1. Introduction

The exponential growth of the vehicle fleet in recent decades has generated a significant increase in polluting emissions, becoming one of the leading environmental challenges at a global level [

1]. Road vehicle growth in developed and developing countries is projected to increase by 45% by 2025, affecting traffic, traffic density, and emissions [

2]. In 2023, the EU approved a series of Commission suggestions to align the EU's climate, energy, transport, and taxation policies to reduce net greenhouse gas emissions by at least 55% by 2030, compared to 1990 levels. This initiative aims to make the EU the first climate-neutral continent by 2050 [

3]. Therefore, reducing environmental pollutant emissions from internal combustion engines (ICEs) requires the development of more efficient engines in terms of fuel consumption, emission generation, and power density [

4]. Harmful components of engine exhaust gases include nitrous oxides (NOx), carbon dioxide (CO

2), carbon monoxide (CO), hydrocarbons (HC), and particulate matter (PM) [

5] which have a direct impact on air quality and are a significant risk factor for human health, contributing to global warming and acid rains [

6].

ICEs are complex systems involving various components: lubrication, friction, charge cycles, supercharging, mixture formation, ignition, combustion systems, electronics and mechanics for engine management, transmission shift control, powertrain, sensors, actuators, cooling, exhaust emissions, operating fluids, filtration, etc., providing alternatives to optimize its performance [

7]. One of these alternatives to reduce fuel consumption and, therefore, minimize the emission of polluting gases into the environment is based on lowering mechanical losses and increasing engine efficiency [

8]. In this regard, strategies have been developed to reduce these losses in the ICEs [

9,

10,

11,

12,

13].

Hybrid surface modification techniques, such as coatings, textures, and nanoparticles, can improve the tribological performance of engine components [

14]. Improving surface coatings through micro-reliefs on the inner surface of cylinder liners can reduce mechanical losses in internal combustion engines by an average of 10.8% and increase mechanical efficiency by 4.0% [

10,

15]. Hazar et al. propose coating engine components with MgO-ZrO

2 and ZrO

2 which provides a thermal barrier, increasing engine power and reducing fuel consumption while improving pollutant emissions [

16].

On the other hand, downsizing internal combustion engines can improve fuel utilization, reduce emissions, and increase efficiency by reducing the weight of moving parts such as pistons and crankshafts [

17,

18] which can reduce CO

2 emissions by about 18% in warm engine conditions for mid-class vehicles [

19]. Podrigalo et al. conclude that a rational reduction in effective engine capacity can lead to a 9.5% reduction in fuel consumption while maintaining the specified maximum speed and dynamic properties of cars [

20]. Likewise, reducing the gap between compression rings and increasing the twist angle can help reduce leakage flows by 37% and contribute to minimizing global emissions [

21].

Similarly, the use of low-viscosity oils (LVO) is adopted to reduce mechanical losses in ICEs due to the ease of implementation costs versus the advantages of reducing pollutant emissions and fuel consumption [

12,

22,

23,

24]. These oils reduce frictional power loss and wear load on compression ring surfaces, leading to maximum fuel economy in internal combustion engines [

25]. LVO can reduce fuel consumption by around 2% in light-duty diesel engines [

22], and 5% in urban transport buses [

26] depending on the test conditions, offering a cost-effective way to increase engine efficiency and reduce CO

2 emissions. Hawley et al. determine up to 3.5% fuel economy improvement in engines using lower-viscosity lubricants, compared to current production lubricants [

27]. In the same way, Ishizaki et al. conclude that ultra-low viscosity engine oils can reduce CO

2 emissions by 0.6% in 1.5-1.8 L gasoline engines in New European Driving Cycles (NEDC) mode and improve fuel efficiency in passenger vehicles, but their cost-effectiveness depends on both viscosity reduction and oil drain interval extension [

28]. However, the use of low-viscosity oils in ICE results in magnified wear due to thinner oil films and requires additional wear protection additives for effective performance [

29,

30].

Another factor that significantly affects fuel consumption and pollutant emissions is altitude. These altitude changes have a direct impact on the performance, fuel consumption, and emissions of ICEs [

31]. Diesel vehicles, in particular, have higher CO

2, CO, and NOx emission factors than gasoline vehicles. These emissions increase with altitude because there is lower atmospheric pressure, temperature, and oxygen concentration, resulting in reduced combustion efficiency in automotive engines with atmospheric pressure being the primary environmental factor affecting emissions [

32] by lengthening the ignition delay, increasing energy release, and prolonging the late combustion period, leading to reduced thermal and combustion efficiency [

33]. Wan et al. declare that as altitude increases from 0 to 2000 meters, engine torque drops by 2.9%, BSFC increases by 2.6%, NOx emissions reduce by 11.8%, and opacity smoke increases by 26.2% [

34], while He et al. state that high altitude increases diesel engine emissions of HC, CO, and smoke, with average increases of 30%, 34%, and 35% at 1000 meters [

35]. NOx emissions vary with engine types and working conditions [

36].

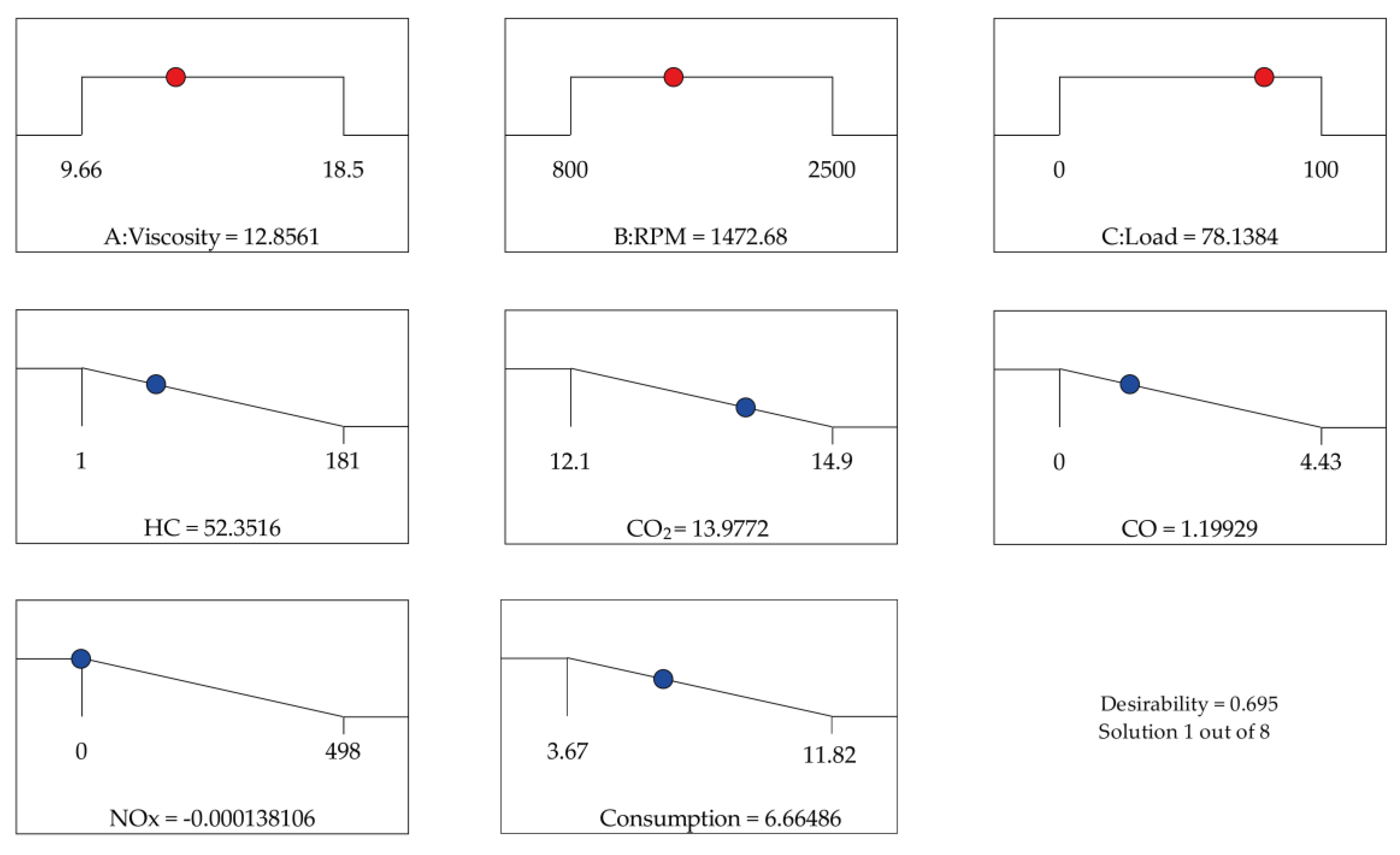

4. RSM Based Optimization

An RSM-based optimization is a method to explore the shape and location of the maximum or minimum of a surface that mathematically represents the relationship between one or more responses and the influencing factors. In the current work, the emissions and fuel consumption of the engine are optimized. In this setup, shown in

Table 15, the goal of minimum criteria was selected. Moreover, the default in the range criterion for study factors was selected.

The engine operating conditions identified by optimization were 13 sCt for viscosity, 1473 rpm, and 78% engine load, rounded to the nearest whole number. The response variables, corresponding to optimized operating conditions, were 52.35 ppm of HC, 13.97 % Vol of CO

2, 1.2 % Vol of CO, 0 ppm for NOx, and 6.66 l/h for consumption. The optimum gained values of study factors and response variables are shown by the red and blue dots in

Figure 8.

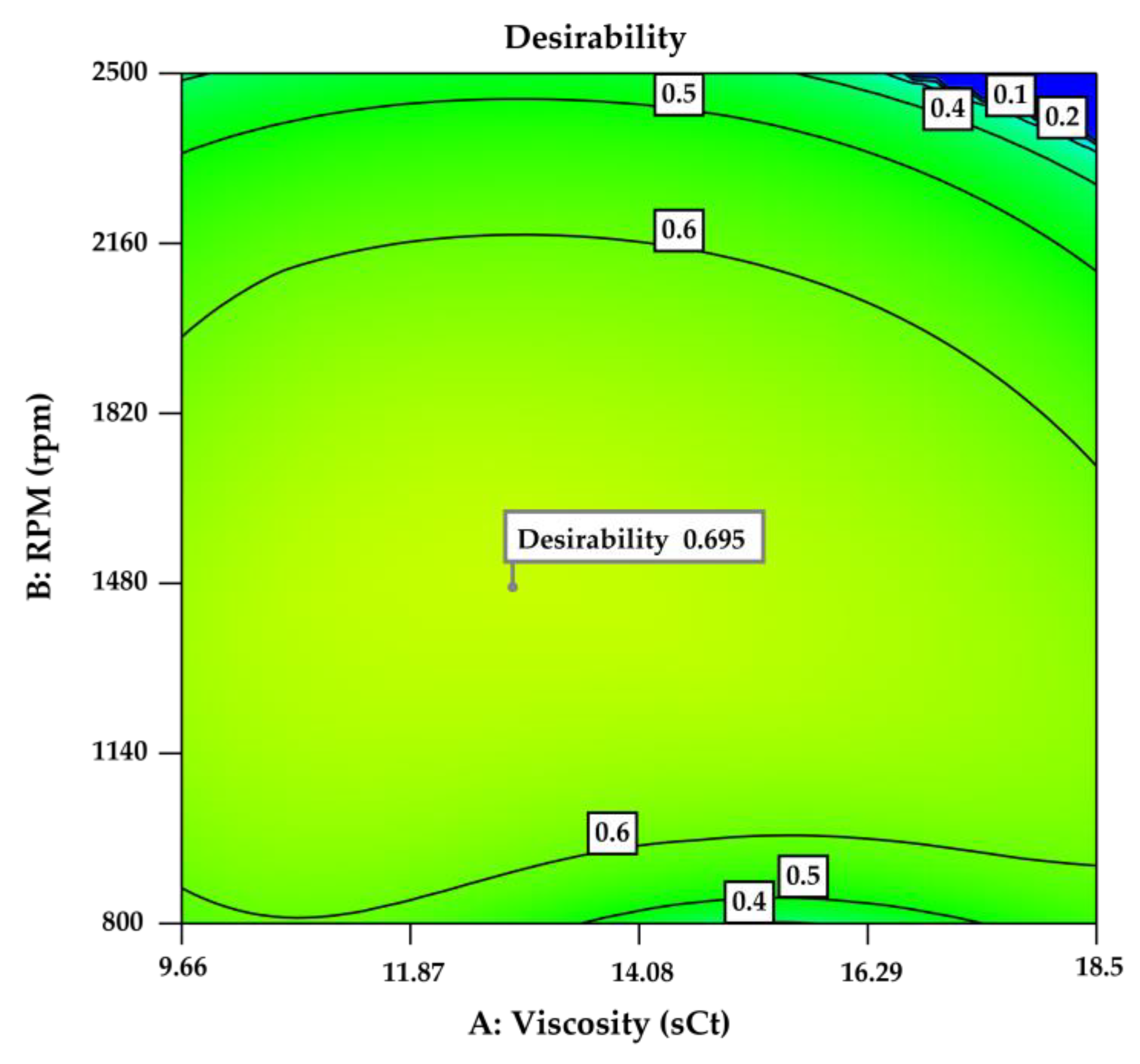

The statistical analysis of optimization and its impact on overall responses was examined using composite desirability (D). This metric, which ranges from 0 to 1, assigns a value of 1 to the best outcomes and 0 to the worst. In this study, the composite desirability achieved a value of 0.695, indicating that the optimization settings yielded positive results for all responses.

Figure 9 displays the contour plot of desirability.

5. Discussion

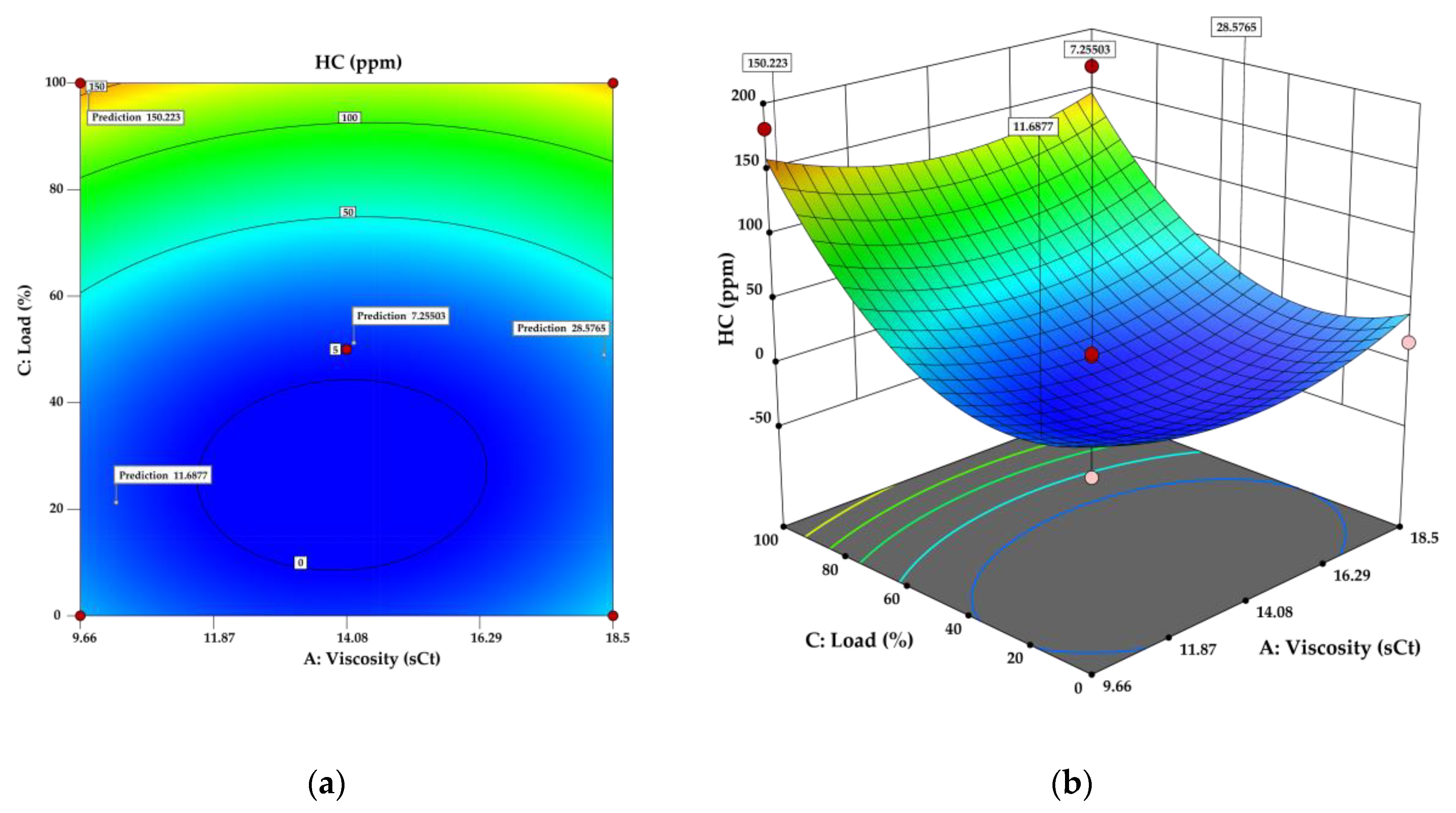

The findings of this study underscore the significant influence of oil viscosity on pollutant emissions and fuel consumption in internal combustion engines at high altitudes, as evidenced by ANOVA analyses. Reducing HC emissions to 7.25 ppm with low-viscosity oils and reduced load highlights that appropriate lubricant selection could be an effective strategy to meet stricter environmental regulations without compromising engine performance. These results are consistent with previous studies, which demonstrated that lower-viscosity lubricants can reduce internal engine friction, thus decreasing pollutant emissions.

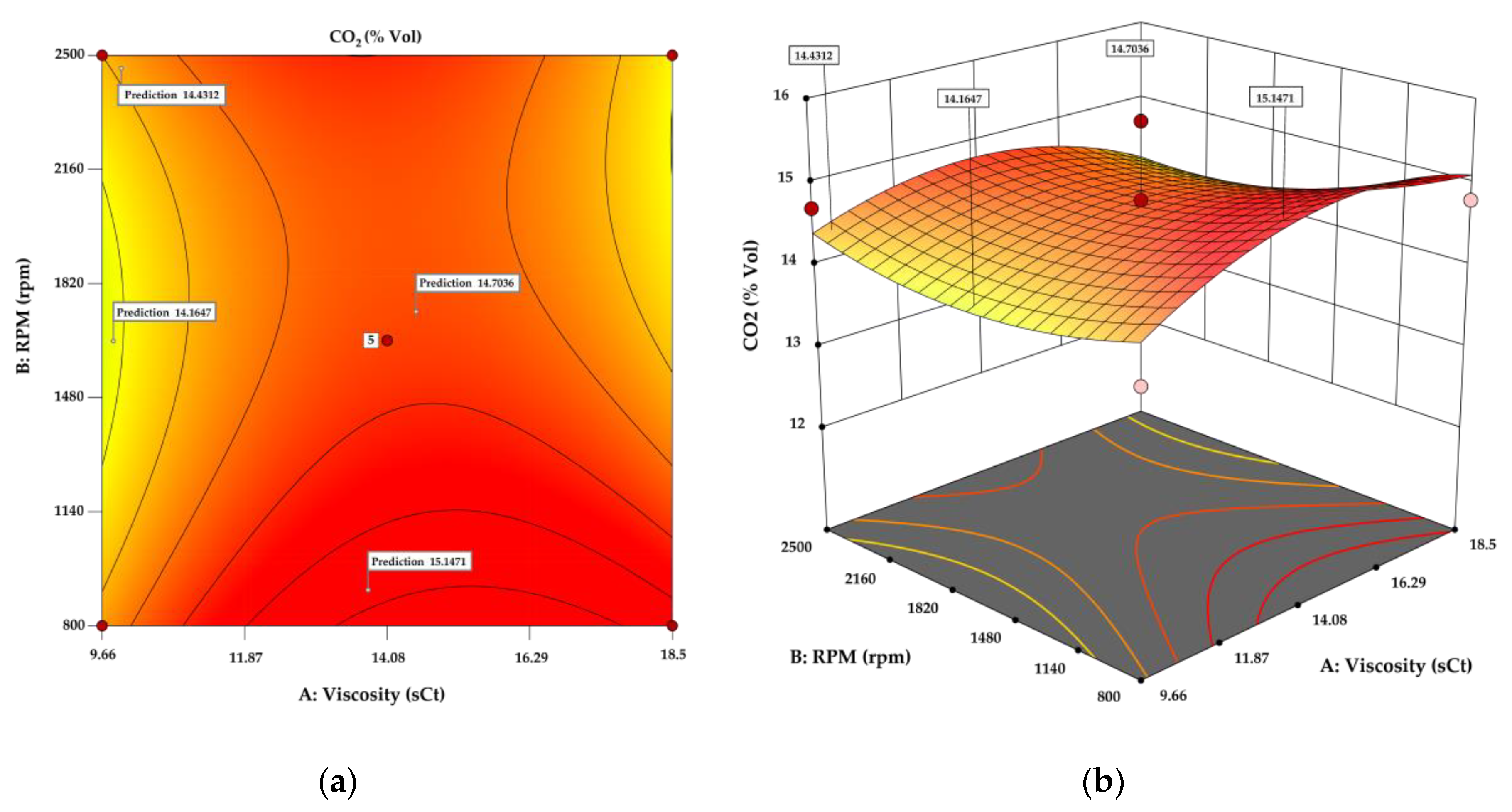

Moreover, the peak in CO2 emissions observed with high-viscosity oils under heavy loads underscores the direct relationship between engine operating conditions and the production of greenhouse gases. This outcome, reinforced by significant ANOVA results, supports the hypothesis that interventions in lubricant formulation and engine operating conditions can play a critical role in mitigating climate change, aligning with global initiatives for carbon reduction.

RSM-based optimization revealed that adjusting the oil viscosity to 13 cSt, along with specific speed and load settings, optimally reduces emissions while maintaining fuel efficiency. This approach provides a robust framework for future research and encourages the exploration of different types of oils and engine design modifications that could further improve performance and environmental sustainability.

Future research could benefit from expanding the range of tested environmental and operational conditions, including different types of fuels and engine configurations, as suggested by the ANOVA models' interaction terms. Additionally, incorporating life cycle analysis to assess the environmental impacts of lubricant production and disposal could provide a more comprehensive understanding of the total ecological footprint.

Further investigation into developing new lubricant compounds that operate effectively across a broader range of temperatures and pressures, mainly designed for high-altitude conditions, would be valuable. Exploring the interaction between these lubricants and hybrid or electric engine technologies could also lead to integrated strategies that maximize energy efficiency and minimize emissions across the entire vehicular system.

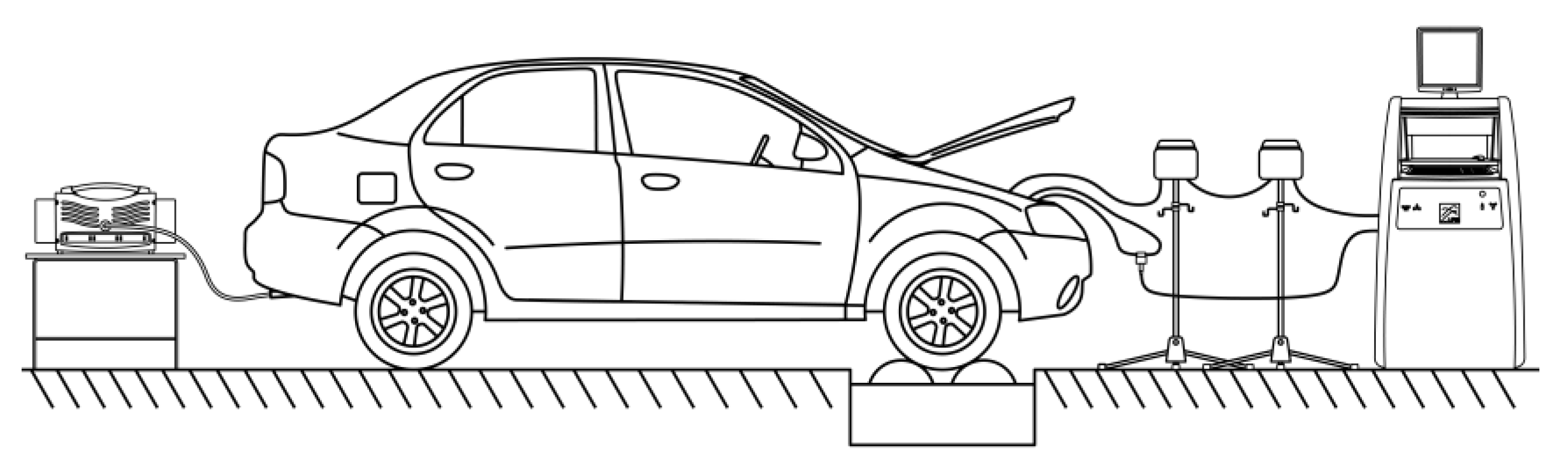

Figure 1.

Experimental unit.

Figure 1.

Experimental unit.

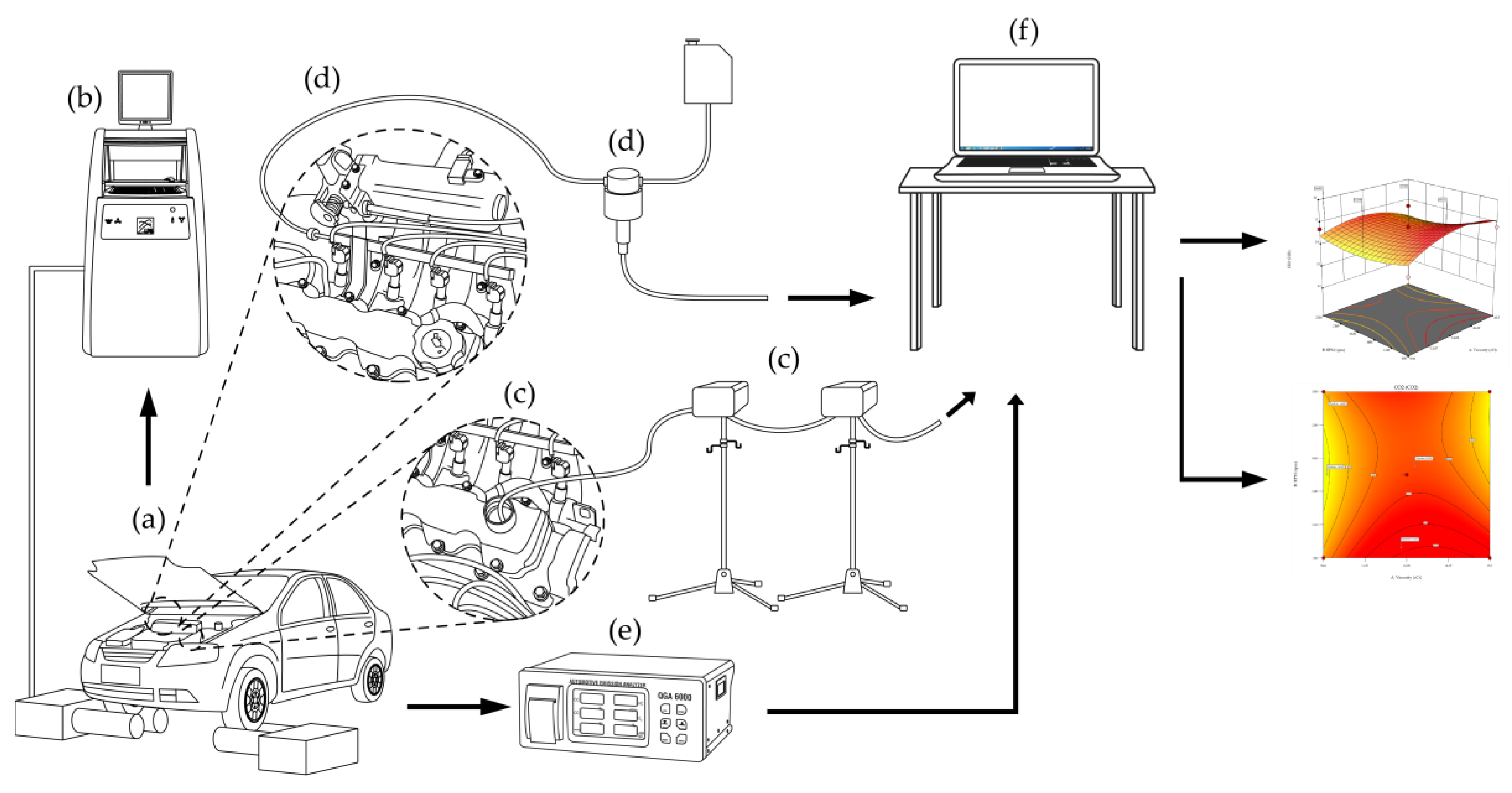

Figure 2.

Schematic of the experimental setup.

Figure 2.

Schematic of the experimental setup.

Figure 3.

(a) Contour plot and (b) Response surface for HC.

Figure 3.

(a) Contour plot and (b) Response surface for HC.

Figure 4.

(a) Contour plot and (b) Response surface for CO2.

Figure 4.

(a) Contour plot and (b) Response surface for CO2.

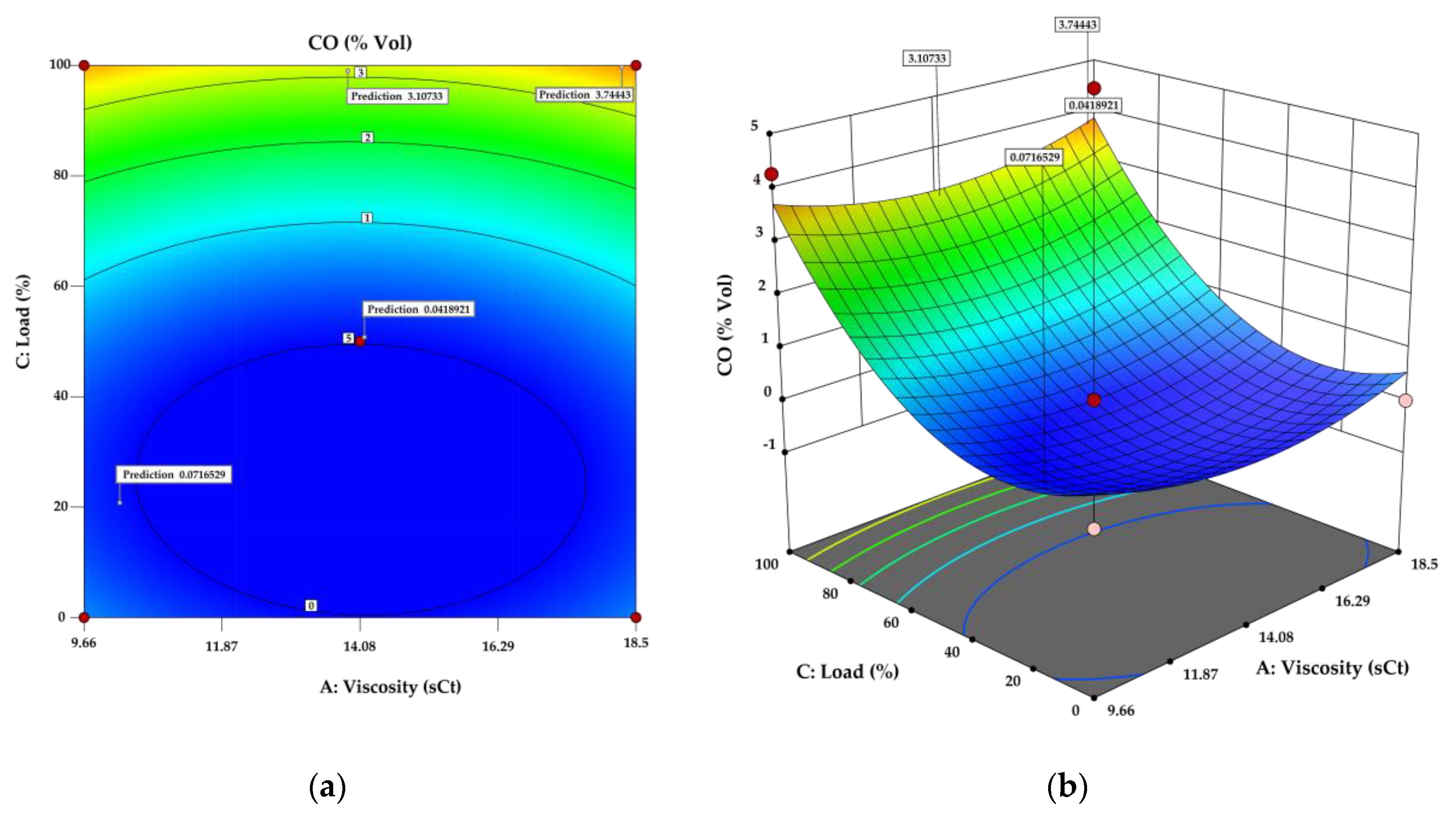

Figure 5.

(a) Contour plot and (b) Response surface for CO

Figure 5.

(a) Contour plot and (b) Response surface for CO

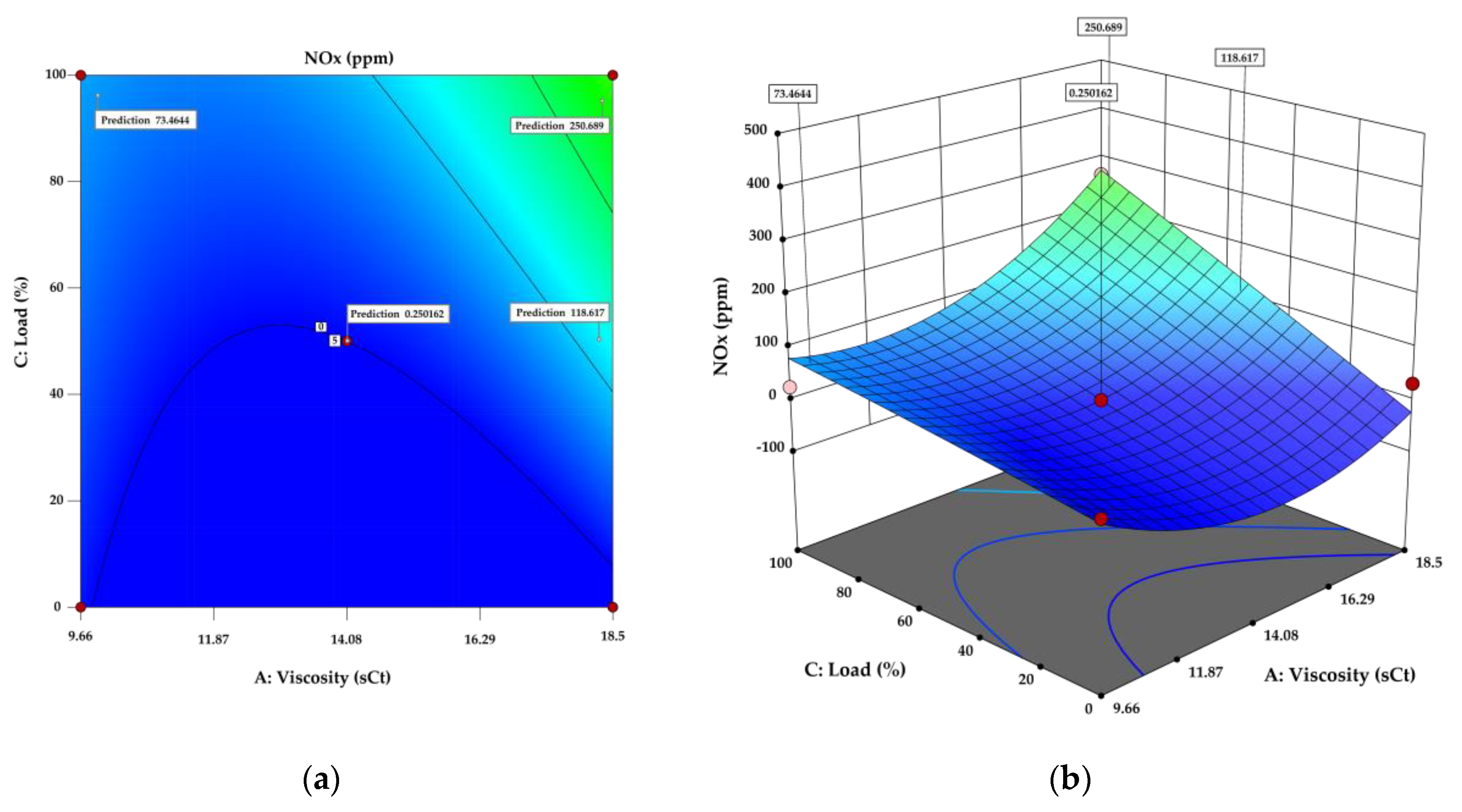

Figure 6.

Contour plot and (b) Response surface for NOx

Figure 6.

Contour plot and (b) Response surface for NOx

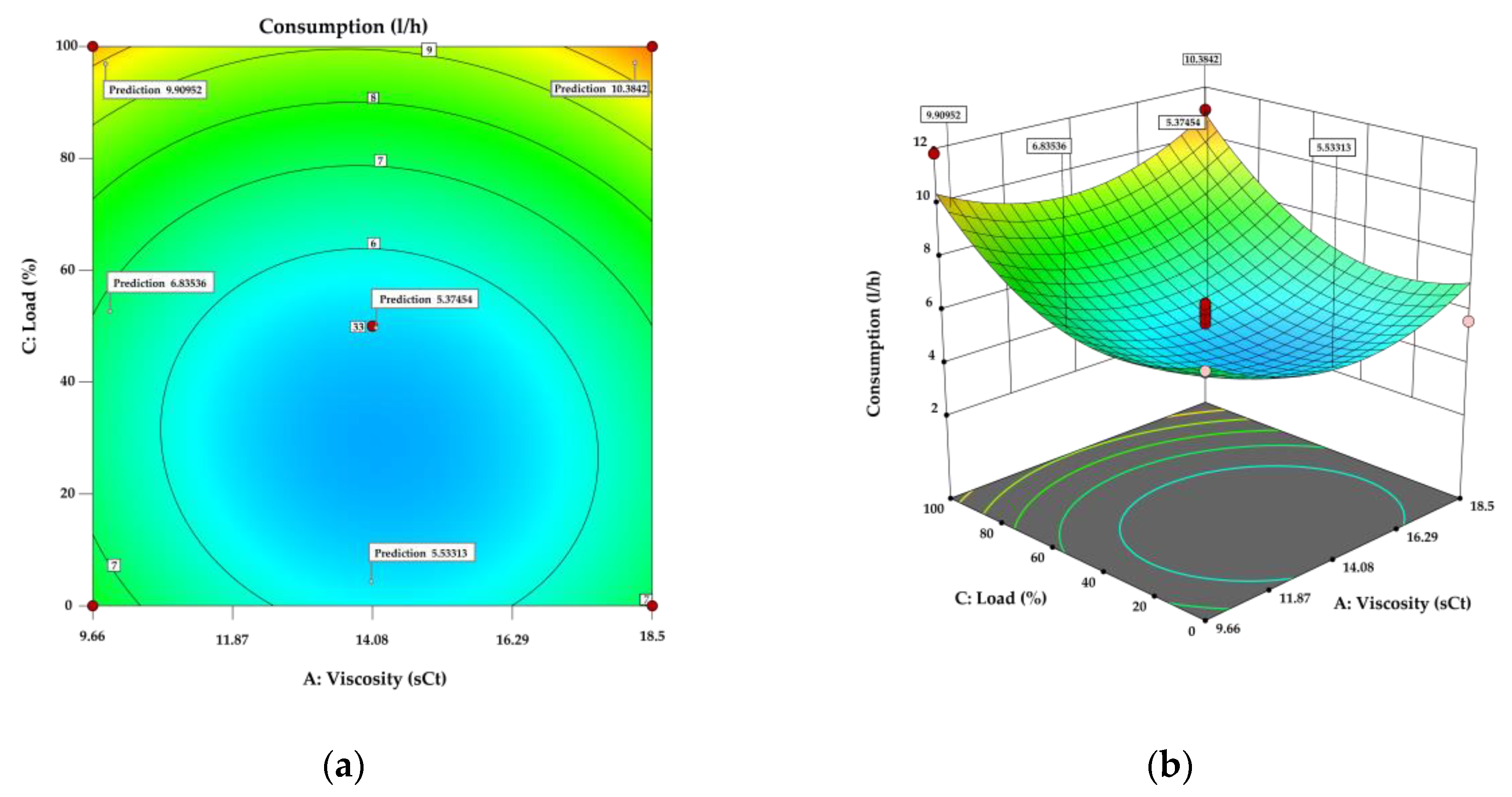

Figure 7.

(a) Contour plot and (b) Response surface of Consumption

Figure 7.

(a) Contour plot and (b) Response surface of Consumption

Figure 8.

Identified optimum point.

Figure 8.

Identified optimum point.

Figure 9.

Contour plot of desirability.

Figure 9.

Contour plot of desirability.

Table 1.

Main characteristics of the test engine.

Table 1.

Main characteristics of the test engine.

| Technical specifications |

|---|

| Engine |

1.5 L SOHC |

| Valves |

8 |

| Number of cylinders |

4 |

| Power (hp @ rpm) |

83 @ 5600 |

| Torque (Nm @ rpm) |

128 @ 3000 |

| Fuel supply |

MPFI |

| Compression ratio |

9.5 |

| Final Ratio |

3.944 |

| Gross vehicle weight |

1,365 Kg |

| Load Capacity |

325 Kg |

Table 2.

Technical specifications of the gas analyzer.

Table 2.

Technical specifications of the gas analyzer.

| Measuring fields |

Range |

Unit |

Resolution |

| CO |

0 – 9,99 |

% vol |

0.01 |

| CO2

|

0 – 19,9 |

% vol |

0.1 |

| HC hexane |

0 – 9,999 |

ppm vol |

1 |

| O2

|

0 – 25 |

% vol |

0.01 |

| NOx |

0 – 5,000 |

ppm vol |

1 |

| Lambda |

0.5 – 5 |

|

0.001 |

| Revolutions Inductance/capacitance |

300 – 9,990 |

rpm |

10 |

| Oil temperature |

20 – 150 |

°C |

1 |

Table 3.

Technical specifications of the oils used in the study.

Table 3.

Technical specifications of the oils used in the study.

| SAE grade |

5w30 |

10w30 |

20w50 |

| Specific Gravity @ 60°F |

0.861 |

0.866 |

0.881 |

| Density, lbs/gal @ 60°F |

7.17 |

7.21 |

7.33 |

| Color, ASTM D1500 |

3.0 |

3.0 |

3.0 |

| Flash Point (COC), °C (°F) |

216 (421) |

229 (444) |

230 (446) |

| Pour Point, °C (°F) |

-39 (-38) |

-39 (-38) |

-30 (-22) |

| Kinematic Viscosity @ cSt @ 40°C |

66.2 |

65.7 |

176 |

| Kinematic Viscosity @ cSt @ 100°C |

9.66 |

14.08 |

18.5 |

| Viscosity Index |

158 |

148 |

128 |

| Cold Cranking Viscosity, cP @ (°C) |

6,150 (-30) |

4,550 (-25) |

7,200 (-15) |

| High-Temp/High-Shear Viscosity, cP @ 150°C |

3.1 |

3.0 |

4.9 |

Table 4.

Input variables and levels of the experiment.

Table 4.

Input variables and levels of the experiment.

| Factor |

Unit |

Lower

level |

Middle

level |

Upper

level |

| Viscosity |

sCt |

9.66 |

14.08 |

18.5 |

| Engine speed |

rpm |

800 |

1650 |

2500 |

| Load |

% |

0 |

50 |

10 |

Table 5.

ANOVA results for HC.

Table 5.

ANOVA results for HC.

| Source |

Sum of Squares |

Df |

Mean Square |

F-value |

p-value |

|

| Model |

56264.32 |

9 |

6251.59 |

6.36 |

0.0117 |

significant |

| A-Viscosity |

12.50 |

1 |

12.50 |

0.0127 |

0.9134 |

|

| B-RPM |

3042.00 |

1 |

3042.00 |

3.09 |

0.1220 |

|

| C-Load |

27144.50 |

1 |

27144.50 |

27.61 |

0.0012 |

|

| AB |

36.00 |

1 |

36.00 |

0.0366 |

0.8537 |

|

| AC |

81.00 |

1 |

81.00 |

0.0824 |

0.7824 |

|

| BC |

4900.00 |

1 |

4900.00 |

4.98 |

0.0607 |

|

| A² |

3035.46 |

1 |

3035.46 |

3.09 |

0.1223 |

|

| B² |

1883.46 |

1 |

1883.46 |

1.92 |

0.2088 |

|

| C² |

16107.04 |

1 |

16107.04 |

16.38 |

0.0049 |

|

| Residual |

6881.80 |

7 |

983.11 |

|

|

|

| Lack of Fit |

6849.00 |

3 |

2283.00 |

278.41 |

< 0.0001 |

significant |

| Pure Error |

32.80 |

4 |

8.20 |

|

|

|

| Cor Total |

63146.12 |

16 |

|

|

|

|

Table 6.

Coefficient of determination for HC.

Table 6.

Coefficient of determination for HC.

| Coefficient of determination |

Value |

| R2

|

0.8910 |

| Adjusted R2

|

0.7509 |

| Predicted R2

|

-0.7362 |

Table 7.

ANOVA results for CO2.

Table 7.

ANOVA results for CO2.

| Source |

Sum of Squares |

Df |

Mean Square |

F-value |

p-value |

|

| Model |

14.13 |

9 |

1.57 |

4.59 |

0.0285 |

significant |

| A-Viscosity |

0.1013 |

1 |

0.1013 |

0.2959 |

0.6034 |

|

| B-RPM |

0.4513 |

1 |

0.4513 |

1.32 |

0.2886 |

|

| C-Load |

8.00 |

1 |

8.00 |

23.38 |

0.0019 |

|

| AB |

0.1600 |

1 |

0.1600 |

0.4675 |

0.5161 |

|

| AC |

0.0025 |

1 |

0.0025 |

0.0073 |

0.9343 |

|

| BC |

1.56 |

1 |

1.56 |

4.57 |

0.0700 |

|

| A² |

0.9904 |

1 |

0.9904 |

2.89 |

0.1327 |

|

| B² |

0.4178 |

1 |

0.4178 |

1.22 |

0.3057 |

|

| C² |

2.43 |

1 |

2.43 |

7.11 |

0.0322 |

|

| Residual |

2.40 |

7 |

0.3422 |

|

|

|

| Lack of Fit |

2.39 |

3 |

0.7958 |

397.92 |

< 0.0001 |

significant |

| Pure Error |

0.0080 |

4 |

0.0020 |

|

|

|

| Cor Total |

16.52 |

16 |

|

|

|

|

Table 8.

Coefficient of determination for CO2.

Table 8.

Coefficient of determination for CO2.

| Coefficient of determination |

Value |

| R2

|

0.8550 |

| Adjusted R2

|

0.6687 |

| Predicted R2

|

-1.3124 |

Table 9.

ANOVA results for CO.

Table 9.

ANOVA results for CO.

| Source |

Sum of Squares |

Df |

Mean Square |

F-value |

p-value |

|

| Model |

39.85 |

9 |

4.43 |

6.57 |

0.0107 |

significant |

| A-Viscosity |

0.0021 |

1 |

0.0021 |

0.0031 |

0.9569 |

|

| B-RPM |

2.07 |

1 |

2.07 |

3.07 |

0.1232 |

|

| C-Load |

20.29 |

1 |

20.29 |

30.09 |

0.0009 |

|

| AB |

0 |

1 |

0 |

0 |

10.000 |

|

| AC |

0.0072 |

1 |

0.0072 |

0.0107 |

0.9205 |

|

| BC |

4.1 |

1 |

4.1 |

6.08 |

0.0431 |

|

| A² |

1.39 |

1 |

1.39 |

2.06 |

0.1942 |

|

| B² |

1.39 |

1 |

1.39 |

2.07 |

0.1936 |

|

| C² |

10.67 |

1 |

10.67 |

15.83 |

0.0053 |

|

| Residual |

4.72 |

7 |

0.6742 |

|

|

|

| Lack of Fit |

4.72 |

3 |

1.57 |

12100.58 |

< 0.0001 |

significant |

| Pure Error |

0.0005 |

4 |

0.0001 |

|

|

|

| Cor Total |

44.57 |

16 |

|

|

|

|

Table 10.

Coefficient of determination for CO.

Table 10.

Coefficient of determination for CO.

| Coefficient of determination |

Value |

| R2

|

0.8941 |

| Adjusted R2

|

0.7579 |

| Predicted R2

|

-0.6943 |

Table 11.

ANOVA results for NOx.

Table 11.

ANOVA results for NOx.

| Source |

Sum of Squares |

Df |

Mean Square |

F-value |

p-value |

|

| Model |

4.95E+05 |

9 |

54953.48 |

12.96 |

0.0014 |

significant |

| A-Viscosity |

13203.13 |

1 |

13203.13 |

3.11 |

0.121 |

|

| B-RPM |

2.05E+05 |

1 |

2.05E+05 |

48.45 |

0.0002 |

|

| C-Load |

69006.13 |

1 |

69006.13 |

16.27 |

0.005 |

|

| AB |

756.25 |

1 |

756.25 |

0.1783 |

0.6855 |

|

| AC |

12769 |

1 |

12769 |

3.01 |

0.1263 |

|

| BC |

35532.25 |

1 |

35532.25 |

8.38 |

0.0232 |

|

| A² |

32606.32 |

1 |

32606.32 |

7.69 |

0.0276 |

|

| B² |

1.18E+05 |

1 |

1.18E+05 |

27.77 |

0.0012 |

|

| C² |

37.89 |

1 |

37.89 |

0.0089 |

0.9273 |

|

| Residual |

29684.25 |

7 |

4240.61 |

|

|

|

| Lack of Fit |

29684.25 |

3 |

9894.75 |

|

|

significant |

| Pure Error |

0 |

4 |

0 |

|

|

|

| Cor Total |

5.24E+05 |

16 |

|

|

|

|

Table 12.

Coefficient of determination for NOx.

Table 12.

Coefficient of determination for NOx.

| Coefficient of determination |

Value |

| R2

|

0.9434 |

| Adjusted R2

|

0.8706 |

| Predicted R2

|

0.0941 |

Table 13.

ANOVA results for Consumption.

Table 13.

ANOVA results for Consumption.

| Source |

Sum of Squares |

Df |

Mean Square |

F-value |

p-value |

|

| Model |

72.69 |

9 |

8.08 |

11.05 |

< 0.0001 |

significant |

| A-Viscosity |

0.0061 |

1 |

0.0061 |

0.0083 |

0.928 |

|

| B-RPM |

0.4278 |

1 |

0.4278 |

0.5855 |

0.4493 |

|

| C-Load |

22.34 |

1 |

22.34 |

30.58 |

< 0.0001 |

|

| AB |

0.81 |

1 |

0.81 |

1.11 |

0.2996 |

|

| AC |

0.2601 |

1 |

0.2601 |

0.3559 |

0.5546 |

|

| BC |

1.92 |

1 |

1.92 |

2.63 |

0.1142 |

|

| A² |

12.91 |

1 |

12.91 |

17.67 |

0.0002 |

|

| B² |

6.9 |

1 |

6.9 |

9.44 |

0.0041 |

|

| C² |

20.7 |

1 |

20.7 |

28.33 |

< 0.0001 |

|

| Residual |

25.58 |

35 |

0.7307 |

|

|

|

| Lack of Fit |

8.8 |

3 |

2.93 |

5.6 |

0.0034 |

significant |

| Pure Error |

16.78 |

32 |

0.5242 |

|

|

|

| Cor Total |

98.27 |

44 |

|

|

|

|

Table 14.

Coefficient of determination for Consumption.

Table 14.

Coefficient of determination for Consumption.

| Coefficient of determination |

Value |

| R2

|

0.7397 |

| Adjusted R2

|

0.6728 |

| Predicted R2

|

-0.6143 |

Table 15.

Optimization Setup.

Table 15.

Optimization Setup.

| Name |

Goal |

Lower Limit |

Upper Limit |

Lower Weight |

Upper Weight |

Importance |

| A: Viscosity (sCt) |

is in range |

9.66 |

18.5 |

1 |

1 |

3 |

| B: RPM (rpm) |

is in range |

800 |

2500 |

1 |

1 |

3 |

| C: Load (%) |

is in range |

0 |

100 |

1 |

1 |

3 |

| HC (ppm) |

minimize |

1 |

181 |

1 |

1 |

3 |

| CO2 (% Vol) |

minimize |

12.1 |

14.9 |

1 |

1 |

3 |

| CO (% Vol) |

minimize |

0 |

4.43 |

1 |

1 |

3 |

| NOx (ppm) |

minimize |

0 |

498 |

1 |

1 |

3 |

| Consumption (l/h) |

minimize |

3.67 |

11.82 |

1 |

1 |

3 |