Submitted:

16 July 2024

Posted:

17 July 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

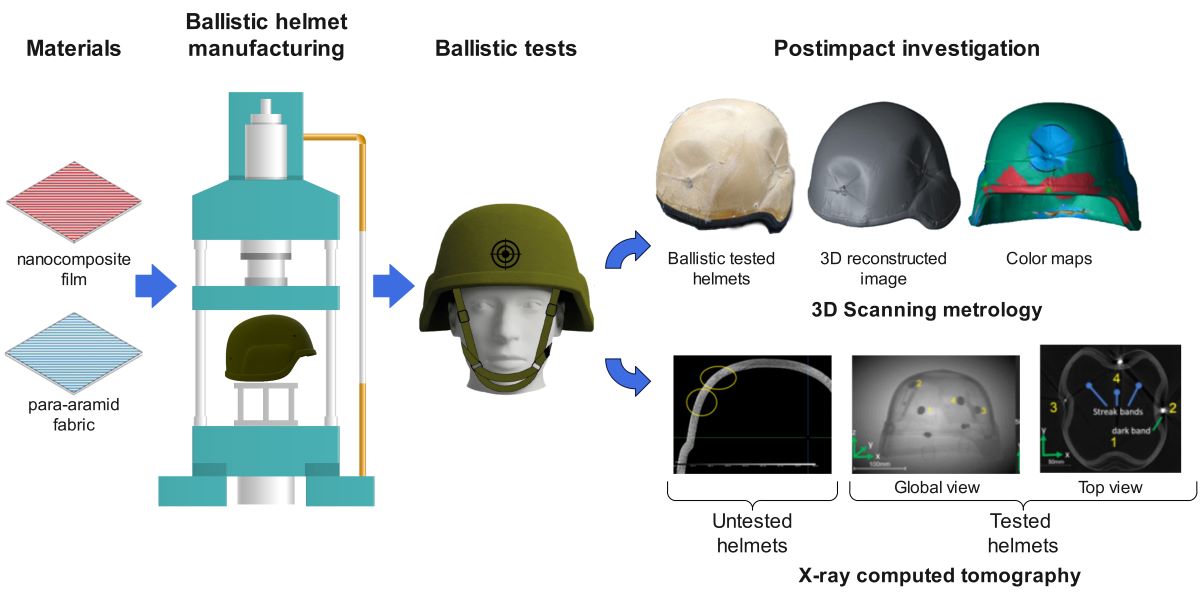

2. Materials and Methods

2.1. Materials

2.2. Ballistic Helmet Manufacturing

2.3. Ballistic Tests

2.4. 3D Scanning Metrology

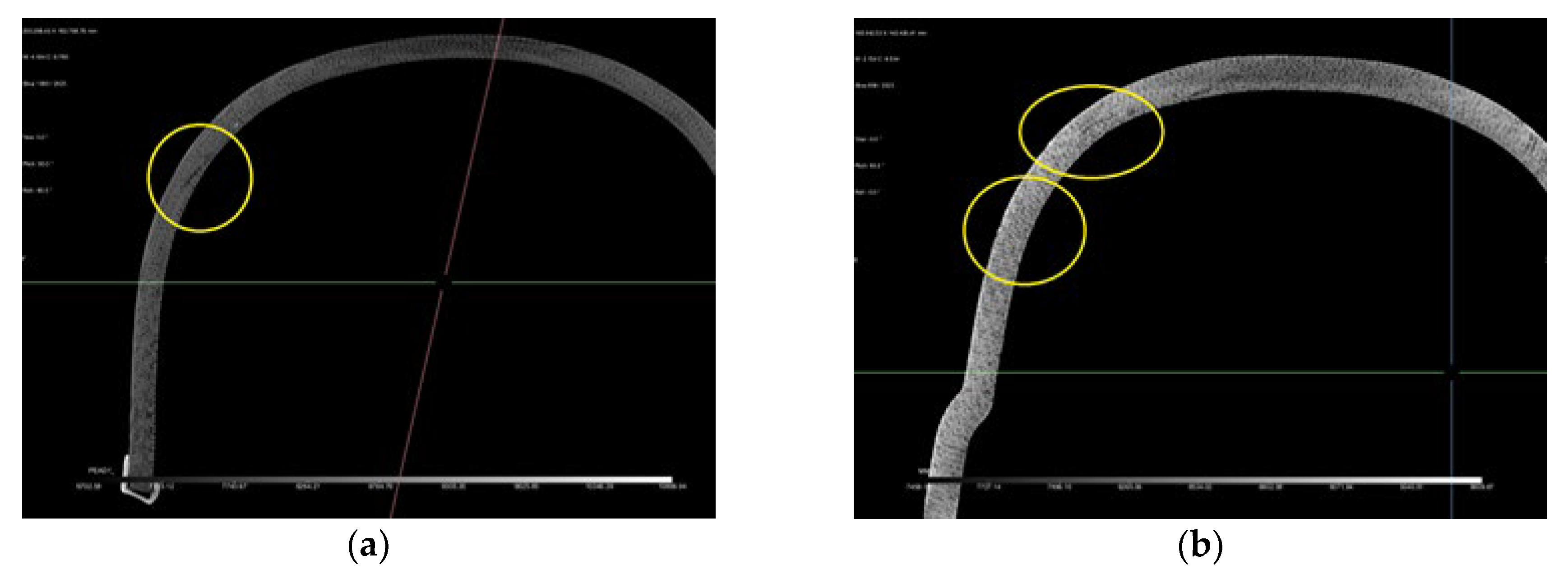

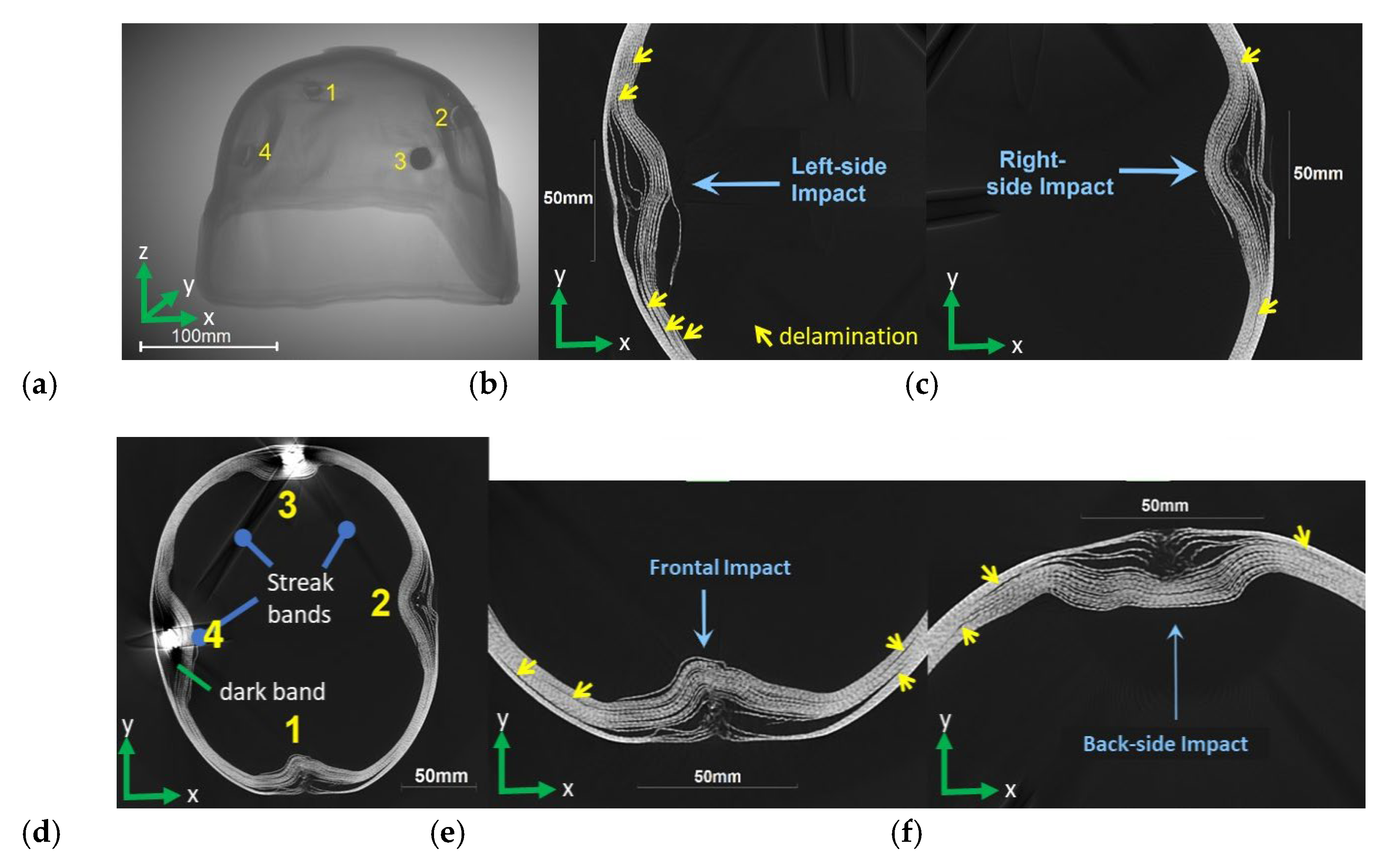

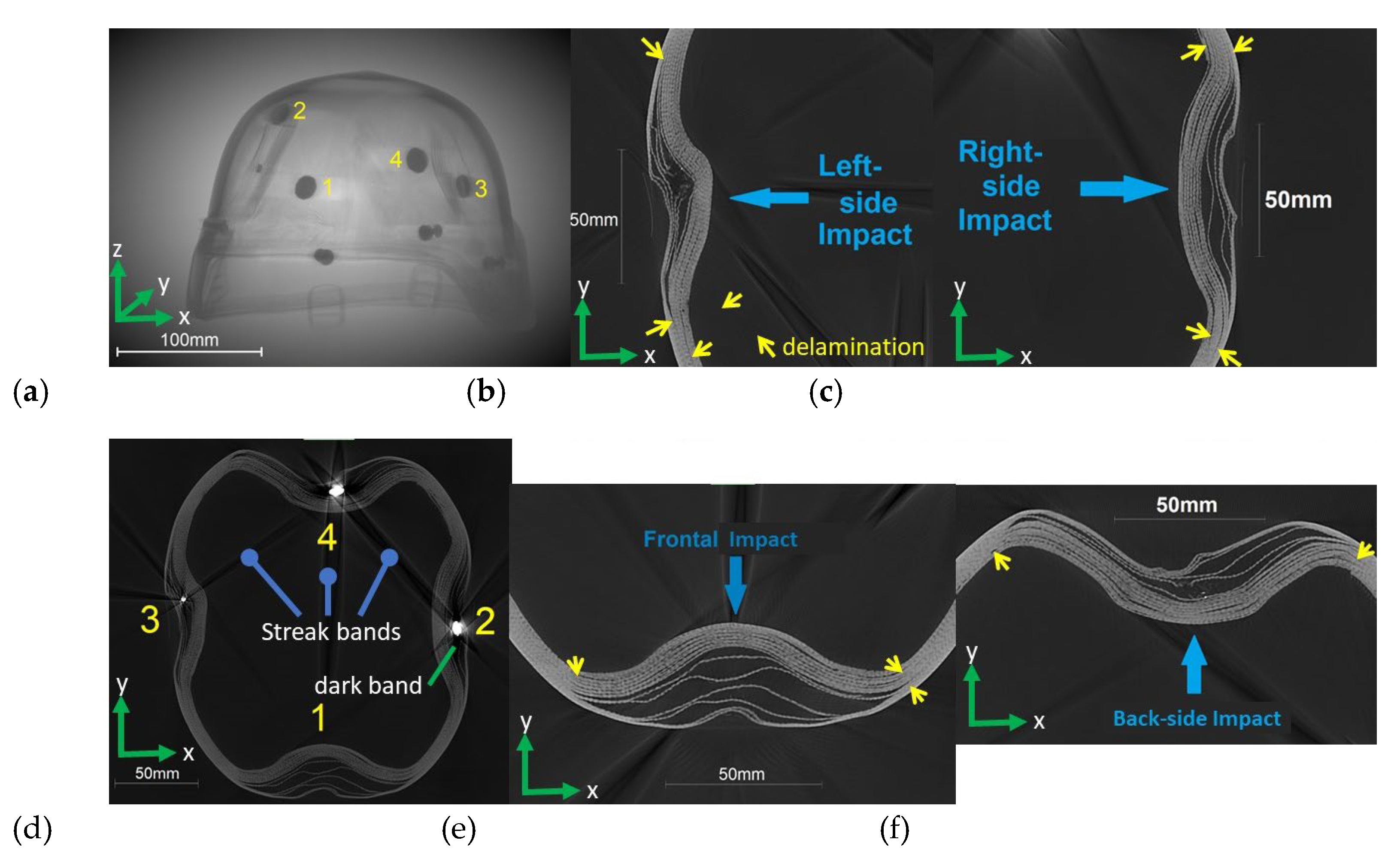

2.5. X-ray Computed Tomography

3. Results and Discussion

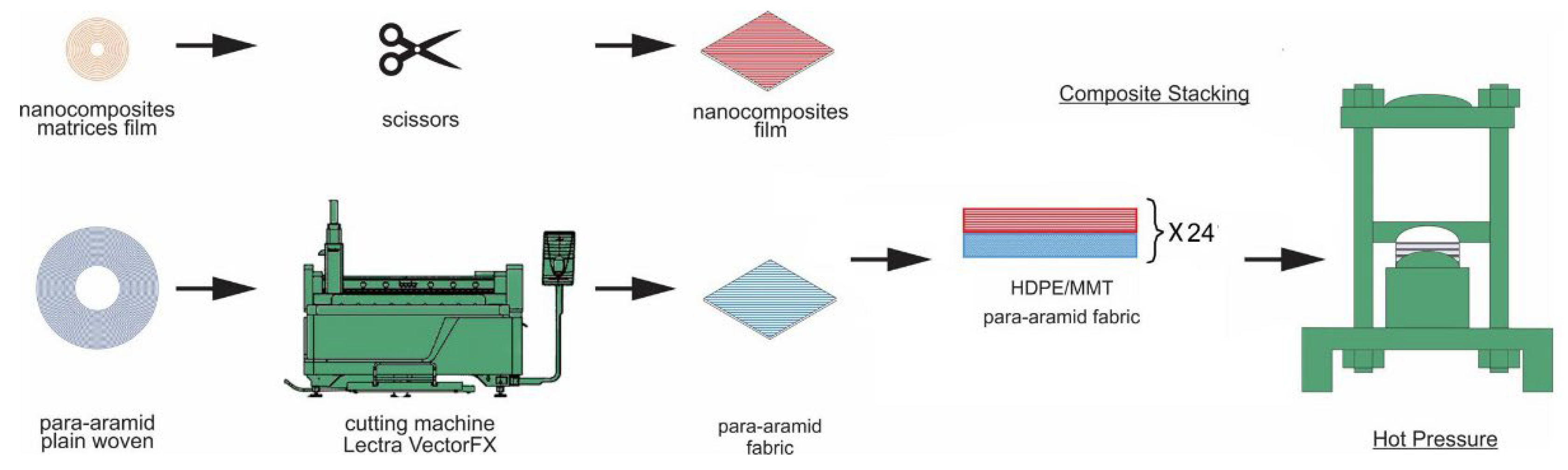

3.1. Ballistic Helmet Manufacturing

- While the thermoplastic matrices were cut with ordinary scissors, the K129 aramid fabric was cut using a Lectra VectorFX mechanical cutting machine.

- The fiber and matrix preforms were stacked one by one manually. Twenty-four layers of fiber and matrix were employed to produce a single ballistic helmet.

- Two different assemblies were studied: HDPE: stacking the 24 layers of fiber and HDPE matrix; and HDPE/MMT: stacking the 24 layers of fibers and the HDPE/MMT matrix;

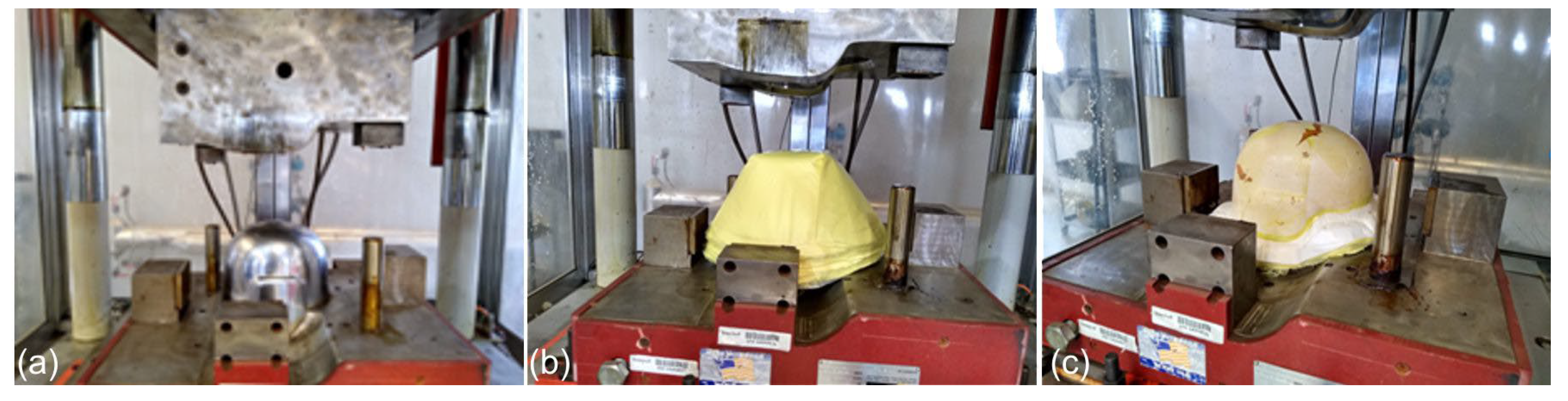

- An FKL 200 ton heat press with a water-cooling system was used to process the helmet shells. The equipment has an ACH mold installed, as shown in Figure 4(a), and the 24 preform layers are placed on the mold, as shown in Figure 4(b), which produces an item with surplus material, as shown in Figure 4(c).

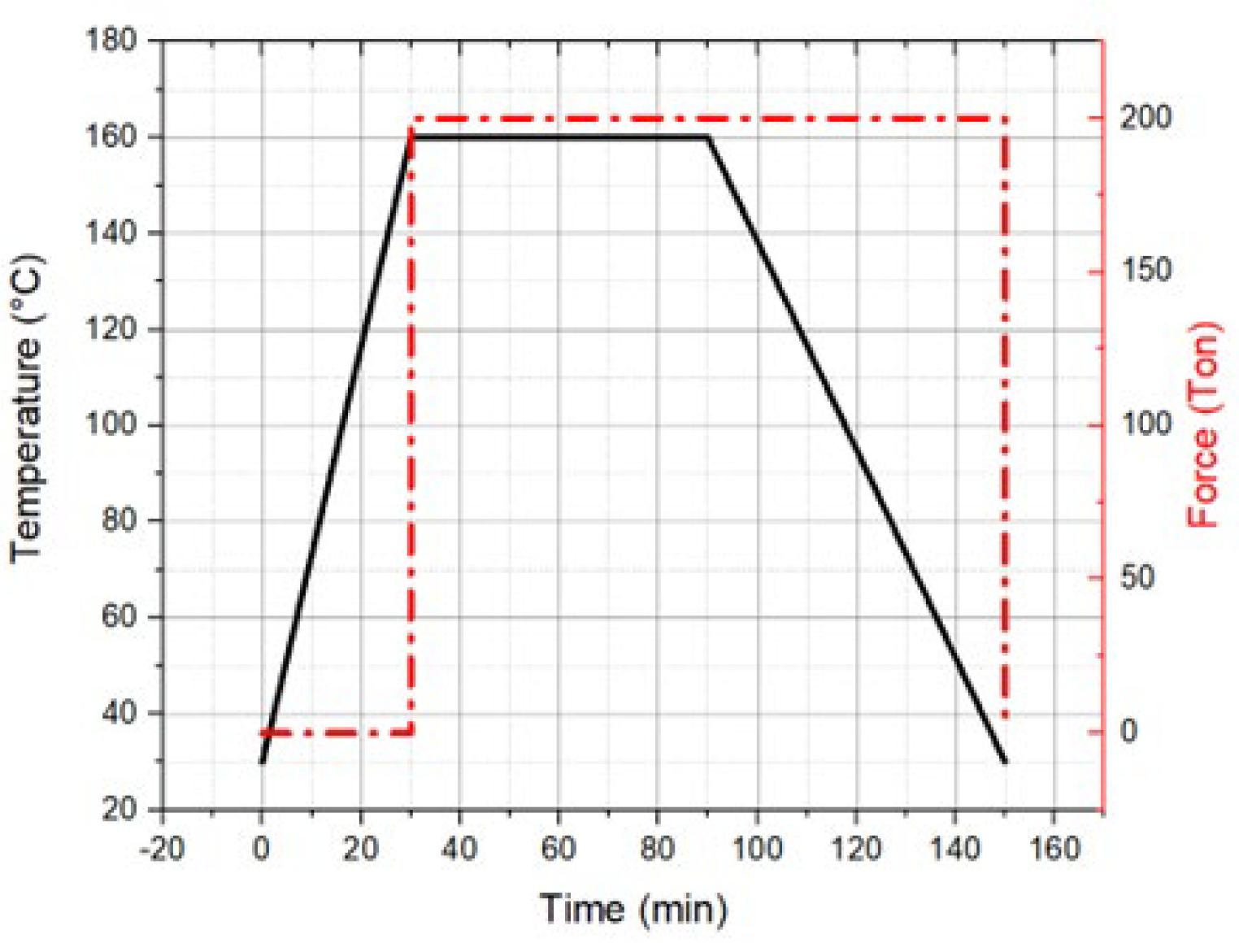

- The temperature and force applied are summarized in Figure 5. A degassing procedure was used to remove air bubbles from the layers, minimizing manufacturing defects.

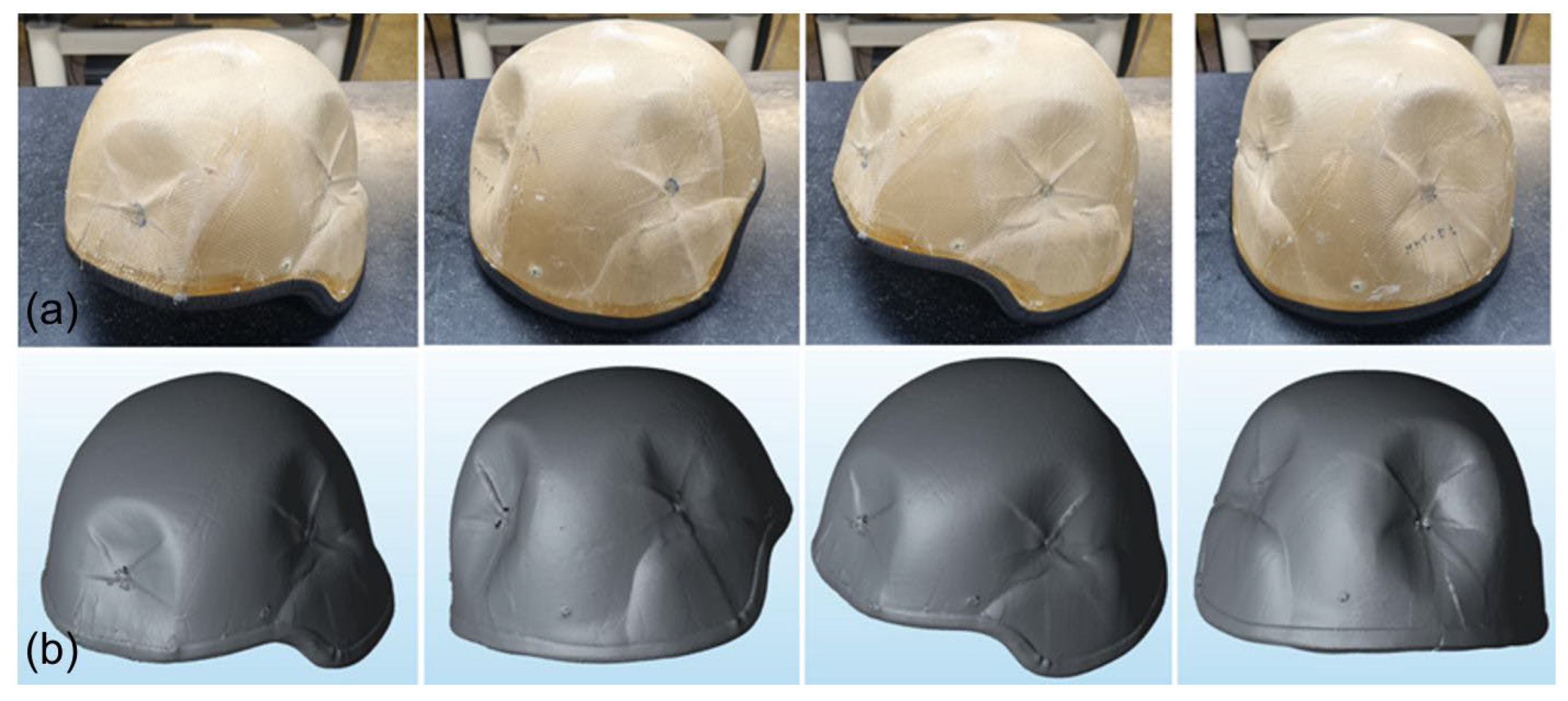

- After heating, the rubber and pads are glued to the shell manually. The chin piece is connected to the shell through four drill holes. The thermoplastic-based ballistic helmets were then ready for testing.

3.2. Ballistic Tests

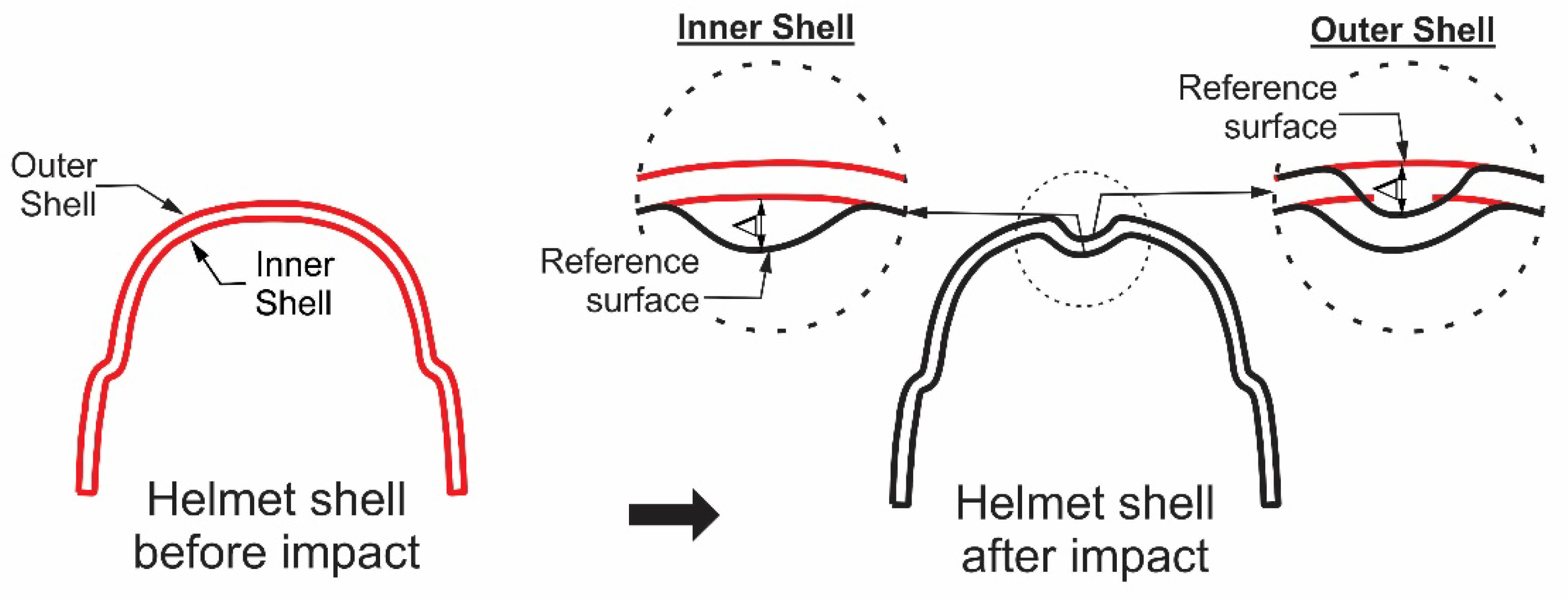

3.3. 3D Scanning Metrology

3.3. X-ray Computed Tomography

4. Conclusions

6. Patents

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Laible RC (2012) Ballistic Materials and Penetration Mechanics. Vol 5. Elsevier, Netherlands.

- Kulkarni SG, Gao XL, Horner SE, Zheng JQ, David NV (2013) Ballistic helmets – Their design, materials, and performance against traumatic brain injury. Compos Struct. 101:313-331. [CrossRef]

- Hamouda AMS, Sohaimi RM, Zaidi AMA, Abdullah S (2012) Materials and design issues for military helmets. In: Sparks E, ed. Advances in Military Textiles and Personal Equipment. 1st edn. Elsevier, Netherlands pp: 103-138. [CrossRef]

- Liang Y, Chen X, Soutis C (2022) Review on Manufacture of Military Composite Helmet. Appl Compos Mater 29(1):305-323. [CrossRef]

- Dias RR, Zattera AJ, Pereira IM, Soares BG (2021) Ballistic impact performance of composite laminates based on high-density polyethylene/montmorillonite nanocomposite and Aramide fiber. Polym Compos 42(10):5586-5597. [CrossRef]

- de Tomasi Tessari B, Vargas N, Rodrigues Dias R, et al. (2022) Influence of the addition of graphene nanoplatelets on the ballistic properties of HDPE/aramid multi-laminar composites. Polym-Plast Technol Mater 61(4):363-373. [CrossRef]

- Vargas-Gonzalez L, Walsh SM, Wolbert J (2011) Impact and Ballistic Response of Hybridized Thermoplastic Laminates. U.S. Army Research Laboratory Report ARL-MR-0769.

- Freitas CJ, Bigger RP, Grimm M v, Mackiewicz J. Resin/Fabric Composites Dynamic Back Face Deflection Characteristics due to Ballistic Impact (2014) In: CAMX Conference Proceedings. Composites and Advanced Materials Expo pp 1-14.

- Sapozhnikov SB, Kudryavtsev OA, Zhikharev MV (2015) Fragment ballistic performance of homogenous and hybrid thermoplastic composites. Int J Impact Eng 81:8-16. [CrossRef]

- Vargas-Gonzalez LR, Gurganus JC (2015) Hybridized composite architecture for mitigation of non-penetrating ballistic trauma. Int J Impact Eng. 86:295-306. [CrossRef]

- Zhang TG, Satapathy SS, Vargas-Gonzalez LR, Walsh SM (2015) Ballistic impact response of Ultra-High-Molecular-Weight Polyethylene (UHMWPE). Compos Struct 133:191-201. [CrossRef]

- Bhatnagar A (2006) Lightweight Ballistic Composites Military and Law-Enforcement Applications. Elsevier, Netherlands.

- Cunniff, Parker (2018) The Effect of Preform Shape on Ballistic Impact Performance, Coverage and Seam Density in Combat Helmets. In: Proceedings of 24th International Symposium on Ballistics.

- Grick SJ (1983) Helmet shell fabric layer and method of making the same. U.S. Patent Documents U.S. US4596056A.

- White MR (1988) Ballistic helmet body. U.S. Patent Documents U.S. US4908877A.

- Hanks JA, West BC, McMinn JH. Composite material: a ballistic resistant article made from same and method of making the article. U.S. Patent Documents U.S. US20130095716A1.

- Walsh SM, Scott BR, Spagnuolo DM (2005) The Development of a Hybrid Thermoplastic Ballistic Material with Application to Helmets. U.S. Army Research Laboratory Report ARL-TR-3700.

- Walsh SM, Scott BR, Spagnuolo DM, Wolbert JP (2006) Hybridized Thermoplastic Aramids: Enabling Material Technology for Future Force Headgear U.S. Army Research Laboratory Report.

- Campbell DT, Cramer DR (2008) Hybrid Thermoplastic Composite Ballistic Helmet Fabrication Study. Adv. Mater. Process Eng.

- Marissen R, Duurkoop D, Hoefnagels H, Bergsma OK (2010) Creep forming of high strength polyethylene fiber prepregs for the production of ballistic protection helmets. Compos Sci Technol 70(7):1184-1188. [CrossRef]

- Fejdyś M, Łandwijt M, Habaj W, Struszczyk MH (2015) Ballistic Helmet Development Using UHMWPE Fibrous Materials. FIBRES & TEXTILES in Eastern. Fibres Text East Eur 23(109):89-97.

- Ning H, Pillay S, Thattaiparthasarathy KB, Vaidya UK (2017) Design and manufacturing of long fiber thermoplastic composite helmet insert. Compos Struct 168:792-797. [CrossRef]

- Ahn H, Kuuttila NE, Pourboghrat F (2018) Mechanical analysis of thermo-hydroforming of a fiber-reinforced thermoplastic composite helmet using preferred fiber orientation model. J Compos Mater. 2018;52(23):3183-3198. [CrossRef]

- National Institute of Justice Standard NIJ-STD 0106.01. Standard for Ballistic Helmets. Published online 1981:1-16.. https://www.ojp.gov/pdffiles1/nij/077182.pdf Accessed December 13, 2022.

- ASTM Standard E1742/E1742M-18. Standard Practice for Radiographic Examination. Published online 2018:1-17. [CrossRef]

- Nguyen T (2010) Effects of Curvature on the Stresses of a Curved Laminated Beams Subjected to Bending. Dissertation, University of Texas.

- Sause MGR. Computed Tomography. In: In Situ Monitoring of Fiber-Reinforced Composites. Springer Germany pp 457-532. [CrossRef]

- Maire E, Withers PJ (2014) Quantitative X-ray tomography. Int Mater Rev 59(1):1-43. [CrossRef]

- Garcea SC, Wang Y, Withers PJ (2018) X-ray computed tomography of polymer composites. Compos Sci Technol 156:305-319. [CrossRef]

| Matrix | Hit | Impact | Back Face | Classification | Speed (m/s) |

|---|---|---|---|---|---|

| HDPE | 1 | Front | Large | NP | 360.72 |

| 2 | Right | Large | NP | 364.22 | |

| 3 | Back | Large | NP | 367.67 | |

| 4 | Left | Large | NP | 360.61 | |

| HDPE/MMT | 1 | Front | Large | NP | 360.48 |

| 2 | Right | Large | NP | 362.62 | |

| 3 | Back | Large | NP | 368.24 | |

| 4 | Left | Large | NP | 364.95 |

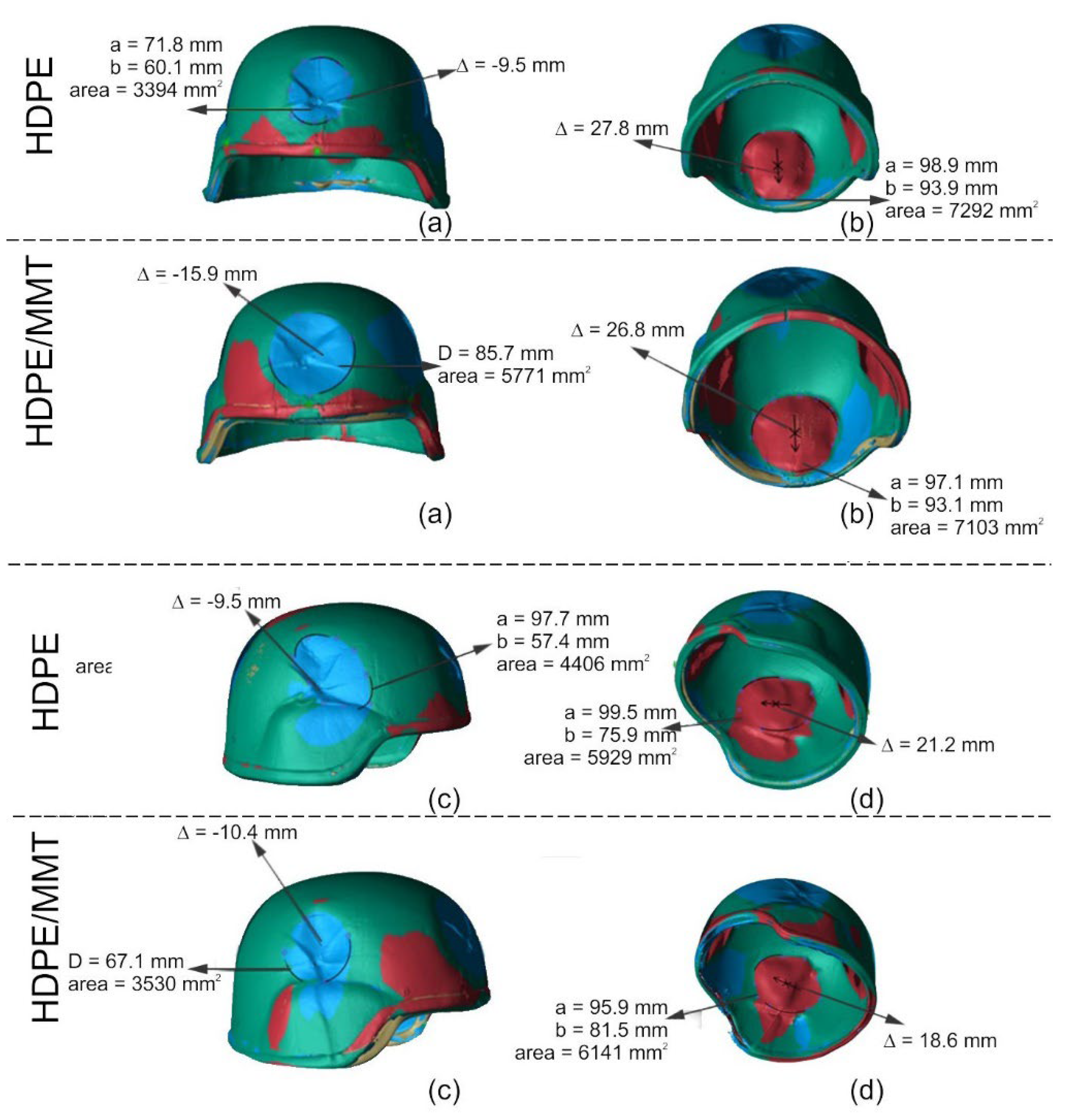

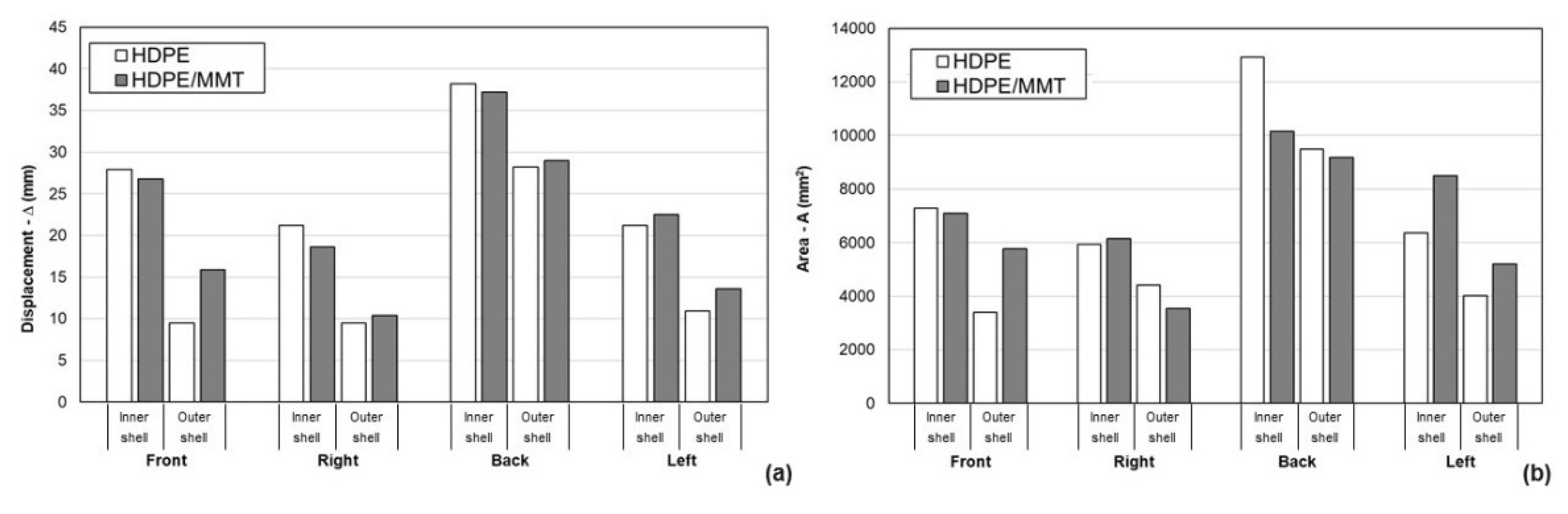

| D (mm) | |||||

| Front | Right | Back | Left | ||

| Inner shell | HDPE | 27.9 | 21.2 | 38.2 | 21.2 |

| HDPE/MMT | 26.8 | 18.6 | 37.2 | 22.5 | |

| Outer shell | HDPE | 9.5 | 9.5 | 28.2 | 10.9 |

| HDPE/MMT | 15.9 | 10.4 | 29 | 13.6 | |

| A (mm2) | |||||

| Front | Right | Back | Left | ||

| Inner shell | HDPE | 7292 | 5929 | 12919 | 6370 |

| HDPE/MMT | 7103 | 6141 | 10154 | 8502 | |

| Outer shell | HDPE | 3394 | 4406 | 9480 | 4006 |

| HDPE/MMT | 5771 | 3530 | 9187 | 5187 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).