Submitted:

27 June 2024

Posted:

03 July 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

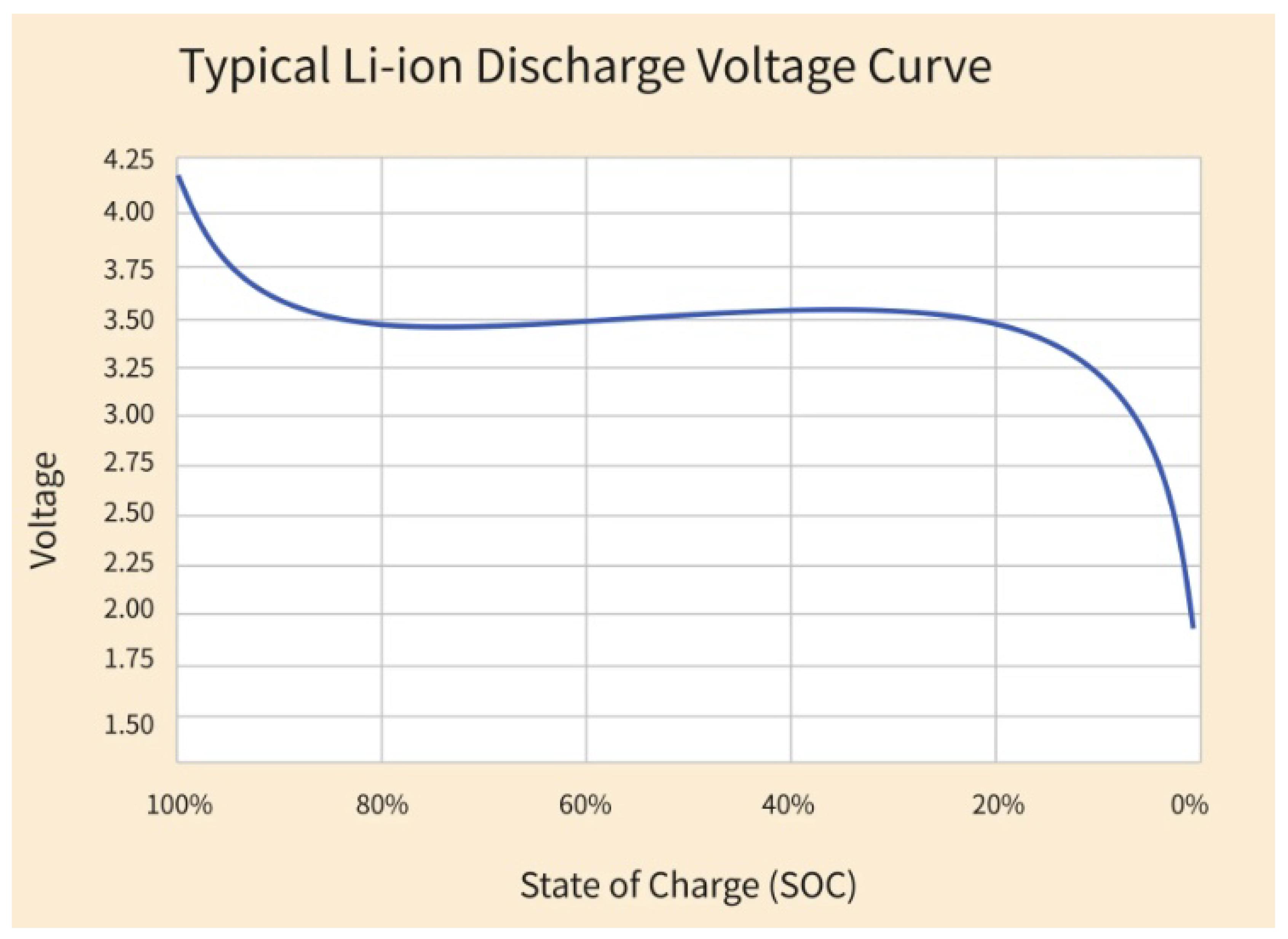

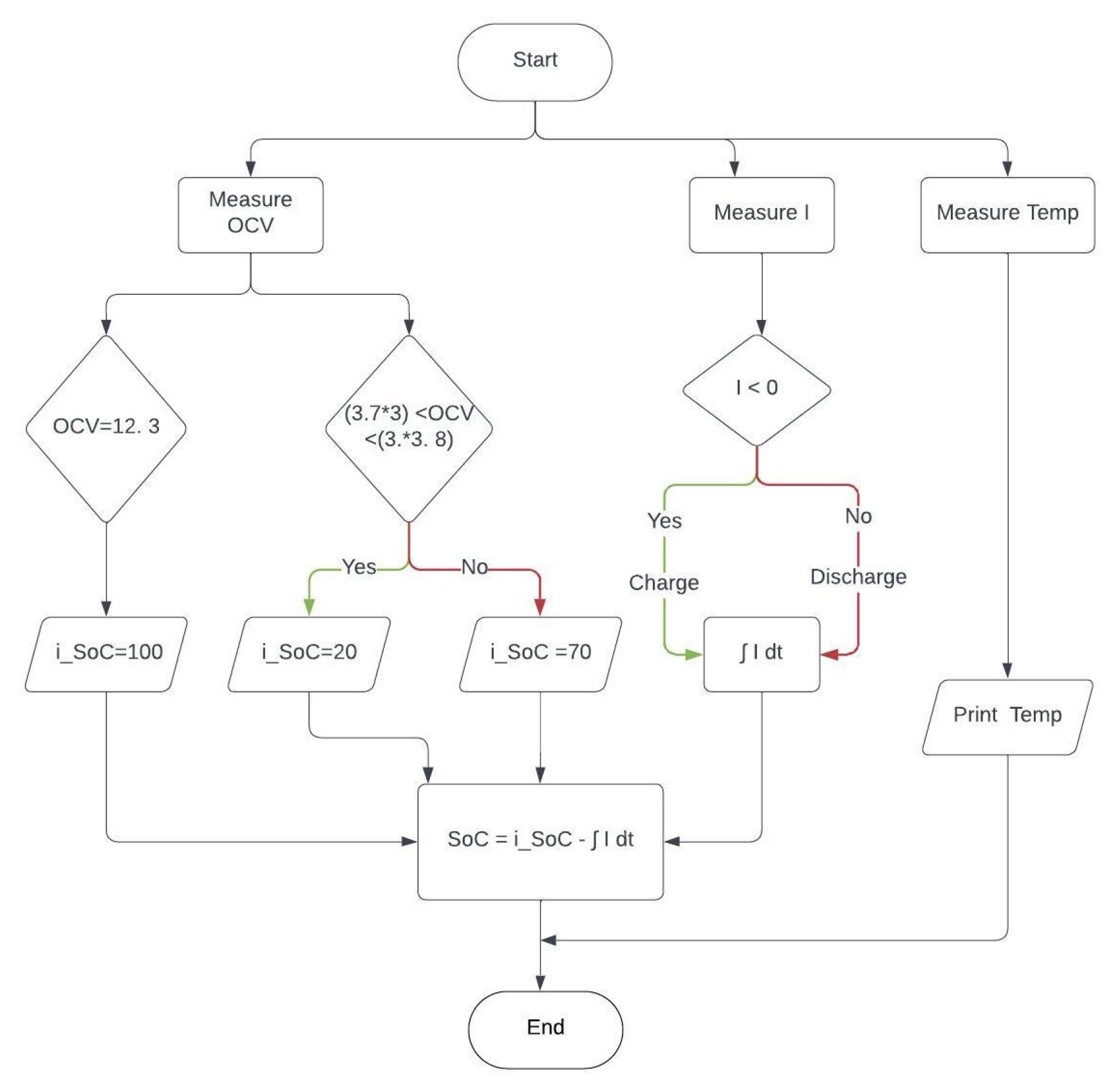

2. State-of-Charge

2.1. Method for Calculating SOC - Coulomb Counting

3. Methodology

3.1. Charging/Discharging of Li-Ion Battery

Charging

- Connect Battery: Plug the lithium-ion battery into the iMAX-B6 charger, ensuring correct polarity.

-

Start Charging: Initiate the charging process. The charger will follow the charging phases (CC, CV) automatically.Constant Current (CC) Phase: Charge at a constant current until a certain voltage is reached.Constant Voltage (CV) Phase: Hold the voltage steady while the current decreases.

- Monitor Parameters: Keep an eye on the charger display to observe current, voltage, and temperature readings. The iMAX B6 typically provides real time data.

- Charge Termination: The charger should automatically stop charging when the battery reaches the set voltage or when a certain amount of time has elapsed.

Discharging

- Connect Load: Connect a suitable load or iMAX-B6 charger/ discharger to the battery output for discharging.

- Start Discharging: Initiate the discharging process. Monitor the charger display for real-time information.

- Monitor Parameters: Keep an eye on the current, voltage, and temperature readings during the discharge process.

- Discharge Termination: The charger should automatically stop discharging when the battery reaches the set voltage or when a certain amount of time has elapsed.

3.2. Sensing of Current, Voltage and Temperature

- Current Sensing: Use a current sensor in series with the battery. This current sensor is to be calibrated. For that, 1A current is passed through the sensor which read 0.038.

- Voltage Sensing: Measure the voltage across the battery terminals. A voltage divider is used as a voltage sensor by creating a circuit with two resistors in series to divide the input voltage down to a level that can be safely measured by a microcontroller.

- Temperature Sensing: Employ a temperature sensor placed near the battery.

3.3. Data to STM

- Connect Sensors: Connect the output of the current, voltage and temperature sensors to the corresponding analog input pins on the STM32.

- Analog to Digital Conversion: The analog values are converted into digital values using edge computing technique of STM.

- To Matlab: The values are then transferred to matlab which are obtained in the range of 0-1. These values are then multiplied by the gain for obtaining the actual values of current/voltage.

- Data Processing: The sensed data is then processed and involves filtering, averaging, or applying algorithms for the calculation of SOC.

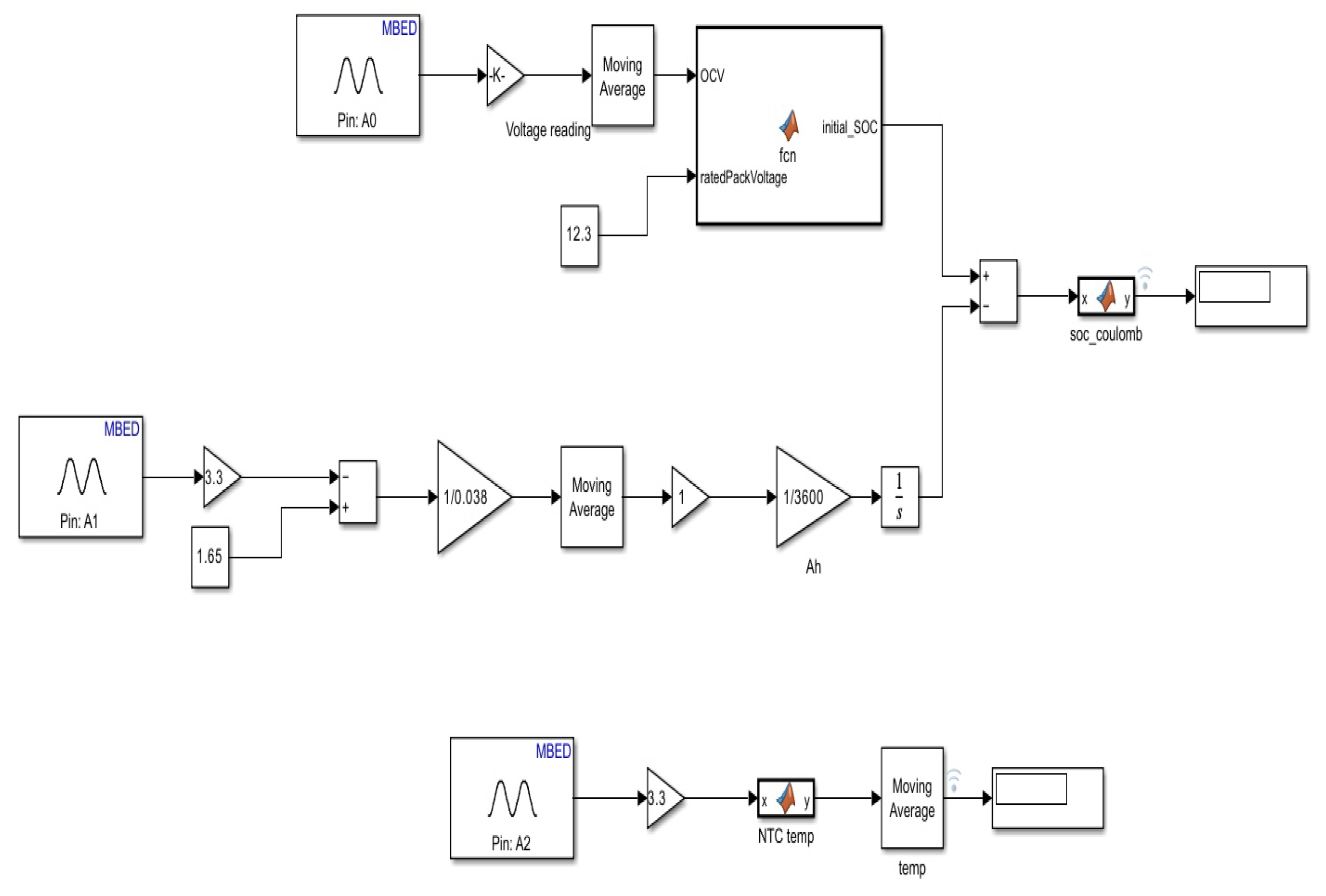

3.4. Matlab

- Installion of Support Package: The STM32 support package is installed from the Add-Ons Explorer within MATLAB.

- Setting Up of STM32F411RE Nucleo Board: Connection of STM32F411RE Nucleo board to computer is done using a USB cable.

- Simulink: Create a new Simulink model. From the Simulink Library Browser, the necessary blocks are dragged and dropped onto the model to configure the communication with the STM32F411RE board.

- Configuration of Parameters: The parameters of STM32 blocks are configured according to the requirements.

- Connection of Blocks: The blocks are connected to define the flow of data and control between the STM32 board and other components of the system.

- Build and Deploy: After the model is ready, initiation is done to generate the code for the STM32F411RE board. Then, the code is deployed to the board using the appropriate options in Simulink.

- Run the Model: After deploying the code, Simulink model is run. MATLAB then communicates with the STM32F411RE board and execute the specified tasks.

- Results: The behaviour of the system is analysed by visualizing the data collected from STM which includes current, voltage, temperature and SOC variations in real time.

3.5. Display of Information

| No. | Components | Specifications |

|---|---|---|

| 1 | Li-Ion Battery | 12V , 20Ah |

| 2 | Charger/Discharger | iMAX-B6AC |

| 3 | Current sensor | 30 Amps, ACS712 30A |

| 4 | Voltage sensor | Voltage Divider |

| 5 | Temperature sensor | Thermistor |

| 6 | STM32 MCU | Nucleo board F411RE |

| 7 | Perforated hardboard | - |

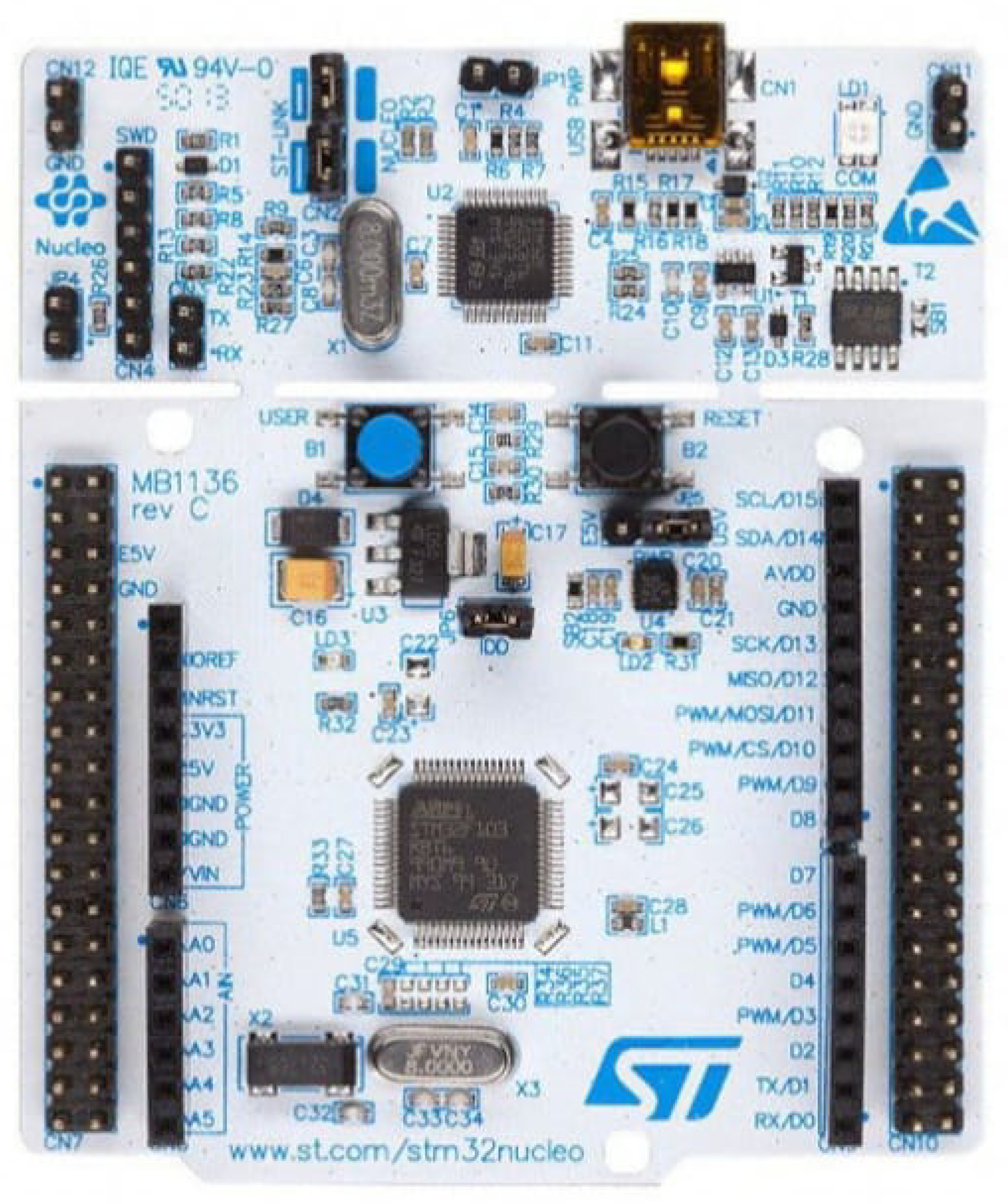

4. STM32 MCU Nucleo Board F411RE

- Microcontroller: The STM32 Nucleo F411RE is built around the STM32F411RE MCU, which belongs to the ARM Cortex-M4 family. It operates at a clock frequency of up to 100 MHz.

- Memory: It typically has 512 KB of Flash memory and 128 KB of RAM, providing sufficient resources for a wide range of embedded applications.

- Integrated Debugger/Programmer: The Nucleo board includes an ST-Link debugger/programmer, allowing for easy programming and debugging of the STM32 MCU.

- Expansion Options: The board features Arduino Uno V3 connectors, making it compatible with a variety of Arduino shields. Additionally, it has ST Morpho extension headers for accessing the MCU’s peripherals.

- Power Supply: The board can be powered through a USB cable or an external source. It also has a built-in ST-LINK/V2-1 for programming and debugging via USB.

- Peripherals: The STM32F411RE MCU on this Nucleo board comes with a variety of peripherals, including GPIO, UART, SPI, I2C, ADC, and more, making it versatile for different applications.

- Integrated Development Environment (IDE): You can use the STM32CubeIDE or other compatible development environments to program and develop applications for the STM32 MCU on this Nucleo board.

- Community and Documentation: STMicroelectronics provides extensive documentation, datasheets, and user manuals for the STM32 Nucleo F411RE. Additionally, there is an active community of developers and users who share knowledge and experiences related to this development board.

5. Simulink Model

5.1. Flowchart

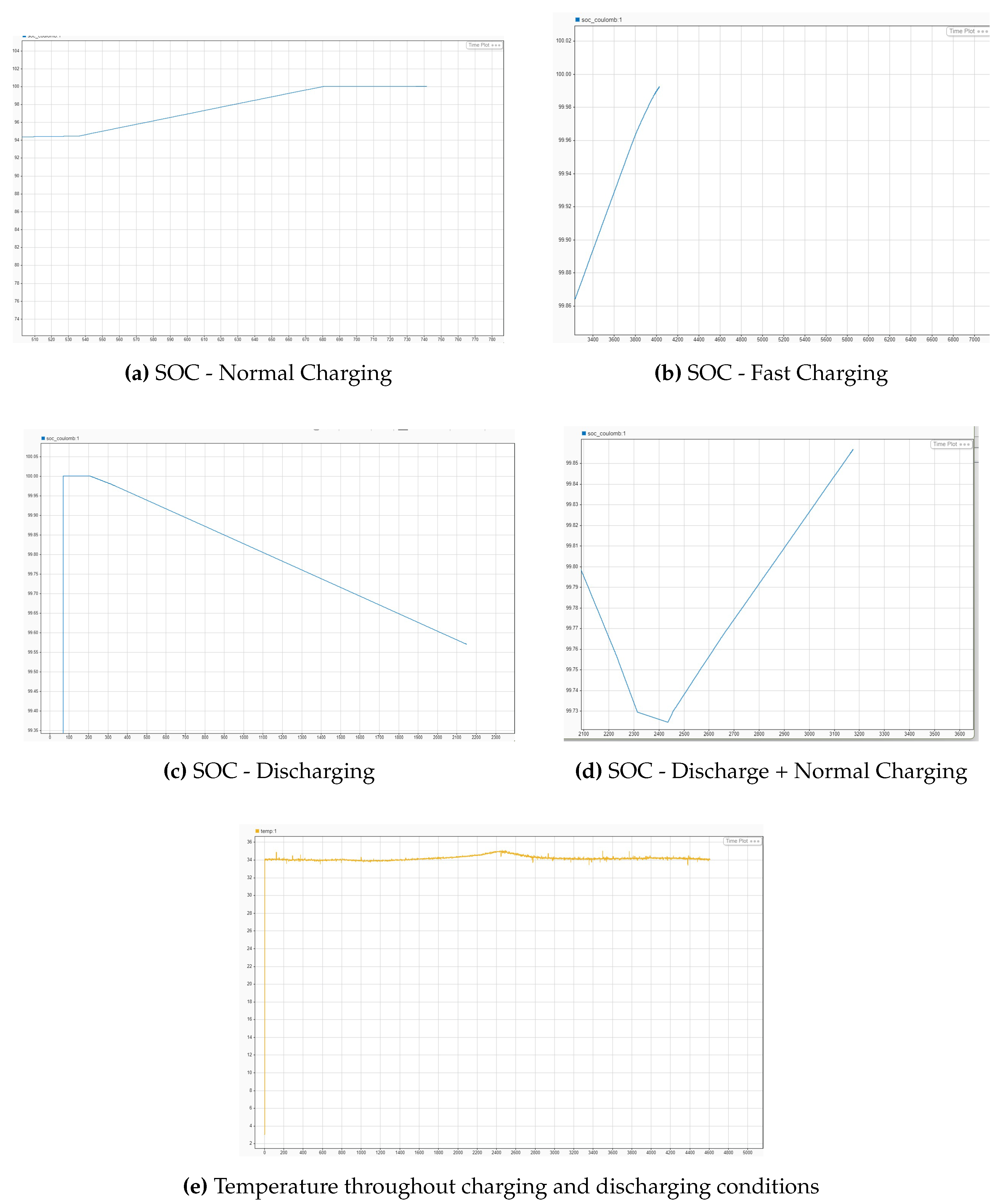

6. Results

7. Result Analysis

| No. | Time(s) | SOC(%) | Temperature(C) |

|---|---|---|---|

| 1 | 2450 | 99.7284 | 34.1 |

| 2 | 2660 | 99.7676 | 34.2 |

| 3 | 2900 | 99.809 | 34.4 |

| 4 | 3197 | 99.8634 | 34.9 |

| No. | Time(s) | SOC(%) | Temperature(C) |

|---|---|---|---|

| 1 | 2450 | 99.7218 | 33.9 |

| 2 | 2660 | 99.774 | 34.029 |

| 3 | 2900 | 99.8337 | 34.094 |

| 4 | 3197 | 99.9067 | 34.104 |

| No. | Time(s) | SOC(%) | Temperature(C) |

|---|---|---|---|

| 1 | 1410 | 99.998 | 34.010 |

| 2 | 1650 | 99.927 | 34.142 |

| 3 | 1900 | 99.853 | 34.246 |

| 4 | 2306 | 99.7316 | 34.725 |

Inference

- Here the partial charging/ discharging of the battery has been done and the variation of SOC and temperature with time has been tabulated.

- From the tables, it can be seen that there are no significant variations in the temperature of the battery. It is around 34∘ C. However there is a slight increase during extended charging/ discharging hours. External factors and internal factors can also contribute to temperature rise of the battery.

- The SOC is found to increase during charging and decrease during discharging.

8. Conclusion

9. Future Scope

References

- Amin Bavand, Ali Khajehoddin, Masoud Ardakani, and Ahmadreza Tabesh, "Online Estimations of Li-Ion Battery SOC and SOH Applicable to Partial Charge/Discharge", IEEE Transactions on Transportation Electrification, VOL. 8, NO. 3, 2022.

- Erik Schaltz, Daniel-loan Stroe, Kjeld Norregaard, Lasse Stenhoj Ingvardsen, and Andreas Christensen, "Incremental Capacity Analysis Applied on Electric Vehicles for Battery State-of-Health Estimation ",IEEE Transactions on Industry Applications, VOL. 57, NO. 2, 2021.

- Yumeng Fu, Jun Xu, Mingjie Shi and Xuesong Mei "A Fast Impedance Calculation-Based Battery State-of-Health Estimation Method", IEEE Transactions on Industrial Electronics, VOL. 69, NO.7,JULY 2022.

- Jichao Hong, Zhenpo Wang, Changhui Qu, Fei Ma, Xiaoming Xu, Jue Yang, Jinghan Zhang, Yangjie Zhou, Tongxin Shan, and Yankai Hou, "Fault Prognosis and Isolation of Lithium-Ion Batteries in Electric Vehicles Considering Real-Scenario Thermal Runaway Risks", IEEE Journal of Emerging and Selected Topics in Power Electronics, VOL. 11, NO. 1, 2023.

- Ruixin Yang, Rui Xiong, Weixiang Shen “On-board Diagnosis of Soft Short Circuit Fault in Lithium-ion Battery Packs for Electric Vehicles Using an Extended Kalman Filter”, CSEE Jornal of Power and Energy Systems, VOL. 8, NO. 1, 2022.

- Mahammad, A. Hannan, MD. Murshadul Hoque, Aini Hussain, Yushaizad Yusof, Pin Jern Ker “State-of-the-Art and Energy Management System of Lithium-Ion Batteries i ikn Electric Vehicle Applications: Issues and Recommendations”, Special Section on Advanced Energy Storage Technologies and Their ApplicationsS, March 21, 2018.

- Zaheer, S. , Gulrez, T., & Thythodath Paramabath, I. A. "From Sensor-Space to Eigenspace – A Novel Real-Time Obstacle Avoidance Method for Mobile Robots". IETE Journal of Research, 68(2), 1512–1524, 2019. [CrossRef]

- Zaheer, S. , & Gulrez, T. "A Path Planning Technique For Autonomous Mobile Robot Using Free-Configuration Eigenspaces". International Journal of Robotics and Automation (IJRA), 6(1), 14, 2015.

- Zaheer, S. , Jayaraju, M., & Gulrez, T. "Performance analysis of path planning techniques for autonomous mobile robots". In 2015 IEEE international conference on electrical, computer and communication technologies (ICECCT) (pp. 1-5). IEEE. 2015.

- Gulrez, T. , Zaheer, S., & Abdallah, Y. "Autonomous trajectory learning using free configuration-eigenspaces". In 2009 IEEE International Symposium on Signal Processing and Information Technology (ISSPIT) (pp. 424-429). IEEE.

- Aravindan, A. , Zaheer, S., & Gulrez, T. (2016, September). "An integrated approach for path planning and control for autonomous mobile robots". In 2016 International Conference on Next Generation Intelligent Systems (ICNGIS) (pp. 1-6). IEEE.

- Zaheer, S. , Jayaraju, M., & Gulrez, T. (2014, March). "A trajectory learner for sonar based LEGO NXT differential drive robot". In 2014 International Electrical Engineering Congress (iEECON) (pp. 1-4). IEEE.

- Marken, R. , Kennaway, R., & Gulrez, T. (2022). "Behavioral illusions: The snark is a boojum". Theory & Psychology, 32(3), 491-514. [CrossRef]

- Gulrez, T., Kekoc, V., Gaurvit, E., Schuhmacher, M., & Mills, T. (2023, March). "Machine Learning Enabled Mixed Reality Systems-For Evaluation and Validation of Augmented Experience in Aircraft Maintenance". In Proceedings of the 2023 7th International Conference on Virtual and Augmented Reality Simulations (pp. 77-83).

- Satoshi, T. , Gulrez, T., Herath, D. C., & Dissanayake, G. W. M. (2005). "Environmental recognition for autonomous robot using slam. real time path planning with dynamical localised voronoi division". International Journal of Japan Society of Mech. Engg (JSME), 3, 904-911.

- Gulrez, T. , Tognetti, A., Yoon, W. J., Kavakli, M., & Cabibihan, J. J. (2016). "A hands-free interface for controlling virtual electric-powered wheelchairs". International Journal of Advanced Robotic Systems, 13(2), 49. [CrossRef]

- Zaheer, S. , & Gulrez, T. (2011, April). "Beta-eigenspaces for autonomous mobile robotic trajectory outlier detection". In 2011 IEEE Conference on Technologies for Practical Robot Applications (pp. 31-34). IEEE.

- Gulrez, T. , & Mansell, W. (2022). "High Performance on Atari Games Using Perceptual Control Architecture Without Training". Journal of Intelligent & Robotic Systems, 106(2), 45. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).