1. Introduction

With the rapid advancement of modern industry, the demands on casting technology have escalated significantly [

1,

2,

3,

4,

5]. High production efficiency, superior casting quality, precise dimensional accuracy, and environmental compliance have become essential trends for casting products [

6,

7,

8,

9,

10]. Among the various casting methods, lost foam casting (LFC) has emerged as an innovative technique within the industry [

11,

12,

13,

14]. This method involves assembling clusters of foam plastic models that resemble the desired cast part in size and shape. These models are coated with a refractory material, dried, and then embedded in dry quartz sand for vibration molding. Under vacuum conditions, molten metal is poured into the mold, causing the foam models to vaporize and be replaced by the metal, which solidifies to form the final casting.

Compared to traditional casting methods, LFC offers a near-net shape, precise forming process. It is suitable for castings with simple geometries as well as complex shapes, free from the constraints of conventional casting techniques [

15,

16]. LFC is widely applicable, accommodating a variety of metals, including cast steel, cast iron, cast copper, and cast aluminum. The process can produce castings of virtually any size, dictated by the melting capacity. Moreover, while LFC boasts numerous advantages such as reduced waste, precise shaping, and environmental friendliness, it is not without its challenges. The primary disadvantages include the potential for higher initial setup costs, the need for precise control over process parameters, and the possible requirement for specialized equipment and training. These factors can limit its adoption, particularly in smaller foundries or industries with limited resources.

A critical component in LFC is the coating, which plays roles in heat transfer, mass transfer, and controlling metal flow characteristics. The use of LFC coatings is integral to the overall process, as they reduce surface roughness and ensure the dimensional accuracy of castings. The quality of these coatings directly impacts the quality of LFC castings and represents a key constraint in the widespread adoption and further development of LFC technology. Therefore, in-depth research and development of coatings for LFC are essential to enhance performance, reduce the environmental impact of solid waste emissions, and improve the quality of cast products.

Research into fiber-reinforced concrete technology offers valuable insights for designing high-performance LFC coatings [

17,

18,

19,

20]. Traditional concrete performance improves significantly when reinforced with fibers, a technique widely applied and proven effective in developing functional coatings and composite materials. Drawing from this research, we propose incorporating carbon fibers directly into the coatings. This approach is straightforward and influences the rheological properties, such as viscosity, of the coatings. Controlling these properties, including viscosity and suspension in their wet state, is crucial for optimizing the application of coatings. For instance, in producing coatings for cast iron LFC, viscosity decreases with increased mixing time, while permeability remains relatively constant. The decline in viscosity with prolonged mixing results from the adequate wetting and dispersion of the refractory aggregates. Continued mixing in a baffle-equipped container leads to a uniform reduction in viscosity due to improved homogeneity and the absence of noticeable solid segregation. Hence, the rheological properties of the coatings significantly affect their application, viscosity, and coverage, ultimately impacting the quality of the cast products. Understanding the rheological characteristics of LFC coatings is thus particularly important.

Carbon fibers are known for their excellent thermal conductivity, high-temperature resistance, abrasion resistance, corrosion resistance, electrical conductivity, adsorption capacity, and mechanical properties [

21,

22,

23,

24,

25]. These attributes make carbon fibers indispensable materials in both economic and defense sectors. Given the superior performance and effectiveness of carbon fibers, this study introduces short fibers as an additive phase, incorporating carbon fibers of varying lengths at mass fractions ranging from 0% to 0.8% into the LFC coatings. In addition to mixing time and fiber content, other parameters significantly affect the coating's performance. These include the particle size of the refractory materials, the type and concentration of binders, the drying conditions, and the application methods. Understanding the interplay of these factors is crucial for optimizing the coating formulation and ensuring consistent quality in LFC products.

In this paper we investigate the effects of fiber content, fiber length, and mixing time on the viscosity, coverage, and suspension properties of the coatings.This comprehensive study aims to bridge the gap between theoretical research and practical application in LFC technology, providing a foundation for further advancements in casting processes that meet the high demands of modern industry. By exploring the intricate dynamics of fiber-reinforced coatings, this research contributes to the development of more efficient, high-quality, and environmentally friendly casting methods.

2. Materials and Methods

2.1. Experimental Materials

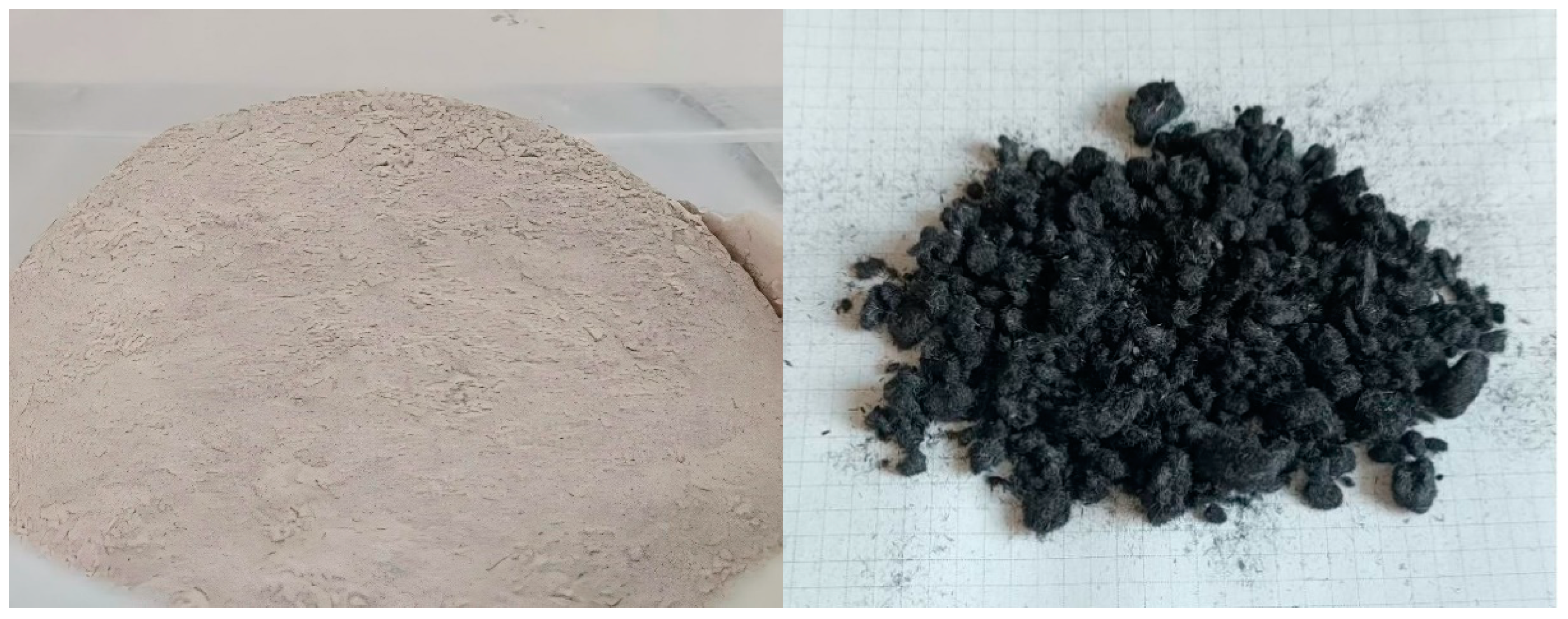

This study investigates the effects of varying sizes of chopped carbon fibers (1 mm, 3 mm, 6 mm) on the properties of high manganese steel lost foam coatings. The experimental fibers and coatings are depicted in

Figure 1, while the main components of the coatings and the properties of the carbon fibers are detailed in

Table 1 and

Table 2, respectively.

The primary equipment and instruments used in this study include beakers, electronic balances, rotational viscometers, JFS series variable frequency high-speed dispersers, and sand body microscopes.

2.2. Experimental Methods and Procedures

A coating mixture weighing 600 grams was prepared with a powder-to-liquid ratio of 1.2:1 and stirred at a speed of 1000 rpm. Subsequently, fibers of varying lengths (1 mm, 3 mm, 6 mm) and contents (0.2%, 0.5%, 0.8% of the total mass) were added to the mixture and stirred for different durations (20 min, 50 min, 80 min). The viscosity and shear stress of the coatings were measured using a rotational viscometer, as shown in

Figure 2. Rotor L3 was selected, and the rotor speeds were set at 6 rpm, 12 rpm, 30 rpm, and 60 rpm to accurately capture the changes in the viscosity properties of the coatings.

To assess the coating performance, the following procedures were employed. For evaluating the coating weight with varying fiber contents, a clean stainless steel plate was used. Initially, the plate's mass (W1) was measured using an electronic balance. The plate, held with a wire, was then slowly immersed into the lost foam coating until fully submerged. After 10 seconds, the plate was slowly removed and suspended to allow excess coating to drip off, as shown in

Figure 3. After 2 minutes, the plate was weighed again to determine its final mass (W2). The difference (W2 - W1) represents the coating weight and was used for a relative evaluation of the coating performance.

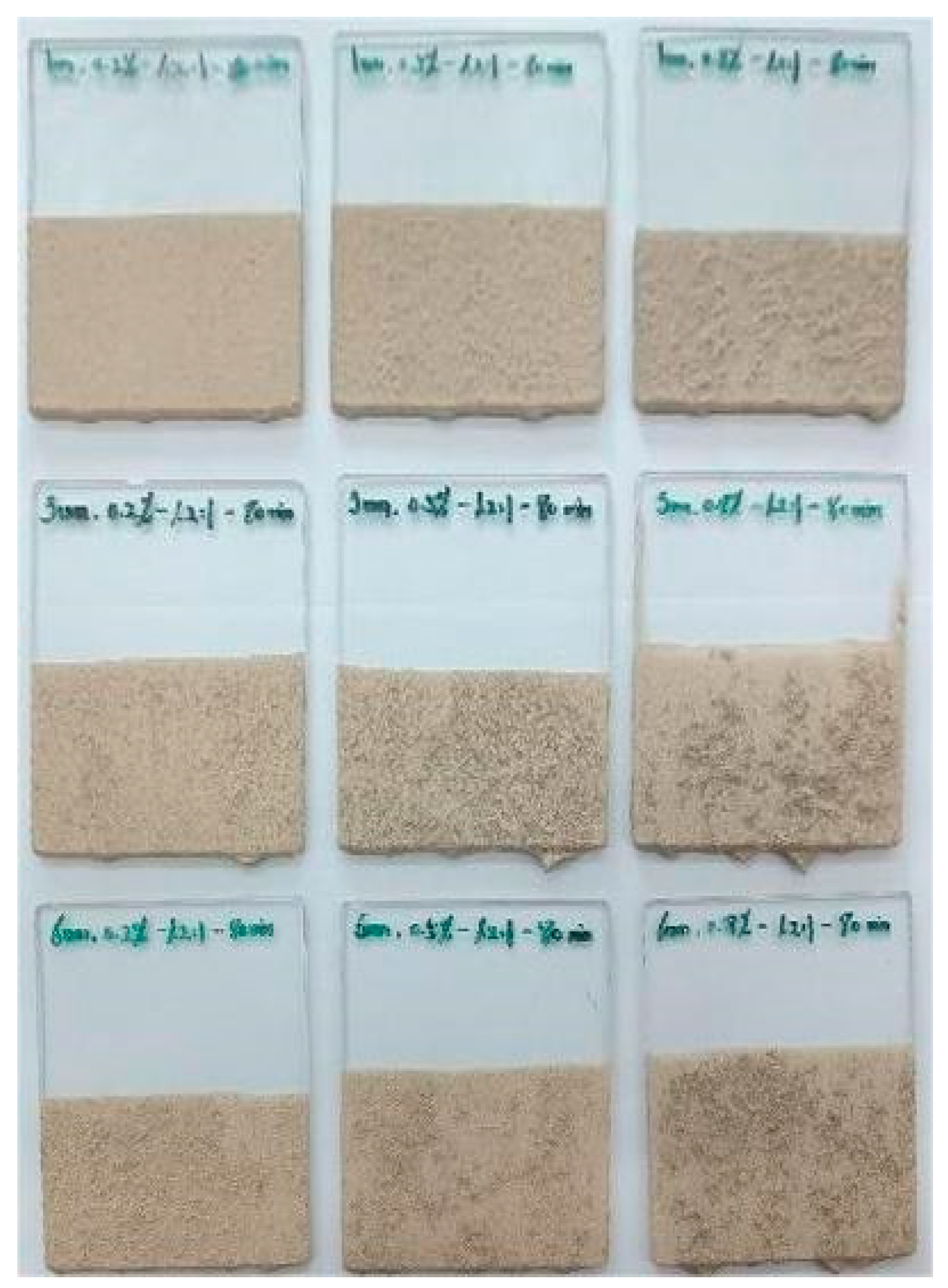

To test coating uniformity, a clean, dry glass plate was used. The glass plate was slowly immersed to a specific depth in the lost foam coating. After 10 seconds, the plate was slowly removed and suspended to allow excess coating to drip off. The plate was then left to air dry at room temperature, as shown in

Figure 4. The surface morphology of the coatings with varying fiber contents was observed to assess their coating uniformity properties.

These carefully controlled procedures ensured a thorough investigation of the effects of fiber length, fiber content, and mixing time on the rheological properties of the lost foam coatings. The findings provide essential data for optimizing the formulation and industrial application of these coatings.

3. Results and Discussion

3.1. Influence of Mixing Time on Coating Viscosity

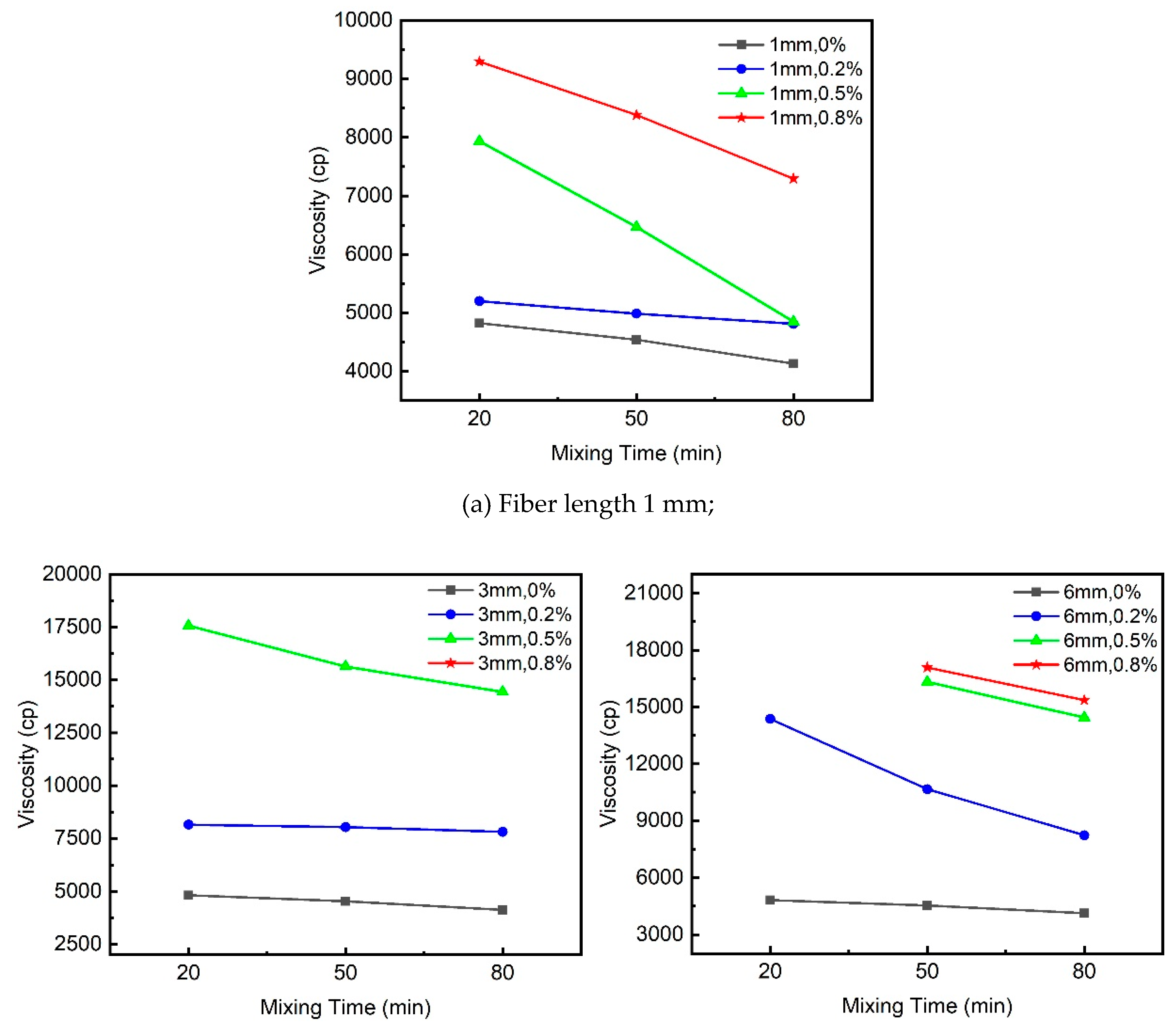

The effect of mixing time on the viscosity of coatings with different fiber lengths and contents is presented in

Figure 5. Viscosity measurements were recorded at a rotor speed of 6 rpm.

As illustrated in

Figure 5, the viscosity of the lost foam coatings decreases with increased mixing time. This trend is attributed to the thorough mixing of the refractory aggregate, binder, and suspending agent over time, which results in the breakdown of large binder molecules, thereby reducing viscosity until it stabilizes. The addition of fibers significantly alters the viscosity compared to fiber-free coatings. The addition of carbon fibers with lengths of 1 mm, 3 mm, and 6 mm substantially increases the viscosity of the lost foam coatings. As the fiber content increases from 0% to 0.8%, the viscosity of the coatings more than doubles. This effect is particularly pronounced with 6 mm fibers: at fiber contents of 0.2% and 0.5%, the viscosity exceeded the measurement range of the instrument within a mixing time of less than 20 minutes.

The changes in viscosity due to fiber addition can be attributed to the interactions between the fibers and the coating materials [

26,

27]. When carbon fibers are introduced, they intertwine and form chain-like or network structures during the mixing process. These structures entrap the materials within the coatings, increasing flow resistance and thus viscosity. With a fixed fiber length, increasing the fiber content enhances these network structures, further elevating the viscosity, sometimes beyond the instrument's measurement capabilities.

These observations suggest that the rheological properties of the coatings are significantly influenced by both fiber length and content. As mixing time progresses, the initial increase in viscosity due to fiber addition eventually stabilizes as the coating components are thoroughly dispersed. Achieving a balance between mixing time and fiber characteristics is crucial for optimizing the application and performance of lost foam coatings in industrial settings.

3.2. Influence of Fiber Content on Rheological Properties

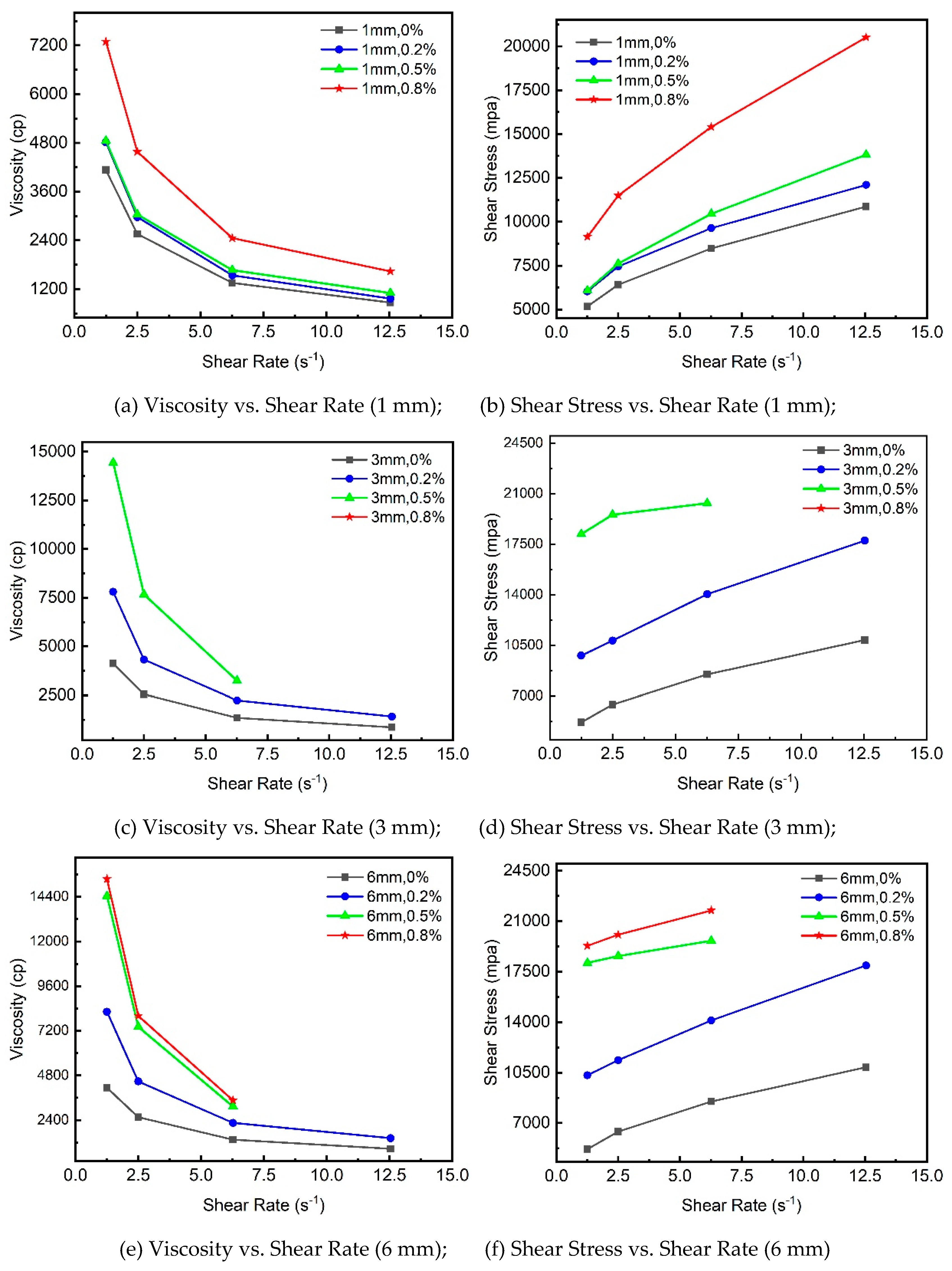

The effect of fiber content on the rheological properties of the coatings is illustrated in

Figure 6.

As shown in

Figure 6, the addition of carbon fibers increases the flow resistance and apparent viscosity of the lost foam coatings compared to those without fibers. However, the effect of different fiber lengths on the viscosity of the coatings varies significantly.

From

Figure 6a,b, it is evident that for 1 mm fibers, the viscosity effects of 0.2% and 0.5% fiber additions are similar, while a 0.8% fiber content significantly increases both viscosity and shear stress. The shorter fiber length means that at 0.2% and 0.5% concentrations, the number of cross-linked network structures is limited, and their binding strength is relatively low. Only when the fiber content reaches 0.8% do these structures sufficiently increase the viscosity. When the fiber length is 3 mm, the increase in fiber content has a more pronounced effect on raising the coating viscosity compared to 1 mm fibers. As the fiber content increases, the apparent viscosity of the coatings shows a mainly linear increase. For coatings with different fiber contents, the apparent viscosity values decrease with increasing rotor speed due to the shear-thinning properties of the coatings. The shear stress results, shown in

Figure 6d, indicate that when 3 mm fibers are added, the shear stress increases linearly with the fiber content. When the fiber length increases to 6 mm, even a small addition of 0.2% significantly affects the apparent viscosity of the coatings. However, increasing the fiber content from 0.5% to 0.8% does not significantly affect the viscosity, as shown in

Figure 6e,f, where the viscosity-shear rate curves for these two concentrations are quite similar. This is because when the fiber length is 6 mm, even a small amount of fibers (e.g., 0.2%) can form a substantial number of cross-linked network structures, rapidly increasing the viscosity [

29,

30]. As fiber content increases further, these structures reach saturation, and the fibers tend to aggregate and entangle, diminishing their effectiveness.

From

Figure 6, it is clear that when the carbon fiber length reaches 6 mm, the fibers are more prone to aggregation and entanglement within the coating, which can negatively impact its performance. It is an intricate balance between fiber content and length in determining the rheological properties of lost foam coatings. Optimal performance is achieved by fine-tuning these parameters to avoid excessive viscosity while maintaining adequate structural integrity. This understanding is critical for developing advanced coatings with tailored properties for industrial applications.

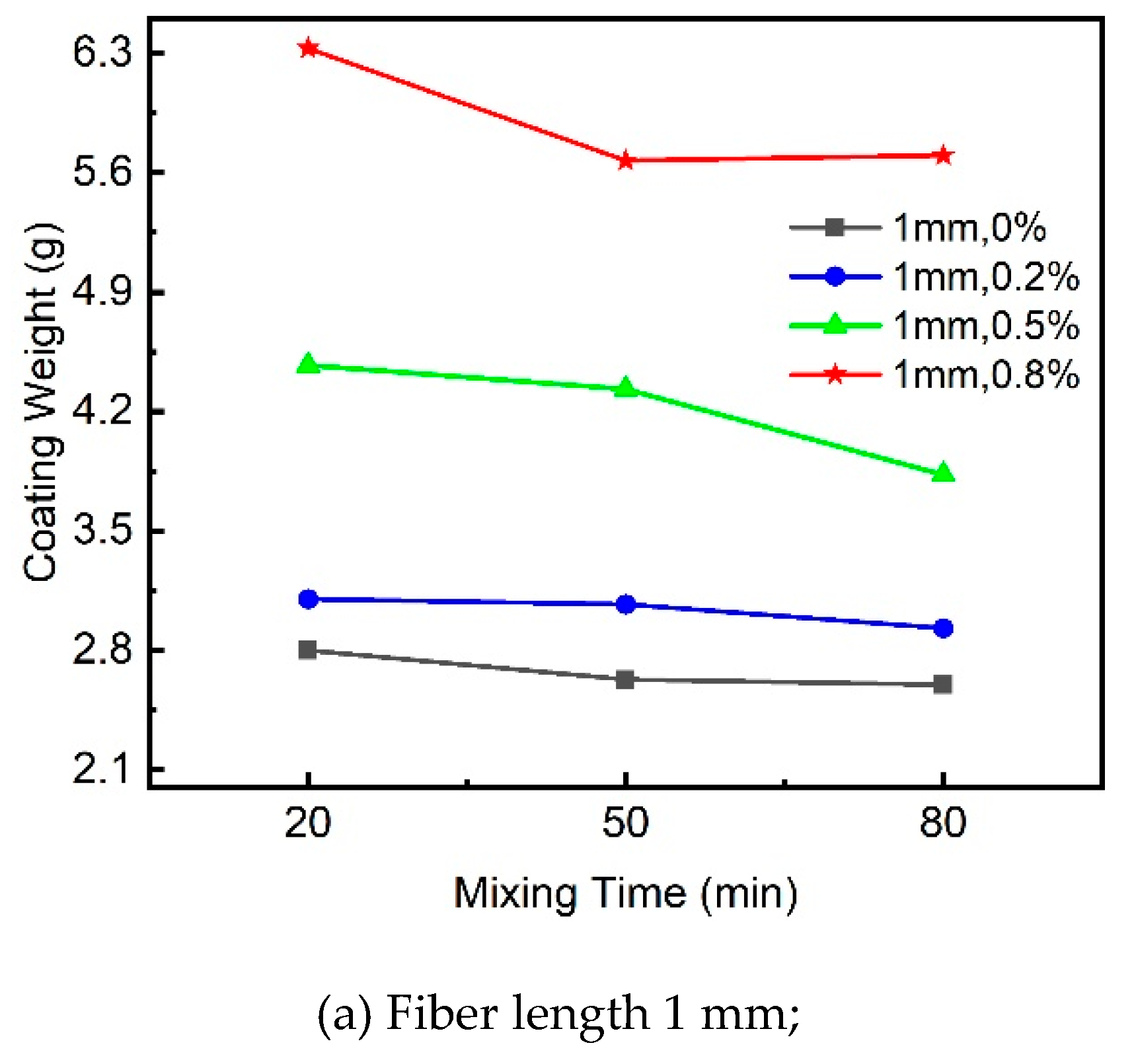

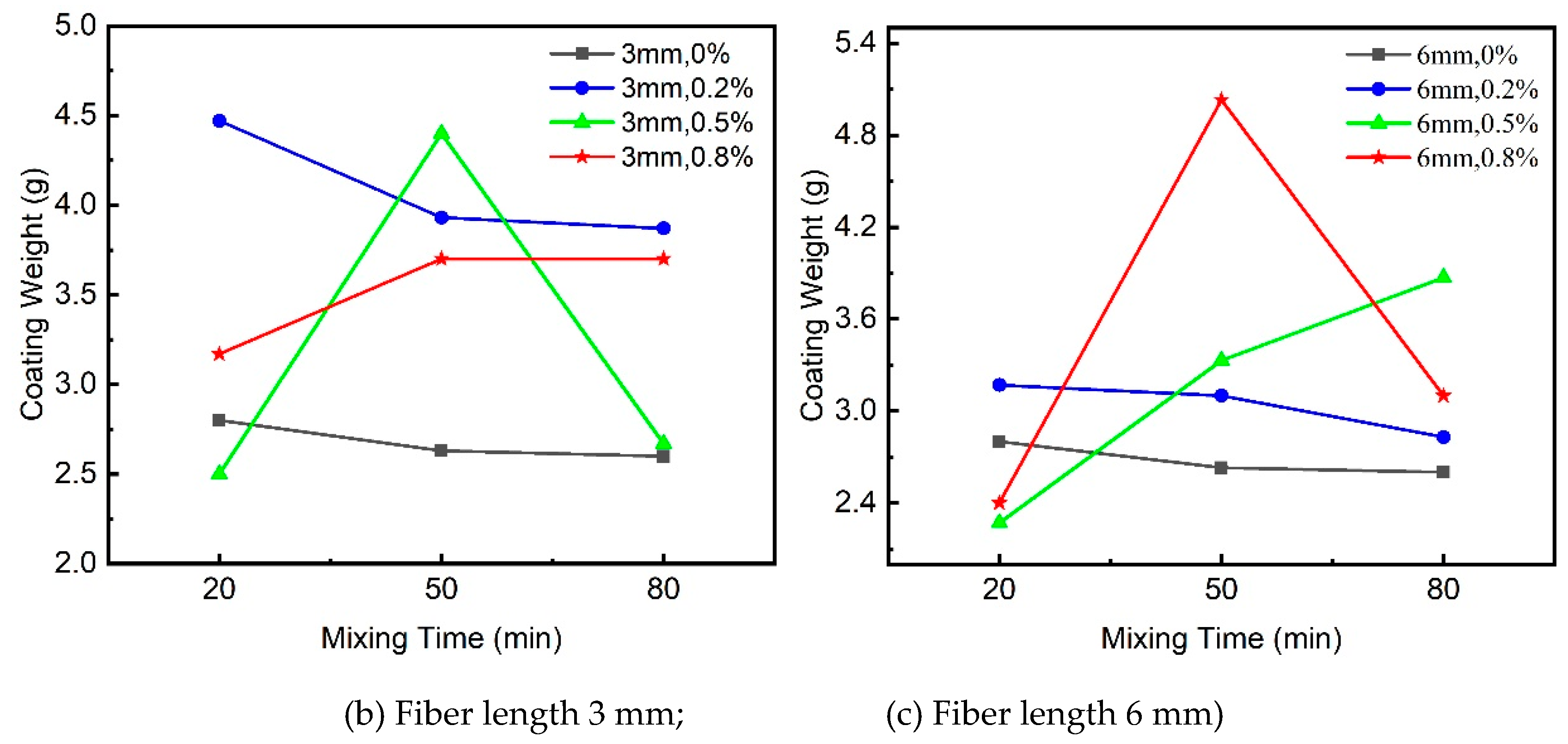

3.3. Influence of Fiber Content on Coating Weight

Coating Weight refers to the ease with which a coating can uniformly cover the surface of a mold or core to a specific thickness without accumulation, dripping, or damaging the surface. While there are no direct methods to measure coating weight, it can be evaluated through a combination of factors such as viscosity, specific gravity, thixotropy, coating thickness, or applied weight. In this study, we used applied weight to assess the coating performance after adding fibers. The effect of mixing time and fiber content on the coating weight was analyzed, and the results are presented in

Figure 7.

The addition of carbon fibers significantly increases the coating weight compared to coatings without fibers, approximately doubling the weight. The influence of different fiber lengths on coating weight varies noticeably with increasing mixing time. From

Figure 7a, it can be seen that for fibers of 1 mm in length, the coating weight generally increases with fiber content, indicating better coating performance than fibers of other lengths. This is likely because the shorter length of 1 mm allows the fibers to mix quickly and evenly within the coating, with minimal entanglement and aggregation. This promotes the formation of a fiber network structure, which enhances coating weight as fiber content increases. For fibers of 3 mm and 6 mm in length, the impact of fiber content on coating weight becomes more complex, as shown in

Figure 7b,c. When fiber content increases from 0.2% to 0.8%, the coating weight does not consistently increase. In fact, when fiber content exceeds 0.5%, there can be a sudden decrease in coating weight. This is because longer fibers (3 mm and 6 mm) distribute unevenly within the coating, leading to more entanglement and aggregation. This results in increased variability and fluctuation in the measured coating weight, reflecting the non-uniformity of the coating. This phenomenon becomes more pronounced as fiber content increases.

These results highlight the significant influence of fiber length and content on coating weight. Shorter fibers (1 mm) tend to result in a more uniform and stable coating with consistent weight over time. In contrast, longer fibers (3 mm and 6 mm) exhibit more complex behaviors, with their impact on coating weight being highly dependent on both the fiber content and mixing time. This complexity likely arises from the network structures formed by the fibers, which can vary in density and distribution based on the specific conditions of the mixture. Understanding these dynamics is crucial for optimizing the coating formulation process. By carefully balancing fiber length and content, it is possible to tailor the coating properties to achieve desired performance characteristics, ensuring consistency and reliability in industrial applications.

3.4. Influence of Fiber Content on Coating Surface Morphology

To evaluate the impact of fiber content on coating surface morphology, clean and dry glass slides were used. Each slide was carefully immersed into the lost foam coating to a specific depth. After a 10 second immersion, the slide was slowly withdrawn and suspended to allow excess coating to drip off. The slides were then left to air dry at room temperature. The macroscopic morphology of the coatings, influenced by fiber length and content, is shown in

Figure 8.

From

Figure 8 it can been seen that fiber length and content have a noticeable impact on the surface morphology of the coatings. When 1 mm fibers were added, the coating surface generally remained uniform. At fiber content levels between 0.2% and 0.5%, no agglomeration was observed, and the surface morphology was satisfactory. However, when the fiber content increased to 0.8%, slight agglomeration was noted in small areas, as depicted in

Figure 8a. This suggests that the optimal fiber length is 1 mm, with the content controlled within 0.5%. For fibers with lengths of 3 mm and 6 mm, the surface morphology of the coatings significantly deteriorated. Noticeable agglomeration occurred, and this effect intensified with increasing fiber content. This is because longer fibers tend to distribute unevenly within the coating, leading to severe entanglement and aggregation, ultimately affecting the coating's surface morphology. These findings highlight the critical balance required in optimizing fiber content and length to achieve desired coating properties. Properly managing these variables can significantly enhance coating performance and quality, making it essential for industrial applications.

Conclusion

This study comprehensively investigates the influence of fiber content, fiber length, and mixing time on the rheological properties, coating weight, and surface morphology of lost foam casting (LFC) coatings. Our findings provide critical insights into optimizing LFC coatings for enhanced performance and industrial applicability.

(1) The experimental results demonstrate that the incorporation of carbon fibers significantly impacts the viscosity and overall rheological behavior of the coatings. Shorter fibers (1 mm) contribute to a more uniform and stable coating with enhanced coverage and minimal aggregation. Conversely, longer fibers (3 mm and 6 mm) tend to aggregate and entangle, particularly at higher concentrations, leading to increased viscosity and less uniform coatings.

(2) Mixing time also plays a crucial role in determining the viscosity and suspension characteristics of the coatings. Extended mixing times result in a gradual decrease in viscosity, attributed to the improved dispersion and wetting of refractory aggregates. However, this effect varies with fiber length and concentration, indicating the need for tailored mixing protocols to optimize coating performance.

(3) The study highlights the importance of balancing fiber content and length to achieve optimal coating weight and surface morphology. Short fibers (1 mm) at lower concentrations (0.2%-0.5%) yield the best results in terms of coating weight and uniformity, while higher fiber contents and longer fibers lead to increased complexity and variability in the coatings.

Author Contributions

Conceptualization, Guojin Sun; methodology, Guojin Sun; formal analysis,Qi Wang; investigation, Guojin Sun and Qi Wang.; data curation, Linqian Xu; writing—original draft preparation, Guojin Sun; writing—review and editing, Guojin Sun; supervision, Guojin Sun. All authors have read and agreed to the published version of the manuscript.

Acknowledgments

The authors acknowledge financial support from Kunlun Talent Project of Qinghai Province(2023-QLGKLYCZX-019).

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Gao, Y.; Bao, Y.; Wang, Y.; et al. Development of a Novel Strand Reduction Technology for the Continuous Casting of Homogeneous High-Carbon Steel Billet. Steel Research International 2023. [Google Scholar] [CrossRef]

- Daronde, S.B.; Kuthe, A.M.; Sarode, B.D. Design and Development of Miniature Low-Cost Vacuum Setup for Sand Casting. 2023.

- Sim, J.G.; Jang, Y.S.; Moon, J.Y.; et al. Development of the Rheocast Diesel Engine Block with ADC10 Alloy via ART (Advanced Rheocasting Technology) System. ISIJ International 2009, 49, 1700–1709. [Google Scholar] [CrossRef]

- Fei, Y.; Gregurich, N.; Silaen, A.; et al. Visualization of Roll Data and Digital Twin Development for Continuous Casting. 8th International Congress on the Science and Technology of Steelmaking 2022.

- Galkin, S.P.; Aleshchenko, A.S.; Gamin, Y.V. Development and Experimental Testing of the Technology for Producing Deformed Bars of Alloy D16T from Continuously Casting Billets of Small Diameter with Low Elongation Ratios. Russian Journal of Non-Ferrous Metals, 2022; 63. [Google Scholar]

- B Y C A, C D Y B, D L Z. Analytical development and experimental investigation of the casting multi-plate damper (CMPD). Engineering structures, 2022(250-Jan.1).

- Li, Q.; Lan, P.; Wang, H.; et al. Formation and control of the surface defect in hypo-peritectic steel during continuous casting: A review. International Journal of Minerals, Metallurgy and Materials 2023, 30, 2281–2296. [Google Scholar] [CrossRef]

- Fajri, A.; Basyirun, B. The Influence Of Sand Casting Mold Solidfication Pressure Variations To The Quality Of Al-Si Alloy Casting Product. The International Journal of Mechanical Engineering and Sciences 2018. [CrossRef]

- Ueda, S.; Sannakanishi, S. Effects of Factors on Contact Forces Analysis between Die and Casting and Validation Using Die-Cast Product. Materials Transactions 2019. [Google Scholar] [CrossRef]

- Ji, C.; Huang, H. A Review of the Twin-roll Casting Process for Complex Section Products. ISIJ International 2020, 9. [Google Scholar] [CrossRef]

- Mirbagheri, S.H.M.; Silk, J.R.; Davami, P. Modelling of foam degradation in lost foam casting process. Journal of Materials Science 2004, 27, 115–124. [Google Scholar] [CrossRef]

- Abdelrahman, M.; Arulanantham, J.P.; Dinwiddie, R.; et al. Monitoring metal-fill in a lost foam casting process. Isa Transactions 2006, 45, 459–475. [Google Scholar] [CrossRef]

- Sun, C.; Cao, Z. Effects of the Wettability Between the Coating and the Liquid EPS on the Filling Process of Lost Foam Casting. International Journal of Metalcasting 2023, 18, 1318–1328. [Google Scholar] [CrossRef]

- Bieniewicz, K.; Reich, M.; Soraruf, N. Improving Metal Flow in LOST FOAM CASTING Through Use of Low Thermal Degradation Hot Melt Adhesives. Modern Casting 2024, 114. [Google Scholar] [CrossRef]

- Jiang, W.; Li, G.; Guan, F.; et al. Preparation of Al2O3/AZ91D Mg Interpenetrating Composites Using Lost Foam Casting Combined with Layered Extrusion Forming. Metals and Materials International 2022, 28. [Google Scholar] [CrossRef]

- Li, G.Y.; Guan, F.; Jiang, W.M.; et al. Effects of mechanical vibration on filling and solidification behavior, microstructure and performance of Al/Mg bimetal by lost foam compound casting. China Foundry 2023, 20, 469–479. [Google Scholar] [CrossRef]

- Zamani, M.A.T. The Role of Fiber Reinforced Concrete Technology in Weight of Structures[C]//The 2nd International Congress on Structure, Architecture & Urban Development.2014.

- Caratelli, A.; Meda, A.; Rinaldi, Z.; et al. Structural behaviour of precast tunnel segments in fiber reinforced concrete. Tunnelling and Underground Space Technology incorporating Trenchless Technology Research 2011, 26, 284–291. [Google Scholar] [CrossRef]

- Shahri, S.F.; Mousavi, S.R. Predicting the Bond Strength Between Concrete and Glass Fiber-Reinforced Polymer Bars Using Soft Computing Models. Iranian Journal of Science and Technology, Transaction of Civil Engineering 2023, 47, 3507–3522. [Google Scholar] [CrossRef]

- Zhao, M.; Miao, J.W.; Xu, Z.; et al. Mechanical and microscopic properties of fiber-reinforced coal gangue-based geopolymer concrete. Nanotechnology Reviews 2022, 11, 526–543. [Google Scholar]

- Liu, J.; Yan, F. Study on flexural behavior of reinforced concrete beams strengthened with geopolymer adhesive bonded CFRP. International journal of structural integrity 2022, 13. [Google Scholar] [CrossRef]

- Cui, H.; Zhang, Q.; Ma, H.; et al. Enhanced interfacial properties of carbon fibers reinforced epoxy or PP composites using modified graphene oxide with two different polymer brushes. Iranian Polymer Journal 2024, 33, 1143–1156. [Google Scholar] [CrossRef]

- Wang, L.; et al. A reconsideration of the relationship between structural features and mechanical properties of carbon fibers. Materials Science & Engineering, A. Structural Materials: Properties, Misrostructure and Processing 2017, 685, 65–70. [Google Scholar]

- Wang, S.; Cao, K.; Xu, L.; et al. Improving electrochemical properties of carbon nanotubes/reduced graphene oxide composite fibers by chemical modification. Applied Physics A 2023, 129, 1–11. [Google Scholar] [CrossRef]

- Ke, F.; Yang, X.; Zhang, M.; et al. Preparation and properties of polyetherimide fibers based on the synergistic effect of carbon nanotubes and ionic liquids. Polymer Composites 2023, 44. [Google Scholar] [CrossRef]

- Kim, G.; Lee, H.; Kim, K.; et al. Effects of Heat Treatment Atmosphere and Temperature on the Properties of Carbon Fibers. Polymers 2022, 14. [Google Scholar] [CrossRef] [PubMed]

- Grigale-Soroina, Z.; Vindedze, E.; Birks, I. Correlation of Mechanical Properties of Polymer Composite Coatings with Viscosity of Unpolymerized System. Key Engineering Materials 2020, 850, 94–99. [Google Scholar] [CrossRef]

- Bertolo, R.V.; Martins, M.C.A.; Plepis, V.G.; Junior, A.M.B. Stanislau.Rheological study of the incorporation of grape seed extract in chitosan and gelatin coatings. Journal of Applied Polymer Science 2021, 138. [Google Scholar]

- Shirzadi Javid, A.A.; Ghoddousi, P.; Aghajani, S.; et al. Investigating the Effects of Mixing Time and Mixing Speed on Rheological Properties, Workability, and Mechanical Properties of Self-Consolidating Concretes. International Journal of Civil Engineering 2021, 19. [Google Scholar] [CrossRef]

- Wo, D.L.; Tanner, R.I. The impact of blue organic and inorganic pigments on the crystallization and rheological properties of isotactic polypropylene. Rheologica Acta 2010, 49, 75–88. [Google Scholar]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).