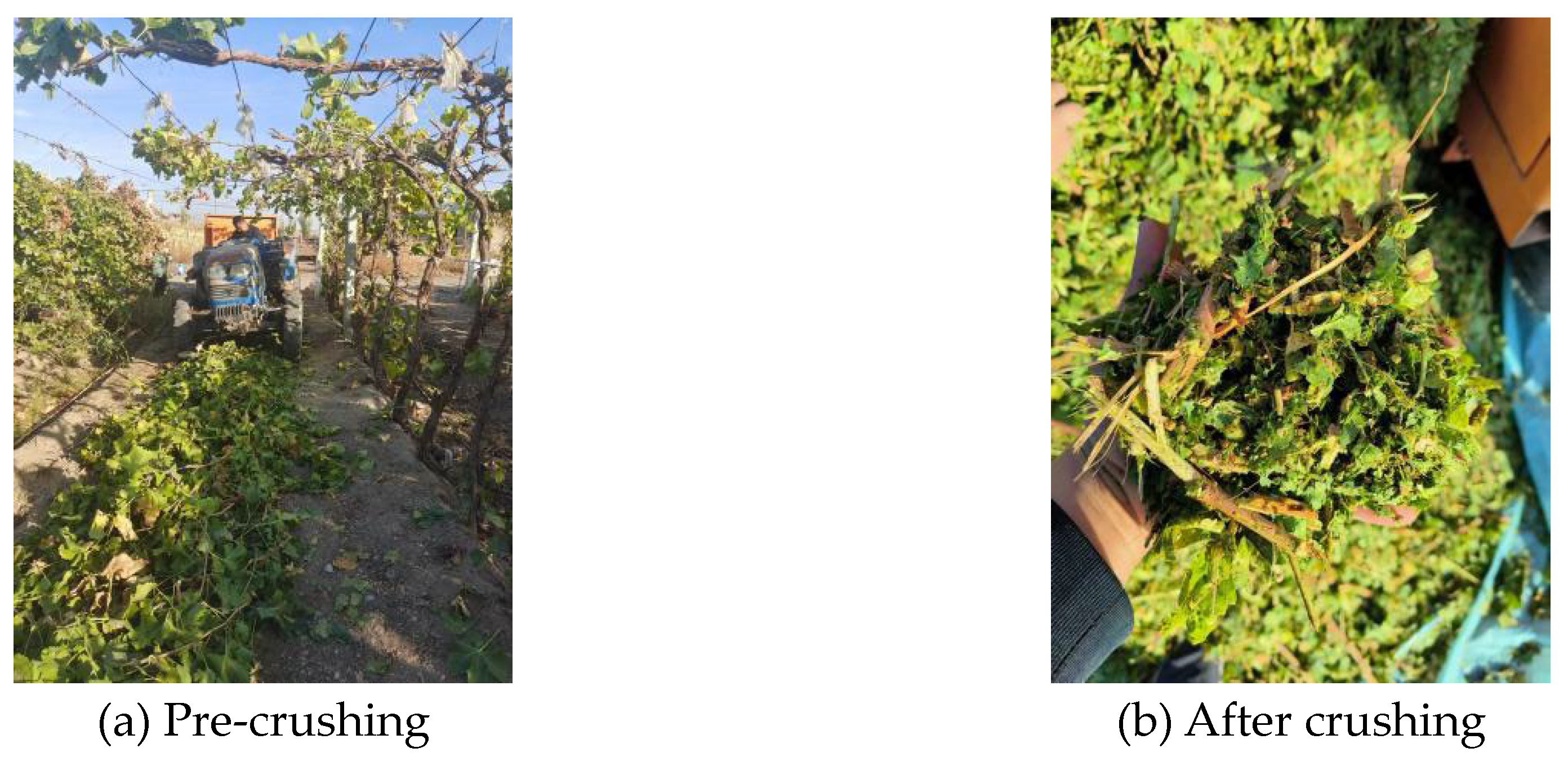

When the branch crushing and collecting machine is in operation, the characteristics of the airflow field in the crushing device affect the feeding of branches, the quality of crushing and the throwing of crushed materials, especially the high-speed rotation of the crushing knife rollers will make the crushing device form a complex flow field. This chapter will establish a simplified model of the crushing device of the branch crushing and collecting machine, based on the CFD numerical simulation method, using Fluent software, simulation and analysis of the characteristics of the airflow field in the crushing device, to obtain the basic characteristics of the flow field in the crushing device, and to compare and analyse the distribution characteristics of the flow field under the conditions of different speed of the crushing knife rollers in order to explore the influence of the speed of rotation on the branch feeding, crushing and transporting, and provide a reference for the subsequent field test of the prototype. This is to investigate the effect of rotational speed on branch feeding, crushing and throwing, and to provide a reference for the subsequent field test of the prototype.

3.2. Model Simulation Parameter Settings

(1) Fluid flow control equations and turbulence model selection

Branch crushing throwing process, branches in the crushing chamber after crushing through the discharge pipe thrown, in which the crushed material is transported in the hammer claw and crushing device under the joint action of the airflow to complete the crushing device in the form of air movement is actually gas - solid two-phase turbulent movement, but the direct analysis is difficult, and the use of Fluent simulation software to analyse the crushing chamber of the gas-phase flow can be indirectly obtained by crushing material Motion form[

10], simulation and analysis process ignoring the air and the energy transfer between the crushed material, crushing device within the gas-phase flow follow the law of conservation of mass and momentum conservation. Mass conservation equation is:

In the equation: div is the dispersion, ρ is the fluid density, and u、v and w are the velocity vectors in the x、y and z directions.

The momentum conservation equation is:

In the equation: Pw is the pressure on the microproducts, t is the time, and ,SU、SV、SW are generalised source terms.

The high-speed rotation of the knife roller in the crushing chamber will make the flow field in the crushing device to produce vortex phenomenon, so in the flow simulation process need to choose the appropriate computational model, in order to obtain and the actual crushing chamber air flow characteristics of the similar results. The flow field in the crushing chamber in this study is dominated by turbulence, so a turbulence model is chosen for the simulation. The

k-ℇ turbulence model in Fluent is computationally stable and efficient and is widely used in turbulence simulation[

11,

12],The

k-models include Standard

k-ℇ, RNG

k-ℇ and Realizable

k-ℇ models, among which Realizable

k-ℇ models are more commonly used and can better solve turbulent flow problems[

13]. Therefore, the Realizable

k-ℇ model is chosen in this simulation to simulate the airflow field in the crushing chamber, and the transport equations for

k and

ℇ are given in Equation (5) and Equation (6).

In the equation:

C1=max[0.43,

η/(

η+5)],

C2=1.0, U

j is the fluid velocity,

k is the turbulent kinetic energy,

μt is the effective viscosity,

ℇ is the turbulent dissipation rate,

xj is the component of x in the j-direction,

St is the generating term of turbulent kinetic energy,

σk is the Prandtl constant related to the turbulent kinetic energy taken as 1, σ is the Prandtl constant related to the turbulent dissipation rate taken as 0.7179,

η is the strain rate,

C1,

C2 is the constant coefficient on the turbulence dissipation,

C1 taken as 1.42,

C2 taken as 1.68[

14].

When using Fluent software to simulate and analyse the airflow field inside the crushing chamber, the Navier-Stokes control equation used to solve the airflow field is:

In the equation:

va is the gas-phase fluid velocity vector, and

Fci represents the momentum sink. Referring to the relevant literature, it can be seen that the turbulent velocity and pressure of pumps, fans and other systems are basically constant and time-independent, which is called the time-averaged value when the system works stably. The turbulence can be expressed by the time-averaged motion parameters called time-averaged turbulence, and the turbulence can be regarded as constant flow, at this time the continuity equation, kinetic energy equation and Bernoulli's equation can be applied to the time-averaged turbulence[

15].

(2) Parameter setting

After the mesh division is finished, the simulation operation condition is set to double precision in Fluent, and after entering the solution interface, the mesh is checked firstly to make sure that there is no negative volume and then continue with the parameter setting. In the simulation, the flow field is regarded as incompressible, the fluid medium is set as air, and the steady state, pressure-based solver is selected. The working conditions of the computational domain are set, the gravitational acceleration is 9.8 m/s

2 in the negative direction of the Z-axis, and the operating pressure is 1.01×10

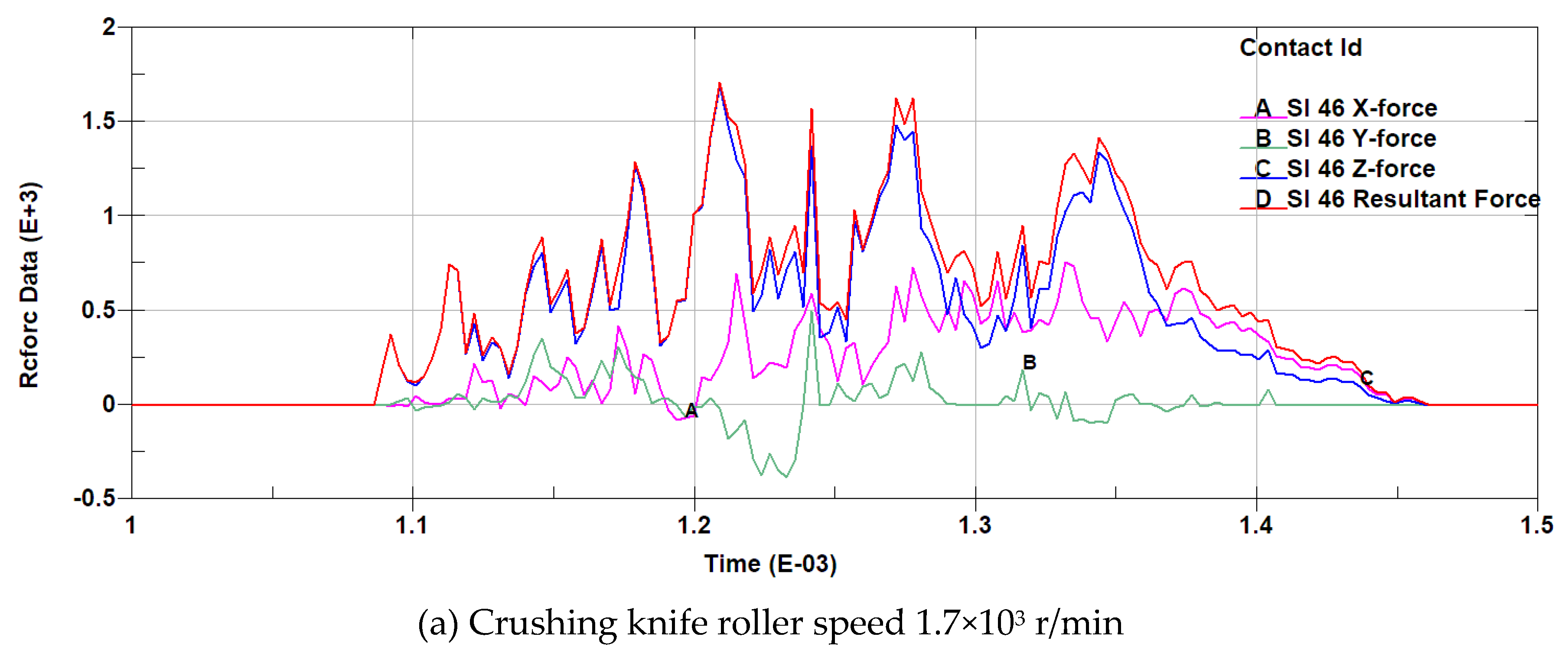

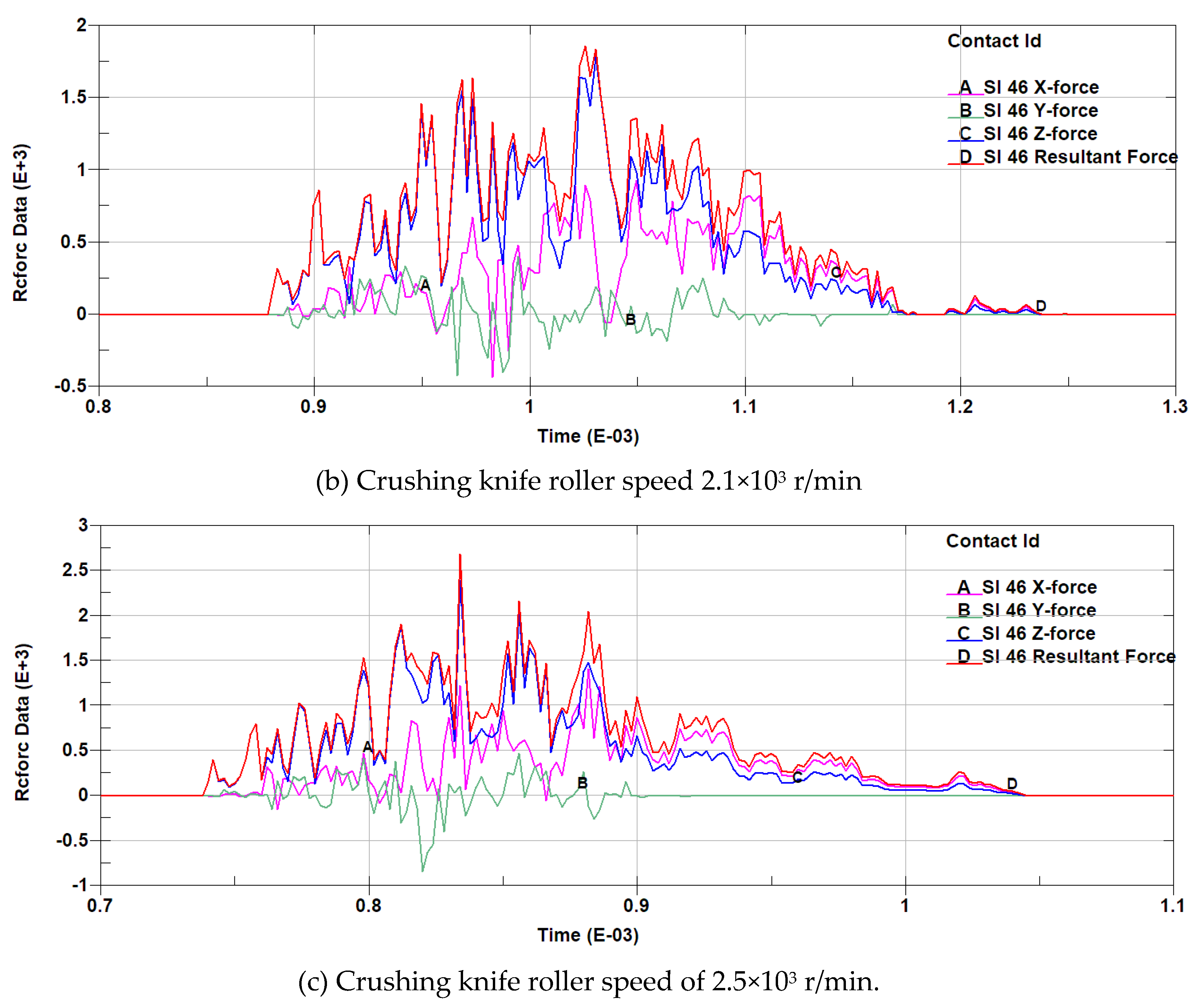

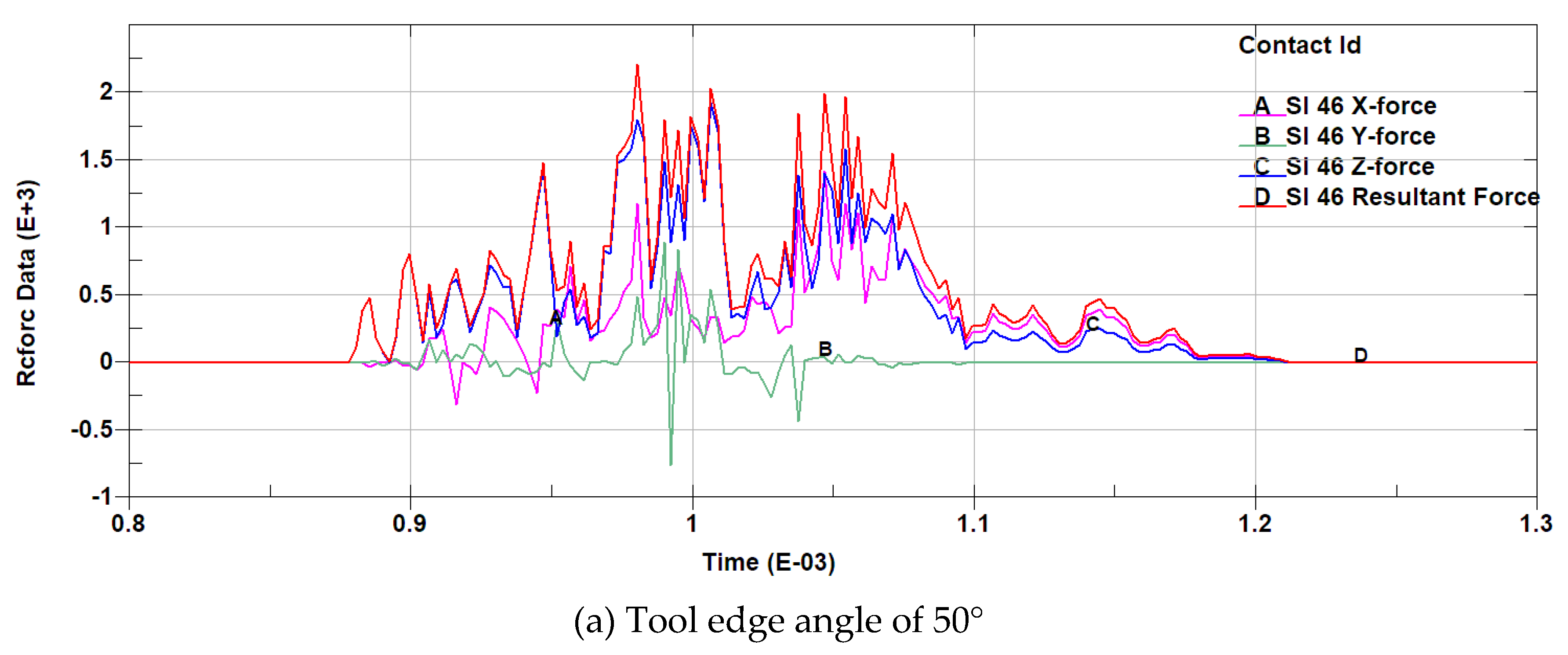

5 Pa (one standard atmospheric pressure). The rotational domain is defined using the multiple reference system model (MRF):According to the demand of this simulation analysis, the knife roller speed is set to 1.7×10

3 r/min, 2.1×10

3 r/min and 2.5×10

3 r/min respectively; define the rotation threshold to rotate around the centre axis, i.e., the Y-axis, in the positive direction. The inlet and outlet of the computational domain are set as pressure inlet and pressure outlet respectively, and the gauge pressure at the inlet and outlet are set to 0 Pa. The solution method is the pressure-velocity coupling algorithm for steady state computation. The solution method is the pressure-velocity coupling algorithm for steady state computation, and the scheme is Simple, the pressure interpolation algorithm is PRESTO algorithm which is suitable for high Xuan-flow and the pressure changes rapidly in the fluid domain[

16,

17,

18], and the momentum, turbulent kinetic energy and dissipation rate are all in the Second Order Upwind format which has a high computational accuracy[

19], and the Warped-Face gradient correction is chosen, and the sub-looseness factor is the default value. The subrelaxation factors are all default values. After initialisation of the mix, set the number of operation iterations to 2000, after which the calculation starts until convergence. After convergence, the entry and exit mass flow reports are viewed and the difference between the entry and exit flows is calculated to be less than 0.5% to ensure that the simulation results are valid.

3.3. Model Simulation Results and Analysis

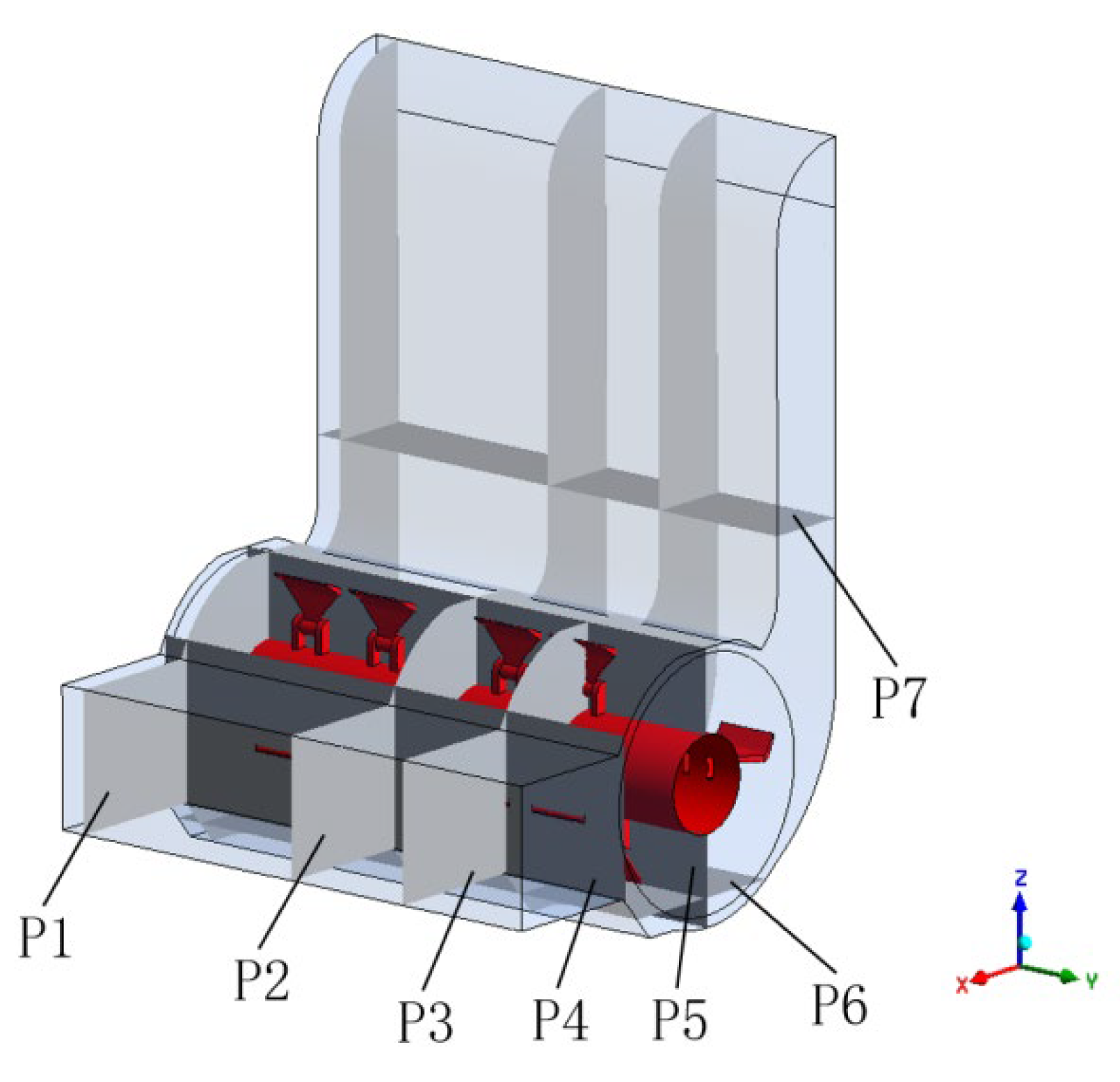

After the end of the flow field simulation operation, the results will be imported into the CFD-Post software for post-processing of the simulation results, in order to more intuitive description of the flow field distribution characteristics of the crushing device, the establishment of seven representative two-dimensional cross-section in the computational domain, the location of the cross-section as shown in Error! Reference source not found..

Figure 10.

Cross section location map of fluid computing domain.

Figure 10.

Cross section location map of fluid computing domain.

The P1 cross-section is at the left boundary of the computational domain, parallel to the XZ plane and Y=-580 mm; the P2 cross-section is a symmetric plane at the centre of the computational domain; the P3 cross-section is in the right region of the fluid domain, parallel to the XZ plane and Y=310 mm; the P4 cross-section is close to the inlet region and passes through the end of the hammer claw, parallel to the YZ plane and X=271 mm; the P5 cross-section is overlapped with the YZ plane and passes through the axial line of the knife roller P6 is located at the bottom of the calculation domain, parallel to the XY plane, Z=-250 mm; P7 is located in the middle and lower part of the discharge pipe, parallel to the XY plane, Z=500 mm.

(1) Crushing indoor velocity field analysis

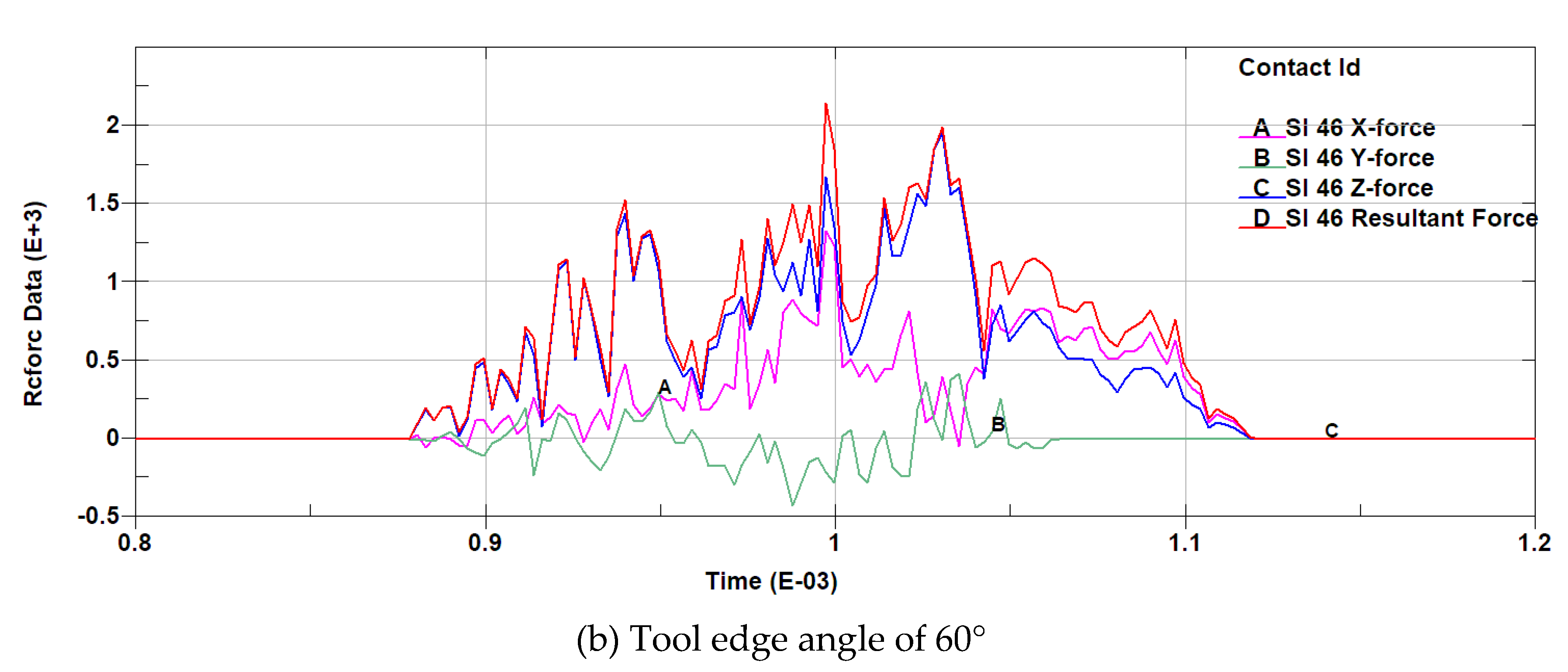

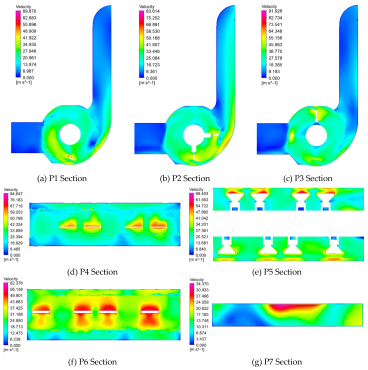

In this section, the velocity field inside the crushing device is analysed at a knife roller speed of 2.1×103 r/min, and the velocity cloud of the P1 ~ P7 cross-section is shown in Error! Reference source not found.. From the P1 ~ P3 and P5 cross-section velocity cloud diagrams, it can be seen that the airflow velocity in the inlet area is lower, and the flow velocity at the bottom area of the inlet is higher; the mean values of the P1 ~ P3 cross-section velocities are 21.383 m/s-2, 27.553 m/s-2, and 28.063 m/s-2, which can be seen that the average velocity in the computational domain located in the boundary is lower, and the average velocity located in the centre area is higher and the change is not It can be seen that the average velocity in the calculation domain is lower at the boundary, and the average velocity in the centre area is higher and does not change much; the air velocity in the rotating area of the knife roller is higher, the air velocity in the rotating area is increasing along the radial direction of the knife roller and the air velocity decreases from the rotating area into the discharge pipe. From P4 and P6 cross-section can be seen in the tool leeward area of the airflow velocity is higher than the windward area, from P1 ~ P3, P7 cross-section velocity cloud can be seen, the discharge pipe near the right side of the crushing device is higher than the speed of the left side of the region near the speed, and the central region of the highest speed, which is consistent with the theoretical design of crushing device. The high-speed rotation of the knife roller will also be in the knife roller rotating region of the outer surface of the formation of the circulation layer, as shown in Error! Reference source not found. (a) ~ (c), due to the design of the hammer claw for the asymmetric helical arrangement, which to a certain extent inhibits the formation of the circulation layer, in the actual design of the crushing chamber should also be added to the wall of the spoiler teeth, in order to destroy the circulation layer to allow the branch to fully crushed and smoothly into the discharge pipe thrown out.

Figure 11.

Speed cloud map of P1~P7 section at a speed of 2100 r/min.

Figure 11.

Speed cloud map of P1~P7 section at a speed of 2100 r/min.

(2) Pressure field analysis inside the crushing chamber

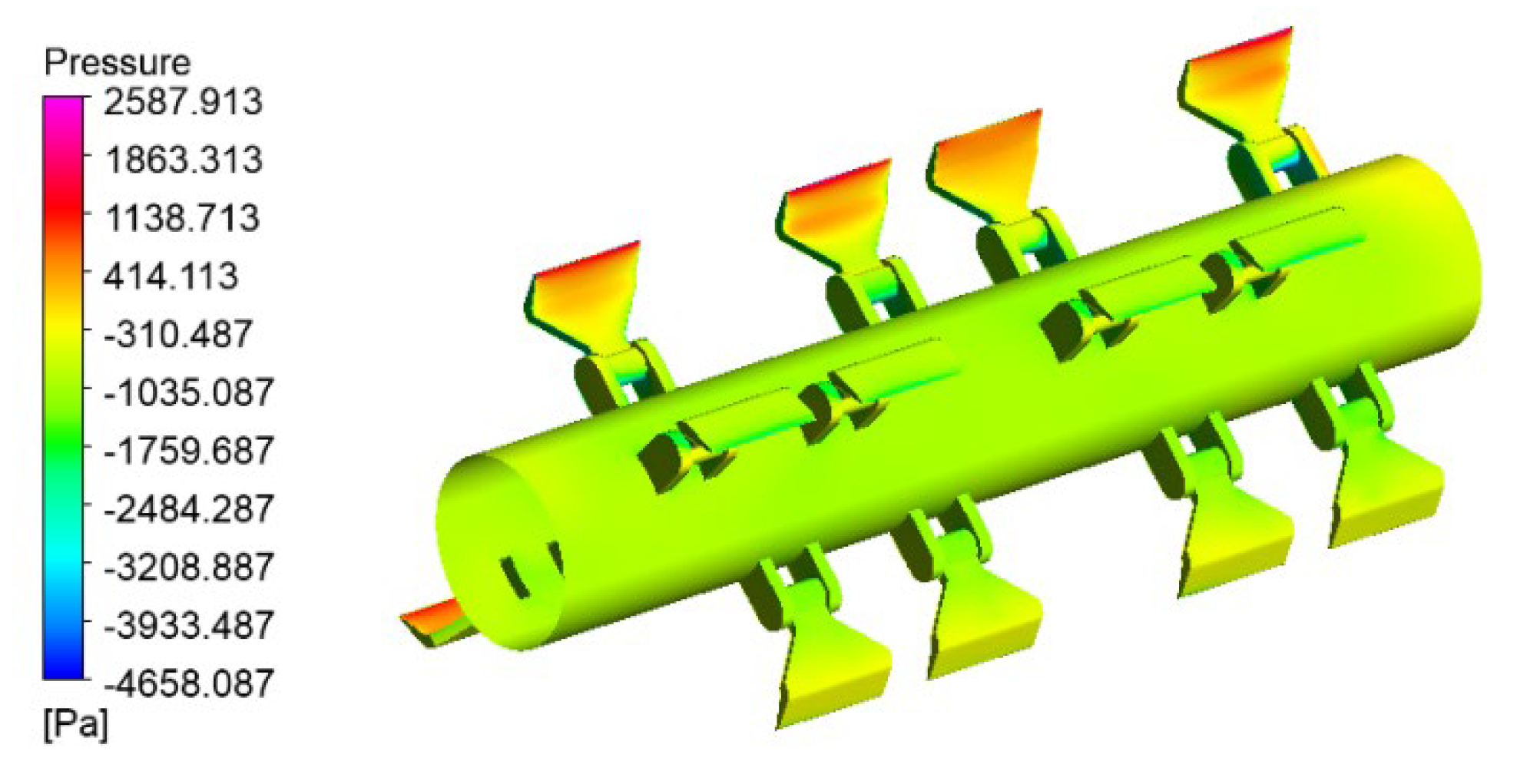

Error! Reference source not found. and

Error! Reference source not found. show the pressure distribution on the surface of the crushing knife roller and the cross-section of P1 ~ P7 when the knife roller rotates at a speed of 2.1×10

3 r/min. It can be seen in

Error! Reference source not found. that the pressure on the windward side of the crushing knife roller shows a gradient distribution along the radial direction, and along the radial direction of the knife roller from the cylindrical surface of the cutter shaft to the top of the hammer claw, the pressure is constantly increasing, and combined with the pressure cloud diagrams of the cross-section of P1 ~ P3 and P6, the pressure on the windward side of the tool is significantly higher than that of the surrounding area. The pressure near the windward side of the tool is obviously higher than the surrounding area, and the higher pressure on the windward side of the hammer and claw type tool is related to the work done on the windward side of the fluid[

20]. The pressure on the windward side of the tool shows discontinuous variations, with the pressure at the bottom and end of the tool being higher than that in the central region, the pressure on the windward side of the tool being lower than that on the windward side, and there being a negative pressure zone around the tool. The change in tool leeward pressure occurs at the corner of the hammer jaw bend, indicating that the change in tool shape also leads to pressure fluctuations in the nearby area.

Figure 12.

Cloud map of surface pressure on the grinding knife roller at a speed of 2100 r/min.

Figure 12.

Cloud map of surface pressure on the grinding knife roller at a speed of 2100 r/min.

Figure 13.

Pressure cloud map of inlet and P1~P7 section at a speed of 2100 r/min.

Figure 13.

Pressure cloud map of inlet and P1~P7 section at a speed of 2100 r/min.

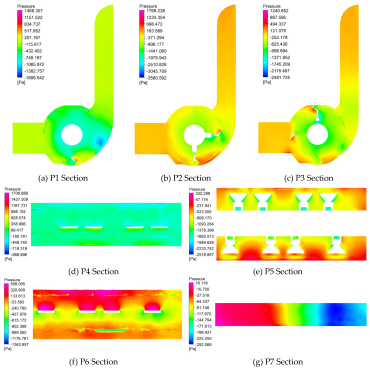

The pressure distribution of the P1 to P7 sections is presented in Error! Reference source not found.. From the P1 ~ P3 and P5 cross-section pressure clouds, it can be seen that in the whole crushing device, the pressure in the feed inlet area and the discharge pipe close to the exit area pressure change is not big; The average values of the pressures of P1 ~ P3 sections are -512.273 Pa, -657.452 Pa and -585.193 Pa, respectively, which shows that in the crushing device, the pressure value of the central area where the P2 section is located is lower; In the knife roller rotary area due to the high-speed rotation of the knife roller, the pressure fluctuation is more obvious, in the rotary area to form a large area of negative pressure area, and the closer to the knife shaft surface the lower the negative pressure value. The P4 cross-section pressure cloud reacts to the pressure distribution at the junction of the inlet area and the crushing chamber, where the pressure value fluctuates less and the average pressure value is -80.954 Pa. P7 cross-section pressure map can be seen, in the cross-section of the discharge pipe near the rotating domain of the existence of negative pressure areas, and due to the influence of the right spiral arrangement of the hammer claw, the right side of the discharge pipe pressure value is lower than that of the left side, the pressure value of the region presents a gradient distribution, so the hammer claw adopts the right spiral arrangement of the vibration is low, the cutter shaft is uniformly affected by the characteristics of the force, but it is necessary to consider the arrangement of the influence of the uniformity of the material thrown.

- 4.

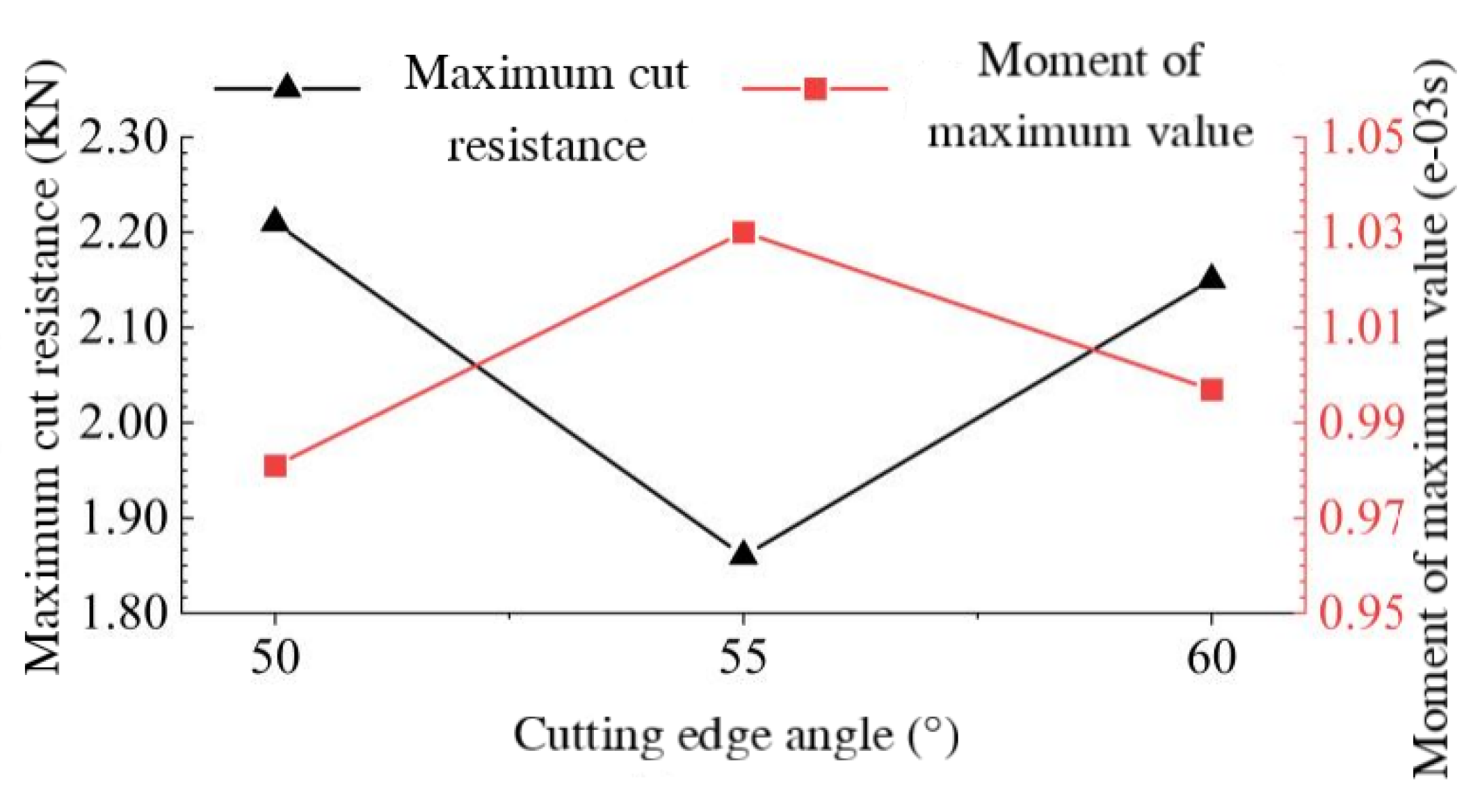

(3) Characterisation of the flow field in the crushing chamber at different knife roller speeds

The rotational speed of the crushing knife roller is the key working parameter of the branch crushing and collecting device, and this study will further analyse the effect of rotational speed on the branch feeding, crushing and crushed material throwing by comparing the distribution of airflow field in the crushing device under different rotational speeds The speed of the crushing knife roller was set to 1.7×103 r/min, 2.1×103 r/min and 2.5×103 r/min, and after the calculation, the post-processing software CFD-Post was used to calculate the inlet flow rate and generate the inlet pressure map and cross-section flow map for analysis and research.

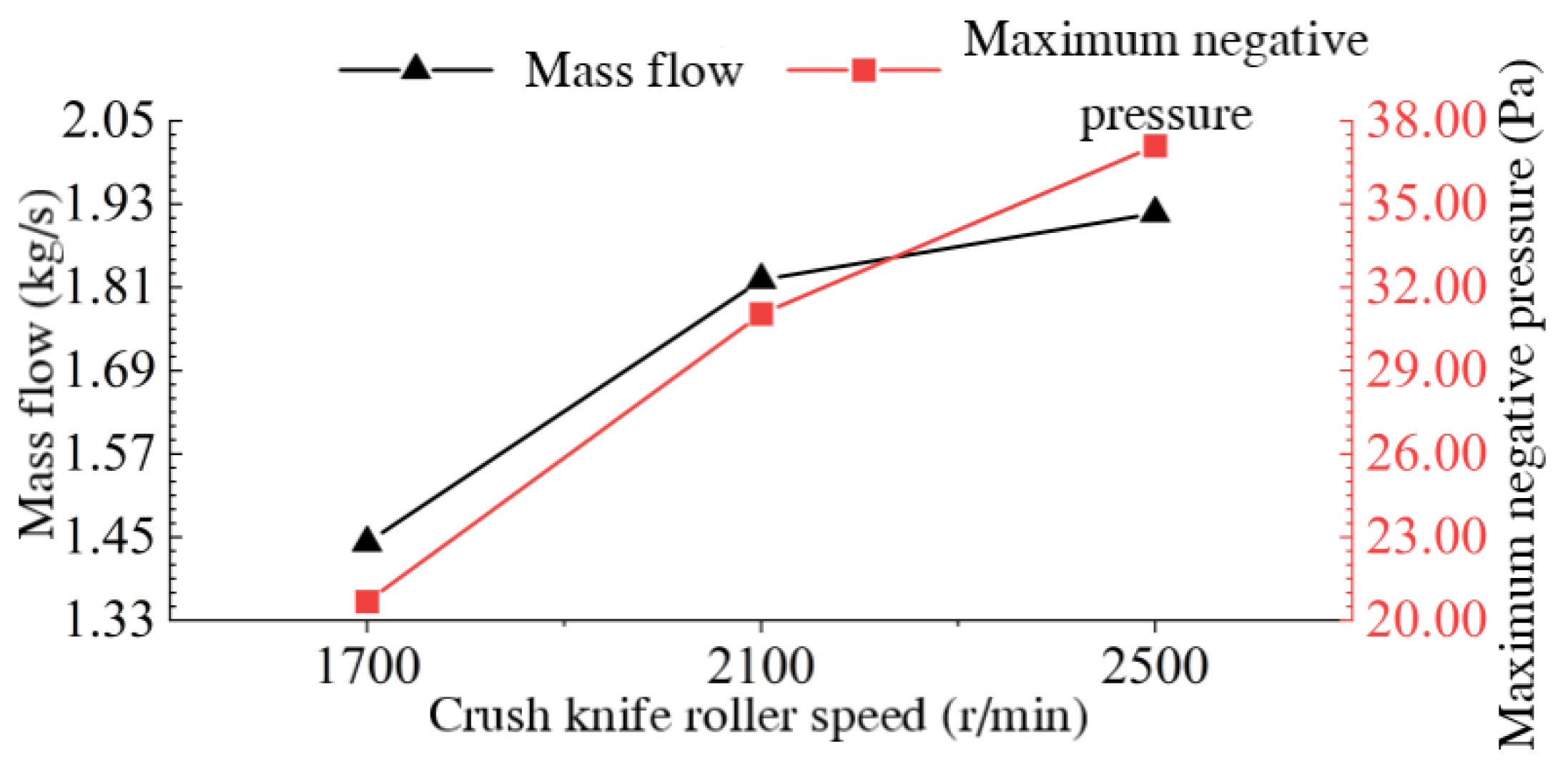

Error! Reference source not found. (a) ~ (c) respectively represent three knife roller speed inlet pressure cloud, three speed inlet area are large negative pressure area, and positive pressure area are present at the bottom of the inlet position, which is related to the bottom of the existence of vortex, the maximum value of the inlet negative pressure were: 20.65 Pa, 31.05 Pa, 37.16 Pa, can be seen with the increase in rotational speed of the entrance of the negative pressure maximum value are increasing. The maximum value of inlet negative pressure is increasing with the increase of rotational speed. As can be seen in Error! Reference source not found., the inlet mass flow rates at the three rotational speeds are 1.44 kg/s, 1.82 kg/s, and 1.92 kg/s, respectively, and as the rotational speed increases, the inlet flow rate also increases. Both the negative pressure at the inlet of the crushing unit and the increase in flow rate will induce more airflow from the inlet into the crushing unit, so increasing the speed of the crushing knife rollers during machine operation will be beneficial to the feeding of the branches.

Figure 14.

Cloud map of inlet pressure at different rotational speeds.

Figure 14.

Cloud map of inlet pressure at different rotational speeds.

Figure 15.

Inlet mass flow rate and maximum negative pressure at different blade roller speeds.

Figure 15.

Inlet mass flow rate and maximum negative pressure at different blade roller speeds.

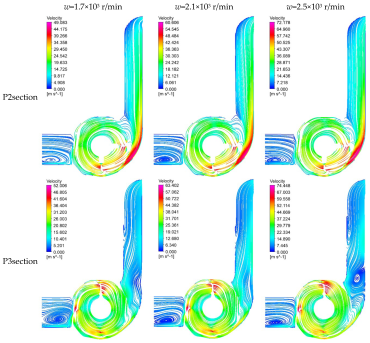

Error! Reference source not found. shows the flow line diagrams of representative cross sections P2 and P3 at different knife roller speeds, and it can be analysed that the airflow velocity on cross sections P2 and P3 increases as the speed increases with the speed. Three rotational speeds under the cross-section P2 streamline distribution changes are not large, and are in the inlet and the knife roller rotating area and the junction of the discharge pipe to produce a vortex of similar size, so the knife roller speed changes on the cross-section P2, that is, the centre of the crushing device region of the air flow mobility of the impact is small, only on the region of the airflow speed.

Figure 16.

P2, P3 cross-sectional streamline diagram at different speeds.

Figure 16.

P2, P3 cross-sectional streamline diagram at different speeds.

Vortices of different shapes and sizes are generated in the inlet area of cross-section P3, at the junction of the knife roll rotation area and the discharge tube, at the lower right side of the discharge tube and at the middle left side of the discharge tube. When the speed is increased from 1.7×103 r/min to 2.5×103 r/min, the vortex at the inlet area moves to the lower left, the vortex in the middle area of the left side of the discharge tube moves to the upper side and the vortex strength there is obviously strengthened at 2.5×103 r/min; when the speed is increased from 1.7×103 r/min to 2.1×103 r/min, the vortex at the junction of the rotating area of the knife roller and the discharge tube and at the lower right side of the discharge tube is weakened. However, when the rotational speed is increased from 2.1×103 r/min to 2.5×103 r/min, the vortex at the junction between the rotating area of the knife roller and the discharge tube is significantly enhanced, and the vortex area at the right bottom of the discharge tube is significantly larger, and the diameter is almost equal to the cross-section width of the discharge tube. Therefore, the variation of the speed of the crushing knife roller has a large effect on the airflow velocity as well as the airflow mobility at the cross-section P3.

Comprehensive analysis of the above, with the increase in the speed of the crushing knife roller speed, the crushing device at the exit of the air flow rate increases, will increase the throwing speed of the material to a certain extent, but the knife roller speed is too high will also lead to the crushing device in part of the region of the enhancement of the vortex, which affects the inlet of the branches of the feed and the discharge pipe crushed material thrown out.

Based on the tool dynamics analysis, branch crushing process simulation analysis and the results of this section of the crushing device under the airflow field characteristics of different knife roller speed, combined with the range of tractor output shaft speed, implement ratio and crushing power consumption and other factors, the final determination of the crushing knife roller speed range of 1.8×103 ~ 2.22×103 r / min.