Submitted:

12 July 2024

Posted:

18 July 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

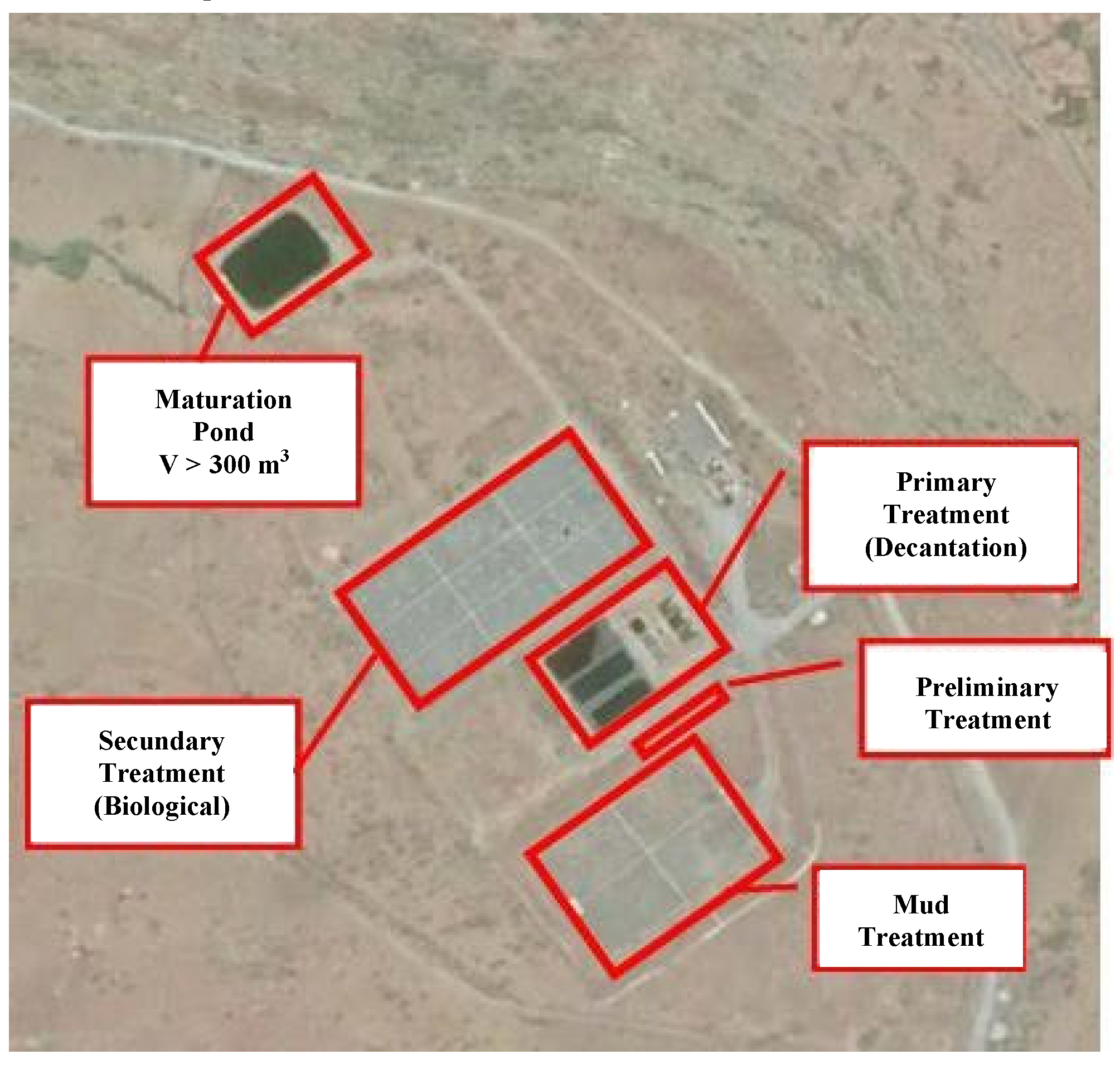

2.1. Description Plant

- -

- Preliminary treatment consisting of roughing screens, this stage will guarantee the proper functioning of the subsequent equipment, avoiding possible obstructions. There are two lines of 0.4 meters wide and 3 meters long.

- -

- Primary treatment (anaerobic lagoons), this process consists of reproducing the self-purification phenomena that occur naturally in rivers and lakes. In this type of lagoons, there are high organic loads that produce oxygen-free conditions and anaerobic bacteria proliferate. This slows down the velocity and causes the heavier suspended particles to settle to the bottom, thus reducing the suspended solids content. These accumulate at the bottom and r e s u l t in the formation of a sludge layer which is usually removed every 5-10 years of operation due to anaerobic stabilization at room temperature, which reduces its volume. There are three lines 3.6 meters deep, 21.8 meters long and 8.8 meters wide. This is followed by a batch discharge system.

- -

- Secondary treatment (Constructed Wetland with Vertical flow): The water coming from the anaerobic lagoon flows vertically through a media is collected in a drainage network at the bottom of the wetland, which is connected to aeration chimneys. The feed is discontinuous. In this case there are 6 vertical flow wetlands 13 meters wide and 26.8 meters long. This is made up of different layers of gravel and sand and has an impermeable membrane at the bottom of the basin.

- -

- The reserve lagoon is covered with a shading mesh made up of two grids of 5 mm Bayco type black polyamide monofilament yarn, arranged in 0.5x0.5 grids, with dynamometer-controlled tensioning tied to the perimeter anchoring structure and a double layer of black polyethylene shading fabric with a minimum 85% shade, located between the two grids of yarns. The dimensions of this water are 31.6 meters long, 20.60 meters wide and 0.5 meters deep, giving a volume of about 325 m3. This lagoon will act as an initial reservoir, where the water treated in the treatment plant will be stored and can be pumped to feed the tertiary treatment.

- -

- Underground treated water tank: The storage volume is 10 m3 . It has two impulsion pumps at the outlet that will propel the water to the filtration system.

- -

- Filtration: In this stage, the aim is to eliminate dissolved solids practically in their entirety, in addition to reducing the microbiological activity of the water. This filtration system consists of a vertical filter with AFM (Activated Filter Media) as the filter medium. These must have a backwashing system with clean water. Two lines are arranged in parallel and at the inlet of this system there is a flow meter to control the flow of water entering the system.

- -

- Refining: Once the water has been filtered, it will be passed through a manual cleaning ring filter with a 50 mm pitch, which will improve the quality of suspended solids and turbidity. In this process there are also two lines, consecutive to the previously mentioned filters.

- -

- Main disinfection: The selected disinfection system is a compact ultraviolet disinfection equipment. This system can interact with the DNA and RNA of bacteria, viruses... preventing their reproduction.

- -

- Final tank: The treated water will be deposited in a 50 m3 closed reinforced concrete tank. This is equipped with a water disinfection system based on the addition of trichlorine tablets.

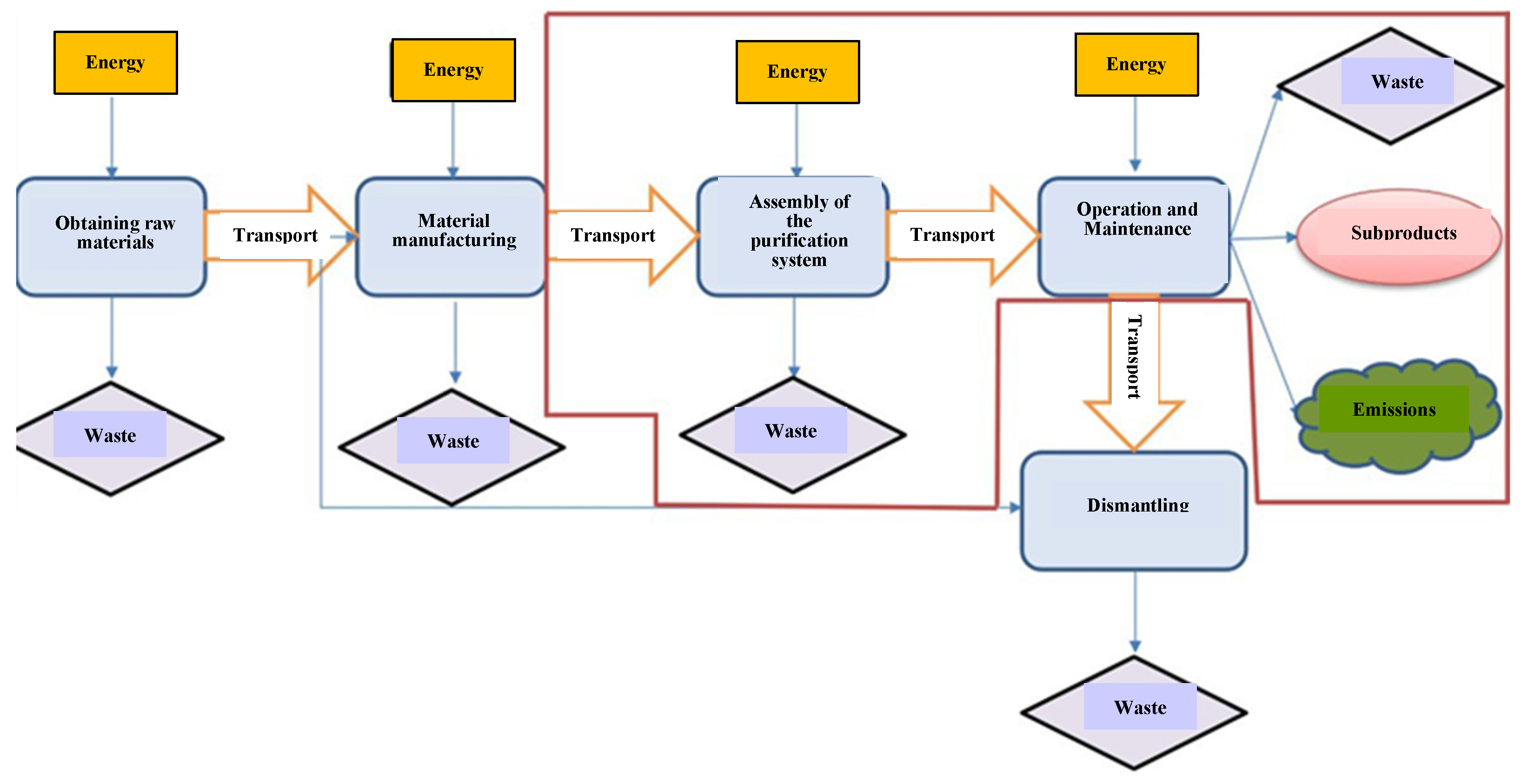

- Materials for the construction of the facilities and their transport.

- Construction of the installation considering the required energy/fuel consumption.

- Maintenance and operation.

- The impact of the treatment and disposal of waste to be landfilled or treated as by-products.

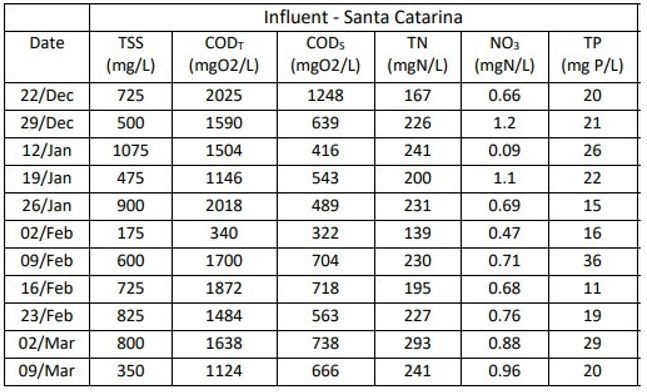

2.2. Inventory

2.2.1. Construction Phase

- -

- Feed pump for tertiary treatment: compact, reliable, horizontal, multistage end-suction centrifugal pump.

- Hydraulic body: stainless steel

- Pump casing: AISI 304

- Impeller: Stainless steel

- -

- Washing pump: single-stage pump with top extraction system for easy disassembly.

- -

- Filtration (AFM filter): In this case, the filter is made of laminated polyester reinforced with glass fibre almost entirely except for the cover.

- -

- Ring filter: This is a physical filtration system produced by the retention of particles in the channels created by the superimposition of a set of rings. The materials used in this case are glass-fibre reinforced polyamide and synthetic rubber for the seals. It is considered to be made entirely of reinforced polyamide. The weight of these devices is approximately 6 kg.

- -

- Main disinfection (UV disinfection): This equipment generates ultraviolet radiation at a frequency of 254 nm, capable of destroying harmful bacteria and persistent viruses in the water without generating harmful by-products. The radiation chamber is made of AISI 314 stainless steel. The weight and whether any other material is in higher proportion than steel is unknown.

- -

- Final secondary disinfection tank (Chlorine): After the filtration, refining and main disinfection stages, the disinfected water is sent to the new reusable water tank, with a volume of 100m3, made of concrete.

- -

-

Tertiary process building: It is proposed that the construction of the building containing the treatment equipment be as follows:

- ∘

- Concrete floor

- ∘

- Concrete block walls

- -

- Global warming (kg CO2 Equivalents)

- -

- Consumption of energy resources (MJ)

- -

- Ozone layer depletion (kg CFC-11 Equivalents)

- -

- Eutrophication (kg NO3 Equivalents)

- -

- Acidification (kg. SO2 equivalents)

- -

- Consumption of raw materials (Tn)

- -

- Formation of photochemical oxidants (kg. C2H4 equivalents)

- -

- Human toxicity

- -

- Ecotoxicity

- -

- Land use (area occupied in m2/year)

- -

- Depletion of mineral and fossil resources.

- -

- Biodiversity (number of species or density of vascular plants representative of species diversity).

- -

- Loss of life-supporting function (data on net primary production)

- -

- Depletion of biotic resources

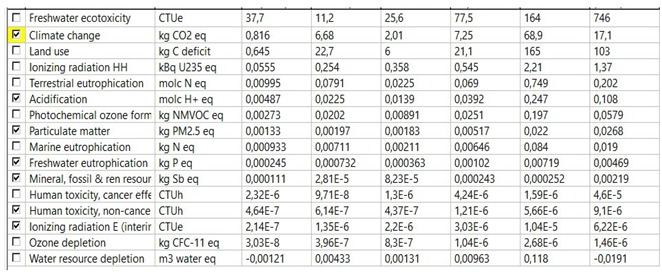

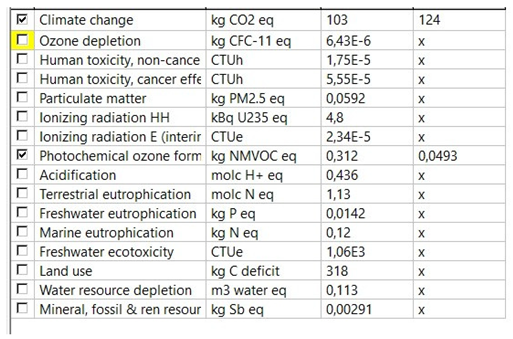

3. Results.

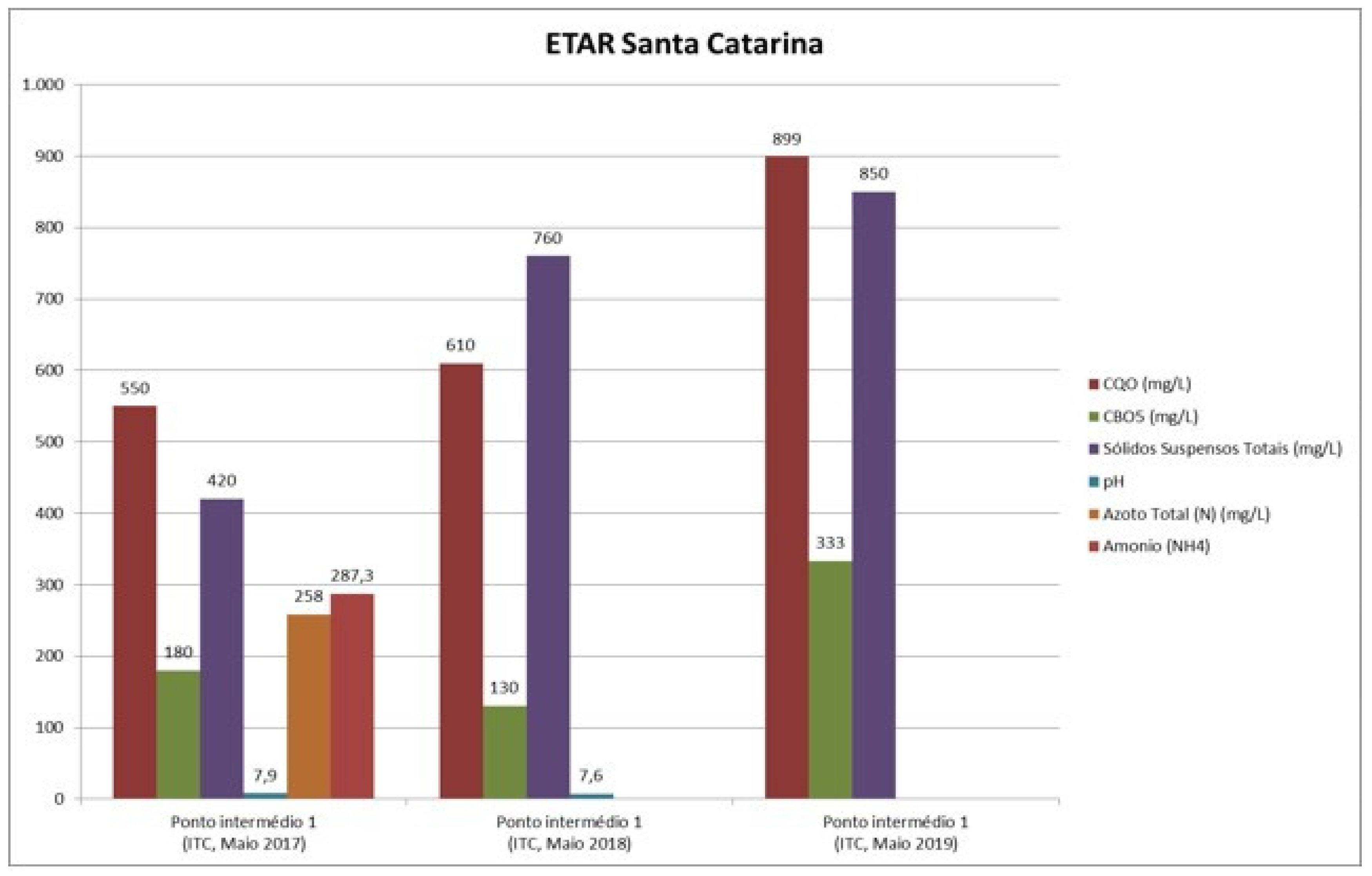

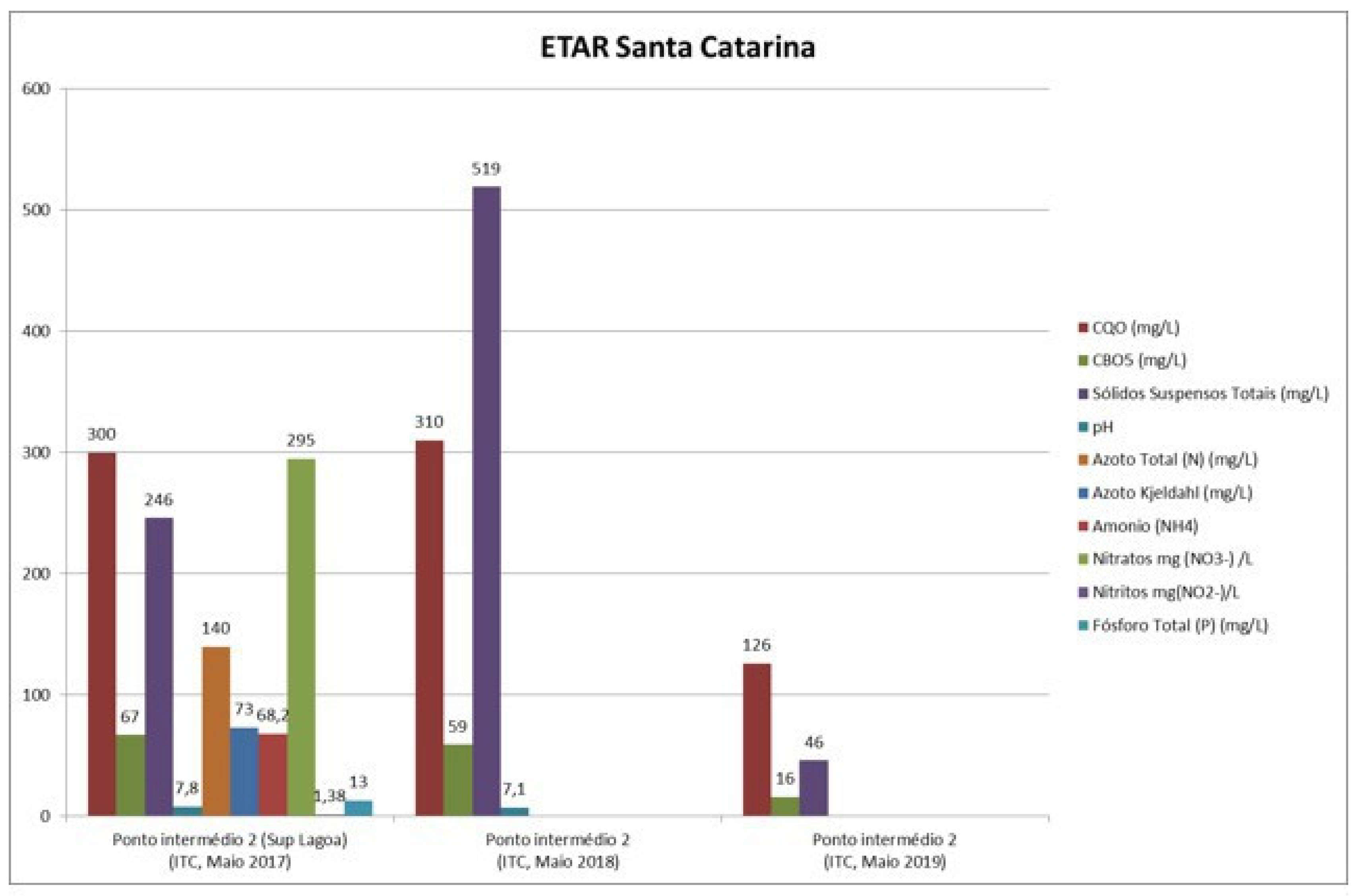

3.1. Operation and Maintenance Phase

6. Discussions and Conclusions

Author Contributions

Funding

References

- Corbella, C.; Puigagut, J.; Garfí, M. Life cycle assessment of constructed wetland systems for wastewater treatment coupled with microbial fuel cells. Sci. Total. Environ. 2017, 584–585, 355–362.

- Kadlec, R.; Wallace, S. Treatment Wetlands, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar]

- Saeed, T.; Sun, G. A review on nitrogen and organics removal mechanisms in subsurface flow constructed wetlands: Dependency on environmental parameters, operating conditions and supporting media. J. Environ. Manag. 2012, 112, 429–448. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, J.; Ngo, H.H.; Guo, W.; Hu, Z.; Liang, S.; Fan, J.; Liu, H. A review on the sustainability of constructed wetlands for wastewater treatment: Design and operation. Bioresour. Technol. 2014, 175, 594–601. [Google Scholar] [CrossRef] [PubMed]

- Bohnes, F.A.; Hauschild, M.Z.; Schlundt, J.; Laurent, A. Life cycle assessments of aquaculture systems: A critical review of reported findings with recommendations for policy and system development. Rev. Aquac. 2018, 11, 1061–1079. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment-Principles and Framework. International Standard: Geneva, Switzerland, 2006.

- Lutterbeck, C.A.; Kist, L.T.; Lopez, D.R.; Zerwes, F.V.; Machado, L. Life cycle assessment of integrated wastewater treatment systems with constructed wetlands in rural areas. J. Clean. Prod. 2017, 148, 527–536. [Google Scholar] [CrossRef]

- Garfí, M.; Flores, L.; Ferrer, I. Life Cycle Assessment of wastewater treatment systems for small communities: Activated sludge, constructed wetlands and high rate algal ponds. J. Clean. Prod. 2017, 161, 211–219. [Google Scholar] [CrossRef]

- Lopsik, K. Life cycle assessment of small-scale constructed wetland and extended aeration activated sludge wastewater treatment system. Int. J. Environ. Sci. Technol. 2013, 10, 1295–1308. [Google Scholar] [CrossRef]

- Nasution, M.A.; Wibawa, D.S.; Ahamed, T.; Noguchi, R. Comparative environmental impact evaluation of palm oil mill effluent treatment using a life cycle assessment approach: A case study based on composting and a combination for biogas technologies in North Sumatera of Indonesia. J. Clean. Prod. 2018, 184, 1028–1040. [Google Scholar] [CrossRef]

- Flores, L.; García, J.; Pena, R.; Garfí, M. Constructed wetlands for winery wastewater treatment: A comparative Life Cycle Assessment. Sci. Total. Environ. 2018, 659, 1567–1576. [Google Scholar] [CrossRef] [PubMed]

- Hassan, A.S.A.; Ahmed, H.Y.; Fadhil, H.A.; Zeghid, M.; Chehri, A.; El-Mottaleb, S.A.A. Implementation of Shared Laser–LED Sources in a Free Space Optics (FSO) Network under Environmental Impact. Electronics 2023, 12, 801. [Google Scholar] [CrossRef]

- DiMuro, J.L.; Guertin, F.M.; Helling, R.K.; Perkins, J.L.; Romer, S. A Financial and Environmental Analysis of Constructed Wetlands for Industrial Wastewater Treatment. J. Ind. Ecol. 2014, 18, 631–640. [Google Scholar]

- Saeed, T.; Afrin, R.; Al Muyeed, A.; Sun, G. Treatment of tannery wastewater in a pilot-scale hybrid constructed wetland system in Bangladesh. Chemosphere 2012, 88, 1065–1073. [Google Scholar] [CrossRef]

- Saeed, T.; Khan, T. Constructed wetlands for industrial wastewater treatment: Alternative media, input biodegradation ratio and unstable loading. J. Environ. Chem. Eng. 2019, 7, 103042. [Google Scholar] [CrossRef]

- Saeed, T.; Muntaha, S.; Rashid, M.; Sun, G.; Hasnat, A. Industrial wastewater treatment in constructed wetlands packed with construction materials and agricultural by-products. J. Clean. Prod. 2018, 189, 442–453. [Google Scholar] [CrossRef]

- Saeed, T.; Yasmin, N.; Sun, G.; Hasnat, A. The use of biochar and crushed mortar in treatment wetlands to enhance the removal of nutrients from sewage. Environ. Sci. Pollut. Res. 2018, 26, 586–599. [Google Scholar] [CrossRef]

- Vandepaer, L.; Treyer, K.; Mutel, C.; Bauer, C.; Amor, B. The integration of long-term marginal electricity supply mixes in the ecoinvent consequential database version 3.4 and examination of modeling choices. Int. J. Life Cycle Assess. 2019, 24, 1409–1428. [Google Scholar] [CrossRef]

- Welz, T.; Hischier, R.; Hilty, L. Environmental impacts of lighting technologies—Life cycle assessment and sensitivity analysis. Environ. Impact Assess. Rev. 2011, 31, 334–343. [Google Scholar]

- Niero, M.; Pizzol, M.; Bruun, H.G.; Thomsen, M. Comparative life cycle assessment of wastewater treatment in Denmark including sensitivity and uncertainty analysis. J. Clean. Prod. 2014, 68, 25–35. [Google Scholar] [CrossRef]

- Zhou, W.; Guan, K.; Peng, B.; Margenot, A.; Lee, D.; Tang, J.; Jin, Z.; Grant, R.; DeLucia, E.; Qin, Z.; et al. How does uncertainty of soil organic carbon stock affect the calculation of carbon budgets and soil carbon credits for croplands in the U.S. Midwest? Geoderma 2023, 429, 116254. [Google Scholar]

- Rodriguez-Garcia, G.; Molinos-Senante, M.; Hospido, A.; Hernández-Sancho, F.; Moreira, M.; Feijoo, G. Environmental and economic profile of six typologies of wastewater treatment plants. Water Res. 2011, 45, 5997–6010. [Google Scholar] [CrossRef]

- Idrees, M.; Akbar, A.; Saeed, F.; Gull, M.; Eldin, S.M. Sustainable production of Low-Shrinkage fired clay bricks by utilizing waste plastic dust. Alex. Eng. J. 2023, 68, 405–416. [Google Scholar] [CrossRef]

- Bošković, I.; Radivojević, A. Life cycle greenhouse gas emissions of hemp-lime concrete wall constructions in Serbia: The impact of carbon sequestration, transport, waste production and end of life biogenic carbon emission. J. Build. Eng. 2023, 66, 105908. [Google Scholar]

- Wang, C.-Q.; Chen, S.; Huang, D.-M.; Huang, Q.-C.; Li, X.-Q.; Shui, Z.-H. Safe environmentally friendly reuse of red mud modified phosphogypsum composite cementitious material. Constr. Build. Mater. 2023, 368, 130348. [Google Scholar]

- Menghini, M.; Pedrazzani, R.; Feretti, D.; Mazzoleni, G.; Steimberg, N.; Urani, C.; Zerbini, I.; Bertanza, G. Beyond the Black Box of Life Cycle Assessment in the Wastewater Treatment Plants: Which Help from the Bioassays? Preprints 2023, 2023010232. [Google Scholar]

- Renou, S.; Thomas, J.; Aoustin, E.; Pons, M. Influence of impact assessment methods in wastewater treatment LCA. J. Clean. Prod. 2008, 16, 1098–1105. [Google Scholar]

- Owsianiak, M.; Laurent, A.; Bjørn, A.; Hauschild, M.Z. IMPACT 2002+, ReCiPe 2008 and ILCD’s recommended practice for characterization modelling in life cycle impact assessment: A case study-based comparison. Int. J. Life Cycle Assess. 2014, 19, 1007–1021. [Google Scholar] [CrossRef]

| BOD5 (mg/L) | |

| Anaerobic lagoon inlet | 310 |

| Anaerobic lagoon outlet | 214 |

| Performance elimination | 45% |

| BOD5 (mg/L) | |

| Entrance | 214 |

| Exit | 47 |

| Performance elimination | 78% |

| Local of in-tervenor | Type of intervention | Frequence | Material used |

|---|---|---|---|

| network | Pressure cleaning | 2 times per week | Pit road |

| Estaçaõ de Bombagem | maintenance cleaning | 2 times per week | Pit lorry/ operator |

| pre- treatment | permanent cleaning of grosso waste | daily and permanent | operator |

| Drying bed | Deferred separation of waste | conveyor of waste | |

| Separator from decanter | waste removal fluctuant | three times a week | clamshell |

| Bottom cleaning | when necessary | Pit lorry | |

| decanter | Removal of waste fluctuating | permanent due to accumulation of two residues | Cable net |

| operation | 2 in simultaneous and 1 in stand by | ||

| removal of slats | from 2 to 2 months (for 30 mn) | manager | |

| Brita Filter | cleaning and effluent removal | every 4 months with pond water discharge | Fossa road |

| removal of gravel | every 3 years and checking gravel quality | ||

| Chasse | cleaning | 2 times per month | Lorry / manager |

| change/operation of caixa | 1 time per week | operator | |

| rest 2 weeks for each operator | operator | ||

| Filtro de Areia | Sand Filter change of operation | box one box for each week | operator |

| Lagoa | Lagoon Emptying/cleaning Lagoon | when necessary | manager and operator |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).