Submitted:

02 July 2024

Posted:

02 July 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

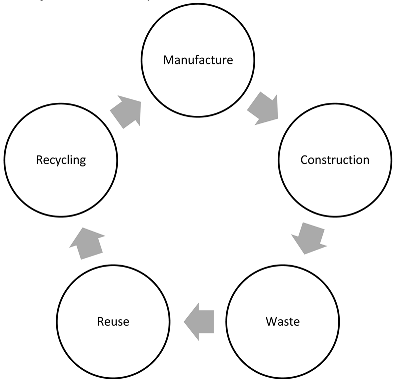

1.1. Construction Industry

1.2. Sustainability and Construction Industry

1.3. Sustainable Construction Materials

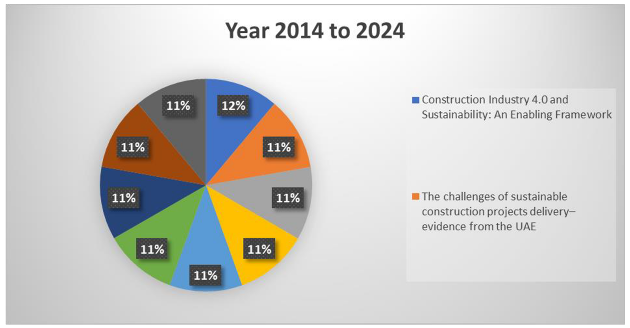

2. Materials and Methods

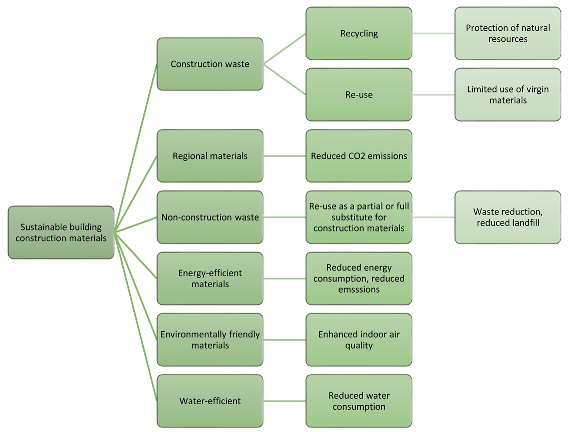

2.1. Sustainable Building Construction Materials

2.2. Construction in UAE

2.3. Sustainable Building Construction in UAE

2.4. Sustainable Construction Materials’ Attributes

2.4.1. Recycled Content

2.4.2. Regional Materials

2.4.3. Solar Reflective Index (SRI)

2.4.4. Light Reflectance Value (LRV)

2.4.5. Volatile Organic Compounds (VOCs): Low-Emitting Materials, Paints, and Coatings

2.4.6. Low-Emitting Materials: Adhesives and Sealants

| Max. VOC Limit | g/l |

| Architectural Application | |

| Indoor carpet adhesive | 50 |

| Carpet pad adhesive | 50 |

| Wood floor adhesive | 100 |

| Rubber floor adhesive | 60 |

| Subfloor adhesive | 50 |

| Ceramic tile adhesive | 65 |

2.4.7. Thermal Transmittance U-Value

2.4.8. Water-Efficient Fittings

2.4.9. Sustainable Concrete

2.4.10. Certified/Accredited Timber

2.4.11. Asbestos-Containing Materials

2.4.12. Lead- or Heavy-Metal-Containing Materials

| Heavy metal | Max. limit allowed(mg/kg) |

| Lead | 100 |

| Cadmium | 500 |

| Chromium VI | 500 |

| Mercury | 100 |

| Arsenic | 100 |

3. Results and Discussion

- Locally produced and sourced;

- Lower transportation costs and environmental impacts;

- Thermally efficient;

- Provide better and healthier indoor air quality to occupants;

- Financially viable;

- Can be obtained by recycling used materials or demolished construction waste;

- Use removable resources;

- A greater initial cost but a lower long-term cost with more sustainable benefits.

4. Conclusion

References

- A PRACTICE GUIDE FOR BUILDING A SUSTAINABLE DUBAI 100. (2020).

- Article ID: IJCIET_11_01_011, Factors Effecting the Cost Management in Construction Projects. (2020). Retrieved from https://www.researchgate.net/publication/343722659_Article_ID_IJCIET_11_01_011_Factors_Effecting_the_Cost_Management_in_Construction_Projects.

- Aslam, M. S., Huang, B., & Cui, L. (2020). Review of construction and demolition waste management in China and USA. Journal of Environmental Management, 264, 110445. [CrossRef]

- Bribián, I. Z., Capilla, A. V., & Usón, A. A. (2010). Life cycle assessment of building materials: Comparative analysis of energy and environmental impacts and evaluation of the eco-efficiency improvement potential. [CrossRef]

- Brundtland Report | Sustainable Development & Global Environmental Issues | Britannica. (1987). Retrieved from https://www.britannica.com/topic/Brundtland-Report.

- Cabeza, L. F., Rincón, L., Vilariño, V., Pérez, G., & Castell, A. (2013). Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: A review. [CrossRef]

- Calautit, J. K., & Yong, L. X. (2023). Fad or future? Navigating challenges and proposing holistic solutions in sustainable building design. One Earth, 6(11), 1430–1434. [CrossRef]

- Chan, M., Masrom, M. A. N., & Yasin, S. S. (2022). Selection of Low-Carbon Building Materials in Construction Projects: Construction Professionals’ Perspectives. Buildings, 12(4), 486. [CrossRef]

- Chau, C. K., Hui, W. K., Ng, W. Y., & Powell, G. (2012). Assessment of CO 2 emissions reduction in high-rise concrete office buildings using different material use options. 22–34. [CrossRef]

- Cherian, A. (2008). The Construction Industry in the Perspective of an Economic Boost of The United Arab Emirates (UAE). International Research Journal of Engineering and Technology, 9001. Retrieved from www.irjet.net.

- Construction Products Regulation 305/2011 - cemarking.net. (2011). Retrieved from https://cemarking.net/eu-ce-marking-directives/construction-products-regulation-3052011/.

- Dorling, D. (2021). World population prospects at the UN: Our numbers are not our problem? In The Struggle for Social Sustainability: Moral Conflicts in Global Social Policy (pp. 129–154). Policy Press. [CrossRef]

- Emissions Gap Report 2020. (2020). Retrieved from https://www.unep.org/emissions-gap-report-2020.

- Empowering Cities for a Net Zero Future. (2021). Empowering Cities for a Net Zero Future. [CrossRef]

- Hossain, M. U., Ng, S. T., Antwi-Afari, P., & Amor, B. (2020). Circular economy and the construction industry: Existing trends, challenges and prospective framework for sustainable construction. Renewable and Sustainable Energy Reviews, 130, 109948. [CrossRef]

- Ibrahimkhil, M. H., Shen, X., & Barati, K. (2020). Enhanced Construction Progress Monitoring through Mobile Mapping and As-built Modeling.

- Kim, S. Y., Nguyen, M. V., & Luu, V. T. (2020). A performance evaluation framework for construction and demolition waste management: stakeholder perspectives. Engineering, Construction and Architectural Management, 27(10), 3189–3213. [CrossRef]

- Kong Yap, C., Seng Leow, C., & Goh, B. (2024). Sustainable construction materials under ESG: a literature review and synthesis. [CrossRef]

- Leskinen, N., Vimpari, J., & Junnila, S. (2020). A Review of the Impact of Green Building Certification on the Cash Flows and Values of Commercial Properties. [CrossRef]

- Murray, P. E., & Cotgrave, A. J. (2007). Sustainability literacy: The future paradigm for construction education? Structural Survey, 25(1), 7–23. [CrossRef]

- Ngowi, A. B., Pienaar, E., Talukhaba, A., & Mbachu, J. (2005). The globalisation of the construction industry-a review. Building and Environment, 40, 135–141. [CrossRef]

- Osuizugbo, I. C., Aina, O. O., & Onokwai, A. O. (2023). Roles of clients in buildability improvement in Nigeria: an exploratory factor analysis. Built Environment Project and Asset Management, 13(6), 862–879. [CrossRef]

- (PDF) Overview of operational and regulatory framework for occupational safety and health in the Zimbabwean construction industry. (2014). Retrieved from https://www.researchgate.net/publication/349311971_Overview_of_operational_and_regulatory_framework_for_occupational_safety_and_health_in_the_Zimbabwean_construction_industry.

- Polyportis, A., Mugge, R., & Magnier, L. (2022). Consumer acceptance of products made from recycled materials: A scoping review. [CrossRef]

- Pomponi, F., & Moncaster, A. (2016). Circular economy for the built environment: A research framework. [CrossRef]

- Schwab, K. (2016). Insight Report.

- Sertyesilisik, B. (2023). Carbon capturing smart construction industry model to foster green and sustainable total factor productivity growth of industries. The Impact of Environmental Emissions and Aggregate Economic Activity on Industry: Theoretical and Empirical Perspectives, 11–23. [CrossRef]

- Sustainable Construction in Malaysia - Developers’ Awareness. (2009). Retrieved from https://www.researchgate.net/publication/242768280_Sustainable_Construction_in_Malaysia_-_Developers’_Awareness.

- Sustainable Materials and Construction Practices in Industrial Buildings. (2023). Retrieved from https://www.researchgate.net/publication/375495465_Sustainable_Materials_and_Construction_Practices_in_Industrial_Buildings.

- Su, Y., Zou, Z., Ma, X., & Ji, J. (2022). Understanding the relationships between the development of the construction sector, carbon emissions, and economic growth in China: Supply-chain level analysis based on the structural production layer difference approach. Sustainable Production and Consumption, 29, 730–743. [CrossRef]

- Su, Y., Zou, Z., Ma, X., Ji, J., & Pomponi, F. (2021). Sustainable Production and Consumption 29 (2022) 730-743 Sustainable Production and Consumption Understanding the relationships between the development of the construction sector, carbon emissions, and economic growth in China: Supply-chain level analysis based on the structural production layer difference approach. [CrossRef]

- Wan, L., & Ng, E. (2016). Assessing the sustainability of the built environment in mountainous rural villages in Southwest China. Mountain Research and Development, 36(1), 4–14. [CrossRef]

- William Dobson, D., Sourani, A., Sertyesilisik, B., & Tunstall, A. (2013). Sustainable Construction: Analysis of Its Costs and Benefits. American Journal of Civil Engineering and Architecture, 1(2), 32–38. [CrossRef]

- Yin, B. C. L., Laing, R., Leon, M., & Mabon, L. (2018). An evaluation of sustainable construction perceptions and practices in Singapore. Sustainable Cities and Society, 39, 613–620. [CrossRef]

- Zabalza Bribián, I., Valero Capilla, A., & Aranda Usón, A. (2011). Life cycle assessment of building materials: Comparative analysis of energy and environmental impacts and evaluation of the eco-efficiency improvement potential. Building and Environment, 46(5), 1133–1140. [CrossRef]

| Roofing Material | SRI Value | Roofing Material | SRI Value |

| Grey EPDM (ethylene propylene diene monomer) | 21 | Light beige concrete tiles | 76 |

| Unpainted cement tiles | 25 | Light brown concrete tiles | 48 |

| Red clay tiles | 36 | Pink and grey concrete tiles | 63 |

| Light gravel | 37 | White ceramic tiles | 90 |

| Aluminium | 56 | White coating | 100 |

| Product Sub-category | Type | VOCs (g/l) | Product Sub-category | Type | VOCs (g/l) |

| Interior matt wall and ceiling (Gloss <25 @60º) | Water-based | 30 | Two-pack reactive performance coating for specific ends such as floors | Water-based | 140 |

| Solvent-based | 30 | Solvent-based | 500 | ||

| Interior matt wall and ceiling (Gloss >25 @60º) | Water-based | 100 | Multi-coloured coatings | Water-based | 100 |

| Solvent-based | 100 | Solvent-based | 100 | ||

| Interior walls of mineral substrate | Water-based | 40 | Decorative effect coatings | Water-based | 200 |

| Solvent-based | 430 | Solvent-based | 200 | ||

| Interior/exterior trim and cladding paints for wood and metal | Water-based | 130 | Primers | Water-based | 30 |

| Solvent-based | 300 | Solvent-based | 350 | ||

| Interior/exterior minimal build wood stains | Water-based | 130 | Binding primers | Water-based | 30 |

| Solvent-based | 400 | Solvent-based | 750 | ||

| Interior/exterior minimal build wood stains | Water-based | 130 | One-pack performance coatings | Water-based | 140 |

| Solvent-based | 700 | Solvent-based | 500 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).