1. Introduction

Composite materials play an important role in addressing the evolving needs of various industries, ranging from aerospace and automotive to construction and electronics. They offer a unique combination of properties, such as a high strength-to-weight ratio, excellent corrosion resistance, good thermal stability, and remarkable design flexibility, making them suitable for diverse applications in critical sectors, including sports, marine, and biomedicine [

1,

2,

3]. The pursuit of ever-improving materials’ performance has led researchers to explore novel avenues of further enhancing the performance of composite materials to meet contemporary sectoral demands.

Recent advancements in nanotechnology has pave the way in developing functional composite materials with enhanced product efficiency, cost-effectiveness, and overall performance improvement [

4]. Properties such as thermal stability, electrical conductivity, strength, and stiffness-to-wight ratio have been significantly improved by the introduction of different nanomaterials into the composite structures [

5]. Nanocomposites, composite materials reinforced with nanoparticles or nanofillers have the potential to revolutionize many advanced engineering sectors because of their unique surface properties, unprecedented levels of functionality, and exceptional performance. Nano-based materials, such as carbon nanotubes (CNTs), graphene, fullerenes, and nanocellulose, possess distinctive characteristics that have captured the interest of researchers. They aimed to harness the potential of these materials for significant advantages across various sectors including composite design and development. This entails the optimal integration of nano-based materials into composites to meet specific performance criteria and address the escalating demand for increasingly complex materials across diverse sectors. Industries such as aerospace, automotive, marine, and biomedicine are increasingly demanding high-performance composite materials for manufacturing components that require multifunctionality [

6,

7]. The emergence of nanocomposite materials is progressively addressing these demands, thanks to their unique combination of properties, in addition to their lightweight nature.

Effective interfacial interaction among the individual constituents is a critical factor in determining the overall performance of composite materials [

8]. Nano-based materials hold promise for enhancing interfacial bonding between the matrix and reinforcement during composite fabrication. This is attributed to the distinctive surface properties of these materials at the nanoscale level [

9]. The exceedingly small size of nano-based materials, coupled with their high surface area and energy, enhances their physical and chemical activities. This characteristic enables them to readily bond with other surfaces compared to materials at the macro or micro levels [

10]. Nanomaterials have been widely employed to improve the properties of composite materials. The effectiveness of these nanomaterials in enhancing the specific characteristics of polymer-based composites depends on the targeted application area [

11,

12]. Ma et al. [

13] employed an analytical model to evaluate the effectiveness of interfacial interactions between multiphase carbon nanotubes and thermoplastic resin in developing high-performance nanocomposites for multifunctional applications.

Nanomaterials exhibit attractive characteristics suitable for impacting a broad spectrum of properties in nanocomposite development [

14]. Integration of nanomaterials into composites has led to improvements in mechanical strength, durability, electrical, thermal, and optical performances, paving the way for their high demand in critical applications such as engineering, transportation, biomedical, and pharmaceutical sectors [

15,

16,

17,

18]. In recent years, engineering sectors have witnessed tremendous growth in developing robust materials for lightweight structural applications, including aerospace, automotive, and construction industries, thanks to the novel chrematistics displayed by nanocomposite materials.

In addition to the lightweight advantages of nanomaterial-based composites, their excellent electrical conductivity and thermal stability can significantly improve the efficiency and safety of electronic components and thermal management systems in vehicles and aircraft [

19,

20]. The use of nanomaterials in the biomedical and pharmaceutical sectors has been extensively explored, as widely reported in the literature [

21,

22,

23,

24]. Nanocomposites offer unique opportunities for the development of advanced materials with improved biocompatibility and tailored functionalities, leading to more effective treatment methods with reduced side effects. This includes novel biocompatible implants, drug delivery systems, and diagnostic tools [

25,

26]. The unique properties of nanomaterials have been attributed to their high surface area-to-volume ratio, tunable surface chemistry, enhanced reactivity, and quantum confinement effects [

27,

28]. Nanomaterials are manufactured at the nanoscale having at least one dimension less than 100 nm. Recently, carbon-based nanomaterials have attracted significant attention as nanofillers for the development of high-performance composites in many applications [

29,

30,

31,

32,

33]. Composite materials in which at least one of the components has a dimension in the nanoscale range are referred to as nanocomposites. Nanocomposites are typically composed of a polymer, ceramic, or metal matrix reinforced with nano-based materials such as nanoparticles or nanofibers. Reports have shown that the advent of nanocomposite has greatly revolutionized many critical sectors, including water treatment, food processing, transportation, and biomedical science [

34,

35]. However, the difficulty in controlling the dispersion and alignment of nanomaterials during composite production has remained a serious challenge among researchers and manufacturers [

36,

37]. Moreover, concerns about their potential environmental impact further complicate the exploration and use of nanomaterials in the production of composites for functional applications.

In this study, we provide a summary of recent advances in nanocomposite development and their potential for advanced applications. Initially, some emerging nanomaterials and their attractive characteristics in advancing composite performance are highlighted. Subsequently, research progress on using various nano-based materials to enhance the mechanical, electrical, thermal, and optical performance of nanocomposites is presented. The study further explores the challenges posed by nanomaterials during composite production and their potential environmental impact during and after the end-of-life usage. Finally, we offer suggestions for future research directions, addressing the current gaps in research, through developing novel and eco-friendly nano-based composites and adopting more sustainable practices in the composite manufacturing sectors.

1.1. Nanomaterials

Nanomaterials refer to those materials having a size of approximately 1–100 nm with dimensions in the nanometer range [

38]. Nanomaterials are among the most advanced materials in recent technological development [

39]. The numerous functions and special physiochemical characteristics of nanomaterials make them very useful for sustainable technology. In general, nanomaterials can be classified into three major groups: organic-based nanomaterials, inorganic-based nanomaterials, and carbon-based nanomaterials [

40]. Several nanomaterials have been successfully used to improve the properties of composite materials for advanced applications, including carbon nanotubes, graphene, nanocellulose, metal nanoparticles, ceramic nanoparticles, and polymer-based nanoparticles [

41,

42,

43,

44].

Organic nanomaterials

Organic-based nanomaterials are a class of materials made of organic compounds or containing organic components that combine the unique properties of nanoscale structures with the flexibility and functionality of organic molecules [

39,

45]. These materials can be synthesized from various organic compounds, including polymers, lipids, peptides, and nucleic acids, using different techniques such as chemical vapor deposition (CVD), bottom-up assembly, and top-down lithography [

46,

47,

48]. These techniques allow precise control over the size, shape, and composition of nanomaterials, which can be tailored to specific applications such as electronic devices, drug delivery systems, solar cells, and batteries. Examples of organic-based nanomaterials include liposomes, micelles, dendrimers, and cyclodextrin. Dendrimers are a special type of organic-based nanomaterials with very highly branched, tree-like molecules that have been developed specifically for biomedical applications such as drug delivery and imaging [

49,

50,

51]. Nanocellulose, which includes microfibrillilated cellulose (MFC), nanocrystalline cellulose (NCC), and bacterial cellulose (BC), are organic nanomaterials derived from natural polymers in wood/plants and bacterial strains, respectively. MFC and NCC are mostly used as reinforcement materials for enhancing the properties of polymer-based composites, whereas BC has applications mainly in biomedicine and water filtration treatment. Generally, nanocellulose can be obtained through various processes, such as mechanical treatment, chemical treatment, or enzymatic approach [

52,

53].

Inorganic nanomaterials

Inorganic-based nanomaterials consist of inorganic elements or compounds that have been synthesized at the nanoscale. These materials can be classified as metal or ceramic-based nanomaterials. Common metal-based nanomaterials include silver (Ag), copper (Cu), gold (Au), aluminum (Al), zinc (Zn), and lead (Pb) nanoparticles. Ceramic or metal oxide-based nanomaterials comprise silica (SiO

2), copper oxide (CuO

2), iron oxides (Fe

2O

3 & Fe

3O

4), titanium oxide (TiO

2), and magnesium aluminum oxide (MgAl

2O

4) [

40,

54]. Inorganic-based nanomaterials have been successfully incorporated into polymer matrices to produce nanocomposites with enhanced properties for various applications such as food packaging, coatings, and biomedicine because of their unique optical, electrical, and other interesting properties [

55]. Nanoclay can also be classified as an inorganic-based nanomaterial derived from clay minerals that have been processed into nanometer-sized particles. Clays are naturally occurring minerals with high mechanical performance, good thermal stability, and are environmentally friendly. Nanoscale particles such as montmorillonite, kaolinite, and halloysite derived from these minerals have been successfully used to enhance the performance of many organic matrices (such as polymers) to develop nanocomposite materials for various applications [

56,

57].

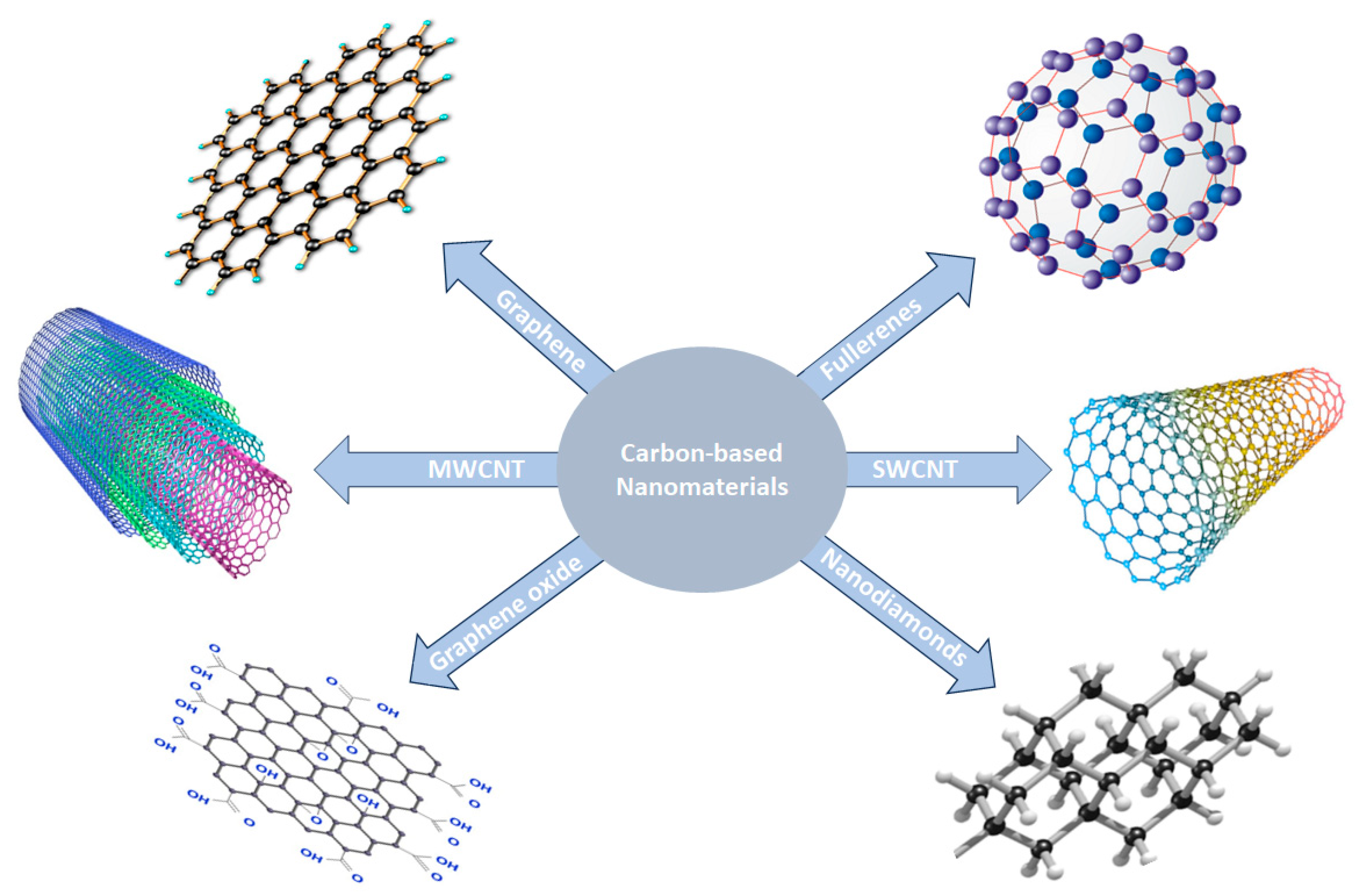

Carbon-based nanomaterials

Carbon-based nanomaterials are special types of nanomaterials that come in different forms or allotropies and contain carbon atoms that are arranged in unique structures at the nanoscale level [

58,

59,

60,

61,

62]. These materials have various shapes and sizes, depending on the type which include carbon nanotubes, graphene, fullerenes, graphene oxides, and many others.

Figure 1 shows the structural arrangement and shapes of different types of carbon-based nanomaterials. Because of the inherent attributes of these carbon-based nanomaterials, which include high electrical conductivity, high chemical stability, acceptable aspect ratio, biocompatibility, and exceptionally high mechanical properties, they have been recognized as promising materials for many critical applications such as biomedicine, biosensors/detectors, energy storage and conversion, functional composite development, surface coating, and environmental remediation [

63].

Graphene (G)

Graphene is a recently discovered carbon material with exceptional properties. It consists of a single layer of graphite with excellent mechanical, electrical, and thermal properties, surpassing those of traditional engineering materials such as metals and ceramics. Graphene consists of sp

2 carbon atoms organized in a hexagonal lattice, forming a two-dimensional (2D) layer. It has an exceptional surface area (2630 m

2/g), a remarkable elastic modulus (1 TPa), high conductivity (intrinsic carrier mobility of 2000000 cm

2/V), impressive optical transparency, and thermal conductivity (5000 W/mK) [

64,

65,

66]. It appears to be the building block for other carbon-based nanomaterials such as carbon nanotubes and fullerenes. It has been described as one of the most promising materials for future technology because of its combined flexibility and excellent properties [

67]. Graphene, often regarded as the thinnest material, also boasts remarkable strength. While steel typically exhibits a breaking strength ranging from 250 to 1200 MPa, equivalent to 0.25–1.2 × 10^9 N/m^2, if hypothetically drawn into sheets as thin as graphite (approximately 3.35 Å), its breaking strength would be reduced to a mere 0.084–0.40 N/m. In contrast, graphene exhibits an impressive breaking strength of 42 N/m, making it approximately a hundred times stronger than steel [

68]. It is highly impermeable to gasses and liquids, making it a useful reinforcement material for nanocomposites by creating an interfacial barrier against gases and moisture absorption when added to a polymer matrix. The suitability or applicability of graphene as a potential reinforcement material in nanocomposite development has been studied by several researchers [

69,

70]. Consequently, graphene-based nanocomposites exhibit excellent mechanical and electrical properties and can be used in various applications, including electronics, energy storage devices, sensors, and biomedicine [

67].

Graphene oxide (GO)

Graphene oxide (GO) is a derivative of graphene that consists of oxygen-containing functional groups, such as hydroxyl, epoxy, and carboxyl groups, attached to the graphene surface [

71,

72]. It is a two-dimensional material containing a single atomic layer arranged in a hexagonal lattice. The additional oxygen-based functional groups in graphene oxides make them highly hydrophilic and easily dissolvable in many polar solvents such as water and organic solutions. In addition, it can be easily functionalized by attaching other molecules or nanoparticles to its surface. Graphene oxides are produced from a crystalline form of carbon (Graphite) with strong oxidizing agents such as potassium permanganate or sodium nitrate [

73,

74]. It has a large surface area-to-volume ratio with excellent thermal stability and chemical reactivity. GO has been widely used as a reinforcement material in composite production, catalysis, biomedical engineering, wastewater treatment, and environmental remediation [

75,

76,

77,

78]. Reports have shown that the presence of oxygen-containing functional groups in GO structures slightly affects its properties, such as electrical conductivity and mechanical strength when compared with pure graphene [

79,

80].

Carbon nanotubes (CNTs)

Carbon nanotubes are cylindrical structures consisting of rolled-up sheets of graphene in a two-dimensional form with a hexagonal lattice pattern arrangement. They were first discovered by a Japanese scientist, Sumio Iijima, in 1991, who first observed them in the soot of an arc discharge between two graphite electrodes and clearly described their formation [

81,

82,

83]. Following their discovery, CNTs have attracted much scientific interest because of their unique physical and chemical properties. They are strong and stiff, yet flexible, and have excellent thermal and electrical conductivity, making them ideal materials for sensitive applications [

84]. Carbon nanotube-based nanocomposites have been used in various applications, including transportation, biomedical science, and sports equipment, mostly because of their exceptional specific strength compared with other engineering materials. Depending on the arrangement of the graphene sheets within the material, CNTs can be classified as either single-walled (SWCNTs) or multi-walled (MWCNTs). SWCNTs consist of a single layer of graphene rolled into a tube to form a cylindrical structure. They have different diameters and chirality, which affect their physical and chemical properties. On the other hand, MWCNTs consist of multiple layers of graphene sheets rolled into nested tubes [

22,

85]. Reports have shown that the properties of MWCNTs largely depend on the number and arrangement of the graphene layers in the structure. MWCNTs are usually more difficult to produce than SWCNTs because of their complex structures; however, they are easier to disperse in the composite matrix than SWCNTs [

86]. Generally, CNTs are widely studied for their unique electrical, mechanical, and optical properties and have potential applications in electronics, energy, and materials science [

84,

87].

Fullerene (F)

Fullerene is a class of carbon-based nanomaterials, initially discovered in 1985 by a research team led by Harold Kroto, Robert Curl, and Richard Smalley. Their pioneering work on fullerenes earned them the 1996 Nobel Prize in Chemistry after 11 years of research. Fullerenes consist of carbon atoms organized in spherical or ellipsoidal molecules, resembling a soccer ball, as shown in

Figure 1. Since its discovery, fullerenes have been the subject of continual and expanding areas of study, which has sparked the creation of a variety of novel and sophisticated materials for biomedical applications. In addition to their role in the medication system, fullerenes are also well known for their potential as superconductors and their capacity to form stable compounds with other molecules [

88,

89]. The versatile nature of fullerenes has led to their wide exploration in diverse fields, contributing significantly to advancements in science and nanotechnology.

2. Recent Advances in Nano-Enhanced Composites

Nanomaterials have emerged as a promising class of materials because of their unique combination of properties derived from the nanoscale. They are characterized by a high surface area-to-volume ratio and quantum effects [

90]. The exceptional combination of properties exhibited by nanomaterials has significantly propelled their use in enhancing the mechanical, electrical, thermal, and optical characteristics of composite materials. This makes them highly desirable for diverse industrial applications, such as electronic devices, energy storage, biomedical devices, and environmental remediation. The ever-increasing interest in developing advanced composite materials to meet contemporary sectoral demands has led to a significant interest in developing nanocomposites with novel characteristics by incorporating various nanomaterials, such as graphene, carbon nanotubes, and metal nanoparticles, within the composite structure [

91]. When nanomaterials are incorporated into composites, they impart novel functionalities which significantly improve the material properties [

92]. Nanomaterials such as graphene possess a high theoretical surface area, enabling better interfacial interaction with the composite constituent phases. This interaction results in improved mechanical and electrical performances as well as enhanced thermal stability of nanocomposites [

93]. Wang et al. [

94] reported significant improvements in the mechanical and electrical properties of CNT-modified carbon fiber-reinforced nanocomposites. In their study, addition of a high mass fraction of approximately 41 wt% CNT resulted in a remarkable improvement in the tensile strength (up to 310 ± 13 MPa) and Young's modulus (up to 2.4 ± 0.1 GPa), along with improved electrical conductivity. Kausar, [

95] summarized the recent progress in the use of fullerene-reinforced polymer matrix nanocomposites, focusing on energy storage applications such as supercapacitors, and concluded that fullerene/polymer nanocomposites have enriched electrical conductivity, adequate mechanical strength, and excellent thermal stability. The unique spherical structures of fullerenes make them interesting alternative materials to CNTs and graphene. They are available in abundance and at a much lower cost than other carbon-based nanomaterials [

96].

Jani et al. [

97] also highlighted the current progress in the use of zero-dimensional (0D) carbon-based nanomaterials (such as fullerenes and carbon dots) in polymer-based nanocomposite for water purification/treatment. According to their findings, incorporation of fullerenes and carbon dots into a variety of polymers to form nanocomposites enhances the interfacial membrane properties for better water permeability, separation efficiency, and antifouling performance. Ng et al. [

98] conducted an investigative overview of the membrane performance of polymer-based nanocomposites for water purification using graphene oxide (GO) and its derivatives as nanofillers. This study showed that the introduction of GO-based nanofillers into polymeric materials can significantly alter the membrane morphology, surface wettability, and functional groups with enhanced wastewater treatment performance. Wang et al. [

99] developed a carbon nanotube/polyurethane composite for efficient electromagnetic interference shielding. The report shows that 5.0 wt% CNT loading in the X-band (8.2–12.4 GHz) resulted in a shielding effectiveness of 30.7 dB. In addition, at 2.0 wt% CNT content, the developed composite displayed healable tensile properties with an elongation at break of 571% ± 31% and self-healing efficiency of 89.2%.

2.1. Mechanical Properties

Nanocomposites exhibit superior mechanical properties that surpass those of conventional composite materials. They offer combination of attractive properties such as high specific strength and stiffness, toughness, and wear resistance because of the synergistic effects of the nanofillers and the matrix component [

100]. Understanding the strengthening mechanism of nanomaterials in nanocomposite development is crucial for optimizing their performance and unlocking their full potential in diverse applications, including the transportation, biomedical, and construction sectors. Several reports have demonstrated the remarkable capability of nanomaterials to significantly enhance the mechanical performance of composite materials. The use of CNTs and other carbon-based nanomaterials has been widely studied because of their remarkable strength and stiffness [

101,

102]. It has been reported that the use of both ex-situ CNTs and in-situ γ-alumina nanoparticles can lead to the development of high-performance metal matrix composites, especially aluminum matrix nanocomposites (Al-MMCs) [

103]. Ma et al. [

104] developed nanocomposites consisting of carbon nanotubes (CNTs) and graphene (G) hybrid aerogel as a conductive network in a polydimethylsiloxane matrix to enhance the piezoresistive performance of the multiscale hybrid nanocomposites. CNTs were grown on graphene sheets through chemical vapor deposition using an in-situ processing approach. The hybrid aerogel improved the interfacial interaction between the conductive network and the polymer matrix, exhibiting high sensitivity and an outstanding linear dependence on the applied stress to the material.

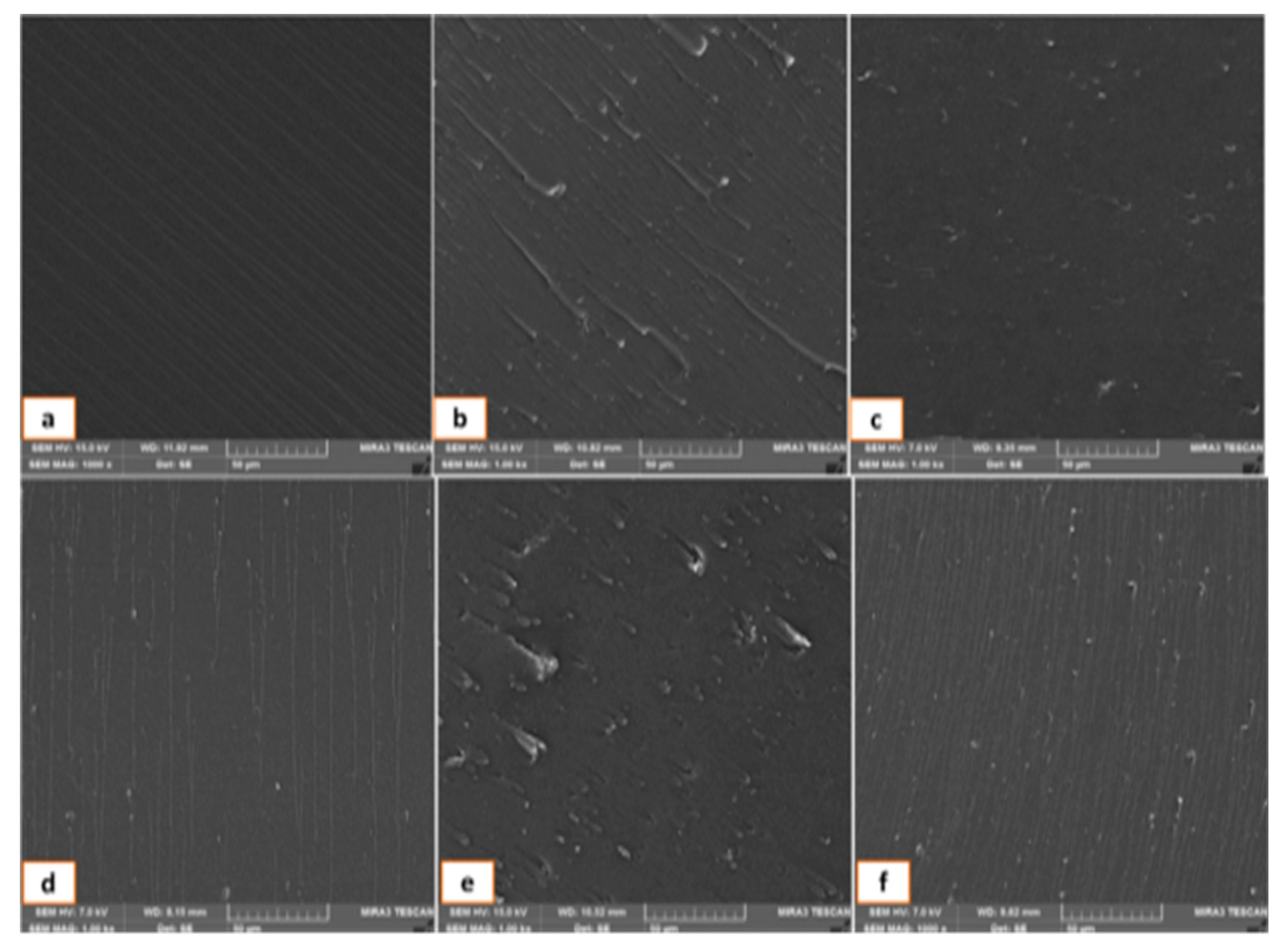

Farshidfar et al. [

105] used hybrid nanofillers (graphene oxide/nano clay) in an unsaturated polyester resin (UPE) to improve the mechanical and thermal properties of the hybrid nanocomposites and reported significant properties improvement due to the homogeneous dispersion of the nanoparticles in the polyester resin. The results of the study also indicated positive synergistic effects of graphene oxide (GO) and nano clay (NC) at unequal ratios of (25GO:75NC and 75GO:25NC) with well-dispersed fillers uniformly distributed within the polymer substrate and a minimum degree of aggregation, as observed in the FE-SEM micrograph in

Figure 2 (d & f). The effect of graphene nanoplatelets (GNPs) on the mechanical and thermal properties of recycled polycarbonate nanocomposites was also studied under various filler contents and other processing parameters. The results showed that Young's modulus and yield strength of the composites were enhanced with increasing GNP loading, as well as the thermal properties of the nanocomposites [

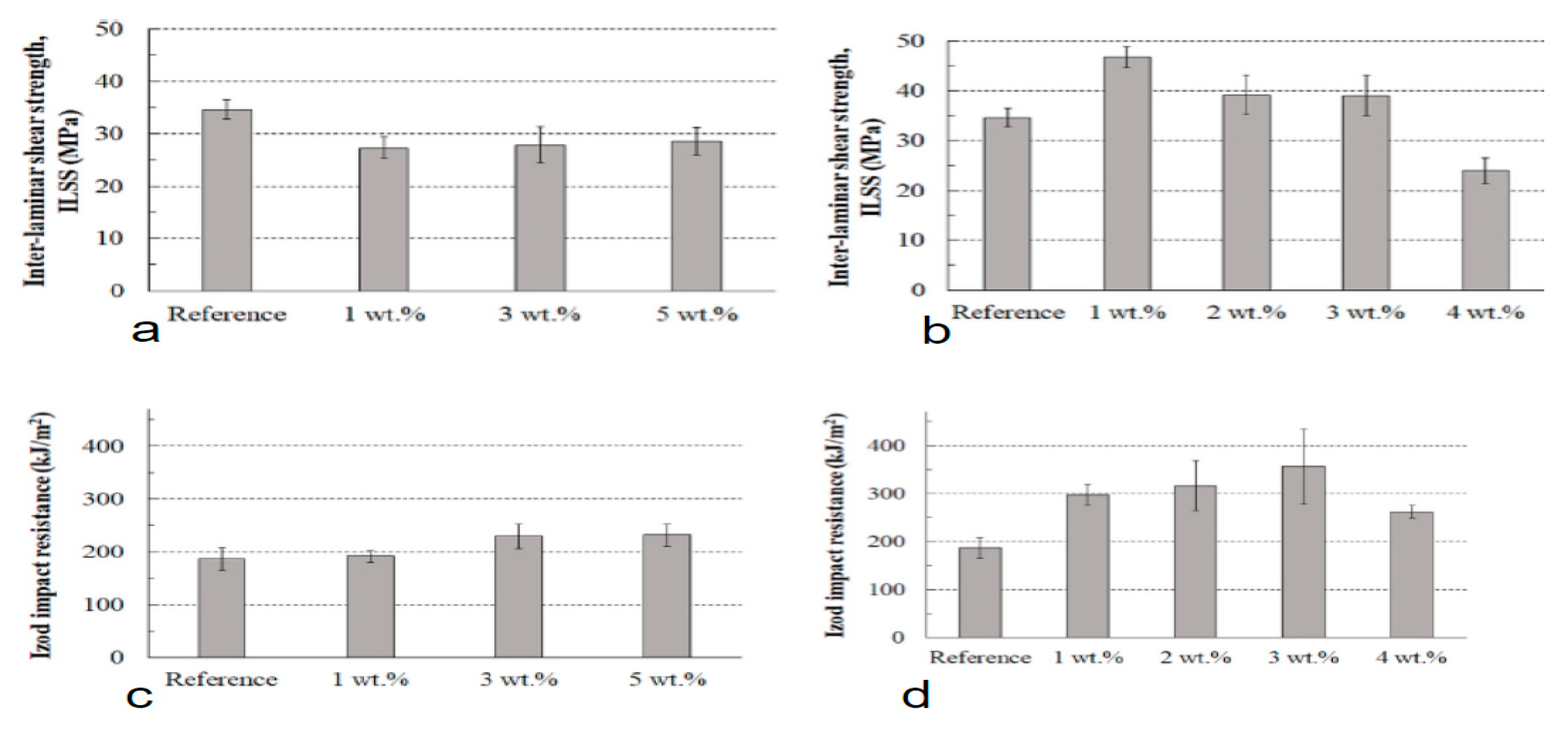

106]. Cheon and Kim [

107] investigated the influence of MWCNTs on the impact resistance and interlaminar shear strength (ILSS) enhancement of carbon fiber-reinforced polyamide 6 composites. This study compared the effectiveness of MWCNTs anchored on carbon fibers (CF) with direct mixing of MWCNTs in thermoplastic resin. The results shown in

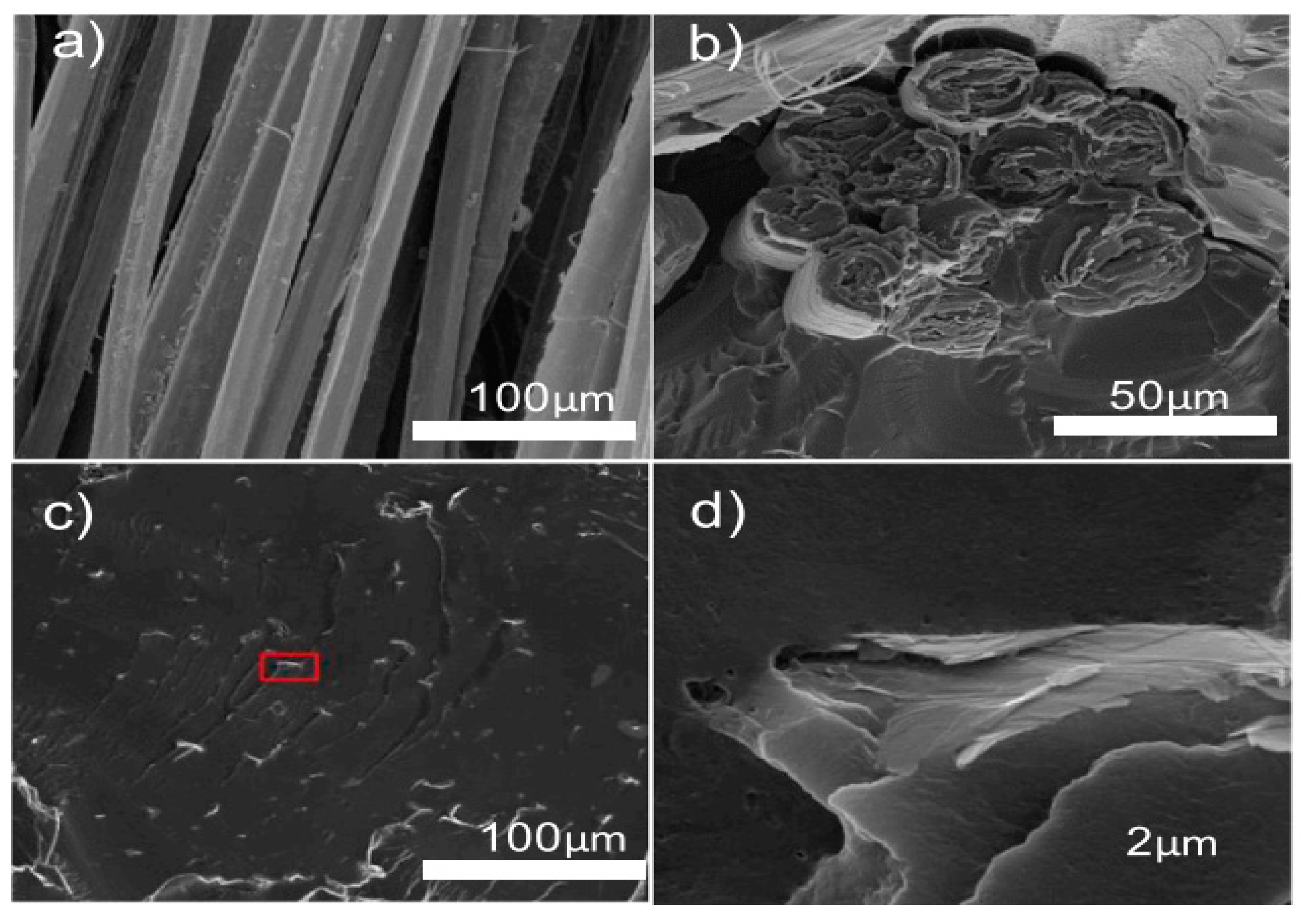

Figure 3 demonstrate that MWCNTs anchored on the carbon fibers improved the interfacial interaction between the fiber and the matrix without increasing the viscosity of the resin. This improvement led to a significant enhancement in both the impact resistance and ILSS of the composites compared with the direct mixing approach.

Abbass et al. [

108] investigated the impact of nanocoating on the mechanical performance and environmental resistance of flax and hemp fibers for masonry retrofitting applications. A nanocomposite coating comprising graphene nanoplatelets (GNPs) and waterborne polyurethane (WPU) was applied to the fibers. The coated fibers exhibited a significant enhancement in their tensile properties with low water absorption. The tensile strength and elastic modulus of the coated hemp yarns were improved by 120% and 163%, respectively, at an optimal weight percent of 0.5 wt% GNPs when compared with the uncoated yarns. This improvement is attributed to the uniform distribution of nanoplatelets within the polymeric matrix, resulting in effective wetting and enhanced interfacial interactions with the polymer matrix, as shown by the SEM image in

Figure 4(d). Zaiemyekeh et al. [

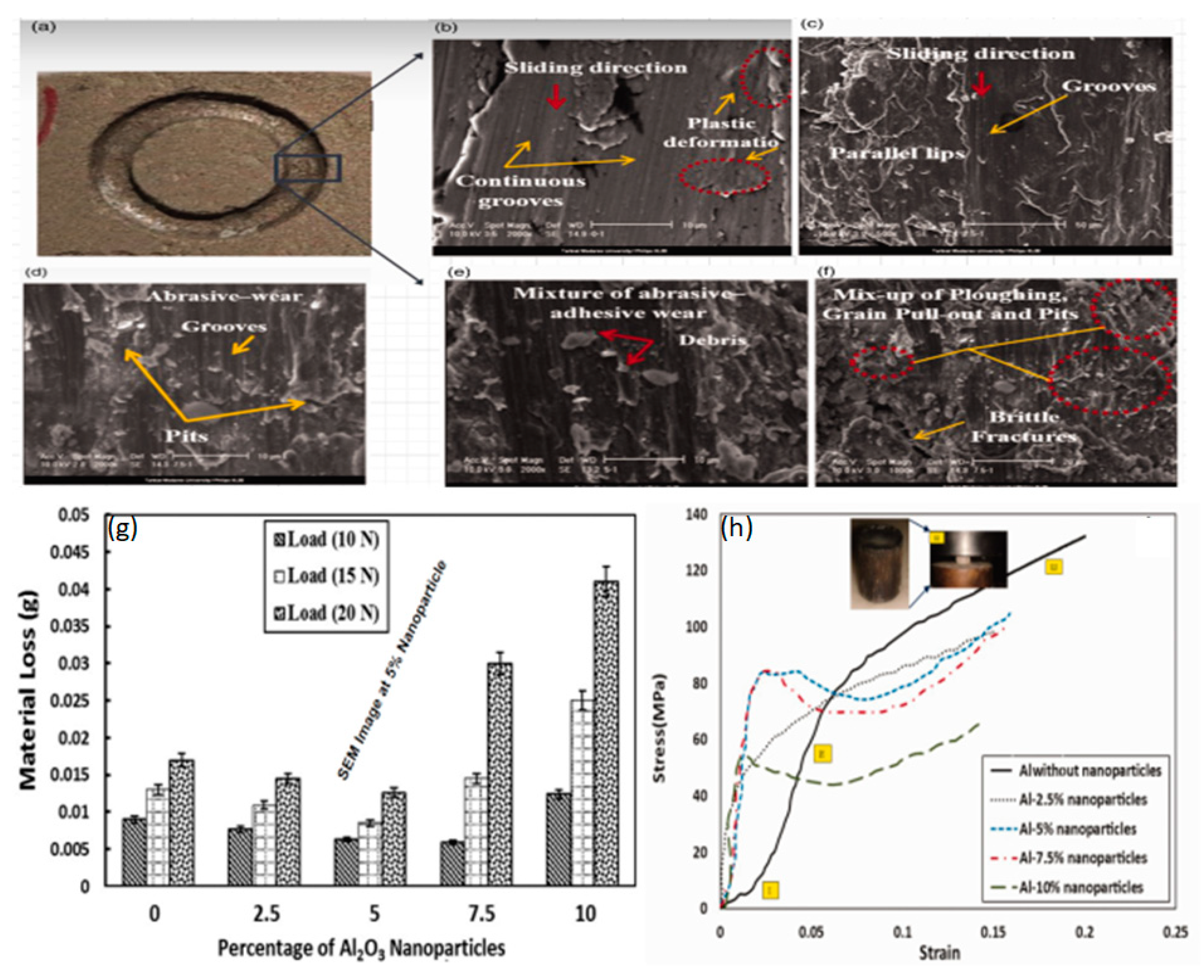

109] studied the compressive and sliding wear resistance of Al/Al₂O₃ nanocomposites by varying the percentage composition of Al₂O₃ nanoparticles. The results showed that the addition of Al₂O₃ nanoparticles into the Al matrix significantly increased both the compressive strength and sliding wear deformation, with optimum properties obtained at a 5% weight fraction, as shown in

Figure 5.

Figure 5 (a-f) shows the wear surface of the samples with and without the addition of alumina nanoparticles.

Figure 5 (d) shows the wear surface of the optimal conditions having a 5% weight fraction of Al

2O

3 nanoparticles. The worn surface of the sample is relatively smooth and uniform compared with that in

Figure 5 (b) (without nanoparticles). There were shallow grooves along the sliding direction on the surface of the samples. These lower-density grooves on the surface of the samples showed a higher resistance to scratch and wear of the material with better resistance to plastic deformation and material flow. These SEM images further explain the wear and compressive test results presented in

Figure 5 (g and h). Katagiri et al. [

110] studied the effects of cellulose nanofiber (CNF) content on the impact properties of carbon fiber-reinforced (CFRP) epoxy composites. This study compares CNFs derived from 2,2,6,6-tetramethylpiperidine-1-oxylradical (TEMPO)-mediated oxidation, followed by mechanical fibrillation and CNFs obtained directly by mechanical fibrillation from hardwood pulp without TEMPO-mediated oxidation. The result shows that the impact energy absorbed by the CFRP specimen increased with increasing CNF content up to a maximum of 21% by the CNF dispersion layers. Cherian et al. [

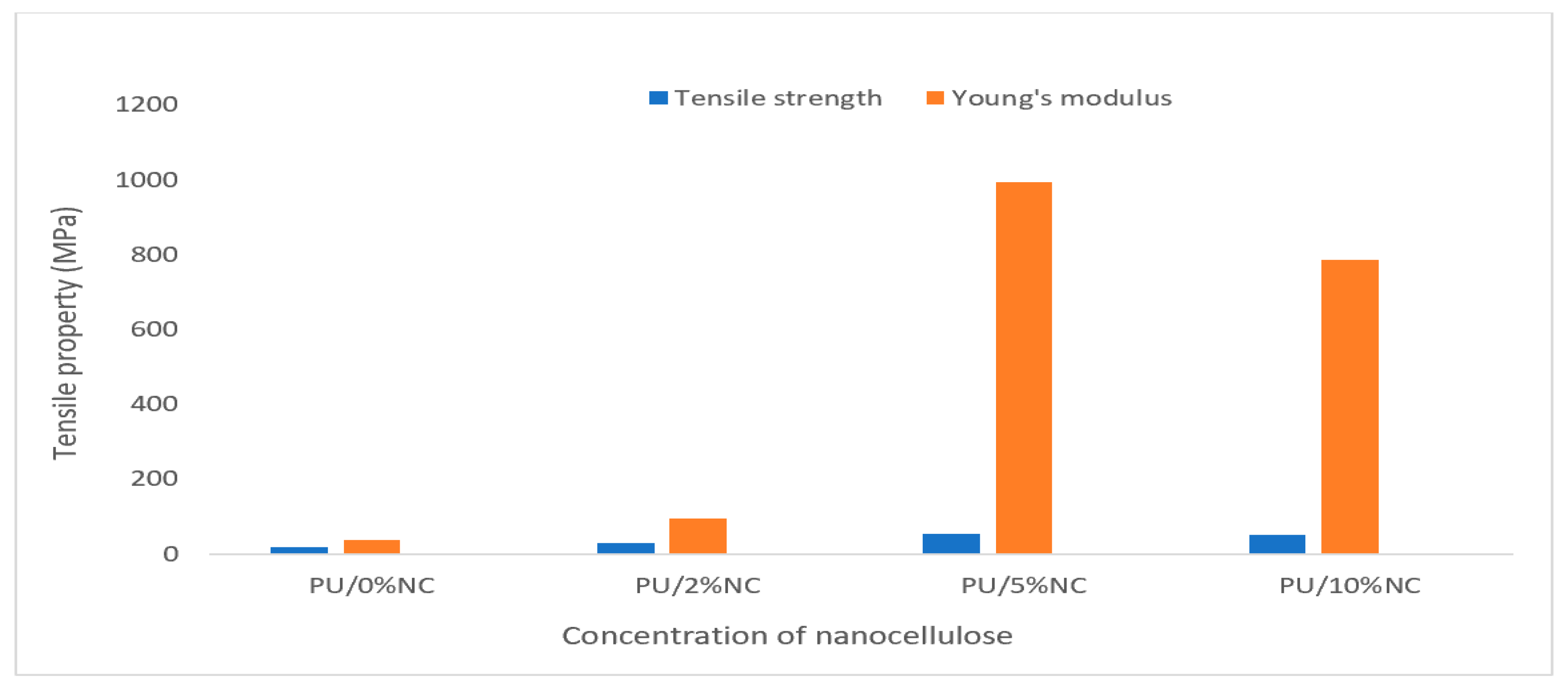

111] developed polyurethane-based (PU) nanocomposites using nanofibers isolated from pineapple leaves as reinforcement. The study showed that the addition of 5 wt% of cellulose nanofibrils to PU yielded nearly 300% and 2600% increases in the tensile strength and stiffness, respectively (

Figure 6). The authors concluded that the developed composites can be potentially used to fabricate various medical implants for biomedicine applications. Ansari et al. [

112] developed nanostructured biocomposites by incorporating a nanocellulose network in an unsaturated polyester (UP) resin and reported a substantial increment in the glass transition temperature (Tg) increases with 45 vol% NC content. The modulus and strength of the composite were three times higher, while both the ductility and apparent fracture toughness were doubled at 45 vol% NC compared with UP.

Lee et al. [

113] synthesized a novel and robust nonwoven sisal fiber preform using bacterial cellulose (BC) as a binder in acrylate-epoxidized soybean oil (AESO) for performance enhancement. This approach significantly improved the storage modulus of the composite and enhanced the fiber–matrix stress transfer.

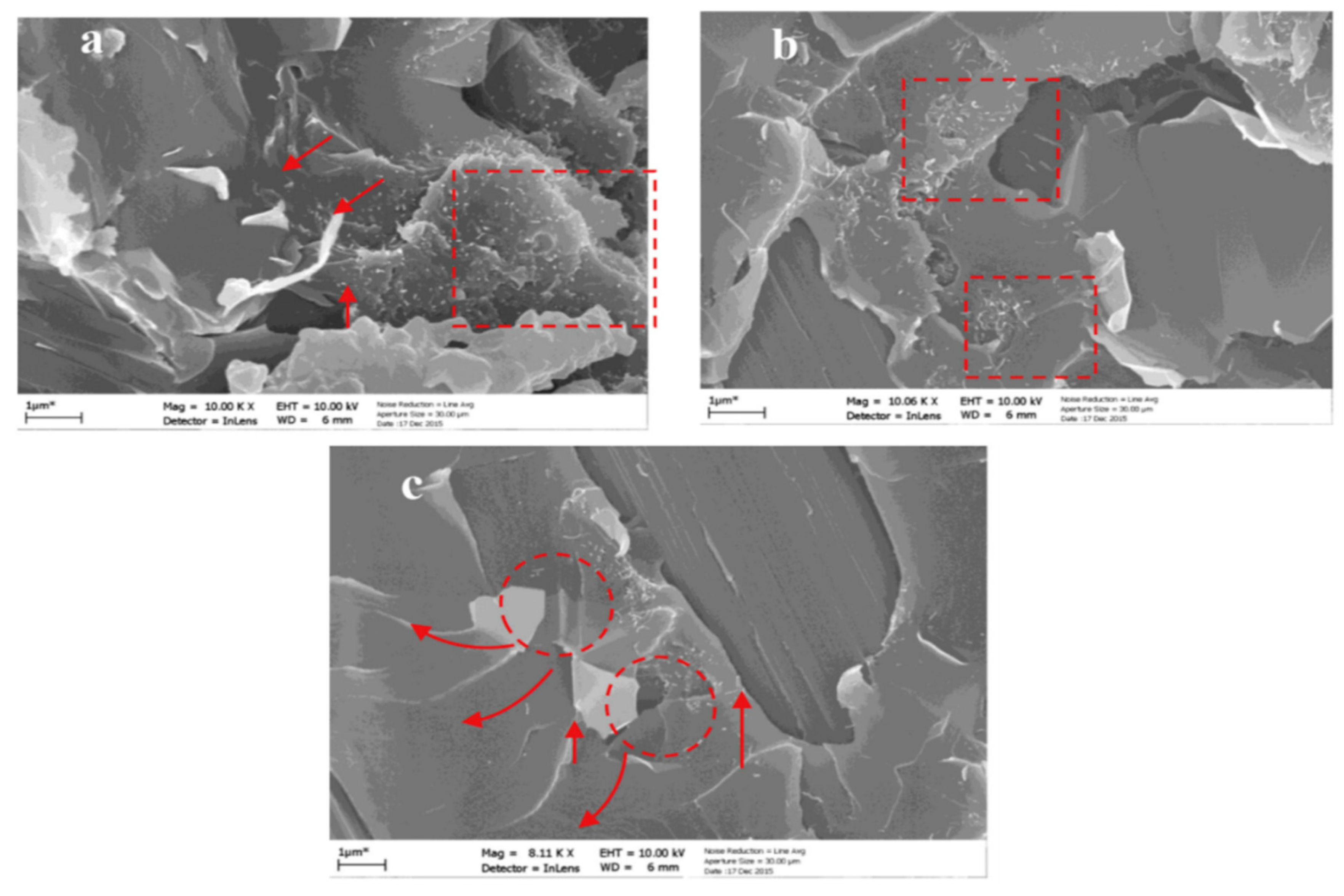

Kostagiannakopoulou et al. [

114] investigated the synergistic effect of two carbon-based nanofillers, few-layered graphene nanoplatelets (GNPs) and multi-walled carbon nanotubes (MWCNTs), on the interlaminar fracture toughness of carbon fiber-reinforced polymer composites (CFRP). Two experimental tests were conducted. In the first experiment, 0.5 wt.% GNPs and 0.5 wt.% MWCNTs were used to modify the polymer matrix. In the second experiment, the concentration of GNPs was held constant, whereas the concentration of MWCNTs was increased to 1 wt.%. The addition of 0.5 wt.% GNPs and 1 wt.% MWCNTs improved the mode I fracture toughness (G

IC) by 45% and mode II (G

IIC) by 25%.

Figure 7 shows the SEM micrographs of the fracture surfaces illustrating the synergistic effects and strengthening mechanisms of the hybrid nanofillers in the composite.

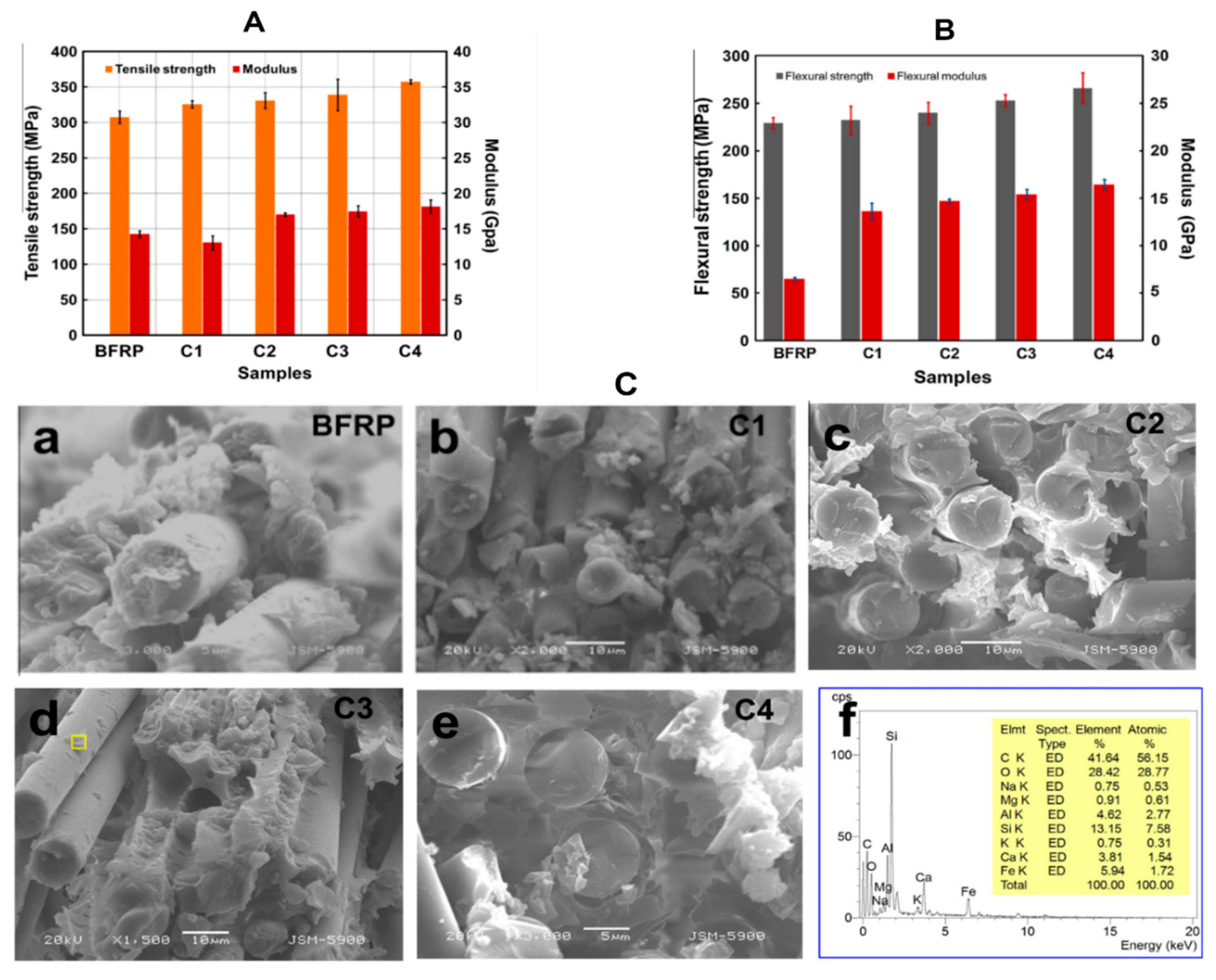

Subagia et al. [

115] conducted an investigation assessing the influence of tourmaline (TM) micro/nanoparticles with varying concentrations (

Table 1) on the tensile and flexural properties of basalt fiber-reinforced epoxy composites. Their findings indicated that the addition of 1 wt% TM loading with a surfactant yielded optimal tensile and flexural strengths, exhibiting an enhancement of approximately 16% compared with the neat basalt/epoxy composite. Moreover, the study demonstrated a remarkable increase of 27.4% and 153.3% in the tensile and flexural moduli, respectively, as shown in

Figure 8 (A and B). The improved performance of the composite laminates was attributed to the effective dispersion of TM particles in the epoxy matrix at a 1 wt% concentration with surfactant, leading to robust interfacial bonding between the basalt fibers (BFs) and the epoxy resins, thereby enhancing interfacial load transfer with few fibers pull-out, as observed in

Figure 8C (C4). Zhu et al. [

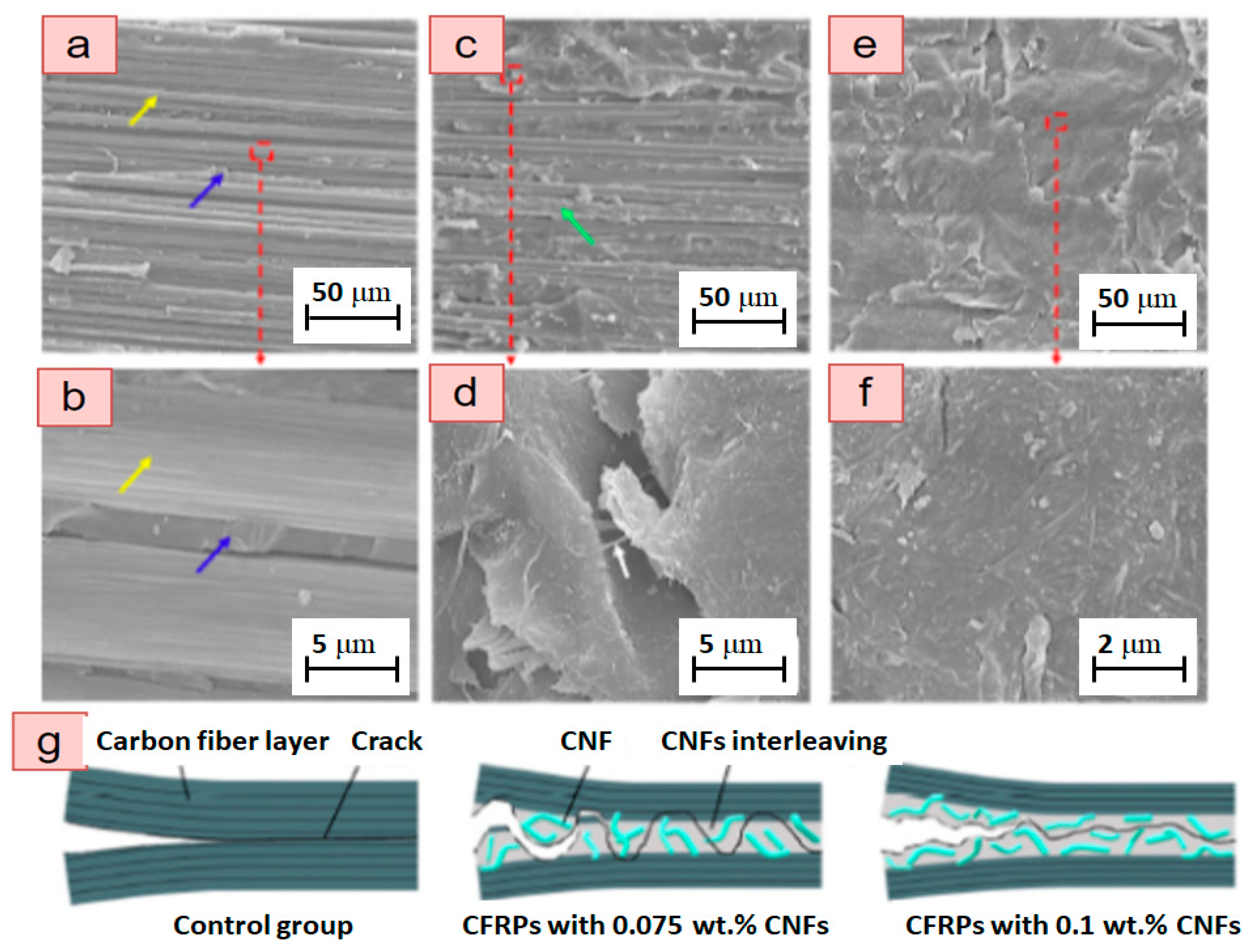

116] investigated the impact of cellulose nanofiber (CNF) content on the interlaminar fracture toughness and damping properties of carbon fiber-reinforced polymer composites (CFRPs). CNF films were developed and infused between the carbon fibers in various stacking sequences to assess the loss factors of the resulting composites. The findings revealed that the incorporation of 0.075 and 0.05 wt.% CNFs led to 22% and 25% improvement in the mode I and mode II interlaminar fracture toughness of CFRPs, respectively. Conversely, the addition of 0.25 wt.% CNFs increased the loss factor by 31%. However, this enhancement in damping properties was accompanied by a slight reduction in the tensile and flexural properties of the CNF-interleaved CFRP. The SEM image presented in

Figure 9 elucidates the strengthening mechanism of the CNF-interleaved CFRP and the fracture surface morphology of the composites.

2.2. Electrical Properties

Nanomaterials are known for their attractive electrical characteristics, which are attributed to their unique features at the nanoscale level. Incorporation of nanoparticles, nanowires, or nanotubes into the composite matrix enables precise control over electrical conductivity, resistivity, and dielectric properties [

117]. Nanomaterials possess excellent electrical properties mainly due to their quantum confinement effect of the nanoscale materials [

118]. The energy required to charge electrons is confined within a limited space, leading to an increasing number of charged electrons with effective mobility of the charged carrier, thereby significantly improving the electrical performance. Composites reinforced with nanomaterials, particularly carbon-based nanomaterials such as graphene, CNTs, and fullerene, offer lightweight advantages, efficient electrical characteristics, and enhanced functionality [

119]. These properties make them suitable for various applications, including electronics, sensors, and energy storage devices. These nanomaterials are recognized for their ability to enhance the dielectric properties of nanocomposites by mitigating partial discharge (PD) and reducing the accumulation of space charge within the composite structures [

120]. This positive impact results from the unique characteristics and interactions of nanomaterials at the interface with the polymer matrix, leading to improved insulation performance and stability in electrical applications.

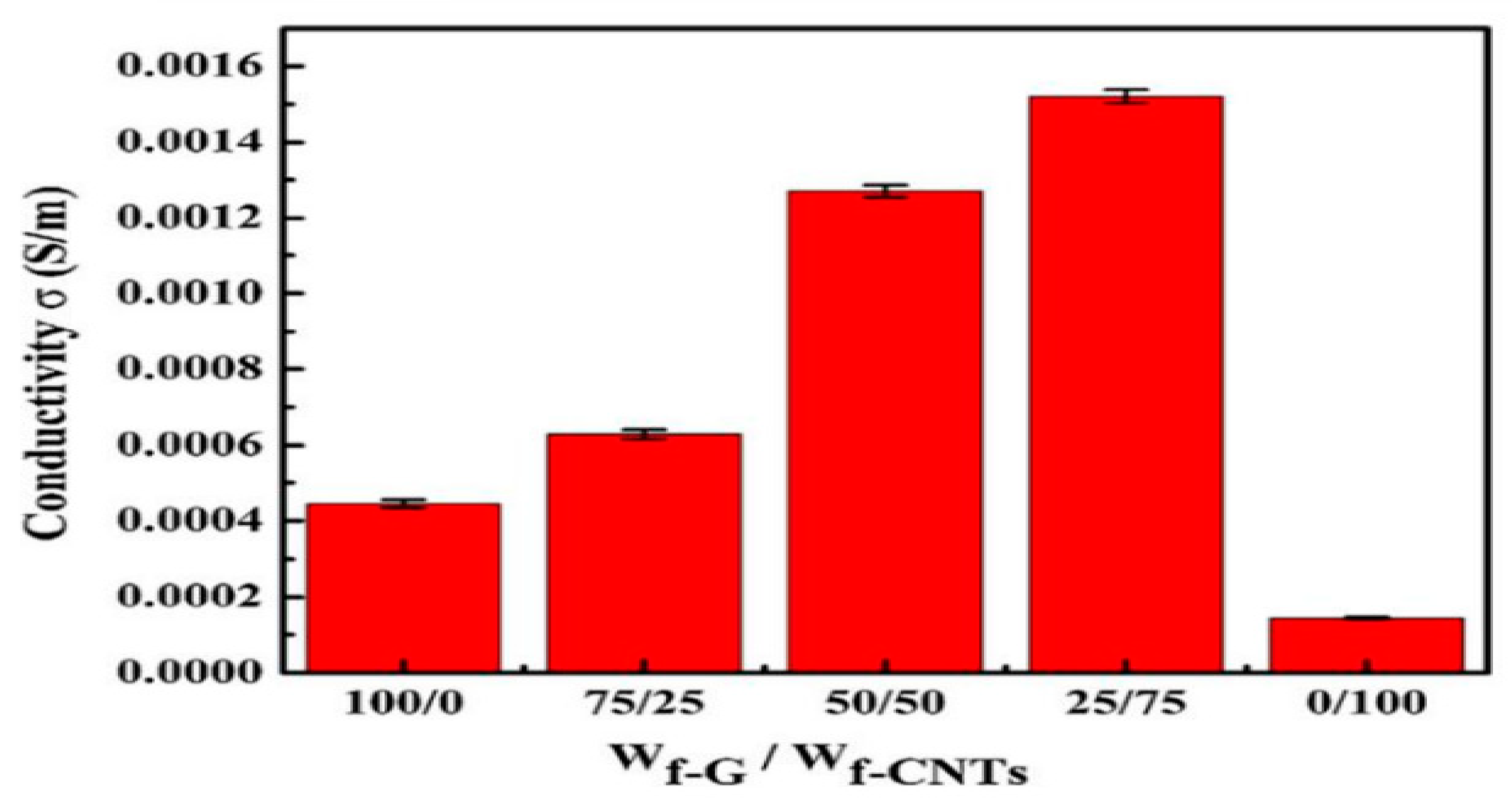

Zhang et al. [

121] explored the individual and synergistic effects of graphene and CNT-mixed fillers on the electrical conductivity of polyether sulfone (PES) polymer composites. They reported that the electrical conductivity of 5 wt.% graphene/PES composites was 5.82 × 10

−4 S/m, surpassing that of CNTs/PES composites (1.43 × 10

−4 S/m). Moreover, the graphene-CNT (graphene/CNTs = 1:1)/PES composite exhibited a lower percolation threshold (0.22 vol%) than the graphene/PES composites, with electrical conductivities of 2.2 and 8.9 times higher than those of the 5 wt.% graphene/PES composite and CNTs/PES composite, respectively. This enhancement was attributed to the high aspect ratio and synergistic effects of the mixed fillers, facilitating the co-dispersion of graphene and CNTs and establishing a more efficient 3D percolation network. In

Figure 10, it is evident that the electrical conductivity of the composite steadily increases as graphene is substituted by CNTs, and exhibits notable optimal performance at a graphene/CNT ratio of 1:3. Moreover, nanocomposites containing only one of the two fillers demonstrated diminished electrical conductivity. He et al. [

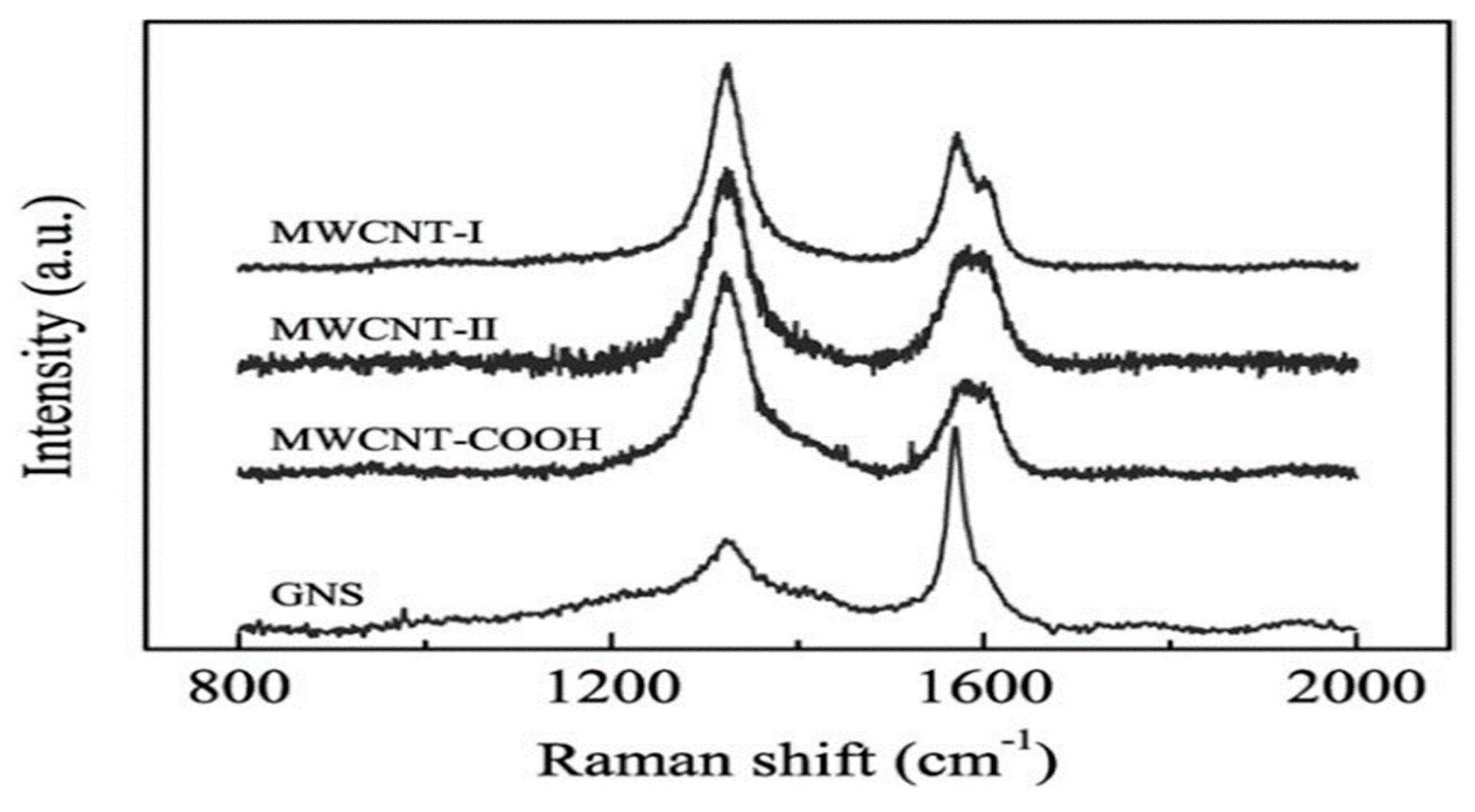

122] investigated the influence of CNTs and graphene functionalization on the electrical properties of epoxy-based nanocomposites. Their findings showed that the pristine MWCNT)/epoxy composite exhibited higher conductivity (0.176 S/m), which was approximately 11 times that of the pure epoxy (1.2 × 10

−12 S/m) and 7 times that of the functionalized MWCNT/epoxy (1.9 × 10

−8 S/m). The Raman spectrum (Fig 11) indicated that the measured conductivity of the highly reduced graphene nanosheets (GNSs) was much smaller than that of the pristine (MWCNT/epoxy) and functionalized (MWCNT-COOH/epoxy) composites. This discrepancy was attributed to the interaction of graphene sheets with epoxy resin, which restricted electrons from hopping between them. The percolation threshold was noted at 0.2 wt.% for pristine MWCNTs and 0.3 wt.% for graphene in epoxy composites.

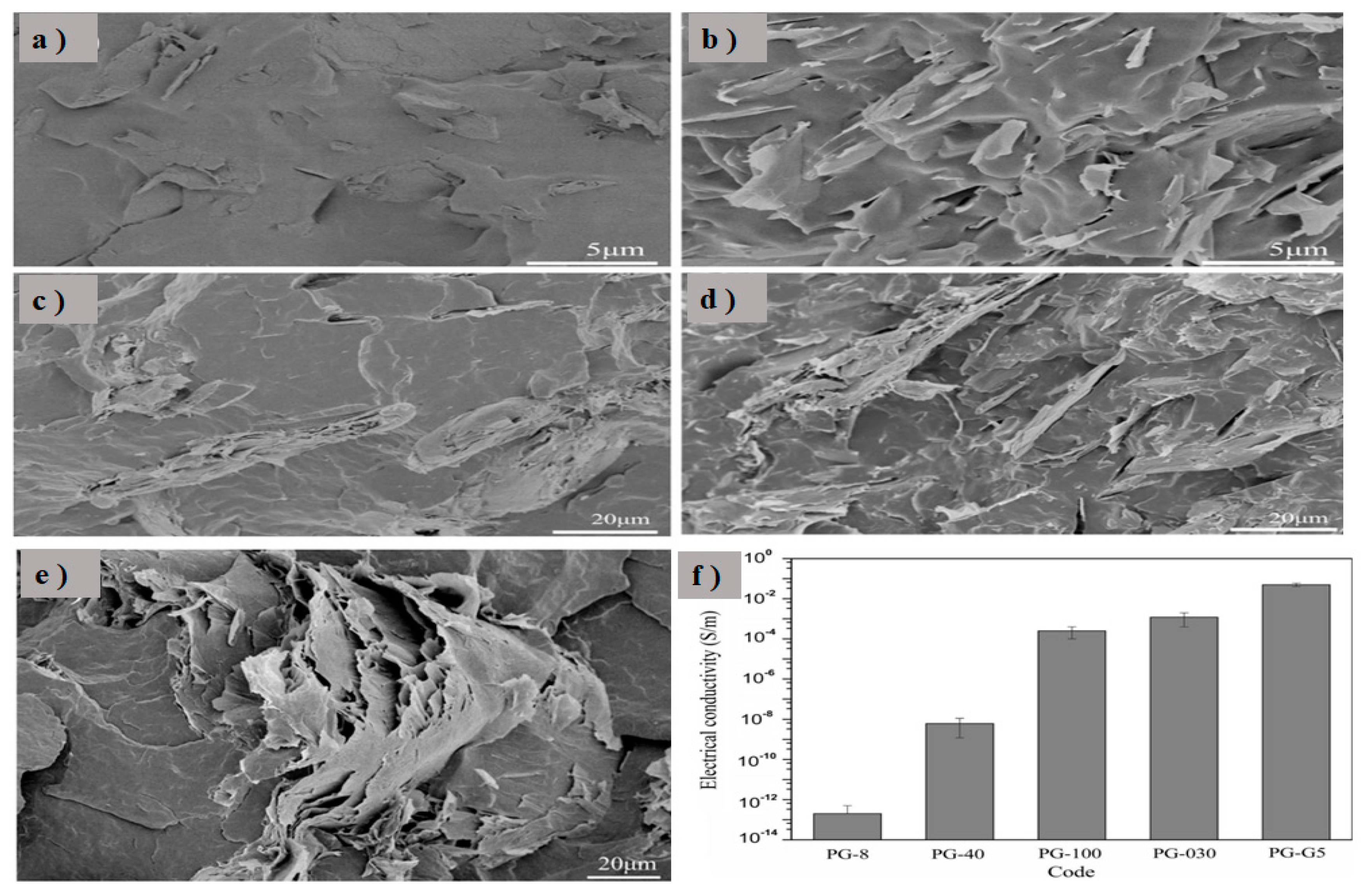

In a separate study conducted by He et al. [

123], the impact of graphene nanoplatelets' (GNPs) aspect ratio on the electrical conductivity of polypropylene (PP) filled with GNPs and their hybrid systems was investigated. The study examined five different aspect ratios of GNPs, including 8 (PG-8), 400 (PG-40), 1000 (PG-100), 1300 (PG-030), and 1500 (PG-G5). PG-8, PG-40, and PG-100 had the same thickness of 100 nm but differed in diameter. The concentration of graphene was fixed at 12 wt.%. This study revealed that GNPs with a larger diameter and smaller thickness are more effective in forming a conductive network. In

Figure 12b, better dispersion was observed for PG-G5 because of its lower thickness. Thicker layers typically result in a lower degree of exfoliation and dispersion in the polymer matrix. This SEM image further elucidated the enhanced conductive network formation shown in

Figure 12f.

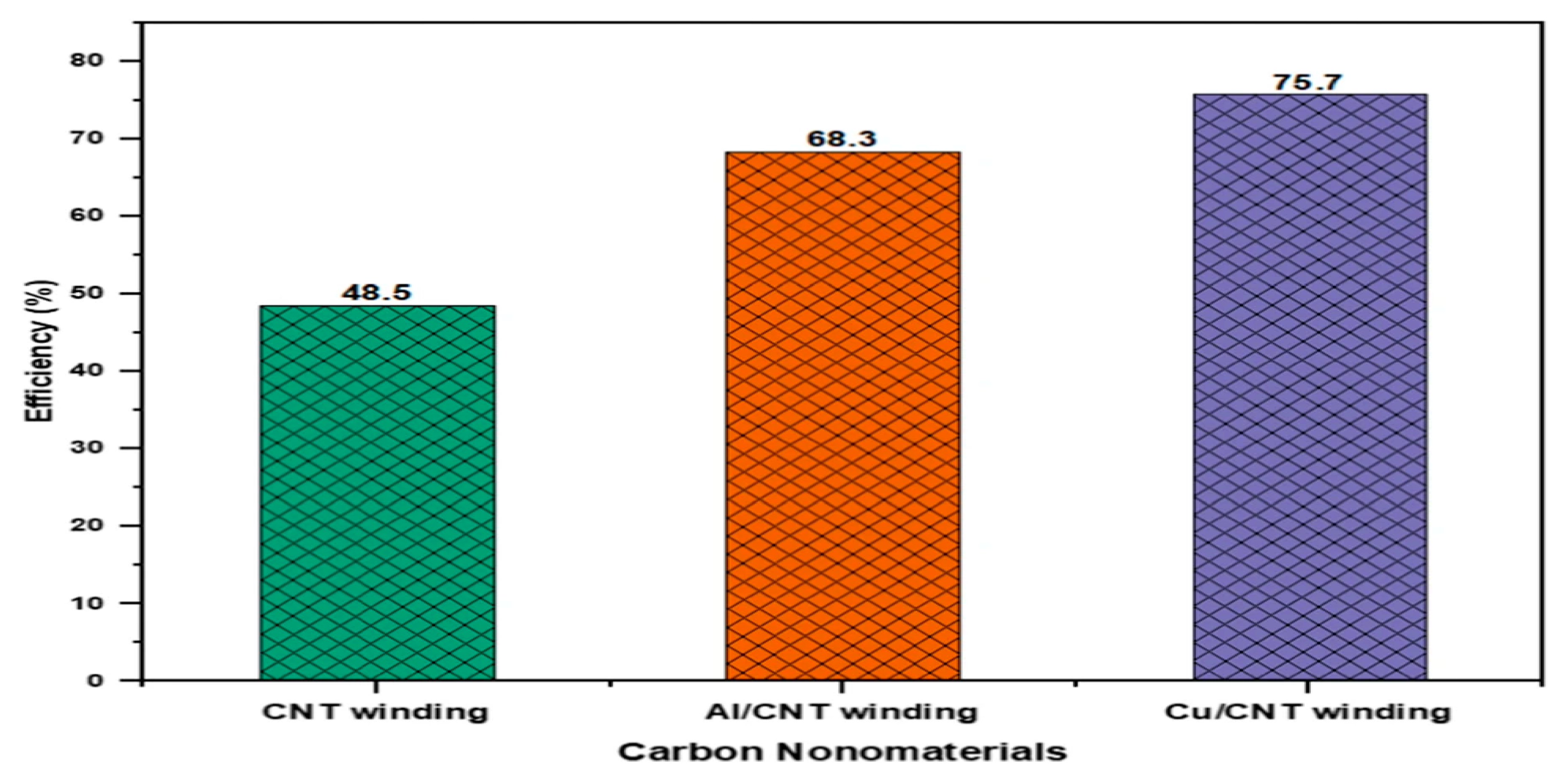

Hassan et al. [

124] compared three CNT-based composites as potential winding materials for permanent magnet generators: CNT yarn, Al/CNT, and Cu/CNT. The authors analyzed the performance of these materials in terms of generated voltages, currents, and efficiencies using a finite-element model simulated in the COMSOL Multiphysics software. Results indicated that the Cu/CNT composite wire generated the highest voltage (70 V) at 100 rpm, followed by Al/CNT (50.1 V) and CNT yarn (15.2 V).

Figure 13 shows the average efficiencies of the permeant magnet generator with various materials winding. This study indicates that carbon nanomaterials have the potential to replace conventional metal-based windings in electrical machines, with Cu/CNT composite wire being particularly favorable compared to CNT yarn for winding applications.

2.3. Thermal Properties

Nanomaterials such as nanoparticles, nanofibers, nanotubes, and graphene offer greater opportunities to improve thermal conductivity, heat dissipation, and thermal stability in composite materials owing to their inherent and unique nanoscale properties. Nanomaterials such as carbon nanotubes (CNTs), graphene, and some metallic nanoparticles possess exceptionally high thermal conductivities. When these nanomaterials are integrated into a composite structure, they facilitate the easy generation of conductive pathways within the composite structure, leading to efficient transfer of heat throughout the composite [

117,

125]. This significantly enhanced the thermal conductivity of the nano-based composites. The unique characteristics of nanomaterials offer versatility in composite design, allowing for the creation of tailored composite structures with the desired thermal properties. By controlling factors such as filler type, filler concentration, dispersion, and orientation, researchers can optimize thermal conductivity and thermal stability to meet specific application requirements [

126]. Ali et al. [

127] reported a significant improvement in the heat transfer ability of paraffin wax through the incorporation of nanographene (NG) for the design of safety helmets. The addition of a 3 wt.% concentration of NG enhanced the thermal conductivity of the NG/paraffin composite to a maximum of 146%. Additionally, a 3% reduction in latent heat was observed in the composite material modified with NG compared with pure paraffin wax. Zhang et al. [

128] used carboxymethylcellulose-boron nitride nanosheets (CMC-BNNS) to enhance the heat resistance of biodegradable poly (propylene carbonate) (PPC). By exfoliating and functionalizing hexagonal boron nitride (h-BN) with sodium carboxymethylcellulose (CMC-Na), improved thermal properties were achieved. The resulting composites exhibited superior heat resistance, thermal conductivity, and dynamic mechanical properties compared with those of PPC/BN composites, offering a promising strategy to address the limitations of biodegradable polymers in practical applications. Zhang et al. [

129] developed high-performance, flexible, and lightweight nanocomposites using natural cellulose nanofiber (CNF) and graphite nanoplatelets (GNPs) derived from wood pulp and graphite powder, respectively. These films were fabricated using a simple bottom-up approach, involving solution mixing, vacuum filtration, and hot-pressing techniques. The composite films exhibited excellent flexibility and lightweight properties; alongside remarkable thermal conductivity of 21.42 W m

−1 K

−1 measured at CNF-GNP-40 film.

The study also considered a wearable device and conducted a comparative experiment to assess the actual thermal management performance of the CNF-GNP-40 film. The experiment involved three scenarios: in the first, the wearable device was directly attached to the skin, while in the others, a film (CNF film and CNF-GNP-40 film separately) was interposed between the device and the skin (refer to

Figure 14). The CNF-GNP-40 film demonstrated the capability to lower the temperature of both the device and the skin to only 40.3 °C and 37.1 °C, respectively (see

Figure 14d), which are significantly lower and safer than those in the former two scenarios. This study indicates that these composites could serve as valuable materials for various structural integrity.

Haghighi et al. [

130] investigated the effect of various nanomaterials, including CuO, TiO

2, Al

2O

3, and graphene, on the thermal performance of a phase change material (PCM), using paraffin as a standard PCM. The results indicated that the nano-enhanced PCM exhibited remarkable thermal performance. A comparison among the investigated PCM-enhanced nanocomposites showed that the nanocomposites containing 2 wt.% TiO

2, with an enthalpy of 179.88 J/g, and 1 wt.% graphene, with an enthalpy of 120.38 J/g, had the highest and lowest energy storage capacities, respectively, compared to non-modified paraffin. A similar study was conducted by AlOtaibi et al. [

131], who reported the successful modification of paraffin wax, used as the standard PCM in this study, with multi-walled carbon nanotubes (MWCNTs) and various concentrations of TiO

2 ranging from 3 wt.% to 7 wt.% at 2 wt.% intervals. The composites exhibited a significant increase in thermal conductivity by 100% at 5 wt.% of TiO

2, along with the highest latent heat of enthalpy of 176 J/g recorded at 3 wt.% of TiO

2. Furthermore, the developed nanocomposites demonstrated improved thermal stability after 15 thermal cycles compared with pure paraffin. Huang et al. [

132] endeavored to enhance the flammability and thermal stability of acrylonitrile–butadiene–styrene copolymers (ABS) to broaden their practical applications. In this study, they employed a graphene-derived flame retardant (Mo5/PN-rGO), which was designed by incorporating functional elements (phosphorus, nitrogen, and molybdate) onto graphene oxide nanosheets. The findings of the study revealed that the ABS nanocomposite containing 1.0 wt% of Mo5/PN-rGO exhibited an increase in the glass transition temperature (Tg) by approximately 12°C, whereas the onset thermal decomposition temperature was significantly delayed by approximately 21°C. In addition, the developed ABS-based nanocomposites displayed a 20% reduction in total heat release and a 45% decrease in total smoke production compared with the pure ABS bulk material. Allahbakhsh et al. [

133] explored the interfacial interactions and thermal performance of Poly (ethylene trisulfide) (PETRS)/graphene oxide (GO) nanocomposites, which were modified with sodium dodecylbenzene sulfonate (SDBS) as a surfactant. Their findings indicate that the interactions between SDBS-modified GO and PETRS extend the melting process and degradation range of the resulting nanocomposites. Furthermore, the presence of SDBS-modified GO nanosheets noticeably increases the melting enthalpy of PETRS macromolecules.

2.4. Optical Properties

Nanomaterials play a crucial role in enhancing the optical performance of nanocomposites because of their unique tunable optical characteristics, quantum confinement effects, and high surface area-to-volume ratio [

134]. These nanoscale materials can influence the various optical properties of nanocomposites, such as their absorption, emission, and scattering characteristics. Moreover, by controlling the size, shape, and surface chemistry of nanoparticles, it is possible to tailor these properties to meet specific requirements for optical applications. For instance, the incorporation of quantum dots or plasmonic nanoparticles can result in enhanced light absorption or emission, enabling advancements in areas such as solar cells, light-emitting diodes (LEDs), optical sensing, and optoelectronic devices like transparent electrodes, touchscreens, and smart windows [

135]. Nanomaterials such as graphene oxide (GO), reduced graphene oxide (RGO), zinc oxide (ZnO), and their hybrids can significantly influence the optical behavior of nanocomposites. Ebrahimi Naghani et al. [

136] investigated the linear and nonlinear optical performance of graphene oxide (GO) and reduced graphene oxide (RGO)-based zinc oxide (ZnO) nanocomposites, and compared with pure GO and RGO. Various characterization techniques, including Fourier transform infrared (FT-IR), ultraviolet-visible (UV-Vis) absorption, X-ray diffraction (XRD), and energy-dispersive X-ray spectroscopy (EDX), were used to characterize the synthesized nanocomposites. The results indicated that the nonlinear absorption coefficient value (β) increased from 5.3 × 10

–4 (GO) to 8.4 × 10

–3 cm/W (RGO-ZnO). In addition, the nonlinear refractive indices (n

2) of GO, RGO, GO-ZnO, and RGO-ZnO were obtained as 10.9 × 10

–10, 14.3 × 10

–10, 22.9 × 10

–10, and 31.9 × 10

–10 cm

2/W respectively. Alshammari et al. [

137] endeavored to develop nanocomposite materials for optoelectronic sensor applications by incorporating various ratios of graphitic carbon nitride (g-C

3N

4) nanosheets (0.0, 0.3, 0.6, and 1.0 wt%) into PVC/PVP polymer nanocomposites. The results indicated that the optical absorbance and energy gaps of the PVC/PVP films improved after the addition of g-C

3N

4. The optical energy gaps exhibited compositional dependence on the g-C

3N

4 content, changing from 5.23 to 5.34 eV for indirect allowed transitions. Furthermore, the refractive index of the blended films increased from 1.83 to 3.96 as the content of g-C

3N

4 changed from 0.0 to 1.0 wt.%. These findings underscored the potential of g-C

3N

4 as an effective sensing material, which is attributed to its advantageous properties, including high surface area, chemical stability, and interaction capabilities with analytes. In summary, this study affirmed the viability of g-C

3N

4-enhanced PVC/PVP polymer nanocomposites for practical implementation in optoelectronic fiber sensor applications. Yao et al. [

138] summarized some recent advances in the use of fullerene-based materials such as fullerene/semiconductors and fullerene/non-semiconductors for photocatalytic applications. The report showed that fullerene can be potentially incorporated into semiconductors to enhance their photocatalytic activity for effective wastewater treatment due to their unique optical and photochemical characteristics.

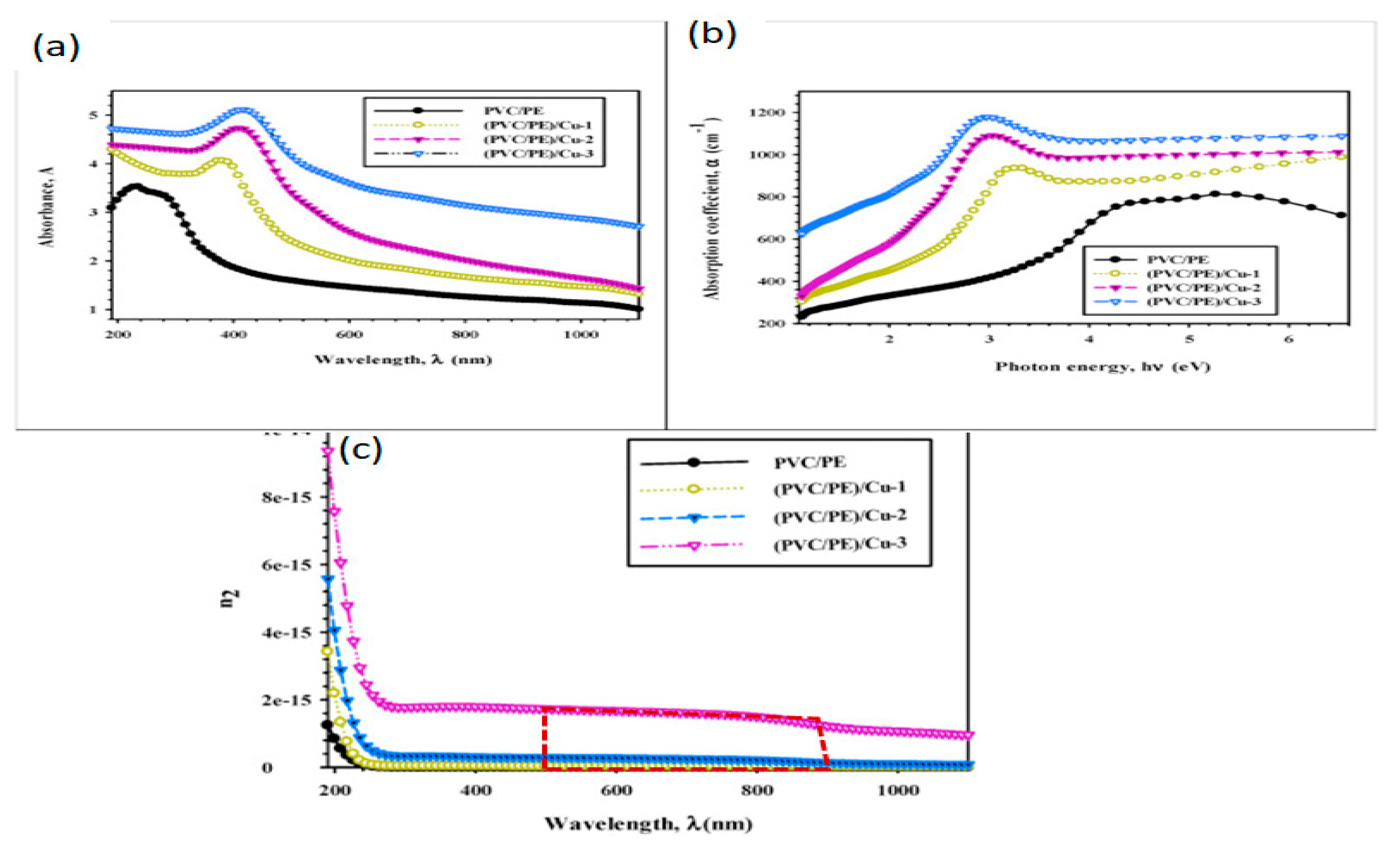

Elbasiony et al. [

139] synthesized PVC/PE/ polymer nanocomposites with 0–3 wt.% copper (Cu) nanoparticles using a melt extrusion approach for potential applications in photonics. The composites displayed enhanced linear and nonlinear optical susceptibilities with an optical absorption bandgap shifted from 3.38 eV to 2.19 eV as the Cu concentration increased from 0 to 3 wt.% (Figure15 a), indicating enhanced visible light absorption. The nonlinear refractive index varied from 1.2 × 10

−8 cm

2/W to 2.1 × 10

−8 cm

2/W across the 500–900 nm wavelengths range for 0–3 wt.% Cu (Figure15 c).

Figure 15.

(a) Absorbance spectra of PVC/PE for different Cu concentrations (b) absorption coefficient (α) versus the incident photon energy (hν) (c) Nonlinear refractive index for different Cu % [

139].

Figure 15.

(a) Absorbance spectra of PVC/PE for different Cu concentrations (b) absorption coefficient (α) versus the incident photon energy (hν) (c) Nonlinear refractive index for different Cu % [

139].

3. Challenges in nanocomposite development

Despite significant advancements in the use of nanomaterials to enhance the performance of composites, some challenges have constrained their production and widespread applications. These challenges involve various aspects, spanning from the manufacturing process and cost of production to environmental impact.

3.1. Dispersibility

The dispersion of nanoparticles into matrix materials during nanocomposite production is exceedingly challenging. Nanomaterials tend to agglomerate or clump together due to their high surface area, resulting in non-uniform dispersion of the particles within the composite matrix [

140,

141]. Poor dispersion or non-uniform distribution of nanomaterials can significantly contribute to the formation of voids and porosity within the composite structure. This phenomenon diminishes interfacial bonding and creates weak stress concentration points. The presence of voids or porosity in composites compromises the effectiveness of stress transfer mechanisms between the fiber and polymer matrix, thereby facilitating crack formation and propagation [

141,

142]. Furthermore, excessive introduction of nanofillers into polymeric resin beyond a certain optimum content may increase the viscosity of the resin. High resin viscosity reduces the volume fraction of the matrix and hinders proper interfacial interaction between the matrix and reinforcement. Weak interfacial interaction leads to a significant reduction in stress transfer and induces crack propagation, which ultimately results in poor mechanical properties [

143]. Therefore, achieving a uniform dispersion of nanomaterials within a polymer matrix is crucial for optimal performance. Proper mixing techniques during composite fabrication have been used to solve this challenge. This involves extended mixing time, employing sonication or high-shear mixing methods, as well as controlling the mixing conditions, including temperature, pressure, humidity, and nanoparticle concentration, to enhance proper and uniform dispersion. The use of additives or surfactants to improve the dispersion of nanomaterials in the polymer matrix has also been widely reported as a way of addressing the dispersibility problems and preventing the agglomeration and clumping of nanoparticles.

3.2. Compatibility

Many nanomaterials are chemically incompatible with most polymeric resins, thereby making adhesion between the component materials very difficult. Therefore, additional processing steps such as surface treatment of both the fiber and the polymer matrix, selection of suitable fabrication techniques, composite formulation and optimization, and compatibility testing between the fiber and the matrix are often required to ensure good interactions between the nanomaterials and the matrix. These steps facilitate adequate interfacial bonding, enhance compatibility, and improve the overall composite performance [

144].

3.3. Production Cost

Compared to conventional composite materials, nanomaterial-based composites are more expensive to produce because of the need for intricate processing techniques, specialized equipment, and expert knowledge. These factors contribute to an elevated overall manufacturing cost for the final nanocomposite products. In addition, the costs associated with synthesizing materials at the nanoscale, designing and testing various nanomaterials before their utilization, and developing optimal compositions to enhance the properties of the resulting nanocomposite further contribute to the economic challenges of manufacturing. Hence, for certain essential applications, the high costs of nanocomposite production may render them economically non-feasible [

145]. Minimizing the production costs of nanocomposites can be addressed by implementing efficient and cost-effective manufacturing processes. This can be achieved by investing in R&D, streamlining production methods, reducing processing steps, maximizing resource utilization, and minimizing material waste through recycling practices. Furthermore, developing efficient manufacturing and recycling processes for waste materials generated during nanocomposite production will not only contribute to cost savings but also significantly minimize the environmental impact.

3.4. Environmental Impact

Nanocomposites offer a range of promising properties and applications across various industries. However, like any emerging technology, the environmental impact of nano-based nanocomposites warrants careful consideration, as it depends largely on the different types of nanoparticles used in the composite development. Handling and disposal of nano-based nanocomposites can release nanoparticles into the environment that may have adverse effects on ecosystems and human health if they are not properly managed. The small size of nano-based materials can make them very reactive and potentially hazardous to humans and the environment in general. Nanoparticles can penetrate many biological barriers, such as cell membranes, and may harm cells, tissues, and lungs [

146,

147,

148]. Some nanomaterials used in nanocomposites have shown potential toxicity under certain circumstances. The behavior of nanoparticles in the environment under different conditions has not been documented. Understanding their behavior will help mitigate any adverse effects they may have on ecosystems and human health. Furthermore, most synthetic-based nanomaterials are non-biodegradable, leading to long-term accumulation in the environment and causing serious environmental impacts [

149].

Therefore, there is a need to carefully manage the production and use of nanomaterials in composite development and other applications by conducting thorough life cycle assessments (LCAs) to identify any environmental impacts associated with nano-based nanocomposites. This involves evaluating the environmental footprint of these materials from raw material extraction to end-of-life disposal. In addition, adequate regulatory frameworks are essential to ensure the safe production, use, and disposal of nanocomposites. Governments and international organizations must develop policies and guidelines to address environmental concerns and minimize potential risks. Finally, the exploration of green-based nanomaterials such as cellulose nanofibrils (CNFs), bacterial cellulose (BC), cellulose nanocrystals (CNCs), chitosan nanoparticles (CnPs), and green-synthesized metal nanoparticles in nanocomposite development is essential. This exploration, coupled with the adoption of more eco-friendly manufacturing processes, will address these environmental and health concerns without significantly compromising their performance and functionality.

4. Applications of Nanocomposites

The applications of nanocomposite materials are vast because of their unique and numerous attractive characteristics, as well as their ability to perform excellently in many critical applications when compared with other traditional engineering materials. Some potential applications of nanocomposites include energy storage, wastewater treatment, food processing, and biomedical sectors [

150,

151,

152]. Recent advances in nanocomposite technology in the biomedical sector have effectively addressed the challenges posed by highly immunosuppressive tumors, by inducing robust immunotherapeutic responses through synergistic functions introduced by various nanosized molecules. The ability to tailor nano-based composite materials to specific properties, such as biocompatibility and controlled release of drugs, encourages their widespread application in the biomedical sector for drug delivery, medical implants, disease diagnosis, and bioimaging [

153,

154]. Nanocomposites have also found interesting applications in aerospace and automobile parts production. These multiscale composites generally exhibit a high strength-to-weight ratio, making them attractive materials in automotive and aerospace applications for enhancing fuel efficiency, reducing emissions, and ensuring long-term durability [

155,

156,

157]. They are used in the design of specific parts such as general body panels, engine components, and tires. In the energy sectors, nanocomposites have been widely used for energy storage and conversion. They are used in components such as supercapacitors, solar cells, fuel cells, and batteries with improved performance and reduced size [

158]. Nanocellulose is an important bio-based nanomaterial used in wastewater treatment because of its significant adsorption quality, photocatalytic degradation, anti-biofouling effect, nanofiltration efficiency, and environmental friendliness [

159]. Namasivayam et al. [

160] demonstrated the effectiveness of nanocellulose acetate membrane technology in wastewater treatment. Their findings highlight a sustainable approach to addressing hazardous invasive aquatic weeds by integrating them into the composite membrane, thus leveraging green nanotechnology principles to enhance wastewater treatment efficacy. You et al. [

161] investigated the potential of employing environmentally friendly and naturally abundant biomass materials to remove heavy metal ions from wastewater before discharge into the environment. The researchers developed a ternary composite comprising nanocellulose/carbon dots/magnesium hydroxide (CCMg) using a simple hydrothermal method. The heavy ion (Cd

2+ and Cu

2+) removal mechanisms by the composite were examined using a combination of experimental techniques and density functional theory calculations. This study demonstrated the efficacy of CCMg in removing heavy metal ions from wastewater, which is attributed to its high adsorption capacity and straightforward recovery operation. The use of nanocomposite materials has witnessed a steady rise across various industries. This growing trend underscores the significance of nanocomposites in addressing diverse industrial needs.

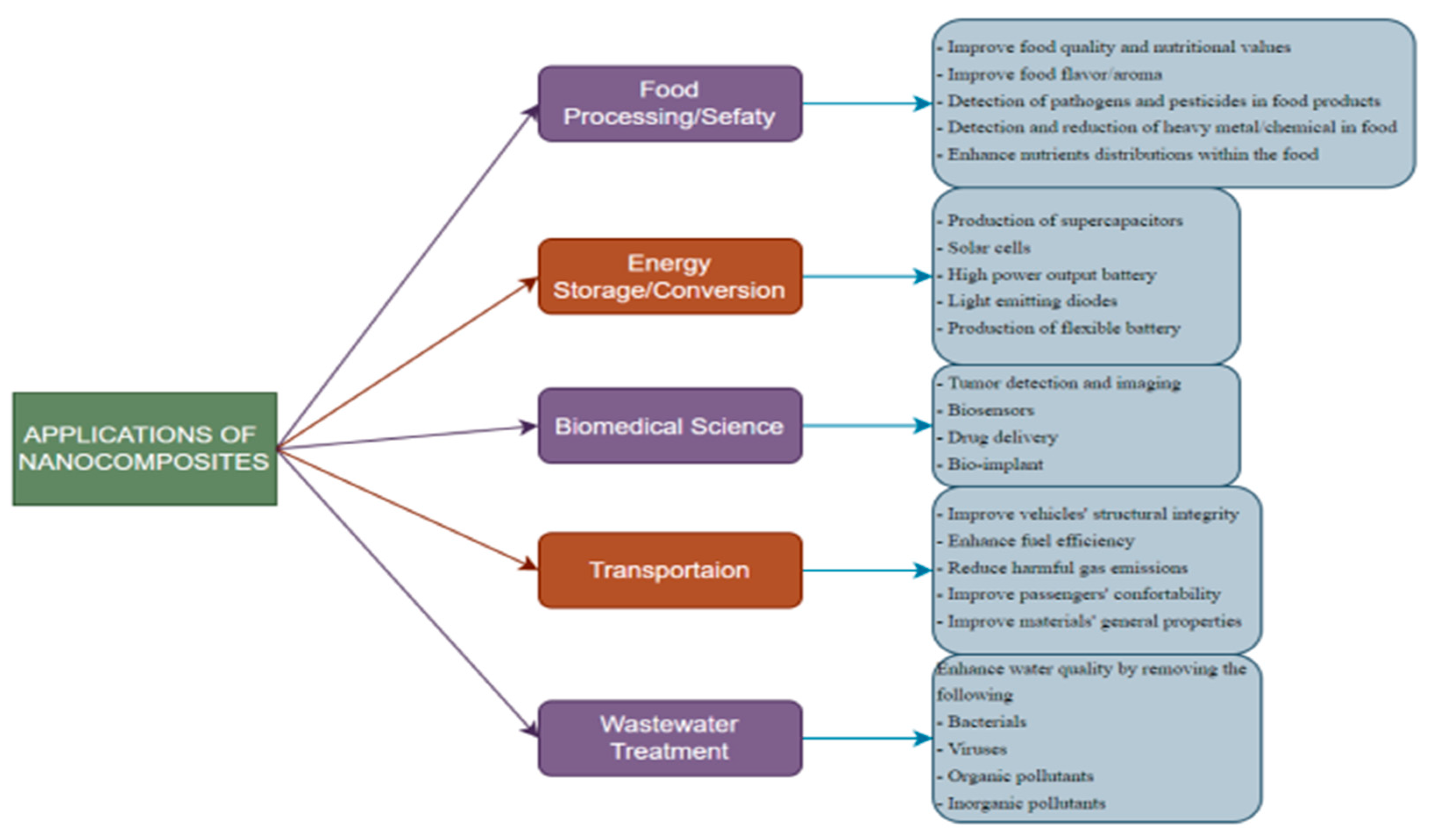

Figure 16 highlights the key application areas of nanocomposite materials along with their specific advantages. Following thorough experimental studies, these materials showcase versatile characteristics tailored to meet specific application requirements.

Table 2 provides a detailed overview of the use of nanocomposite materials and their reported performance across different sectors.

5. Future Outlook

Nanomaterials have already demonstrated great potential in enhancing the performance of nanocomposites in terms of mechanical strength, thermal and electrical conductivity, sensing capability, and barrier properties, paving the way for their wider applications across many industries. Today, researchers are further exploring more nanomaterials with captivating and enhanced properties compared to the current existing traditional nanomaterials. Therefore, the use of nanomaterials in nanocomposite development is expected to grow significantly in the future due to the increasing research interest in this field. Efforts are being directed toward improving the compatibility and dispersion efficiency of nanomaterials within composite matrices, which are crucial for achieving the desired composite properties. This involves optimizing nanomaterial properties and integration into matrices to achieve superior performance in specific applications, resulting in multifunctional nanocomposites suitable for tasks such as self-healing, shape memory, biomedical implants, and conductive materials for flexible electronics. To address environmental concerns, future developments will focus on environmentally friendly nanocomposite materials that use organic-based nanomaterials as reinforcement phases. This will reduce the reliance on fossil-based resources, minimize waste generation, and mitigate environmental and health risks. Renewable nanomaterials sourced from cellulose, chitin, or lignin, along with eco-friendly synthesis methods and recycling processes, will play a crucial role in this endeavor. Nanocomposites exhibit remarkable potential in advanced and specialized fields. As the technology of merging nanomaterials into composite matrices continues to progress, there is a likelihood of witnessing more economical and efficient manufacturing techniques in this sector, which will further widen the application of nanocomposites across diverse industries. At present, nanocomposites are used in various applications; however, as research in this area advances, there are several potential future applications of nano-based materials and nanocomposites in critical and advanced sectors of the economy such as quantum computing, energy harvesting, and storage, tissue engineering, food packaging, and safety, as well as nanomedicine.

In summary, the future holds immense potential for nanomaterials and nanocomposites, driving innovation and addressing complex challenges across critical and advanced sectors of the economy. Continued research and development efforts will unlock new possibilities and create new and advanced nanocomposite materials through nanotechnology.

Conclusion

Nanomaterials are valuable additives for enhancing the overall properties of composite materials owing to their unique characteristics. The incorporation of nanomaterials into polymer matrices has led to the development of polymer-based nanocomposites featuring superior mechanical strength, enhanced electrical conductivity, improved thermal stability, and other critical attributes. These advancements open up new horizons for applications in diverse fields such as transportation, construction, sports, electronics, and biomedicine. However, the widespread adoption of nano-based materials in composite development faces certain limitations that have not been thoroughly delineated. These constraints encompass the high cost associated with nanomaterials and their synthesis, elevated manufacturing expenses related to the production of nanocomposites, and concerns about health and environmental implications linked to nano-based products. To fully unlock the potential benefits of these innovative materials for advanced applications, it is imperative to engage in sustained research endeavors within this domain. Addressing challenges such as cost-effectiveness, efficient synthesis methods, and, most importantly, ensuring health and environmental safety will facilitate their comprehensive utilization in composite developments. Continued research efforts in this field are crucial for fully exploring the potential benefits of nanocomposites and establishing them as essential components for a diverse range of state-of-the-art applications.

Data Availability

No data were used for the research described in this article.

Author Contribution

All authors listed have significantly contributed to the development and writing of this article.

Acknowledgment

The authors wish to express their sincere appreciation to the Partnership for Skills in Applied Sciences, Engineering, and Technology (PASET) – Regional Scholarship and Innovation Fund (RSIF) and the African University of Science and Technology, Abuja, Nigeria, for their support.

Conflict of Interest

The Author(s) declare(s) that there are no conflicts of interest associated with this work.

References

- Hsissou, R.; Seghiri, R.; Benzekri, Z.; Hilali, M.; Rafik, M.; Elharfi, A. Polymer Composite Materials: A Comprehensive Review. Compos Struct 2021, 262. [Google Scholar] [CrossRef]

- Bhong, M.; Khan, T.K.H.; Devade, K.; Vijay Krishna, B.; Sura, S.; Eftikhaar, H.K.; Pal Thethi, H.; Gupta, N. Review of Composite Materials and Applications. Mater Today Proc 2023. [Google Scholar] [CrossRef]

- Fan, Q.; Duan, H.; Xing, X. A Review of Composite Materials for Enhancing Support, Flexibility and Strength in Exercise. Alex Eng J 2024, 94. [Google Scholar] [CrossRef]

- Rashid, A. Bin; Haque, M.; Islam, S.M.M.; Uddin Labib, K.M.R. Nanotechnology-Enhanced Fiber-Reinforced Polymer Composites: Recent Advancements on Processing Techniques and Applications. Heliyon 2024, 10. [Google Scholar] [CrossRef]

- Ali, Z.; Yaqoob, S.; Yu, J.; D’Amore, A. Critical Review on the Characterization, Preparation, and Enhanced Mechanical, Thermal, and Electrical Properties of Carbon Nanotubes and Their Hybrid Filler Polymer Composites for Various Applications. Compos Part C Open Access 2024, 13. [Google Scholar] [CrossRef]

- Kausar, A. Polyurethane Composite Foams in High-Performance Applications: A Review. Polym - Plast Technol Eng 2018, 57. [Google Scholar] [CrossRef]

- Hassan, T.; Salam, A.; Khan, A.; Khan, S.U.; Khanzada, H.; Wasim, M.; Khan, M.Q.; Kim, I.S. Functional Nanocomposites and Their Potential Applications: A Review. J Polym Res 2021, 28. [Google Scholar] [CrossRef]

- Huang, S.; Wang, B.; Yan, L. Interphase and Interfacial Properties of Composite Materials. Compos Mater Manuf Prop Appl 2021, 151–177. [Google Scholar] [CrossRef]

- Jiang, Y. Using Nano-Powders to Improve the Interfacial Bonding Strength of Carbon Fiber/Epoxy Composites. Fibers Polym 2022, 23. [Google Scholar] [CrossRef]

- Mekuye, B.; Abera, B. Nanomaterials: An Overview of Synthesis, Classification, Characterization, and Applications. Nano Sel 2023, 4. [Google Scholar] [CrossRef]

- Jagtiani, E. Advancements in Nanotechnology for Food Science and Industry. Food Front 2022, 3. [Google Scholar] [CrossRef]

- Yang, K.; Zhang, F.; Chen, Y.; Zhang, H.; Xiong, B.; Chen, H. Recent Progress on Carbon-Based Composites in Multidimensional Applications. Compos Part A Appl Sci Manuf 2022, 157. [Google Scholar] [CrossRef]

- Ma, H.; Geng, P.; Xu, T.; Kumar Bandaru, A.; Aravand, A.; Falzon, B.G. Analytical Fracture Toughness Model for Multiphase Epoxy Matrices Modified by Thermoplastic and Carbon Nanotube/Thermoplastic. Compos Part A Appl Sci Manuf 2024, 177. [Google Scholar] [CrossRef]

- Omanović-Mikličanin, E.; Badnjević, A.; Kazlagić, A.; Hajlovac, M. Nanocomposites: A Brief Review. Health Technol (Berl) 2020, 10. [Google Scholar] [CrossRef]

- Qin, R.; Zhou, A.; Yu, Z.; Wang, Q.; Lau, D. Role of Carbon Nanotube in Reinforcing Cementitious Materials: An Experimental and Coarse-Grained Molecular Dynamics Study. Cem Concr Res 2021, 147. [Google Scholar] [CrossRef]

- Qiu, L.; Zhu, N.; Feng, Y.; Michaelides, E.E.; Żyła, G.; Jing, D.; Zhang, X.; Norris, P.M.; Markides, C.N.; Mahian, O. A Review of Recent Advances in Thermophysical Properties at the Nanoscale: From Solid State to Colloids. Phys Rep 2020, 843. [Google Scholar] [CrossRef]

- Kara, Y.; Acar, V.; Seydibeyoglu, M.O. Mechanical Properties of Nanoparticle-Based Polymer Composites. Nanoparticle-Based Polym Compos 2022, 95–108. [Google Scholar] [CrossRef]

- Xie, P.; Yuan, W.; Liu, X.; Peng, Y.; Yin, Y.; Li, Y.; Wu, Z. Advanced Carbon Nanomaterials for State-of-the-Art Flexible Supercapacitors. Energy Storage Mater 2021, 36. [Google Scholar] [CrossRef]

- Barako, M.T.; Gambin, V.; Tice, J. Integrated Nanomaterials for Extreme Thermal Management: A Perspective for Aerospace Applications. Nanotechnology 2018, 29. [Google Scholar] [CrossRef]

- Abbasi, S.; Peerzada, M.H.; Nizamuddin, S.; Mubarak, N.M. Functionalized Nanomaterials for the Aerospace, Vehicle, and Sports Industries. Handb Funct Nanomater Ind Appl 2020, 795–825. [Google Scholar] [CrossRef]

- Bououdina, M.; Rashdan, S.; Bobet, J.L.; Ichiyanagi, Y. Nanomaterials for Biomedical Applications: Synthesis, Characterization, and Applications. J Nanomater 2013, 2013. [Google Scholar] [CrossRef]

- de Almeida Barcelos, K.; Garg, J.; Ferreira Soares, D.C.; de Barros, A.L.B.; Zhao, Y.; Alisaraie, L. Recent Advances in the Applications of CNT-Based Nanomaterials in Pharmaceutical Nanotechnology and Biomedical Engineering. J Drug Deliv Sci Technol 2023, 87. [Google Scholar] [CrossRef]

- Nandhini, J.; Karthikeyan, E.; Rajeshkumar, S. Nanomaterials for Wound Healing: Current Status and Futuristic Frontier. Biomed Technol 2024, 6. [Google Scholar] [CrossRef]

- Patel, P.; Geed, S.R. Recent Advancements in the Application of Nanomaterial in Modern Drug Delivery and Future Perspective. In Environmental Science and Engineering; 2024; Vol. Part F2070.

- Kumar, S.; Sarita; Nehra, M.; Dilbaghi, N.; Tankeshwar, K.; Kim, K.H. Recent Advances and Remaining Challenges for Polymeric Nanocomposites in Healthcare Applications. Prog Polym Sci 2018, 80. [Google Scholar]

- Zein, M.A.; Asghar, B.H.; Almohyawi, A.M.; Alqahtani, N.F.; Alharbi, A.; Alkabli, J.; Elshaarawy, R.F.M.; Ismail, L.A. Multifunctional Nanocomposites Integrated Green Synthesized Amphiphilic Chitosan/Thyme Extract/Nanosilver for Antimicrobial and Anti-Biofilm Applications. React Funct Polym 2024, 194. [Google Scholar] [CrossRef]

- Asha, A.B.; Narain, R. Nanomaterials Properties. Polym Sci Nanotechnol Fundam Appl 2020, 343–359. [Google Scholar] [CrossRef]

- Joudeh, N.; Linke, D. Nanoparticle Classification, Physicochemical Properties, Characterization, and Applications: A Comprehensive Review for Biologists. J Nanobiotechnology 2022, 20. [Google Scholar] [CrossRef] [PubMed]

- Hu, J.; Jiao, Z.; Han, X.; Liu, J.; Ma, M.; Jiang, J.; Hou, Y.; Wang, X.; Feng, C.; Ma, Y. Facile Synthesis of FeNi Nanoparticle-Loaded Carbon Nanocomposite Fibers for Enhanced Microwave Absorption Performance. J Mater Sci Technol 2024, 175. [Google Scholar] [CrossRef]

- Cai, Y.; Chen, Z.; Wang, S.; Chen, J.; Hu, B.; Shen, C.; Wang, X. Carbon-Based Nanocomposites for the Elimination of Inorganic and Organic Pollutants through Sorption and Catalysis Strategies. Sep Purif Technol 2023, 308. [Google Scholar] [CrossRef]

- Venkateswara Raju, C.; Hwan Cho, C.; Mohana Rani, G.; Manju, V.; Umapathi, R.; Suk Huh, Y.; Pil Park, J. Emerging Insights into the Use of Carbon-Based Nanomaterials for the Electrochemical Detection of Heavy Metal Ions. Coord Chem Rev 2023, 476. [Google Scholar] [CrossRef]

- Wang, M.; Yang, J.; You, X.; Liao, C.; Yan, J.; Ruan, J.; Dong, S. Nanoinfiltration Behavior of Carbon Nanotube Based Nanocomposites with Enhanced Mechanical and Electrical Properties. J Mater Sci Technol 2021, 71. [Google Scholar] [CrossRef]

- Chowdhury, M.I.S.; Autul, Y.S.; Rahman, S.; Hoque, M.E. Polymer Nanocomposites for Automotive Applications. Adv Polym Nanocomposites Sci Technol Appl 2022, 267–317. [Google Scholar] [CrossRef]

- Jafarzadeh, S.; Jafari, S.M. Impact of Metal Nanoparticles on the Mechanical, Barrier, Optical and Thermal Properties of Biodegradable Food Packaging Materials. Crit Rev Food Sci Nutr 2020. [Google Scholar] [CrossRef] [PubMed]

- Yashas Gowda, T.G.; Mavinkere Rangappa, S.; Siengchin, S.; Parameswaranpillai, J. Introduction to Nanoparticle-Based Materials and Their Composites. Nanoparticle-Based Polym Compos 2022, 1–14. [Google Scholar] [CrossRef]

- Guan, L.Z.; Tang, L.C. Dispersion and Alignment of Carbon Nanotubes in Polymer Matrix. In Handbook of Carbon Nanotubes; 2022.

- Zhang, Z.; Du, J.; Li, J.; Huang, X.; Kang, T.; Zhang, C.; Wang, S.; Ajao, O.O.; Wang, W.J.; Liu, P. Polymer Nanocomposites with Aligned Two-Dimensional Materials. Prog Polym Sci 2021, 114. [Google Scholar] [CrossRef]

- Khan, I.; Saeed, K.; Khan, I. Nanoparticles: Properties, Applications and Toxicities. Arab J Chem 2019, 12. [Google Scholar] [CrossRef]

- Rizwan, M.; Shoukat, A.; Ayub, A.; Razzaq, B.; Tahir, M.B. Types and Classification of Nanomaterials. Nanomater Synth Charact Hazards Saf 2021, 31–54. [Google Scholar] [CrossRef]

- Majhi, K.C.; Yadav, M. Synthesis of Inorganic Nanomaterials Using Carbohydrates. Green Sustain Process Chem Environ Eng Sci Green Inorg Synth 2021, 109–135. [Google Scholar] [CrossRef]

- Tshikovhi, A.; Mishra, S.B.; Mishra, A.K. Nanocellulose-Based Composites for the Removal of Contaminants from Wastewater. Int J Biol Macromol 2020, 152. [Google Scholar] [CrossRef]

- Colorado, H.A.; Gutierrez-Velasquez, E.I.; Gil, L.D.; de Camargo, I.L. Exploring the Advantages and Applications of Nanocomposites Produced via Vat Photopolymerization in Additive Manufacturing: A Review. Adv Compos Hybrid Mater 2024, 7. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Bayraktar, E.; Norrrahim, M.N.F.; Aisyah, H.A.; Abdullah, N.; Asyraf, M.R.M. Nanofillers for Sustainable Applications; 2023.

- Khan, T.; Chauhan, A. Polymer-Based Bionanomaterials for Biomedical Applications. Bionanotechnol Emerg Appl Bionanomaterials 2022, 187–225. [Google Scholar] [CrossRef]

- Singh, V.; Yadav, P.; Mishra, V. Recent Advances on Classification, Properties, Synthesis, and Characterization of Nanomaterials. In Green Synthesis of Nanomaterials for Bioenergy Applications; 2020.

- Husen, A.; Siddiqi, K.S. Advances in Smart Nanomaterials and Their Applications; 2023.

- Kumar, N.; Sinha Ray, S. Synthesis and Functionalization of Nanomaterials BT - Processing of Polymer-Based Nanocomposites: Introduction. In Springer Series in Materials Science; 2018.

- Dhand, C.; Dwivedi, N.; Loh, X.J.; Jie Ying, A.N.; Verma, N.K.; Beuerman, R.W.; Lakshminarayanan, R.; Ramakrishna, S. Methods and Strategies for the Synthesis of Diverse Nanoparticles and Their Applications: A Comprehensive Overview. RSC Adv 2015, 5. [Google Scholar] [CrossRef]

- Kumar, S.; Singhal, A.; Narang, U.; Mishra, S.; Kumari, P. Recent Progresses in Organic-Inorganic Nano Technological Platforms for Cancer Therapeutics. Curr Med Chem 2018, 27. [Google Scholar] [CrossRef] [PubMed]

- Najafi, F.; Salami-Kalajahi, M.; Roghani-Mamaqani, H. A Review on Synthesis and Applications of Dendrimers. J Iran Chem Soc 2021, 18. [Google Scholar] [CrossRef]

- Pandey, J.; Dubey, R.; Kate, A.; Prasad, B.; Sinha, A.; Mishra, M.S. Nanomedicines: A Focus on Nanomaterials as Drug Delivery System with Current Trends and Future Advancement. Drug Res (Stuttg) 2022, 72. [Google Scholar] [CrossRef] [PubMed]

- Thakur, V.; Guleria, A.; Kumar, S.; Sharma, S.; Singh, K. Recent Advances in Nanocellulose Processing, Functionalization and Applications: A Review. Mater Adv 2021, 2. [Google Scholar] [CrossRef]

- Ribeiro, R.S.A.; Pohlmann, B.C.; Calado, V.; Bojorge, N.; Pereira, N. Production of Nanocellulose by Enzymatic Hydrolysis: Trends and Challenges. Eng Life Sci 2019, 19. [Google Scholar] [CrossRef] [PubMed]

- Kumar, V.V.; Anthony, S.P. Antimicrobial Studies of Metal and Metal Oxide Nanoparticles. Surf Chem Nanobiomaterials Appl Nanobiomaterials 2016, 265–300. [Google Scholar] [CrossRef]

- Chandrasekar, M.; Kumar, T.S.M.; Senthilkumar, K.; Nurazzi, N.M.; Sanjay, M.R.; Rajini, N.; Siengchin, S. Inorganic Nanofillers-Based Thermoplastic and Thermosetting Composites. In Lightweight Polymer Composite Structures; 2020.

- Ahmad, M.; Riaz, U.; Iqbal, S.; Rasheed, H.; Mousa Mousa, M.A.; Al-Farraj, A.S.F.; Al-Wabel, M.I. Advances in the Development and Applications of Clay-Based Composites. In; 2023.

- Bulut, M.; Bozkurt, Ö.Y.; Erkliğ, A.; Yaykaşlı, H.; Özbek, Ö. Mechanical and Dynamic Properties of Basalt Fiber-Reinforced Composites with Nanoclay Particles. Arab J Sci Eng 2020, 45. [Google Scholar] [CrossRef]

- Nasir, S.; Hussein, M.Z.; Zainal, Z.; Yusof, N.A. Carbon-Based Nanomaterials/Allotropes: A Glimpse of Their Synthesis, Properties and Some Applications. Materials (Basel) 2018, 11. [Google Scholar] [CrossRef]

- Geng, H.; Peng, Y.; Qu, L.; Zhang, H.; Wu, M. Structure Design and Composition Engineering of Carbon-Based Nanomaterials for Lithium Energy Storage. Adv Energy Mater 2020, 10. [Google Scholar] [CrossRef]

- Karaca, B.; Karataş, Y.; Cakar, A.B.; Gülcan, M.; Şen, F. Carbon-Based Nanostructures and Nanomaterials. Nanoscale Process 2021, 103–130. [Google Scholar] [CrossRef]

- Siqueira, J.R.; Oliveira, O.N. Carbon-Based Nanomaterials. Nanostructures 2017, 233–249. [Google Scholar] [CrossRef]

- Rao, N.; Singh, R.; Bashambu, L. Carbon-Based Nanomaterials: Synthesis and Prospective Applications. In Proceedings of the Materials Today: Proceedings; 2021; Vol. 44. [Google Scholar]

- Joshi, A.; Kim, K.H. Recent Advances in Nanomaterial-Based Electrochemical Detection of Antibiotics: Challenges and Future Perspectives. Biosens Bioelectron 2020, 153. [Google Scholar] [CrossRef]

- Mittal, G.; Rhee, K.Y.; Mišković-Stanković, V.; Hui, D. Reinforcements in Multi-Scale Polymer Composites: Processing, Properties, and Applications. Compos Part B Eng 2018, 138. [Google Scholar] [CrossRef]

- Ibrahim, A.; Klopocinska, A.; Horvat, K.; Hamid, Z.A. Graphene-Based Nanocomposites: Synthesis, Mechanical Properties, and Characterizations. Polymers (Basel) 2021, 13. [Google Scholar] [CrossRef] [PubMed]

- Goenka, S.; Sant, V.; Sant, S. Graphene-Based Nanomaterials for Drug Delivery and Tissue Engineering. J Control Release 2014, 173. [Google Scholar] [CrossRef] [PubMed]

- Madurani, K.A.; Suprapto, S.; Machrita, N.I.; Bahar, S.L.; Illiya, W.; Kurniawan, F. Progress in Graphene Synthesis and Its Application: History, Challenge and the Future Outlook for Research and Industry. ECS J Solid State Sci Technol 2020, 9. [Google Scholar] [CrossRef]

- De Leon, A.C.; Chen, Q.; Palaganas, N.B.; Palaganas, J.O.; Manapat, J.; Advincula, R.C. High Performance Polymer Nanocomposites for Additive Manufacturing Applications. React Funct Polym 2016, 103. [Google Scholar] [CrossRef]

- Pena-Pereira, F.; Romero, V.; de la Calle, I.; Lavilla, I.; Bendicho, C. Graphene-Based Nanocomposites in Analytical Extraction Processes. TrAC - Trends Anal Chem 2021, 142.

- Dahiya, M.; Bansal, S.A. Graphene-Reinforced Nanocomposites: Synthesis, Micromechanics Models, Analysis and Applications – a Review. Proc Inst Mech Eng Part C J Mech Eng Sci 2022, 236. [Google Scholar] [CrossRef]

- Khine, Y.Y.; Wen, X.; Jin, X.; Foller, T.; Joshi, R. Functional Groups in Graphene Oxide. Phys Chem Chem Phys 2022, 9. [Google Scholar] [CrossRef] [PubMed]

- Yu, W.; Sisi, L.; Haiyan, Y.; Jie, L. Progress in the Functional Modification of Graphene/Graphene Oxide: A Review. RSC Adv 2020, 10. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.B.; Parvaz, M.; Khan, Z.H. Graphene Oxide: Synthesis and Characterization. In Advanced Structured Materials; 2017; Vol. 83.

- Loudiki, A.; Matrouf, M.; Azriouil, M.; Laghrib, F.; Farahi, A.; Bakasse, M.; Lahrich, S.; El Mhammedi, M.A. Graphene Oxide Synthesized from Zinc-Carbon Battery Waste Using a New Oxidation Process Assisted Sonication: Electrochemical Properties. Mater Chem Phys 2022, 275. [Google Scholar] [CrossRef]