Introduction

The importance of the base course to the pavement structure is highlighted by its role in distributing the traffic load generated on its surface to the underlying subbase and subgrade. In addition, its filtering characteristics stand out, which prevent the accumulation of water and direct it towards the drainage systems. It is mentioned by Günes et al. (2018) that the penetration and accumulation of water within the road structure (base, subbase, and subgrade) reduce the effective contact stresses between the coarse aggregate. In fine aggregates, an increase in water pressure is observed within the porous medium, leading to increased deformations and a consequent reduction in the ability of the overall structure to provide support and serviceability (Berthelot et al., 2009 and Xiao et al., 2012). Several quality control parameters are required for this layer, depending on its use and the type of pavement structure. This study analyzes a flexible asphalt surface that, unlike a rigid surface, is more susceptible to deformation and allows the progressive entry of water throughout its surface. It is found that the rate of entry and accumulation can vary depending on the quality of the material and the construction controls implemented.

Permeability and California Bearing Ratio (CBR) tests are frequently used to understand the drainage and strength characteristics of aggregate. As suggested by Harpreet et al. (2014), Structure leaks are addressed by implementing a permeable system with two or more filtration layers. Discussed by Yong et al. (2012), and Forsyth et al. (1987) is the efficiency of permeable systems, including base course along with cement and asphalt treatments. Additionally, Bouchedid and Humphrey (2005) mention that a pavement with adequate subdrainage can extend the useful life two to three times compared to one with poor drainage, potentially offering savings of up to $162,000 per kilometer in construction. and maintenance costs for ten years.

The resilience module is based on most researchers like Cetin et al. (2010) and Stolle et al., (2009) for the structural evaluation of the base layer, providing information on the dynamic behavior and deformations of the layer, not only its resistance like CBR. The consideration of this analysis through correlations with the CBR or property tests such as the cyclic triaxial test is necessary, although it is not required by the current Secretaría de Infraestructura, Comunicaciones, Infraestructura y Transportes (SICT) standards: N-CMT-4-02-002/11. Influenced by various parameters, such as slight variations in the optimal moisture content (Soliman and Shalaby, 2015, and Montes-Arvizu et al., 2020) or the nature of the materials, as in the case of clean floors where the change in moisture content is minimal (Hicks and Monismith, 1971), are the changes in the resilient module. It has been observed that in clean granular soils, the influence of the fine material on the resilient modulus becomes significant when it exceeds 5% of the total sample, and its rigidity tends to decrease when it is compacted with a moisture content higher than the optimal one (Khosravifar et al., 2013).

The implementation of the previous recommendations presents certain construction challenges, since materials with a very low percentage of fines (< 5%) lose cohesion in their structure. It is important to note that its stability and mechanical characteristics are not compromised but remain efficient. However, the presence of water in these permeable materials does not affect the CBR value over a prolonged period, ensuring that the support is not dramatically compromised even when the value decreases significantly under saturated conditions compared to the material in its optimal moisture content. A problem with pavements is their behavior in the presence of underlying and surface water; Actually not considered in the regulations established by the SICT: N-CMT-4-02-002/11 (2011) is the permeability coefficient, a critical parameter that reflects this behavior. Thus, the analysis of the resilient modulus is necessary, either through correlations with the CBR or with appropriate equipment such as the cyclic triaxial chamber, as well as the maintenance of the drainage system, which if inadequate leads to saturation of the surface making it unsafe for traffic and progressively leading to failure. To be considered permeable, the base layer must receive an annual precipitation greater than 125 mm (Hazen, 1911), and according to the annual reports (2014 and 2015) of the National Water Commission (CONAGUA), the precipitation for the study region ranges between 600 to 700 mm.

In this research, the mentioned parameters are measured and the variables that should be focused on to improve the materials are identified. Based on regional materials, it is evaluated how far they are from the recommended parameters in both permeability and load capacity (CBR), which will help inform strategies to improve formulations.

Background

2.1. Moisture in Pavement Structures

Moisture levels in pavement layers vary constantly over time. During the construction phase, materials are compacted close to their optimal moisture content to achieve maximum dry density. After construction, the moisture content in the layers is altered to a natural equilibrium state that is generally suboptimal, influenced by environmental factors such as precipitation, existing surface fractures, and groundwater level. Consequently, it is necessary to evaluate the mechanical properties of these layers based on their dependence on humidity changes.

In the study carried out by Abdolreza et al. (2017), CBR tests were compared for saturated and unsaturated samples, and it was observed that the most significant variation (a 20% difference) occurred when the dust content ratio (the relationship between the percentage passing the sieve No. 200 and the percentage passing the No. 40 sieve) was 0.4. Furthermore, the resilience modulus of unbound aggregate materials, which reflects the behavior of the granular base material, has been shown to be directly affected by moisture content. According to Smith and Nair (1973) and Vuong (1992), the resilient response of the unbound aggregate material in the dry state is similar to that of the granular base material. Haynes and Yoder (1963) have shown that the resilience modulus of an unbound aggregate base decreases by 50% when the saturation increases from 70% to 97%, that is, when the moisture content exceeds the optimum (Hicks, 1970).

Bouchedid and Humphrey (2005) analyzed the relationship between gravimetric properties (such as fines content and uniformity coefficient) and hydraulic properties by testing 25 samples in a rigid-wall permeameter, 18 in a triaxial permeameter, and 32 under field conditions. A general correlation was found indicating that a higher fines content and uniformity coefficient result in lower permeability, with the triaxial tests showing the highest correlation.

2.2. The Bearing Capacity and Permanent Deformation

Permanent deformation is constituted as a portion of the total deformation that is not recoverable and accumulates throughout the useful life of the pavement (Lima and Mota, 2016). It manifests itself as variations in the thickness of the pavement layers that receive the most load concentrations. It is experienced by granular materials when subjected to cyclic loading for prolonged periods (Berthelot et al., 2009 and Xiao et al., 2012). Werkmeister et al. (2004) have emphasized that the analysis of permanent deformation behavior in base layers is essential to guarantee satisfactory pavement performance. It has been observed by Lekarp et al. (2000), Uthus et al. (2006) and Tutumluer and Pan (2008) that factors such as the state of stress, the frequency of load applications, the moisture content, the degree of saturation, the nature of the aggregate, the dry density and the grain. The size distribution affects the behavior of granular materials under permanent deformation.

The California Bearing Ratio (CBR) test, which involves penetration testing to evaluate the mechanical behavior of the road’s base and subbase layers, is essential to determine the maximum strength of materials used in pavement design (Haider et al., 2014). Unlike the CBR test, the resilience modulus test provides information on the stiffness of the material under confinement and cyclic axial loading, as described in AASHTO 307 (2002). The structural stability of unbound aggregate bases has been found to be influenced by the gradation of the aggregate, the shape of the particles and the angularity of coarse aggregates, as pointed out by Puppala (2008) and Tutumluer et al. (2000). The resilient modulus generally increases with the density of the material, as stated by Kolisoja (1997), Molenaar and van Niekerk (2002) and Berthelot et al. (2009). However, the resilient modulus of granular materials depends on moisture and stress, particularly when the fines content exceeds 5% of the total weight, and their stiffness tends to decrease when compacted on the wetter side of the optimal fine content. humidity, as indicated by Pacheco and Nazarian. (2011). Such permanent deformation conditions are known to increase the probability of cracks and ultimately lead to structural failure (Dawson et al., 1996 and Tutumler and Pan, 2008).

Materials and Methods

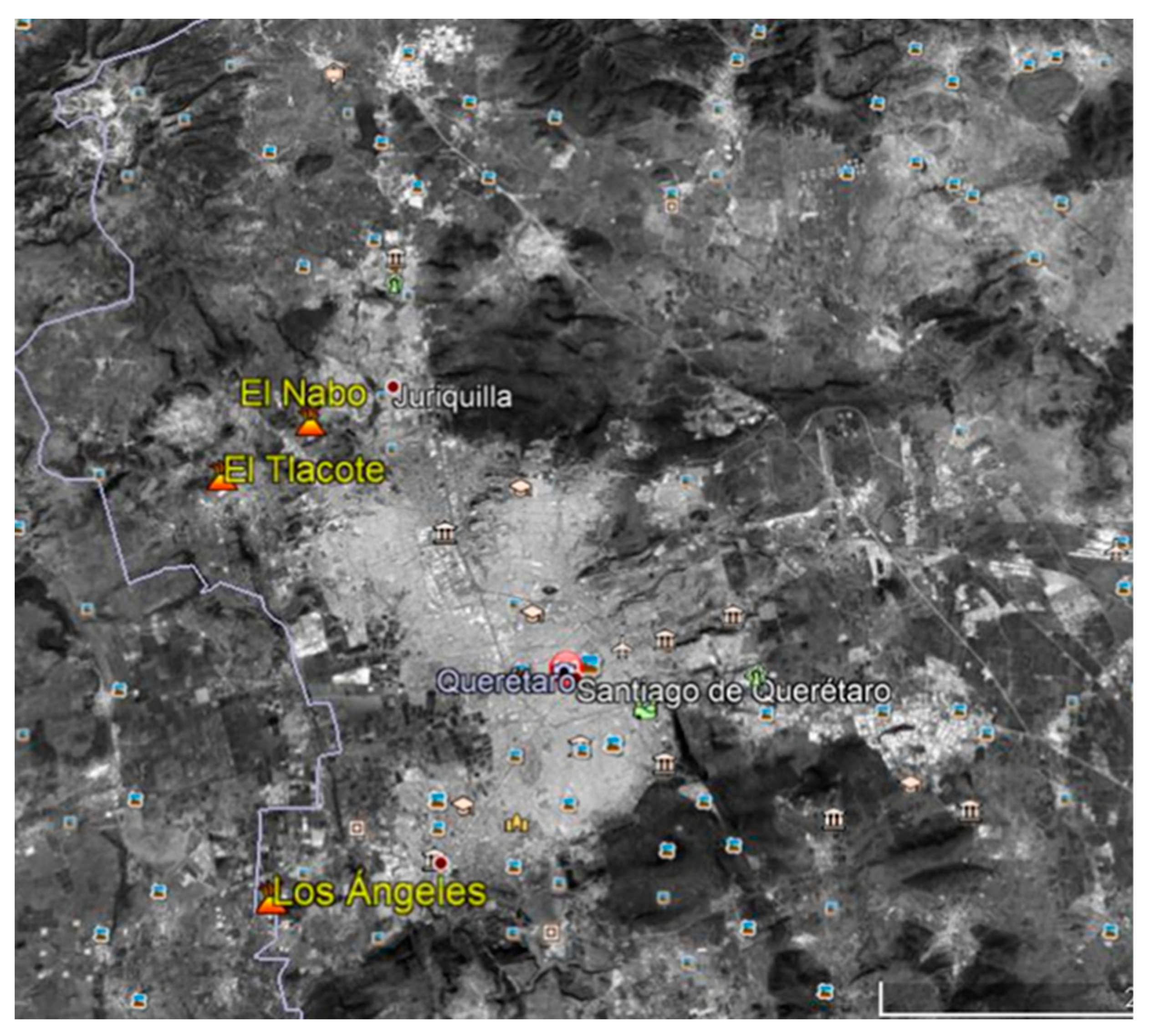

The research sites are located in the cities of Puebla de Los Ángeles and Santiago de Querétaro. In the first case, a quarry called “La Letra” was selected, located near the metropolitan area south of Puebla de Los Ángeles. In the second case, two quarries were chosen, “El Nabo” and “El Tlacote”, located west of Santiago de Querétaro, and another quarry, “Los Ángeles”, located southeast of the city. Sampling of materials for the hydraulic base was carried out in accordance with the ASTM D-75 (2019) standard.

3.1. Sample Size

The maximum aggregate size (MAS) observed ranged from one to two inches. Samples were collected in accordance with ASTM D75 (2019), with each sample weighing approximately 50 kg to 75 kg to cover additional testing requirements.

For the coarse fraction, following the ASTM C136 standard, samples were taken depending on the MAS: 10 kg for MAS of 1 inch and 20 kg for MAS of 2 inches. For the fine fraction, in accordance with ASTM C117, at least 300 g of material was collected and passed through Sieve No. 4. Maximum dry density tests for the aggregate were performed according to ASTM D1557, using method “C “, which specifies around eight kg of material per test, aiming for a minimum of four and a maximum of five density points, resulting in an estimated total material weight of 40 kg per particle size. The same weight was required for the California Bearing Ratio (CBR) test, where it was estimated that approximately 512 kg of material was needed for 64 samples. The permeability tests were carried out using a CBR mold, using a similar amount of material for each test.

3.2. Characterization and Methods:

The granulometric distributions of the samples were determined following the ASTM C136 and C117 standards. The specific gravities of the soils were measured according to ASTM C127 and C128. Classification of samples was performed in accordance with the Unified Soil Classification System (USCS) as described in ASTM D2487.

The maximum dry density of the material was determined by applying the modified stress of 2700 kN-m/m³ as specified in ASTM D1557, using a 6-inch mold for test “C”, with the material compacted in five layers and subjected to 56 strokes per layer.

For the California Bearing Ratio (CBR) tests, an automatic compression press with a five-ton capacity was used, performing the tests under unsaturated conditions as described in ASTM D1883. The procedure involved placing weight plates on the compacted material and performing 12 penetration cycles, except when the load reached five tons before penetrating 12.7 mm, which was the case in most tests.

Permeability experiments were performed using the prototype permeameter prepared in the same CBR mold for ease of testing. Two PVC plugs with rubber membranes were used to hermetically seal the system and plasticine was used to ensure that the hydraulic head was not lost. The installation was secured with two triangular steel plates and plastic hoses. The flow of water through the sample was induced and measured at specific intervals in a one-liter test tube, as shown in

Figure 1. Permeability calculations were performed in accordance with the regulations for test method A. or constant head, with the permeability coefficient k given by Equation (1).

where

k = hydraulic conductivity, m/s,

Q = quantity of flow, taken as the average of inflow and outflow, cm3,

L = length of specimen along path flow, cm,

A = cross-sectional area of specimen, cm2,

t = interval of time, s, over which the flow Q occurs, and

h = difference in hydraulic head across the specimen, m of water.

Results

Gradation

All quarries conform to the particle size specifications of the SICT, except for “La Letra,” which presents a gradation similar to the permeable models proposed by the FHWA in 1990. The origin of the materials is predominantly extrusive igneous, except for “El Nabo,” which consists of sedimentary conglomerates. The four quarries contain more than 50% gravel, classified by both AASHTO and SUCS as being of good to medium quality for use as base materials.

Table 1 displays the classification and geotechnical properties of the quarries selected for this study.

In the four quarries, only one met the criterion of having less than 5% fine content. However, in the proposed mixtures, which vary from 65% to 80% gravel and 35% to 20% sand, the proportions of 80% gravel to 20% sand consistently contain less than 5% fine material, with the sole exception of the Tlacote quarry.

4.1. Maximum Dry Density Achieved for Base Mixtures

Table 2 shows dry densities obtained and their respective optimum moisture content values carried by the Proctor modified assay. The average of each blend is shown and as it is in the quarry.

Table 2.

Main characteristics of samples from the different quarries.

Table 2.

Main characteristics of samples from the different quarries.

| Quarry |

|

LVW (kg/m3) |

SD

Ss

|

Modified Proctor Compaction test |

CBR (%) |

USCS |

| LL (%) |

PI (%) |

Direct values |

Corrected values |

(%) |

CE (kN*m/m3) |

|

(kg/m3) |

opt (%) |

(kg/m3) |

opt (%) |

| 1 |

25 |

8 |

1670 |

2.85 |

2158 |

6.2 |

2267 |

5.0 |

4.9 |

2686 |

82 |

GW |

| 2 |

N.P. |

N.P. |

1811 |

2.72 |

2230 |

5.3 |

2272 |

4.4 |

5.3 |

2642 |

86 |

SP |

| 3 |

N.P. |

N.P. |

1681 |

2.67 |

2162 |

2.6 |

2294 |

1.6 |

2.6 |

2642 |

92 |

GW |

| 4 |

N.P. |

N.P. |

1704 |

2.70 |

2304 |

5.9 |

2346 |

4.4 |

5.9 |

2645 |

139 |

GP |

Table 2.

Results of modified Proctor test for all materials.

Table 2.

Results of modified Proctor test for all materials.

| Material |

Mixture |

PI % |

Passing No. 200 sieve (%) |

OMC |

Maximum dry density (kg/m3) |

| El Nabo |

Original |

9.4 |

10.6 |

10.9 |

1913.4 |

| 65-35 |

7.6 |

9.2 |

1871.4 |

| 70-30 |

6.5 |

6.9 |

1825.7 |

| 75-25 |

5.4 |

6.9 |

1819.3 |

| 80-20 |

4.4 |

6.0 |

1838.7 |

| Los Ángeles |

Original |

3.6 |

8.6 |

7.5 |

2109.5 |

| 65-35 |

7.1 |

6.6 |

2044.9 |

| 70-30 |

6.1 |

6.5 |

1972.8 |

| 75-25 |

5.1 |

6.1 |

2028.9 |

| 80-20 |

4.1 |

4.4 |

1968.3 |

| Tlacote |

Original |

NP |

10.3 |

10.9 |

1851.1 |

| 65-35 |

NA |

NA |

NA |

| 70-30 |

9.3 |

9.1 |

1846.2 |

| 75-25 |

7.8 |

7.5 |

1825.0 |

| 80-20 |

6.2 |

5.6 |

1795.2 |

| La letra |

Original |

12.3 |

3.6 |

10.0 |

1881.1 |

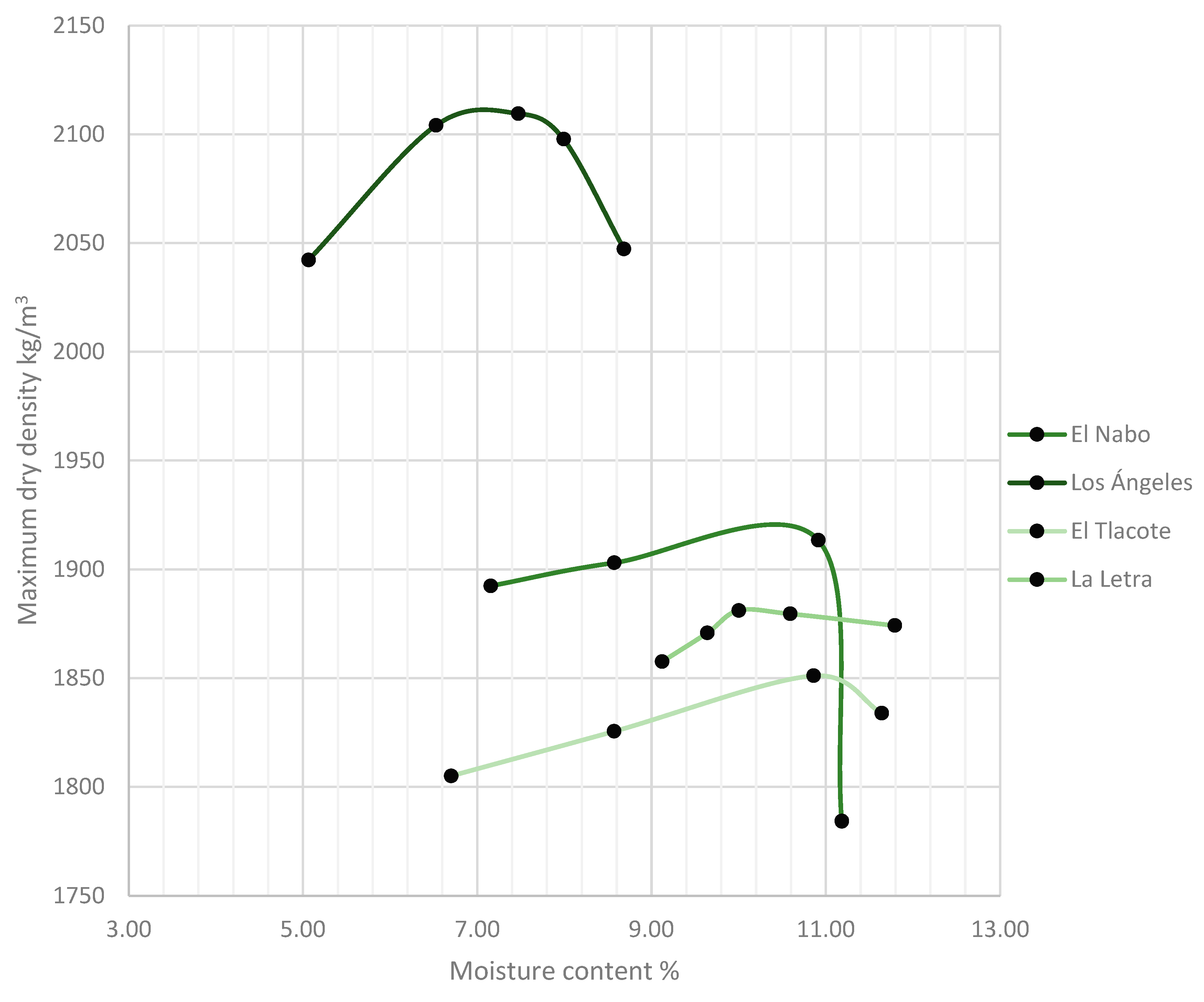

It is observed that an increase in the material passing through the No. 200 sieve leads to higher density values. Additionally, mixtures with a greater sand content consistently exhibit the highest maximum densities. The material with the lowest Plasticity Index (PI) achieves the highest maximum dry density, whereas a higher PI corresponds to lower maximum dry density values.

Figure 2 displays the graphs resulting from the modified Proctor test, illustrating that the material from the Los Ángeles quarry is the densest. This observation is corroborated by petrographic analysis, which shows that the gravel from this quarry has a higher specific gravity compared to the conglomerates from

El Nabo, which are characterized by a vesicular structure that is prone to fracturing. Similarly, the material from

Tlacote contains numerous clay lumps; these contribute significantly to the volume of the sample but do not enhance the compaction of the material, ultimately not benefiting the structural arrangement.

4.2. Unsoaked CBR Test Models

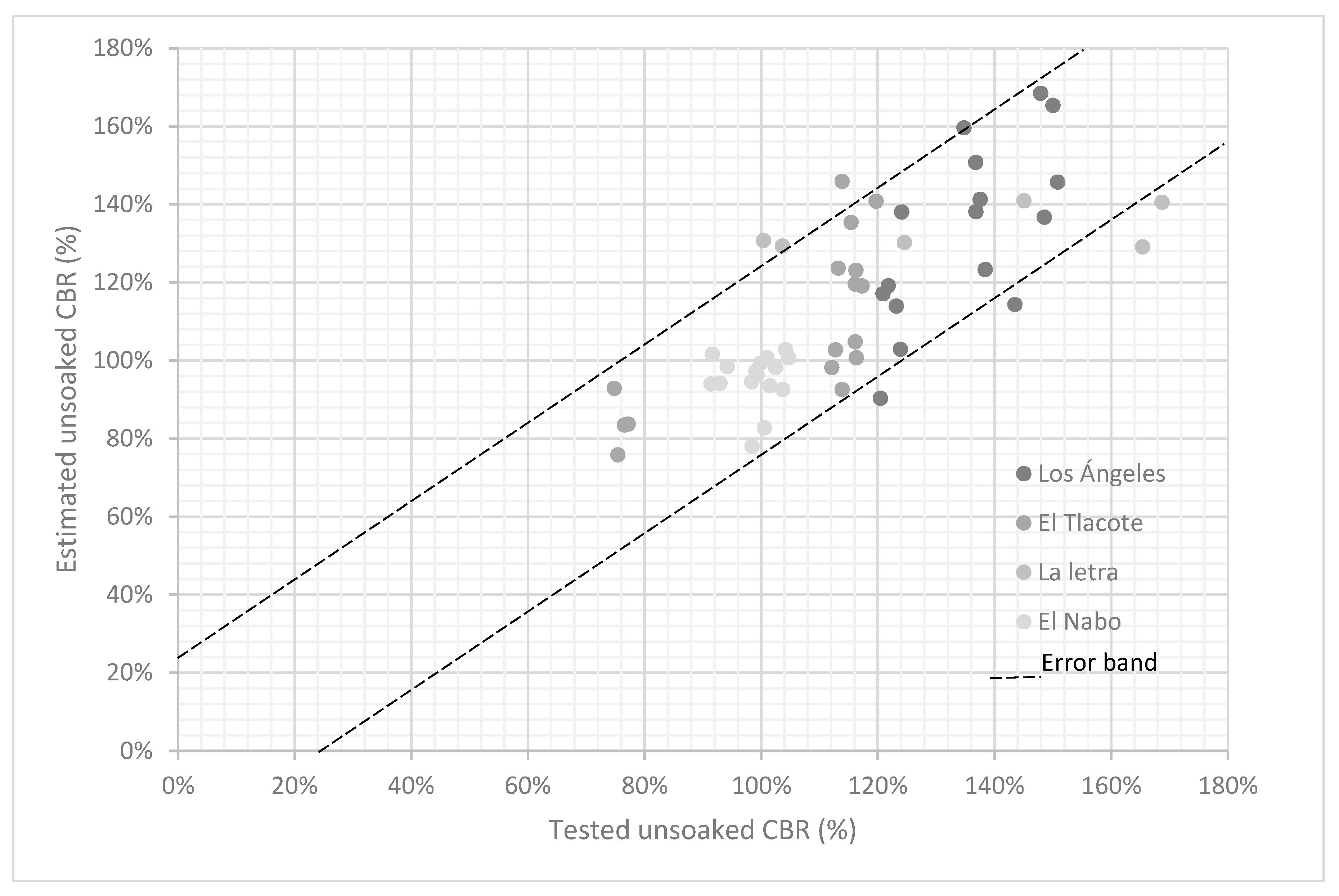

The results were analyzed for each gradation proposal and quarry, as depicted in

Table 3, which demonstrates the behavior he results were analyzed for each gradation proposal and quarry, as depicted in

Table 3, which demonstrates the behavior of various mixtures. It was observed that the quarries of

El Nabo,

Los Ángeles, and

Tlacote all registered their lowest California Bearing Ratio (CBR) values in the mixtures with the least sand content (80-20 ratio). Conversely, higher CBR values were noted in mixtures with ratios of 70-30 and 75-25, surpassing the CBR values of the original grain sizes from the quarries. The data presented represent the averages of all tests, including standard deviations. Notably, the highest standard deviation occurred in the

Tlacote quarry, likely due to the significant number of clay lumps in the mixture. These lumps offer minimal resistance to penetration during the loading process, thereby affecting the CBR results. On the other hand, the

El Nabo quarry showed the least variation, yet failed to meet the minimum values as prescribed by the SICT regulations or of various mixtures. It was observed that the quarries of

El Nabo,

Los Ángeles, and

Tlacote all registered their lowest California Bearing Ratio (CBR) values in the mixtures with the least sand content (80-20 ratio). Conversely, higher CBR values were noted in mixtures with ratios of 70-30 and 75-25, surpassing the CBR values of the original grain sizes from the quarries. The data presented represent the averages of all tests, including standard deviations. Notably, the highest standard deviation occurred in the Tlacote quarry, likely due to the significant number of clay lumps in the mixture. These lumps offer minimal resistance to penetration during the loading process in the press, thereby affecting the CBR results. On the other hand, the

El Nabo quarry showed the least variation, yet failed to meet the minimum values as recommended by the SICT regulations.

Table 3.

Summary of unsoaked CBR test, average value and standard deviation.

Table 3.

Summary of unsoaked CBR test, average value and standard deviation.

| Statistical parameter |

Material |

Gradation mixtures |

|

| 65-35 |

70-30 |

75-25 |

80-20 |

Original |

| Average |

El Nabo |

97% |

99% |

97% |

88% |

87% |

| Standard deviation |

3.17 |

3.81 |

2.29 |

8.46 |

8.43 |

| Average |

Los Ángeles |

86% |

132% |

121% |

84% |

100% |

| Standard deviation |

2.73 |

9.40 |

12.86 |

6.03 |

11.01 |

| Average |

El Tlacote |

NA |

154% |

138% |

113% |

126% |

| Standard deviation |

NA |

13.27 |

9.85 |

6.29 |

25.89 |

| Average |

La Letra |

NA |

NA |

NA |

NA |

135% |

| Standard deviation |

NA |

NA |

NA |

NA |

0.27 |

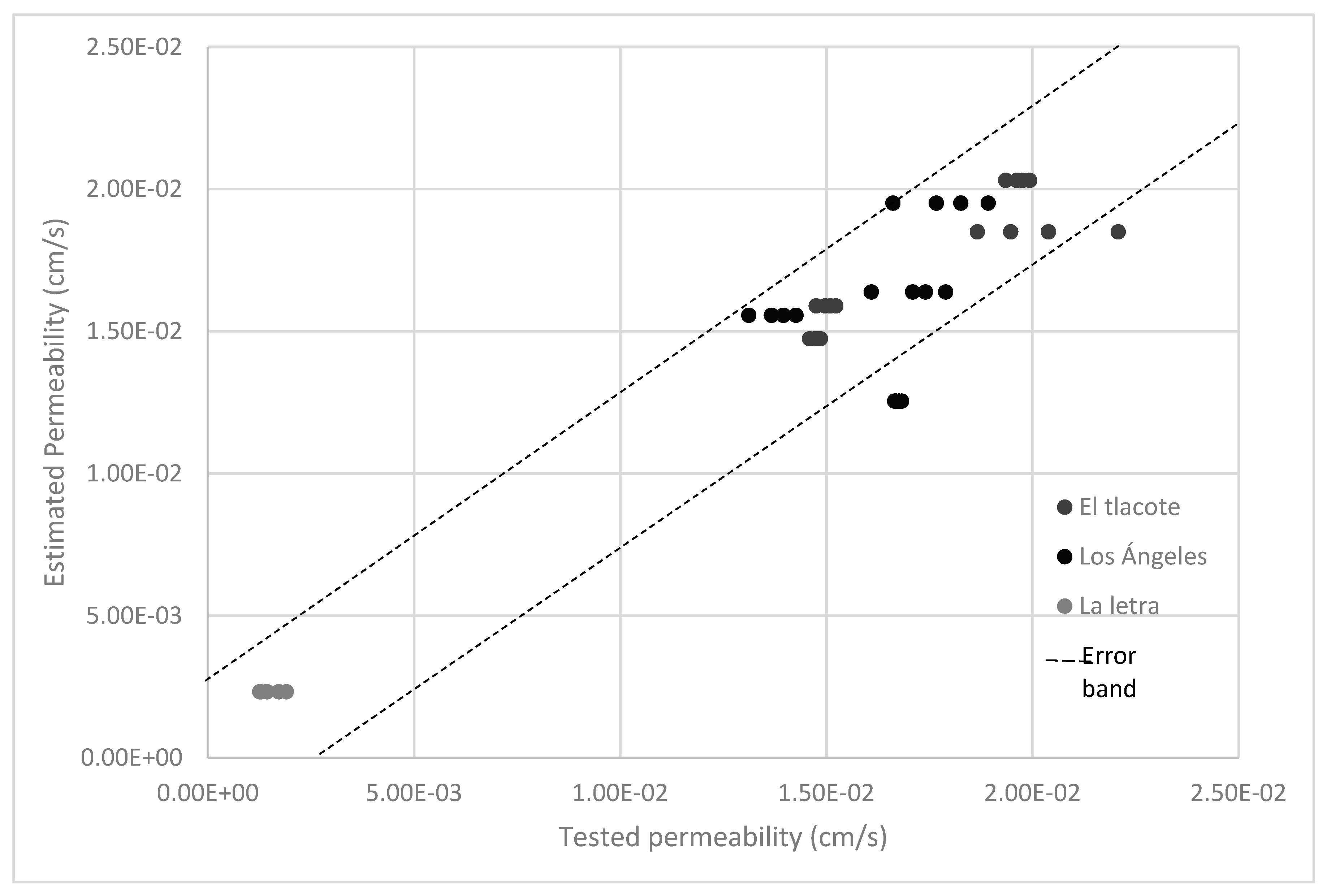

4.3. Permeability Test

The hydraulic conductivity test was performed for four quarries of materials, for a total of 36 tests. The average values obtained from permeability is in a range of 1.38 * 10-2 cm/s (39 ft /day) for the material of Los Ángeles to 2.02* 10-2 cm/s (57 ft / day) for The

Tlacote material (

Table 4).

The results of the permeabilities observed in this study are comparable to those found in graded aggregated base (GAB) materials analyzed by Haider et al. (2014) from Rockville, Bladensburg, Churchville, and Havre de Grace in Maryland, which ranged from 1.3 × 10^-2 cm/s (36 ft/day) to 2.7 × 10^-2 cm/s (76 ft/day). These materials, like those used in our project, are crushed rock products with physical properties characterized by a basaltic origin and similar specific gravities. In our quarries, an increase in hydraulic conductivity was noted when the mixture contained a lesser amount of sand. This enhancement in permeability, however, detrimentally impacted the California Bearing Ratio (CBR) values, as documented in

Table 3. Mixtures with the highest permeability exhibited the lowest CBR values. This phenomenon can be attributed to the reduced cohesive material in the mix, which increases the voids within the material matrix. Consequently, during the CBR testing, the increased voids allow for greater particle movement under the piston, thus reducing the mixture’s resistance to penetration.

4.4. Prediction Model of Permeability and Unsoaked CBR

The process for obtaining the values of the permeability test falls on an investment of significant time and a series of procedures time-consuming, since the compaction of the specimen in the mold until the inflow of water and cleaning the mold for testing another specimen again, it takes a time of about 1hour for a single person, considering that we have already the weighted specimen for the proctor test. In the case of CBR the procedure it is similar to timing issues, after the compaction process the penetration press loading of the specimen, and cleaning equipment carries approximately 40 minutes.

The development of a predictive model for the test values not only saves time but also facilitates the formulation of a theoretical proposal. This proposal integrates both evaluated parameters and aligns them with the quality standards of bases as established by the SICT.

The model was constructed using regression analysis, incorporating data from 60 CBR tests and 36 permeability tests conducted using statistical analysis. Equations 2 and 3 in the model consider the permeability and CBR values based on known index characteristics and physical properties. For the permeability model, the required inputs include the percentage of gravel, sand, d60, and the percentage of material passing through the No.200 sieve. For the CBR model, the necessary inputs are the percentage of gravels, optimum moisture content (OMC), coefficient of curvature (Cc), and the particle size d10.

where

G = percentage of gravels

S = percentage of sand

d60 = size of sieve hole in which 60% of soil will passes through them

F = percentage passing the No. 200 sieve.

where

G = percentage of gravels

OMC = optimum moisture content

Cc = coefficient of curvature

d10 = sieve of sieve hole in which 10% of soil will passes through them

Figure 3 and

Figure 4 were developed using the prediction models Equations (2) and (3). In both cases it is observed that the prediction models provide a reasonable correlation between predicted and measured for the CBR values and permeability, differentiated quarries, in order to ensure that the models are consistent for all quarries tested.

The predictive model yielded values for permeability with an error margin of 16% and for CBR within 17%. The model was validated for specimens containing 3.6 to 10% of material passing the No. 200 sieve, a coefficient of curvature (Cc) ranging from 2 to 18, a particle size (d10) from 0.2 to 1.1, and a d60 between 11 and 18. The optimum moisture content (OMC) was found to be between 5 to 10%, with gravel content between 70 to 80% and sand content from 20 to 30%. This prediction model has proven applicable for the crushed materials analyzed in this study, indicating its robustness and reliability for assessing similar types of materials

Discussion

The significance of developing CBR-k predictive models, such as those detailed in this study, lies in the efficiency and simplicity of the laboratory tests used to obtain the model parameters. These tests are characterized by their rapid execution and ease of use, with minimal interference from the operator. This approach not only saves time but also maintains precision, enhancing the practicality and effectiveness of the testing process for engineering applications.

Conclusions

This study provides a comprehensive analysis of the California Bearing Ratio (CBR) and permeability of base course materials sourced from local quarries in Querétaro and Puebla, Mexico, highlighting the significant potential of these materials in meeting and even exceeding international pavement standards. By validating the methodology used to calculate permeability—closely aligning with the findings from Haider et al. (2014) in terms of petrography and index characteristics. This research confirms the efficacy of the permeameter prototype (rigid wall CBR) used in testing.

The study materials and experimental designs were validated, showing great similarities with established research, thereby reinforcing the reliability of our permeability measurements. These results demonstrate the capability of locally sourced materials to achieve permeability coefficients close to the recommended value of 0.35 cm/s (1000 ft/day) by the Federal Highway Administration (FHWA), albeit two to three decimal places lower.

Findings indicate a clear correlation between the granulometric variations and the permeability coefficients. Mixtures with a lower sand content notably increased the permeability coefficient but reduced the support value as measured by CBR. This underscores the need to balance material composition to optimize both permeability and load-bearing capabilities of the pavement structures.

The predictive models developed for permeability and CBR values demonstrated a reasonable agreement between predicted and measured values, with an error margin of 16-17%. These models prove to be robust and reliable when the material characteristics are consistent with those tested, offering a valuable tool for preliminary assessments in pavement design.

It is recommended to further refine these models and expand testing to include a wider range of materials and environmental conditions to enhance their applicability and accuracy. Future research should also focus on long-term field performance to validate these laboratory findings and to adjust mix designs for optimized performance in specific regional contexts.

This research advocates for adjustments in local and international standards, suggesting that tailored proposals based on specific index specifications could lead to better-aligned and more effective pavement solutions. Ensuring that the materials meet the Mexican standards of the SICT and the FHWA recommendations could lead to significant improvements in pavement durability and cost-effectiveness.

Aknowledgments

Authors are gratefully acknowledged the financial support of the Consejo Nacional de Ciencia y Tecnología (CONACYT) for this research. Under the 209837 CVU grant.

References

- Abdolreza, O., Sajjad, S., Goran, O., Erol, T., Sheila, B., Heather, S., & Mathew, E. (2017). Results of soaked and unsoaked California bearing rate test on unbound aggregates with varying amounts of fines and dust ratios. Transportation Research Record: Journal of the Transportation Research Board, 2655, 13-19. [CrossRef]

- American Association of State Highway and Transportation Officials. (2002). AASHTO T 307-99 (2002): Standard Method of Test for Determining the Resilient Modulus of Soils and Aggregate Materials. Washington, D.C.: AASHTO.

- ASTM International. (2012). ASTM D1557-12: Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Modified Effort (56,000 ft-lbf/ft³ (2,700 kN-m/m³)). West Conshohocken, PA: ASTM International. [CrossRef]

- ASTM International. (2015). ASTM C127-15: Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate. West Conshohocken, PA: ASTM International. [CrossRef]

- ASTM International. (2015). ASTM C128-15: Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate. West Conshohocken, PA: ASTM International. [CrossRef]

- ASTM International. (2016). ASTM D1883-16: Standard Test Method for California Bearing Ratio (CBR) of Laboratory-Compacted Soils. West Conshohocken, PA: ASTM International. [CrossRef]

- ASTM International. (2017). ASTM C117-17: Standard Test Method for Materials Finer than 75-μm (No. 200) Sieve in Mineral Aggregates by Washing. West Conshohocken, PA: ASTM International. [CrossRef]

- ASTM International. (2019). ASTM D75/D75M-19: Standard Practice for Sampling Aggregates. West Conshohocken, PA: ASTM International. [CrossRef]

- ASTM International. (2019). ASTM C136/C136M-19: Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. West Conshohocken, PA: ASTM International. [CrossRef]

- Berthelot, C., Podborochynski, D., Marjerison, B., & Gerbrandt, R. (2009). Saskatchewan field case study of triaxial frequency sweep characterization to predict failure of a granular base across increasing fines content and traffic speed applications. Journal of Transportation Engineering, 135(11), 907-914. [CrossRef]

- Bouchedid, B., & Humphrey, N. (2005). Permeability of base material for Maine roads. Transportation Research Record, 1936, 142-149. [CrossRef]

- Cetin, B., Aydilek, A. H., & Guney, Y. (2010). Stabilization of recycled base material using high carbon fly ash. Resources, Conservation and Recycling, 54(11), 879-892. [CrossRef]

- Dawson, A. R., Paute, J. L., & Thom, N. H. (1996). Mechanical characteristics of unbound granular materials as a function of condition. In A. Gomes Correia (Ed.), Flexible Pavements (pp. 35-45). Balkema, Rotterdam.

- Forsyth, R. A., Wells, G. K., & Woodstrom, J. H. (1987). Economic impact of pavement subsurface drainage. Transportation Research Record, No. 1121, TRB, National Research Council, Washington, D.C., 77-85.

- FHWA Technical Guide Paper on Subsurface Pavement Drainage. (1990). Technical Paper 90-01. FHWA Pavement Division, Office of Engineering, U.S. Department of Transportation, Washington, D.C.

- Günes, A., Tevfik, M., & Vefa, M. (2018). Investigation of the effect of recycled asphalt pavement material on permeability and bearing capacity in the base layer. Advances in Civil Engineering, 2018, 1-6. [CrossRef]

- Harpreet, K., Deletic, A., & McCarthy, D. (2014). Assessment of impact of filter design variables on clogging in stormwater filters. Water Resources Management, 28, 1873-1885. [CrossRef]

- Haider, I., Kaya, Z., Cetrin, A., Haitipoglu, M., Cetin, B., & Aydilek, A. H. (2014). Drainage and mechanical behavior of highway base materials. Journal of Irrigation and Drainage Engineering, 140(1), 1-14. [CrossRef]

- Hazen, A. (1911). Discussion of dams on sand foundations. Transactions of the American Society of Civil Engineers, 73, 199-203.

- Haynes, J. H., & Yoder, E. J. (1963). Effects of repeated loading on gravel and crushed stone base course materials used in the AASHO road test. Joint Highway Research Project, Purdue University, Lafayette, Indiana.

- Hicks, R. (1970). Factors influencing the resilient properties of granular materials (Ph. D. thesis), University of California, Berkeley, Calif.

- Hicks, R. G., & Monismith, C. L. (1971). Factors influencing the resilient properties of granular materials. Transportation Research Record, 345, 15-31.

- Khosravifar, S., Asefzadeh, A., & Schwartz, W. (2013). Increase of resilient modulus of unsaturated granular materials during drying after compaction. In Proceedings of the Geo-Congress 2013: Stability and Performance of Slopes and Embankments III (pp. 2009-2042). ASCE, Alexandria, VA. [CrossRef]

- Kolisoja, P. (1997). Resilient deformation characteristics of granular materials (Ph. D. thesis). Tampere University of Technology, Tampere, Finland.

- Lima, C., & Motta, L. (2016). Study of permanent deformation and granulometric distribution of graded crushed stone pavement material. Advances in Transportation Geotechnics, 143, 1-8. [CrossRef]

- Lekarp, F., Isacsson, U., & Dawson, A. (2000). State of the art, I: Resilient response of aggregates. Journal of Transportation Engineering, 126, 66-75. [CrossRef]

- Molenaar, A. A. A., & Van, Niekerk, A. A. (2002). Effects of gradation, composition, and degree of compaction on the mechanical characteristics of recycled unbound materials. Transportation Research Record, 1787, 73-82. [CrossRef]

- Montes-Arvizu, M. E., Chavez-Alegria, O., Rojas-Gonzalez, E., Gaxiola-Camacho, J. R., & Millan-Almaraz, J. R. (2020). CBR Predictive Models for Granular Bases Using Physical and Structural Properties. Applied Sciences, 10(4), 1414. [CrossRef]

- Pacheco, L. G., & Nazarian, S. (2011). Impact of moisture content and density on stiffness-based acceptance of geomaterials. Transportation Research Record, 2212, 1-13. [CrossRef]

- Puppala, A., National Research Council, U.S. Transportation Research Board, National Cooperative Highway Research Program, American Association Of State Highway And Transportation Officials, & United States Federal Highway Administration. (2008). Estimating stiffness of subgrade and unbound materials for pavement design. Washington, D.C.: Transportation Research Board. [CrossRef]

- Secretaría de Infraestructura, Comunicaciones y Transportes. (2011). N-CMT-4-02-002/11: Normas de calidad de materiales. Procedimiento para la determinación del contenido de humedad en suelos y materiales pétreos. Diario Oficial de la Federación.

- Smith, W., & Nair, K. (1973). Development of procedures for characterization of untreated granular base course and asphalt-treated base course materials. Federal Highway Administration. Final report DOT-FH-7785.

- Soliman, H., & Shalaby, A. (2015). Permanent deformation behavior of unbound granular base materials with varying moisture and fines content. Transportation Geotechnics, 4, 1-12. [CrossRef]

- Stolle, D., Guo, P., & Liu, Y. (2009). Resilient modulus properties of granular highway materials. Canadian Journal of Civil Engineering, 36(4), 639-654. [CrossRef]

- Tutumluer, E., & Pan, T. (2008). Aggregate morphology affecting strength and permanent deformation behavior of unbound aggregate materials. Journal of Materials in Civil Engineering, 20(9), 617-627. [CrossRef]

- Tutumluer, E., Mishra, D., & Butt, A. A. (2000). Characterization of Illinois aggregates for subgrade replacement and subbase. Illinois Center for Transportation. Report ICT-09-060, 2009-2042.

- Uthus, L., Saarelainen, S., & Makkonen, L. (2006). A study on the influence of water and fines on the deformation properties and frost heave of unbound aggregates. Proceedings of the 13th International Conference on Cold Regions Engineering. Orono, Maine: American Society of Civil Engineers. Vuong, B. (1992). Influence of density and moisture content on dynamic stress-strain behavior of a low plasticity crushed rock. Road and Transport Research, 1(2), 88-100. [CrossRef]

- Werkmeister, S., Dawson, A., & Wellner, F. (2004). Permanent deformation behavior of granular materials. Road Materials and Pavement Design, 6, 31-51. [CrossRef]

- Xiao, Y., Tutumluer, E., Qian, Y., & Siekmeier, J. A. (2012). Gradiation effects influencing mechanical properties of aggregate base-granular subbase materials in Minnesota. Transportation Research Record, 2267. [CrossRef]

- Yong, C. F., McCarthy, D. T., & Deletic, A. (2012). Predicting physical clogging of porous and permeable pavements. Journal of Hydrology, 481, 48-55.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).