1. Introduction

High-temperature materials withstand extreme thermal conditions across a wide variety of applications including jet propulsion and energy generation. Such environments necessitate materials that can retain physical strength at elevated temperatures [

1]. Nickel-based superalloys have become ubiquitous with such applications but require complex processing and compositional tuning to achieve the necessary mix of properties. The chemical complexity responsible for the forming stable face centered cubic (FCC or γ) + ordered coherent precipitates (L1

2 or γ’) microstructures reinforced with hard secondary phases such as carbide and borides, as well as the reliance on critical elements such as Ni, Co and various refractory additives, introduces challenges such as sensitivity to scrap feedstock [

2] and macro-segregation. Moreover, nearly all high-temperature materials are plagued by increased flow stresses or even brittle transitions at low temperatures (such as refractory metal alloys and ceramics), which make any form of wrought processing costly and energy-intensive, often relying on alternate processing such as powder metallurgy (P/M)) and investment casting to avoid cracking when fabricating into components [

1].

The high entropy alloys (HEAs) with impressive strength and ductility in the as-cast state [

3,

4,

5,

6,

7,

8,

9,

10] have been actively researched and thus proposed to replace Ni-superalloys with Ni/Co-lean alloys. Largely based on the FCC CoCrFeNi system, with higher Fe compared to what is added to typical Ni or Co based alloys along with additions of Al and Ti have been found to reproduce a number of critical microstructural templates. Minor additions of Al and Ti reproduce the FCC+L1

2 structure found in Ni superalloys, while increasing Al content results in an FCC+B2 duplex structure and further addition of Ti producing an L1

2+B2 structure [

11,

12,

13]. Guo et al. achieved room temperature strengths of 2.56GPa at max strain of 31.8% in an as-cast AlCoCrFeTi0.5Ni2.5 HEA [

13] and showed that the alloy maintained a yield strength over 1000MPa at temperatures up to 600

oC [

14]. The authors attributed this to the hierarchical dual phase structure in the as-cast alloy, with nanoscale phases of L1

2 and BCC dispersed through the macroscale FCC and B2 phases respectively.

While previous work has displayed the efficacy of phase ordering in extending the strength of these as-cast HEAs to higher temperatures, comparable performance in strength to Ni superalloys at 800

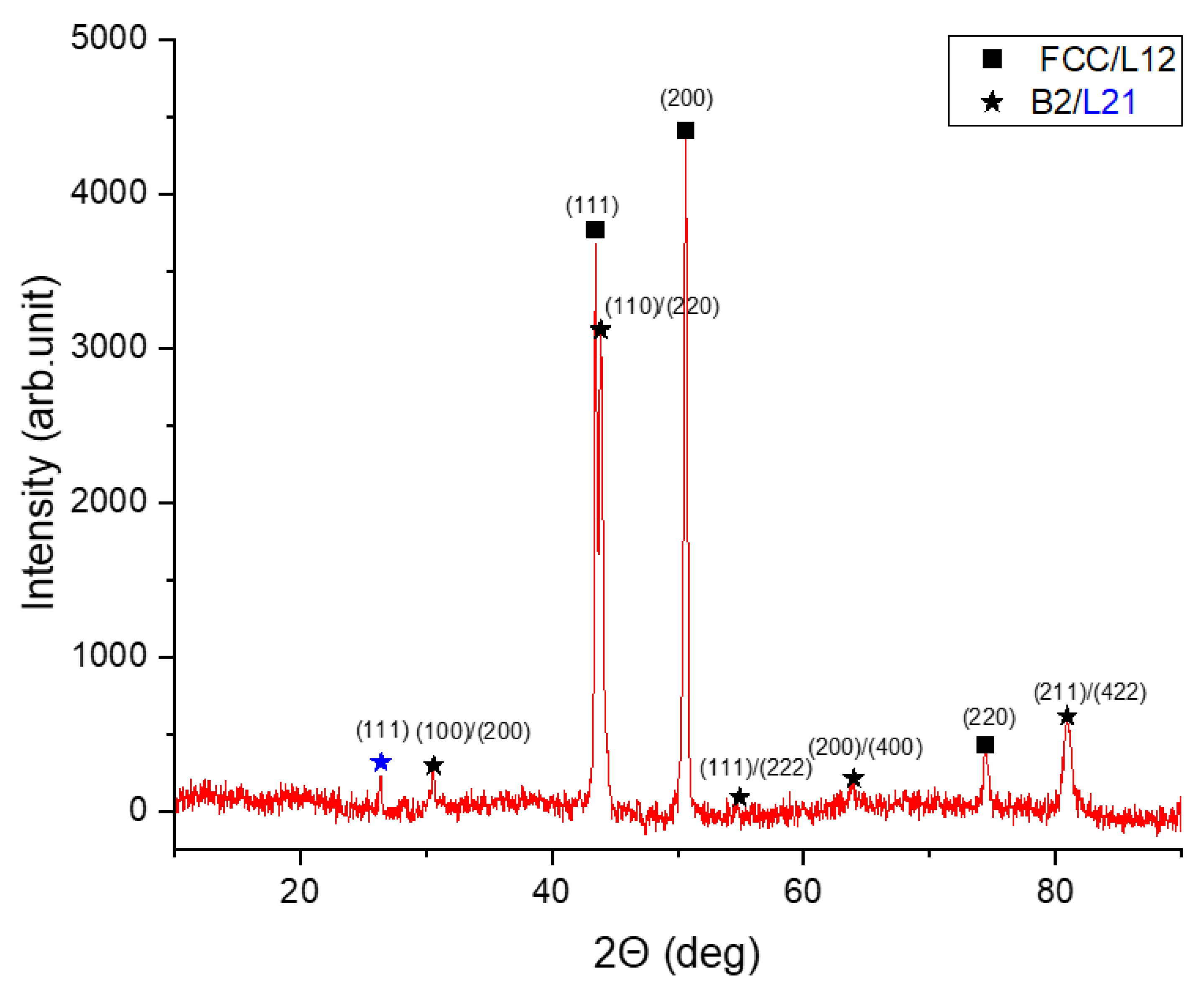

oC and above has yet to be achieved. In the present study, an FCC+BCC AlCoCrFeNiTi alloy (

Figure 1a) with reduced Ni content that displays strong ordering in both the FCC and BCC phases of the as-cast structure is interrogated for mechanical workability at room temperature and elevated temperatures, with a focus on temperatures between 800

oC and 1000

oC. Additionally, a single step, high temperature annealing treatment was performed on the cast structure to improve its room temperature workability, and the resulting changes to high temperature deformability were characterized.

3. Results and Discussion

Chemistry optimization was conducted to broaden the FCC+BCC phase field and enhance precipitation strengthening in both these phases [

11]. A composition of Al

0.5Co

0.5CrFeNi

1.5Ti

0.25 was melted for validation purposes. Further additions of Zr and Cu were introduced to promote solid solution strengthening and the formation of fine-scale nano-precipitates. From

Figure 1b it can be seen that for our alloy composition the predicted phase proportion and transition plot shows a broad thermal range of stability for a BCC+FCC microstructure, in particular at higher temperatures, along with a number of ordered intermetallic phases forming in lower temperature regimes.

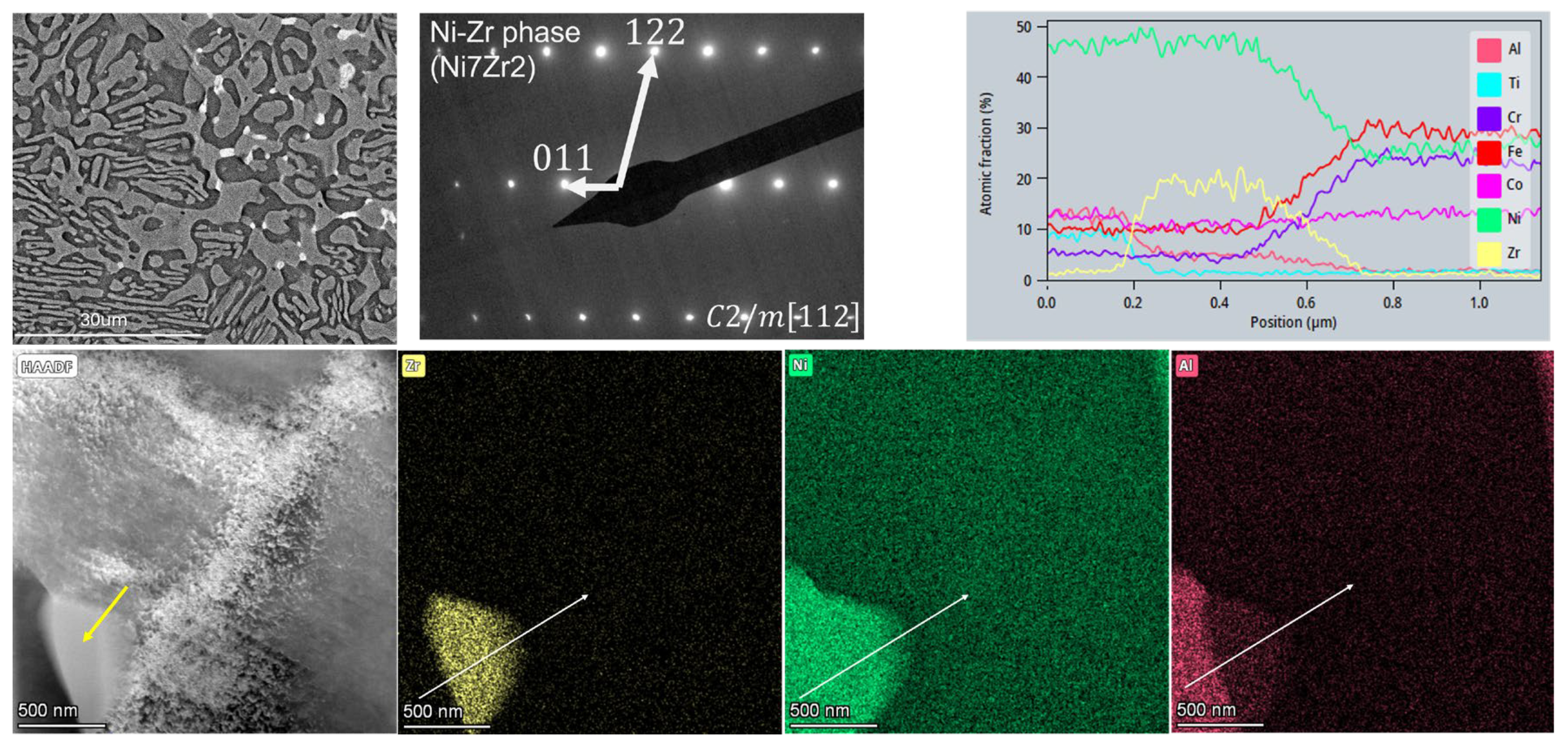

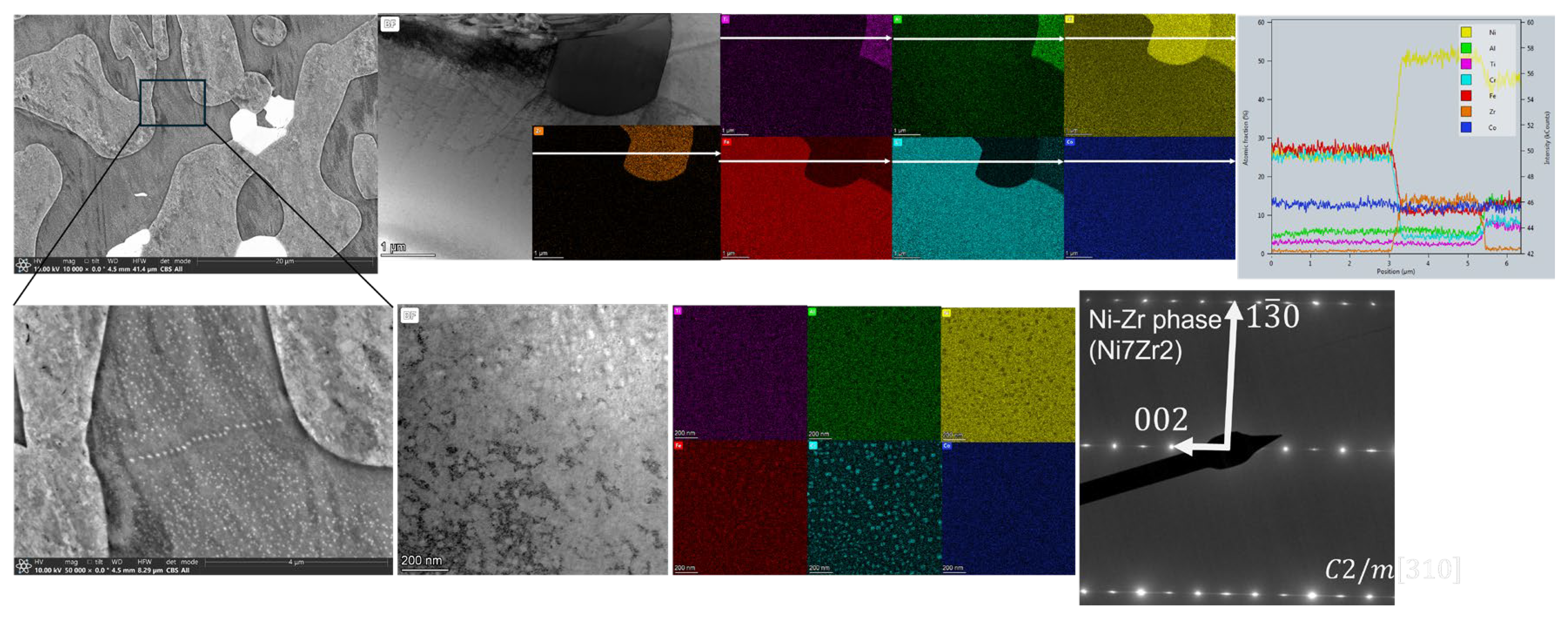

Initial SEM and EDS reveal the as-cast microstructure to be composed of a coarse Fe-Cr enriched FCC phase encircling regions of lamellar Fe-Cr rich FCC and Ni-Al-Ti rich BCC. This microstructural pattern of an idiomorphic decomposition of FCC and BCC surrounded by allotriomorphic FCC, to utilize the terminology employed by John et al. [

15], has been observed previously in a number of Fe, Ni rich alloys in the AlCrFeNi HEA system [

8,

9,

15,

16,

17]. The decomposed regions appear to contain a mixture of conventional Widmanstatten structures and ultrafine vermicular structures. Such regions have been established as the result of a solid state decomposition within the solidified material, with vermicular structures proposed to occur in instances where high cooling rates kinetically frustrate the formation of the Widmastatten platelets [

16]. Of particular note is that the coarse FCC is much coarser than in previously reported alloys, contributing to a higher fraction of the cellular microstructure in this alloy condition. Additionally, a third minor phase is seen within these boundary regions, revealed by EDS to contain high Zr and Ni and later identified as Ni

7Zr

2 type monoclinic phase (

Figure A1). Analysis of the SEM micrographs via contrast thresholding was used to quantify the phase fractions (5.2% bright, 53.5% grey and 41.3% dark phase),

Figure 1c.

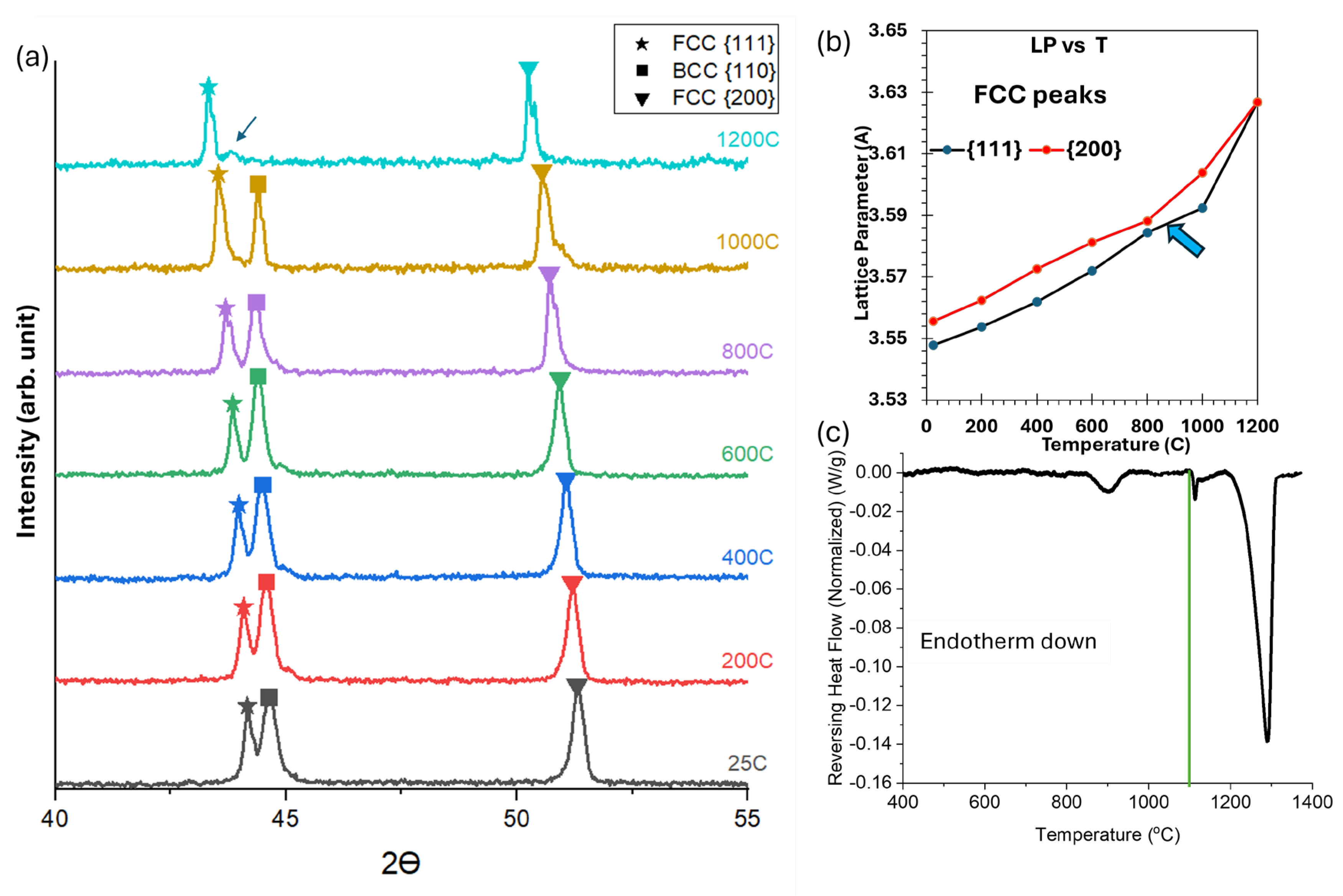

In the results from in-situ high temperature XRD, shown in

Figure 2a, the (111) and (200) FCC peaks as well as the (110) BCC peak persist with increasing temperature up to 1200

oC, at which the BCC peak disappears. Analysis of the change in FCC lattice parameter with temperature from

Figure 2b reveals an increase in thermal expansion between 800

oC and 1000

oC, likely corresponding to a disordering transformation in the FCC phase. DSC, shown in

Figure 2c more precisely narrows the temperature ranges for these transitions with three endotherms observable between 400

oC and 1500

oC. The broad endotherm centered on 900

oC corresponds to the order-disorder transition in the FCC phase shown in

Figure 2b with additional sharp endotherms centered at 1150

oC and 1300

oC corresponding to the disappearance of the BCC structure and melting of the alloy, respectively. Both XRD and DSC indicated that the order-disordered transformation in FCC phase occurred ~1000

oC or below and hence, to soften the alloy and improve plasticity 1100

oC was chosen to be the annealing temperature.

After annealing for 50H at 1100

oC and quenching in water, the microstructure coarsened significantly. The previously cellular structure transformed to a bicontinuous network of FCC and BCC phases, with some regions retaining a morphological similarity to the prior parallel lamellar domains. Similar fractions of FCC to BCC as compared to the as cast indicates that the FCC+BCC phase fields display the extended range of thermal stability desired for maintaining mechanical properties at temperatures approaching 800

oC-1000

oC. Additionally, the Ni-Zr intermetallic phase has ripened with high temperature annealing, becoming more distinct particles (

Figure A2).

The effects of globularization of lamellar domains on room temperature mechanical behavior was previously investigated in Al

0.7CoCrFeNi, and it was found that even partial transformation of the lamellar domains resulted in a marked decrease in the initial flow stress, but was accompanied by an increase in work hardening [

15]. When subjected to cold rolling, the HTA condition was able to undergo ~40% reduction in thickness before crack formation, whereas the as-cast condition failed by cracking below 5% reduction in thickness. This indicates that the microstructural changes from annealing at elevated temperatures within the disordered region of the phase field and quenching can improve the room temperature workability of these high temperature alloys. Further enhancement in the rollability of the HTA condition can be achieved by more in-depth investigation into the work hardening behavior of the alloy, which likely resulted in the localized fracture.

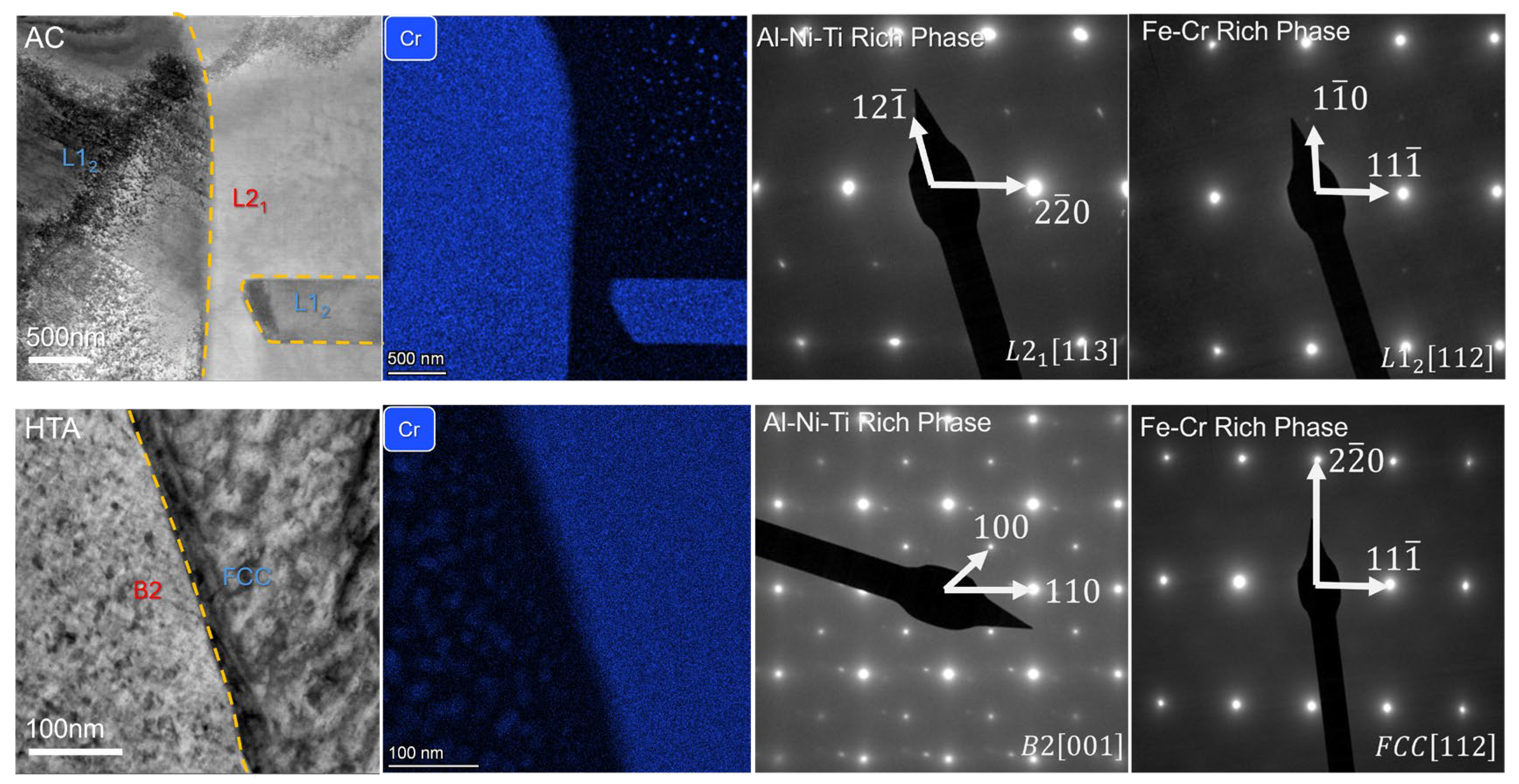

Figure 4.

STEM-BF with STEM EDS showing presence of Cr rich nanophase in the AC and HTA microstructures, with SAED patterns showing phase ordering.

Figure 4.

STEM-BF with STEM EDS showing presence of Cr rich nanophase in the AC and HTA microstructures, with SAED patterns showing phase ordering.

TEM analysis reveals that the FCC regions of both the AC and HTA conditions are chemically uniform, while a dispersion of Cr rich nanoprecipitates can be observed in the BCC phase before and after annealing. Formation of coherent Cr rich BCC nano-precipitates within the Ni-Al-Ti rich ordered BCC phase has been seen previously in these systems and matches well with the absence of additional lattices in the diffraction pattern [

12,

13]. Super lattice spots in the SAED of the AC sample at

and

indicate presence of L1

2 and L2

1 ordering in the FCC and BCC phases respectively. Although the

reflection is typically forbidden in L2

1 ordered structures, it can still be seen due to multiple scattering in thicker regions of the foil and lacks an equivalent planar spacing in the smaller unit cells of BCC/A2 and B2. This is further confirmed by the presence of the L2

1 (111) peak observed in XRD (

Figure A3). The L1

2+L2

1 cast structure can be seen transforming to FCC+B2 after annealing at 1100°C, however the presence of Cr-rich BCC nanoprecipitates persists in the B2 phase. The high temperature stability of this BCC nanophase has similarly been observed by Srimark et al. [

17] and Eshed et al. [

18] though the transformation pathway by which it forms out of the ordered BCC phase remains a topic of investigation, with the latter proposing spinodal decomposition. However, Srimark et al. observed multiple generations of Cr-rich precipitates which would seem to contradict the broad, simultaneous decomposition that a spinodal decomposition-based explanation entails, and instead point to a coherent nucleation pathway. Nucleation and growth would be further substantiated by the presence of a denuded zone, mixed with the spherical shape of the precipitates observed in the as-cast sample. In contrast to this, the disordered BCC phase is seemingly present in higher density, with a significant reduction in thickness of the precipitate free zone approaching the FCC phase after annealing. The morphology of the BCC particles is also more modulated, lending more support for the spinodal transformation mechanism with high temperature annealing.

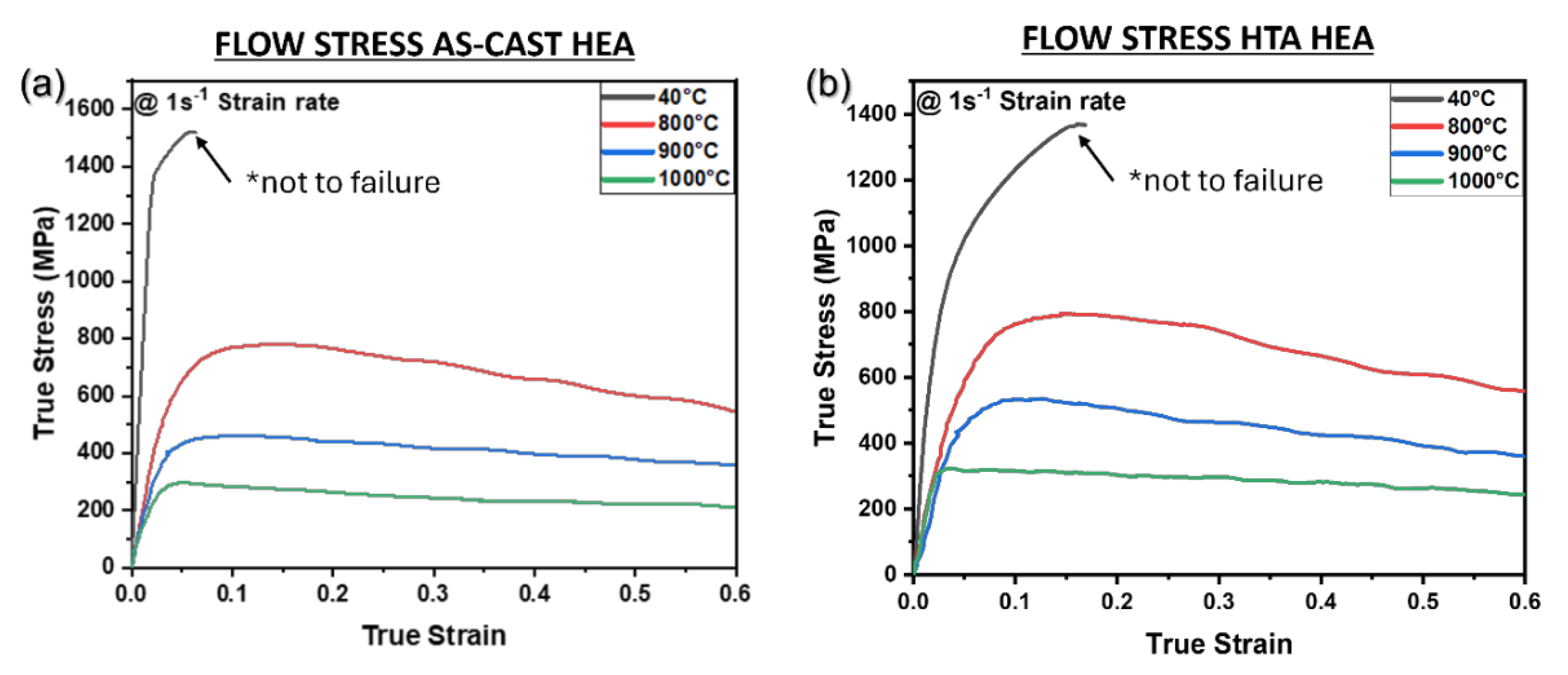

Figure 5.

True stress strain compression curves tested at temperatures of 40C, 800C, 900C, and 1000C at a strain rate of 1s^-1 for (a) As-Cast and (b) high temperature annealed conditions.

Figure 5.

True stress strain compression curves tested at temperatures of 40C, 800C, 900C, and 1000C at a strain rate of 1s^-1 for (a) As-Cast and (b) high temperature annealed conditions.

Vickers microhardness of the AC condition was measured as 358.13

+13.51Hv, comparable to ATI 718Plus

® cast Ni-superalloy at 350Hv [

19] and AlCoCrFeNi

2.1, an FCC+ B2 eutectic HEA (EHEA) with a hardness of 310Hv in the as-cast [

20]. With the microstructural coarsening and disordering which accompany the high temperature annealing, hardness is reduced in the HTA condition to 249.2Hv. This change in RT flow behavior is similarly observed with room temperature compression, where both the AC and HTA condition achieved the force limit of the load cell, but the stress at plastic onset decreased from around 1.4 GPa to around 800MPa and a strain of 0.161 was achieved post annealing, up from the 0.059 in the AC state.

Despite the clear differences in room temperature compression, the effects annealing on compression appear to be more subdued. Both the AC and HTA conditions display a sharp initial peak followed by a narrow, but extant work hardening regime and then continuous strain softening. The width of the work hardening regime as well as the rate of strain softening decrease with increasing temperature in both conditions, approaching steady state at 1000oC. Deformation at 800oC is similar, with the AC and HTA conditions experiencing peak flow stresses of 782.33MPa and 793.45MPa at strains of 0.137 and 0.144 respectively. The HTA samples display a slight increase in peak flow stress over the AC at 900oC (535.12MPa and 464.34MPa respectively) and 1000oC (324.40MPa and 304.13MPa respectively).

Reported values for peak flow stresses in AlCoCrFeNi

2.1 EHEA at 1/s strain rate are 650MPa at 800

oC, 450MPa at 900

oC and 260MPa at 1000

oC [

21], all below those achieved by both the AC and HTA conditions. In a study from Liu et al. [

22], the addition of Nb

0.25 to the single phase FCC CoCrFeNi produced a hypoeutectic FCC+ lamellar FCC and Laves microstructure, with the refractory component adding additional phase strengthening over an extended range of thermal stability. Under the presented test conditions, peak flow stresses of 780MPa, 580MPa, and 390MPa were reported at 800

oC, 900

oC, and 1000

oC respectively. A similar addition of (Mo, Nb)

0.25 to the AlCrFe

2Ni

2 EHEA system produced an FCC+B2+BCC+Laves multi-eutectic structure which displayed peak flow stress of 574.35MPa and 371.04MPa at 900

oC and 1000

oC respectively [

23]. Despite the lower refractory content, the HTA condition performed similarly to both these compositions at 800

oC but is outperformed at 900

oC and 1000

oC. The addition of Nb in CoCrFeNi has been shown to decrease ductility with an increase in strength [

24] while the addition of a minor amount of Mo and Nb to AlCrFe2Ni2 increased yield stress, fracture strength, and ductility in room temperature quasistatic compression [

10]. Additional room temperature testing to failure of the AC and HTA conditions is required for adequate comparison of room temperature workability to prior literature but falls outside the capabilities of the current study. All of the alloys discussed previously still fall short of the performance of ATI 718Plus

®, reported at a peak flow stress of 1.1GPa and 575MPa at 850

oC and 950

oC respectively [

25], however necessitating multiple processing steps after initial casting to achieve the desired properties as compared to a single annealing treatment [

26].