Submitted:

02 July 2024

Posted:

03 July 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

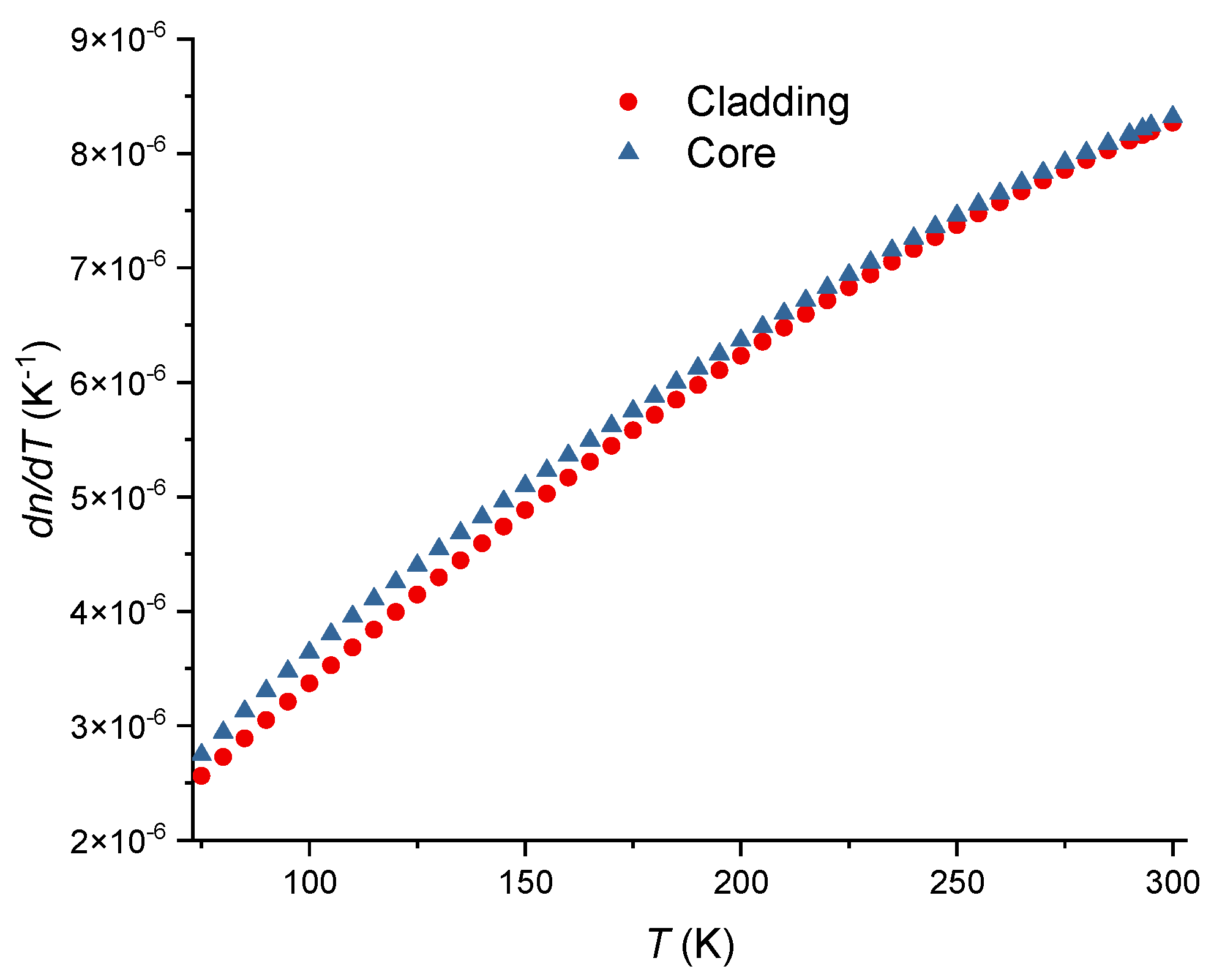

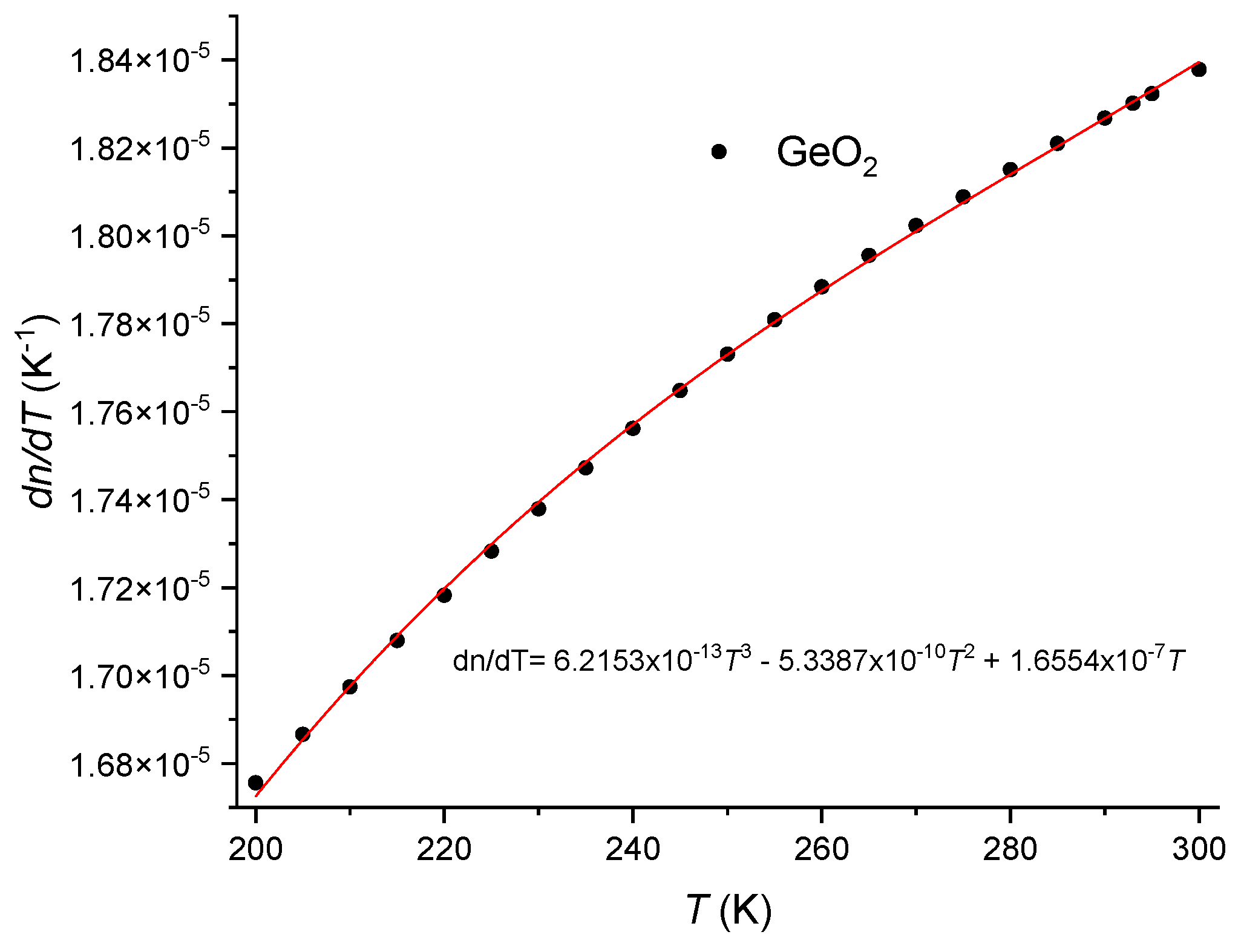

2. Ge-Doped Silica Glass Fiber

3. Fiber Bragg Gratings

4. Effective Parameters ν, p11 and p12 for the SMF-28 Fiber

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rego, G. Temperature Dependence of the Thermo-Optic Coefficient of SiO2 Glass. Sensors 2023, 23, 6023. [Google Scholar] [CrossRef] [PubMed]

- Kouskousis, B.; Kitcher, D.J.; Collins, S.; Roberts, A.; Baxter, G.W. Quantitative phase and refractive index analysis of optical fibers using differential interference contrast microscopy. Appl. Opt. 2008, 47, 5182–5189. [Google Scholar] [CrossRef] [PubMed]

- Boilard, T.; Vallée, R.; Bernier, M. Probing the dispersive properties of optical fibers with an array of femtosecond-written fiber Bragg gratings. Sci. Rep. 2022, 12, 1–8. [Google Scholar] [CrossRef]

- Drouin, A.; Lorre, P.; Boisvert, J.-S.; Loranger, S.; Iezzi, V.L.; Kashyap, R. Spatially resolved cross-sectional refractive index profile of fs laser–written waveguides using a genetic algorithm. Opt. Express 2019, 27, 2488–2498. [Google Scholar] [CrossRef] [PubMed]

- Yablon, A.D. Multi-Wavelength Optical Fiber Refractive Index Profiling by Spatially Resolved Fourier Transform Spectroscopy. J. Light. Technol. 2009, 28, 360–364. [Google Scholar] [CrossRef]

- Bélanger, E.; Bérubé, J.-P.; de Dorlodot, B.; Marquet, P.; Vallée, R. Comparative study of quantitative phase imaging techniques for refractometry of optical waveguides. Opt. Express 2018, 26, 17498–17510. [Google Scholar] [CrossRef] [PubMed]

- Mangini, F.; Ferraro, M.; Zitelli, M.; Niang, A.; Tonello, A.; Couderc, V.; Sidelnikov, O.; Frezza, F.; Wabnitz, S. Experimental observation of self-imaging in SMF-28 optical fibers. Opt. Express 2021, 29, 12625–12633. [Google Scholar] [CrossRef] [PubMed]

- Wang, P.; Jenkins, M.H.; Gaylord, T.K. Arc-discharge effects on residual stress and refractive index in single-mode optical fibers. Appl. Opt. 2016, 55, 2451–2456. [Google Scholar] [CrossRef] [PubMed]

- Raine, K.; Baines, J.; Putland, D. Refractive index profiling-state of the art. J. Light. Technol. 1989, 7, 1162–1169. [Google Scholar] [CrossRef]

- Gisin, N.; Passy, R.; Perny, B. Optical fiber characterization by simultaneous measurement of the transmitted and refracted near field. J. Light. Technol. 1993, 11, 1875–1883. [Google Scholar] [CrossRef]

- Chavez-Gutierrez, F.; Martinez-Rios, A.; Toral-Acosta, D.; Torres-Armenta, D.; Guerrero-Viramontes, J.A. Measurement of optical fiber parameters and thermal core diffusion characteristics by digital image processing. Appl. Opt. 2018, 57, 4331–4336. [Google Scholar] [CrossRef] [PubMed]

- Martinez, F.; Hussey, C. (E)ESI determination from mode-field diameter and refractive index profile measurements on single-mode fibres. Iee Proc. J Optoelectron. 1988, 135, 202–210. [Google Scholar] [CrossRef]

- Young, M. Optical fiber index profiles by the refracted-ray method (refracted near-field scanning). Appl. Opt. 1981, 20, 3415–3422. [Google Scholar] [CrossRef] [PubMed]

- Bayuwati, D.; Waluyo, T.B.; Mulyanto, I. Determination of the effective cut-off wavelength of several single-mode fiber patchcords. J. Physics: Conf. Ser. 2018, 985, 012002. [Google Scholar] [CrossRef]

- Marcuse, D. Gaussian approximation of the fundamental modes of graded-index fibers. J. Opt. Soc. Am. 1978, 68, 103–109. [Google Scholar] [CrossRef]

- elikel, O. , Mode field diameter and cut-off wavelength measurements of single mode optical fiber standards used in OTDR calibrations. Optical and Quantum Electronics 2005, 37, 587–604. [Google Scholar] [CrossRef]

- Schermer, R.T.; Cole, J.H. Improved Bend Loss Formula Verified for Optical Fiber by Simulation and Experiment. IEEE J. Quantum Electron. 2007, 43, 899–909. [Google Scholar] [CrossRef]

- Kokubun, Y.; Iga, K. Refractive-index profile measurement of preform rods by a transverse differential interferogram. Appl. Opt. 1980, 19, 846–851. [Google Scholar] [CrossRef] [PubMed]

- Raine, K.W., J. G. Baines, and R.J. King Comparison of refractive index measurements of optical fibres by three methods. IEE Proceedings J (Optoelectronics) 1988, 135, 190–195. [Google Scholar]

- Hutsel, M.R.; Gaylord, T.K. Concurrent three-dimensional characterization of the refractive-index and residual-stress distributions in optical fibers. Appl. Opt. 2012, 51, 5442–5452. [Google Scholar] [CrossRef]

- Jenkins, M.H.; Gaylord, T.K. 3D Characterization of the Refractive-Index and Residual-Stress Distributions in Optical Fibers.

- Pace, P.; Huntington, S.T.; Roberts, A.; Love, J.D.; Lyytikäinen, K. Refractive index profiles of Ge-doped optical fibers with nanometer spatial resolution using atomic force microscopy. Opt. Express 2004, 12, 1452–1457. [Google Scholar] [CrossRef] [PubMed]

- Hutsel, M.R.; Ingle, R.; Gaylord, T.K. Accurate cross-sectional stress profiling of optical fibers. Appl. Opt. 2009, 48, 4985–4995. [Google Scholar] [CrossRef] [PubMed]

- Rego, G.M.; Santos, J.L.; Salgado, H.M. Refractive index measurement with long-period gratings arc-induced in pure-silica-core fibres. Opt. Commun. 2005, 259, 598–602. [Google Scholar] [CrossRef]

- Juelich, F.; Roths, J. OP2 - Determination of the Effective Refractive Index of Various Single Mode Fibres for Fibre Bragg Grating Sensor Applications. 2009.

- Gloge, D. Weakly Guiding Fibers. Appl. Opt. 1971, 10, 2252–2258. [Google Scholar] [CrossRef] [PubMed]

- Snyder, A.W.; Rühl, F. Single-mode, single-polarization fibers made of birefringent material. J. Opt. Soc. Am. 1983, 73, 1165–1174. [Google Scholar] [CrossRef]

- Dragic, P. Simplified model for effect of Ge doping on silica fibre acoustic properties. Electron. Lett. 2009, 45, 256–257. [Google Scholar] [CrossRef]

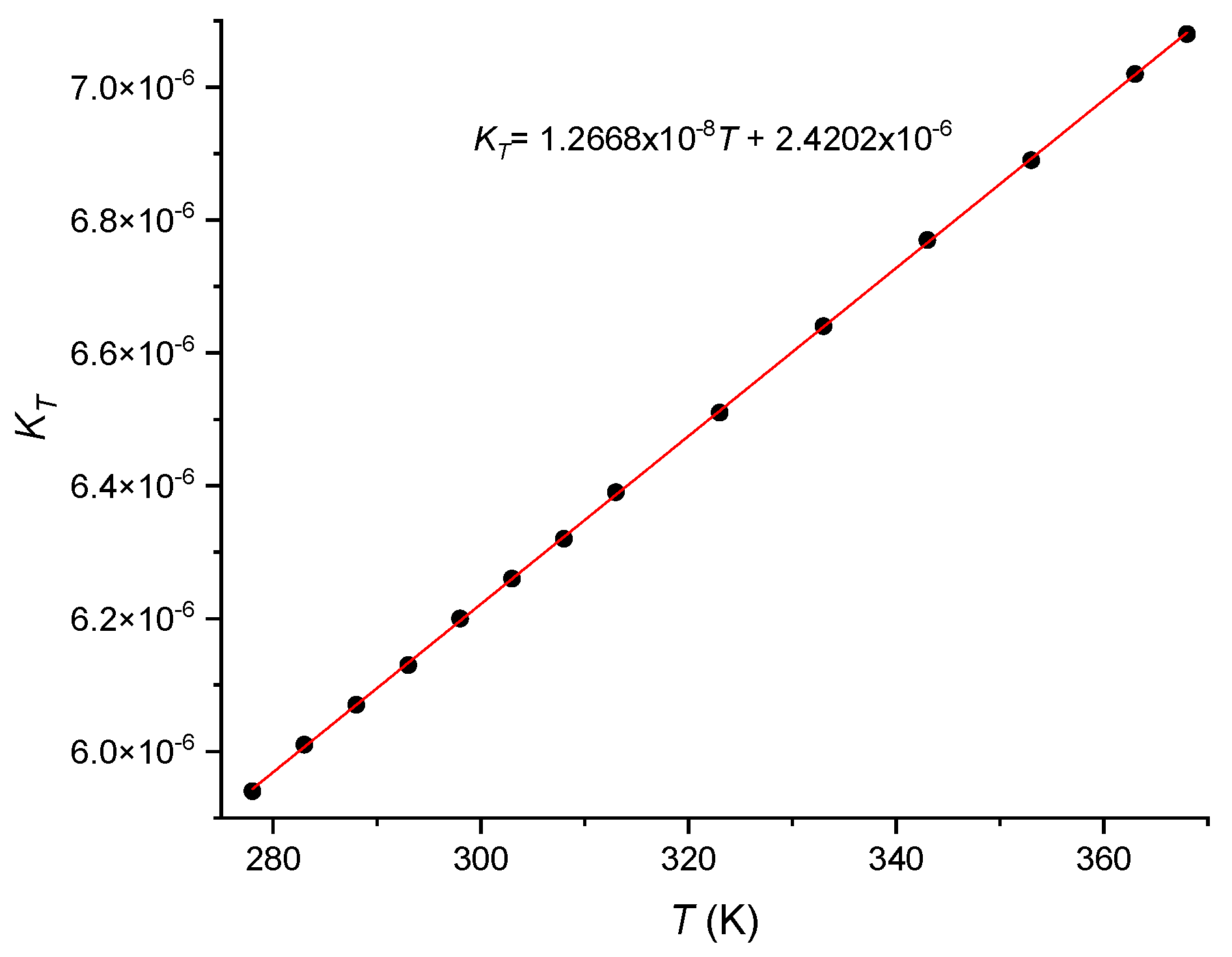

- Pan, G. , et al. , Thermo-optic coefficient of B2O3 and GeO2 co-doped silica fibers. Optical Materials Express 2020, 10, 1509–1521. [Google Scholar]

- Uhlmann, D.R. and N. J. Kreidl. Optical properties of glass. 1991.

- Yablon, A.D. Optical and Mechanical Effects of Frozen-in Stresses and Strains in Optical Fibers. IEEE J. Sel. Top. Quantum Electron. 2004, 10, 300–311. [Google Scholar] [CrossRef]

- Roselló-Mechó, X.; Delgado-Pinar, M.; Díez, A.; Andrés, M.V. Measurement of Pockels’ coefficients and demonstration of the anisotropy of the elasto-optic effect in optical fibers under axial strain. Opt. Lett. 2016, 41, 2934–2937. [Google Scholar] [CrossRef] [PubMed]

- Ryan, C.; Dragic, P.; Furtick, J.; Kucera, C.J.; Stolen, R.; Ballato, J. Pockels Coefficients in Multicomponent Oxide Glasses. Int. J. Appl. Glas. Sci. 2015, 6, 387–396. [Google Scholar] [CrossRef]

- Malitson, I.H. Interspecimen comparison of the refractive index of fused silica. J. Opt. Soc. Am. 1965, 55, 1205–1209. [Google Scholar] [CrossRef]

- Fleming, J. Material dispersion in lightguide glasses. Electron. Lett. 1978, 14, 326–328. [Google Scholar] [CrossRef]

- Leviton, D.B.; Frey, B.J. Temperature-dependent absolute refractive index measurements of synthetic fused silica. in Proceedings of SPIE - The International Society for Optical Engineering. 2006.

- Yablon, A.D.; Yan, M.F.; Wisk, P.; DiMarcello, F.V.; Fleming, J.W.; Reed, W.A.; Monberg, E.M.; DiGiovanni, D.J.; Jasapara, J.; Lines, M.E. Refractive index perturbations in optical fibers resulting from frozen-in viscoelasticity. Appl. Phys. Lett. 2004, 84, 19–21. [Google Scholar] [CrossRef]

- Hibino, Y.; Hanawa, F.; Horiguchi, M. Drawing-induced residual stress effects on optical characteristics in pure-silica-core single-mode fibers. J. Appl. Phys. 1989, 65, 30–34. [Google Scholar] [CrossRef]

- Anuszkiewicz, A.; Bidus, M.; Filipkowski, A.; Pysz, D.; Dlubek, M.; Buczynski, R. Experimental analysis of axial stress distribution in nanostructured core fused silica fibers. Opt. Mater. Express 2019, 9, 4370–4378. [Google Scholar] [CrossRef]

- Kawachi, M., T. Edahiro, and H. Toba Microlens formation on VAD single-mode fibre ends. Electronics Letters 1982, 18, 71–72. [Google Scholar]

- Devyatykh, G.G.; Dianov, E.M.; Karpychev, N.S.; Mazavin, S.M.; Mashinskiĭ, V.M.; Neustruev, V.B.; Nikolaĭchik, A.V.; Prokhorov, A.M.; I Ritus, A.; I Sokolov, N.; et al. Material dispersion and Rayleigh scattering in glassy germanium dioxide, a substance with promising applications in low-loss optical fiber waveguides. Sov. J. Quantum Electron. 1980, 10, 900–902. [Google Scholar] [CrossRef]

- Grobnic, D.; Mihailov, S.J.; Ballato, J.; Dragic, P.D. Type I and II Bragg gratings made with infrared femtosecond radiation in high and low alumina content aluminosilicate optical fibers. Optica 2015, 2, 313. [Google Scholar] [CrossRef]

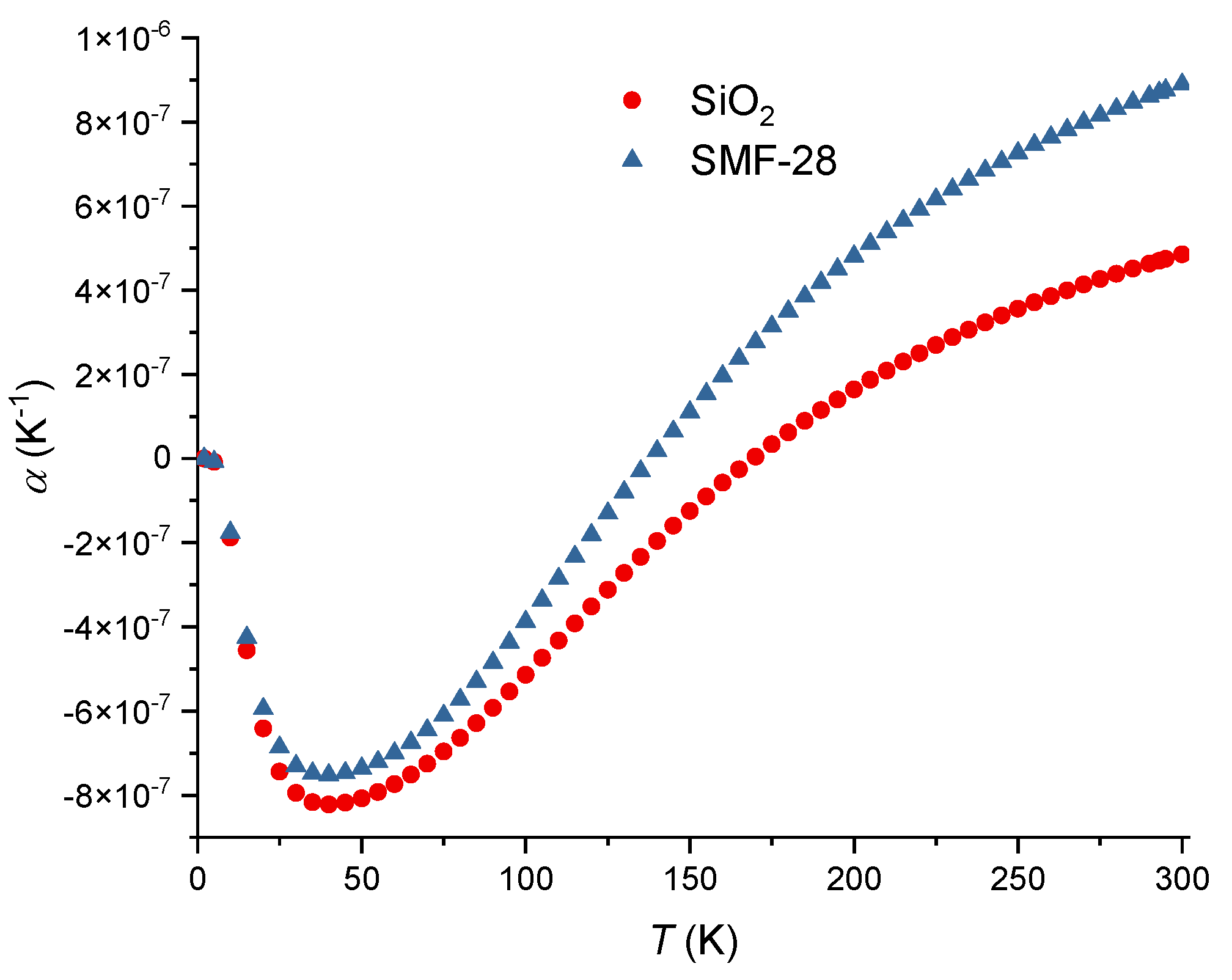

- Cavillon, M.; Dragic, P.D.; Ballato, J. Additivity of the coefficient of thermal expansion in silicate optical fibers. Opt. Lett. 2017, 42, 3650–3653. [Google Scholar] [CrossRef]

- Dragic, P.D.; Cavillon, M.; Ballato, A.; Ballato, J. A unified materials approach to mitigating optical nonlinearities in optical fiber. II. A. Material additivity models and basic glass properties. Int. J. Appl. Glas. Sci. 2017, 9, 278–287. [Google Scholar] [CrossRef]

- Dianov, E.M. and V. M. Mashinsky, Germania-based core optical fibers. Journal of Lightwave Technology 2005, 23, 3500–3508. [Google Scholar]

- Erdogan, T. , Fiber grating spectra. Journal of Lightwave Technology 1997, 15, 1277–1294. [Google Scholar] [CrossRef]

- Pal, S.; Mandal, J.; Sun, T.; Grattan, K.T.V.; Fokine, M.; Carlsson, F.; Fonjallaz, P.Y.; A Wade, S.; Collins, S.F. Characteristics of potential fibre Bragg grating sensor-based devices at elevated temperatures. Meas. Sci. Technol. 2003, 14, 1131–1136. [Google Scholar] [CrossRef]

- Filho, E.S.d.L.; Baiad, M.D.; Gagné, M.; Kashyap, R. Fiber Bragg gratings for low-temperature measurement. Opt. Express 2014, 22, 27681–27694. [Google Scholar] [CrossRef] [PubMed]

- Frazão, O.; Santos, J.L. Simultaneous measurement of strain and temperature using a Bragg grating structure written in germanosilicate fibres. J. Opt. A: Pure Appl. Opt. 2004, 6, 553–556. [Google Scholar] [CrossRef]

- Durr, F.; Rego, G.; Marques, P.; Semjonov, S.; Dianov, E.; Limberger, H.; Salathe, R. Tomographic stress profiling of arc-induced long-period fiber gratings. J. Light. Technol. 2005, 23, 3947–3953. [Google Scholar] [CrossRef]

- Rego, G.; Caldas, P.; Ivanov, O.; Santos, J.L. Investigation of the long-term stability of arc-induced gratings heat treated at high temperatures. Opt. Commun. 2010, 284, 169–171. [Google Scholar] [CrossRef]

- Flockhart, G.M.H.; Maier, R.R.J.; Barton, J.S.; MacPherson, W.N.; Jones, J.D.C.; Chisholm, K.E.; Zhang, L.; Bennion, I.; Read, I.; Foote, P.D. Quadratic behavior of fiber Bragg grating temperature coefficients. Appl. Opt. 2004, 43, 2744–2751. [Google Scholar] [CrossRef]

- Imas, J.J.; Bai, X.; Zamarreño, C.; Matias, I.; Albert, J. Accurate compensation and prediction of the temperature cross-sensitivity of tilted FBG cladding mode resonances. Appl. Opt. 2023, 62, E8–E15. [Google Scholar] [CrossRef]

- Brückner, R. Properties and structure of vitreous silica. II. J. Non-Crystalline Solids 1971, 5, 177–216. [Google Scholar] [CrossRef]

- Kühn, B.; Schadrack, R. Thermal expansion of synthetic fused silica as a function of OH content and fictive temperature. J. Non-Crystalline Solids 2009, 355, 323–326. [Google Scholar] [CrossRef]

- Patrick, E. , Expansivity of fused quartz glass measured within 6 x 10^-10 /K. 2023.

- Okaji, M.; Yamada, N.; Nara, K.; Kato, H. Laser interferometric dilatometer at low temperatures: application to fused silica SRM 739. Cryogenics 1995, 35, 887–891. [Google Scholar] [CrossRef]

- Hahn, T.A. and R. K. Kirby, Thermal Expansion of Fused Silica from 80 to 1000 K - Standard Reference Material 739. AIP Conference Proceedings 1972, 3, 13–24. [Google Scholar]

- Bennett, S.J. An absolute interferometric dilatometer. J. Phys. E: Sci. Instruments 1977, 10, 525–530. [Google Scholar] [CrossRef]

- Birch, K.P. An automatic absolute interferometric dilatometer. J. Phys. E: Sci. Instruments 1987, 20, 1387–1392. [Google Scholar] [CrossRef]

- Berthold, J.W.; Jacobs, S.F. Ultraprecise thermal expansion measurements of seven low expansion materials. Appl. Opt. 1976, 15, 2344–2347. [Google Scholar] [CrossRef]

- Wang, H.; Yamada, N.; Okaji, M. Precise Dilatometric Measurements of Silica Glasses. Netsu Bussei 1999, 13, 17–22. [Google Scholar] [CrossRef]

- White, T.H.K.B.a.G.K. , Heat capacity and thermal expansion at low temperatures. International cryogenics monograph series. 1999: New York : Kluwer Academic/Plenum.

- Gulati, S.T. and J. D. Helfinstine, Fatigue Behavior of GeO2-SiO2 Glasses. MRS Online Proceedings Library 1998, 531, 133–141. [Google Scholar] [CrossRef]

- Riebling, E.F. , Nonideal Mixing in Binary Ge0,-SiO, Glasses. Journal of the American Ceramic Society 1968, 51, 406–407. [Google Scholar] [CrossRef]

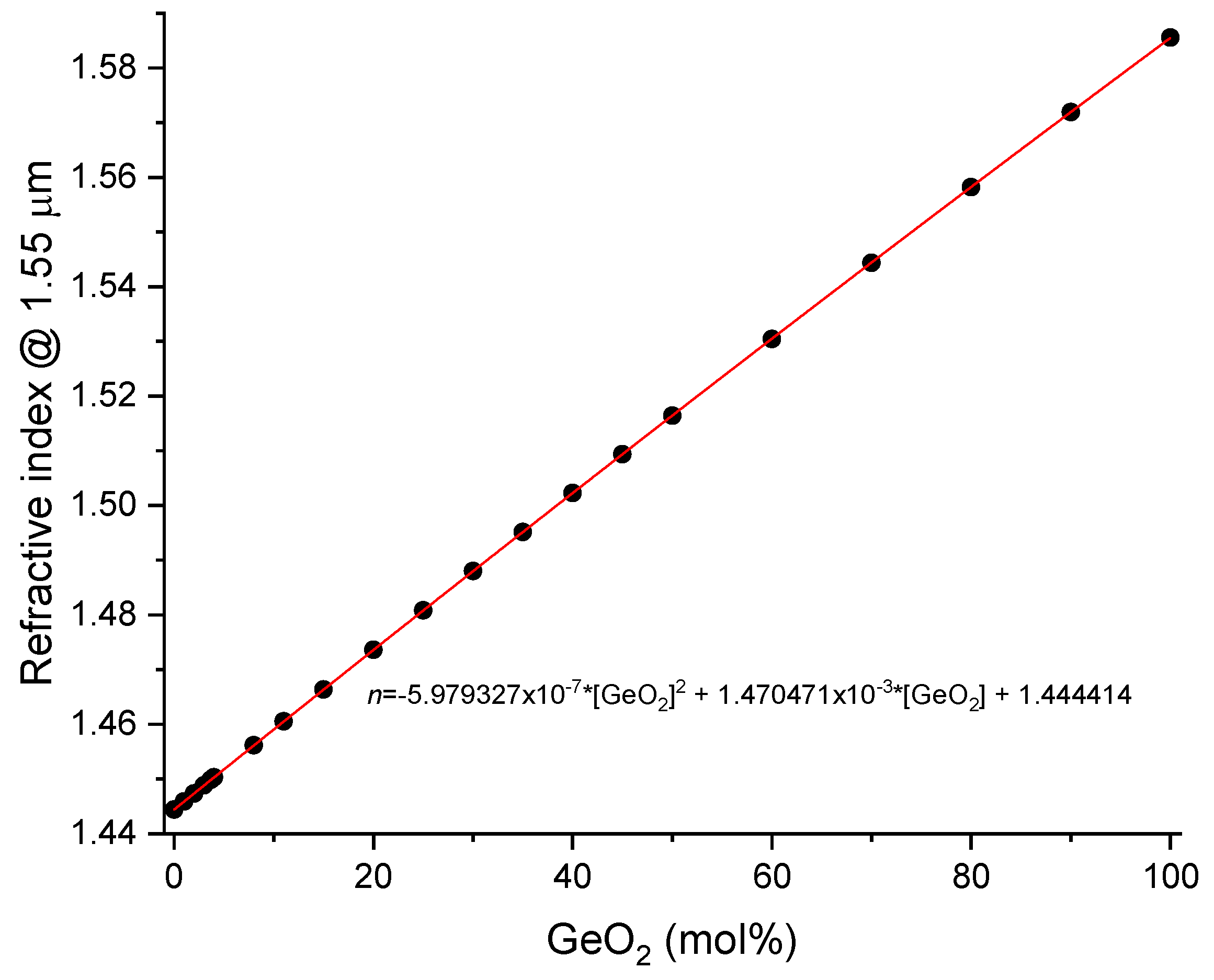

- Huang, Y.; Sarkar, A.; Schultz, P. Relationship between composition, density and refractive index for germania silica glasses. J. Non-Crystalline Solids 1978, 27, 29–37. [Google Scholar] [CrossRef]

- Mackenzie, J.D. Density and Expansivity of Vitreous Germania. J. Am. Ceram. Soc. 1959, 42, 310–310. [Google Scholar] [CrossRef]

- Napolitano, A.; Macedo, P. Spectrum of Relaxation Times in GeO2 Glass. J. Res. Natl. Bur. Stand. Sect. A: Phys. Chem. 1968, 72, 425–433. [Google Scholar] [CrossRef] [PubMed]

- Adamovsky, G.; Lyuksyutov, S.F.; Mackey, J.R.; Floyd, B.M.; Abeywickrema, U.; Fedin, I.; Rackaitis, M. Peculiarities of thermo-optic coefficient under different temperature regimes in optical fibers containing fiber Bragg gratings. Opt. Commun. 2012, 285, 766–773. [Google Scholar] [CrossRef]

- Sánchez, L.A.; Diez, A.; Cruz, J.L.; Andrés, M. High accuracy measurement of Poisson’s ratio of optical fibers and its temperature dependence using forward-stimulated Brillouin scattering. Opt. Express 2021, 30, 42–52. [Google Scholar] [CrossRef] [PubMed]

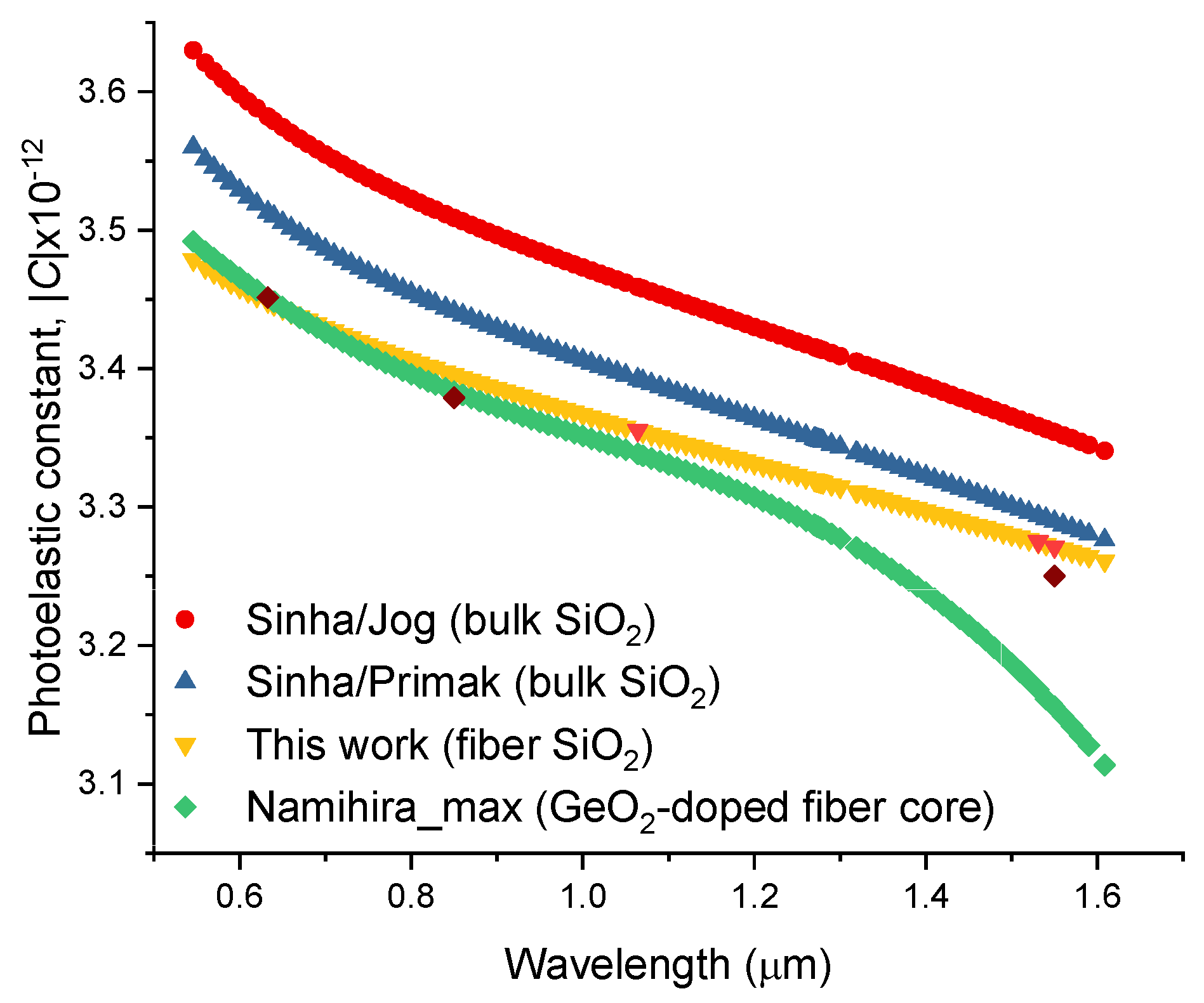

- Jog, E.S.; Krishnan, R.S. Dispersion of the Photoelastic Constants of Fused Silica. Nature 1957, 179, 540–541. [Google Scholar] [CrossRef]

- Biegelsen, D.K.; Zesch, J.C. Optical frequency dependence of the photoelastic coefficients of fused silica. J. Appl. Phys. 1976, 47, 4024–4025. [Google Scholar] [CrossRef]

- Jenkins, A.; Sutherland, C.; Werner-Zwanziger, U.; Zwanziger, J. Wavelength-dependent elasto-optic tensor elements from acoustic Bragg diffraction. J. Non-Crystalline Solids 2023, 620. [Google Scholar] [CrossRef]

- Martina, D.-P. , et al., Whispering Gallery Modes for Accurate Characterization of Optical Fibers’ Parameters, in Applications of Optical Fibers for Sensing, C.-L. Christian, Editor. 2018, IntechOpen: Rijeka. Ch. 8.

- Barlow, A.; Payne, D. The stress-optic effect in optical fibers. IEEE J. Quantum Electron. 1983, 19, 834–839. [Google Scholar] [CrossRef]

- Bertholds, A.; Dandliker, R. Determination of the individual strain-optic coefficients in single-mode optical fibres. J. Light. Technol. 1988, 6, 17–20. [Google Scholar] [CrossRef]

- Schuh, R.; Shan, X.; Siddiqui, A. Polarization mode dispersion in spun fibers with different linear birefringence and spinning parameters. J. Light. Technol. 1998, 16, 1583–1588. [Google Scholar] [CrossRef]

- Sánchez, L.A.; Díez, A.; Cruz, J.L.; Andrés, M.V. Strain and temperature measurement discrimination with forward Brillouin scattering in optical fibers. Opt. Express 2022, 30, 14384–14392. [Google Scholar] [CrossRef] [PubMed]

- Zou, W., Z. He, and K. Hotate, Investigation of Strain- and Temperature-Dependences of Brillouin Frequency Shifts in GeO$_{2}$ -Doped Optical Fibers. Journal of Lightwave Technology 2008, 26, 1854–1861. [Google Scholar]

- Deroh, M.; Kibler, B.; Maillotte, H.; Sylvestre, T.; Beugnot, J.-C. Large Brillouin gain in Germania-doped core optical fibers up to a 98 mol% doping level. Opt. Lett. 2018, 43, 4005–4008. [Google Scholar] [CrossRef] [PubMed]

- Beugnot, J.-C.; Laude, V. Electrostriction and guidance of acoustic phonons in optical fibers. Phys. Rev. B 2012, 86. [Google Scholar] [CrossRef]

- Lambin-Iezzi, V.; Loranger, S.; Saad, M.; Kashyap, R. Stimulated Brillouin scattering in SM ZBLAN fiber. J. Non-Crystalline Solids 2013, 359, 65–68. [Google Scholar] [CrossRef]

- Zou, W.; He, Z.; Yablon, A.D.; Hotate, K. Dependence of Brillouin Frequency Shift in Optical Fibers on Draw-Induced Residual Elastic and Inelastic Strains. IEEE Photon- Technol. Lett. 2007, 19, 1389–1391. [Google Scholar] [CrossRef]

- Le Parc, R.; Levelut, C.; Pelous, J.; Martinez, V.; Champagnon, B. Influence of fictive temperature and composition of silica glass on anomalous elastic behaviour. J. Physics: Condens. Matter 2006, 18, 7507–7527. [Google Scholar] [CrossRef]

- Thomas, P.J.; Rowell, N.L.; van Driel, H.M.; Stegeman, G.I. Normal acoustic modes and Brillouin scattering in single-mode optical fibers. Phys. Rev. B 1979, 19, 4986–4998. [Google Scholar] [CrossRef]

- Zou, W.; He, Z.; Hotate, K. Two-Dimensional Finite-Element Modal Analysis of Brillouin Gain Spectra in Optical Fibers. IEEE Photon- Technol. Lett. 2006, 18, 2487–2489. [Google Scholar] [CrossRef]

- Dragic, P.D. Brillouin spectroscopy of Nd–Ge co-doped silica fibers. J. Non-Crystalline Solids 2009, 355, 403–413. [Google Scholar] [CrossRef]

- Koyamada, Y.; Sato, S.; Nakamura, S.; Sotobayashi, H.; Chujo, W. Simulating and Designing Brillouin Gain Spectrum in Single-Mode Fibers. J. Light. Technol. 2004, 22, 631–639. [Google Scholar] [CrossRef]

- Jen, C.-K. , et al. , Acoustic Characterization of Silica Glasses. Journal of the American Ceramic Society 1993, 76, 712–716. [Google Scholar]

- Nikles, M.; Thevenaz, L.; Robert, P. Brillouin gain spectrum characterization in single-mode optical fibers. J. Light. Technol. 1997, 15, 1842–1851. [Google Scholar] [CrossRef]

- Lagakos, N.; Bucaro, J.A.; Hughes, R. Acoustic sensitivity predictions of single-mode optical fibers using Brillouin scattering. Appl. Opt. 1980, 19, 3668–3670. [Google Scholar] [CrossRef]

- Munro, R.G. Elastic Moduli Data for Polycrystalline Oxide Ceramics | NIST. 2002.

- Clowes, J.; Syngellakis, S.; Zervas, M. Pressure sensitivity of side-hole optical fiber sensors. IEEE Photon- Technol. Lett. 1998, 10, 857–859. [Google Scholar] [CrossRef]

- Li, P.; Fu, C.; Zhong, H.; Du, B.; Guo, K.; Meng, Y.; Du, C.; He, J.; Wang, L.; Wang, Y. A Nondestructive Measurement Method of Optical Fiber Young’s Modulus Based on OFDR. Sensors 2022, 22, 1450. [Google Scholar] [CrossRef] [PubMed]

- Antunes, P.; Lima, H.; Monteiro, J.; André, P.S. Elastic constant measurement for standard and photosensitive single mode optical fibres. Microw. Opt. Technol. Lett. 2008, 50, 2467–2469. [Google Scholar] [CrossRef]

- Suito, K. , et al., Elastic Properties of Obsidian, Vitreous SiO2, and Vitreous GeO2 under High Pressure up to 6 GPa, in High-Pressure Research: Application to Earth and Planetary Sciences. 1992, 219–225.

- Makishima, A. and J. D. Mackenzie, Calculation of bulk modulus, shear modulus and Poisson's ratio of glass. Journal of Non-Crystalline Solids 1975, 17, 147–157. [Google Scholar]

- Rocherulle, J. , et al. , Elastic moduli of oxynitride glasses: Extension of Makishima and Mackenzie's theory. Journal of Non-Crystalline Solids 1989, 108, 187–193. [Google Scholar]

- Dragic, P.D. The Acoustic Velocity of Ge-Doped Silica Fibers: A Comparison of Two Models. Int. J. Appl. Glas. Sci. 2010, 1, 330–337. [Google Scholar] [CrossRef]

- Urbanczyk, W.; Martynkien, T.; Bock, W.J. Dispersion effects in elliptical-core highly birefringent fibers. Appl. Opt. 2001, 40, 1911–1920. [Google Scholar] [CrossRef] [PubMed]

- Galtarossa, A.; Grosso, D.; Palmieri, L. Accurate Characterization of Twist-Induced Optical Activity in Single-Mode Fibers by Means of Polarization-Sensitive Reflectometry. IEEE Photon- Technol. Lett. 2009, 21, 1713–1715. [Google Scholar] [CrossRef]

- Galtarossa, A.; Palmieri, L. Measure of twist-induced circular birefringence in long single-mode fibers: theory and experiments. J. Light. Technol. 2002, 20, 1149–1159. [Google Scholar] [CrossRef]

- Ivanov, O.V. Experimental Investigation of Rotation of Polarization in Strongly Twisted Optical Fibers of Various Types. in 2018 International Conference Laser Optics (ICLO). 2018.

- El-Khozondar, H.J. , et al. Experimental investigation of polarization rotation in twisted optical fibers. in 2009 International Symposium on Optomechatronic Technologies. 2009.

- Roths, J. and F Jülich. Determination of strain sensitivity of free fiber Bragg gratings. in Photonics Europe. 2008.

- Jülich, F.; Aulbach, L.; Wilfert, A.; Kratzer, P.; Kuttler, R.; Roths, J. Gauge factors of fibre Bragg grating strain sensors in different types of optical fibres. Meas. Sci. Technol. 2013, 24, 094007. [Google Scholar] [CrossRef]

- Acheroy, S.; Merken, P.; Geernaert, T.; Ottevaere, H.; Thienpont, H.; Berghmans, F. Algorithms for determining the radial profile of the photoelastic coefficient in glass and polymer optical fibers. Opt. Express 2015, 23, 18943–54. [Google Scholar] [CrossRef]

- Namihira, Y. Opto-elastic constant in single mode optical fibers. J. Light. Technol. 1985, 3, 1078–1083. [Google Scholar] [CrossRef]

- Sinha, N.K. , Normalised dispersion of birefringence of quartz and stress optical coefficient of fused silica and plate glass. Physics and Chemistry of Glasses 1978, 19, 69–77. [Google Scholar]

- Primak, W.; Post, D. Photoelastic Constants of Vitreous Silica and Its Elastic Coefficient of Refractive Index. J. Appl. Phys. 1959, 30, 779–788. [Google Scholar] [CrossRef]

- Riebling, E.F. Nonideal Mixing in Binary Ge0,-SiO, Glasses. J. Am. Ceram. Soc. 1968, 51, 406–407. [Google Scholar] [CrossRef]

- Huang, Y.; Sarkar, A.; Schultz, P. Relationship between composition, density and refractive index for germania silica glasses. J. Non-Crystalline Solids 1978, 27, 29–37. [Google Scholar] [CrossRef]

- Mackenzie, J.D. Density and Expansivity of Vitreous Germania. J. Am. Ceram. Soc. 1959, 42, 310–310. [Google Scholar] [CrossRef]

- Doweidar, H. , Considerations on the structure and physical properties of B2O3–SiO2 and GeO2–SiO2 glasses. Journal of Non-Crystalline Solids 2011, 357, 1665–1670. [Google Scholar] [CrossRef]

- Napolitano, A.; Macedo, P. Spectrum of Relaxation Times in GeO2 Glass. J. Res. Natl. Bur. Stand. Sect. A: Phys. Chem. 1968, 72, 425–433. [Google Scholar] [CrossRef] [PubMed]

- Spinner, S. and G. W. Cleek, Temperature Dependence of Young's Modulus of Vitreous Germania and Silica. Journal of Applied Physics 1960, 31, 1407–1410. [Google Scholar]

- Krause, J.T.; Kurkjian, C.R. Vibrational Anomalies in Inorganic Glass Formers. J. Am. Ceram. Soc. 1968, 51, 226–227. [Google Scholar] [CrossRef]

- Shelby, J.E. , Properties and structure of B2O3–GeO2 glasses. Journal of Applied Physics 1974, 45, 5272–5277. [Google Scholar] [CrossRef]

- Filho, E.S.d.L. , et al. , Fiber Bragg gratings for low-temperature measurement. Optics Express 2014, 22, 27681–27694. [Google Scholar] [PubMed]

- Wenyuan, W. , et al. Measurements of thermo-optic coefficient of standard single mode fiber in large temperature range. in Proc.SPIE. 2015.

- Wang, W. , et al. Fiber-Optic Intrinsic Fabry-Perot Temperature Sensor Fabricated by Femtosecond Lasers. in Optical Sensors and Biophotonics II. 2010. Shanghai: Optica Publishing Group.

- Chang, S. , et al. , Heterodyne interferometric measurement of the thermo-optic coefficient of single mode fiber. 2000, 38, 437–442. [Google Scholar]

- Li, L.L.L.; Zhang, D.Z.D.; Wen, X.W.X.; Peng, S.P.S. FFPI-FBG hybrid sensor to measure the thermal expansion and thermo-optical coefficient of a silica-based fiber at cryogenic temperatures. Chin. Opt. Lett. 2015, 13, 100601–100605. [Google Scholar] [CrossRef]

- Gao, H.; Jiang, Y.; Cui, Y.; Zhang, L.; Jia, J.; Jiang, L. Investigation on the Thermo-Optic Coefficient of Silica Fiber Within a Wide Temperature Range. J. Light. Technol. 2018, 36, 5881–5886. [Google Scholar] [CrossRef]

- Du, Y.; Liu, T.; Ding, Z.; Han, Q.; Liu, K.; Jiang, J.; Chen, Q.; Feng, B. Cryogenic Temperature Measurement Using Rayleigh Backscattering Spectra Shift by OFDR. IEEE Photon- Technol. Lett. 2014, 26, 1150–1153. [Google Scholar] [CrossRef]

- Kreger, S.T. , et al. High Resolution Distributed Strain or Temperature Measurements in Single-and Multi-mode Fiber Using Swept-Wavelength Interferometry. in Optical Fiber Sensors. 2006. O: Cancun.

- Chaccour, L. Rayleigh Backscattered Signal Enhancement in Highly GeO₂-Doped-Core Silica Fibers. IEEE Photon- Technol. Lett. 2022, 34, 345–348. [Google Scholar] [CrossRef]

- Terra, O. Optoelectronic oscillations for thermo-optic coefficient measurement of optical fibers. Meas. Sci. Technol. 2019, 30, 035205. [Google Scholar] [CrossRef]

- Zou, X.; Liu, X.; Li, W.; Li, P.; Pan, W.; Yan, L.; Shao, L. Optoelectronic Oscillators (OEOs) to Sensing, Measurement, and Detection. IEEE J. Quantum Electron. 2015, 52, 1–16. [Google Scholar] [CrossRef]

| Material | M (g/mol) | ρ (kg/m3) | α (x10-6 K-1) | P11 | P12 | ν |

|---|---|---|---|---|---|---|

| SiO2 | 60.08 | 2200 | 0.45 | 0.121 | 0.270 | 0.170 |

| GeO2 | 104.64 | 3650 | 7.7 | 0.130 | 0.288 | 0.212 |

| GeO2 concentration (mol%) | Brillouin frequency, fB (GHz) | Longitudinal velocity, vL (m/s) |

| 0 | 11.143 (extrapolated) | 5986.5 (extrapolated) |

| 3.65 | 10.872 | 5819.5 |

| 3.67 | 10.863 | 5818.5 |

| 8.0 | 10.542 | 5620.3 |

| SiO2 | SMF-28 (3.67 mol% GeO2) | |

| ncl or neff | 1.444414 | 1.446973 |

| p11 | 0.130 | 0.125 |

| p12 | 0.266 | 0.258 |

| p44 | -0.0676 | -0.0662 |

| g | 0.141 | 0.139 |

| C1(Pa-1) | 7.81x10-13 | 8.90x10-13 |

| C2(Pa-1) | 4.06x10-12 | 4.14x10-12 |

| C(Pa-1) | -3.27x10-12 | -3.25x10-12 |

| M(GPa) | 78.86 | 76.36 |

| E(GPa) | 73.08 | 71.63 |

| G(GPa) | 31.12 | 30.83 |

| ν | 0.174 | 0.161 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).