Submitted:

20 July 2024

Posted:

22 July 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

1.1. Brief Review: Shale and Tight Gas Reservoirs

1.2. Carbon Sequestration

2. Non-Darcy Flow

3. Two-Component Flow

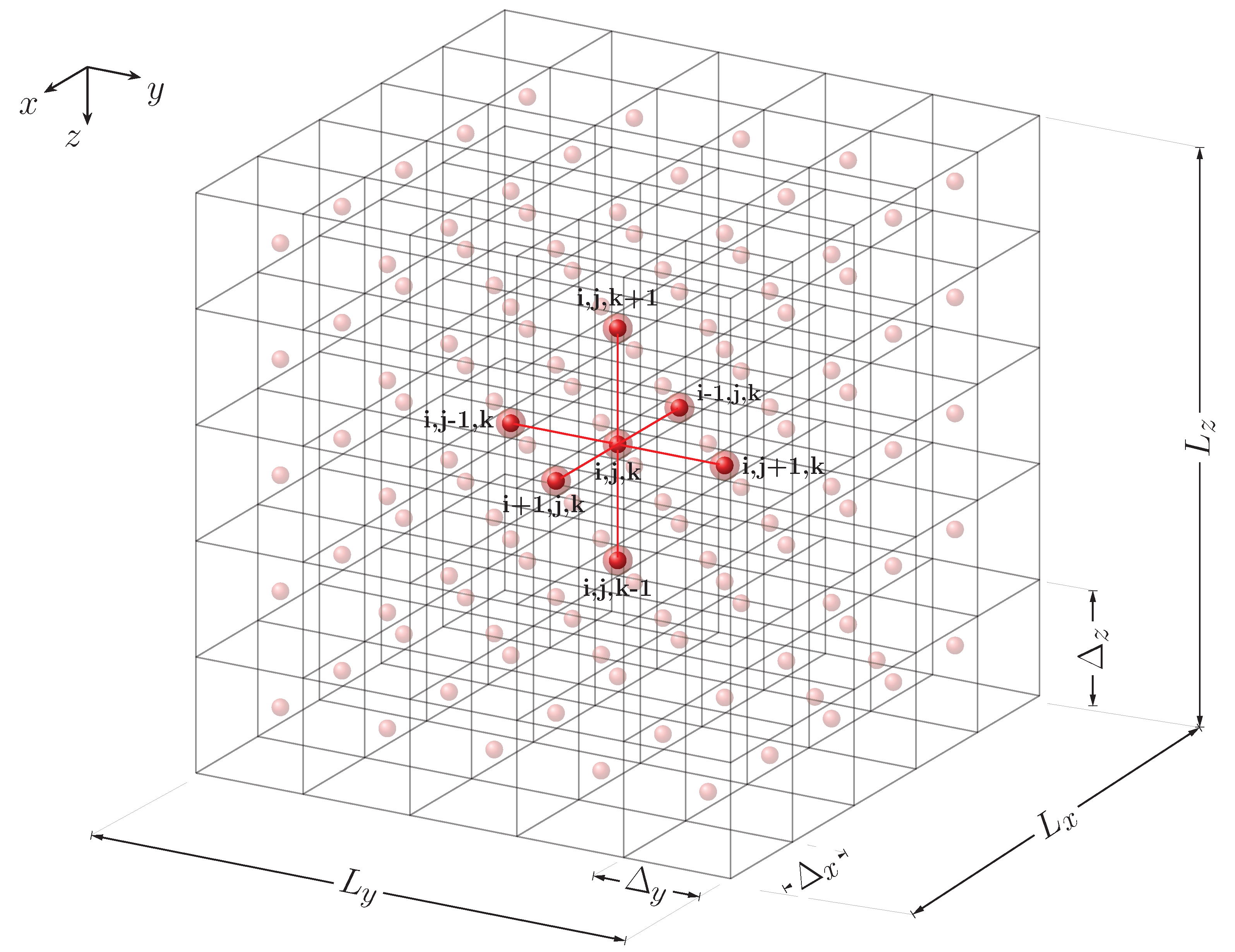

4. Finite Volume Formulation

4.1. Auxiliary Conditions

4.2. Mesh Refinement

4.3. Solving Systems of Algebraic Equations

4.4. Numerical Validation

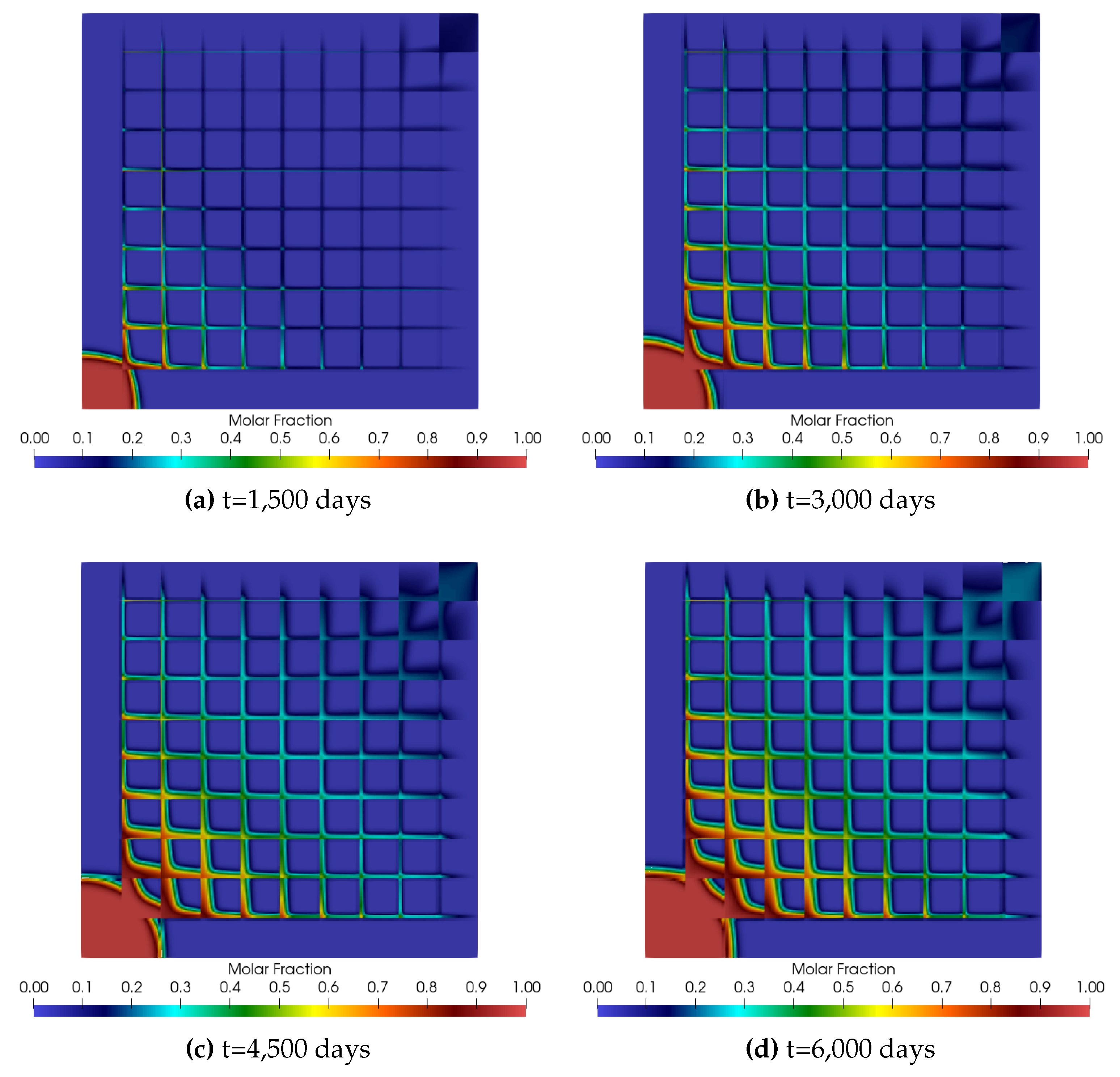

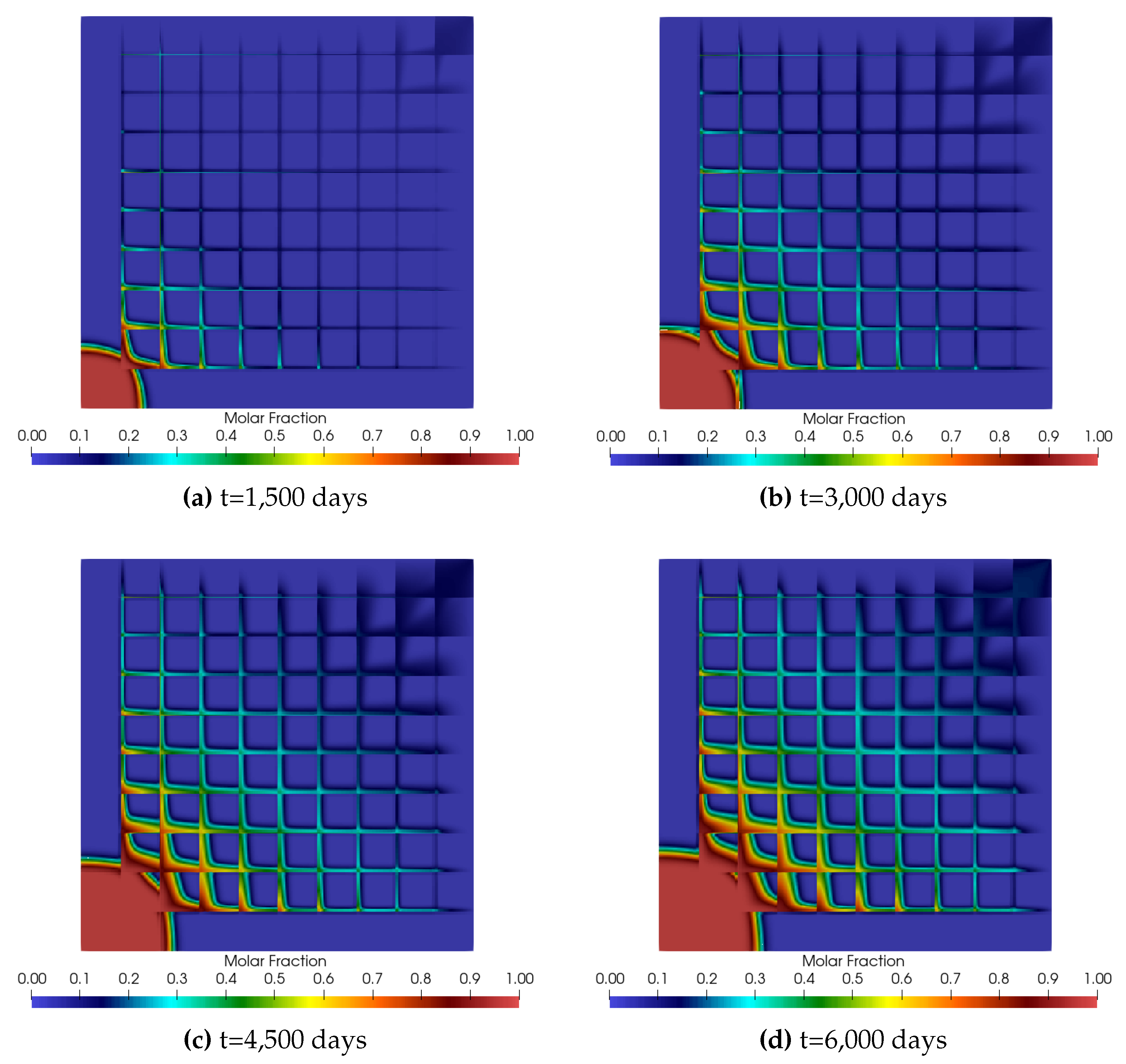

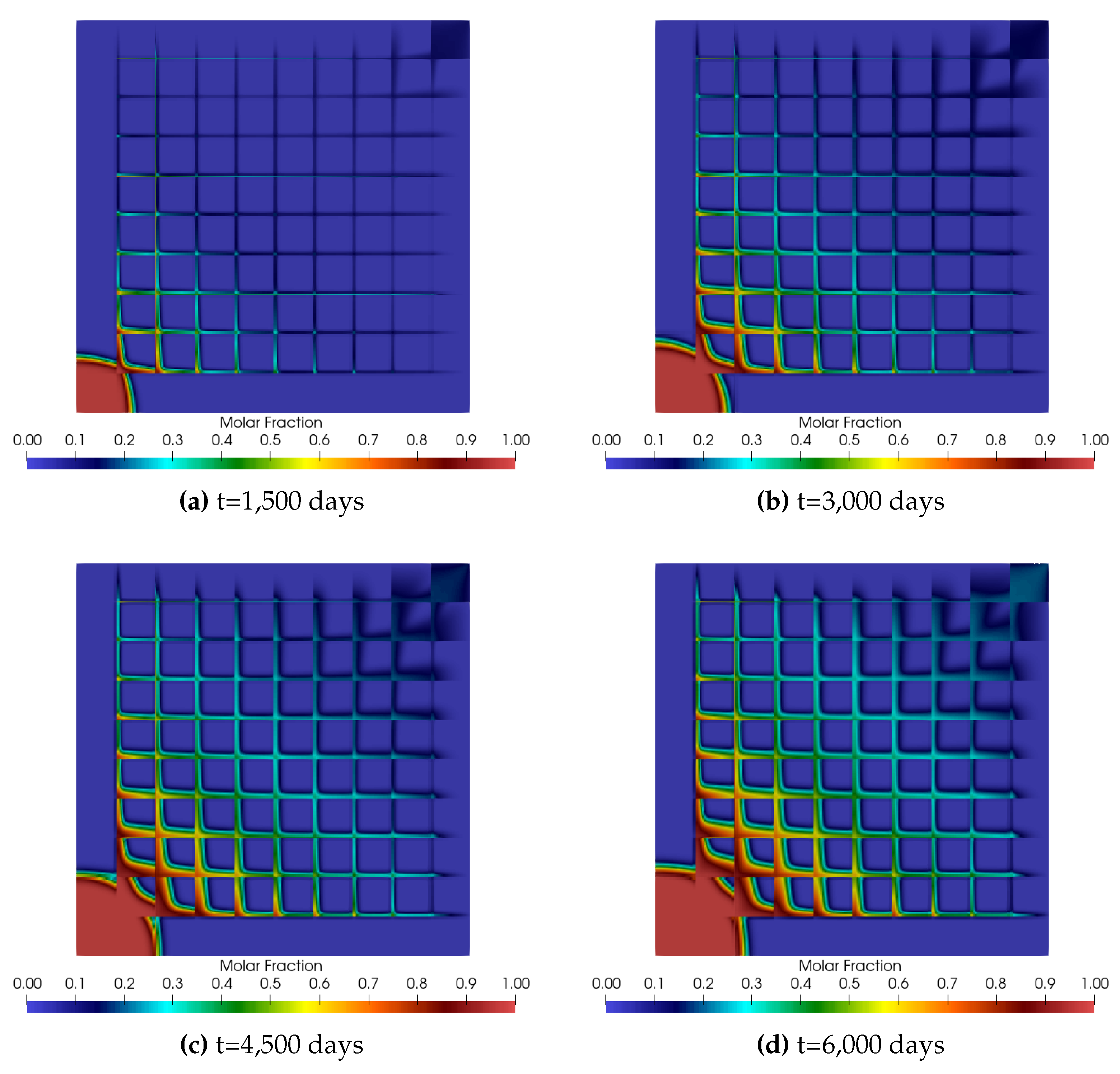

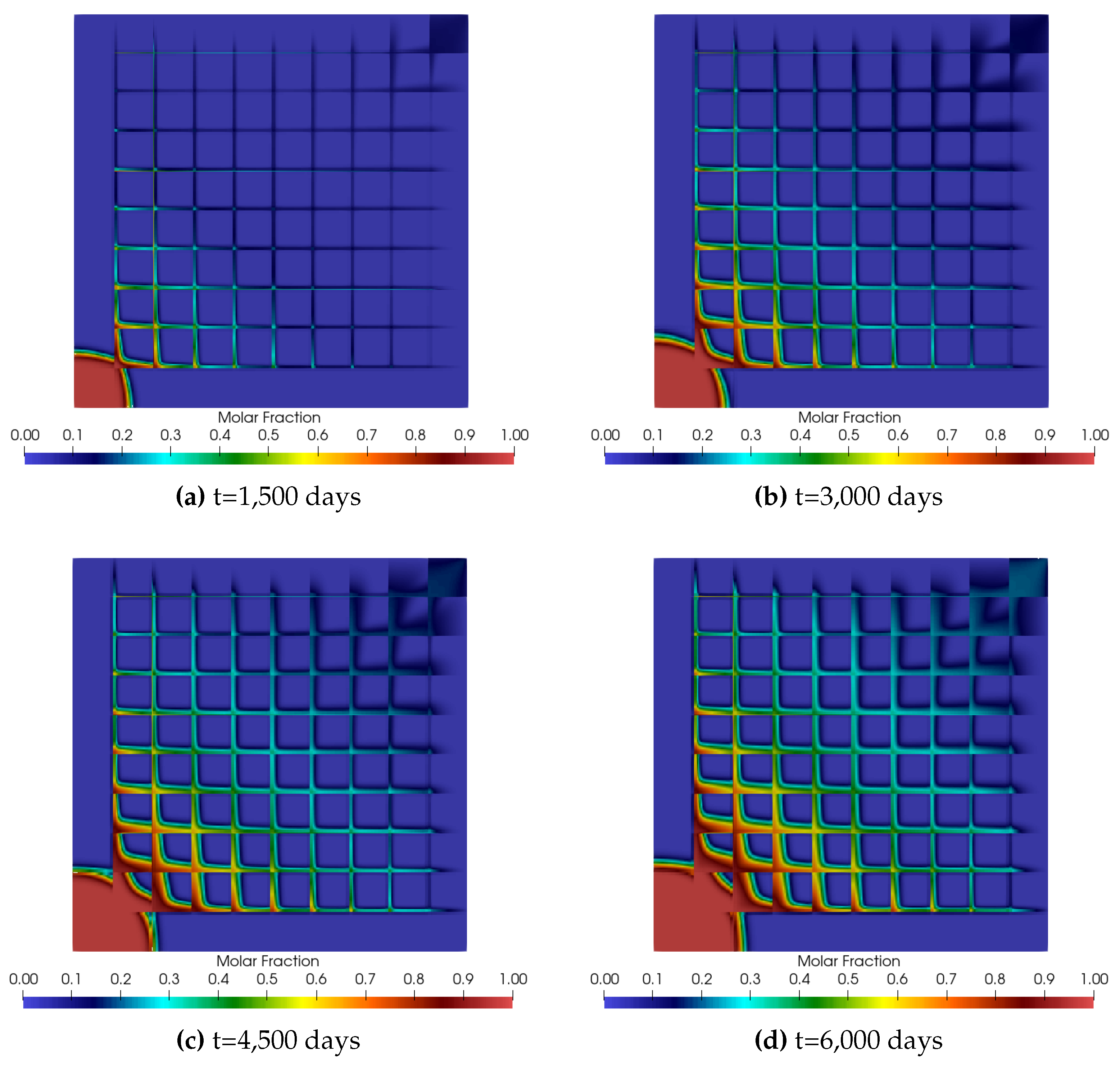

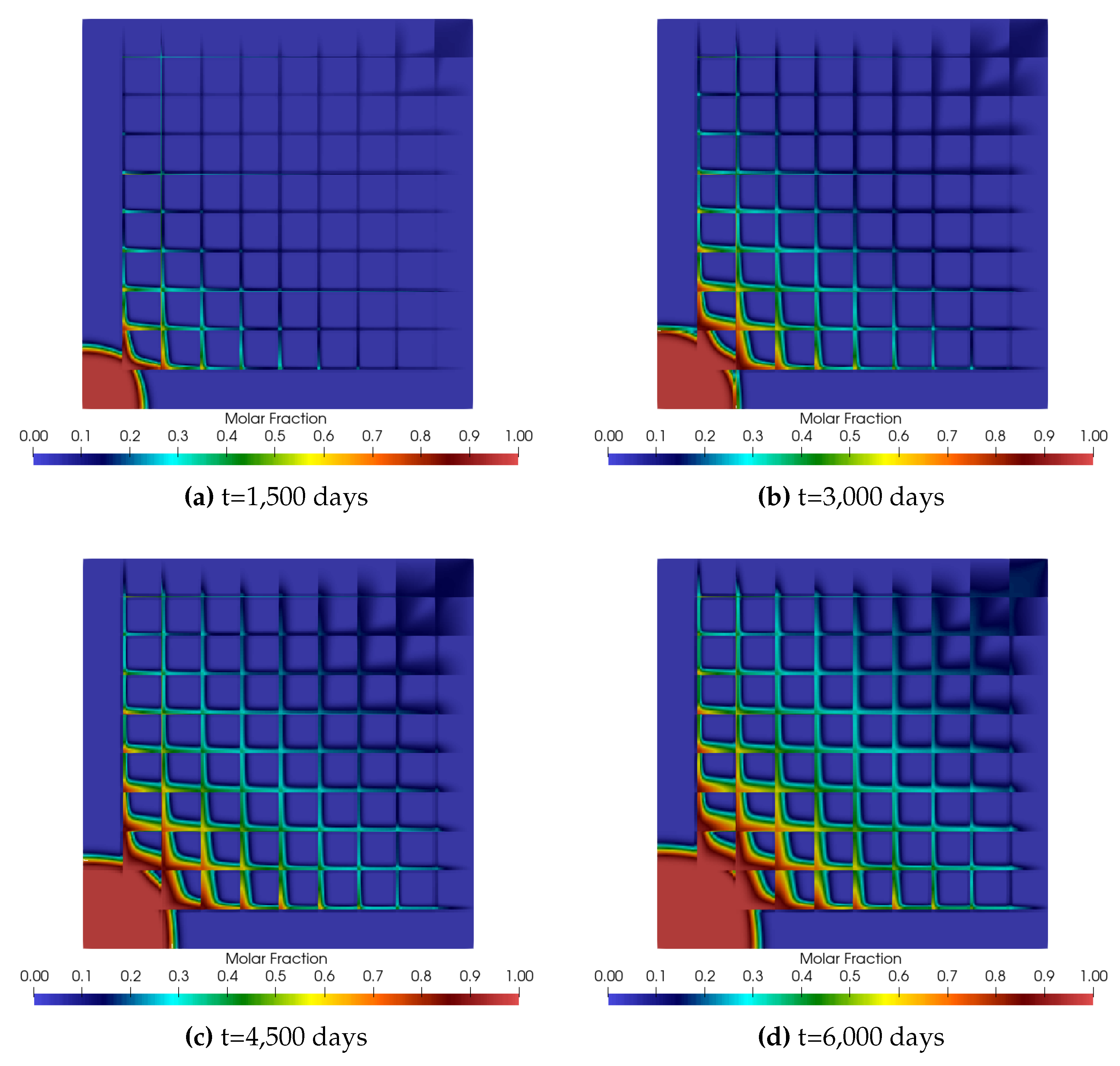

5. Results and Discussion

5.1. Mesh Refinement

5.2. Numerical Results

6. Conclusions

Author Contributions

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| EGR | Enhanced Gas Recovery |

| CG | Conjugate Gradient Method |

| CSEGR | CO2 Storage with Enhanced Gas Recovery |

| BiCGSTAB | Biconjugate Gradient Stabilized Method |

| DFN | Discrete Fracture Networks |

| FVM | Finite Volume Method |

References

- Bear, J. Modeling Phenomena of Flow and Transport in Porous Media; Springer: Cham, 2018. [Google Scholar]

- Halsey, T.C. Computational sciences in the upstream oil and gas industry. Philosophical Transactions of Royal Society 2016, 374, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Boudet, H.; Clarke, C.; Bugden, D.; Maibach, E.; Roser-Renouf, C.; Leiserowitz, A. Fracking controversy and communication: Using national survey data to understand public perceptions of hydraulic fracturing. Energy Policy 2014, 65, 57–67. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, L.; Shan, B. Mathematical model of fractured horizontal well in shale gas reservoir with rectangular stimulated reservoir volume. Journal of Natural Gas Science and Engineering 2018, 59, 67–79. [Google Scholar] [CrossRef]

- Sheng, G.; Javadpour, F.; Su, Y. Effect of microscale compressibility on apparent porosity and permeability in shale gas reservoirs. International Journal of Heat and Mass Transfer 2018, 120, 56–65. [Google Scholar] [CrossRef]

- Shi, J.; Li, X.; Li, Q.; Wang, F.; Sepehrnoori, K. Gas permeability model considering rock deformation and slippage in low permeability water-bearing gas reservoirs. Journal of Petroleum Science and Engineering 2014, 120, 61–72. [Google Scholar] [CrossRef]

- Moghaddam, R.N.; Jamiolahmady, M. Fluid transport in shale gas reservoirs: Simultaneous effects of stress and slippage on matrix permeability. International Journal of Coal Geology 2016, 163, 87–99. [Google Scholar] [CrossRef]

- Afagwu, C.; Abubakar, I.; Kalam, S.; Al-Afnan, S.F.; Awotunde, A.A. Pressure-transient analysis in shale gas reservoirs: A review. Journal of Natural Gas Science and Engineering 2020, 78, 103319. [Google Scholar] [CrossRef]

- Miao, Y.; Li, X.; Zhou, Y.; Lee, J.; Sun, Z.; Chang, Y.; Wang, S.; Hou, C. A new rate-transient analysis model for shale gas reservoirs coupled the effect of slip flow and surface diffusion. International Journal of Heat and Mass Transfer 2018, 124, 1–10. [Google Scholar] [CrossRef]

- Li, B.; Zhou, F.; Fan, W.; Ren, D.; Li, H.; Li, M. Experimental investigation and theoretical modeling of stress-dependent permeability in naturally fractured tight gas reservoir. Journal of Petroleum Science and Engineering 2020, 188, 106949. [Google Scholar] [CrossRef]

- Wang, L.; Wang, S.; Zhang, R.; Wang, C.; Xiong, Y.; Zheng, X.; Li, S.; Jin, K.; Rui, Z. Review of multi-scale and multi-physical simulation technologies for shale and tight gas reservoirs. Journal of Natural Gas Science and Engineering 2017, 37, 560–578. [Google Scholar] [CrossRef]

- Fu, J.; Su, Y.; Li, L.; Wang, W.; Wang, C.; Li, D. Productivity model with mechanisms of multiple seepage in tight gas reservoir. Journal of Petroleum Science and Engineering 2022, 209, 109825. [Google Scholar] [CrossRef]

- Zhang, Y.; Jin, Y.; Yang, D. Semi-analytical modeling of transient pressure behaviour for a multifractured horizontal well in a gas reservoir with a complex fracture network by considering effects of slippage, stress-sensitivity, and gas adsorption/desorption. Journal of Petroleum Science and Engineering 2022, 214, 110504. [Google Scholar] [CrossRef]

- Song, H.; Cao, Y.; Yu, M.; Wang, Y.; Killough, J.E.; Leung, J. Impact of permeability heterogeneity on production characteristics in water-bearing tight gas reservoirs with threshold pressure gradient. Journal of Natural Gas Science and Engineering 2015, 22, 172–181. [Google Scholar] [CrossRef]

- Guria, C. Pressure- and temperature-dependent Klinkenberg slippage effect in porous media to non-ideal gases. Geoenergy Science and Engineering 2023, 224, 211629. [Google Scholar] [CrossRef]

- Rubin, C.; Zamirian, M.; Takbiri-Borujeni, A.; Gu, M. Investigation of gas slippage effect and matrix compaction effect on shale gas production evaluation and hydraulic fracturing design based on experiment and reservoir simulation. Fuel 2019, 241, 12–24. [Google Scholar] [CrossRef]

- Ding, J.; Yang, S.; Nie, X.; Wang, Z. Dynamic threshold pressure gradient in tight gas reservoir. Journal of Natural Gas Science and Engineering 2014, 20, 155–160. [Google Scholar] [CrossRef]

- Friedel, T.; Voigt, H.D. Investigation of non-Darcy flow in tight-gas reservoirs with fractured wells. Journal of Petroleum Science and Engineering 2006, 54, 112–128. [Google Scholar] [CrossRef]

- Clarkson, C.; Jensen, J.; Chipperfield, S. Unconventional gas reservoir evaluation: What do we have to consider? Journal of Natural Gas Science and Engineering 2012, 8, 9–33. [Google Scholar] [CrossRef]

- Ye, Z.; Chen, D.; Wang, J. Evaluation of the non-Darcy effect in coalbed methane production. Fuel 2014, 121, 1–10. [Google Scholar] [CrossRef]

- Wang, C.; Li, Z.P.; Li, H.; Wei, Q.; Bai, R.T. A new method to calculate the productivity of fractured horizontal gas wells considering non-Darcy flow in the fractures. Journal of Natural Gas Science and Engineering 2015, 26, 981–991. [Google Scholar] [CrossRef]

- Farahani, M.; Saki, M.; Ghafouri, A.; Khaz’ali, A.R. Laboratory measurements of slippage and inertial factors in carbonate porous media: A case study. Journal of Petroleum Science and Engineering 2018, 162, 666–673. [Google Scholar] [CrossRef]

- Feng, R.; Chen, S.; Bryant, S.; Liu, J. Stress-dependent permeability measurement techniques for unconventional gas reservoirs: Review, evaluation, and application. Fuel 2019, 256, 115987. [Google Scholar] [CrossRef]

- Wang, J.; Yu, L.; Yuan, Q. Experimental study on permeability in tight porous media considering gas adsorption and slippage effect. Fuel 2019, 253, 561–570. [Google Scholar] [CrossRef]

- Luo, H.; Li, H.; Zhou, X.; Li, Y.; Li, Y.; Zhu, X. Modeling temperature behavior of multistage fractured horizontal well with two-phase flow in low-permeability gas reservoirs. Journal of Petroleum Science and Engineering 2019, 173, 1187–1209. [Google Scholar] [CrossRef]

- Liu, G.; Xie, S.; Tian, W.; Wang, J.; Li, S.; Wang, Y.; Yang, D. Effect of pore-throat structure on gas-water seepage behaviour in a tight sandstone gas reservoir. Fuel 2022, 310, 121901. [Google Scholar] [CrossRef]

- Sun, H.; Ouyang, W.; Zhu, S.; Wan, Y.; Tang, Y.; Cao, W. A new numerical well test method of multi-scale discrete fractured tight sandstone gas reservoirs and its application in the Kelasu Gas Field of the Tarim Basin. Natural Gas Industry B 2023, 10, 103–113. [Google Scholar] [CrossRef]

- Tang, C.; Zhou, W.; Chen, Z.; Wei, J. Numerical simulation of CO2 sequestration in shale gas reservoirs at reservoir scale coupled with enhanced gas recovery. Energy 2023, 277, 127657. [Google Scholar] [CrossRef]

- Tapia, J.F.D.; Lee, J.Y.; Ooi, R.E.; Foo, D.C.; Tan, R.R. A review of optimization and decision-making models for the planning of CO2 capture, utilization and storage (CCUS) systems. Sustainable Production and Consumption 2018, 13, 1–15. [Google Scholar] [CrossRef]

- Zhao, X.; Chen, Z.; Wang, B.; Liao, X.; Li, D.; Zhou, B. A Multi-medium and Multi-mechanism model for CO2 injection and storage in fractured shale gas reservoirs. Fuel 2023, 345, 128167. [Google Scholar] [CrossRef]

- Liu, S.Y.; Ren, B.; Li, H.Y.; Yang, Y.Z.; Wang, Z.Q.; Wang, B.; Xu, J.; Agarwal, R. CO2 storage with enhanced gas recovery (CSEGR): A review of experimental and numerical studies. Petroleum Science 2022, 19, 594–607. [Google Scholar] [CrossRef]

- Haq, B.; Salahu Muhammed, N.; Liu, J.; Tong Chua, H. Enhanced natural gas production using CO2 injection: Application to sustainable hydrogen production. Fuel 2023, 347, 128474. [Google Scholar] [CrossRef]

- Aminu, M.D.; Manovic, V. A modelling study to evaluate the effect of impure CO2 on reservoir performance in a sandstone saline aquifer. Heliyon 2020, 6, E04597. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Vuik, C.; Hajibeygi, H. CO2 Storage in deep saline aquifers: impacts of fractures on hydrodynamic trapping. International Journal of Greenhouse Gas Control 2022, 113, 103552. [Google Scholar] [CrossRef]

- Parvin, S.; Masoudi, M.; Sundal, A.; Miri, R. Continuum scale modelling of salt precipitation in the context of CO2 storage in saline aquifers with MRST compositional. International Journal of Greenhouse Gas Control 2020, 99, 103075. [Google Scholar] [CrossRef]

- Zeng, F.; Zhao, G. Semianalytical Model for Reservoirs with Forchheimer’s Non-Darcy Flow. Society of Petroleum Engineers Reservoir Evaluation & Engineering 2008, 11, 280–291. [Google Scholar] [CrossRef]

- Amao, A.M. Mathematical Model for Darcy-Forchheimer Flow with Applications to Well Performance Analysis. Master’s thesis, Texas Tech University, Lubbock, Texas, USA, 2007. [Google Scholar]

- Barree, R.D.; Conway, M.W. Beyond Beta Factors: A Complete Model for Darcy, Forchheimer, and Trans-Forchheimer Flow in Porous Media. Society of Petroleum Engineers Annual Technical Conference and Exhibition;, 2004. [CrossRef]

- Lai, B.; Miskimins, J.L.; Wu, Y.S. Non-Darcy Porous Media Flow According to the Barree and Conway’s Model: Laboratory and Numerical Modeling Studies. Society of Petroleum Engineers Rocky Mountain Petroleum Technology Conference;, 2009. [CrossRef]

- Souza, G.; Amaral Souto, H.P. A comparative study of non-Darcy flows in naturally fractured gas reservoirs. Journal of the Brazilian Society of Mechanical Sciences and Engineering 2016, 38, 1701–1715. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, D. Modeling two-phase flow behaviour in a shale gas reservoir with complex fracture networks and flow dynamics. Gas Science and Engineering 2023, 119, 205112. [Google Scholar] [CrossRef]

- Civan, F.; Rai, C.S.; Sondergeld, C.H. Shale-Gas Permeability and Diffusivity Inferred by Improved Formulation of Relevant Retention and Transport Mechanisms. Transport in Porous Media 2011, 86, 925–944. [Google Scholar] [CrossRef]

- Florence, F.A.; Rushing, J.A.; Newsham, K.E.; Blasingame, T.A. Improved Permeability Prediction Relations for Low-Permeability Sands. SPE Rocky Mountain Petroleum Technology Conference / Low Permeability Reservoirs Symposium. 2007. [Google Scholar] [CrossRef]

- Wang, S.; Lukyanov, A.A.; Wu, Y.S. Second-order gas slippage model for the Klinkenberg effect of multicomponent gas at finite Knudsen numbers up to 1. Fuel 2019, 235, 1275–1286. [Google Scholar] [CrossRef]

- de Queiroz, R.Z.H.G.; do Rosário, R.C.D.; de Souza, G.; Amaral Souto, H.P. On the numerical simulation of wellbore pressure in gas reservoirs incorporating the phenomena of slippage, formation damage and wellbore storage. International Journal of Advanced Engineering Research and Science 2020, 7, 224–239. [Google Scholar] [CrossRef]

- Secchi, S.; Schrefler, B.A. A method for 3-D hydraulic fracturing simulation. International Journal of Fracture 2012, 178, 245–258. [Google Scholar] [CrossRef]

- Chen, Z. Reservoir Simulation – Mathematical Techniques in Oil Recovery; Society of Industrial and Applied Mathematics, 2007. [Google Scholar]

- Debossam, J.G.S.; dos Santos Heringer, F.D.; de Souza, G.; Amaral Souto, H.P. Numerical simulation of single-phase two-components flow in naturally fractured oil reservoirs. Coupled Systems Mechanics 2019, 8, 129–146. [Google Scholar] [CrossRef]

- Debossam, J.G.S.; de Souza, G.; Amaral Souto, H.P.; Pires, A.P. Numerical simulation of single-phase two-component non-Darcy flow in naturally fractured reservoirs for enhanced gas recovery and carbon dioxide storage. Brazilian Journal of Chemical Engineering 2023, 41, 197–219. [Google Scholar] [CrossRef]

- Böttcher, N.; Singh, A.K.; Kolditz, O.; Liedl, R. Non-isothermal, compressible gas flow for the simulation of an enhanced gas recovery application. Journal of Computational and Applied Mathematics 2012, 236, 4933–4943. [Google Scholar] [CrossRef]

- Soave, G. Equilibrium constants from a modified Redlich-Kwong equation of state. Chemical Engineering Science 1972, 27, 1197–1203. [Google Scholar] [CrossRef]

- Lohrenz, J.; Bray, B.G.; Clark, C.R. Calculating viscosities of reservoir fluids from their compositions. Journal of Petroleum Technology 1964, 16, 1171–1176. [Google Scholar] [CrossRef]

- Versteeg, H.K.; Malalasekera, W. An introduction to Computational Fluid Dynamics: the finite volume method; Pearson, 2007. [Google Scholar]

- Ertekin, T.; Abou-Kassem, J.; King, G. Basic Applied Reservoir Simulation; Society of Petroleum Engineers: Richardson, USA, 2001. [Google Scholar]

- Biryukov, D.; Kuchuk, F.J. Transient Pressure Behavior of Reservoirs with Discrete Conductive Faults and Fractures. Transport in Porous Media 2012, 95, 239–268. [Google Scholar] [CrossRef]

- Vennemo, S. Multiscale Simulation of Thermal Flow in Porous Media. Master’s thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2016. [Google Scholar]

- Saad, Y. Iterative Methods for Sparse Linear Systems, 2nd ed.Society of Industrial and Applied Mathematics, 2003. [Google Scholar]

- Warren, J.E.; Root, P.J. The behavior of naturally fractured reservoirs. Society of Petroleum Engineers Journal 1963, 3, 245–255. [Google Scholar] [CrossRef]

- Barenblatt, G.; Zheltov, I.; Kochina, I. Basic concepts in the theory of seepage of homogeneous liquids in fissured rocks [strata]. Journal of Applied Mathematics and Mechanics 1960, 24, 1286–1303. [Google Scholar] [CrossRef]

- do Rosário, R.C.D.; de Souza, G.; Amaral Souto, H.P. A comparative study of some well-reservoir coupling models in the numerical simulation of oil reservoirs. International Journal of Advanced Engineering Research and Science 2020, 7, 126–148. [Google Scholar] [CrossRef]

| Parameter | Unit | Value |

|---|---|---|

| kPa−1 | 3 10−11 | |

| m2/s | 1 10−8 | |

| – | 0.013 | |

| mDarcy | 0.1 | |

| m | 1,000 | |

| m | 1,000 | |

| m | 10 | |

| MPa | 30 | |

| mol/day | 50 103 | |

| K | 394 | |

| kPa−1 | 3 10−5 | |

| – | 1.2 | |

| – | 2.958 | |

| m−1 | ||

| m−1 | 5,000 | |

| – | 0.1 |

| Parameter | Unit | CO2 | CH4 |

|---|---|---|---|

| MPa | 7.38 | 4.61 | |

| K | 304.1 | 190.6 | |

| – | 0.239 | 0.0116 |

| Parameter | Unit | Value |

|---|---|---|

| m | 1,000 | |

| w | m | 0.01 |

| mDarcy | 7.0 104 | |

| – | 0.75 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).