1. Introduction

Kefir grains vary in size from 1 to 4 cm in length and resemble small cauliflower florets with an irregular shape and a color ranging from white to light yellow and are made up of lactose-fermenting and non-lactose-fermenting yeasts [

1]. Kefir is a homemade viscous and slightly effervescent beverage obtained by milk fermentation with kefir grains, which are built up by a complex community of lactic acid and acetic acid bacteria and yeasts confined in a matrix of proteins and polysaccharides and its consumption has been associated with a wide range of functional and probiotic properties that could be attributed to the microorganisms present in kefir and/or to the metabolites synthesized by them during milk fermentation [

2].

Regular consumption of kefir is important for the health of the gastrointestinal tract and has been associated with better digestion, as kefir fermented dairy products generally have β-galactosidase activity and a reduced lactose content compared to milk, making them ideal for those suffering from lactose intolerance [

3,

4]. In addition, kefir has been associated with many other health benefits, including cardiovascular, immune, nervous system, cancer prevention and therapeutic agent in clinical trials [

5]. Its importance in cancer prevention is due to the antimutagenic action and antitumor properties of the lactic acid bacteria in kefir [

6].

Fermented foods with probiotic properties have the ability to modulate the intestinal microbiota, improve the control of intestinal permeability, increase its barrier function and assist in the production of short-chain fatty acids (SCFA) which have an anti-inflammatory and protective effect on the intestinal mucosa [

7,

8]. In this regard, probiotics can improve the immune function of the mucosa of the digestive tract and consequently of the body through the anti-inflammatory effect related to its probiotic microbiota and its own substances metabolized in the intestine, such as (SCFA) [

9]. The role of microbiota-derived (SCFA) in neurological disorders and other diseases associated with intestinal bacterial dysbiosis together with dietary modulation, probiotics, prebiotics and fecal microbiota transplantation are potentially capable of changing inflammatory nervous diseases [

10].

The production of (SCFA), such as butyrate, produced by fermentation in the large intestine by the intestinal microbiota has been shown to be protective against insulin resistance and fatty liver [

11,

12]. A normally low production of butyrate has an effect on the autoimmunity associated with type I diabetes [

13] and may decrease the intestinal microbiota of patients with type II diabetes, compared to healthy individuals [

14]. An imbalance of the intestinal microbiome that affects SCFA-producing bacteria often occurs in patients with inflammatory bowel diseases, irritable bowel syndrome, type 2 diabetes, obesity, autoimmune diseases or in patients with cancer [

15,

16,

17,

18,

19].

Most studies on kefir consumption only focus on the production of short-chain fatty acids present in the intestine. However, there is also a need to investigate the effect of kefir with an emphasis on the production of short-chain fatty acids and also other important fatty acids, such as oleic acid during the fermentation process in food products.

The probiotics available on the market are fermented beverage made with milk, because dairy products serve as an ideal vehicle for the survival of probiotics in gastric juice, as they have a buffering and protective effect. Nevertheless, several challenges remain regarding the stability and functionality of probiotics in dairy products. Cheeses are equally efficient as a vehicle compared to fermented milks and yogurts. Consequently, a new challenge arises in designing and monitoring probiotic foods that can preserve probiotic function until the moment of consumption [

20,

21]. The determination of the fatty acid profile during the fermentation process using kefir in the production of creamy cheese directs future research and possible applications in dairy products richer in fatty acids beneficial to human health.

Our artisan cream cheese with fermented cream with kefir grains is a functional rich in oleic fatty acid and innovative product compared to current products on the market and was well received by the younger public. In this context, the objective of the present study was to develop and characterize cream cheese fermented with kefir grains; determine its fatty acid profile with an emphasis on short-chain fatty acids and carry out sensory analysis of the product's global acceptance. In this context, the objective of the present study was to develop and characterize cream cheese fermented with kefir grains; determine its fatty acid profile with an emphasis on short-chain fatty acids and carry out sensory analysis of the product's global acceptance.

2. Materials and Methods

2.1. Artisan Cheese Cream Fermented with Kefir Grains

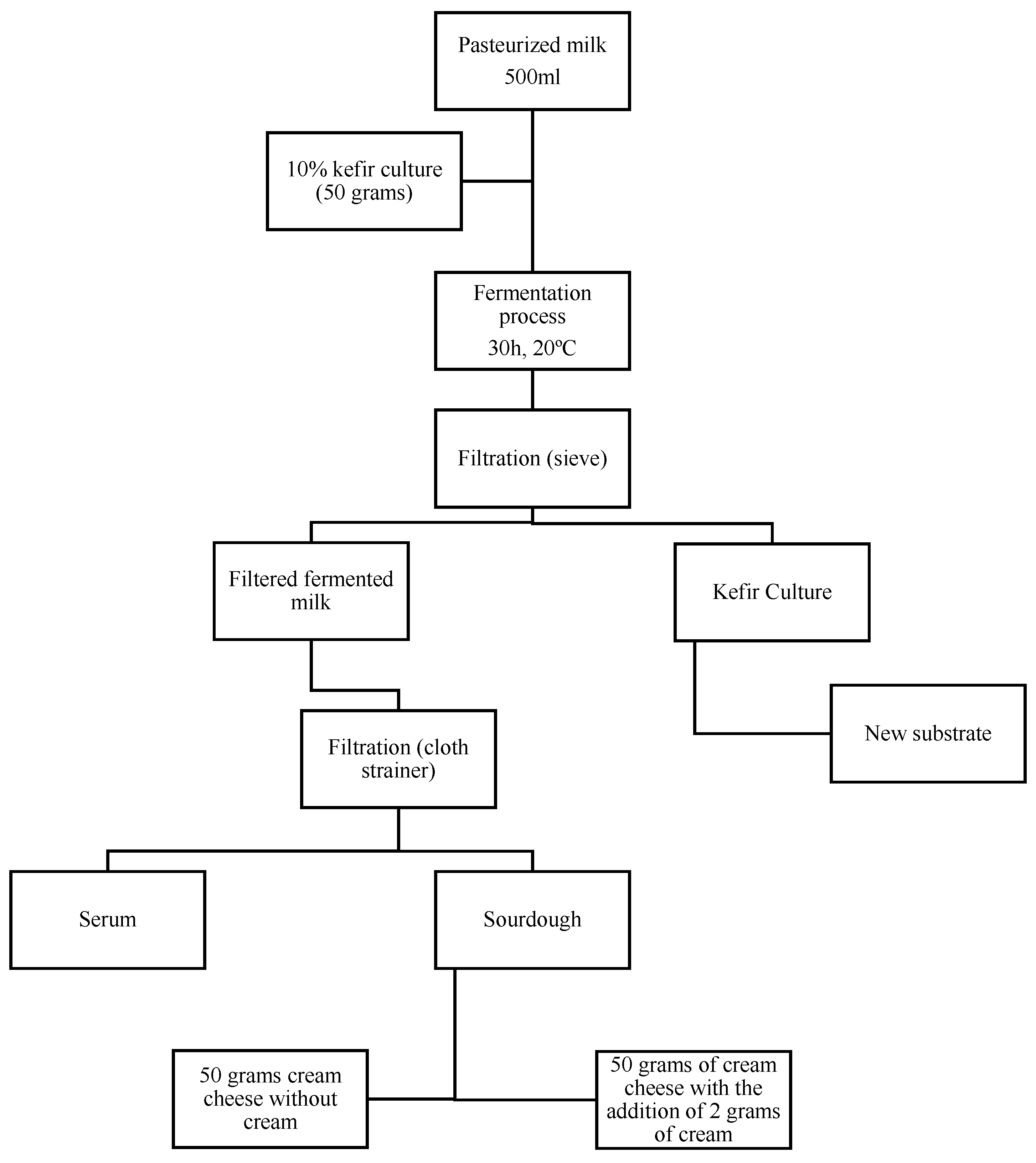

The whole raw milk was pasteurized and at room temperature 50 g of milk kefir grains were added to 500 ml of milk. The fermentation period was 30 hours at a temperature of 20 °C. Subsequently, the sample was filtered through a sieve to remove the kefir grains and then a cloth filter was used to separate the serum and obtain a paste mass (50 g) to which 2 g of cream was added to obtain creamy cheese (

Figure 1).

2.2. Lactic Acid Bacteria Count

The sample was prepared (

Figure 1) according to the methodology [

22]. The total count of viable lactic bacteria was performed using serial dilutions (between 10

-6 and 10

-8) and spreading in plates containing MRS Agar medium and incubation at 37 °C. The number of viable lactic cells was obtained by direct plate count and was expressed in colony forming units (CFU) per mL.

2.3. Soluble Solids, pH, Acidity Measurement, Centesimal Composition and Determination of Carbohydrate Reduction in Lactose

The concentration of soluble solids for brix scale measurements was analyzed in portable analog refractometer (Bel RTS). The pH measurement was analyzed in digital pHmetro (Mettler Toledo). The measurement of acidity, centesimal composition and determination of carbohydrate reduction in lactose was based on the method described by [

23].

2.4. Fatty Acid Profile

For analyze the fatty acid profile, artisanal cream cheese fermented with kefir grains with the addition of cream and without the addition of cream was compared with commercial brand cream cheese.

The sample preparation was based on the method described by [

24,

25]. Methylation of samples according to methodology [

26]. The quantification and identification of short chain fatty acids was performed using undecanonical acid (Chem Service Inc) as internal standard and fatty acid methyl ester (FAME, Sigma Aldrich) and a gas chromatograph with Flame Ionization Detector (FID) detector methodology described by [

27]. Chromatographic Conditions were: column: J&W DB-FastFAME GC Column, 30 m, 0.25 mm, 0.25 µm, 7 inch cage; Column temperature: 250 °C; Runtime: 19 minutes; Injection volume (Loop): 1.0 µl; Split: 50:1; Temperature: 250 °C and 250 °C.

Figure 1.

Flowchart of artisanal production of fermented kefir grains to obtain cream cheese.

Figure 1.

Flowchart of artisanal production of fermented kefir grains to obtain cream cheese.

2.5. Sensory Analysis

A total of 120 people received two samples of the artisanal cream cheese with cream to assess the overall acceptance of the product. The cream cheese was served on toast and people were given a 180 ml glass of water to cleanse their taste buds between one sample and the next. The acceptance test with Hedonic Scale (1-hated to 9-loved it) was applied, and in addition, the questionnaire: 1) Would you buy this product? ( )yes, ( )no, ( ) maybe; 2) Is this product similar to you? ( ) Cottage cheese; ( ) Cream cheese; ( ) Yogurt; ( ) None of the above.

3. Results

This section may be divided by subheadings. It should provide a concise and precise description of the experimental results, their interpretation, as well as the experimental conclusions that can be drawn.

3.1. Lactic Acid Bacteria Count

The samples of cheese cream fermented with kefir grains showed a high amount of lactic bacteria, with an average of colony forming units (CFU) of 5.6 × 10

7 CFU/ml

-1, characterizing a product formed by lactobacilli. To ensure a continuous effect on the human body, Normative Instruction 46/2007 [

28] of the Ministry of Agriculture, Livestock and Supply (Brazil), establishes the minimum count of total lactic bacteria in kefir-based foods of 10

7 CFU/ml

-1. Fermented milk contains 10

9 to 10

10 CFU/mL

-1 of viable lactic acid bacteria [

29]. The kefir microbial community comprises a complex mixture of lactic acid bacteria, acetic acid bacteria and yeasts. Strains of the genus Lactobacillus are recognized for their therapeutic capacity, highlighting their anti-inflammatory and anticarcinogenic activities [

30,

31]. Probiotics are the target of studies due to their functional capacity that covers endocrine, immunological and gastrointestinal aspects. The consumer’s search for foods that offer additional health benefits has grown considerably and, in this sense, industries have sought innovation to meet these expectations.

3.2. Soluble Solids, pH, Acidity Measurement and Determination of Carbohydrate Reduction in Lactose

The values of brix-grade soluble solids in samples of whole milk and whole milk fermented with kefir before and 30 hours after fermentation are 9,2 and 6, respectively. Whole milk fermented with kefir presented significantly lower Brix level (p < 0.05) compared to the initial sample without fermentation. Whole milk fermented with kefir presented lower soluble solids contente. This is because during the fermentation process, kefir consumes milk soluble solids for its growth and converts them into other products and various important metabolites such as peptides, amino acids, vitamins, ethanol and CO2 that contribute to the flavor and aroma of the product [

32,

33].

The pH value decreased and the percentage of lactic acid increased (p < 0.05) in the samples after 30 hours of fermentation, respectively (

Table 1). The pH value decreased and the percentage of lactic acid increased. In the literature, similar pH values were found ranging from 3 to 4 in fermented milk [

34,

35]. The pH can also reduce the level of alcohol produced during the process, for example, using kefir grains to 1% at a pH of 4.5 led to a decrease in alcohol level to 0.3% in goat milk [

36]. Lactic acid is produced from lactose degradation, while diacetyl and acetoin are formed from citric acids and lactose. While acetaldehyde is produced from the degradation of proteins, it is used as a source of growth for microorganisms. Kefir fermentation must contain an acidity of less than 1,0 g of lactic acid/100 g. According to the quality standards of fermented milk, the acidity was within the values determined by the legislation [

37]. Studies found higher acidity values of 0.88 to 1.17 g/100 g in fermented products sold in the country and similar values with average values of 0.87 to 1.20 g/100 g [

34,

35]. the lactic acid value of 1.89 is considered ideal for a kefir grain concentration of 5% [

38].

Table 2 describes the analysis of the reduction of carbohydrates in lactose. A significant reduction (p < 0.05) in lactose was observed after the fermentation process of fermented cheese cream with cream and without cream compared to pasteurized whole milk. A significant reduction in lactose was observed after the fermentation process of fermented cheese cream with cream and without cream compared to pasteurized whole milk. Lactose originally present in fermented beverages undergoes lactic acid fermentation, so its concentration is lower than in processed milk [

39]. This process has already been observed with hard cheeses that have proven to be the most suitable for consumption by people with lactose intolerance. Milk-based probiotic products for vegan and lactose intolerant populations are therapeutic and dietary support for the gastrointestinal tract [

3]. The challenge of the dairy industry is to develop new products with reduced lactose content, but what you see is a range of plant products that do not have the same concentration of vitamins and bioavailable calcium as those found in milk and its derivatives.

3.3. Centesimal Composition

Table 3 describes the centesimal composition of fermented cheese cream without and added cream.

According to the USDA food composition table [

40], when fermented cheese cream without added cream is compared with some commercially available dairy products, it resembles the composition of the whole yogurt sample in (g) (moisture: 85.3, carbohydrates: 5.57, protein: 3.82, lipids: 4.48 and ash: 0.85), but with higher carbohydrate and protein content and compared to ricotta cheese in (g) (moisture: 72.9, carbohydrates: 6.86, protein: 7.81, lipid: 11 and ash: 1.36) has lower protein content, lipids and ashes. In our study, 2 g of cream at 50 g of fermetada per kefir was added to obtain the cream cheese, which adds 4% fat to the product, even lower compared to extra fat cheese with a fat content equivalent to 60%; fat cheese with a content between 45 and 59.9%; semi-fat cheese 25 to 44.9%; low-fat cheese with a content of 10 to 24.9%; skimmed cheese with a content of less than 10%. Commercial cream cheese is characterized by a minimum fat content in the dry extract of 25 g/100 g and a maximum moisture content of 78 g/100 g [

37].

3.4. Fatty Acid Profile

In the analysis of the profile of commercial cream cheese fatty acids, cream of fermented cheese without and with cream (

Table 4), the concentrations of butyric fatty acid (C4:0) to caprice fatty acid (C10:0) stood out in cream of cheese fermented with cream. Probably the addition of cream and/ or the fermentation process itself of the cheese has contributed to the increase of short chain fatty acids in the product. This result counters what most research holds that SCFA are the result of fermentation of complex carbohydrates (fiber and starch) that digestive enzymes are not able to decompose. SCFA production can occur in the product, even before being consumed, this fact adds value to the product and defines its functionalities. [

7,

8,

41] the SCFA has the ability to modulate the intestinal microbiota, improve the control of intestinal permeability, increase its barrier function, anti-inflammatory action, activation of digestive enzymes.

Saturated fatty acids with the potential to develop cardiovascular diseases such as lauric, myristic, palmitic and stearic fatty acids were higher in fermented cream cheese with cream than in commercial cream cheese. The amount of saturated fatty acids in dairy fat can vary depending on the type of milk and the production process, but in general, dairy fat contains about 60% of saturated fatty acids that are mainly long-chain, including lauric acid, palmitic acid and stearic acid [

42]. Previously, all saturated fatty acids such as myristic, palmitic and stearic were related to the increase in the concentrations of LDL cholesterol and apolipoprotein B [

43] but, the stearic fatty acid reduced LDL cholesterol, was neutral in relation to HDL cholesterol and reduced directionally the ratio between total cholesterol and HDL cholesterol [

44]. On the other hand, palmitic acid did not present associations with cardiovascular risk factors or with inflammatory markers and stearic acid was neutral on blood lipids but is associated with biomarkers of inflammatory and endothelial dysfunction in individuals with cardiovascular risk [

45].

Table 4.

Fatty acid profile in commercial cream cheese brand, fermented cream cheese without cream and fermented cream cheese with cream.

Table 4.

Fatty acid profile in commercial cream cheese brand, fermented cream cheese without cream and fermented cream cheese with cream.

Acido Graxo

Trivial names (g/100 g) |

Cream Cheese Commercial |

Cream of Cheese

Fermented without Cream |

Cream of Cheese Fermented with Cream |

| C4:0 (butyric) |

0,01b ± 0,01 |

0,004c ± 0,00 |

0,08a ± 0,00 |

| C6:0 (caproic) |

0,02b ± 0,02 |

0,004c ± 0,00 |

0,08a ± 0,05 |

| C8:0 (caprylic) |

0,01b ± 0,01 |

0,002c ± 0,00 |

0,06a ± 0,03 |

| C10:0 (capric) |

0,04b ± 0,02 |

0,014c ± 0,00 |

0,15a ± 0,05 |

| C12:0 (laurico) |

0,08b ± 0,03 |

0,039c ± 0,00 |

0,22a ± 0,06 |

| C14:0 (myristico) |

0,37a ± 0,08 |

0,209c ± 0,01 |

0,95a ± 0,28 |

| C14:1 (myristoleic) |

0,03b ± 0,01 |

0,014c ± 0,00 |

0,08a ± 0,02 |

| C15:0 (pentadecanoic) |

0,04b ± 0,01 |

0,031c ± 0,00 |

0,11a ± 0,03 |

| C16:0 (palmitic) |

1,62c ± 0,01 |

0,973b ± 0,08 |

1,84a ± 0,20 |

| C16:1 (trans-palmitolaidic) |

0,05b ± 0,01 |

0,031c ± 0,00 |

0,13a ± 0,03 |

| C17:0 (heptadecanoic) |

0,03b ± 0,00 |

0,028b ± 0,00 |

0,08a ± 0,03 |

| C18:0 (stearic) |

0,79c ± 0,00 |

0,929b ± 0,10 |

1,51a ± 0,66 |

| C18:1 n9 (oleic) |

1,24c ± 0,06 |

1,401b ± 0,14 |

3,26a ± 0,17 |

| C18:2 n6 (linoleic) |

0,08b ± 0,01 |

0,071c ± 0,00 |

0,13a ± 0,04 |

| C20:0 (arachidic) |

0,10c ± 0,01 |

0,175b ± 0,02 |

0,26a ± 0,05 |

| C22:0 (beenic) |

0,00a ± 0,00 |

0,008a ± 0,00 |

0,01a ± 0,00 |

| C20:4 (arachidonic) |

0,00a ± 0,00 |

0,01a ± 0,00 |

0,08a ± 0,00 |

| Total fatty acids |

| Saturated |

3,13b |

2,43c |

5,35a |

| Unsaturated |

1,60b |

1,35c |

7,62a |

| Trans fatty acid |

0 |

0 |

0 |

| Monounsaturated |

1,31c |

1,45b |

3,47a |

| Polyunsaturated |

0,09b |

0,09b |

0,15a |

| Omega 3 |

0c |

0,01b |

0,02a |

| Omega 6 |

0,08b |

0,08b |

0,45a |

| Omega 9 |

1,24c |

1,40b |

3,30a |

Although the saturated fatty acids were higher in increasing order in cream cheese with cream, cream cheese without cream and in commercial cream cheese, it was also observed that the concentration of unsaturated was also higher and the monounsaturated were highlighted, concentration of oleic fatty acid (C18:1 ω9). In this sense, fermented cheese creams with and without cream showed a profile of fatty acids that contribute to a healthier diet. The review by [

46] reports that oleic fatty acid is an antitumor agent in different types of cancer and mainly has antiproliferative action including suppression of migration and proliferation of breast cancer cells, as well as stimulation of tumor suppressor genes. In some studies a diet rich in oleic fatty acid has positive results in disorders related to inflammation and protects against metabolic syndrome and risk factors for cardiovascular diseases [

47,

48,

49]. Replacing 1% of lauric and palmitic acids with Mono or Polyunsaturated fatty acids reduces the risk of coronary heart disease. This effect is associated with the impact of unsaturated plasma lipids that reduced the concentrations of total cholesterol (TC), low density lipoprotein (LDL) and high density lipoprotein (HDL) [

50].

3.5. Sensory Analysis

In the overall evaluation of product acceptance, the majority of the participants in the research, 71.7% were female. The predominance of age was in the age group from 21 to 25 years (37%), under 20 years (36%). On average 14% of the survey participants answered that they liked it slightly, 24% liked it moderately, 24% liked it very much, 18% loved it and only 1 to 3% disliked the artisanal cheese cream with cream fermented with kefir grains. Regarding the questionnaire question: would you buy this product? 60% answered yes, 30% answered maybe and 10% answered no and for you this product resembles? ( ) Cottage cheese; ( ) Creamy cheese; ( ) Yogurt; ( ), 44.17% answered that the product resembles yogurt, due to the acidity present in the product, 27.5% resembles a creamy cheese, due to its firmer consistency, less moist, 25% found similar to curd and 3,33% none of the alternatives. In the overall evaluation of product acceptance, generally speaking, the artisanal cheese cream with cream fermented with kefir grains was well accepted by the young public and and 60% responded that they would buy the product.

4. Conclusions

The artisanal cheese cream fermented with kefir grains is a functional product with an innovative character compared to current products on the market and was well accepted by the younger audience.

The artisanal cheese cream by the presence of short chain fatty acids and oleic fatty acid, high amount of lactic bacteria characterizing the product formed by lactobacilli and low concentration of lactose due to the fermentation process, comes as an option for those who need to change their eating habits and maintain a healthy lifestyle.

Author Contributions

The authors’ responsibilities were as follows—MRM, DRF: conceived the manuscript; ESK: collaborated with laboratory analyzes; DRF; analyzed data; MRM, DRF: wrote the manuscript; MRM: supervised and revised the manuscript; MRM: had primary responsibility for the final content; and approved subsequent drafts of the manuscript; and all authors: read and approved the final manuscript. All authors have read and agreed to the publishing version of the manuscript.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are inclued in the article, further inquires can be directed to the corresponding author.

Acknowledgments

This study was carried out with the support of the Coordination of Improvement of Higher Education Personnel - Brazil (CAPES).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Braccini, V.P.; Arbello, D.D.R.; Erhardt, M.M.; Jiménez, M.S.E.; Pedroso, M.A.P.; Richards, N.S. Leite fermentado: kefir. Brazilian Journal of Development 2021, 7, 21121–21135. [Google Scholar] [CrossRef]

- Bengoa, A.A.; Iraporda, C.; Garrote, G.L.; Abraham, A.G. Kefir micro-organisms: their role in grain assembly and health properties of fermented milk. Journal of Applied Microbiology 2019, 126, 686–700. [Google Scholar] [CrossRef] [PubMed]

- Maldonado, R.R.; Aguiar-Oliveira, E.; Kamimura, E.S.; Mazalli, M.R. Kefir and Kombucha Beverages: New Substrates and Nutritional Characteristics. In Fermented Food Products; CRC Press, 2020; pp. 295–295. [Google Scholar]

- de Souza, H.F.; Monteiro, G.F.; Bogáz, L.T.; Freire, E.N.S.; Pereira, K.N.; de Carvalho, M.V.; Kamimura, E.S. Bibliometric analysis of water kefir and milk kefir in probiotic foods from 2013 to 2022: A critical review of recent applications and prospects. Food Research International 2023, 113716. [Google Scholar] [CrossRef] [PubMed]

- Bessa, M.K.; Bessa, G.R.; Bonamigo, R.R. Kefir as a therapeutic agent in clinical research: a scoping review. Nutrition Research Reviews 2023, 1–42. [Google Scholar] [CrossRef] [PubMed]

- Azizi, N.F.; Kumar, M.R.; Yeap, S.K.; Abdullah, J.O.; Khalid, M.; Omar, A.R.; Alitheen, N.B. Kefir and its biological activities. Foods 2021, 10, 1210. [Google Scholar] [CrossRef] [PubMed]

- Bell, V.; Ferrão, J.; Pimentel, L.; Pintado, M.; Fernandes, T. One health, fermented foods, and gut microbiota. Foods 2018, 7, 195. [Google Scholar] [CrossRef] [PubMed]

- Peluzio, M.D.C.G.; Dias, M.M.E.; Martinez, J.A.; Milagro, F.I. Kefir and intestinal microbiota modulation: Implications in human health. Front Nutr 2021, 22, 638740. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; Wang, J.; Du, L.; Chen, J.; Zheng, Q.; Li, P.; Liao, Z. Kefir microbiota and metabolites stimulate intestinal mucosal immunity and its early development. Critical Reviews in Food Science and Nutrition 2024, 64, 1371–1384. [Google Scholar] [CrossRef] [PubMed]

- Mirzaei, R.; Bouzari, B.; Hosseini-Fard, S.R.; Mazaheri, M.; Ahmadyousefi, Y.; Abdi, M.; Karampoor, S. Role of microbiota-derived short-chain fatty acids in nervous system disorders. Biomedicine & Pharmacotherapy 2021, 139, 111661. [Google Scholar] [CrossRef]

- Mollica, M.P.; Mattace Raso, G.; Cavaliere, G.; Trinchese, G.; De Filippo, C.; Aceto, S.; Meli, R. Butyrate regulates liver mitochondrial function, efficiency, and dynamics in insulin-resistant obese mice. Diabetes 2017, 66, 1405–1418. [Google Scholar] [CrossRef]

- Gonzalez, A.; Krieg, R.; Massey, H.D.; Carl, D.; Ghosh, S.; Gehr, T.W.; Ghosh, S.S. Sodium butyrate ameliorates insulin resistance and renal failure in CKD rats by modulating intestinal permeability and mucin expression. Nephrology Dialysis Transplantation 2019, 34, 783–794. [Google Scholar] [CrossRef] [PubMed]

- Tanca, A.; Palomba, A.; Fraumene, C.; Manghina, V.; Silverman, M.; Uzzau, S. Clostridial butyrate biosynthesis enzymes are significantly depleted in the gut microbiota of nonobese diabetic mice. Msphere 2018, 3, 10-1128. [Google Scholar] [CrossRef]

- Zheng, Y.; Ley, S.H.; Hu, F.B. Global aetiology and epidemiology of type 2 diabetes mellitus and its complications. Nature Reviews Endocrinology 2018, 14, 88–98. [Google Scholar] [CrossRef] [PubMed]

- Sun, M.; Wu, W.; Liu, Z.; Cong, Y. Microbiota metabolite short chain fatty acids, GPCR, and inflammatory bowel diseases. J. Gastroenterol. 2017, 52, 1–8. [Google Scholar] [CrossRef]

- Hu, J.; Lin, S.; Zheng, B.; Cheung, P.C.K. Short-chain fatty acids in control of energy metabolism. Crit. Rev. Food Sci. Nutr. 2018, 58, 1243–1249. [Google Scholar] [CrossRef]

- Nagpal, R.; Wang, S.; Ahmadi, S.; Hayes, J.; Gagliano, J.; Subashchandrabose, S.; Kitzman, D.W.; Becton, T.; Read, R.; Yadav, H. Human-origin probiotic cocktail increases short-chain fatty acid production via modulation of mice and human gut microbiome. Sci. Rep. 2018, 8, 12649. [Google Scholar] [CrossRef]

- Markowiak-Kopeć, P.; Śliżewska, K. The effect of probiotics on the production of short-chain fatty acids by human intestinal microbiome. Nutrients 2020, 12, 1107. [Google Scholar] [CrossRef]

- Singh, V.; Lee, G.; Son, H.; Koh, H.; Kim, E.S.; Unno, T.; Shin, J.H. Butyrate producers, “The Sentinel of Gut”: Their intestinal significance with and beyond butyrate, and prospective use as microbial therapeutics. Frontiers in Microbiology 2023, 13, 1103836. [Google Scholar] [CrossRef] [PubMed]

- Gao, J.; Li, X.; Zhang, G.; Sadiq, F.A.; Simal-Gandara, J.; Xiao, J.; Sang, Y. Probiotics in the dairy industry-Advances and opportunities. Comprehensive Reviews in Food Science and Food Safety 2021, 20, 3937–3982. [Google Scholar] [CrossRef]

- Furse, S.; Torres, A.G.; Koulman, A. Fermentation of milk into yoghurt and cheese leads to contrasting lipid and glyceride profiles. Nutrients 2019, 11, 2178. [Google Scholar] [CrossRef]

- Silva, N. Manual de métodos de análise microbiológica de alimentos, 3nd ed.; Livraria Varela: São Paulo, 2007. [Google Scholar]

- Instituto Adolfo Lutz. Métodos físicos-químicos para análise de alimentos (IV). São Paulo, 2008. [Google Scholar]

- Mazalli, M.R.; Saldanha, T.; Bragagnolo, N. Determinação de colesterol em ovos: comparação entre um método enzimático e um método por cromatografia líquida de alta eficiência. Revista do Instituto Adolfo Lutz 2003, 62, 49–54. [Google Scholar] [CrossRef]

- Ortiz, C.M.L.; Moya, M.S.P.; Navarro, V.B. A rapid chromatogr aphic method for simultaneous determination of β-sitosterol and tocopherol homologues in vegetable oils. Journal of Food Composition and Analysis 2006, 19, 141–149. [Google Scholar] [CrossRef]

- Kramer, J.K.; Fellner, V.; Dugan, M.E.; Sauer, F.D.; Mossoba, M.M.; Yurawecz, M.P. Evaluating acid and base catalysts in the methylation of milk and rumen fatty acids with special emphasis on conjugated dienes and total trans fatty acids. Lipids 1997, 32, 1219–1228. [Google Scholar] [CrossRef]

- Metz, P.A.M.; Menezes, L.F.G.D.; Santos, A.P.D.; Brondani, I.L.; Restle, J.; Lanna, D.P.D. Perfil de ácidos graxos na carne de novilhos de diferentes idades e grupos genéticos terminados em confinamento. Revista Brasileira De Zootecnia 2009, 38, 523–531. [Google Scholar] [CrossRef]

- Brasil. Ministério da Agricultura Pecuária e Abastecimento. Instrução Normativa no 46, de 23 de outubro de 2007. Regulamento técnico de identidade e qualidade de leites fermentados. Diário Oficial da República Federativa do Brasil, Brasília, DF. 2007. Available online: https://www.cidasc.sc.gov.br/inspecao/files/2019/09/INSTRUÇÃO-NORMATIVA-N-46-de-23-de-outubro-de-2007-Leites-Fermentados.pdf (accessed on 10 May 2024).

- Bengoa, A.A.; Iraporda, C.; Acurcio, L.B.; de Cicco Sandes, S.H.; Costa, K.; Guimarães, G.M.; Abraham, A.G. Physicochemical, immunomodulatory and safety aspects of milks fermented with Lactobacillus paracasei isolated from kefir. Food Research International 2019, 123, 48–55. [Google Scholar] [CrossRef]

- Bousmaha-Marroki, L.; Boutillier, D.; Marroki, A.; Grangette, C. In vitro anti-staphylococcal and anti-inflammatory abilities of lacticaseibacillus rhamnosus from infant gut microbiota as potential probiotic against infectious women mastitis. Probiotics Antimicrob Proteins 2021, 13, 970–981. [Google Scholar] [CrossRef]

- Zhao, X.; Zhong, X.; Liu, X.; Wang, X.; Gao, X. Therapeutic and improving function of lactobacilli in the prevention and treatment of cardiovascular-related diseases: a novel perspective from gut microbiota. Frontiers in Nutrition 2021, 8, 693412. [Google Scholar] [CrossRef] [PubMed]

- Karaçali, R.; Özdem, I.R.N.; Çon, A.H. Aromatic and functional aspects of kefir produced using soya milk and Bifidobacterium species. Int. J. Dairy Technol. 2018, 71, 921–933. [Google Scholar] [CrossRef]

- Sharma, H.; Ozogul, F.; Bartkiene, E.; Rocha, J.M. Impact of lactic acid bacteria and their metabolites on the techno-functional properties and health benefits of fermented dairy products. Critical Reviews in Food Science and Nutrition 2023, 63, 4819–4841. [Google Scholar] [CrossRef]

- Araújo, T.F.; Sant’Anna, M.D.S.L.; Rodrigues, V.C.; Costa, É.C.; de Almeida Paula, H.A.; Teixeira, T.F.S. Avaliação do perfil de conformidade de diferentes leites fermentados com a legislação brasileira de alimentos. Revista do Instituto de Laticínios Cândido Tostes 2011, 66, 40–45. https://revistadoilct.com.br/rilct/article/view/167.

- de Medeiros, E.J.L.; de Lima, A.R.C.; Moura, M.D.; Moreira, R.T. Leite fermentado de marcas comerciais: estudo da aceitação e correlação com ph e acidez. Revista do Instituto de Laticínios Cândido Tostes 2011, 66, 46–51. https://rilct.emnuvens.com.br/rilct/article/view/175.

- Setyawardani, T.; Rahardjo, A. Physiochemical and organoleptic features of goat milk kefir made of different kefir grain concentration on controlled fermentation. Anim. Prod. J. 2014, 16, 48–54. http://animalproduction.net/index.php/JAP/article/view/444.

- Brasil. Ministério da Agricultura Pecuária e Abastecimento. Instrução Normativa No 71, de 24 de julho de 2020. Secretaria de Defesa Agropecuária (2020). Available online: https://wikisda.agricultura.gov.br/dipoa_baselegal/in_71-2020_rt_cream_chesse.pdf (accessed on 10 May 2024).

- Triwibowo, B.; Wicaksono, R.; Antika, Y.; Ermi, S.; Jarmiati, A.; Setiadi, A.A.; Syahriar, R. The effect of kefir grain concentration and fermentation duration on characteristics of cow milk-based kefir. Journal of Physics: Conference Series 2020, 1444, 012001. [Google Scholar] [CrossRef]

- Czyżak-Runowska, G.; Wójtowski, J.A.; Łęska, B.; Bielińska-Nowak, S.; Pytlewski, J.; Antkowiak, I.; Stanisławski, D. Lactose content and selected quality parameters of sheep milk fermented beverages during storage. Animals 2022, 12, 3105. [Google Scholar] [CrossRef]

- USDA. Nutrient Database for Standard Reference. Food Data Central, 2023. Available online: https://fdc.nal.usda.gov/data-documentation.html (accessed on May 2024).

- Batista, M.C.M.; De Jesus, K.A.; Freitas, F.M.N. de O. Evaluation of the effects of kefir on the intestinal microbiota. Brazilian Journal of Development 2021, 7, 93727–93744. [Google Scholar] [CrossRef]

- Bhupathi, V.; Mazariegos, M.; Cruz Rodriguez, J.B.; Deoker, A. Dairy intake and risk of cardiovascular disease. Current Cardiology Reports 2020, 22, 1–6. [Google Scholar] [CrossRef]

- Zock, P.L.; De Vries, J.H.; Katan, M.B. Impact of myristic acid versus palmitic acid on serum lipid and lipoprotein levels in healthy women and men. Arterioscler Thromb 1994, 14, 567–575. [Google Scholar] [CrossRef] [PubMed]

- Hunter, J.E.; Zhang, J.; Kris-Etherton, P.M. Cardiovascular disease risk of dietary stearic acid compared with trans, other saturated, and unsaturated fatty acids: a systematic review. Am J Clin Nutr 2010, 91, 46–63. [Google Scholar] [CrossRef]

- Gonçalinho, G.H.F.; Sampaio, G.R.; Soares-Freitas, R.A.M.; Damasceno, N.R.T. Stearic Acid, but not Palmitic Acid, is Associated with Inflammatory and Endothelial Dysfunction Biomarkers in Individuals at Cardiovascular Risk. Arquivos Brasileiros de Cardiologia 2023, 120, e20220598. [Google Scholar] [CrossRef]

- Farag, M.A.; Gad, M.Z. Omega-9 fatty acids: potential roles in inflammation and cancer management. Journal of Genetic Engineering and Biotechnology 2022, 20, 48. [Google Scholar] [CrossRef]

- Carrillo, C.; Cavia Mdel, M.; Alonso-Torre, S. Role of oleic acid in immune system; mechanism of action: a review. Nutr Hosp 2012, 27, 978–990. [Google Scholar] [CrossRef] [PubMed]

- Gillingham, L.G.; Harris-Janz, S.; Jones, P.J. Dietary monounsaturated fatty acids are protective against metabolic syndrome and cardiovascular disease risk factors. Lipids 2011, 46, 209–228. [Google Scholar] [CrossRef] [PubMed]

- Arsic, A.; Stojanovic, A.; Mikic, M. Oleic acid-health benefits and status in plasma phospholipids in the Serbian population. Experimental and Applied Biomedical Research (EABR) 2019, 20, 3–8. [Google Scholar] [CrossRef]

- Izar, M.C.D.O.; Lottenberg, A.M.; Giraldez, V.Z.R.; Santos Filho, R.D.D.; Machado, R.M.; Bertolami, A.; Machado, V.A. Position statement on fat consumption and cardiovascular health. Arquivos Brasileiros de Cardiologia 2021, 116, 160–212. [Google Scholar] [CrossRef] [PubMed]

Table 1.

Values of pH and percentage of lactic acid in samples of pasteurized whole milk and whole milk fermented with kefir before and after fermentation.

Table 1.

Values of pH and percentage of lactic acid in samples of pasteurized whole milk and whole milk fermented with kefir before and after fermentation.

Whole milk

before fermentation |

Whole milk fermented with kefir

30 hours after fermentation |

| pH |

| 6,67 a |

3,94 b |

| 6,72 a |

3,92 b |

| 6,73 a |

3,93 b |

| 6,71 ± 0,03 a |

3,93 ± 0,01 b |

| 6,67 a |

3,94 b |

| % lactic acid |

| 0,32103 b |

0,50271 a |

| 0,33149 b |

0,62922 a |

| 0,34483 b |

0,79341 a |

| 0,33 ± 0,01 b |

0,64 ± 0,08 a |

Table 1.

Analysis of the reduction of reducing carbohydrates in lactose.

Table 1.

Analysis of the reduction of reducing carbohydrates in lactose.

| % |

Pasteurized whole milk |

Fermented Cheese Cream with Cream |

Fermented Cream Cheese without Cream |

| Total carbohydrates |

3,71a |

2,46b |

1,97c |

| Glucose-reducing carbohydrates |

3,73a |

2,46b |

2,07c |

| Total carbohydrates in Glucose |

3,71a |

2,46b |

1,97c |

| Lactose |

5,19a |

3,42b |

2,88c |

| Sucrose |

0 |

0 |

0 |

Table 3.

Centesimal composition.

Table 3.

Centesimal composition.

| (%) |

Fermented Cream Cheese without Cream |

Fermented Cheese Cream with Cream |

| Humidity |

80,4 |

80,1 |

| Carbohydrates |

8,9 |

8,9 |

| Protein |

5,7 |

5,7 |

| Lipid |

4,3 |

4,6 |

| Ashes |

0,7 |

0,7 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).