1. Introduction

With increasing industrialization, both the diversity and quantity of industrial waste are increasing day by day. In particular, heavy metals and toxic substances contained in industrial waste constitute a problem for human life and ecological balance. Rapid economic growth, technological development, urbanization, population growth, and welfare increases also lead to an increase in the amount of waste produced. According to the National Recycling Strategy Document and Action Plan (2014–2017) of the Ministry of Science, Industry, and Technology, the difficulties faced by the increasing amount of waste require a “waste management approach” which aims at production and consumption without waste or as little waste as possible [

1]. Disposal of waste without damaging the environment is important for ecological balance, human health, and the economy.

According to the OECD, waste is defined as: “a non-product of which the producer does not use, wish to discard and/or should be disposed of for consumption, conversion, or production purposes.” [

2]. All the unused substances in the form of solids, liquids, and gases that are formed as a result of production and consumption during the life cycle process constitute waste. Wastes are divided into different categories in different literature in terms of source. Wastes are classified into five types: domestic, industrial, commercial, institutional, agricultural, and private wastes. Industrial wastes may contain domestic, hazardous, non-hazardous, and special wastes. Such wastes can be classified as solid, liquid, or gas wastes according to their structure, and they can be analyzed as harmful or harmless wastes.

The total waste generated by all economic activities and households in the EU in 2020 was 2,135 million tonnes or 4,815 kg per capita. In the same year, 32.2 % of which was disposed of in landfills and 39.2% of waste were recycled [

3]. In the EU, the construction sector accounted for 37.5 % of the waste was followed by mining and quarrying (23.4%), waste and water services (10.8%), manufacturing (10.6%), and households (8.2%) in 2020. Among the waste produced in the EU in 2020, 95.5 million tonnes (5.1 % of the total) were classified as hazardous waste. In 2020, the EU produced 5.1% more hazardous trash than it did in 2010. With a peak of 102.0 million tonnes in 2018, there has been an increase in quantity from 90.8 to 95.5 million tonnes. Türkiye (28.5%) and North Macedonia (28.2%) had the highest percentages of hazardous waste and total waste generation among non-EU nations. If dangerous waste is not handled and thrown away in a safe way, it poses a high risk to human health and the environment. In EU policies, especially with the EU Sustainable Development Strategy, 6th and 7th Environmental Action Plan (EAP), the importance given to resource utilization, resource efficiency, and waste has increased. The sustainable use of resources and the objective of sustainable growth of the Europe 2020 Strategy and increasing waste recycling are also addressed in the “Resource Efficient Europe” document [

4].

According to Fedotkina et al. (2019), solid waste collection, processing, and recycling are shared responsibilities among all stakeholders in the ecosystem.The federal government, local governments, private citizens, companies, and newcomers, such as regional operators and eco-industrial parks, are all considered stakeholders. The government provides other players with financial incentives, financing for infrastructure development, and regulations. Local governments are in responsible of handling waste in their communities. Solid waste collection, processing, and recycling methods are the responsibility of businesses. The task of collecting separate waste falls on households. From a garbage tank to the range or processing facility, regional operators are in charge of overseeing all waste management practices [

5].

Every nation has laws requiring waste management in place because it is so important to public health. Although towns are legally obligated to offer or organize services, their actual implementation is frequently insufficient in developing nations, primarily because of the limited financial and technical resources available to municipal administrations. In these situations, it can be useful to supplement the public sector by working with a variety of various private sector service providers, from big private firms to tiny and microenterprises, in order to guarantee locally relevant and reasonably priced services [

6]. An effective waste management system will also contribute to sustainable economic growth with the effect of reducing dependence in sectors with high dependence on raw materials and intermediate goods. This will ensure the protection of natural resources and the environment and protect human health.

According to Taelman et al. (2018), the creation of a life cycle thinking-based conceptual sustainability framework for waste management can assist businesses, regional and local authorities, and policy makers in identifying resource-efficient ways to improve social, environmental, and economic performance [

7]. Starting with an analysis of the current wate management system is crucial. This includes determining how materials move through urban and rural areas of a city and beyond, as well as the quantity and value of streams, the stakeholders and actors involved, their links and proximity, the role of land and infrastructure, and other factors that vary depending on the metropolitan area. Authors analyzed the recently developed sustainability frameworks with models they used for waste management by summarizing 22 articles which proposed. Methods/tools commonly used are multi-criteria and optimization techniques, life cycle analysis, flow and value analysis methods, Life Cycle Costing and Social Life Cycle Assessment [

7].

When literature reviewing critical success factors in waste management is examined, it is seen that different criteria are considered by different authors in different industries but not prioritized by using one of the multi-criteria decision making methods in industrial waste management area. Prioritization is important in terms of macro-action plans at the country level and micro-action and investment plans at the enterprise level. The aim of this study is to determine the main critical success factors in industrial waste management as well as the sub-factors and put forward the AHP-based prioritization methodology that will eliminate the lack of the literature. Thus, decision makers will pay attention to priorities and make effective investments when making decisions in waste management with a limited budget. Furthermore, the waste management CSF priorities according to the experts from different industries were determined by AHP method and employees’ thoughts on the same issue were prioritized through a survey.

2. Related Works

In this section, critical success factors of waste management in different industries as well as factors affecting the circular economy and green supply chain have been tried to be examined. The findings in this section were also helpful for the critical success factors used in this research methodology.

The main purpose of the waste management system is to ensure less waste production and then to recycle or compost the resulting waste into the system. The main regulation in the field of waste management is the Waste Framework Directive 2008/98/EC. The Framework Directive defines the hierarchy of waste management [

8]. According to the waste management hierarchy, waste management strategies should focus primarily on the prevention of waste generation at the source. Where this is not possible, waste materials must be reused and, if not, recycled. Waste materials that cannot be recycled should be used for recovery (e.g., energy recovery). The safe disposal of waste in incineration plants or landfills is the last option in the waste management hierarchy. Industrial wastes, in general terms, are wastes arising from industrial activities. In recent years, interest in industrial waste has become an important issue due to the growing population and consumption of industrial products. i. To reduce the amount of waste that needs to be reduced and the use of harmful substances during manufacturing processes, ii. internalize environmental thinking in the use of materials by using recycled products and creating markets.

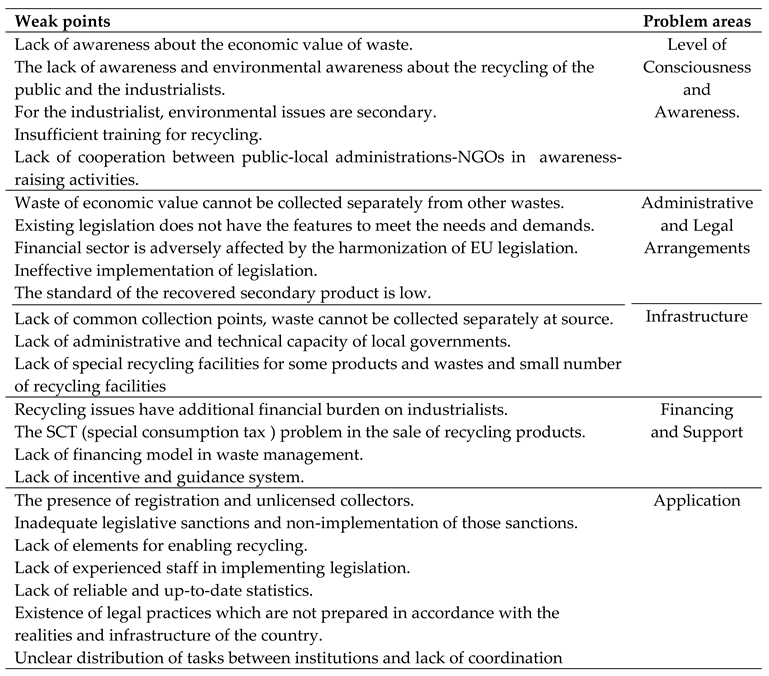

The Turkish National Recycling Strategy Document and Action Plan of the Ministry of Science, Industry, and Technology of Türkiye for the period 2014–2017 explains why a waste management approach is needed [

9]. After doing a SWOT analysis related to the recycling area, the problem areas shown in

Table 1 were highlighted in that plan, which guided us in determining critical success factors in our study.

Özbay (2006) included the subject of solid waste management and general objectives in his book and summarized the points to be considered in solid waste management as follows:

Ensuring the circulation of waste in society,

reducing raw material consumption,

Reducing the use of solid waste,

Reusing the materials,

Seeking ways to regain materials,

Providing energy savings,

Carrying out solid waste management [

10].

Büyüközkan and Vardaloğlu (2008) published a literature study titled “Green Supply Chain Management”. In this study, they have discussed the green managerial approaches that should be in the enterprises. From the procurement of raw materials to after-sales services, they examined the environment-friendly approach that must be in every process and the enterprises that make production with this approach and revealed the key success factors that should be in all these processes. According to Büyüközkan and Vardaloğlu, the low concentration of hazardous, harmful and toxic substances is one of the key success factors in product and by-product design. The amount of energy and raw materials used is another key success factor, and if a product is produced in processes that reduce energy and raw material consumption in an enterprise, it means that green production activities take place in that supply chain. Another key success factor is the use of recyclable, reusable and reprocessable materials in product design [

11].

Lu and Yuan (2010) found that economic growth in China has produced large amounts of construction and demolition waste in the last 30 years, but the best way to achieve this has not yet been explored, although a better waste management system is needed. They found that economic growth in China has produced large amounts of construction and demolition waste in the last 30 years, but the best way to achieve this has not yet been explored, although a better waste management system is needed. From this point of view, they prepared a study aimed at identifying critical success factors for waste management in China’s construction and demolition. In the study, Shenzhen was chosen as the research area in the south of China, the leading city for construction and demolition waste management. Practitioners, researchers, and government officials in Shenzhen City were selected as participants in this survey. The following 18 critical success factors were found. Thirteen of them came from the people who took part in the study, and the other five came from the research. A questionnaire was sent to 75 different participants and it was stated that 51 of them received feedback. Identified CSFs are as follows: material usage and storing system, fewer design change, developing contribution among the project attendees, waste management lice cycle, Waste management regulation, recycling and reuse, in situ waste audit system, in situ classification of waste, construction technologies including fewer waste, Awareness, Improving Traditional construction process, environmental management system, waste management system, dwelling industrialization program, research and development activities in waste management, occupational training in waste management, measurable waste management system, considering waste management in bidding and tendering processes. As a result of the analysis of survey data with SPSS 15.0, 7 critical success factors with the highest level of importance for managing construction and demolition waste were identified. These: (1) Waste management regulation, (2) Waste management system, (3) Awareness, (4) Low-waste construction technologies, (5) Fewer design changes, (6) Waste management research and development, and (7) Waste management vocational training [

12].

In 2012, Renwick et al. discussed the “Green Human Resources Management” approach in order to create waste management and environmental awareness in enterprises and to apply this awareness at every stage of business processes. In this work, they included the selection and recruitment factors of the employees within the scope of talent development; included performance management and evaluation factors within the scope of training and development; employee motivation; and critical success factors related to employee engagement, empowerment, and participation; climate of supportive organizational culture; employee engagement; and trade union tasks in environmental management within the scope of wage and reward system [

13].

Jibril et al. (2012) talk about 3R’s strategic approach to raise awareness among people who make waste in order to lower the cost of running the system and reduce the amount of solid waste made, which is important for managing waste in higher education institutions in an efficient and effective way. This study classified critical success factors according to the waste management hierarchy, which includes waste prevention and mitigation, recycling and reuse, waste treatment, and disposal. As a result of the study, they emphasized that the reduction, reuse and recycling of solid wastes can be achieved with the 3R strategic approach fully implemented in higher education institutions, thus reducing costs and improving performance. They stated that traditional practices of solid waste management in higher education institutions should be replaced by integrated approaches for a cleaner environment and efficient cost effectiveness of the whole system [

14].

Jibril et al. (2013) researched the importance of awareness of 3R critical success factors in “Green Higher Education Institutions”. In this study, they also classified critical success factors in waste management according to the 3R approach, namely Reduce: Decrease, Reuse: Use, Recycle: Recycling. They stated that energy and water saving as subcritical success factors, using fewer packaging and packaging materials, using waste materials in new designs or selling them to other institutions for evaluation, and adding waste products or packaging products to the recycling chain. They stated that the “awareness” factor was an important factor in determining the failure or success of the solid waste management system in higher education institutions all over the world [

15].

Omran and Eltayed (2016) published a study to identify and prioritize critical success factors for waste management in construction projects in Khartoum, Sudan. They identified 18 critical success factors to analyze and compared previous studies. A quantitative method was used to collect the data. With the aim of project manager, contractor and consultant, 65 surveys were sent to different companies in Khartoum city where construction activities are intense. SPSS 20.0 was used to look at the data from 45 questionnaires, and the 10 most important success factors that came out of the analysis are listed below: material use and storage systems; better communication between project participants; in-house waste control system; research and development in waste management; vocational training in waste management; improvement of traditional construction processes; waste management systems; waste management awareness in construction and demolition processes; waste management regulations; and waste management awareness in the bid-tender process [

16].

Baaki et al. (2017) published a case study to identify critical success factors for medical waste management in Nigeria. The aim of their work is to identify the critical success factors of medical waste management in developing countries and to assess the recognition and implementation of these factors to ensure that medical waste management in Benue State, Nigeria, does not achieve its goals. In a study conducted to develop the National Health Waste Management Plan of Angola, it was found that environmental policies and legislation are the most important critical success factors as a result of the study, which is based on some critical factors required for medical waste management application. They stated that there are special and detailed regulations regarding medical waste in accordance with international environmental rules and regulations as the second critical factor, and that the third most critical factor is infrastructure and an adequate and productive labor force within the scope of financing and investment [

17]

Ding et al. (2018) mentioned that prior research mostly addressed the broad facets of construction waste management, including policy, the environment, the economy, society, and management issues [

18]. According to Maranesi and De Giovanni (2020) the limits of the companies must be expanded under the circular environment paradigm to include supply chain (SC) partners who share the same commitment to circularity. Circular SC is defined as incorporating circular thinking into supply chain management and the surrounding industrial and ecological ecosystems which systematically restores materials toward a zero-waste vision. To be successful, senior management and shareholders must work together to advance technological and innovative projects, forge business alliances in order to establish integrated circular supply chains, and successfully advocate for organizational and cultural reforms [

19].

For the purpose of identifying and categorizing drivers and Critical Success Factors in the context of circular economy (CE), a final collection of 55 articles was chosen by the authors and these CSFs were suggested for furher research on CE: technological, economic and financial, institutional, strategic and external [

20].

In order to contribute to a broader understanding of the early stages of the introduction of circular economy related business models inside SMEs, the authors focused on the investigation of the role of organizational learning processes and related contextual elements which includes the identification of intraorganizational and interorganizational learning processes that may support the sustainable evolution of the business models [

21]. The identification of cultural, structural, regulatory, and procedural contextual aspects at the external, supply chain, and organizational levels, as well as how those elements connect to relevant intraorganizational and interorganizational learning processes, were the main implications of their study.

The fundamental and crucial function that green supply chain management (GSCM) plays in achieving the goal of sustainable development. Agrawal et al. (2023) analyzed the critical success factors for the manufacturing industry’s successful implementation of GSCM procedures by using AHP, TOPSIS, and DEMATEL methodologies [

22]. They selected nine CSFs after the literature review and these were confirmed by 189 management experts. Reverse logistics management was found as the primary factor leading to the successful implementation of SGSCM methods, and it has been determined that top management commitment is the most significant critical success factor. Other CSFs were listed in importance order as adoption of new technology and process, employee involvement, customer requirement, government regulations and standards, brand image building, training, sustainability, and reverse logistics management [

22].

Critical success factors (CSFs) were identified, prioritized, and their relationships with one another were examined using an integrated multi-criteria decision-making methodology by the authors to implement green SCM practices in the apparel manufacturing industry [

23]. Debnath et al. (2023) listed the ranking of the CSFs according to influence level: demand from buyers, economic and tax benefits, government rules and regulations, sustainable adoption of green technologies, sustainable supplier selection, top management commitment, achieving and sustaining environmental certifications, green awareness, global competition factor, availability of qualified and skilled manpower , sustainable energy management and reduction of fossil fuel usage, efficient reverse logistics management, sustainable waste management system, sustainable logistics and inventory management, supplier training and cooperation and green sourcing and procurement [

23]. Bhattacharjee et al. (2023) contributed to the literature by examining the key success factors (CSFs) of circular economy implementation in the waste electrical and electronic equipment (WEEE) sector and determining their causal links and order of importance [

24]. Authors found that “Market Contenders”, “Formation of Cross-functional Teams” , “Global Standard” , “Skilled Manpower”, Financial Sustainability” and “Consumer Awareness” as prominent CSFs in WEEE.

Dixit and Dutta (2024) used structural modelling embedded fuzzy decision-making trial to identify the most imprtant critical success factors for adopting a circular economy in health care industry [

25]. Among 17 critical success factors, authors found that 12 CSFs ‘Information visibility & transparency’, ‘Service Provider Responsibility’, ‘Government Responsibility’, ‘Manufacturer/Corporate Responsibility’, ‘Budget Allocation’, ‘Consumer Responsibility’, ‘Training & empowerment’, ‘Tax Incentive’, ‘Monitoring & Regulation’, ‘Publicity/Awareness’, ‘Stakeholders Participations’ and ‘Segregation/Collection’ are accepted under cause group. The rest five CSFs are documented as under effect group: ‘Public Ethics’, ‘Product Design’, ‘Infrastructure Design and Development’, ‘Technology Involvement’ and ‘Data Estimation’.

4. Discussion

Baaki et al. published a case study to identify critical success factors in medical waste management in Nigeria. In this study they published, it was revealed that environmental policies and regulations are the most important critical success factor, and the second critical factor is specific and detailed regulations on medical waste [

17].

In their study aiming to define critical success factors for construction and demolition waste management in China, Lu and Yuan stated (i) waste management regulation and (ii) waste management system as the two most important critical success factors in their study [

12].

In our study, (i) National-Local waste management strategies and policies, (ii) waste management strategies and policies of the enterprise were the most important critical success factors. The results are in agreement with these two studies. From this, we can also conclude that the approach to waste management should be the same, no matter how different the sources of waste are.

In a literature study titled “Green Supply Chain Management,” the authors discussed the green managerial approaches that should be adopted in businesses. As a result of the study, they stated that the strategy and policies of the enterprise are the most important critical success factors. The results were found to be compatible with our study. The reason why recycling management is ranked lower in our study is thought to be due to the fact that our study focused on the whole enterprise, while Büyüközkan and Vardaloğlu’s study focused on the supply chain management sub-unit [

11].

In

Table 16, the comparison of our research findings and the literature is discerned.

Yeh et al. (2020) mentions that increased relationship trust and a greater alignment between stakeholder environmental awareness and company awareness can foster positive communication and improve the reputation of firms [

30]. According to (Menzie and Freshman 1997), scientists, policy makers and the public should be educated about the ecological risk assessment process and how important it is to make decisions. Likewise, with this tool and philosophy, managers in the industry should give priority to the enterprise’s “waste management strategies and policies” from material use to warehouse management; from compliance with the green design principle in product design to fewer design changes to products; from allocation of adequate budget for waste management to rewarding those who propose environmental management [

31]. There is evidence to suggest that willingness to participate in waste management is significantly correlated with general understanding about waste management [

32].

5. Conclusion and Future Studies

5.1. Conclusion

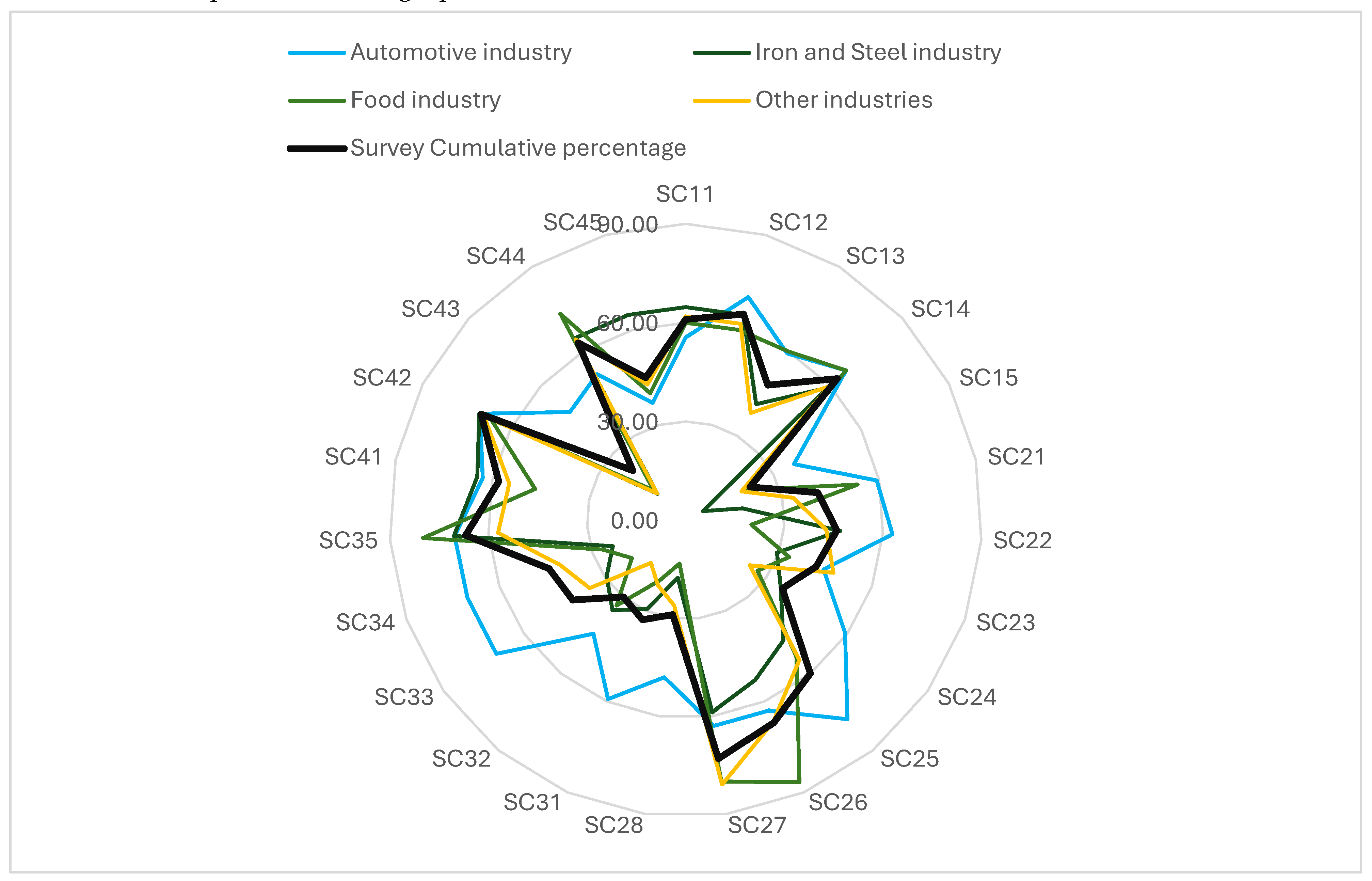

In this study, critical success factors in industrial waste management are examined and prioritized by utilizing AHP and expert opinion. Industrial waste management on a sectorial basis has been addressed in the literature, and CSF prioritization has not been found with multiple criteria decision making techniques before. In this study, the most important critical success factors in industrial waste management, sub-factors and importance percentages of each CSF were found and valuable contributions were made to the lack of the literature. The main objective in the formation of a hierarchical structure is the selection of a critical success factor in industrial waste management. In this study, there are four main criteria and 23 sub-criteria: (1) National-Local waste management strategies and policies; (2) Enterprise waste management strategies and policies; (3) Recovery management; and (4) Awareness-raising. As a result of the AHP analysis, “National/Local waste management strategies and policies” was determined as the most important critical success factor with an importance level of 0.4561. It is followed by “Business Policies” with a significance level of 0.3394. As a result of the analyses, “Recovery management,” with a significance level of 0.1300, was the third, and “Awareness raising,” with an importance level of 0.0745, was the fourth critical success factor

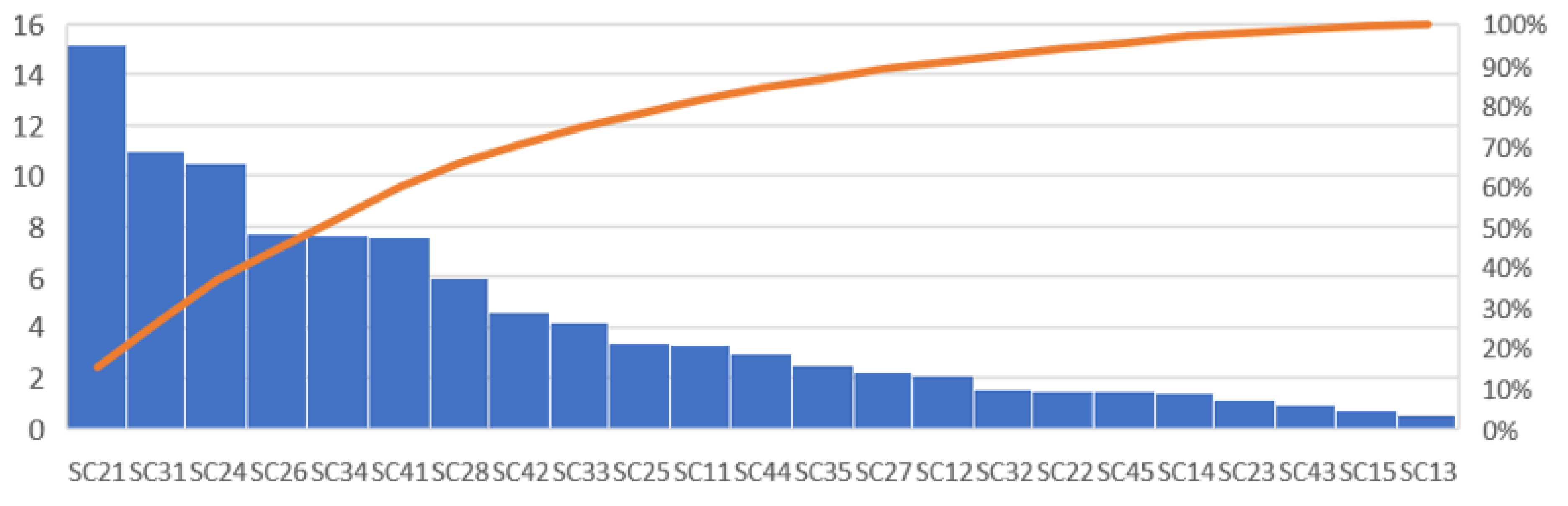

When we compare the survey results and expert opinions on a sectoral basis, we see that they are in agreement with each other. When we look at the expert opinions and survey results in the automotive industry, they stated that the waste management strategies and policies of the business are the most important success factor. In this case, we can say that the most important critical success factor for the automotive industry is the company’s strategies and policies.

Likewise, for the food sector, both the AHP results based on expert opinion and the survey results filled out by employees showed parallelism, and as a result of both analyses, the waste management strategies and policies of the enterprise were the most important critical success factor.

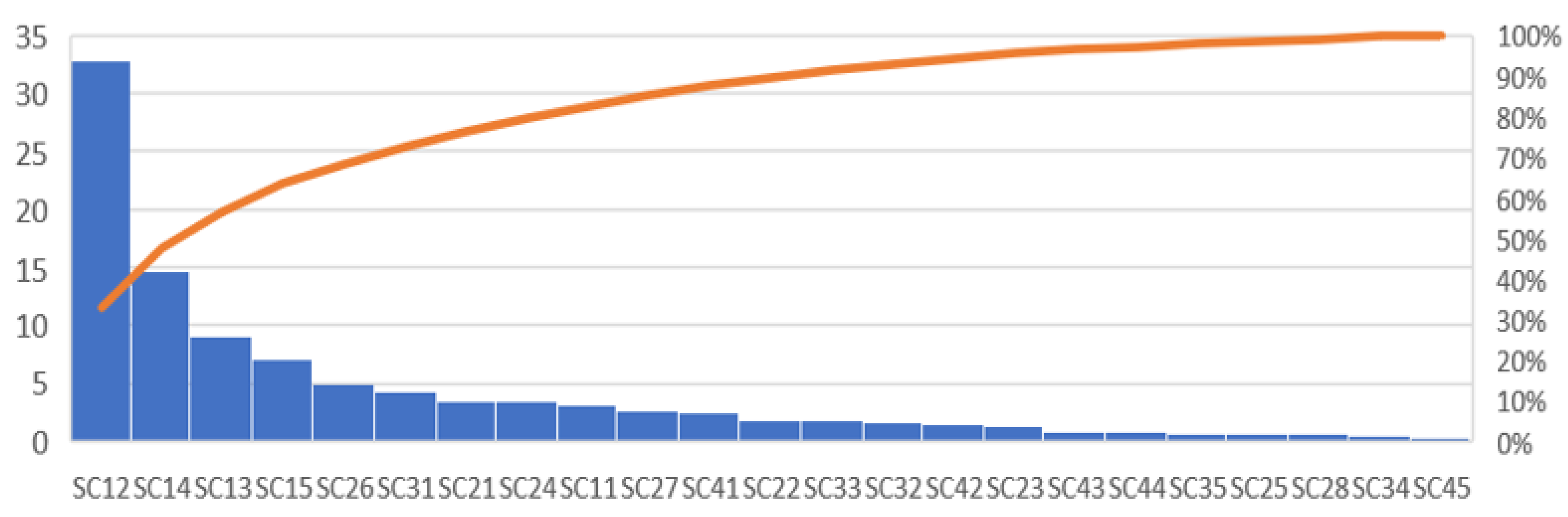

When we look at the iron and steel sector, expert opinion has stated that national/local strategies and policies are the most important success factor, and as a result of the survey, it has been seen that national/local waste management strategies and policies and waste management strategies and policies of the enterprise are of equal importance. The fact that the second success factor in the iron and steel sector, in expert opinion, is the waste management strategies and policies of the enterprise, shows us that the expert opinion in the sector and the opinions of employees in the sector are parallel.

Observation of differences in sectoral success factors may depend on whether the legal regulations of the relevant sector are defined or whether the defined legislations can meet the demand and need, the dynamics within the sector itself, production processes, waste types and sources.

According to Menzie and Freshman (1997), scientists, policy makers, and the public should be educated about the ecological risk assessment process and how important it is to make decisions. Likewise, with this tool and philosophy, managers in the industry should give priority to the enterprise’s “waste management strategies and policies.” from material use to warehouse management, compliance with the green design principle in product design, fewer design changes to products, allocation of an adequate budget for waste management, and rewarding those who propose environmental management.

5.2. Future Study Suggestions

The study was conducted to determine the critical success factors in the management of industrial waste. However, there are not only industrial wastes but also medical wastes, hazardous wastes, urban wastes, institutional wastes, agricultural wastes, and special wastes. Such work for waste in these areas will benefit both in terms of approaching waste management as a whole and in creating data when preparing national waste management plans. In this study, expert opinions only in the automotive, steel and food industries have been taken. The study can be done with expert opinions in other industries as well.

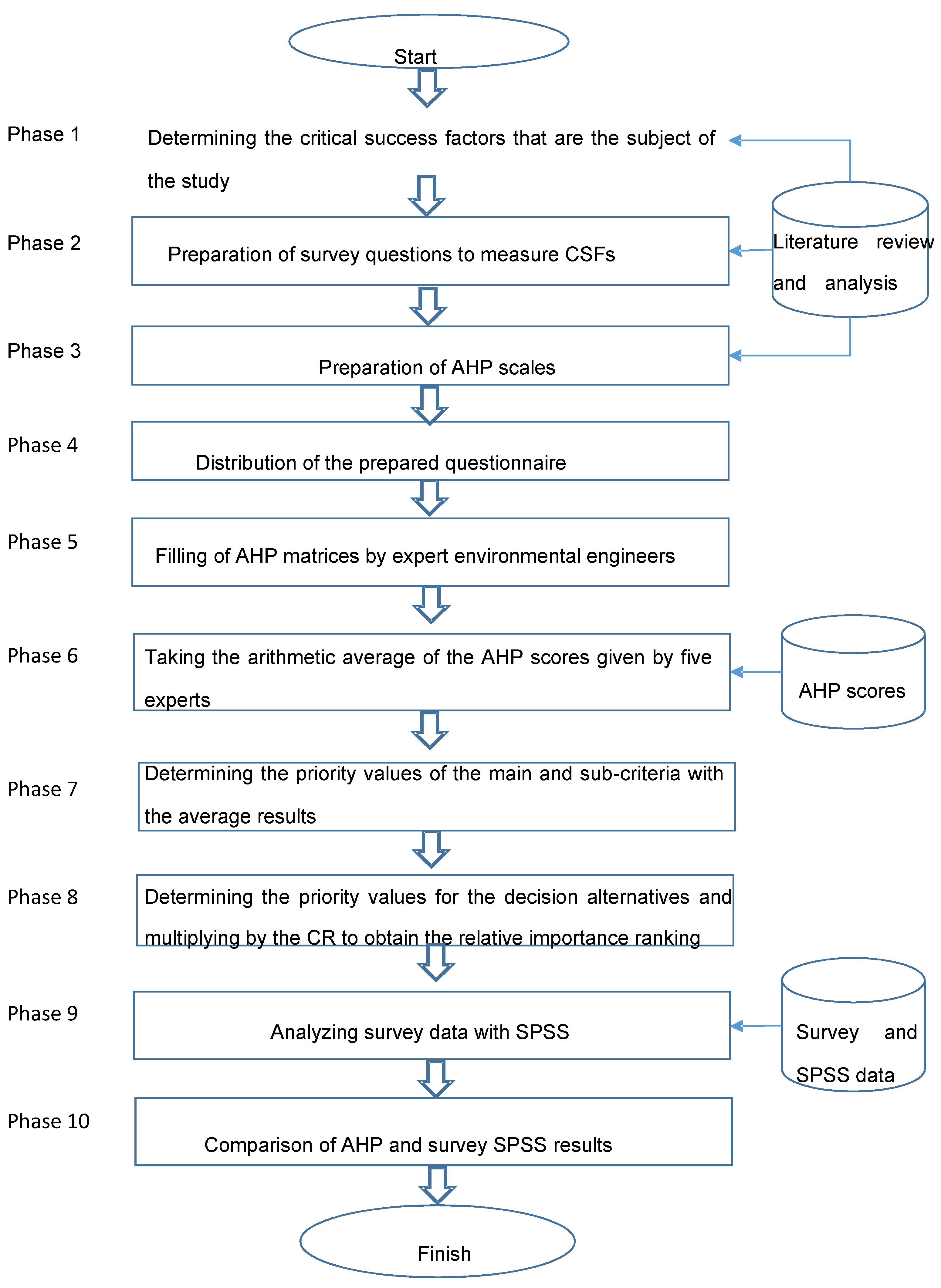

Figure 1.

Methodology phases.

Figure 1.

Methodology phases.

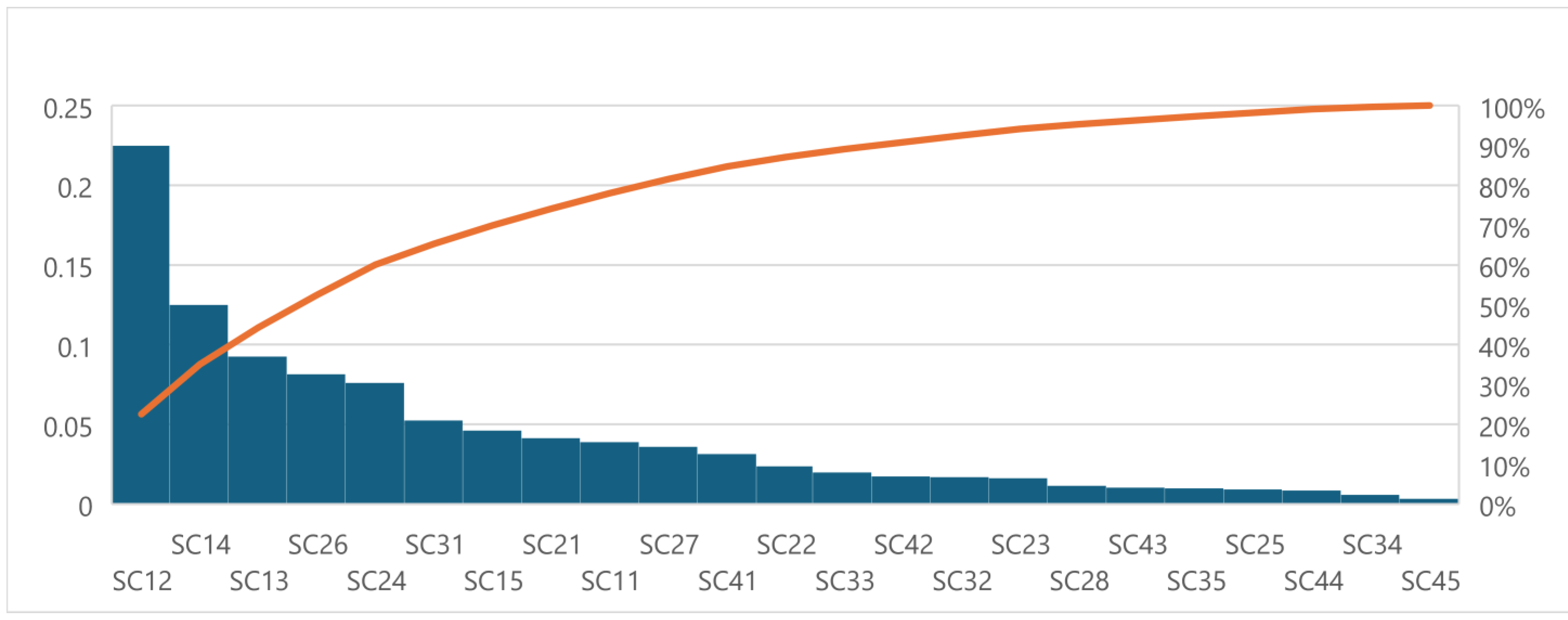

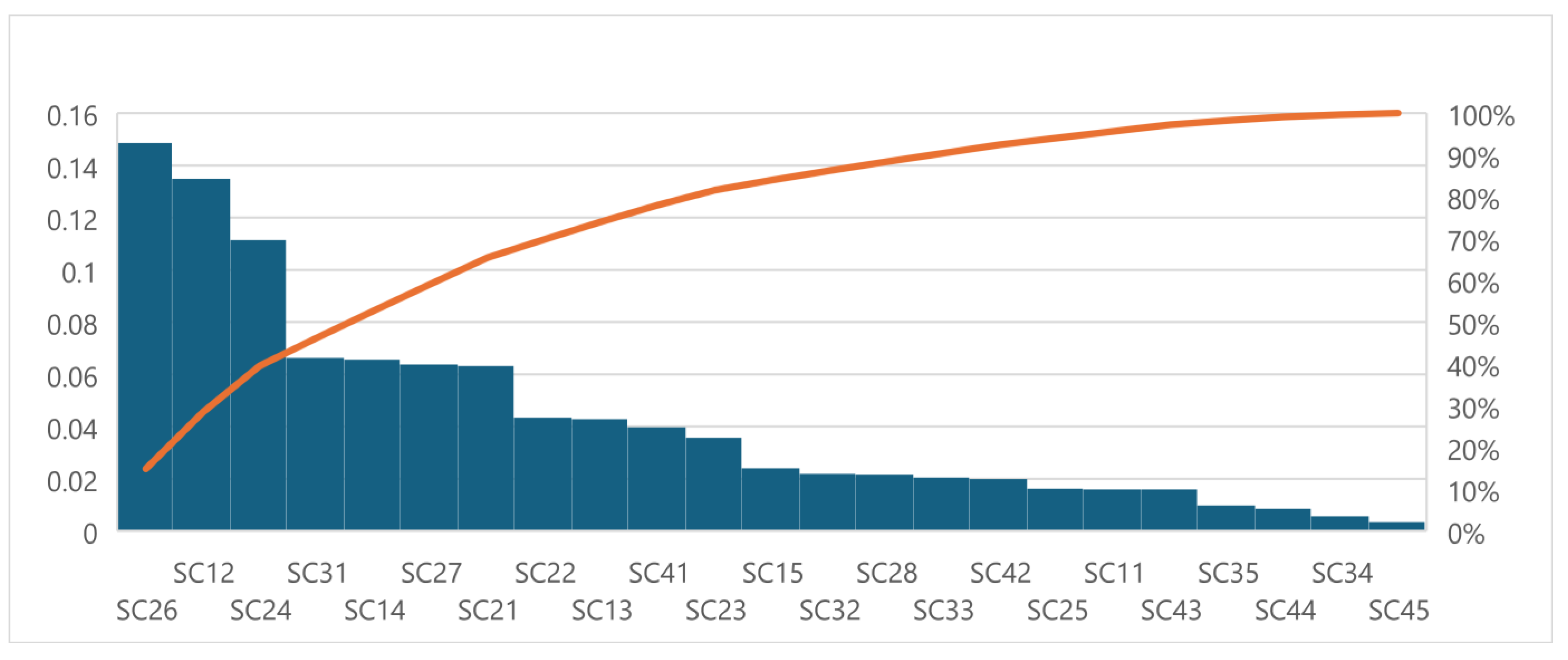

Figure 2.

Pareto chart for general priority list of the 23 sub-criteria.

Figure 2.

Pareto chart for general priority list of the 23 sub-criteria.

Figure 3.

Pareto chart for automotive industry ranking of 23 sub-criteria.

Figure 3.

Pareto chart for automotive industry ranking of 23 sub-criteria.

Figure 4.

Pareto chart iron and steel industry ranking of 23 sub-criteria.

Figure 4.

Pareto chart iron and steel industry ranking of 23 sub-criteria.

Figure 5.

Pareto chart for food industry ranking of 23 sub-criteria.

Figure 5.

Pareto chart for food industry ranking of 23 sub-criteria.

Figure 6.

Radar chart for 23 sub-criteria according to the industry.

Figure 6.

Radar chart for 23 sub-criteria according to the industry.

Table 1.

Türkiye’s National Recycling Strategy Document-Action Plan Priority Problem Areas [

9].

Table 1.

Türkiye’s National Recycling Strategy Document-Action Plan Priority Problem Areas [

9].

Table 2.

The hierarchical model for the problem.

Table 2.

The hierarchical model for the problem.

| Level 1 : CSF Selection in Industrial Waste Management |

|---|

| Level 2 |

LEGAL REGULATIONS |

BUSINESS POLICIES |

RECYCLING |

EDUCATION & AWARENESS |

Level 3 |

-To be able to meet the legislative demands and needs. (SC11)**

-Effective implementation of legislation. (SC12)

-The presence of adequately equipped personnel in the implementation of the legislation. (SC13)

-Effective implementation of sanctions and sanctions for waste management. (SC14)

-Adequate standards for the secondary product recycled. (SC15) |

-Material handling and storage systems have a zero waste principle. (SC21)

-Reduce the amount of packaging used in products. (SC22)

-Attaching importance to electronic Communication . (SC23)

-To have green design principle in product design. And less design changes to be made. (SC24)

-Energy saving. (SC25)

-Adequate budget and resource allocation for waste management. (SC26)

-Having an on-site waste control system. (SC27)

-Rewarding the suggestions of employees in environmental management. (SC28) |

-Use of environmentally friendly materials in the production of less hazardous properties. (SC31)

-Reduce the use of raw materials. (SC32)

-Ensuring the reuse of waste as raw materials. (SC33)

-Recycling of waste. (SC34)

-Ensuring the use of classified trash cans. (SC35) |

-Providing training to create awareness of prevention and reduction of waste. (SC41)

-Providing training for waste recovery awareness. (SC42)

-Organization of reuse project competitions. (SC43)

-Supporting the behavior of managers to ensure the participation of employees in environmental management. (SC44)

-To include environmental substances in job descriptions. (SC45) |

| Level 4 |

1. National /Local Waste Management Strategy and Policies |

2. Business waste management strategy and policies |

3. Recycling management |

4. Ensuring Awareness |

* Level 1 – Decision problem, Level 2 – Main criteria, Level 3- Sub Criteria Level, 4- Decision Alternatives

**Symbol explanation: SCmn m:main-criterion number, n:sub-criterion number) |

Table 3.

Comparison of Main Criteria Matrix and Importance Levels.

Table 3.

Comparison of Main Criteria Matrix and Importance Levels.

| Critical Success Factor |

Legal

Regulations |

Business

Policies |

Recycling |

Education & Awareness |

Importance

Level |

| Legal Regulations |

1.00 |

3.00 |

5.00 |

5.00 |

0.5280 |

| Business Policies |

0.33 |

1.00 |

4.00 |

5.00 |

0.2956 |

| Recycling |

0.20 |

0.25 |

1.00 |

2.00 |

0.1052 |

| Education & Awareness |

0.20 |

0.20 |

0.50 |

1.00 |

0.0712 |

Table 4.

Comparison matrix for the sub-criteria of the Legal Regulations main criterion.

Table 4.

Comparison matrix for the sub-criteria of the Legal Regulations main criterion.

Critical Success Factor |

To be able to meet the demands and needs of the legislation |

Effective implementation of legislation |

Availability of adequately equipped personnel in the implementation of the legislation |

Effective implementation of sanctions and penalties for waste management |

Adequate standards for the recycled secondary product |

Importance Level |

| To be able to meet the demands and needs of the legislation |

1.00 |

0.25 |

0.20 |

0.50 |

0.50 |

0.0737 |

| Effective implementation of legislation |

4.00 |

1.00 |

4.00 |

2.00 |

5.00 |

0.4261 |

| Availability of adequately equipped personnel in the implementation of the legislation |

5.00 |

0.25 |

1.00 |

0.50 |

2.00 |

0.1757 |

| Effective implementation of sanctions and penalties for waste management |

2.00 |

0.50 |

2.00 |

1.00 |

4.00 |

0.2370 |

| Adequate standards for the recycled secondary product |

2.00 |

0.20 |

0.50 |

0.25 |

1.00 |

0.0875 |

Table 5.

Comparison matrix for the sub-criteria of the main criteria of Business Policies.

Table 5.

Comparison matrix for the sub-criteria of the main criteria of Business Policies.

Critical Success Factor |

Material handling and storage systems have zero waste principle. |

Reduce the amount of packaging used in products.

|

Attaching importance to electronic Communication.

|

To have green design principle in product design. And less design changes to be made.

|

Energy saving.

|

Adequate budget and resource allocation for waste management.

|

Having an on-site waste control system.

|

Rewarding the suggestions of employees in environmental management |

Importance Level |

| Material handling and storage systems have zero waste principle. |

1.00 |

3.00 |

4.00 |

0.50 |

4.00 |

0.25 |

0.50 |

7.00 |

0.1402 |

| Reduce the amount of packaging used in products. |

0.33 |

1.00 |

3.00 |

0.20 |

4.00 |

0.20 |

0.50 |

3.00 |

0.0802 |

| Attaching importance to electronic Communication. |

0.25 |

0.33 |

1.00 |

0.20 |

4.00 |

0.17 |

0.33 |

2.00 |

0.0552 |

| To have green design principle in product design And less design changes. |

2.00 |

5.00 |

5.00 |

1.00 |

5.00 |

1.00 |

4.00 |

5.00 |

0.2576 |

| Energy saving. |

0.25 |

0.25 |

0.25 |

0.20 |

1.00 |

0.20 |

0.25 |

0.50 |

0.0307 |

| Adequate budget and resource allocation for waste management. |

4.00 |

5.00 |

6.00 |

1.00 |

5.00 |

1.00 |

3.00 |

5.00 |

0.2755 |

| Having an on-site waste control system. |

2.00 |

2.00 |

3.00 |

0.25 |

4.00 |

0.33 |

1.00 |

3.00 |

0.1216 |

| Rewarding the suggestions of employees in environmental management |

0.14 |

0.33 |

0.50 |

0.20 |

2.00 |

0.20 |

0.33 |

1.00 |

0.0390 |

Table 6.

Comparison matrix for the sub-criteria of the Recycling main criterion.

Table 6.

Comparison matrix for the sub-criteria of the Recycling main criterion.

Critical Success Factor |

Use of environmentally friendly materials with less dangerous properties in production |

Reduction of the use of non- processed raw materials |

Ensuring the reuse of wastes as raw materials |

Ensuring the recovery of waste |

Ensuring the use of classified trash cans |

Importance level |

| Use of environmentally friendly materials with less dangerous properties in production |

1.00 |

4.00 |

5.00 |

6.00 |

4.00 |

0.5006 |

| Reduction of the use of non- processed raw materials |

0.25 |

1.00 |

0.50 |

3.00 |

3.00 |

0.1613 |

| Ensuring the reuse of wastes as raw materials |

0.20 |

2.00 |

1.00 |

4.00 |

2.00 |

0.1893 |

| Ensuring the recovery of waste |

0.17 |

0.33 |

0.25 |

1.00 |

0.50 |

0.0555 |

| Ensuring the use of classified trash cans |

0.25 |

0.33 |

0.50 |

2.00 |

1.00 |

0.0933 |

Table 7.

Comparison matrix for the sub-criteria of the main criteria of Education and Awareness.

Table 7.

Comparison matrix for the sub-criteria of the main criteria of Education and Awareness.

Critical Success Factor

|

Providing trainings to create awareness of prevention and reduction of waste |

Providing trainings for waste recovery awareness. |

Organization of reuse project competitions. |

Supporting the behavior of managers in order to ensure employee participation in environmental management. |

To include environmental substances in job descriptions. |

Importance Level |

| Providing trainings to create awareness of prevention and reduction of waste. |

1.00 |

3.00 |

3.00 |

4.00 |

6.00 |

0.4414 |

| Providing trainings for waste recovery awareness. |

0.33 |

1.00 |

3.00 |

2.00 |

5.00 |

0.2442 |

| Organization of reuse project competitions. |

0.33 |

0.33 |

1.00 |

2.00 |

3.00 |

0.1456 |

| Supporting the behavior of managers in order to ensure employee participation in environmental management. |

0.25 |

0.50 |

0.50 |

1.00 |

4.00 |

0.1204 |

| To include environmental substances in job descriptions. |

0.17 |

0.20 |

0.33 |

0.25 |

1.00 |

0.0484 |

Table 8.

Importance Values (Importance level) of Sub-Criteria according to 5 Experts.

Table 8.

Importance Values (Importance level) of Sub-Criteria according to 5 Experts.

| Main criteria |

Main criteria

Importance level |

Sub –criteria |

Values |

Importance Levels |

Legal

Regulations |

0.5280 |

Legislation is capable of meeting the demands and needs. |

0.0737 |

0.0389 |

| Effective implementation of legislation. |

0.4261 |

0.2250 |

| The presence of adequately equipped personnel in the implementation of the legislation. |

0.1757 |

0.0927 |

| Effective implementation of sanctions and penalties for waste management. |

0.2370 |

0.1251 |

| Adequate standards for the recycled secondary product. |

0.0875 |

0.0462 |

Business

Policies |

0.2956 |

Material handling and storage systems have zero waste principle. |

0.1402 |

0.0414 |

| Reduce the amount of packaging used in products. |

0.0802 |

0.0237 |

| Attaching importance communication in electronic environment. |

0.0552 |

0.0163 |

| To have a green desing principle in the product design and to make less design changes. |

0.2576 |

0.0761 |

| Energy saving. |

0.0307 |

0.0091 |

| Adequate budget and resource allocation for waste management. |

0.2755 |

0.0815 |

| Having on-site waste control systems. |

0.1216 |

0.0359 |

| Rewarding the suggestions of employees in environmental management. |

0.0390 |

0.0115 |

| Recycling |

0.1052 |

Use of environmentally friendly materials with less dangerous properties in production |

0.5006 |

0.0526 |

| Reduction of the use of non-processed raw materials |

0.1613 |

0.0170 |

| Ensuring the reuse of wastes as raw materials |

0.1893 |

0.0199 |

| Ensuring the recovery of waste |

0.0555 |

0.0058 |

| Ensuring the use of classified trash cans |

0.0933 |

0.0098 |

Education and

Awareness |

0.0712 |

Providing trainings to create awareness of prevention and reduction of waste |

0.4414 |

0.0314 |

| Providing trainings for waste recovery awareness |

0.2442 |

0.0174 |

| Organization of reuse project competitions |

0.1456 |

0.0104 |

| Supporting the behavior of managers to ensure employee participation in environmental management |

0.1204 |

0.0086 |

| To include environmental substances in job descriptions |

0.0484 |

0.0034 |

| |

|

Table 9.

Comparative Table of Critical Success Factors in Industrial Waste Management According to Sub-Criteria.

Table 9.

Comparative Table of Critical Success Factors in Industrial Waste Management According to Sub-Criteria.

| Sub criteria priority value |

Sub criteria |

National / local waste management strategy and policies |

Business waste management strategy and policies |

Recycling management |

Ensuring awareness |

Consistency ratio |

| 0,0389 |

SC11 |

0,3800 |

0,4100 |

0,1420 |

0,0680 |

0,0284 |

| 0,2250 |

SC12 |

0,4790 |

0,3141 |

0,1392 |

0,0676 |

0,0417 |

| 0,0927 |

SC13 |

0,4523 |

0,3477 |

0,1270 |

0,0730 |

0,0399 |

| 0,1251 |

SC14 |

0,4365 |

0,3543 |

0,1292 |

0,0800 |

0,0514 |

| 0,0462 |

SC15 |

0,4020 |

0,3770 |

0,1255 |

0,0954 |

0,0364 |

| 0,0414 |

SC21 |

0,4640 |

0,3301 |

0,1209 |

0,0850 |

0,0454 |

| 0,0237 |

SC22 |

0,4448 |

0,3349 |

0,1386 |

0,0817 |

0,0356 |

| 0,0163 |

SC23 |

0,4523 |

0,3477 |

0,1270 |

0,0730 |

0,0399 |

| 0,0761 |

SC24 |

0,4293 |

0,3693 |

0,1227 |

0,0787 |

0,0696 |

| 0,0091 |

SC25 |

0,4896 |

0,3054 |

0,1264 |

0,0786 |

0,0180 |

| 0,0815 |

SC26 |

0,4667 |

0,3146 |

0,1392 |

0,0795 |

0,0210 |

| 0,0359 |

SC27 |

0,5099 |

0,3239 |

0,1043 |

0,0619 |

0,0788 |

| 0,0115 |

SC28 |

0,4930 |

0,3012 |

0,1296 |

0,0762 |

0,0769 |

| 0,0526 |

SC31 |

0,5185 |

0,2943 |

0,1265 |

0,0606 |

0,0790 |

| 0,0170 |

SC32 |

0,4544 |

0,3767 |

0,1020 |

0,0669 |

0,0635 |

| 0,0199 |

SC33 |

0,3827 |

0,3851 |

0,1469 |

0,0854 |

0,0953 |

| 0,0058 |

SC34 |

0,3954 |

0,3923 |

0,1383 |

0,0741 |

0,0974 |

| 0,0098 |

SC35 |

0,4244 |

0,3812 |

0,1196 |

0,0748 |

0,0730 |

| 0,0314 |

SC41 |

0,4705 |

0,3215 |

0,1286 |

0,0794 |

0,0970 |

| 0,0174 |

SC42 |

0,4691 |

0,3497 |

0,1124 |

0,0689 |

0,0364 |

| 0,0104 |

SC43 |

0,4315 |

0,3662 |

0,1262 |

0,0761 |

0,0569 |

| 0,0086 |

SC44 |

0,4691 |

0,3497 |

0,1124 |

0,0689 |

0,0364 |

| 0,0034 |

SC45 |

0,4457 |

0,3712 |

0,1084 |

0,0748 |

0,0661 |

Table 10.

The Importance Values of the Sub-Criteria as a result of the Five Expert Engineers.

Table 10.

The Importance Values of the Sub-Criteria as a result of the Five Expert Engineers.

| |

Symbol |

Sub –criteria (SC) |

Legal

Regulations |

Business Policies |

Recycling |

Awareness &

Education |

| 0.0389 |

SC11 |

To be able to meet the legislative demands and needs |

0.0148 |

0.0160 |

0.0055 |

0.0026 |

| 0.2250 |

SC12 |

Effective implementation of legislation |

0.1078 |

0.0707 |

0.0313 |

0.0152 |

| 0.0927 |

SC13 |

The availability of adequately equipped personnel in the implementation of the legislation |

0.0419 |

0.0323 |

0.0118 |

0.0068 |

| 0.1251 |

SC14 |

Effective implementation of sanctions and penalties for waste management |

0.0546 |

0.0443 |

0.0162 |

0.0100 |

| 0.0462 |

SC15 |

Adequate standards for the recycled secondary product |

0.0186 |

0.0174 |

0.0058 |

0.0044 |

| 0.0414 |

SC21 |

Material handling and storage systems have a zero waste principle. |

0.0192 |

0.0137 |

0.0050 |

0.0035 |

| 0.0237 |

SC22 |

Reduce the amount of packaging used in products. |

0.0106 |

0.0079 |

0.0033 |

0.0019 |

| 0.0163 |

SC23 |

Attaching importance to electronic Communication. |

0.0074 |

0.0057 |

0.0021 |

0.0012 |

| 0.0761 |

SC24 |

To have green design principles in product design and fewer design changes. |

0.0327 |

0.0281 |

0.0093 |

0.0060 |

| 0.0091 |

SC25 |

Energy saving. |

0.0044 |

0.0028 |

0.0011 |

0.0007 |

| 0.0815 |

SC26 |

Adequate budget and resource allocation for waste management. |

0.0380 |

0.0256 |

0.0113 |

0.0065 |

| 0.0359 |

SC27 |

Having an on-site waste control system. |

0.0183 |

0.0116 |

0.0037 |

0.0022 |

| 0.0115 |

SC28 |

Rewarding the suggestions of employees in environmental management |

0.0057 |

0.0035 |

0.0015 |

0.0009 |

| 0.0526 |

SC31 |

Use of environmentally friendly materials with less dangerous properties in production |

0.0273 |

0.0155 |

0.0067 |

0.0032 |

| 0.0170 |

SC32 |

Reduction of the use of non- processed raw materials |

0.0077 |

0.0064 |

0.0017 |

0.0011 |

| 0.0199 |

SC33 |

Ensuring the reuse of waste as raw materials |

0.0076 |

0.0077 |

0.0029 |

0.0017 |

| 0.0058 |

SC34 |

Ensuring the recovery of waste |

0.0023 |

0.0023 |

0.0008 |

0.0004 |

| 0.0098 |

SC35 |

Ensuring the use of classified trash cans |

0.0042 |

0.0037 |

0.0012 |

0.0007 |

| 0.0314 |

SC41 |

Providing training to create awareness of prevention and reduction of waste. |

0.0148 |

0.0101 |

0.0040 |

0.0025 |

| 0.0174 |

SC42 |

Providing training for waste recovery awareness. |

0.0082 |

0.0061 |

0.0020 |

0.0012 |

| 0.0104 |

SC43 |

Organization of reuse project competitions. |

0.0045 |

0.0038 |

0.0013 |

0.0008 |

| 0.0086 |

SC44 |

Supporting the behavior of managers in order to ensure employee participation in environmental management. |

0.0040 |

0.0030 |

0.0010 |

0.0006 |

| 0.0034 |

SC45 |

To include environmental substances in job descriptions. |

0.0015 |

0.0013 |

0.0004 |

0.0003 |

| |

Total |

|

0.4561 |

0.3394 |

0.1300 |

0.0745 |

Table 11.

Ranking of Critical Success Factors in Industrial Waste Management.

Table 11.

Ranking of Critical Success Factors in Industrial Waste Management.

| Priority Ranking |

Main Criteria |

Importance Level |

| 1 |

National \ Local waste management strategies and policies |

0.4561 |

| 2 |

Waste management strategies and policies |

0.3394 |

| 3 |

Recycling management |

0.1300 |

| 4 |

Awareness raising and education |

0.0745 |

| Total |

1.0000 |

Table 12.

CSFs Ranking by Industry.

Table 12.

CSFs Ranking by Industry.

| |

Importance Level |

| CSF Industry |

Automotive |

Iron and Steel |

Food |

General |

| Legal Regulations |

0.1084 |

0.6355 |

0.2989 |

0.4561 |

| Business Policies |

0.3904 |

0.2023 |

0.4822 |

0.3394 |

| Recycling |

0.3244 |

0.1033 |

0.1389 |

0.1300 |

| Awareness & education |

0.1769 |

0.0589 |

0.0800 |

0.0745 |

| Total |

1.0000 |

1.0000 |

1.0000 |

1.0000 |

Table 13.

Descriptive Statistics of Survey Respondents .

Table 13.

Descriptive Statistics of Survey Respondents .

| Variables |

Groups |

n |

% |

| Gender |

Female |

49 |

48.5 |

| |

Male |

52 |

51.5 |

| Age Group |

20-39 |

80 |

79.2 |

| |

40-54 |

21 |

20.8 |

| Education level |

Associate Degree |

3 |

2.9 |

| |

BA. BS. |

53 |

52.5 |

| |

MS. MBA |

45 |

44.6 |

| Industry |

Automotive |

27 |

26.7 |

| |

Iron and Steel |

17 |

16.8 |

| |

Food |

15 |

14.9 |

| |

Energy |

10 |

9.9 |

| |

Chemical, Petroleum, Rubber and Plastic |

9 |

8.9 |

| |

Woodworking, Paper and Paper Products |

8 |

7.9 |

| |

Glass, Cement and Soil |

3 |

3.0 |

| |

Other |

12 |

11.9 |

| Position |

Business Owner / Partner |

1 |

0,9 |

| |

Senior Manager |

6 |

5,9 |

| |

Mid-Level Manager |

32 |

31,6 |

| |

White Collar Employee |

62 |

61,3 |

| Waste Management Training Status |

I have never received |

18 |

17.8 |

| |

I received once |

58 |

57.5 |

| |

I receive training once a year. |

22 |

21.8 |

| |

I receive training more than twice every year |

3 |

2.9 |

| Waste Management applied in their company |

Yes |

98 |

97.1 |

| |

No |

3 |

2.9 |

| Satisfaction with waste management service |

Yes |

70 |

69.3 |

| |

No |

31 |

30.7 |

| The most important problem in waste man. |

Lack of my knowledge |

19 |

18,8 |

| |

The intensity of my work |

10 |

9,9 |

| |

I don’t find the subject important. |

1 |

0,9 |

| |

Sufficient budget and resources are not allocated. |

33 |

32,7 |

| |

The absence of any control system |

38 |

37,6 |

| Satisfaction with the waste collection method |

Yes |

71 |

70.3 |

| |

No |

19 |

18.8 |

| |

I don’t know\I have no idea |

11 |

10.9 |

| Throwing waste in segregated bins |

Lack of knowledge |

2 |

2.0 |

| |

The intensity of my work |

1 |

1.0 |

| |

I don’t find the subject important. |

0 |

0 |

| |

Insufficient number of segregated buckets |

22 |

21.8 |

| |

Only in limited areas in their segregated buckets |

33 |

32.7 |

| |

The absence of any control system in this regard |

22 |

21.8 |

| |

I don’t have any problems, I parse it every time |

21 |

20.8 |

Table 14.

Importance Level Distribution of the Main Criteria According to Survey Findings.

Table 14.

Importance Level Distribution of the Main Criteria According to Survey Findings.

| Main criteria |

|

Importance Score |

Mean |

Priority |

| n |

1 |

2 |

3 |

4 |

5 |

|

|

| Legal Regulations |

101 |

1 |

6 |

27 |

35 |

32 |

26.27 |

2 |

| Business Policies |

101 |

0 |

2 |

16 |

48 |

35 |

27.93 |

1 |

| Recycling |

101 |

8 |

27 |

28 |

23 |

15 |

20.87 |

4 |

| Education and Awareness |

101 |

0 |

10 |

25 |

32 |

34 |

26.20 |

3 |

Table 15.

Importance Level Distribution of the Main Criteria According to Survey Findings.

Table 15.

Importance Level Distribution of the Main Criteria According to Survey Findings.

| Main criteria |

Sub –criteria |

Importance Score*

1 2 3 4 5 |

Mean |

Priority |

| Legal Regulations |

To be able to meet the legislative demands and needs |

0 |

9 |

31 |

35 |

26 |

25.40 |

10 |

| Effective implementation of legislation |

1 |

11 |

24 |

35 |

30 |

25.67 |

8 |

| The availability of adequately equipped personnel in the implementation of the legislation |

1 |

24 |

28 |

33 |

15 |

22.67 |

13 |

| Effective implementation of sanctions and penalties for waste management (WM) |

2 |

10 |

26 |

29 |

34 |

25.73 |

5 |

| Adequate standards for the recycled secondary product |

9 |

30 |

40 |

20 |

2 |

18.60 |

21 |

Business Policies

|

Material handling and storage systems have a zero waste principle. |

2 |

15 |

43 |

29 |

12 |

22.47 |

14 |

| Reduce the amount of packaging used in products. |

1 |

15 |

39 |

34 |

12 |

22.93 |

12 |

Attaching importance to electronic communication.

|

2 |

23 |

34 |

34 |

8 |

21.73 |

16 |

| Having green design principle in product design & less design changes. |

9 |

26 |

30 |

28 |

8 |

20.20 |

19 |

Energy saving.

|

0 |

5 |

36 |

33 |

27 |

25.67 |

6 |

Adequate budget and resource allocation for waste management.

|

0 |

2 |

32 |

36 |

31 |

26.60 |

2 |

Having an on-site waste control system.

|

0 |

5 |

23 |

46 |

27 |

26.53 |

3 |

Rewarding the suggestions of employees in environmental man.

|

13 |

33 |

26 |

23 |

6 |

18.60 |

22 |

| Recycling |

Use of environmentally friendly materials with less dangerous properties in production |

4 |

25 |

39 |

23 |

10 |

20.87 |

18 |

| Reduction of the use of non- processed raw materials |

9 |

25 |

37 |

21 |

9 |

19.93 |

20 |

| Ensuring the reuse of waste as raw materials |

1 |

29 |

29 |

25 |

17 |

22.07 |

15 |

| Ensuring the recovery of waste |

3 |

8 |

46 |

28 |

16 |

23.27 |

11 |

| Ensuring the use of classified trash cans |

0 |

6 |

28 |

46 |

21 |

25.67 |

7 |

| Education and Awareness |

Providing training to create awareness of prevention and reduction of waste. |

1 |

2 |

40 |

27 |

31 |

25.87 |

4 |

| Providing training for waste recovery awareness. |

0 |

3 |

28 |

37 |

33 |

26.87 |

1 |

| Organization of reuse project competitions. |

22 |

38 |

19 |

18 |

4 |

16.47 |

23 |

| Supporting the behavior of managers in order to ensure employee participation in environmental management. |

1 |

7 |

30 |

38 |

25 |

25.47 |

9 |

| To include environmental substances in job descriptions. |

14 |

10 |

32 |

32 |

13 |

21.53 |

17 |

| *1: very unimportant, 5: very important |

|

Table 16.

Comparison of Research Findings and the Literature.

Table 16.

Comparison of Research Findings and the Literature.

| |

Literature |

| CSF |

Baaki [17] |

Omran and Eltayed [28] |

Jibril J. et al. [14] |

Renwick et al. [13] |

Evli [29] |

Lu ve Yuan [12] |

Büyüközkan and Vardaloğlu [11] |

Özbay [10] |

Literature Comparison |

| Legal Regulations |

X |

|

|

|

X |

X |

|

|

Agree |

| Business Policies |

X |

X |

|

|

|

X |

X |

|

Agree |

| Recycling |

|

|

|

|

|

|

X |

X |

Disagree |

| Education and Awareness |

|

|

X |

X |

|

|

|

|

Disagree |