There are diverse types of structures for these reservoirs, particularly capsules, hollow fibers and capillary networks, typically consisting of an inert material compatible with the matrix and intended to protect the repairing agents from unwanted reactions or changes on their chemical properties. Generally, to achieve an efficient self-healing composite, it is necessary to consider some important factors concerning the reservoirs, namely strength, which should ensure safe handling and processing and good storage stability, so that no deformation takes place and breakage only happens when the material’s damage occurs, and excellent interface adhesion, which guarantees that, when the fracture is formed, the container ruptures and the healing agent is released. In some cases, compatibilizers might be necessary for that purpose. Likewise, the incorporation of the reservoirs in the matrix is relevant, considering that they must be rightly embedded and uniformly distributed [1

,2

,13

,18

,19]. Ultimately, the quantity, shape and size of these reservoirs can be adjusted to the material’s final application [

17].

When it comes to the healing agents, they should ensure not only high reactivity, but also good flowability and adhesion/compatibility with the polymeric matrix, despite the possibility of either being different of the matrix or not [

18]. Additionally, such reactivity must allow them to also react quickly and effectively regenerate the composite material in question. Other relevant properties of these reactants include good storage stability within the structures that contain them, so that they do not react undesirably, degrade at common composites’ manufacturing temperatures or entail safety risks. Furthermore, surface tension, contact angle and permeability must be adequate, so that the diffusion process is efficient and gaps are quickly filled. [1

,4

,20].

On the early development stages of extrinsic self-healing composites, one pioneer approach was the employment of dicyclopentadiene which undergoes ring-opening metathesis polymerization catalyzed by the Grubb’s catalyst. However, in late years research has been dedicated to developing more efficient healing agents, not only based on catalyzed ring-opening polymerization, such as 5-ethylene-2-norbornene, that exhibits a superior healing efficiency, but also resorting to polymers similar to the matrix, as is the case of epoxy resins combined with curing agents [8

,18]. These stand out for having a better affinity with the mentioned matrix and lower curing temperature, resulting in superior self-healing potential, however they are also more viscous and less reactive than catalyst-based systems and can, therefore, create limitations concerning processability [

18].

To promote a better performance of the reservoir-based self-healing systems, the possibility of using solvents has also been addressed either to facilitate the transport of the catalyst [

21] or to penetrate the polymeric matrix, weaken the intermolecular forces, intensify the movement of the polymeric chains and lead to swelling of the material, which will improve the contact between the fracture components and facilitate repair [

22]. Furthermore, for systems where encapsulated resins are used, it should be considered that, even if the curing agent can react at room temperature, the viscosity of the resin, at such conditions, can be a limitation when it comes to its ability to infiltrate fractures.

Other nanomaterials of which carbon nanotubes are example can also be stored inside the reservoirs as an additional component that can not only promote the reinforcement of the newly solidified polymer (either on a resin/hardener system or on a monomer/initiator one), improving the mechanical properties’ recovery, but also potentially contribute to the restoration of other functional properties, such as electrical conductivity [23,24].

2.2.1. Capsules

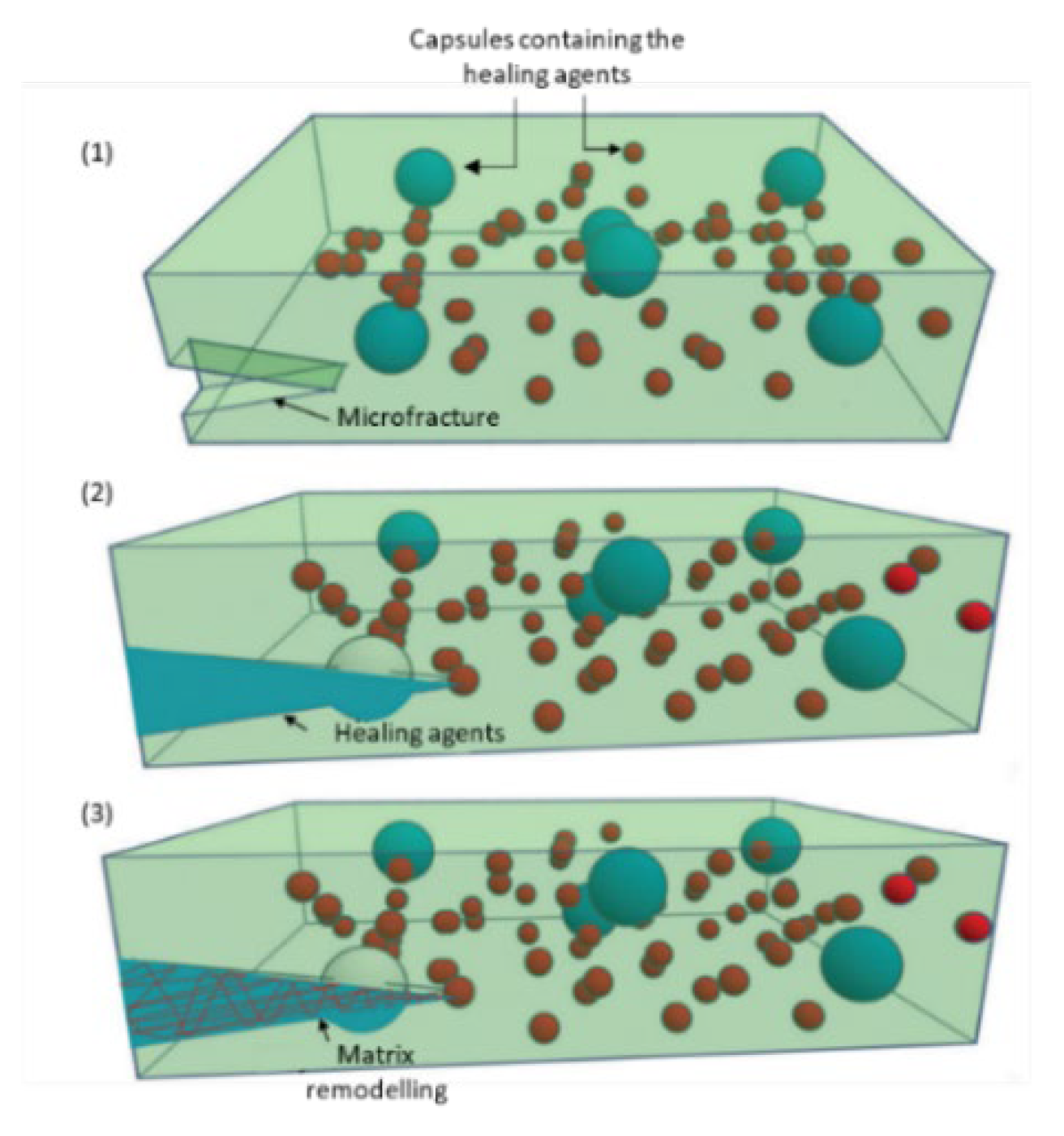

Capsule-based self-healing composites (

Figure 2 [

1]) are the most extensively studied ones, particularly the ones that resort to microcapsules, due to the variety and the easiness of implementation in different polymeric systems, resulting in a thorough description of the fabrication methods. Capsules can either be single, with, for example, the catalyst embedded in the matrix, or double, containing more than one regenerating reactant in the same capsule or in different capsules [

1].

Within this context, H.Hu et al. [

25] explored the development of an epoxy resin based composite, where two different types of microcapsules were used: one containing the same polymer as the matrix (12 wt%) and the other containing an amine curing agent (8 wt%) that would react with the first one. The healing conditions consisted of 24 h at room temperature, followed by 6 h, at 50 ºC. It was concluded that the healing efficiency, evaluated through the fracture toughness, was about 80,4 %. Alternatively, C. Y. Zhang et al. [

26] proposed the encapsulation of styrene and benzoyl peroxide separately, so that the first was polymerized through initiation with the second, upon microcapsule breakage. Such reservoirs were incorporated into an epoxy-based matrix and a maximum healing efficiency of 65 % was attained, through impact tests, when 15 wt% of styrene loaded capsules and 3 wt% of benzoyl peroxide loaded capsules were employed and after 24 h, at 25 ºC. The materials’ multi-repairability was also analyzed and a reduction of about 20 % to 30 % was detected for the second and third repairs. On a different approach, H. H. Zamal et al. [

27] encapsulated a mixture of monomers of 5-ethylidene-2-norbornene with multi-walled carbon nanotubes, which were then dispersed (10 wt%) in an epoxy polymeric matrix, together with a ruthenium Grubbs catalyst, responsible for initiating ring opening metathesis polymerization reaction. It was highlighted that an ambient temperature curing resin was chosen for the matrix to prevent catalyst degradation. The main conclusions were firstly that the presence of the microcapsules contributed to the reinforcement of the material and secondly that the carbon nanotubes increased the strength of the polymer synthesized upon capsule rupture, which was reflected on an improved healing efficiency of 97 %, calculated by fracture toughness, after healing at room temperature, for 48 h. Another distinct concept worth analyzing is the one brought by R. Rodriguez et al. [

28] where microcapsules (20 wt%) containing an epoxy resin (equal to the matrix one) on the inside and a curing initiator catalyst (Scandium triflate (III)) on the outer surface were prepared. This type of structure amplified the probability of the encapsulated resin reacting with the catalyst and, consequently, an efficiency of 79,1 % was attained after healing at 120 ºC, for 24 h, analyzed in terms of fracture toughness recovery. Furthermore, Shunze Cao et al. [

15] explored the utilization of multicore-like bilayer calcium-alginate capsules, containing epoxy resin on the inside core, whereas a curing agent was on the outer one. Such structures were synthesized through multi-stage encapsulation and incorporated (15 % volume fraction) into epoxy-based foams whose purpose was to integrate foam core sandwich structures. The advantage of this type of microcapsules was their capability to promote a more adequate mixture of the two healing agents. It was suggested that, when compared to conventional dual capsule systems, the multicore capsules exhibited better multiple self-healing performance, with a maximum efficiency greater than 80 % for the first cycle, determined through the elastic modulus. Nevertheless, this efficiency decreased throughout the cycles. Moreover, the compressive strength and stiffness of the foams were improved.

On their work, Amanda R. Jones et al. [

29] explored the self-healing of carbon fiber/epoxy interfaces, aiming to prevent fiber/matrix debonding, which has consequences on the mechanical properties of the material. For that purpose, micro-capsules containing a resin solvent solution responsible for interface regeneration were incorporated into the reinforcing carbon fibers’ surface. Upon debonding, the microcapsules underwent rupture, releasing the healing agents that repaired the interface. The usage of a binder to stabilize the capsules on the fibers’ surface was assessed, as well has the impact of the coverage of microcapsules at the interface. It was concluded that a maximum of 91 % recovery of the interfacial shear strength could be achieved. Finally, an innovative concept was introduced by Wrihao Yuan et al. [

30], that, aside from incorporating microcapsules containing epoxy resin and mercaptan into the polymeric matrix, modified silver nanoparticles on the surface of the reinforcing carbon fibers. The purpose of such approach was that the reaction between the epoxy resin and mercaptan repaired the polymeric matrix, while a coordination connection was stablished between the sulfhydryl group of the mercaptan and the silver nanoparticles, contributing to the regeneration of the fiber/matrix interface. Besides that, the healing reaction between the epoxy resin and the mercaptan is strongly exothermic, therefore thermal signals were released from the crack healing, which were then captured by an infrared thermal imager, thus the damage and the healing reaction could be monitored. A healing efficiency of 80 % was attained after 24 h, at room temperature, for a microcapsules’ content of 15 wt%, evaluated by fracture toughness. Besides that, the healing effectiveness at the interface, analyzed resorting to the interface shear strength, reached 74 %, for the same microcapsule content.

Nevertheless, these structures have some limitations, particularly with regard to the amount of repairing agent they contain, making it impossible to know when it has been completely consumed or to feed it back into the system, as the number of capsules is finite [3,12]. Other effects that must be considered include the probability of microfractures meeting the capsules randomly dispersed in the matrix, so that the repair agent is released; the material, size distribution and thickness of these capsules, the aforementioned compatibility with the matrix, the hypothesis of particle coalescence and the influence that these characteristics have on the properties of the matrix itself. Furthermore, after the capsules break and the regenerating compound is released, the empty capsule remains in the matrix, allowing the accumulation of tension at the site, which could have negative consequences, especially in the case of structural composites, ultimately leading to the re-occurrence of a damage in the same location. However, this behavior is still little studied. Besides that, after the second impact, the failures must follow a path that assures that the crack meets the unbroken microcapsules, otherwise the damage might not be healed, routing the possibility of microcrack expansion into a more complicated macro-damage. Additionally, microcapsules may not be suitable for composites which are manufactured under high pressures, considering that their shape can be deformed [14,18,26]. Urea-formaldehyde, melamine-urea-formaldehyde and polyurethane capsules are preferably used, considering that they exhibit mechanical resistance so as not to be degraded during processing, but are still soft enough to rupture relatively quickly when necessary [4,18]. Commonly in situ or interfacial polymerization or generally methods that resort to emulsion or melt dispersion are used, where the core content of the microcapsules is dispersed in a solution of the shell polymer’s components or vice-versa. Initially droplets are formed and then the polymeric layer is synthetized and solidified around them. There are some parameters that are determinant for the morphology and size of the microcapsules, that, in turn, influence the composite’s characteristics and these include: stirring rate, temperature, reaction time, weight ratio of core/shell material and emulsifier content, if applicable. For instance, smaller microcapsules with a smoother surface and no evidence of collapse stand out for promoting less negative impacts on the composite’s mechanical properties, since they possess smaller tendency to agglomerate, reduce the stress concentration and cause less filling fiber misorientation. [14,18,25,31].

2.2.2. Hollow Fibers

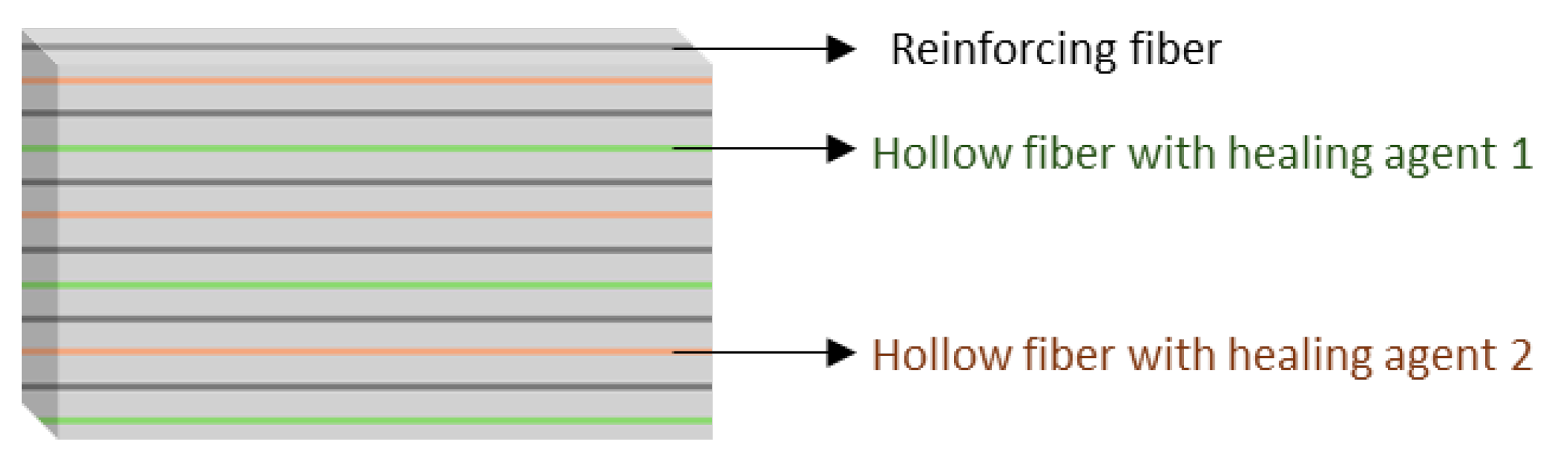

In what concerns hollow fibers (

Figure 3 [

4]), their operating principle is similar to that of capsules, however, they allow to overcome some of the lasts’ limitations, particularly with regard to storing larger volumes of healing agent and transporting them to greater distances. It is also worth noting that the fibers may cover a greater volume of the material, increasing the probability of the reservoir breaking when the fracture occurs, and can be arranged on demand, contributing to a more uniform distribution of the healing agents through the final material, even benefiting the stoichiometric mixture of the referred reactants. These fibers can be incorporated directly between the reinforcing fibers. Similarly to the microcapsules, two healing agents can circulate on different fibers, as shown in

Figure 3 [1

,4

,18].

In this setting, A. Adili et al. [

32] developed a healing system combining an epoxy resin and an amine curing agent, both equal do the matrix’s materials and each one deposited inside a different glass fiber. It was observed that, when empty, the glass fibers negatively affected the material’s strength, due to stress concentration and crack initiation. Despite that, it was concluded that smaller distances between the fibers were synonymous of a higher amount of healing agent and, therefore, resulted in an improved healing performance. Additionally, when positioned in angles of 45 º, the fibers underwent higher shear stress and consequently were more prone to fracture, ensuing a wider diffusion of the healing agents and contributing to a better healing efficiency, which was 42 %, determined by tensile strength, after 48 h, at 70 ºC. By contrast, S. Kling [

33] proposed a healing response based on a polyester resin system stored inside tin hollow glass fibers, with an outer diameter of 13 µm, and integrated into an epoxy matrix composite. One type of fiber was filled with the catalyzed unsaturated polyester resin and the other one contained the initiator (methyl ethyl ketone peroxide) dissolved in dimethyl phthalate. This option was justified by the fact that this reacting system is not as sensitive to the mixing ratio and method as others. It was demonstrated that the composite was self-healable at 23 ºC, during 120 h. A method based on the combined answer of a monomer and catalyst can also be applied to these structures, as I. Radovic et al. [

21] proposed. Herein, the monomer dicyclopentadiene was mixed with a solvent (N, N′-dimethylformamide) and fed to one type of fiber, whereas the first generation Grubbs catalyst, also dissolved in a solvent (preferably toluene, since other solvents such as dichloromethane can deactivate the catalyst during processing) was fed to another type. In this case it was found that, when filled with the healing components, the fibers actually operated as reinforcing agents, and the healing efficiency, determined through impact tests, achieved a value of 53 %, after 24 h, at 25 ºC.

On a different approach, S. A. M. Sadeghi et al. [

34] developed a core-shell nanofibers mat resorting to single nozzle electrospinning, where epoxy resin and a mercaptan-based epoxy hardener were enclosed. This mat was then incorporated into an epoxy resin-based composite and it was noted that the presence of healing agent on the surface of the nanofibers promoted a good adhesion between the matrix and the mat. The conclusion was that the material was able to self-heal and restore flexural modulus and strength, after being kept at 10 ºC, for 200 min.

A groundbreaking strategy was developed by Y. Zhu et al. [

35] where the mixing of the healing agents with a foaming agent was evaluated, together with the utilization of polypropylene tubes. These tubes were chosen, considering that they allow for the healing agents to be easily filled into larger tubes whose diameter can then be reduced, overcoming not only the difficulty of filling narrow tubes, but also preventing the weakening of the mechanical properties caused by larger tubes. Besides that, the tubes’ flexibility admits their knitting together with the traditional reinforcing fibers, in this case glass fibers, which is beneficial for materials with complicated shapes. Although polypropylene’s natural non-polarity can compromise interfacial adhesion, there is the possibility of modifying its physicochemical properties in order to improve such interaction. Finally, this polymer does not tend to react with the healing compounds that it contains. Nevertheless, the polypropylene tubes had to be irradiated by UV light with the aim of embrittling and polarizing the surface, so that they would break upon damage of the composite. The healing response relied on an epoxy resin cured by a thiol and amine mixture, and 2,2’-Azobis-(2,4-dimethylvaleronitrile) was added as the foaming agent, that does not affect the healing agents’ cure. The material was previously pressurized so that when damage occurred the high internal pressure of the foaming agent favored the spreading of the healing reactants over the damages. The healing efficiency, determined through flexural strength of the healed specimen in comparison to the virgin one, was about 93 %, but a decrease on such parameter was identified when the storage time increased, due to leakage of the pressurized foaming agent, and therefore it was suggested that polypropylene impermeability could be improved.

At this point, it can be highlighted that the main challenge of this approach is the filling of the hollow fibers, due to their reduced diameter. Some techniques include filling from top or drawing from bottom, and typically they are achieved by capillary action assisted by vacuum to aid the infiltration [

14]. Besides that, if the diameter of the fibers is too small, the viscosity of the regenerating agent can limit its transport to the damaged area. As shown, the utilization of glass fibers is typically reported, considering that they break at lower energy levels, and it is conjectured that they can act not only as a transport route for the repairing agents in question, but also as a structural reinforcement of the composite material [1

,4

,16]. The application of carbon nanotubes is also suggested, however it is assumed that their high resistance may not allow breakage during fracture formation [

17]. Besides that, the amount and spatial distribution of the fibers should also be object of scrutiny due to their effects on the mechanical behavior and healing response of the composite, as some of the previously mentioned articles highlight [

16].

Figure 3.

Scheme of a composite consisting of hollow fibers containing the healing agents and reinforcing fibers.

Figure 3.

Scheme of a composite consisting of hollow fibers containing the healing agents and reinforcing fibers.

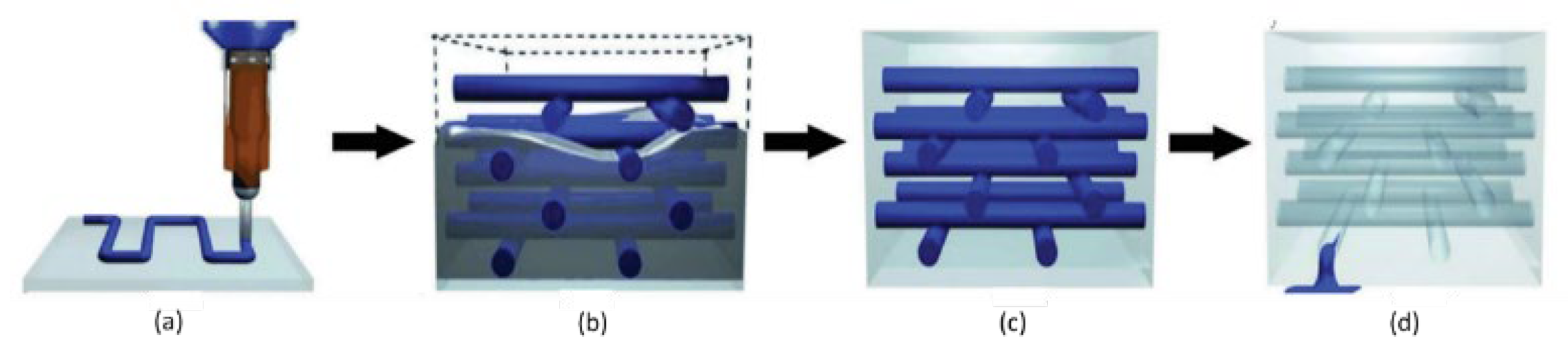

2.2.3. Microvascular Networks

To overcome the limitations associated to capsules and hollow fibers, interest has grown in studying the distribution of the healing agents through capillary networks which, as the name suggests, consist of 2D or 3D networks of interconnected microchannels that transport the compounds in question to the damaged areas. This method is, in part, similar to the previous one, however, the connected network of channels makes it possible to continuously feed the damage site, allowing more than one repair event to be carried out in the same location, which is complemented by the fact that the system can be refed. Hence, fresh healing agent can be supplied, preventing it from being stored for too long and eventually lose its activity. In this context, the hypothesis of integrating reservoirs capable of automatically detecting the need for repair and consequently feeding the healing agent to the system has already been considered [1

,17

,18]. With this model, it is also possible to add the repairing compounds in distinct types of capillaries. This perspective is, therefore, considered one of the most promising ones in the field of auto repair materials [1

,3]. Still, the development and practical application of this concept is difficult, especially in large-scale materials. Capillary networks can be developed based on non-removable or removable preforms. In the first case, like the other types of reservoirs, the capillaries must be broken so that the repairing reactants are released in the fracture, arising concerns already mentioned. In the second case, the structure of the material intrinsically integrates the hollow capillary network where the repaired agents circulate, meaning that they can flow immediately to the damage, when it is formed, without the need for reservoir breakage. However, this last option poses some limitations, on the one hand the compounds circulating in the network are not protected, being in direct contact with the matrix, and on the other hand there is possibility of channels’ deformation during the manufacturing process [18

,36]. The proposals for the development of removable preforms involve wires coated with a release agent that allows manual extraction of such wires, or 3D printing using a non-permanent material/fugitive organic ink made up of a mixture of high and low molecular weight hydrocarbons, for example a mixture of 60 % petroleum jelly and 40 % microcrystalline wax. The vascular network is developed at an initial stage and only then the material itself is formed, as shown in

Figure 4 [

1]. The mentioned fugitive ink is removed after the matrix resin has cured, by heating at a moderate temperature, under light vacuum, so that it is liquified. In such way, the final material is left with space in channels than can be filled with the healing agents [1

,14

,19

,37].

On that matter, R. Eslami-Farsani et al. [

38] designed a microvascular network resorting to digital light processing method, based on the Vat polymerization technique and using a 3D printer. Such network was made of two different sub-networks: one where the epoxy resin flowed (the same as the matrix) and another with the curing agent. Besides the microvascular system, the composite was also reinforced with glass fiber. It was concluded that the network presence led to a reduction on composite’s tensile strength, however, it was also suggested that such problem could be overcame by selecting a more rigid material for the network. A healing efficiency of 89 % was calculated resorting to tensile strength, after 7 days at ambient conditions. Moreover, R. S. Amano et al. [

39] imprinted a vascular network on one layer of glass fiber reinforced composite. The vascular network was filled with dicyclopentadiene, while Grubbs catalyst was infused in this same layer, such system was responsible for the self-healing response. Two types of patterns for the vascular networks were analyzed: square and hexagonal. It was concluded that the average strength of the composite, attained via three-point bending test, nearly doubled after recovery, which is attributed to the reaction of the healing agents and the formation of polydicyclopentadiene which is about 50 % as strong as the matrix’s epoxy resin. Additionally, it was observed that a hexagonal grid favors the access to the contained healing agent, during the damage formation. The final purpose of these developed materials was to produce self-healing wind turbine blades.

O. Fifo et al. [

19] proposed an alternative approach where an in vivo vascular channel was employed for self-healing of a glass fiber polyester composite. It preferably resorted to an automated process of injection of a single-part adhesive (cyanoacrylate adhesive) into a 2D network of hollow channels directly integrated within de composite. Such network was built resorting to a nylon cord coated with wax that was removed at the end of the preparation. This network was located at the material’s mid-plane, so that damages originating from either surface could contact the hollow channels. An average recovery of 84 % of the flexural stiffness and 46 % of the loading strength was determined, based on bending tests, after self-healing at ambient conditions, for 24 h. Furthermore, J. F. Patrick et al. [

37] resorted to sacrificial poly(lactic acid) monofilaments arranged in two different patterns through the woven fabric of an epoxy resin based fiber reinforced composite that were removed after the composite’s cure. The healing answer was based on the action of an epoxy resin and an amine-based curing agent, both of low viscosity. The first configuration was parallel, with the mixing of the two components being limited to adjacent layers, while the second one was a herringbone design, where the blending of the healing components was favored by the overlapping of the networks. For that reason, it was concluded that the herringbone design provided higher healing efficiencies for specimens healed at 30 ºC, for 48 h. Additionally, over 100 % healing efficiency as observed due to the higher fracture toughness of the healed polymer, when compared to the structural matrix. Tree successive healing cycles were performed and after each one, higher loads were necessary for the crack to propagate.

Relevant parameters for the microvascular networks include the microchannels’ dimensions, as well as the network feeding mode, the pressure of the vascular system and the viscosity of the repairing agent, to ensure that it is properly distributed. Therefore, if necessary, pumps can be incorporated outside to direct the flow of the repair agent to the damaged areas [1,14,17].

Figure 4.

Manufacturing process of a self-healing composite material consisting of a capillary network: (a) Deposition of the non-permanent material to develop the network of capillaries, (b) Deposition of the matrix material, (c) Solidification of the material, (d) Removal of the non-permanent material and final shape of the composite with the network of capillaries. Adapted from " Progress and challenges in self-healing composite materials" by Shafiqul Islam and Gajanan Bhat, used under CC BY 3.0. [

https://doi.org/10.1039/D0MA00873G] [

1].

Figure 4.

Manufacturing process of a self-healing composite material consisting of a capillary network: (a) Deposition of the non-permanent material to develop the network of capillaries, (b) Deposition of the matrix material, (c) Solidification of the material, (d) Removal of the non-permanent material and final shape of the composite with the network of capillaries. Adapted from " Progress and challenges in self-healing composite materials" by Shafiqul Islam and Gajanan Bhat, used under CC BY 3.0. [

https://doi.org/10.1039/D0MA00873G] [

1].

There is also the possibility of combining the aforementioned approaches based on reservoirs, in order to take advantage of the benefits that each one provides. For example, the resin can be in hollow fibers, while the corresponding curing agent is microencapsulated [

40].