshgarf, H.; Ahmadi Nadooshan, A.; Raisi, A. An overview on properties and applications of magnetorheological fluids: Dampers, batteries, valves and brakes. J. Energy Storage 2022, 50, 104648. [Google Scholar] [CrossRef]

- Musialek, K.; Musialek, I.; Osowski, K.; Olszak, A.; Mikulska, A.; Kesy, Z.; Kesy, A.; Choi, S.B. A New Type of Hydraulic Clutch with Magnetorheological Fluid: Theory and Experiment. Micromachines 2024, 15. [Google Scholar] [CrossRef]

- Bica, I.; Anitas, E.; Averis, L.; Bunoiu, M. Magnetodielectric effects in composite materials based on paraffin, carbonyl iron and graphene. J. Ind. Eng. Chem. 2015, 21, 1323–1327. [Google Scholar] [CrossRef]

- Kang, S.S.; Choi, K.; Nam, J.D.; Choi, H.J. Magnetorheological Elastomers: Fabrication, Characteristics, and Applications. Materials 2020, 13. [Google Scholar] [CrossRef]

- Fei, C.; Haopeng, L.; Mengmeng, H.; Zuzhi, T.; Aimin, L. Preparation of magnetorheological fluid with excellent sedimentation stability. Mater. Manuf. Process. 2020, 35, 1077–1083. [Google Scholar] [CrossRef]

- Prajapati, H.; Shahanand, J.; Nimkar, H.; Lakdawala, A. Methods for sedimentation study of magnetorheological fluids. Mater. Today: Proc. 2020, 28, 40–44. [Google Scholar] [CrossRef]

- Marikkar, J.; Yanty, N. Effect of Chemical and Enzymatic Modifications on the Identity Characteristics of Lard: A Review. Int. J. Food Prop. 2014, 17, 321–330. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, K.; Yang, H.; Yue, K.; Liu, R.; Bi, Y.; Ma, C. Characterization of lard from different adipose tissues: Physicochemical properties, thermodynamics characteristics and crystallization behaviors. J. Food Compos. Anal. 2023, 115, 105021. [Google Scholar] [CrossRef]

- Alipal, J.; Mohd Pu’ad, N.; Lee, T.; Nayan, N.; Sahari, N.; Basri, H.; Idris, M.; Abdullah, H. A review of gelatin: Properties, sources, process, applications, and commercialisation. Mater. Today: Proc. 2021, 42, 240–250. [Google Scholar] [CrossRef]

- Janchiva, A.; Ohb, Y.; Choic, S. High quality biodiesel production from pork lard by high solvent additive. ScienceAsia 2012, 38, 95–101. [Google Scholar] [CrossRef]

- Liu, S.; Ye, T.T.; Liu, X.; Wang, Z.C.; Chen, D.W. Pork phospholipids influence the generation of lipid-derived lard odorants in dry rendering process. LWT 2021, 152, 112284. [Google Scholar] [CrossRef]

- Koontanatechanon, A.; Wongphatcharachai, M.; Nonthabenjawan, N.; Jariyahatthakij, P.; Khorporn, T.; Parnsen, W.; Keattisin, B.; Leksrisompong, P.; Srichana, P.; Prasopdee, S.; et al. Effects of Omega-3-Rich Pork Lard on Serum Lipid Profile and Gut Microbiome in C57BL/6NJ Mice. Int. J. Food Sci. 2022, 2022, 9269968. [Google Scholar] [CrossRef]

- Becker, L.C.; Bergfeld, W.F.; Belsito, D.V.; Hill, R.A.; Klaassen, C.D.; Liebler, D.C.; Marks, J.G.; Shank, R.C.; Slaga, T.J.; Snyder, P.W.; et al. Lard and Lard-Derived Ingredients. Int. J. Toxicol. 2023, 42, 58S–60S. [Google Scholar] [CrossRef]

- Julie Chandra, C.S.; Sasi, S.; Bindu Sharmila, T.K. , Material Applications of Gelatin. In Handbook of Biopolymers; Thomas, S.; AR, A.; Jose Chirayil, C.; Thomas, B., Eds.; 2023; pp. 749–782. [CrossRef]

- Iacobescu, G.E.; Bica, I.; Chirigiu, L.M.E. Physical Mechanisms of Magnetic Field Effects on the Dielectric Function of Hybrid Magnetorheological Suspensions. Materials 2021, 14. [Google Scholar] [CrossRef]

- Kalina, K.A.; Metsch, P.; Brummund, J.; Kästner, M. A macroscopic model for magnetorheological elastomers based on microscopic simulations. Int. J. Solids Struct. 2020, 193-194, 200–212. [Google Scholar] [CrossRef]

- Calderon, O.G.; Melle, S. Dynamics of simple magnetorheological suspensions under rotating magnetic fields with modulated Mason number. J. Phys. D: Appl. Phys. 2002, 35, 2492. [Google Scholar] [CrossRef]

- Osial, M.; Pregowska, A.; Warczak, M.; Giersig, M. Magnetorheological fluids: A concise review of composition, physicochemical properties, and models. J. Intell. Mater. Syst. Struct. 2023, 34, 1864–1884. [Google Scholar] [CrossRef]

- Stejskal, J.; Sapurina, I.; Vilčáková, J.; Plachý, T.; Sedlačík, M.; Bubulinca, C.; Gořalík, M.; Trchová, M.; Kolská, Z.; Prokeš, J. Conducting and Magnetic Composites Polypyrrole Nanotubes/Magnetite Nanoparticles: Application in Magnetorheology. ACS Appl. Nano Mater. 2021, 4, 2247–2256. [Google Scholar] [CrossRef]

- Munteanu, A.; amd Lenka Munteanu, T.P.; Ngwabebhoh, F.A.; Stejskal, J.; Trchová, M.; Kubík, M.; Sedlačík, M. Bidisperse magnetorheological fluids utilizing composite polypyrrole nanotubes/magnetite nanoparticles and carbonyl iron microspheres. Rheol. Acta 2023, 62, 461–472. [Google Scholar] [CrossRef]

- Jurca, M.; Vilcakova, J.; Kazantseva, N.E.; Munteanu, A.; Munteanu, L.; Sedlacik, M.; Stejskal, J.; Trchova, M.; Prokes, J. Conducting and Magnetic Hybrid Polypyrrole/Nickel Composites and Their Application in Magnetorheology. Materials 2024, 17. [Google Scholar] [CrossRef]

- Djatna, S.T.; Tedja, I.T.; Fauzi, A.M. Application of Electrical Properties to Differentiate Lard from Tallow and Palm Oil. J. Anim. Sci. Technol. 2013, 10, 32–39. [Google Scholar] [CrossRef]

- Gadhave, R.V. Improving the performance of gelatine glue using biocompatible polymers. Polym. Bull. 2024, 81, 8177–8193. [Google Scholar] [CrossRef]

- Bica, I.; Anitas, E. Magnetic flux density effect on electrical properties and visco-elastic state of magnetoactive tissues. Compos. Part B 2019, 159, 13–19. [Google Scholar] [CrossRef]

- Ji, D.; Luo, Y.; Ren, H.; Wei, D.; Shao, J. Numerical Simulation and Experimental Analysis of Microstructure of Magnetorheological Fluid. J. Nanomater. 2019, 2019, 6312606. [Google Scholar] [CrossRef]

- Bica, I.; Iacobescu, G.E.; Chirigiu, L.M.E. Magneto-Tactile Sensor Based on a Commercial Polyurethane Sponge. Nanomaterials 2022, 12. [Google Scholar] [CrossRef]

| (g/cm) | (× 10) | ||

|---|---|---|---|

| Lard | 0.8845 | 25.1483 | 8.09291 |

| GP | 0.5649 | 22.9860 | 5.091925 |

| CI | 3.3600 | 39.339 | 2.515722 |

| (cm) | (cm) | (cm) | (vol.%) | (vol.%) | (vol.%) | |

|---|---|---|---|---|---|---|

| MRS | 3.6 | 0.4 | 0.0 | 90 | 10 | 0 |

| MRS | 3.2 | 0.4 | 0.4 | 80 | 10 | 10 |

| MRS | 2.8 | 0.4 | 0.8 | 70 | 10 | 20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).