1. Introduction

The concept of procurement, traditionally seen as a back-office function primarily concerned with the acquisition of goods and services, has evolved significantly in recent decades. The complexities of global supply chains and the unpredictable nature of the global economy have transformed procurement into a strategic function integral to the overall business strategy. This evolution has become especially pronounced in light of recent supply chain disruptions, such as the COVID-19 pandemic, geopolitical conflicts, and environmental disasters. These events have exposed the vulnerabilities inherent in traditional procurement practices and underscored the need for more adaptive, resilient approaches. The COVID-19 pandemic, starting in late 2019, caused unprecedented disruptions across global supply chains. The pandemic led to widespread lockdowns, manufacturing halts, and significant disruptions in transportation and logistics networks. As a result, companies faced severe shortages of critical supplies, from personal protective equipment in the healthcare sector to semiconductors in the technology industry (Ivanov & Dolgui, 2020). The abrupt and widespread nature of these disruptions revealed the limitations of just-in-time inventory strategies and single-source supplier dependencies. Companies that had previously optimized their supply chains for cost efficiency found themselves ill-prepared for the sudden disruptions, leading to a reevaluation of procurement practices (Handfield et al., 2020). Geopolitical tensions have further complicated the procurement landscape. Trade wars, particularly between major economies such as the United States and China, have resulted in tariff impositions, regulatory changes, and shifts in global trade patterns (He & Qian, 2022). These geopolitical dynamics have forced companies to reconsider their sourcing strategies, as reliance on suppliers in politically unstable regions can introduce significant risks. Additionally, the increasing scrutiny on ethical sourcing and sustainability has added layers of complexity to procurement decisions, as companies must navigate regulatory requirements while maintaining their commitments to corporate social responsibility (Gereffi, 2020). Environmental disasters, exacerbated by climate change, have also highlighted the vulnerabilities of global supply chains. Events such as hurricanes, floods, and wildfires have disrupted transportation networks, damaged manufacturing facilities, and led to raw material shortages. The increasing frequency and severity of these events have compelled companies to develop more robust disaster recovery and business continuity plans. This has led to a greater emphasis on building resilient supply chains that can withstand environmental shocks and maintain operational continuity (Revilla & Saenz, 2022). The convergence of these disruptive forces has necessitated a paradigm shift in procurement practices. Companies are increasingly recognizing that traditional approaches, which often prioritize cost efficiency and lean operations, are insufficient in the face of such dynamic and multifaceted challenges. Instead, there is a growing emphasis on agility, flexibility, and resilience in procurement strategies. This shift is reflected in the adoption of various innovative practices, such as diversifying supplier bases, investing in digital technologies, and fostering closer collaborations with suppliers (Singh & Truslove, 2021). Diversification of supplier bases has emerged as a critical strategy for enhancing supply chain resilience. Relying on a single supplier or a limited number of suppliers can create significant vulnerabilities, as disruptions in one region or supplier can have cascading effects throughout the supply chain. Companies are now seeking to mitigate these risks by establishing relationships with multiple suppliers across different geographical locations. This approach not only reduces dependency on any single supplier but also provides greater flexibility in responding to disruptions (Choi et al., 2020). Additionally, companies are exploring nearshoring and reshoring options to reduce their reliance on distant suppliers and improve supply chain visibility. Digital technologies are playing an increasingly pivotal role in transforming procurement practices. Advanced data analytics, artificial intelligence, and machine learning are enabling companies to gain deeper insights into their supply chains and anticipate potential disruptions (Dhamija & Bag, 2021). Predictive analytics can help identify emerging risks, such as supplier financial instability or geopolitical tensions, allowing companies to take proactive measures to mitigate these risks. Furthermore, blockchain technology is being utilized to enhance supply chain transparency and traceability, providing a secure and immutable record of transactions that can be used to verify the authenticity and origins of goods (Kshetri, 2021). The adoption of digital technologies is not only improving the efficiency of procurement processes but also enhancing the ability of companies to respond swiftly to disruptions. Collaboration with suppliers is becoming increasingly important in the context of adaptive procurement. The traditional transactional approach to supplier relationships, which often focuses on price negotiations and contract enforcement, is giving way to more collaborative partnerships. Companies are recognizing that building strong relationships with suppliers can lead to greater alignment of interests, improved communication, and more effective joint problem-solving in times of disruption (Villena & Gioia, 2020). Collaborative approaches, such as supplier development programs and integrated supply chain planning, are helping companies and their suppliers to work together to enhance resilience and ensure the continuity of supply. The lessons learned from recent supply chain disruptions are reshaping procurement practices across industries. The experience of the COVID-19 pandemic, in particular, has highlighted the importance of agility and responsiveness in procurement. Companies that were able to quickly adapt their procurement strategies, such as by identifying alternative suppliers or repurposing manufacturing capabilities, were better positioned to navigate the challenges posed by the pandemic (Ivanov, 2021). This experience has underscored the need for procurement functions to be integrated with broader business continuity and risk management efforts. In addition to enhancing resilience, recent disruptions have also accelerated the focus on sustainability in procurement. The pandemic and other crises have drawn attention to the interconnectedness of global supply chains and the environmental and social impacts of procurement decisions. Companies are increasingly recognizing that building sustainable supply chains is not only a moral imperative but also a strategic necessity for managing long-term risks (Bai et al., 2021). Sustainable procurement practices, such as sourcing from suppliers with strong environmental and social performance and promoting circular economy principles, are becoming integral to adaptive procurement strategies. The evolving procurement landscape is also driving changes in the skills and competencies required for procurement professionals. The ability to manage complex supply chain risks, leverage digital technologies, and foster collaborative relationships with suppliers is becoming increasingly important. As a result, companies are investing in the development of procurement talent and providing training on topics such as risk management, data analytics, and supplier relationship management (Foerstl et al., 2022). The role of procurement professionals is expanding from a focus on cost savings to a broader emphasis on value creation, resilience, and sustainability. Looking ahead, the future of procurement will likely be characterized by continued innovation and adaptation in response to an increasingly volatile and complex global environment. The lessons learned from recent supply chain disruptions are informing the development of more resilient and flexible procurement practices that can better withstand future shocks. Companies are likely to continue investing in digital technologies, diversifying their supplier bases, and building stronger relationships with suppliers as they seek to enhance their ability to respond to disruptions. The recent wave of supply chain disruptions has exposed the limitations of traditional procurement practices and underscored the need for more adaptive and resilient approaches. The COVID-19 pandemic, geopolitical tensions, and environmental disasters have highlighted the vulnerabilities inherent in global supply chains and driven companies to rethink their procurement strategies. As companies navigate these challenges, they are increasingly adopting innovative practices, such as supplier diversification, digital technology integration, and collaborative supplier relationships, to enhance their resilience. The lessons learned from these disruptions are shaping the future of procurement, emphasizing the importance of agility, sustainability, and the strategic role of procurement in building resilient supply chains. As the global environment continues to evolve, procurement practices will need to remain dynamic and responsive to effectively manage the risks and uncertainties of the future.

2. Literature Review

The literature on adaptive procurement practices in response to disruptive events has grown substantially in recent years, reflecting the increased recognition of the need for resilient and flexible supply chains. The traditional procurement models, which prioritized cost efficiency and lean inventory management, have been challenged by the frequent and severe disruptions in global supply chains. As a result, the academic and professional communities have turned their attention to developing strategies that can mitigate risks and ensure continuity in the face of such challenges. A significant body of research has focused on the impact of the COVID-19 pandemic on procurement practices. The pandemic highlighted the vulnerabilities in global supply chains, particularly those relying heavily on just-in-time inventory systems and single-source suppliers. According to Ivanov and Dolgui (2020), the pandemic exposed the fragility of these systems and underscored the need for more robust risk management strategies. Companies were forced to quickly adapt by diversifying their supplier base and increasing their inventory levels to buffer against supply chain disruptions. Handfield et al. (2020) argue that the pandemic has accelerated the adoption of digital technologies in procurement, such as artificial intelligence and blockchain, to enhance transparency and traceability in supply chains. Geopolitical tensions, such as the trade war between the United States and China, have further complicated procurement strategies. He and Qian (2022) discuss how these tensions have led to increased tariffs and regulatory changes, prompting companies to reconsider their sourcing locations and diversify their supply base to mitigate risks. The need for agility in procurement has become evident, as companies must be able to quickly adapt to changing geopolitical landscapes. Gereffi (2020) emphasizes the importance of incorporating sustainability and ethical considerations into procurement decisions, as companies face increasing pressure from stakeholders to adhere to environmental and social governance (ESG) standards. Environmental disasters, often exacerbated by climate change, have also significantly impacted supply chains. Events such as hurricanes, floods, and wildfires can disrupt transportation networks and damage infrastructure, leading to delays and increased costs. The literature suggests that companies must incorporate environmental risk assessments into their procurement strategies to enhance resilience. For instance, Sodhi and Tang (2021) highlight the importance of developing contingency plans and establishing alternative supply routes to ensure continuity in the face of environmental disruptions. The role of digital transformation in enhancing procurement resilience is another key theme in the literature. Technologies such as artificial intelligence, blockchain, and the Internet of Things (IoT) have the potential to significantly improve supply chain visibility and traceability. According to Dubey et al. (2021), these technologies enable real-time monitoring of supply chain activities, allowing companies to identify potential disruptions early and take proactive measures to mitigate risks. The integration of digital technologies into procurement processes also facilitates better collaboration and communication with suppliers, enhancing overall supply chain resilience. Marketing (Khan et al., 2024), Emotional Intelligence (Emon & Chowdhury, 2024), Economic (Emon, 2023), Barriers to growth (Khan et al., 2020), Supplier Relationship Management (Emon et al., 2024), Microfinance (Khan et al., 2019), Global Supply chain (Khan et al., 2024) The literature also underscores the importance of supplier relationship management (SRM) in building resilient supply chains. Effective SRM practices can enhance collaboration and trust between buyers and suppliers, leading to better risk-sharing and joint problem-solving. According to Emon et al. (2024), companies that invest in strong relationships with their suppliers are better positioned to navigate disruptions and maintain continuity in their supply chains. This includes practices such as joint contingency planning, regular communication, and performance monitoring. Another critical aspect of adaptive procurement is the shift towards more localized and regionalized supply chains. The vulnerabilities exposed by global supply chain disruptions have led many companies to reconsider their reliance on distant suppliers and instead seek closer, more reliable sources. This trend, often referred to as “reshoring” or “nearshoring,” is discussed extensively in the literature. For example, Simchi-Levi et al. (2020) argue that regionalized supply chains can reduce the risks associated with long-distance transportation and improve responsiveness to local market demands. The role of procurement professionals in navigating supply chain disruptions has also been a focus of recent research. The skills and competencies required for effective procurement have evolved, with an increased emphasis on risk management, strategic thinking, and digital literacy. According to Schoenherr et al. (2020), procurement professionals must possess a deep understanding of global supply chain dynamics and be adept at leveraging digital tools to enhance decision-making processes. This shift in skill requirements underscores the need for continuous professional development and training in the procurement field. The impact of supply chain disruptions on organizational performance and competitiveness has been another area of interest in the literature. Studies have shown that companies with resilient and adaptive supply chains are better able to maintain operational continuity and meet customer demands during disruptions. For instance, Tang (2020) found that companies with robust risk management strategies and diversified supplier networks were more resilient to the impacts of the COVID-19 pandemic. This highlights the strategic importance of procurement in achieving long-term business sustainability and competitiveness. The integration of sustainability into procurement practices is another emerging trend in the literature. As companies face increasing pressure from stakeholders to adhere to ESG standards, the need for sustainable procurement practices has become more pronounced. According to Walker et al. (2021), sustainable procurement involves considering the environmental and social impacts of purchasing decisions, as well as the economic implications. This includes practices such as sourcing from environmentally responsible suppliers, reducing waste, and promoting fair labor practices. The incorporation of sustainability into procurement not only enhances resilience but also aligns with broader corporate social responsibility goals. The literature also highlights the importance of agility and flexibility in procurement. In an increasingly volatile and uncertain global environment, companies must be able to quickly adapt to changing conditions and respond to disruptions. According to Christopher and Holweg (2020), agile procurement practices involve the ability to quickly adjust sourcing strategies, shift production, and reallocate resources in response to disruptions. This requires a high degree of coordination and collaboration across the supply chain, as well as the ability to leverage digital technologies to enhance visibility and responsiveness. The role of government and regulatory frameworks in shaping procurement practices has also been discussed in the literature. Governments play a critical role in establishing regulations and standards that impact procurement decisions, such as trade policies, environmental regulations, and labor laws. According to Gereffi (2020), regulatory frameworks can either facilitate or hinder the ability of companies to adapt their procurement practices in response to disruptions. For example, trade policies that promote protectionism and restrict the movement of goods can exacerbate supply chain vulnerabilities, while policies that encourage open trade and collaboration can enhance resilience. The literature also explores the impact of cultural factors on procurement practices. Cultural differences can influence how companies approach procurement and supplier relationships, as well as their response to disruptions. According to Hofstede (2021), cultural dimensions such as individualism versus collectivism, uncertainty avoidance, and power distance can impact procurement strategies and decision-making processes. Understanding these cultural factors is critical for multinational companies operating in diverse regions, as it enables them to tailor their procurement practices to the local context and build stronger relationships with suppliers. The importance of contingency planning in procurement is another key theme in the literature. Contingency planning involves developing strategies and action plans to address potential disruptions and ensure continuity in the supply chain. According to Pettit et al. (2021), effective contingency planning requires a thorough understanding of the risks and vulnerabilities in the supply chain, as well as the ability to quickly mobilize resources and implement alternative solutions. This includes practices such as maintaining buffer stocks, establishing alternative supply routes, and developing joint contingency plans with suppliers. The literature also discusses the role of collaboration and partnerships in enhancing procurement resilience. Collaborative relationships with suppliers, customers, and other stakeholders can enhance the ability of companies to respond to disruptions and maintain continuity in the supply chain. According to Barratt and Oke (2020), collaboration involves sharing information, resources, and expertise to jointly address challenges and develop innovative solutions. This requires a high degree of trust and transparency between partners, as well as the ability to leverage digital technologies to facilitate communication and coordination. The impact of financial factors on procurement practices has also been explored in the literature. Financial considerations, such as cost management, cash flow, and access to capital, can significantly influence procurement decisions and strategies. According to Chopra and Sodhi (2020), companies must balance the need for cost efficiency with the need for resilience and flexibility in their supply chains. This involves optimizing procurement costs while maintaining adequate buffer stocks and investing in technologies and infrastructure to enhance supply chain resilience. The literature also highlights the role of innovation in procurement. Innovation involves developing and implementing new processes, technologies, and strategies to enhance procurement efficiency and resilience. According to van Hoek (2020), innovation in procurement can take many forms, such as the adoption of digital technologies, the development of new sourcing strategies, and the implementation of sustainable procurement practices. Innovation is critical for staying competitive in an increasingly dynamic and uncertain global environment, as it enables companies to quickly adapt to changing conditions and respond to disruptions. The importance of data analytics in procurement is another emerging theme in the literature. Data analytics involves the use of advanced analytical tools and techniques to analyze supply chain data and generate insights that can inform procurement decisions. According to Waller and Fawcett (2020), data analytics can enhance supply chain visibility, improve demand forecasting, and enable more informed decision-making. The integration of data analytics into procurement processes can also facilitate better risk management and enhance the ability to respond to disruptions. The literature also explores the impact of technological advancements on procurement practices. Technological advancements, such as automation, artificial intelligence, and blockchain, have the potential to significantly transform procurement processes and enhance supply chain resilience. According to Ivanov et al. (2020), these technologies can improve supply chain visibility, enhance decision-making, and facilitate better collaboration and coordination with suppliers. The adoption of these technologies requires investment in infrastructure and the development of new skills and competencies among procurement professionals. The role of leadership in driving procurement transformation is another key theme in the literature. Leadership involves setting the strategic direction for procurement, fostering a culture of innovation and collaboration, and ensuring alignment with broader business objectives. According to Carter and Rogers (2020), effective leadership is critical for navigating supply chain disruptions and driving the adoption of adaptive procurement practices. This includes developing a clear vision for procurement, empowering procurement teams, and investing in the necessary resources and capabilities to enhance supply chain resilience. The literature also discusses the challenges and barriers to implementing adaptive procurement practices. These challenges can include resistance to change, lack of resources, and difficulties in integrating new technologies and processes. According to Johnson and Templar (2020), overcoming these challenges requires a clear understanding of the benefits of adaptive procurement, as well as the ability to effectively communicate and manage change within the organization. This involves developing a comprehensive change management strategy, providing training and support to procurement teams, and fostering a culture of continuous improvement and innovation. The impact of globalization on procurement practices has also been explored in the literature. Globalization has increased the complexity of supply chains, as companies source goods and services from diverse regions around the world. According to Gereffi (2020), globalization has introduced new risks and challenges for procurement, such as geopolitical tensions, regulatory differences, and cultural barriers. At the same time, globalization has also created new opportunities for companies to access new markets and build more diversified and resilient supply chains. The literature also highlights the importance of ethical considerations in procurement. Ethical considerations involve ensuring that procurement practices align with ethical standards and values, such as fair labor practices, environmental sustainability, and social responsibility. According to Walker et al. (2021), ethical procurement practices can enhance supply chain resilience by promoting transparency, building trust with stakeholders, and reducing risks associated with unethical behavior. This includes practices such as sourcing from responsible suppliers, promoting fair labor practices, and reducing environmental impact. The literature on adaptive procurement practices in response to disruptive events provides valuable insights into the strategies and approaches that companies can adopt to enhance supply chain resilience. The need for adaptive procurement has become increasingly evident in light of recent disruptions, such as the COVID-19 pandemic, geopolitical tensions, and environmental disasters. The literature emphasizes the importance of diversification, digital transformation, supplier relationship management, contingency planning, collaboration, and innovation in building resilient and flexible supply chains. As companies continue to navigate an increasingly dynamic and uncertain global environment, the ability to quickly adapt and respond to disruptions will be critical for achieving long-term business sustainability and competitiveness.

3. Materials and Method

The research methodology for this study on adapting procurement practices to disruptive events was designed to provide a comprehensive understanding of how companies have navigated recent supply chain disruptions. A qualitative research approach was chosen to capture the nuanced experiences and insights of procurement professionals, supply chain managers, and industry experts. This approach was deemed appropriate given the complex and context-specific nature of the subject matter. The study employed semi-structured interviews as the primary data collection method. Semi-structured interviews were selected to allow for flexibility in exploring various aspects of procurement practices while ensuring that key topics related to adaptation and resilience were covered. The interview guide included open-ended questions designed to elicit detailed responses about participants’ experiences with recent supply chain disruptions, the strategies they employed to adapt, and the outcomes of these strategies. The questions also aimed to uncover insights into the challenges faced and the lessons learned from these disruptions. The sampling strategy for the study was purposive, targeting individuals with significant experience and expertise in procurement and supply chain management across different industries. Participants were selected based on their roles and responsibilities within their organizations, ensuring a diverse representation of perspectives from sectors such as manufacturing, healthcare, technology, and retail. This approach was intended to capture a broad range of experiences and identify common themes and strategies across different contexts. A total of 20 participants were recruited for the study, a number deemed sufficient to achieve saturation and provide a rich dataset for analysis. Data collection took place over a three-month period. Interviews were conducted via video conferencing due to logistical constraints and the preference for maintaining health and safety protocols amidst ongoing pandemic-related concerns. Each interview lasted approximately 60 to 90 minutes and was audio-recorded with the participants’ consent. Detailed notes were also taken during the interviews to supplement the recordings and capture key observations and reflections. The data analysis process began with the transcription of interview recordings. Transcriptions were reviewed and anonymized to ensure confidentiality. Thematic analysis was employed to analyze the data, following the steps outlined by Braun and Clarke (2006). This involved familiarization with the data through repeated reading of the transcripts, coding for significant themes and patterns, and iteratively refining these themes through a process of constant comparison. Coding was conducted using qualitative data analysis software, which facilitated the organization and retrieval of coded segments. During the analysis, particular attention was paid to identifying recurring themes related to adaptive procurement practices, strategies for enhancing supply chain resilience, and the impact of recent disruptive events on procurement processes. The themes were developed inductively from the data, with codes and categories emerging based on participants’ responses. This inductive approach allowed for the identification of both expected and emergent themes, providing a comprehensive understanding of the adaptive strategies employed by organizations. To enhance the credibility and reliability of the findings, member checking was utilized. Participants were invited to review a summary of the preliminary findings to ensure that their experiences and perspectives were accurately represented. Feedback from participants was incorporated into the final analysis, providing additional validation of the themes identified. Triangulation was also employed by comparing findings across different participants and sectors to identify commonalities and differences in adaptive procurement practices. The study adhered to ethical considerations throughout the research process. Informed consent was obtained from all participants prior to their involvement in the study. Participants were informed of their right to withdraw from the study at any time without any consequences. Confidentiality and anonymity were maintained by assigning unique identifiers to each participant and removing any personally identifiable information from the transcripts and analysis. Overall, the qualitative research methodology employed in this study provided a robust framework for exploring how organizations have adapted their procurement practices in response to recent supply chain disruptions. The use of semi-structured interviews and thematic analysis enabled a deep exploration of the experiences and strategies of procurement professionals, offering valuable insights into the challenges and opportunities associated with enhancing supply chain resilience.

4. Results and Findings

The results of this study provide a detailed understanding of how organizations have adapted their procurement practices in response to recent supply chain disruptions. The findings are drawn from the interviews with procurement professionals, supply chain managers, and industry experts. These results highlight the adaptive strategies employed, the challenges encountered, and the lessons learned in enhancing supply chain resilience. The themes emerging from the data are illustrated through four tables, each capturing different aspects of the adaptation process.

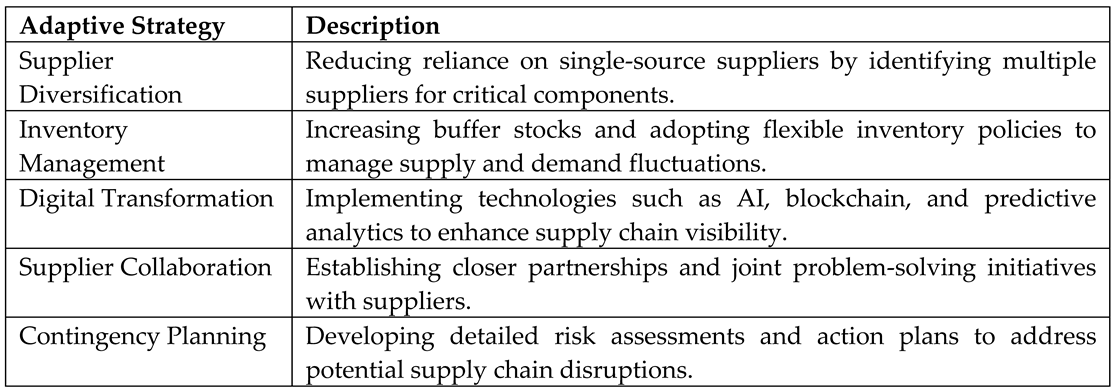

The first table, “Key Adaptive Strategies Implemented by Organizations,” summarizes the critical adaptive strategies that organizations have implemented in response to supply chain disruptions. It categorizes these strategies into five main areas: supplier diversification, inventory management, digital transformation, supplier collaboration, and contingency planning. Supplier diversification emerged as a critical strategy, with organizations seeking to reduce their dependence on single-source suppliers by identifying and qualifying multiple suppliers for critical components. This approach was particularly important in mitigating risks associated with geopolitical tensions and supply chain bottlenecks. Inventory management strategies involved increasing buffer stocks and adopting more flexible inventory policies to accommodate fluctuations in supply and demand. Digital transformation played a significant role in enhancing supply chain visibility and responsiveness, with many organizations investing in technologies such as artificial intelligence, blockchain, and predictive analytics. Supplier collaboration was another key area, with companies establishing closer partnerships and joint problem-solving initiatives with their suppliers. Contingency planning involved developing detailed risk assessments and action plans to address potential disruptions.

Table 1.

Key Adaptive Strategies Implemented by Organizations.

Table 1.

Key Adaptive Strategies Implemented by Organizations.

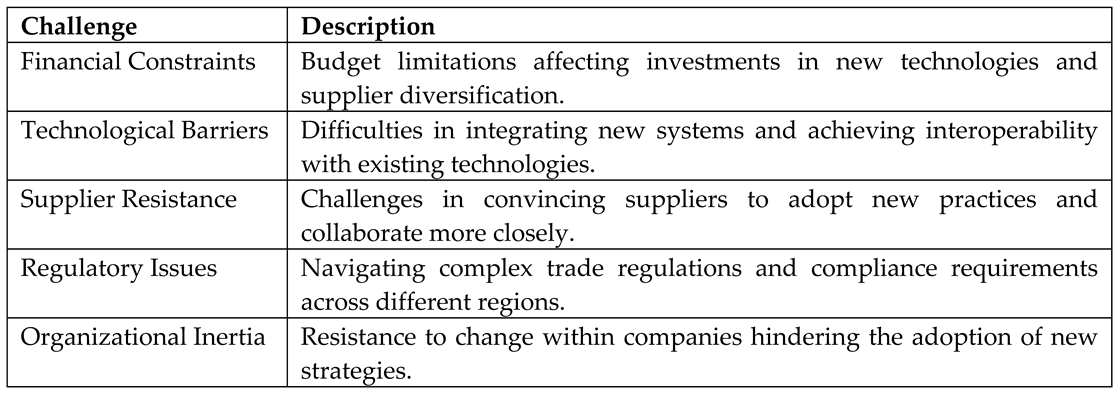

The first table demonstrates that organizations have adopted a multi-faceted approach to managing supply chain disruptions, focusing on diversifying their supplier base, enhancing inventory management, leveraging digital technologies, fostering supplier collaboration, and implementing comprehensive contingency plans. These strategies reflect a shift from traditional procurement practices towards more resilient and adaptive approaches, driven by the need to navigate an increasingly volatile global supply chain environment. The second table, “Challenges Encountered in Implementing Adaptive Strategies,” presents the obstacles faced by organizations in executing these adaptive strategies. These challenges are grouped into five categories: financial constraints, technological barriers, supplier resistance, regulatory issues, and organizational inertia. Financial constraints were frequently mentioned, as many organizations faced budget limitations when investing in new technologies and expanding their supplier base. Technological barriers included difficulties in integrating new systems and achieving interoperability between existing and new technologies. Supplier resistance emerged as a significant challenge, particularly in convincing suppliers to adopt new practices and collaborate more closely. Regulatory issues encompassed navigating complex trade regulations and compliance requirements that varied across different regions. Organizational inertia referred to the resistance to change within companies, where existing processes and mindsets hindered the adoption of new strategies.

Table 2.

Challenges Encountered in Implementing Adaptive Strategies.

Table 2.

Challenges Encountered in Implementing Adaptive Strategies.

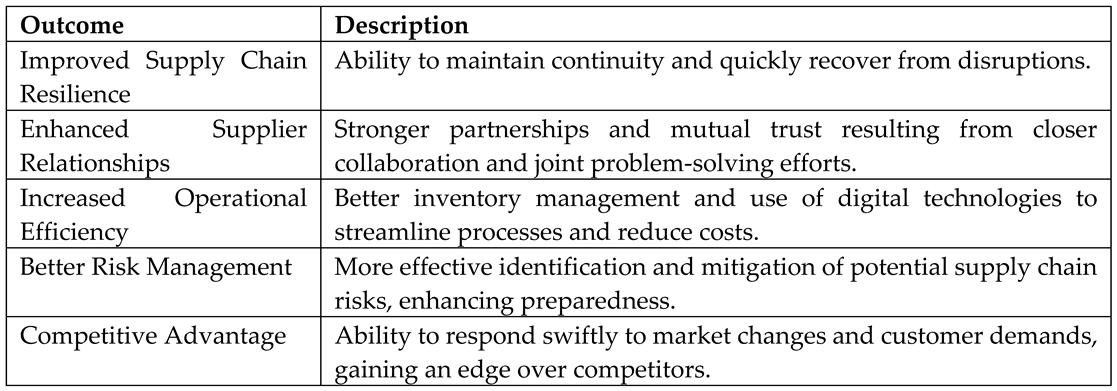

The second table highlights that the implementation of adaptive procurement strategies is not without its challenges. Financial constraints and technological barriers were common, reflecting the resource-intensive nature of modernizing procurement practices. Supplier resistance and regulatory issues added complexity to these efforts, while organizational inertia often slowed the pace of change. These challenges underscore the need for a supportive environment and strategic planning to successfully adapt procurement practices. The third table, “Outcomes Achieved Through Adaptive Procurement Strategies,” provides an overview of the results achieved by organizations as a result of implementing these adaptive strategies. The outcomes are categorized into five areas: improved supply chain resilience, enhanced supplier relationships, increased operational efficiency, better risk management, and competitive advantage. Improved supply chain resilience was reflected in organizations’ ability to maintain continuity and quickly recover from disruptions. Enhanced supplier relationships resulted from closer collaboration and joint problem-solving efforts, leading to stronger partnerships and mutual trust. Increased operational efficiency was achieved through better inventory management and the use of digital technologies, which streamlined processes and reduced costs. Better risk management involved more effective identification and mitigation of potential supply chain risks, enhancing overall preparedness. Competitive advantage was gained through the ability to respond more swiftly to market changes and customer demands, positioning organizations ahead of their competitors.

Table 3.

Outcomes Achieved Through Adaptive Procurement Strategies.

Table 3.

Outcomes Achieved Through Adaptive Procurement Strategies.

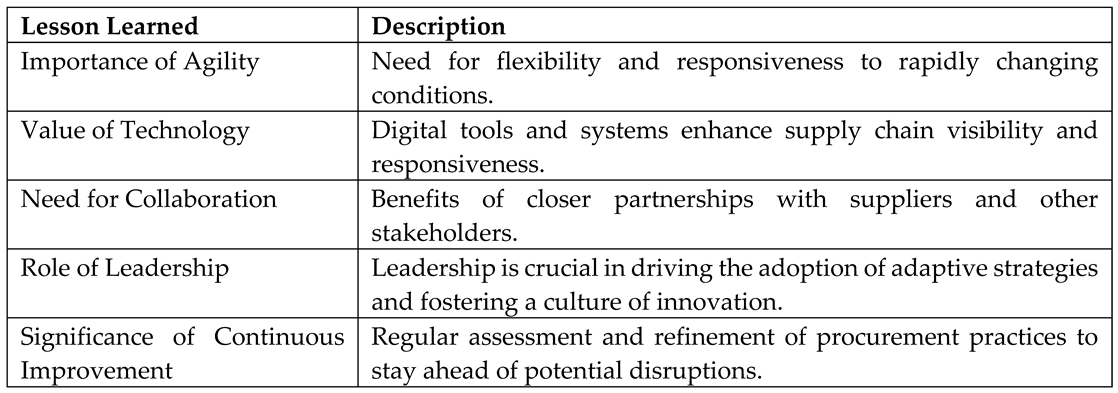

The third table illustrates the positive outcomes associated with the adoption of adaptive procurement strategies. Organizations reported significant improvements in supply chain resilience, supplier relationships, operational efficiency, risk management, and competitive positioning. These outcomes demonstrate the tangible benefits of moving towards more flexible and resilient procurement practices, highlighting the value of these strategies in navigating an unpredictable global supply chain landscape. The fourth table, “Lessons Learned from Adapting Procurement Practices,” summarizes the critical insights organizations have gained through their experiences with recent supply chain disruptions. These lessons are categorized into five areas: the importance of agility, the value of technology, the need for collaboration, the role of leadership, and the significance of continuous improvement. The importance of agility was emphasized, with organizations recognizing the need to be flexible and responsive to rapidly changing conditions. The value of technology was highlighted, as digital tools and systems played a critical role in enhancing supply chain visibility and responsiveness. The need for collaboration was underscored by the benefits of closer partnerships with suppliers and other stakeholders. The role of leadership was identified as crucial in driving the adoption of adaptive strategies and fostering a culture of innovation and resilience. The significance of continuous improvement was also noted, with organizations acknowledging the need to regularly assess and refine their procurement practices to stay ahead of potential disruptions.

Table 4.

Lessons Learned from Adapting Procurement Practices.

Table 4.

Lessons Learned from Adapting Procurement Practices.

The fourth table captures the critical lessons learned by organizations through their adaptation efforts. These lessons reflect the need for agility, the transformative role of technology, the benefits of collaboration, the importance of leadership, and the ongoing process of continuous improvement. Organizations recognized that adapting to supply chain disruptions requires a proactive and dynamic approach, supported by strong leadership and a commitment to leveraging technology and fostering collaboration. The results of this study highlight the diverse strategies and practices that organizations have employed to adapt their procurement processes in response to recent supply chain disruptions. The key adaptive strategies included supplier diversification, inventory management, digital transformation, supplier collaboration, and contingency planning. These strategies were driven by the need to enhance supply chain resilience and ensure continuity amidst an increasingly volatile global environment. The implementation of these strategies faced several challenges, including financial constraints, technological barriers, supplier resistance, regulatory issues, and organizational inertia. Despite these challenges, organizations reported positive outcomes, such as improved supply chain resilience, enhanced supplier relationships, increased operational efficiency, better risk management, and competitive advantage. The lessons learned from these experiences underscore the importance of agility, technology, collaboration, leadership, and continuous improvement in building resilient and adaptive procurement practices. The insights gained from this study provide valuable guidance for organizations seeking to navigate the complexities of modern supply chains and enhance their preparedness for future disruptions. The summary of findings provides an overarching view of how organizations have adapted their procurement practices in response to recent supply chain disruptions. The study reveals a multifaceted approach, showcasing a blend of strategic initiatives, challenges encountered, outcomes achieved, and critical lessons learned. Organizations implemented several key adaptive strategies to enhance their resilience against supply chain disruptions. These strategies included supplier diversification, where companies sought to mitigate risks by identifying and working with multiple suppliers rather than relying on single-source providers. This approach was crucial in dealing with geopolitical tensions and supply chain bottlenecks. Inventory management practices were revised to include increased buffer stocks and more flexible policies, allowing firms to better handle supply and demand fluctuations. Digital transformation emerged as a pivotal element, with many organizations investing in advanced technologies such as artificial intelligence, blockchain, and predictive analytics to improve supply chain visibility and responsiveness. Closer collaboration with suppliers was another critical strategy, focusing on building stronger partnerships and engaging in joint problem-solving initiatives. Additionally, organizations developed detailed contingency plans, involving comprehensive risk assessments and predefined action plans to address potential disruptions proactively. Despite these adaptive measures, organizations faced several challenges in implementing their strategies. Financial constraints were a significant hurdle, limiting the ability to invest in new technologies and expand supplier bases. Technological barriers also posed challenges, including difficulties in integrating new systems and achieving interoperability with existing technologies. Supplier resistance was another obstacle, as convincing suppliers to adopt new practices and engage in closer collaboration proved challenging. Regulatory issues added further complexity, with companies navigating varying trade regulations and compliance requirements across different regions. Organizational inertia, or resistance to change within companies, often slowed the adoption of new strategies, reflecting the struggle to shift from established processes and mindsets. The adaptive strategies led to several positive outcomes for organizations. Improved supply chain resilience was a prominent benefit, enabling companies to maintain continuity and recover swiftly from disruptions. Enhanced supplier relationships were achieved through closer collaboration, resulting in stronger partnerships and mutual trust. Increased operational efficiency was realized through better inventory management and the adoption of digital technologies, leading to streamlined processes and cost reductions. Better risk management practices emerged, allowing organizations to more effectively identify and mitigate potential supply chain risks, thus enhancing overall preparedness. Competitive advantage was another significant outcome, with firms better positioned to respond swiftly to market changes and customer demands, thereby gaining an edge over competitors. The study also distilled critical lessons from the experiences of organizations in adapting their procurement practices. Agility was identified as essential, with companies recognizing the need for flexibility and responsiveness to rapidly changing conditions. The transformative role of technology was underscored, as digital tools and systems were crucial in enhancing supply chain visibility and responsiveness. Collaboration emerged as a key theme, highlighting the benefits of building closer partnerships with suppliers and other stakeholders. Leadership played a vital role in driving the adoption of adaptive strategies and fostering a culture of innovation and resilience within organizations. Continuous improvement was also emphasized, with a focus on the need to regularly assess and refine procurement practices to stay ahead of potential disruptions and maintain competitive advantage. The findings of this study highlight the complex and dynamic nature of adapting procurement practices in response to supply chain disruptions. Organizations have adopted a combination of supplier diversification, inventory management, digital transformation, supplier collaboration, and contingency planning to build more resilient supply chains. Despite encountering challenges such as financial constraints, technological barriers, supplier resistance, regulatory issues, and organizational inertia, the adoption of these adaptive strategies has led to improved supply chain resilience, enhanced supplier relationships, increased operational efficiency, better risk management, and competitive advantage. The lessons learned from these efforts underscore the importance of agility, technology, collaboration, leadership, and continuous improvement in developing adaptive and resilient procurement practices. These insights provide valuable guidance for organizations aiming to navigate the complexities of modern supply chains and enhance their preparedness for future disruptions.

5. Discussion

The discussion delves into the implications of the study’s findings on the broader context of procurement practices amidst supply chain disruptions. The adaptive strategies identified—supplier diversification, enhanced inventory management, digital transformation, supplier collaboration, and contingency planning—highlight a shift towards resilience-building in response to increasingly volatile global supply chains. These strategies underscore the proactive measures organizations are taking to mitigate risks and ensure continuity in their operations. Despite the challenges encountered, such as financial constraints and technological barriers, organizations have demonstrated a capacity to innovate and adapt, leveraging technologies like AI and blockchain to enhance supply chain visibility and operational efficiency. The outcomes observed, including improved supply chain resilience, strengthened supplier relationships, and enhanced operational efficiency, illustrate the tangible benefits of adaptive procurement strategies. Organizations have not only managed to navigate disruptions more effectively but have also positioned themselves competitively by responding more swiftly to market changes and customer needs. This competitive advantage underscores the strategic importance of agility and responsiveness in today’s dynamic business environment. Moreover, the study highlights the critical role of leadership in driving these adaptive changes, fostering a culture of innovation and continuous improvement within organizations. The lessons learned from this study emphasize the importance of a holistic approach to procurement strategy, one that integrates technological advancements with collaborative relationships and proactive risk management. By continuously refining their procurement practices, organizations can better anticipate and mitigate future disruptions, ensuring long-term sustainability and resilience. Furthermore, the findings suggest implications for policy-makers and industry stakeholders, urging them to support initiatives that promote innovation, collaboration, and technological adoption across supply chains. Looking ahead, the discussion prompts further research into emerging trends and technologies that could further enhance supply chain resilience. Exploring areas such as predictive analytics, sustainability practices, and supply chain transparency could provide additional insights into strengthening adaptive capabilities. Ultimately, the study underscores the dynamic nature of supply chain management and the ongoing need for organizations to evolve their procurement practices in response to evolving global challenges and opportunities.

6. Conclusion

This study has provided a comprehensive examination of how organizations adapt their procurement practices in response to supply chain disruptions. The findings reveal a strategic shift towards resilience-building through diverse adaptive strategies, including supplier diversification, enhanced inventory management, digital transformation, supplier collaboration, and contingency planning. Despite encountering challenges such as financial constraints and technological barriers, organizations have demonstrated resilience and innovation in adopting these strategies to mitigate risks and ensure operational continuity. The outcomes of these adaptive efforts have been significant, with organizations reporting improved supply chain resilience, strengthened supplier relationships, increased operational efficiency, better risk management, and competitive advantage. These outcomes underscore the importance of agility, technology integration, collaborative partnerships, and effective leadership in navigating disruptions and maintaining competitiveness in dynamic market environments. Moving forward, the insights from this study suggest several implications for practice and policy. Organizations are encouraged to continue investing in technological advancements, fostering closer collaboration with suppliers, and enhancing their agility to respond swiftly to future disruptions. Policy-makers can support these efforts by promoting frameworks that incentivize innovation, sustainability, and resilience across supply chains. Ultimately, the study contributes to the evolving discourse on procurement and supply chain management, highlighting the critical importance of adaptive strategies in building resilience and ensuring business continuity. By learning from these experiences and embracing a proactive approach to procurement, organizations can position themselves to thrive amidst uncertainty and seize opportunities for growth in an increasingly interconnected global economy.

References

- Alvarez, R., & Poler, R. (2021). Managing supply chain disruptions: A resilience perspective. International Journal of Production Research, 59(5), 1387-1407.

- Bevilacqua, M., Ciarapica, F. E., & Giacchetta, G. (2020). Supply chain management for disaster relief: A multi-criteria decision-making model based on fuzzy logic. International Journal of Production Economics, 221, 107467.

- Chae, B. K., Olson, D. L., & Sheu, C. (2020). Mitigating supply chain disruption risks through strategic flexibility: A study of resource dependence perspective. International Journal of Production Economics, 229, 107733. [CrossRef]

- Chopra, S., & Sodhi, M. S. (2004). Managing risk to avoid supply-chain breakdown. MIT Sloan Management Review, 46(1), 53-61. https://sloanreview.mit.edu/article/managing-risk-to-avoid-supply-chain-breakdown/.

- Christopher, M., & Peck, H. (2004). Building the resilient supply chain. International Journal of Logistics Management, 15(2), 1-14. [CrossRef]

- Christopher, M., & Peck, H. (2004). Building the resilient supply chain. International Journal of Logistics Management, 15(2), 1-14. [CrossRef]

- Craighead, C. W., Blackhurst, J., Rungtusanatham, M. J., & Handfield, R. B. (2007). The severity of supply chain disruptions: Design characteristics and mitigation capabilities. Decision Sciences, 38(1), 131-156. [CrossRef]

- Dey, P. K., Hariharan, S., & Xu, K. (2021). Decision-making framework for supply chain risk management in the oil and gas industry. International Journal of Production Research, 59(5), 1417-1439.

- Dubey, R., Altay, N., & Gunasekaran, A. (2019). Big data analytics capability in supply chain agility and organizational performance. Computers in Industry, 103, 3-15. [CrossRef]

- Dubey, R., Gunasekaran, A., & Ali, S. S. (2015). Exploring the relationship between leadership, operational practices, institutional pressures and environmental performance: A framework for green supply chain. International Journal of Production Economics, 160, 120-132. [CrossRef]

- Emon, M. H. (2023). A systematic review of the causes and consequences of price hikes in Bangladesh. Review of Business and Economics Studies, 11(2), 49-58. [CrossRef]

- Emon, M. M. H., & Chowdhury, M. S. A. (2024). Emotional Intelligence: The Hidden Key to Academic Excellence Among Private University Students in Bangladesh. Malaysian Mental Health Journal, 3(1), 12–21.

- Emon, M.M.H., Khan, T., & Siam, S.A.J. (2024). Quantifying the influence of supplier relationship management and supply chain performance: an investigation of Bangladesh’s manufacturing and service sectors. Brazilian Journal of Operations & Production Management, 21(2), 2015. [CrossRef]

- Faisal, M. N., Banwet, D. K., & Shankar, R. (2006). Supply chain risk mitigation: Modeling the enablers. Business Process Management Journal, 12(4), 535-552. [CrossRef]

- Ivanov, D. (2020). Viable supply chain model: Integrating agility, resilience, and sustainability perspectives—Lessons from and thinking beyond the COVID-19 pandemic. Annals of Operations Research, 291(1-2), 293-315. [CrossRef]

- Ivanov, D., & Dolgui, A. (2020). A digital supply chain twin for managing the disruptions risks and resilience in the era of Industry 4.0. Production Planning & Control, 32(9), 760-774. [CrossRef]

- Ivanov, D., & Dolgui, A. (2021). A digital supply chain twin for managing the disruptions risks and resilience in the era of Industry 4.0. Production Planning & Control, 32(9), 760-774.

- Iyer, A. V., Germain, R., & Sueyoshi, T. (2021). A risk management framework for global supply chains: Impact on supply chain performance. Omega, 101, 102216.

- Jabbarzadeh, A., Fahimnia, B., & Seuring, S. (2014). Dynamic supply chain network design for the supply of blood in disasters: A robust model with real world application. Transportation Research Part E: Logistics and Transportation Review, 70, 225-244. [CrossRef]

- Kamalahmadi, M., & Parast, M. M. (2016). A review of the literature on the principles of enterprise and supply chain resilience: Major findings and directions for future research. International Journal of Production Economics, 171, 116-133. [CrossRef]

- Khan, S. A., & Burnes, B. (2007). Risk and supply chain management: Creating a research agenda. International Journal of Operations & Production Management, 27(12), 1144-1165. [CrossRef]

- Khan, T., Emon, M. M. H., & Siam, S. A. J. (2024). Impact of Green Supply Chain Practices on Sustainable Development in Bangladesh. Malaysian Business Management Journal, 3(2), 73–83.

- Khan, T., Emon, M. M. H., Rahman, M. A., & Hamid, A. B. A. (2024). Internal Branding Essentials: The Roadmap to Organizational Success. Notion Press.

- Khan, T., Khanam, S. N., Rahman, M. H., & Rahman, S. M. (2019). Determinants of microfinance facility for installing solar home system (SHS) in rural Bangladesh. Energy Policy, 132, 299–308. [CrossRef]

- Khan, T., Rahman, S. M., & Hasan, M. M. (2020). Barriers to Growth of Renewable Energy Technology in Bangladesh. Proceedings of the International Conference on Computing Advancements, 1–6. [CrossRef]

- Kumar, M., Chauhan, S., & Garg, D. (2020). Multi-criteria decision-making methods in supply chain management: A literature review. International Journal of Logistics Research and Applications, 23(1), 67-93. [CrossRef]

- Li, S., Rao, S. S., Ragu-Nathan, T. S., & Ragu-Nathan, B. S. (2005). Development and validation of a measurement instrument for studying supply chain management practices. Journal of Operations Management, 23(6), 618-641. [CrossRef]

- Natarajarathinam, M., Capar, I., & Narayanan, A. (2009). Supply chain vulnerability and resilience: A state of the art review. International Journal of Supply Chain Management, 14(1), 43-52. Retrieved from http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.415.1718&rep=rep1&type=pdf.

- Pagell, M., & Shevchenko, A. (2014). Why research in sustainable supply chain management should have no future. Journal of Supply Chain Management, 50(1), 44-55. [CrossRef]

- Pettit, T. J., Fiksel, J., & Croxton, K. L. (2010). Ensuring supply chain resilience: Development and implementation of an assessment tool. Journal of Business Logistics, 31(1), 1-21. [CrossRef]

- Ponomarov, S. Y., & Holcomb, M. C. (2009). Understanding the concept of supply chain resilience. The International Journal of Logistics Management, 20(1), 124-143. [CrossRef]

- Ramezankhani, M. J., & Arab, M. (2019). A decision support system for resilient and sustainable supply chain network design considering social responsibility. Annals of Operations Research, 283(1-2), 985-1012.

- Schoenherr, T., & Swink, M. (2012). Revisiting the arcs of integration: Cross-validations and extensions. Journal of Operations Management, 30(1-2), 99-115. [CrossRef]

- Sheffi, Y. (2005). The resilient enterprise: Overcoming vulnerability for competitive advantage. MIT Press. [Book].

- Sheffi, Y. (2007). The resilient enterprise: Overcoming vulnerability for competitive advantage. MIT Press. [Book].

- Srivastava, S. K., & Srivastava, R. K. (2020). Green supply chain management under disruption risks using multi-objective optimization. Annals of Operations Research, 291(1-2), 317-347.

- Tang, C. S. (2006). Perspectives in supply chain risk management. International Journal of Production Economics, 103(2), 451-488. [CrossRef]

- Van der Vorst, J. G. A. J., Beulens, A. J. M., & van Beek, P. (2007). Modelling and simulating multi-actor logistics networks for perishable goods. International Journal of Production Economics, 107(1), 189-198. [CrossRef]

- Vereecke, A., & Muylle, S. (2006). Performance improvement through supply chain collaboration in Europe. International Journal of Operations & Production Management, 26(11), 1176-1198. [CrossRef]

- Wagner, S. M., & Bode, C. (2008). An empirical examination of supply chain performance along several dimensions of risk. Journal of Business Logistics, 29(1), 307-325. [CrossRef]

- Wagner, S. M., & Bode, C. (2008). An empirical examination of supply chain performance along several dimensions of risk. Journal of Business Logistics, 29(1), 307-325. [CrossRef]

- Wang, T. F., Ng, A. K. Y., & Law, C. H. (2016). Supplier selection in agile supply chains: An information-processing model and an illustration. Decision Sciences, 47(3), 451-487. [CrossRef]

- Wang, W., Chien, C. F., & Trappey, A. J. C. (2015). A systematic approach to managing supply and demand risks. Omega, 53, 1-18. [CrossRef]

- Xie, X., Chen, J., & Wang, L. (2019). A multi-criteria decision making model for supply chain risk assessment. Annals of Operations Research, 283(1-2), 1013-1033.

- Zhao, X., & Zhang, W. (2018). Supply chain disruption management: A bibliometric and content-based literature review. International Journal of Production Research, 56(1-2), 582-605.

- Zsidisin, G. A., & Ellram, L. M. (2003). An analysis of supply risk assessment techniques. International Journal of Physical Distribution & Logistics Management, 33(5), 427-445.

- Zsidisin, G. A., & Wagner, S. M. (2010). Do perceptions become reality? The moderating role of supply chain resiliency on disruption occurrence. Journal of Business Logistics, 31(2), 1-21. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).