Submitted:

09 July 2024

Posted:

10 July 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

- (a)

- Selective Space Mesh Utilization: The introduction of a selective space mesh for generating neighbors focuses on key configurations of the problem, effectively reducing the search space. This strategy optimizes exploration by restricting it to specific neighborhoods with high potential for improvement.

- (b)

- Improved Initial Temperature Equation: Improving the initial temperature equation involves considering the average losses of “n” initial solutions, which effectively tailors the algorithm to the network size. This approach allows fine-tuning of the temperature initialization process by leveraging collective insights gained from multiple initial solutions.

- (c)

- Incorporation of Hybrid Cooling and Stopping Criteria: Incorporating stopping criteria and hybrid cooling methods improves solution acceptance and reduces iteration requirements. This dynamic combination of cooling strategies not only optimizes exploration of the search space but also enhances the algorithm’s effectiveness in finding high-quality solutions more efficiently.

- (d)

- Introduction of Cooling Rate Criteria: The proposal suggests advancing to the next temperature after accepting a specific number of neighbors, which enhances algorithm convergence and significantly reduces necessary computation time. This approach enables focusing computational efforts on promising regions within the search space.

- (e)

- Computational Efficiency and Reliable Solution Attainment: The study confirms that the ISA-HC algorithm not only demonstrates computational efficiency but also consistently ensures the attainment of high-quality global solutions.

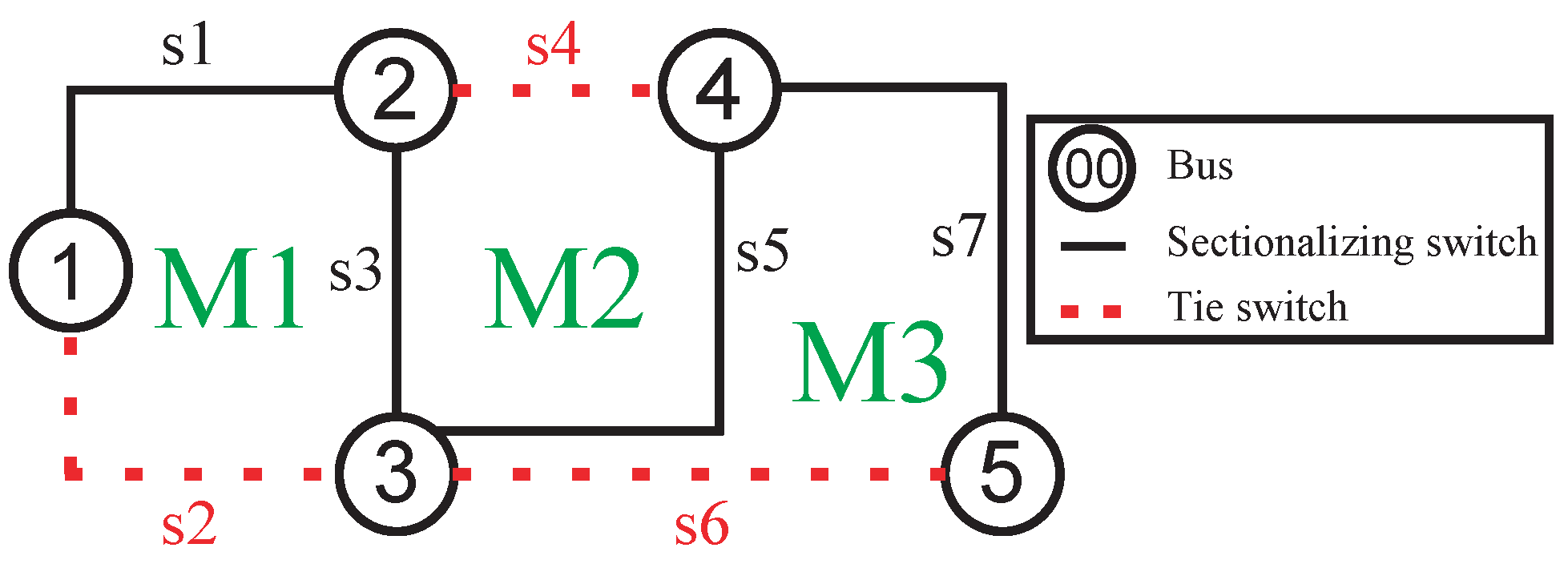

2. Distribution Network Reconfiguration (DNR)

2.1. Constraints

2.1.1. Voltage Constraints

2.1.2. Current Constraints

2.1.3. Radiality Constraints

-

The number of meshes in the system when all switches are closed can be determined using the following formula:Here, is the number of meshes, is the total number of active lines, and is the total number of buses in the system.

-

The total number of lines in the system can be obtained by subtracting the number of sources from the total number of buses:Here, is the number of active lines, is the total number of buses, and is the number of sources.

- The entire system must be connected and energized, meaning that all loads are supplied by a substation or sources.

3. Classical Simulated Annealing Algorithm

3.1. Simulated Annealing Strategy

- Use of a starting solution;

- Random generation of new solutions based on the current solution;

- Progressively elitist criterion to change the random solution for the current one.

3.2. Mathematical Representation and Parameters

- Objective function: This function defines the property that needs to be minimized or maximized depending on the application.

- Initial population: The iterative technique requires an initial guess for the parameter values.

- Initial temperature: The control parameter ’temperature’ is carefully defined, since it controls the rule defined in (6). Initial temperature: The ’temperature’ control parameter is critical as it governs the acceptance rule in Equation (6). The value of T should be high enough to allow escape from local minima but not too high to stray from a global minimum. An example of the initial temperature definition is shown in Equation (7) used in [22]:

- Perturbation mechanism: This method creates new solutions from the current solution.

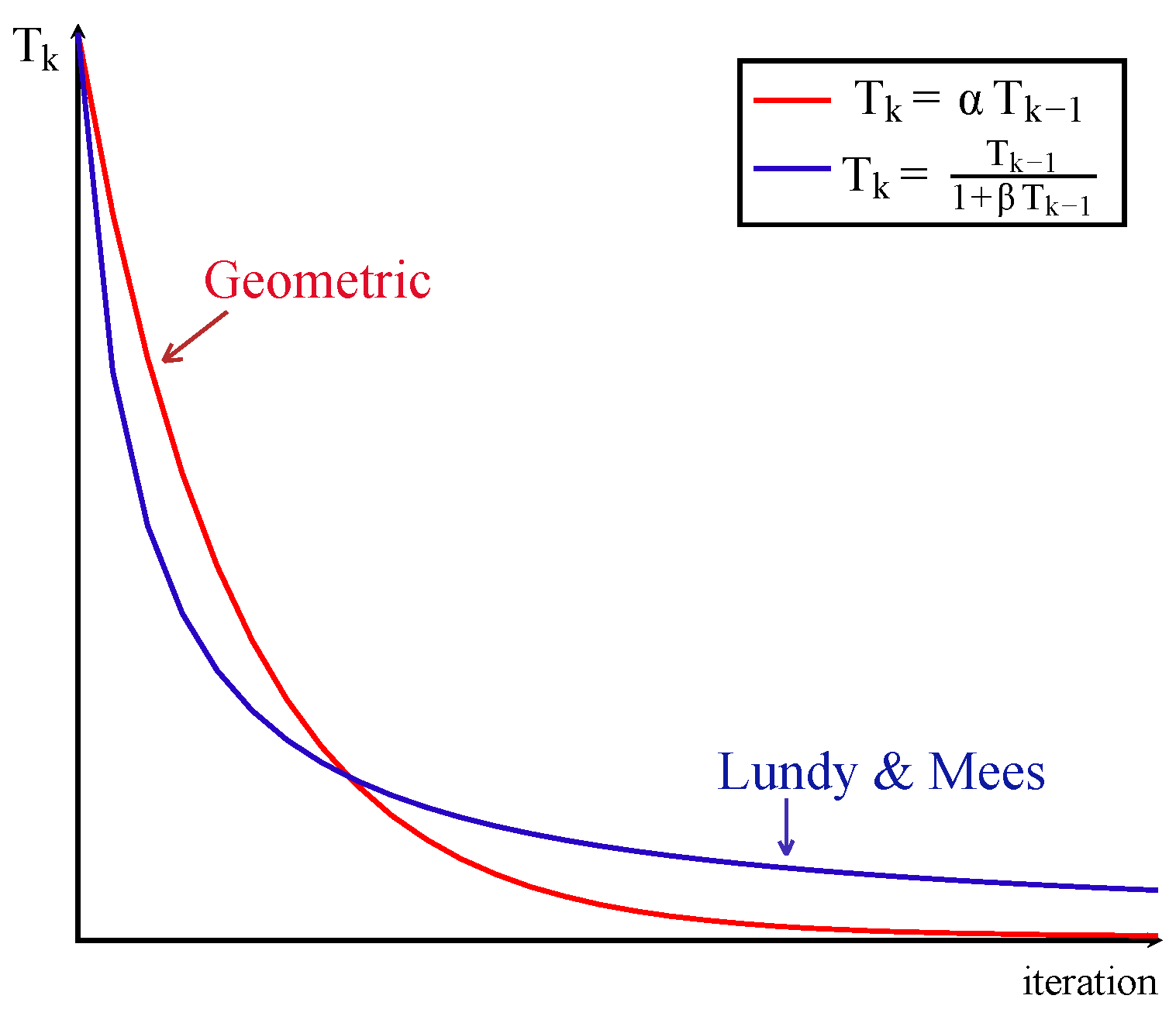

- Cooling: The geometric rule is commonly used to reduce the temperature.

- Termination criteria: Various methods exist to control the completion of Simulated Annealing as mentioned in [36].

4. Proposed Method

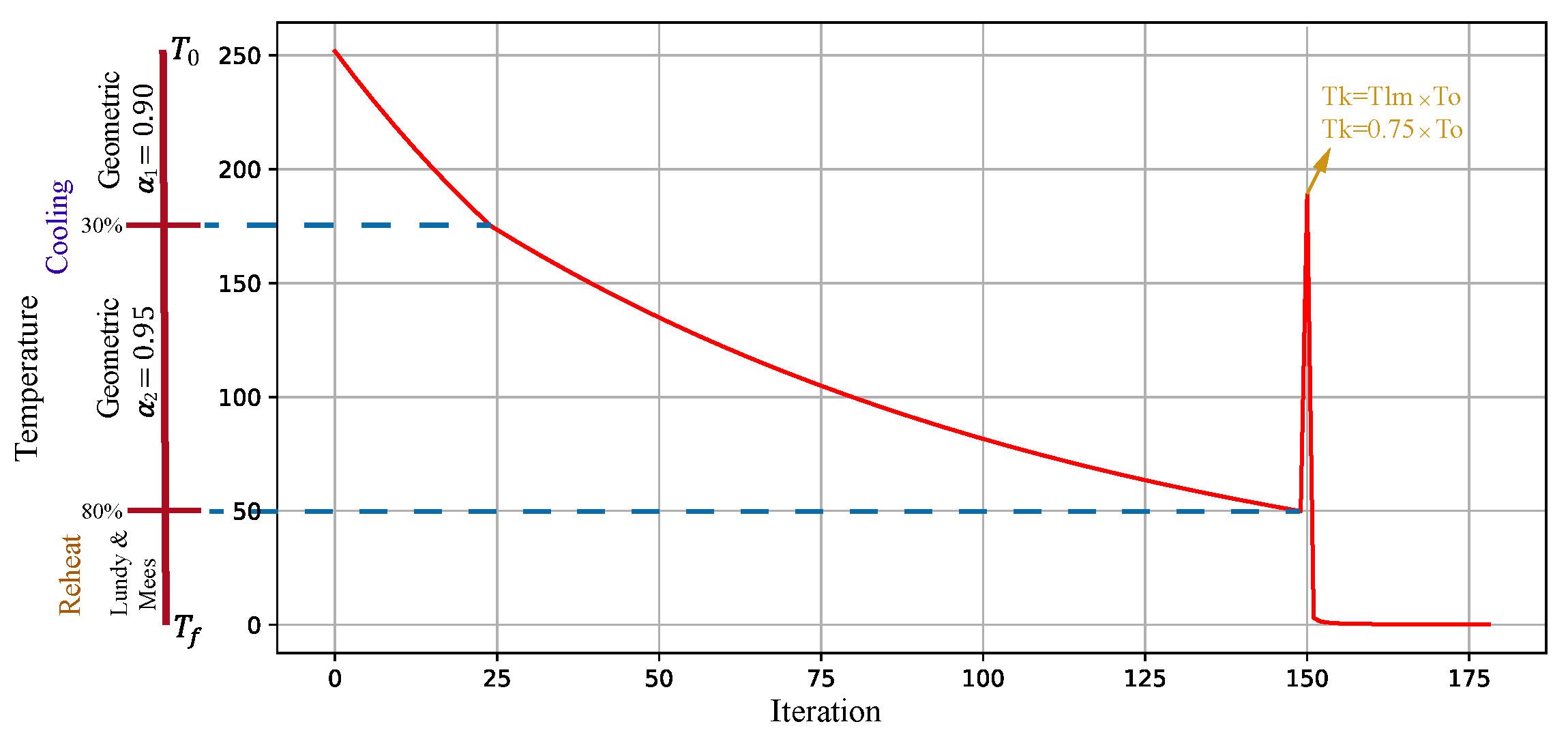

4.1. Initial Solution and Initial Temperature

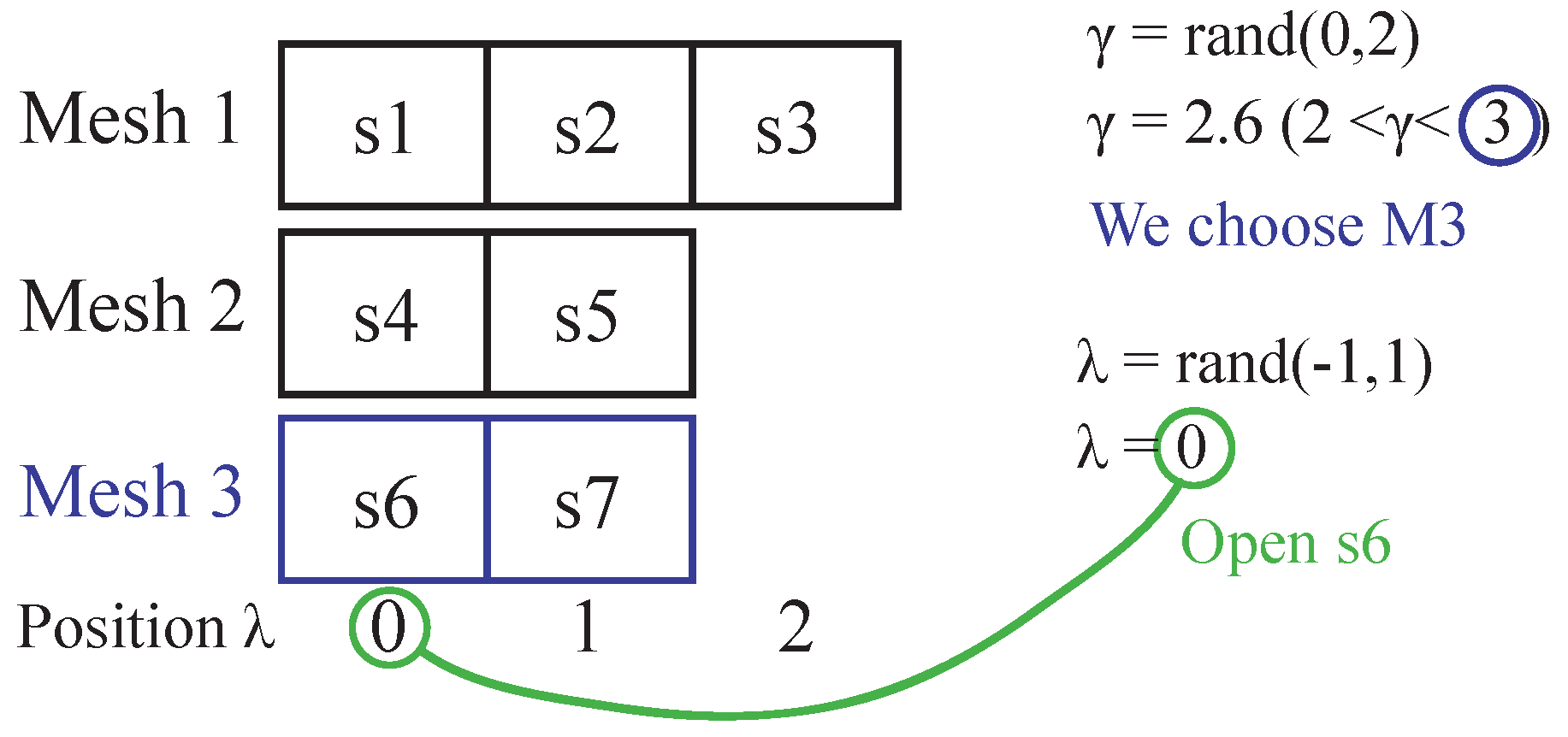

4.2. Selective Space Mesh (SSM)

4.3. Cooling Mechanisms

4.4. Cooling Rate

4.5. Acceptance Criterion

4.6. Stopping Criteria

4.7. Neighbor Generator

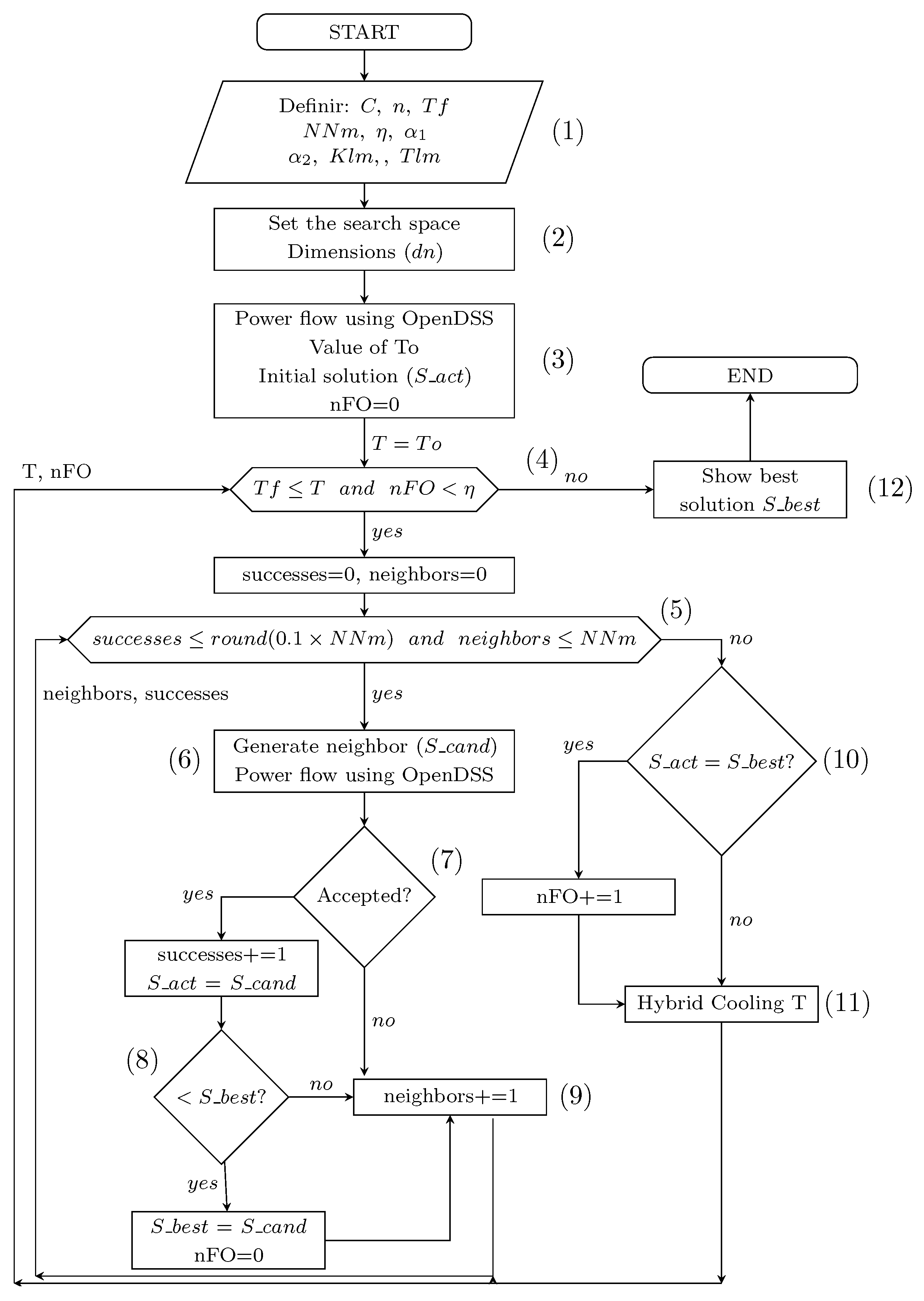

5. Application of the ISA-HC in DNR

- Declare input data, network configuration, constants, and parameters.

- Define search spaces dimensions.

- If the temperature is greater than the Tf and the number of repetitions of the best solution found is less than the maximum number of repetitions, continue with step 5, otherwise go to step 12.

- If the number of successes is less than Equation (16) and the generated neighbors are less than the maximum number allowed, go to step 6, otherwise go to step 10.

- Generate a random nearest neighbor using the method described in the proposed methodology, calculate the fitness function for the generated neighbor by running a load flow analysis using OpenDSS.

- If the candidate solution improves the losses, it is updated as the best solution and the repetition count is restarted.

- The neighbor counter increases by one and return to step 5.

- If the candidate solution matches the best solution, the number of repetitions increases by one. Go to step 11

- Apply hybrid temperature cooling using Equation (11) and proceed to step 4.

- Displays the results.

6. Simulation and Results

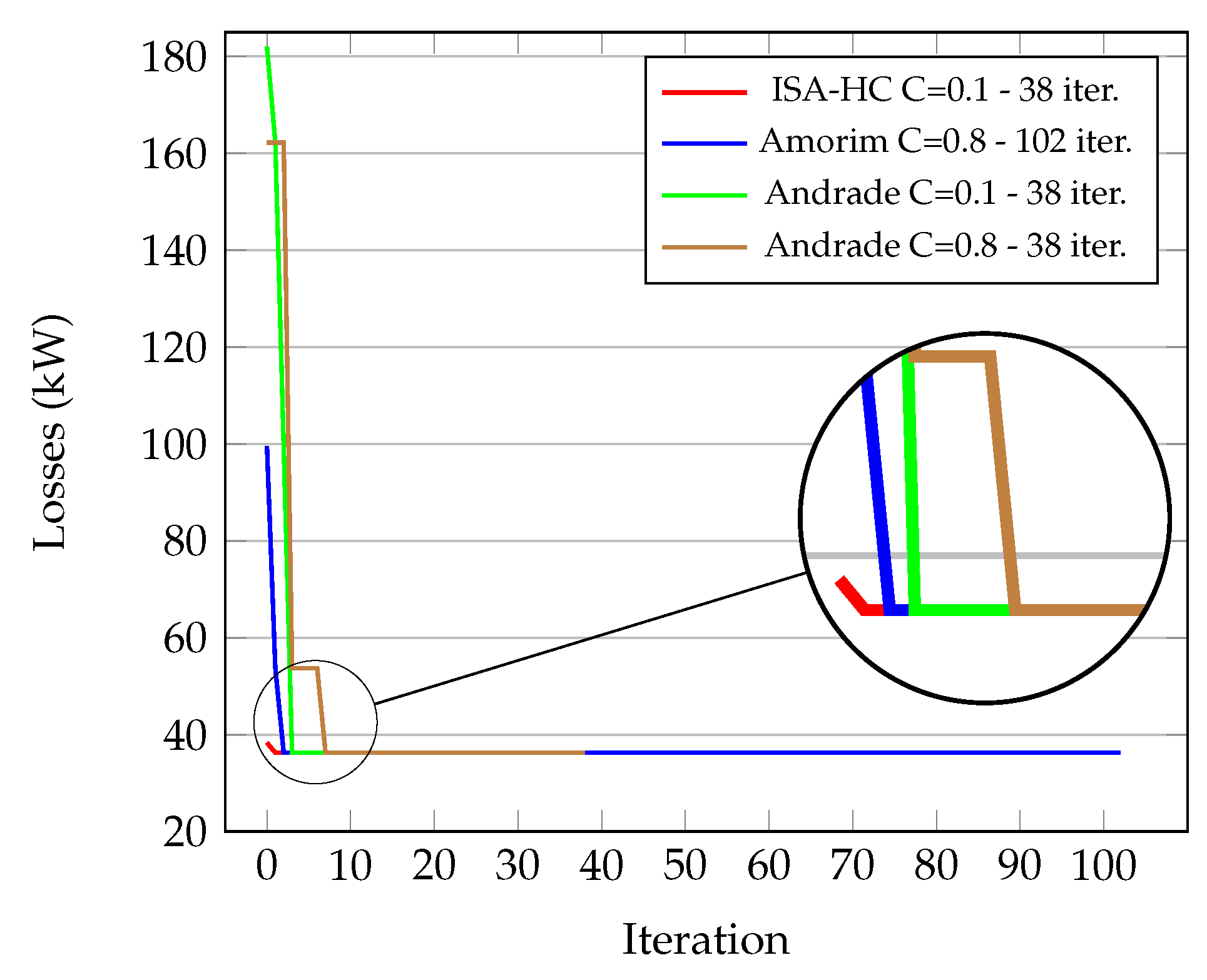

6.1. Case Study 1

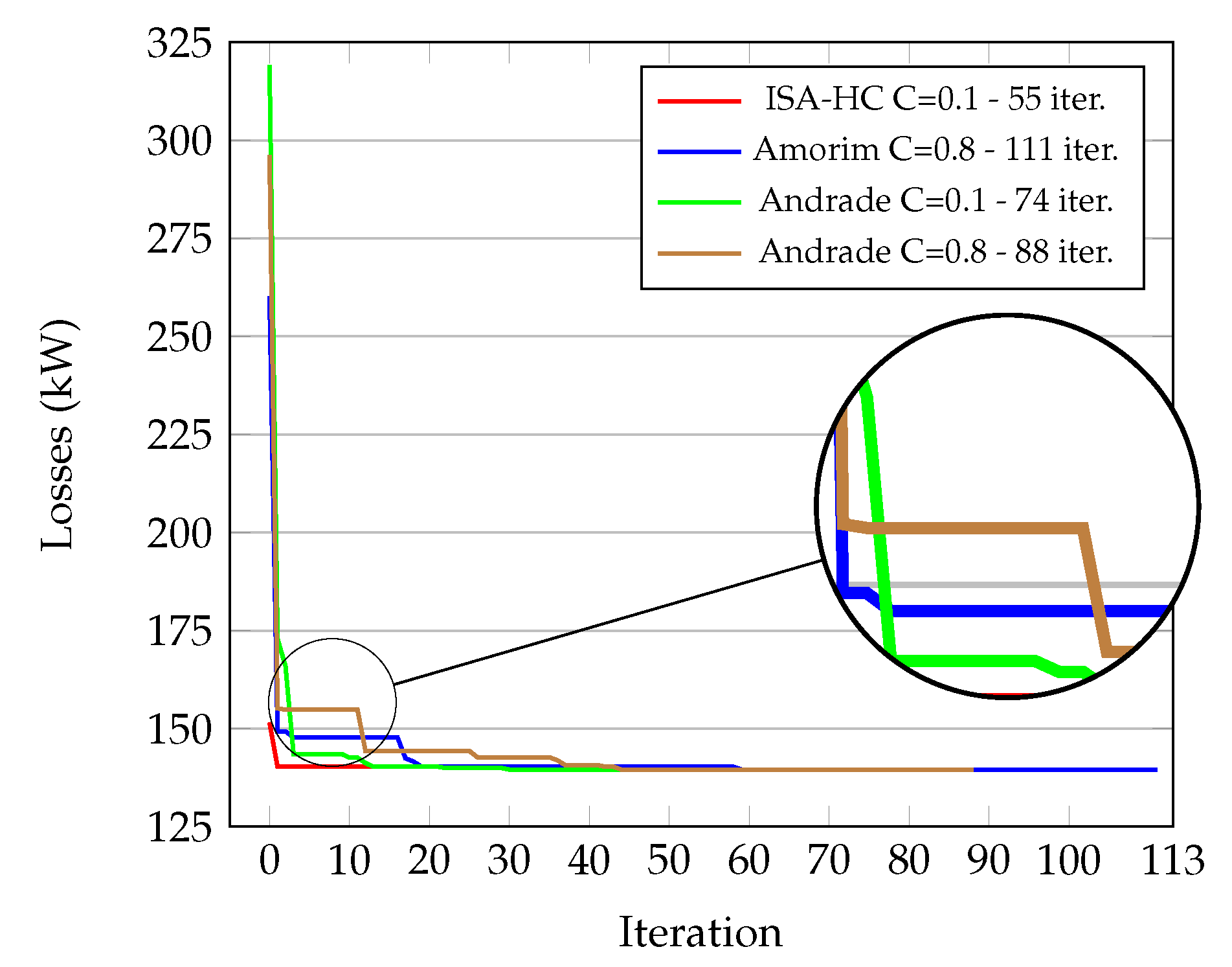

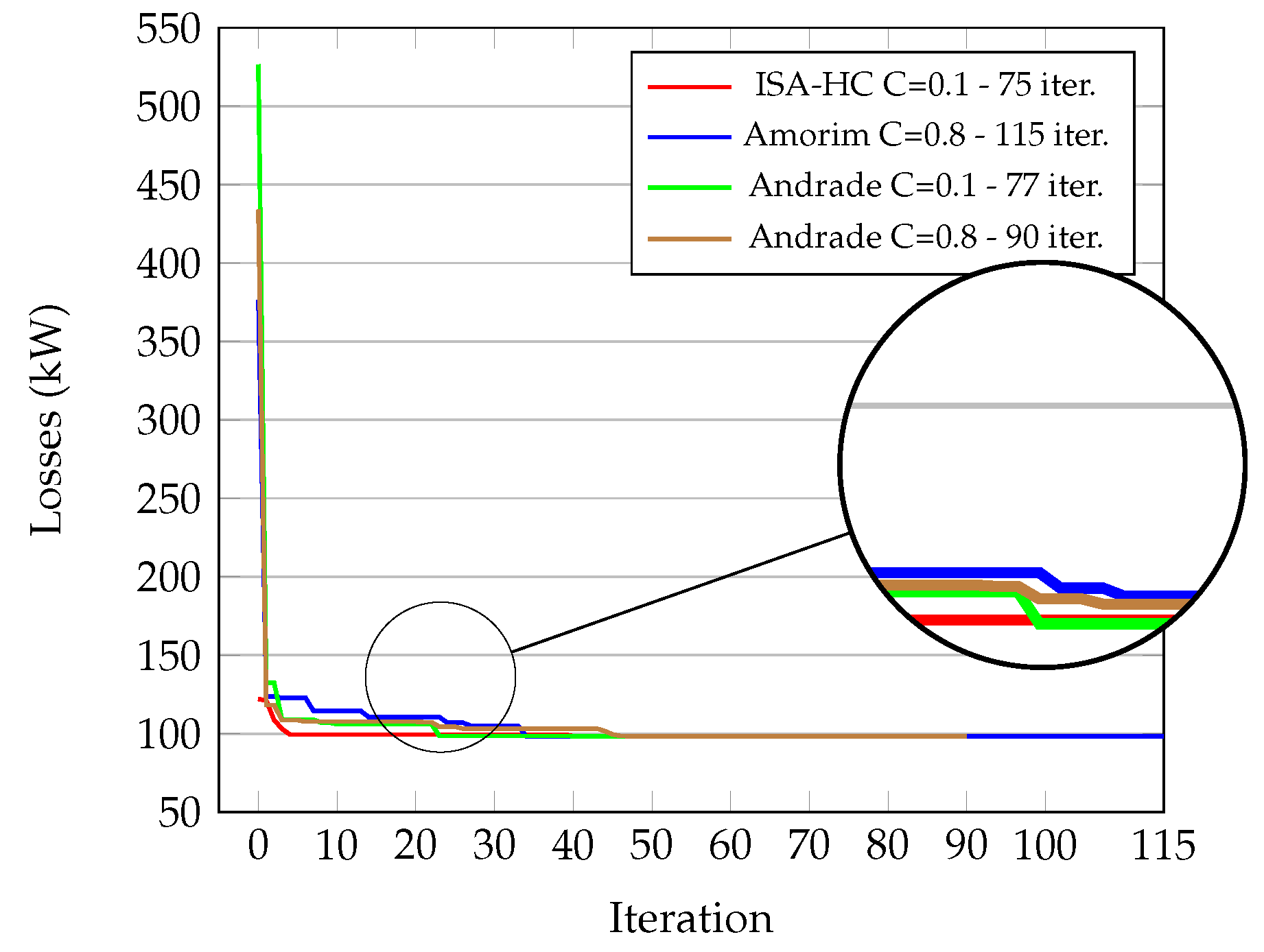

6.2. Case Study 2

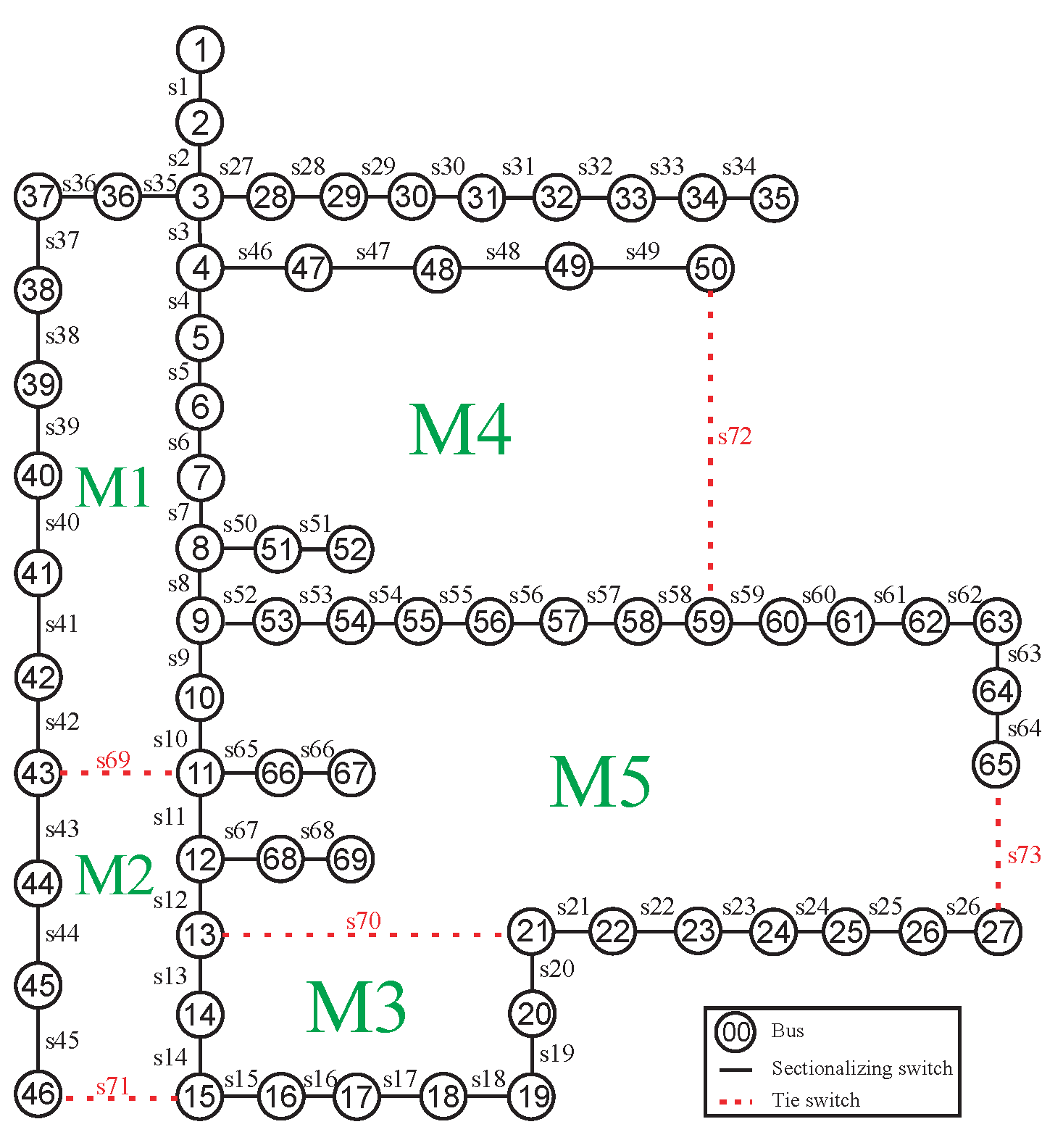

6.3. Case Study 3

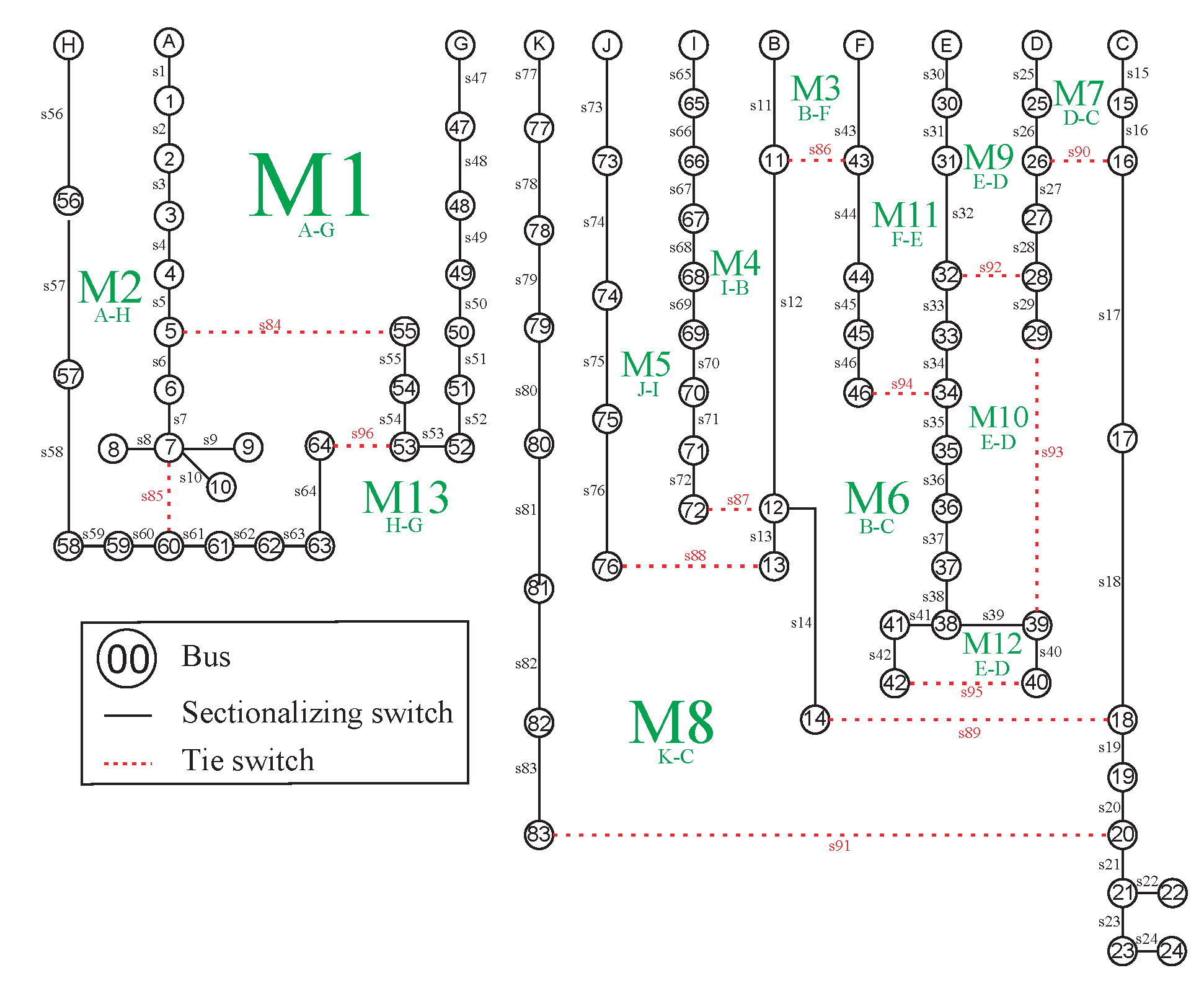

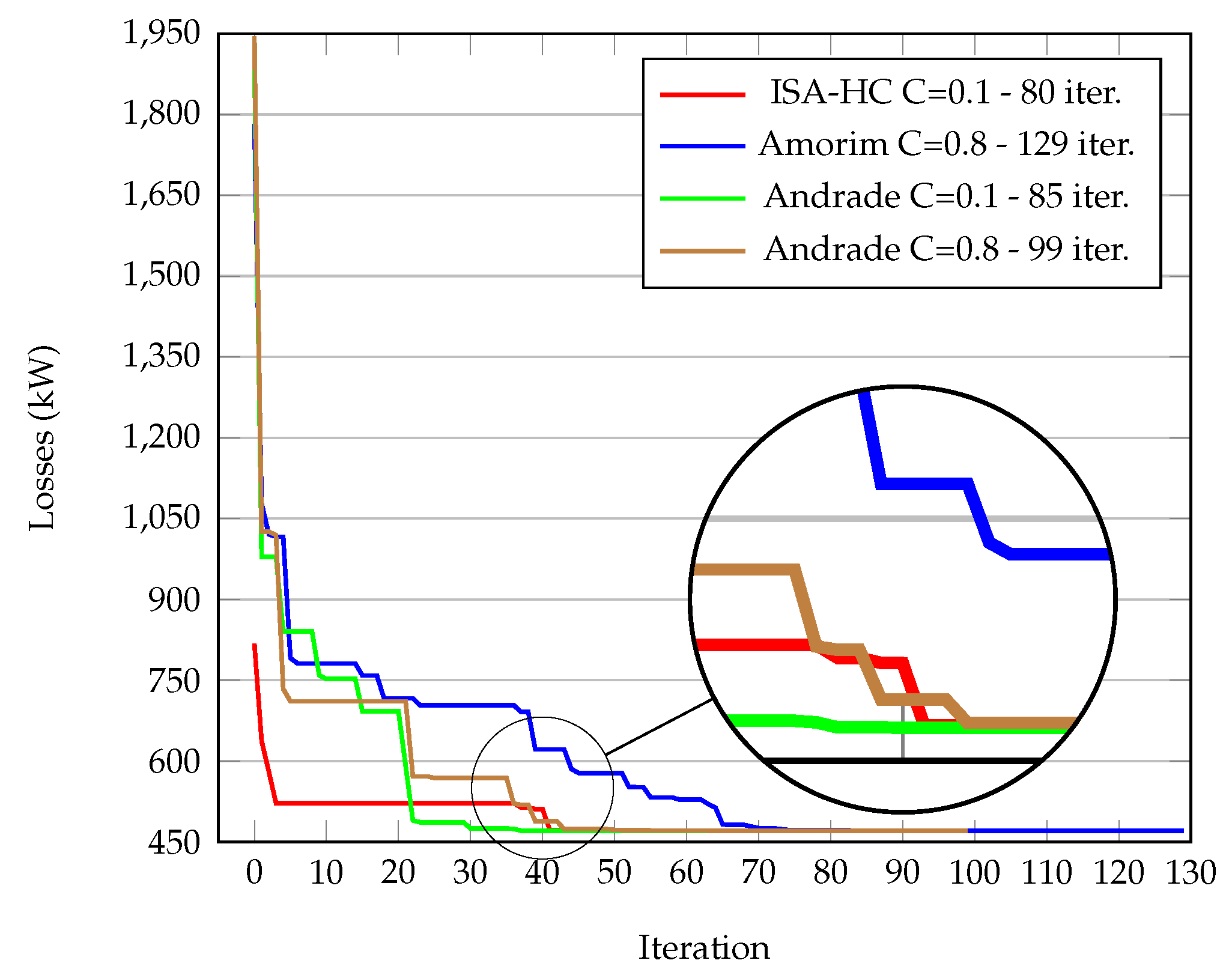

6.4. Case Study 4

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pegado, R.D.A. Reconfiguração de Redes de Distribuição de Energia eléTrica Usando Otimização por Enxame de partíCulas Aprimorado. Master’s Thesis, Universidade Federal da Paraíba, João Pessoa, Brazil, 2019. [Google Scholar]

- Pinheiro Filho, L.O. Reconfiguração de Redes de Distribuição Utilizando Algoritmo de Busca Tabu. Master’s Thesis, Universidade Federal da Paraíba, João Pessoa, Brazil, 2022. [Google Scholar]

- Pegado, R.; Ñaupari, Z.; Molina, Y.; Castillo, C. Radial distribution network reconfiguration for power losses reduction based on improved selective BPSO. Electr. Power Syst. Res. 2019, 169, 206–213. [Google Scholar] [CrossRef]

- Anteneh, D.; Khan, B.; Mahela, O.P.; Alhelou, H.H.; Guerrero, J.M. Distribution network reliability enhancement and power loss reduction by optimal network reconfiguration. Comput. Electr. Eng. 2021, 96, 107518. [Google Scholar] [CrossRef]

- Dias Santos, J.; Marques, F.; Garcés Negrete, L.P.; Andrêa Brigatto, G.A.; López-Lezama, J.M.; Muñoz-Galeano, N. A Novel Solution Method for the Distribution Network Reconfiguration Problem Based on a Search Mechanism Enhancement of the Improved Harmony Search Algorithm. Energies 2022, 15, 2083. [Google Scholar] [CrossRef]

- Nie, S.; Fu, X.P.; Li, P.; Gao, F.; Ding, C.D.; Yu, H.; Wang, C.S. Analysis of the impact of DG on distribution network reconfiguration using OpenDSS. In Proceedings of the IEEE PES Innovative Smart Grid Technologies, Berlin, Germany, 14–17 October 2012; pp. 1–5. [Google Scholar] [CrossRef]

- Marques, R.C.; Eichkoff, H.S.; de Mello, A.P.C. Analysis of the distribution network reconfiguration using the OpenDSS® software. In Proceedings of the 2018 Simposio Brasileiro de Sistemas Eletricos (SBSE), Niteroi Brazil, 12–16 May 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Mello, A.P.C.d. Reconfiguração de Redes de Distribuição Considerando multivariáVeis e Geração Distribuída. Master’s Thesis, Universidade Federal de Santa Maria, Santa Maria, Brazil, 2014. [Google Scholar]

- Bernardon, D.P. Novos Métodos para Reconfiguração das Redes de Distribuição a partir de Algoritmos de Tomadas de Decisão Multicritérios. Ph.D. Thesis, Universidade Federal de Santa Maria, Santa Maria, Brazil, 2007; p. 229. [Google Scholar]

- Antončič, M.; Mikec, M.; Blažič, B. Development of distribution network model in OpenDSS using MATLAB and GIS data. In Proceedings of the 2019 7th International Youth Conference on Energy (IYCE), Bled, Slovenia, 3–6 July 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Zeb, M.Z.; Imran, K.; Khattak, A.; Janjua, A.K.; Pal, A.; Nadeem, M.; Zhang, J.; Khan, S. Optimal Placement of Electric Vehicle Charging Stations in the Active Distribution Network. IEEE Access 2020, 8, 68124–68134. [Google Scholar] [CrossRef]

- De Andrade, B.A.R.; Ferreira, N.R. Simulated annealing and tabu search applied on network reconfiguration in distribution systems. In Proceedings of the 2018 Simposio Brasileiro de Sistemas Eletricos (SBSE), Niteroi, Brazil, 12–16 May 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Chiang, H.D.; Jean-Jumeau, R. Optimal network reconfigurations in distribution systems. I. A new formulation and a solution methodology. IEEE Trans. Power Deliv. 1990, 5, 1902–1909. [Google Scholar] [CrossRef]

- Gerez, C.; Coelho Marques Costa, E.; Sguarezi Filho, A.J. Distribution Network Reconfiguration Considering Voltage and Current Unbalance Indexes and Variable Demand Solved through a Selective Bio-Inspired Metaheuristic. Energies 2022, 15, 1686. [Google Scholar] [CrossRef]

- Zhigang, M. Study on distribution network reconfiguration based on genetic simulated annealing algorithm. In Proceedings of the 2008 China International Conference on Electricity Distribution, Guangzhou, China, 10–13 December 2008; pp. 1–7. [Google Scholar] [CrossRef]

- Skoonpong, A.; Sirisumrannukul, S. Network Reconfiguration for Reliability Worth Enhancement in Distribution Systems by Simulated Annealing. In Proceedings of the 2008 5th International Conference on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology, Krabi, Thailand, 14–17 May 2008; Volume 2, pp. 937–940. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, F.; Zhang, Y. Distribution Network Reconfiguration Based on Simulated Annealing Immune Algorithm. Energy Procedia 2011, 12, 271–277. [Google Scholar] [CrossRef]

- Chen, E.K.; Zhang, S.; Wang, T. Research on distribution network reconstruction based on improved simulated annealing—Ant colony algorithm. In Proceedings of the 2017 Chinese Automation Congress (CAC), Jinan, China, 20–22 October 2017; pp. 3575–3579. [Google Scholar] [CrossRef]

- Koziel, S.; Rojas, A.L.; Moskwa, S. Power loss reduction through distribution network reconfiguration using feasibility-preserving simulated annealing. In Proceedings of the 2018 19th International Scientific Conference on Electric Power Engineering (EPE), Brno, Czech Republic, 16–18 May 2018; pp. 1–5. [Google Scholar] [CrossRef]

- Zhang, J.; Li, Z.; Wang, B. Within-day rolling optimal scheduling problem for active distribution networks by multi-objective evolutionary algorithm based on decomposition integrating with thought of simulated annealing. Energy 2021, 223, 120027. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Nguyen, T.T.; Le, B. Optimization of electric distribution network configuration for power loss reduction based on enhanced binary cuckoo search algorithm. Comput. Electr. Eng. 2021, 90, 106893. [Google Scholar] [CrossRef]

- Amorim, J.R.B.d.C. Reconfiguração da Rede de Distribuição Inteligente Usando Recozimento Simulado. Master’s Thesis, Universidade Federal da Paraíba, João Pessoa, Brazil, 2022. [Google Scholar]

- Stojanović, B.; Rajić, T.; Šošić, D. Distribution network reconfiguration and reactive power compensation using a hybrid Simulated Annealing—Minimum spanning tree algorithm. Int. J. Electr. Power Energy Syst. 2023, 147, 108829. [Google Scholar] [CrossRef]

- Tomczyk, M.; Mielnik, R.; Plichta, A.; Goldasz, I.; Sułowicz, M. Identification of Inter-Turn Short-Circuits in Induction Motor Stator Winding Using Simulated Annealing. Energies 2021, 15, 117. [Google Scholar] [CrossRef]

- Wu, M.; Chen, W.; Tian, X. Optimal energy consumption path planning for quadrotor UAV transmission tower inspection based on simulated annealing algorithm. Energies 2022, 15, 8036. [Google Scholar] [CrossRef]

- Tabak, A.; İlhan, İ. An effective method based on simulated annealing for automatic generation control of power systems. Appl. Soft Comput. 2022, 126, 109277. [Google Scholar] [CrossRef]

- Mohammad, K.; Basu, S.; Prasad, T.N.; Muthu, R.; Naidu, R.C. Optimizing Hydrogen Consumption in Fuel cells Using Simulated Annealing Algorithm. In Proceedings of the 2022 7th International Conference on Environment Friendly Energies and Applications (EFEA), Bagatelle Moka MU, Mauritius, 14–16 December 2022; pp. 1–5. [Google Scholar]

- Kida, A.A.; Rivas, A.E.L.; Gallego, L.A. An improved simulated annealing—Linear programming hybrid algorithm applied to the optimal coordination of directional overcurrent relays. Electr. Power Syst. Res. 2020, 181, 106197. [Google Scholar] [CrossRef]

- Sexauver, J. New User Primer: The Open Distribution System Simulator (OpenDSS). Train. Mater 2012, 7.6, 1–35. [Google Scholar]

- Montenegro, D. Introduction to the Next Generation of Distribution Analysis Tools—Summer course D1. In Proceedings of the 2019 IEEE Workshop on Power Electronics and Power Quality Applications (PEPQA), Manizales, Colombia, 30–31 May 2019; pp. 1–105. [Google Scholar]

- Dugan, R.C.; Montenegro, D. Reference Guide: The Open Distribution System Simulator (OpenDSS); Electric Power Research Institute, Inc: Washington, DC, USA, 2020; Volume 9. [Google Scholar]

- Lavorato, M.; Franco, J.F.; Rider, M.J.; Romero, R. Imposing radiality constraints in distribution system optimization problems. IEEE Trans. Power Syst. 2011, 27, 172–180. [Google Scholar] [CrossRef]

- Niknam, T.; Azadfarsani, E.; Jabbari, M. A new hybrid evolutionary algorithm based on new fuzzy adaptive PSO and NM algorithms for distribution feeder reconfiguration. Energy Convers. Manag. 2012, 54, 7–16. [Google Scholar] [CrossRef]

- Goldbarg, E.; Goldbarg, M.; Luna, H. Otimização Combinatória e Metaheurísticas: Algoritmos e Apliacações; Elsevier: Rio de Janeiro, Brasil, 2017. [Google Scholar]

- Brownlee, J. Clever Algorithms: Nature-Inspired Programming Recipes; Jason Brownlee: West Point, MS, USA, 2011. [Google Scholar]

- Chibante, R. Simulated Annealing: Theory with Applications; BoD—Books on Demand: Norderstedt, Germany, 2010. [Google Scholar]

- Aguiar, M.; Mauri, G. Introdução aos Métodos Heurísticos de Otimização com Python; Universidade Federal do Espírito Santo: Vitória, Brazil, 2018. [Google Scholar]

- Pereira, F.S.; Vittori, K.; da Costa, G.R.M. Ant colony based method for reconfiguration of power distribution system to reduce losses. In Proceedings of the 2008 IEEE/PES Transmission and Distribution Conference and Exposition: Latin America, Bogota, Colombia, 13–15 August 2008; pp. 1–5. [Google Scholar] [CrossRef]

- Gerez, C.; Silva, L.I.; Belati, E.A.; Sguarezi Filho, A.J.; Costa, E.C.M. Distribution Network Reconfiguration Using Selective Firefly Algorithm and a Load Flow Analysis Criterion for Reducing the Search Space. IEEE Access 2019, 7, 67874–67888. [Google Scholar] [CrossRef]

- Baran, M.E.; Wu, F.F. Network reconfiguration in distribution systems for loss reduction and load balancing. IEEE Power Eng. Rev. 1989, 9, 101–102. [Google Scholar] [CrossRef]

- Abd Rahman, N.H.; Zobaa, A.F. Integrated mutation strategy with modified binary PSO algorithm for optimal PMUs placement. IEEE Trans. Ind. Inform. 2017, 13, 3124–3133. [Google Scholar] [CrossRef]

- Dong, J.; Li, Q.; Deng, L. Design of fragment-type antenna structure using an improved BPSO. IEEE Trans. Antennas Propag. 2017, 66, 564–571. [Google Scholar] [CrossRef]

- Chiang, H.D.; Jean-Jumeau, R. Optimal network reconfigurations in distribution systems. II. Solution algorithms and numerical results. IEEE Trans. Power Deliv. 1990, 5, 1568–1574. [Google Scholar] [CrossRef]

- Savier, J.S.; Das, D. Impact of Network Reconfiguration on Loss Allocation of Radial Distribution Systems. IEEE Trans. Power Deliv. 2007, 22, 2473–2480. [Google Scholar] [CrossRef]

- Su, C.T.; Lee, C.S. Network reconfiguration of distribution systems using improved mixed-integer hybrid differential evolution. IEEE Trans. Power Deliv. 2003, 18, 1022–1027. [Google Scholar] [CrossRef]

| Parameter | Results | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Average | Standard | Worst Solution | Best Solution | Nro | Average | Average | ||||||

| C | n | NNm | Value | Deviation | Losses | Solution | Losses | Solution | Recu. | Time | Iteration | |

| (kW) | (kW) | (kW) | (s) | |||||||||

| 0.1 | 2 | 5 | 20 | 36.248 | 0.000 | 36.248 | [3, 4, 7] | 36.248 | [3, 4, 7] | 100 | 0.51 | 38 |

| 0.1 | 2 | 5 | 15 | 36.422 | 1.737 | 53.703 | [1, 5, 7] | 36.248 | [3, 4, 7] | 99 | 0.27 | 35 |

| 0.1 | 2 | 5 | 25 | 36.248 | 0.000 | 36.248 | [3, 4, 7] | 36.248 | [3, 4, 7] | 100 | 0.39 | 46 |

| 0.1 | 2 | 10 | 20 | 36.248 | 0.000 | 36.248 | [3, 4, 7] | 36.248 | [3, 4, 7] | 100 | 0.58 | 40 |

| 0.1 | 2 | 15 | 20 | 36.248 | 0.000 | 36.248 | [3, 4, 7] | 36.248 | [3, 4, 7] | 100 | 0.95 | 45 |

| 0.1 | 3 | 5 | 20 | 36.248 | 0.000 | 36.248 | [3, 4, 7] | 36.248 | [3, 4, 7] | 100 | 0.36 | 40 |

| 0.1 | 4 | 5 | 20 | 36.256 | 0.080 | 37.053 | [1, 4, 7] | 36.248 | [3, 4, 7] | 99 | 0.35 | 68 |

| Parameter | Results | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Average | Standard | Worst Solution | Best Solution | Nro | Average | Average | ||||

| C | n | Value | Deviation | Losses | Solution | Losses | Solution | Recu. | Time | Iteration |

| (kW) | (kW) | (kW) | (s) | |||||||

| 0.1 | 2 | 36.248 | 0.000 | 36.248 | [3, 4, 7] | 36.248 | [3, 4, 7] | 100 | 0.51 | 38 |

| 0.2 | 2 | 36.248 | 0.000 | 36.248 | [3, 4, 7] | 36.248 | [3, 4, 7] | 100 | 0.53 | 52 |

| 0.3 | 2 | 36.248 | 0.000 | 36.248 | [3, 4, 7] | 36.248 | [3, 4, 7] | 100 | 0.51 | 73 |

| 0.4 | 2 | 36.248 | 0.000 | 36.248 | [3, 4, 7] | 36.248 | [3, 4, 7] | 100 | 0.35 | 42 |

| 0.5 | 2 | 36.248 | 0.000 | 36.248 | [3, 4, 7] | 36.248 | [3, 4, 7] | 100 | 0.37 | 60 |

| 0.6 | 2 | 36.248 | 0.000 | 36.248 | [3, 4, 7] | 36.248 | [3, 4, 7] | 100 | 0.36 | 40 |

| 0.7 | 2 | 36.248 | 0.000 | 36.248 | [3, 4, 7] | 36.248 | [3, 4, 7] | 100 | 0.35 | 46 |

| 0.8 | 2 | 36.248 | 0.000 | 36.248 | [3, 4, 7] | 36.248 | [3, 4, 7] | 100 | 0.37 | 52 |

| 0.9 | 2 | 36.248 | 0.000 | 36.248 | [3, 4, 7] | 36.248 | [3, 4, 7] | 100 | 0.36 | 53 |

| Method | Global Solution |

Standard Deviation |

Solution | ||||

|---|---|---|---|---|---|---|---|

| Open Switches | Losses (kW) | ||||||

| ISA-HC (C = 0.1) | 100 | 0 | Best | 3-4-7 | 36.248 | ||

| J.Amorim-SA (2022) [22] | 100 | 0 | Best | 3-4-7 | 36.248 | ||

| R.Pegado-PSO (2019) [1] | 100 | 0 | Best | 3-4-7 | 36.248 | ||

| C.Gerez (2019) [39] | 100 | 0 | Best | 3-4-7 | 36.248 | ||

| Andrade (2018) [12] | 100 | 0 | Best | 3-4-7 | 36.248 | ||

| Parameter | Results | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Average | Standard | Worst Solution | Best Solution | Nro | Average | Average | ||||||

| C | n | NNm | Value | Deviation | Losses | Solution | Losses | Solution | Recu. | Time | Iteration | |

| (kW) | (kW) | (kW) | (s) | |||||||||

| 0.1 | 2 | 20 | 20 | 139.55 | 0.00 | 139.55 | [7, 9, 37, 14, 32] | 139.55 | [7, 9, 37, 14, 32] | 100 | 4.25 | 55 |

| 0.1 | 2 | 20 | 15 | 139.56 | 0.04 | 139.95 | [7, 9, 28, 14, 32] | 139.55 | [7, 9, 37, 14, 32] | 99 | 3.38 | 61 |

| 0.1 | 2 | 20 | 25 | 139.55 | 0.00 | 139.55 | [7, 9, 37, 14, 32] | 139.55 | [7, 9, 37, 14, 32] | 100 | 4.53 | 58 |

| 0.1 | 2 | 15 | 20 | 139.55 | 0.00 | 139.55 | [7, 9, 37, 14, 32] | 139.55 | [7, 9, 37, 14, 32] | 100 | 3.57 | 53 |

| 0.1 | 2 | 25 | 20 | 139.55 | 0.00 | 139.55 | [7, 9, 37, 14, 32] | 139.55 | [7, 9, 37, 14, 32] | 100 | 4.27 | 66 |

| 0.1 | 3 | 20 | 20 | 139.55 | 0.00 | 139.55 | [7, 9, 37, 14, 32] | 139.55 | [7, 9, 37, 14, 32] | 100 | 3.96 | 61 |

| 0.1 | 4 | 20 | 20 | 139.55 | 0.00 | 139.55 | [7, 9, 37, 14, 32] | 139.55 | [7, 9, 37, 14, 32] | 100 | 3.90 | 54 |

| Parameter | Results | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Average | Standard | Worst Solution | Best Solution | Nro | Average | Average | ||||

| C | n | Value | Deviation | Losses | Solution | Losses | Solution | Recu. | Time | Iteration |

| (kW) | (kW) | (kW) | (s) | |||||||

| 0.1 | 2 | 139.55 | 0.00 | 139.55 | [7, 9, 37, 14, 32] | 139.55 | [7, 9, 37, 14, 32] | 100 | 4.25 | 55 |

| 0.2 | 2 | 139.55 | 0.00 | 139.55 | [7, 9, 37, 14, 32] | 139.55 | [7, 9, 37, 14, 32] | 100 | 4.46 | 60 |

| 0.3 | 2 | 139.55 | 0.00 | 139.55 | [7, 9, 37, 14, 32] | 139.55 | [7, 9, 37, 14, 32] | 100 | 4.12 | 51 |

| 0.4 | 2 | 139.55 | 0.00 | 139.55 | [7, 9, 37, 14, 32] | 139.55 | [7, 9, 37, 14, 32] | 100 | 3.92 | 54 |

| 0.5 | 2 | 139.55 | 0.00 | 139.55 | [7, 9, 37, 14, 32] | 139.55 | [7, 9, 37, 14, 32] | 100 | 3.91 | 54 |

| 0.6 | 2 | 139.55 | 0.00 | 139.55 | [7, 9, 37, 14, 32] | 139.55 | [7, 9, 37, 14, 32] | 100 | 3.78 | 57 |

| 0.7 | 2 | 139.55 | 0.00 | 139.55 | [7, 9, 37, 14, 32] | 139.55 | [7, 9, 37, 14, 32] | 100 | 3.79 | 61 |

| 0.8 | 2 | 139.55 | 0.00 | 139.55 | [7, 9, 37, 14, 32] | 139.55 | [7, 9, 37, 14, 32] | 100 | 3.94 | 57 |

| 0.9 | 2 | 139.55 | 0.00 | 139.55 | [7, 9, 37, 14, 32] | 139.55 | [7, 9, 37, 14, 32] | 100 | 3.82 | 55 |

| Method | Global Solution |

Standard Deviation |

Solution | ||||

|---|---|---|---|---|---|---|---|

| Open Switches | Losses (kW) | ||||||

| ISA-HC (C = 0.1) | 100 | 0 | Best | 7-9-14-32-37 | 139.55 | ||

| Worst | 7-9-14-32-37 | 139.55 | |||||

| J.Amorim-SA (2022) [22] | 100 | 0 | Best | 7-9-14-32-37 | 139.55 | ||

| Worst | 7-9-14-32-37 | 139.55 | |||||

| IS-BPSO (2019) [3] | 100 | 0 | Best | 7-9-14-32-37 | 139.55 | ||

| Worst | 7-9-14-32-37 | 139.55 | |||||

| Andrade; Ferreira (2018) [12] | 100 | 0 | Best | 7-9-14-32-37 | 139.55 | ||

| Worst | 7-9-14-32-37 | 139.55 | |||||

| N.H.A. Rahman (2017) [41] | 30 | 1.676 | Best | 7-9-14-32-37 | 139.55 | ||

| Worst | 7-9-13-32-37 | 143.09 | |||||

| J.Dong (2017) [42] | 20 | 1.605 | Best | 7-9-14-32-37 | 139.55 | ||

| Worst | 7-9-13-32-37 | 143.09 | |||||

| Param. | Results | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Average | Standard | Worst Solution | Best Solution | Nro | Average | Average | ||||||

| C | n | NNm | Value | Deviation | Losses | Solution | Losses | Solution | Recu. | Time | Iteration | |

| (kW) | (kW) | (kW) | (s) | |||||||||

| 0.1 | 4 | 25 | 20 | 98.398 | 0.00 | 98.398 | [69, 14, 70, 55, 61] | 98.398 | [69, 14, 70, 55, 61] | 100 | 13.74 | 75 |

| 0.1 | 4 | 25 | 15 | 98.398 | 0.00 | 98.398 | [69, 14, 70, 55, 61] | 98.398 | [69, 14, 70, 55, 61] | 100 | 13.84 | 103 |

| 0.1 | 4 | 25 | 25 | 98.398 | 0.00 | 98.398 | [69, 14, 70, 55, 61] | 98.398 | [69, 14, 70, 55, 61] | 100 | 15.61 | 99 |

| 0.1 | 4 | 20 | 20 | 98.398 | 0.00 | 98.398 | [69, 14, 70, 55, 61] | 98.398 | [69, 14, 70, 55, 61] | 100 | 12.92 | 94 |

| 0.1 | 4 | 30 | 20 | 98.398 | 0.00 | 98.398 | [69, 14, 70, 55, 61] | 98.398 | [69, 14, 70, 55, 61] | 100 | 17.88 | 93 |

| 0.1 | 2 | 25 | 20 | 98.398 | 0.00 | 98.398 | [69, 14, 70, 55, 61] | 98.398 | [69, 14, 70, 55, 61] | 100 | 13.90 | 94 |

| 0.1 | 6 | 25 | 20 | 98.398 | 0.00 | 98.398 | [69, 14, 70, 55, 61] | 98.398 | [69, 14, 70, 55, 61] | 100 | 12.84 | 111 |

| Param. | Results | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Average | Standard | Worst Solution | Best Solution | Nro | Average | Average | ||||

| C | n | Value | Deviation | Losses | Solution | Losses | Solution | Recu. | Time | Iteration |

| (kW) | (kW) | (kW) | (s) | |||||||

| 0.1 | 4 | 98.398 | 0.00 | 98.398 | [69, 14, 70, 55, 61] | 98.398 | [69, 14, 70, 55, 61] | 100 | 13.74 | 75 |

| 0.2 | 4 | 98.398 | 0.00 | 98.398 | [69, 14, 70, 55, 61] | 98.398 | [69, 14, 70, 55, 61] | 100 | 16.38 | 94 |

| 0.3 | 4 | 98.398 | 0.00 | 98.398 | [69, 14, 70, 55, 61] | 98.398 | [69, 14, 70, 55, 61] | 100 | 13.33 | 116 |

| 0.4 | 4 | 98.398 | 0.00 | 98.398 | [69, 14, 70, 55, 61] | 98.398 | [69, 14, 70, 55, 61] | 100 | 12.61 | 116 |

| 0.5 | 4 | 98.398 | 0.00 | 98.398 | [69, 14, 70, 55, 61] | 98.398 | [69, 14, 70, 55, 61] | 100 | 13.47 | 116 |

| 0.6 | 4 | 98.398 | 0.00 | 98.398 | [69, 14, 70, 55, 61] | 98.398 | [69, 14, 70, 55, 61] | 100 | 13.97 | 110 |

| 0.7 | 4 | 98.398 | 0.00 | 98.398 | [69, 14, 70, 55, 61] | 98.398 | [69, 14, 70, 55, 61] | 100 | 13.73 | 110 |

| 0.8 | 4 | 98.398 | 0.00 | 98.398 | [69, 14, 70, 55, 61] | 98.398 | [69, 14, 70, 55, 61] | 100 | 14.31 | 95 |

| 0.9 | 4 | 98.398 | 0.00 | 98.398 | [69, 14, 70, 55, 61] | 98.398 | [69, 14, 70, 55, 61] | 100 | 14.85 | 83 |

| Method | Global Solution |

Standard Deviation |

Solution | ||||

|---|---|---|---|---|---|---|---|

| Open Switches | Losses (kW) | ||||||

| ISA-HC (C = 0.1) | 100 | 0 | Best | 55-69-14-70-61 | 98.398 | ||

| Worst | 55-69-14-70-61 | 98.398 | |||||

| J.Amorim-SA (2022) [22] | 100 | 0 | Best | 55-69-14-70-61 | 98.398 | ||

| Worst | 55-69-14-70-61 | 98.398 | |||||

| L.Pinheiro-Tabu (2022) [2] | 100 | 0 | Best | 55-69-14-70-61 | 98.398 | ||

| Worst | 55-69-14-70-61 | 98.398 | |||||

| Andrade; Ferreira (2018) [12] | 100 | 0 | Best | 55-69-14-70-61 | 98.398 | ||

| Worst | 55-69-14-70-61 | 98.398 | |||||

| Param. | Results | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Aver. | Stand. | Configuration | Losses | Nro | Average | Average | ||||||

| C | n | NNm | Value | Dev. | Worst | Worst (kW) | Recu. | Time | Iteration | |||

| (kW) | best. | Best. (kW) | (s) | |||||||||

| 0.1 | 6 | 35 | 30 | 470.67 | 0 | [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | 100 | 20.26 | 80 | ||

| [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | |||||||||||

| 0.1 | 6 | 35 | 25 | 470.67 | 0 | [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | 100 | 15.40 | 89 | ||

| [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | |||||||||||

| 0.1 | 6 | 35 | 35 | 470.67 | 0 | [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | 100 | 18.68 | 101 | ||

| [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | |||||||||||

| 0.1 | 6 | 30 | 30 | 470.67 | 0.05 | [55, 7, 86, 72, 13, 89, 90, 82, 92, 39, 34, 42, 62] | 471.20 | 99 | 14.46 | 88 | ||

| [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | |||||||||||

| 0.1 | 6 | 40 | 30 | 470.67 | 0 | [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | 100 | 17.16 | 76 | ||

| [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | |||||||||||

| 0.1 | 4 | 35 | 30 | 470.67 | 0 | [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | 100 | 17.19 | 87 | ||

| [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | |||||||||||

| 0.1 | 8 | 35 | 30 | 470.98 | 3.06 | [54, 6, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 61] | 501.40 | 98 | 17.14 | 97 | ||

| [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | |||||||||||

| Param. | Results | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Aver. | Stand. | Configuration | Losses | Nro | Average | Average | ||||

| C | n | Value | Dev. | Worst | Worst (kW) | Recu. | Time | Iteration | ||

| (kW) | best. | Best. (kW) | (s) | |||||||

| 0.1 | 6 | 470.67 | 0 | [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | 100 | 20.26 | 80 | ||

| [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | |||||||||

| 0.2 | 6 | 470.67 | 0 | [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | 100 | 18.23 | 80 | ||

| [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | |||||||||

| 0.3 | 6 | 470.67 | 0 | [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | 100 | 17.57 | 84 | ||

| [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | |||||||||

| 0.4 | 6 | 470.67 | 0 | [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | 100 | 17.05 | 91 | ||

| [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | |||||||||

| 0.5 | 6 | 470.67 | 0 | [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | 100 | 24.04 | 83 | ||

| [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | |||||||||

| 0.6 | 6 | 470.67 | 0 | [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | 100 | 16.46 | 78 | ||

| [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | |||||||||

| 0.7 | 6 | 470.67 | 0 | [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | 100 | 16.69 | 112 | ||

| [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | |||||||||

| 0.8 | 6 | 470.67 | 0 | [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | 100 | 20.44 | 76 | ||

| [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | |||||||||

| 0.9 | 6 | 470.67 | 0 | [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | 100 | 17.77 | 77 | ||

| [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | |||||||||

| Method | Global Solution |

Standard Deviation |

Solution | ||||

|---|---|---|---|---|---|---|---|

| Open Switches | Losses (kW) | ||||||

| ISA-HC (C = 0.1) | 100 | 0 | Best | [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | ||

| Worst | [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | |||||

| J.Amorim-SA (2022) [22] | 100 | 0 | Best | [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | ||

| Worst | [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | |||||

| L.Pinheiro (2022) [2] | 100 | 0 | Best | [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | ||

| Worst | [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | |||||

| IS-BPSO (2019) [3] | 99 | 0.098 | Best | [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | ||

| Worst | [55, 7, 86, 72, 13, 89, 90, 82, 92, 39, 34, 42, 63] | 471.37 | |||||

| Andrade (2018) [12] | 100 | 0 | Best | [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | ||

| Worst | [55, 7, 86, 72, 13, 89, 90, 83, 92, 39, 34, 42, 62] | 470.67 | |||||

| J.Dong (2017) [42] | 0 | 2.1896 | Best | [55, 7, 86, 72, 13, 89, 90, 82, 92, 93, 34, 40, 62] | 471.49 | ||

| Worst | [84, 7, 86, 87, 76, 89, 90, 91, 92, 29, 34, 40, 64] | 488.68 | |||||

| Rahman (2017) [41] | 0 | 12.7050 | Best | [84, 7, 86, 72, 13, 89, 90, 83, 92, 93, 34, 40, 63] | 471.16 | ||

| Worst | [84, 85, 86, 87, 13, 89, 90, 83, 92, 93, 34, 40, 96] | 509.45 | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).