1. Introduction

Pipeline inspection is a crucial element in building maintenance. The condition of pipes requires intensive management due to its impact on living environment comfort, energy consumption, and maintenance costs [

1]. Pipes are difficult to visually inspect for issues such as cracks, blockages, and aging, making preemptive detection challenging. Repair costs can be substantial once problems arise [

2,

3]. Therefore, a strategic approach to pipeline maintenance is essential.

In Korea, inspection of Ondol heating system pipes has emerged as a critical issue. Ondol, a representative heating method in Korea, circulates hot water through pipes embedded in the floor slab to heat the floor and subsequently the indoor space with its radiant heat [

4]. This method offers advantages over conventional heating systems that blow hot air or directly heat, providing higher comfort and sustained warmth indoors. However, due to the installation of pipes embedded in floor finishes and cement mortar, inspection and maintenance pose challenges [

5]. Inspection of Ondol pipes should be considered not only during usage but also from the installation phase. Ondol pipes are installed in a coil form on top of the floor slab, alternating between curves and straight sections, and are then embedded by topping concrete. Therefore, inspection of these embedded concrete pipes is necessary not only during maintenance but also immediately after pipe installation before topping concrete, and during commissioning after topping, due to the characteristics of concrete-embedded Ondol pipes. During the pipe installation process, minor holes may occur due to pipe tearing, nails, and improper construction at pipe joints. Furthermore, during concrete topping, careless handling by workers can lead to damage or blockages at the construction site [

6]. Demolition and reinstallation of once-topped concrete result in significant project losses, prolonged time for leakage detection on concrete surfaces, and difficulties in pinpointing leakage spots accurately. Moreover, improper functioning of Ondol heating can lead to reduced quality of life and increased costs, making maintenance of heating pipes crucial, especially as leaks in pipes can lead to damage in finishing materials, becoming a major factor in defect disputes in residential buildings [

7].

However, despite the characteristics and importance of inspecting these Ondol pipes, current inspection methods are highly reliant on manpower and have limitations in terms of reliability and efficiency. Existing inspection methods for Ondol pipes can be broadly categorized into four main types. The first method involves pressure differential testing, where changes in pipe pressure are measured to determine if there are leaks. This method requires specialized skills and its accuracy depends on the expertise of the personnel involved. The second method is acoustic detection, using sensitive listening devices placed on the floor to detect sound emitted during leaks. This approach involves the inconvenience of manually inspecting the entire floor and the challenge of maintaining leak sounds consistently detectable. The third method employs thermal imaging cameras to detect leaks by observing heat dispersion when hot water flows through the pipes. Lastly, the fourth method utilizes wired endoscopic cameras for direct internal inspection. While this method provides close-range accuracy, it has limitations in inspecting the entire pipeline. These traditional inspection methods suffer from limitations in accuracy, reliability dependent on the expertise of the operators, and challenges in maintaining comprehensive inspection records and data acquisition [

6,

8].

Therefore, this study aims to develop a robot capable of inspecting the condition of Ondol pipeline systems and validate its performance. Initially, we analyzed the characteristics of Ondol pipes to tailor the inspection system, deriving system requirements based on this analysis to guide our development direction. Subsequently, we developed a prototype of a compact capsule-shaped inspection robot and conducted laboratory tests. Through these tests, we verified that the system proposed in this study ensures performance suitable for field application by assessing curvature maneuverability and image quality according to Ondol characteristics. This research aims to realistically contribute to the advancement of pipeline inspection technology and the smart maintenance of Ondol heating systems by implementing and validating a system customized for inspecting Ondol pipes.

2. Literature Review

Pipelines are the safest, most economical, and widely used method for transporting fluids in both industrial and residential settings [

3]. Aging and contamination, both internally and externally, can lead to performance degradation and increased operational costs, underscoring the critical importance of regular inspections [

9]. Therefore, regular inspections are necessary to maintain the proper functionality and cost efficiency of pipelines [

10,

11]. Consequently, research on robots for inspecting the interiors of pipelines has garnered ongoing interest [

12,

13]. Using pipeline inspection robots can improve efficiency compared to traditional, manual methods, which include visual inspections. These robots can replace labor-intensive and hazardous tasks while enhancing productivity in maintenance operations through capabilities such as data collection and cleaning [

14,

15].

Research on internal inspection robots for pipelines can be categorized into two main areas: review studies identifying technological trends in pipeline robots, and studies proposing driving mechanisms and developing robots according to the pipeline’s purpose, diameter, and shape. First, review studies have continually examined various types of pipeline robots based on diverse characteristics such as inspection accuracy, adaptability to size and shape, flexibility, vertical mobility, scalability, cost, speed, design complexity, impact on the pipeline, and movement efficiency [

1,

2,

3,

9,

10,

11,

14,

15,

16,

17,

18]. Additionally, studies focusing on specific driving mechanisms, such as wheel-based [

12], wall-pressing [

13,

19], hybrid [

20], and worm-like [

21] mechanisms, have been conducted to analyze technological trends. Research involving the direct development of robots has also been consistently ongoing.

Table 1 below summarizes studies that have designed and developed driving mechanisms suitable for specific pipeline purposes and sizes.

These studies target pipelines with diameters ranging from 25 to 1440 mm. They propose driving mechanisms for movement in various pipeline forms, including horizontal, vertical, inclined, and curved pipes. Representative driving mechanisms include diameter-adaptive [

22,

23,

24] wheel-type robots [

25,

26,

27,

28,

29,

30], ball-type robots [

31,

32,

33], bug-type robots [

34], and crawler-type robots [

35]. Their performance has been validated through field applications and laboratory tests. Each proposed robot has its advantages, such as fast horizontal mobility, but also has drawbacks, such as being unsuitable for inclined and curved pipes, or vice versa, having slower speeds or requiring cable connections for power supply [

35].

While previous studies have proposed systems adaptable to various pipe sizes and shapes, there has been no development of robots suitable for the small internal diameters characteristic of Ondol heating pipes. Just as previous studies have designed systems considering the specific properties of target pipes, the inspection of Ondol heating pipes requires the development of customized robots that account for the unique characteristics of these pipes.

3. Conceptual Design

3.1. Subsection Characteristic Analysis of Ondol Pipeline Installation

3.1.1. Installation Form and Size

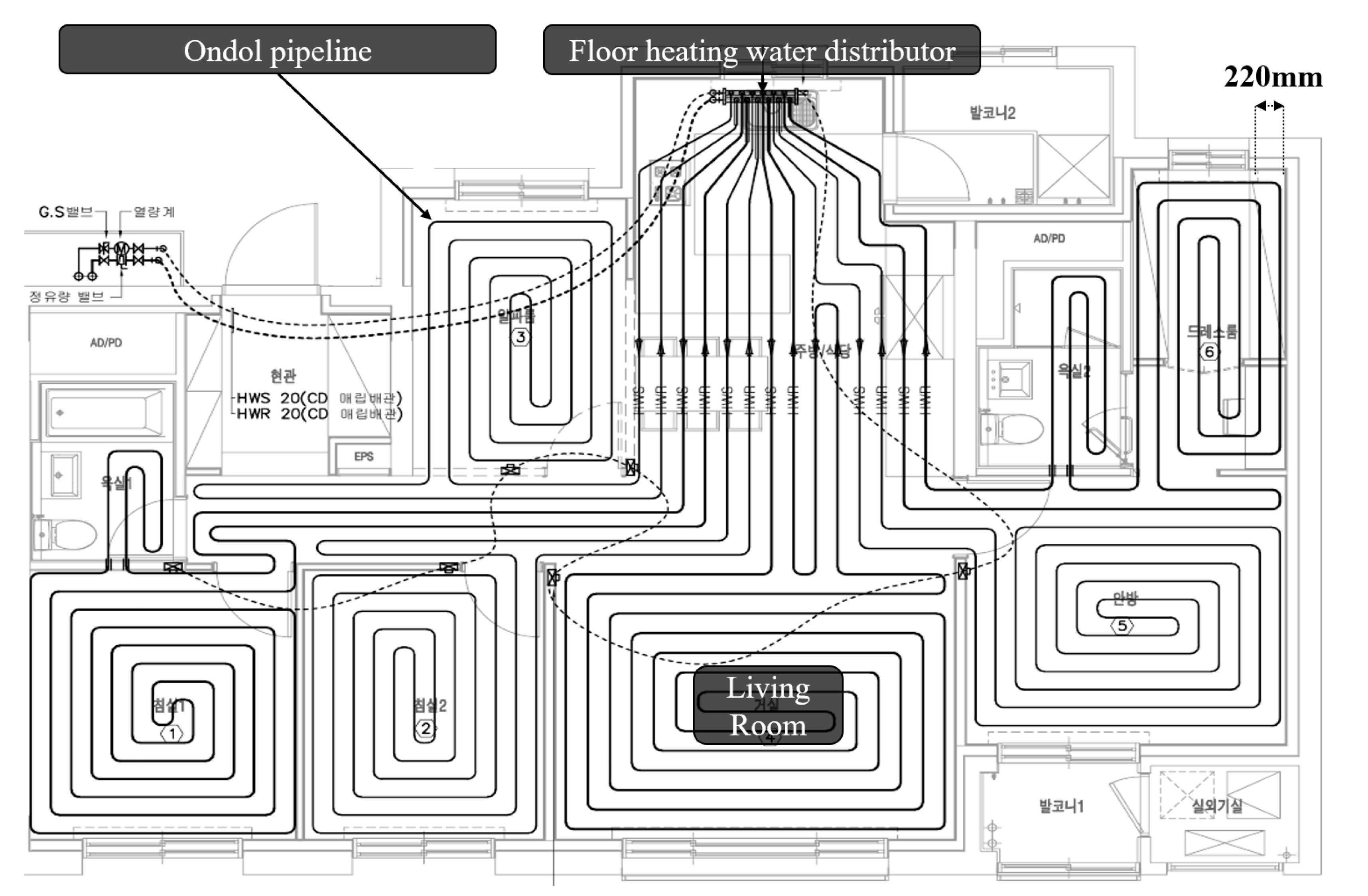

The Ondol piping system is an underfloor heating system. The piping is installed on the floor slab in a pattern of curves and straight lines, and then embedded in cement mortar. Heated water is circulated through these embedded pipes via a floor heating water distributor, raising the floor temperature and providing heating through the resulting warmth. This Ondol piping is installed in almost all rooms within a residential floor plan.

Figure 1 shows the heating pipe layout of an 84㎡ apartment, the most commonly constructed type in South Korea. The pipes, connected to the distributor, are laid in each room and return to the distributor. In this sample layout, the longest pipe, installed in the living room, is 82 meters long. The total length of all the pipes in this layout is approximately 397 meters.

The Ondol piping is embedded in cement mortar, and the starting and ending parts of the piping are connected to the distributor. Therefore, the inspection robot must be inserted at the connection between the distributor and the piping, travel through the piping, and then return to the distributor. For example, a robot inserted at the starting part of the distributor to inspect the living room piping will have to travel the 82-meter-long living room piping and return to the distributor, resulting in a long travel distance. If this robot is wired, it means that the cable length must be longer than this travel distance. Such wired communication and power supply can be inefficient for inspection work. Therefore, the inspection robot should be developed to enable wireless communication and use a rechargeable battery instead of a power cable supply. Additionally, since rechargeable batteries have limited capacity, equipping the robot with a self-propulsion system like a motor will result in a short operation time and the risk of loss. Thus, it should be designed with a non-powered propulsion system, implying the need for auxiliary equipment to move the robot.

3.1.2. Installation Specifications and Patterns

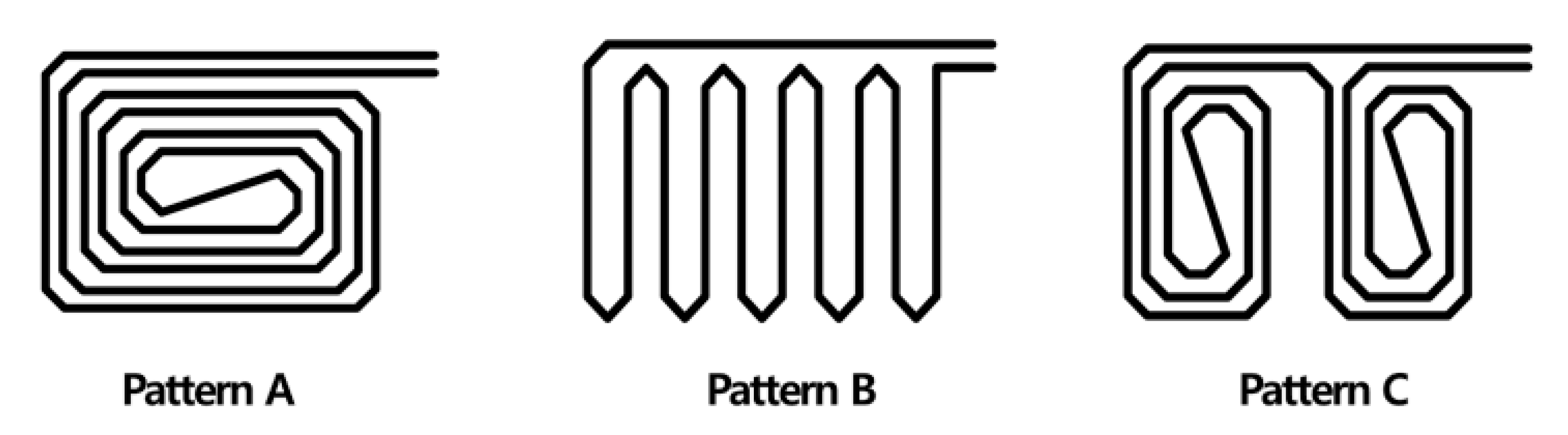

Cross-linked polyethylene and polybutylene pipes are commonly used in Ondol piping. These two types of pipes are used for hot water Ondol, industrial applications, and sanitary water supply. In the field, cross-linked polyethylene is referred to as X-L pipes, and polybutylene pipes are referred to as PB pipes. Generally, they are produced with a thickness of 2mm and an inner diameter of 12-25mm, but pipes with an inner diameter of 16mm are mainly applied in Ondol piping. Therefore, the inspection robot needs to be developed with a diameter smaller than 16mm. Additionally, the robot must be able to pass through curved sections that occur according to the installation pattern of the pipes. The representative patterns of Ondol pipelines are shown in

Figure 2 below. The pattern A in

Figure 2 is the same as the pattern shown in

Figure 1, which is the most common. Depending on the size of the room, it can also be installed in the forms of patterns B and C.

The reason why the curved section of this pattern is important is that the originally circular cross-section of the pipe changes to an elliptical shape in the curved section. Therefore, the horizontal diameter inside the pipe becomes smaller than it originally was in the curved section.

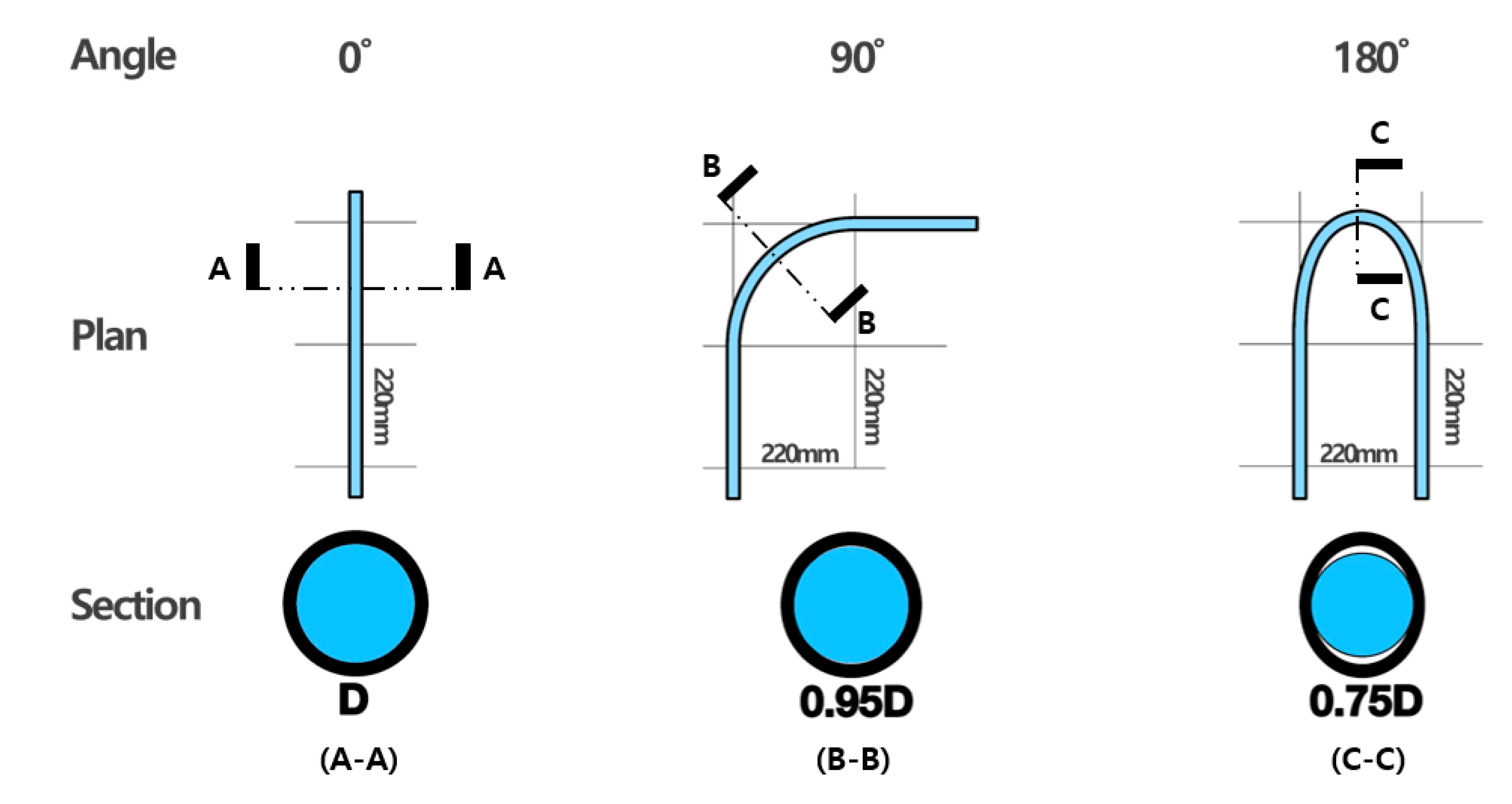

Figure 3 below illustrates the situation where the horizontal diameter of the cross-section decreases, dividing the sections of the pattern into straight, 90-degree rotation, and 180-degree rotation.

For example, in the case of a pipe with an inner diameter of D, the inner diameter remains D in the straight section. However, in a 90-degree curved section, the inner diameter of the pipe decreases to 95%, becoming 0.95D, and in the largest 180-degree section, it decreases to 75%, becoming 0.75D.

Figure 4 below shows an image of the cross-section of a 16mm pipe in a 180-degree section that is actually installed. The cross-section becomes elliptical, with the horizontal diameter measuring 12mm. On the other hand, the vertical diameter measures longer than 16mm, but for the robot to pass through, the smallest diameter must be considered. Therefore, the robot needs to be designed smaller than 12mm.

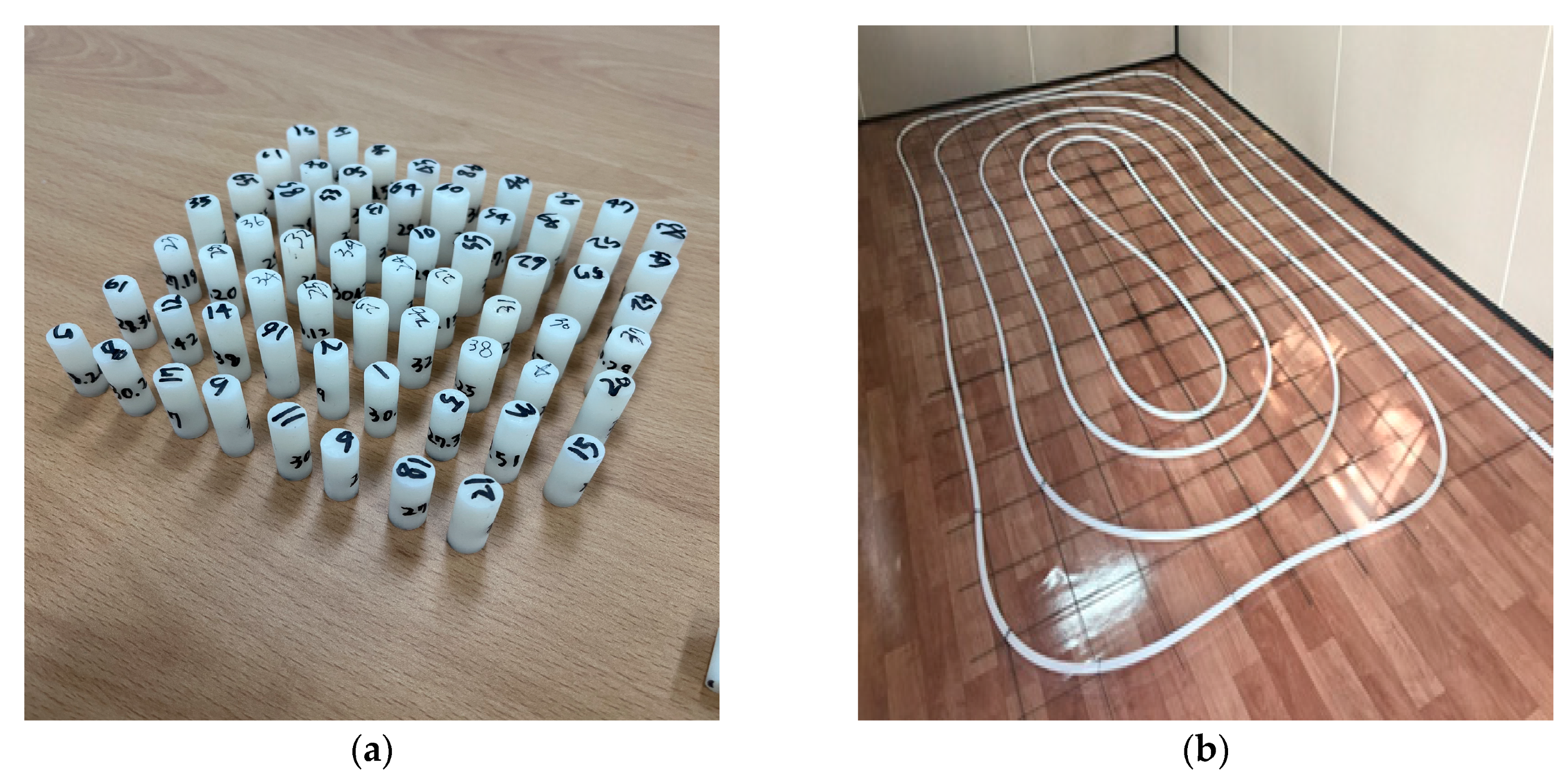

For the design of the robot, determining the size that can pass through the piping is the most critical priority. This is a very important and fundamental requirement, and it becomes the standard for deciding the size of all components and the type of system applied to the robot. Incorrectly determining the size can lead to serious trial and error. Therefore, a preliminary experiment to determine the size of the robot was conducted before the design of the robot.

Figure 5a below shows the dummy robot made for the test, and

Figure 5b shows the piping for the experiment. The purpose of the test is to determine the optimal diameter and length of the robot that can smoothly pass through the piping. To achieve this, the piping with straight, 90-degree, and 180-degree sections was constructed in the same way as the actual installation. Additionally, various sizes of dummy robots were made through 3D printing. A total of 65 dummies were made with diameters ranging from 9mm to 12mm and lengths ranging from 26mm to 34mm, divided into approximately 0.1mm increments. Starting with the smallest dummy, the dummies were repeatedly inserted into the piping to find the largest dummy size that could move smoothly. As a result, it was concluded that the robot should be made with a diameter of 11.4mm and a length of 32mm or less.

3.1.2. Installation Environment

The actual installation of Ondol piping is shown in

Figure 6 below. Ondol piping is installed on the floor slab, and then cement mortar is poured. At this time, the thickness of the cement mortar is generally about 20mm. The inspection robot is required to move through the piping embedded in this cement mortar, capture video, and have the communication capability to transmit this video data to a monitoring system. As mentioned earlier, the inserted robot should apply a wireless communication system, not a wired one, and the technology applied must enable smooth transmission and reception without being obstructed by the cement mortar covering the piping. Additionally, since it has to capture images inside the dark piping, a camera module and lighting that can respond to this are required.

3.2. System Requirements and Design

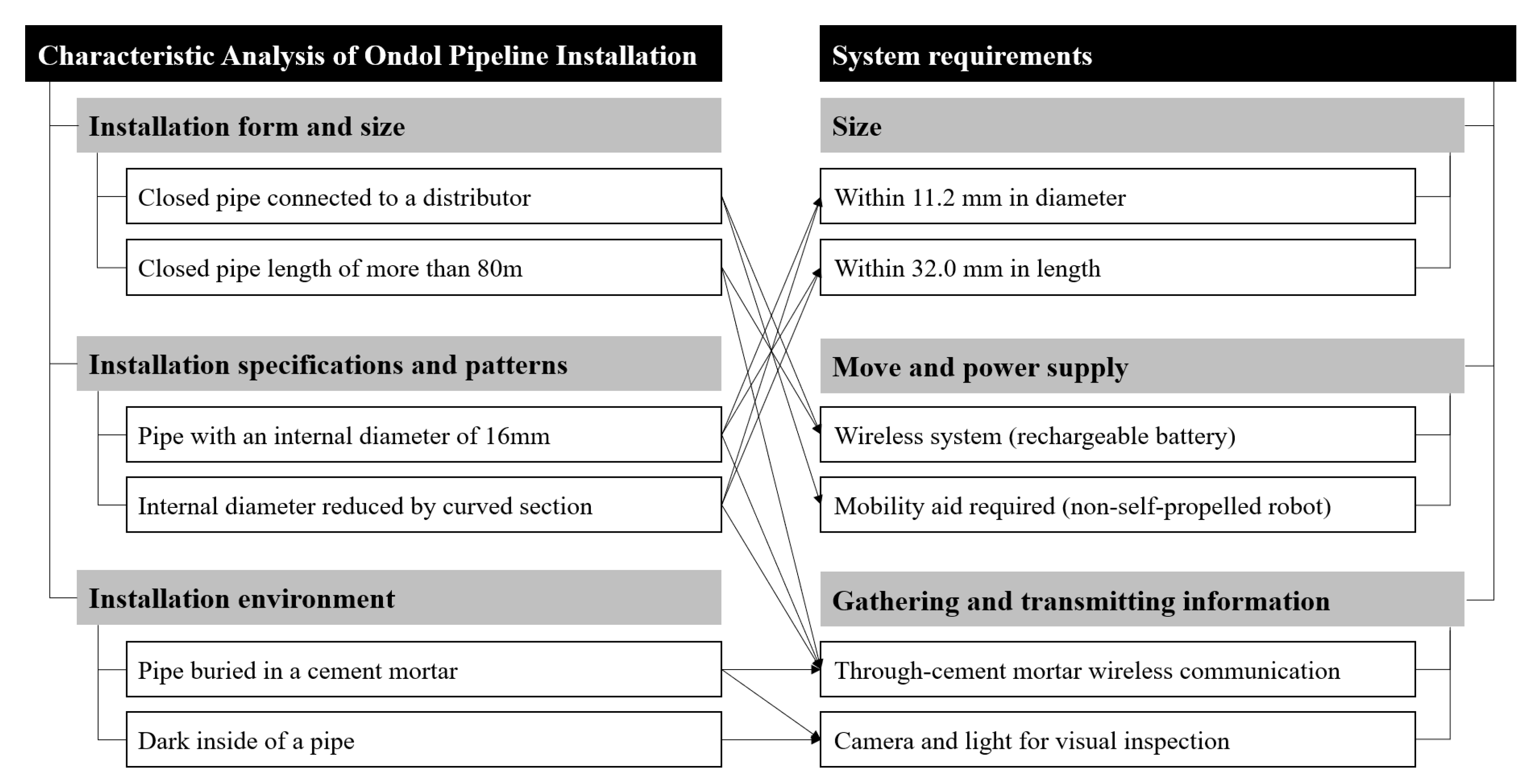

The characteristics of Ondol pipes were analyzed for system design, and the results of deriving system requirements based on this are summarized in

Figure 7 below.

In the system requirements section of

Figure 7, it can be seen that the robot's size should be manufactured with a diameter of 11.4mm or less and a length of 32mm or less. This is based on the pre-experiment results considering the curved sections and narrowing of the inner diameter of the most commonly applied 16mm inner diameter piping. Additionally, the robot should be a rechargeable battery type with a wireless system and requires auxiliary equipment for movement without self-driving capability. Ondol pipes have a closed structure where the inlet and outlet are connected at the distributor, and due to the small inner diameter, it was decided to move the robot using an air compression method that pushes air to move it. Finally, because the piping is embedded in 20mm thick cement mortar, the performance of wireless communication must be ensured, and determining the communication method for transmitting the captured video is important. The setting of the communication method was carried out through preliminary study [

6]. In this study, the communication capabilities of three wireless communication methods, such as, Wi-Fi, Bluetooth, and Radio Frequency embedded in cement mortar were tested, and Wi-Fi was found to be the most appropriate. Therefore, a Wi-Fi module was decided as the communication system. The most basic components included a camera module for video inspection inside the piping, LED lights, a charging port, and an on/off switch for controlling the robot's power. Reflecting these requirements, the design of the capsule-type piping inspection robot was finally completed.

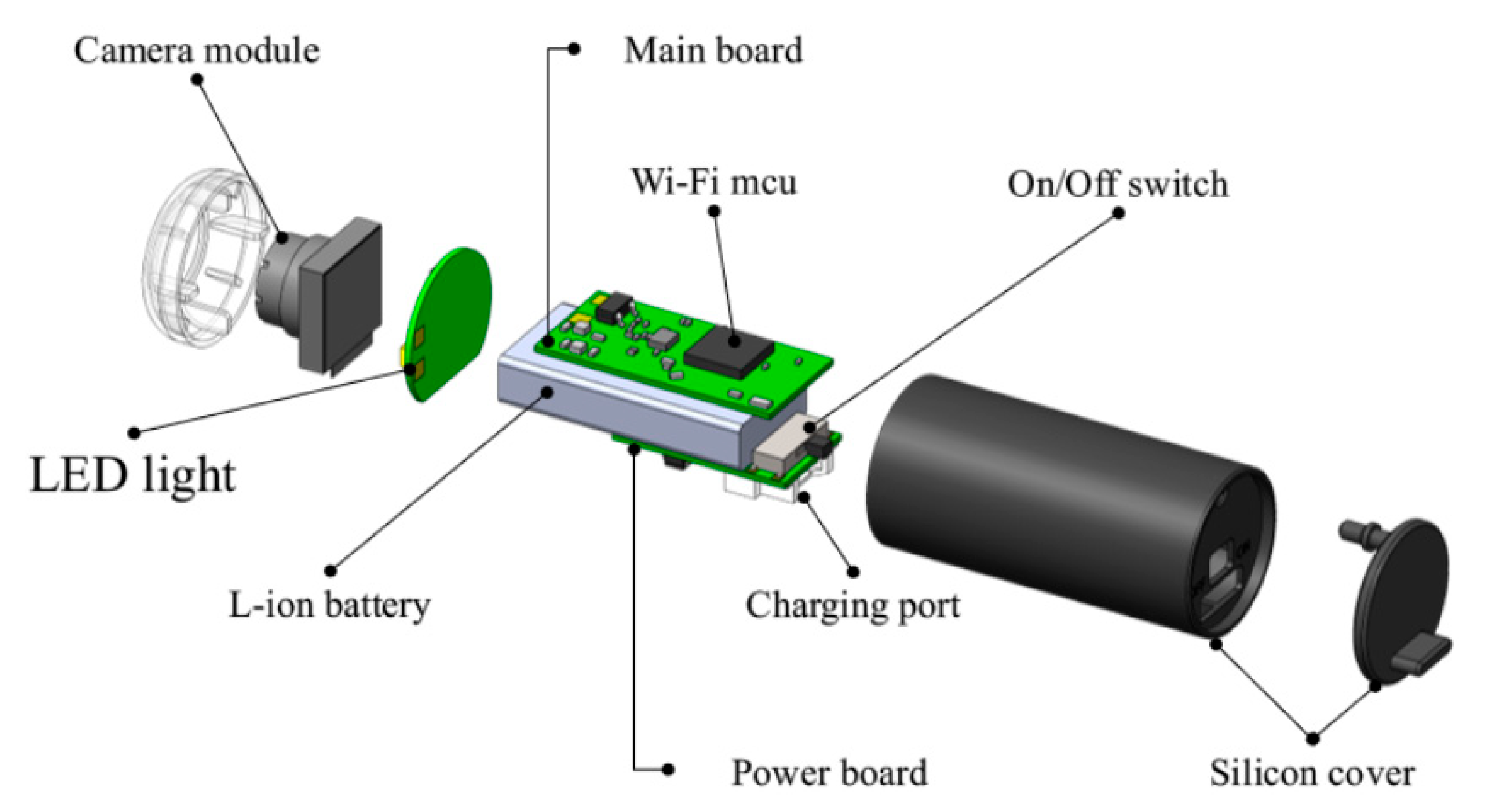

Figure 8 below shows the configuration of the robot reflecting the above system requirements.

4. Development of Prototype and Performance Experiment

4.1. Prototype System

The inspection robot presented in this study is designed to be inserted into the pipeline, move inside, capture real-time video, and transmit the video to nearby monitoring equipment via wireless communication. The system for utilizing this robot for pipeline inspection consists of three main components. First, the inspection robot that is inserted into the pipeline, a monitoring system connected to the robot via Wi-Fi to check the captured video in real-time, and an air compressor to provide the propulsion needed to move the robot inside the pipeline.

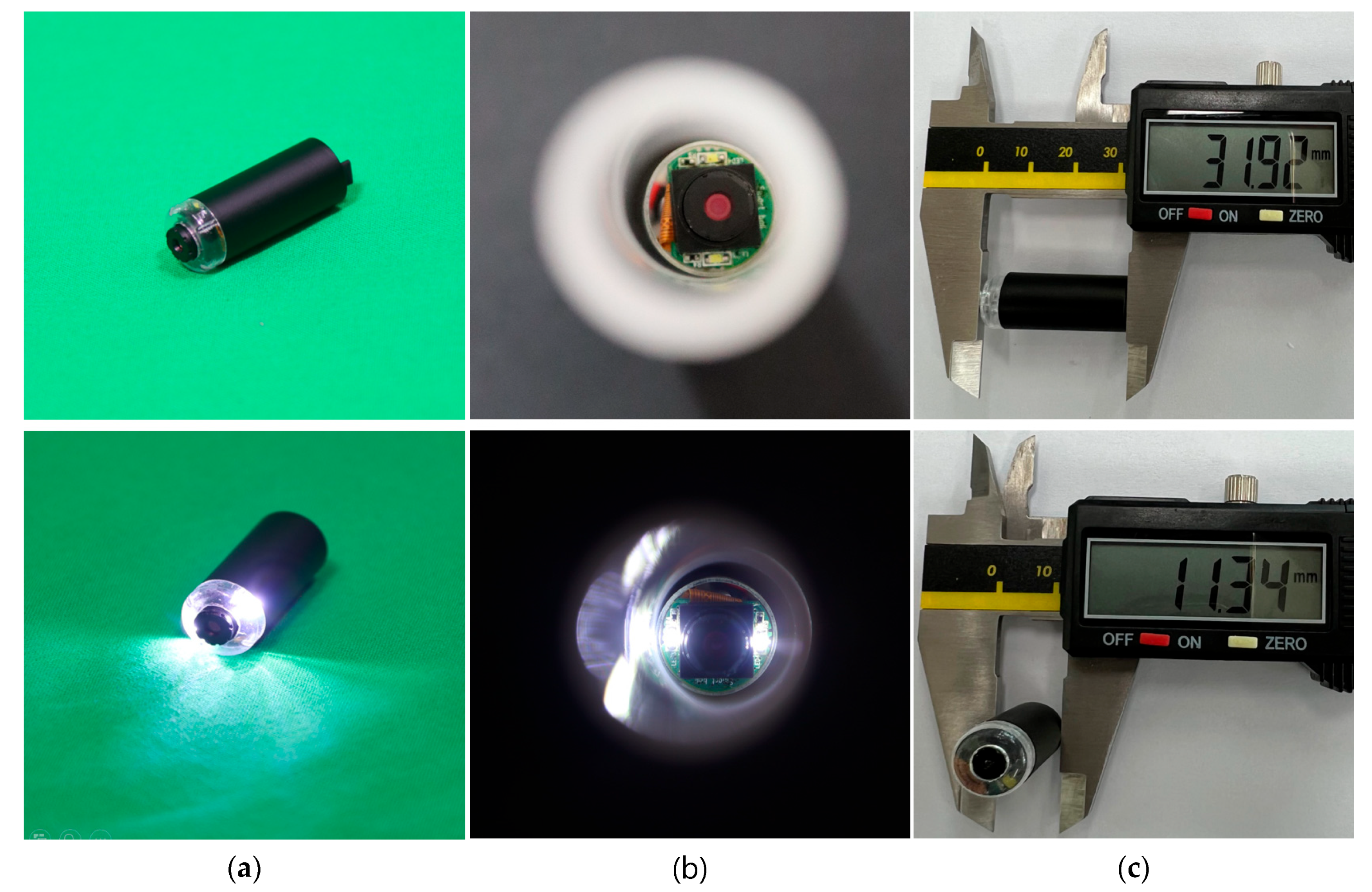

Figure 9 below shows the system requirements and the appearance of the capsule-type inspection robot that was manufactured reflecting these requirements.

Figure 9a shows the prototype with the LED in the on/off state.

Figure 9b shows the robot inserted into the pipeline, and

Figure 9c is an image verifying the size of the prototype with a digital caliper. Looking at the representative specifications of the detailed components, the robot was manufactured with a diameter of 11.34mm and a length of 31.92mm. The camera has a resolution of 2 million pixels, and the battery is a rechargeable 3.7V, 55mAh lithium-ion type. The LED lighting includes four LEDs with low power consumption and a wide viewing angle, each with a maximum of 320mcd. The Wi-Fi module operates at 2.4GHz.

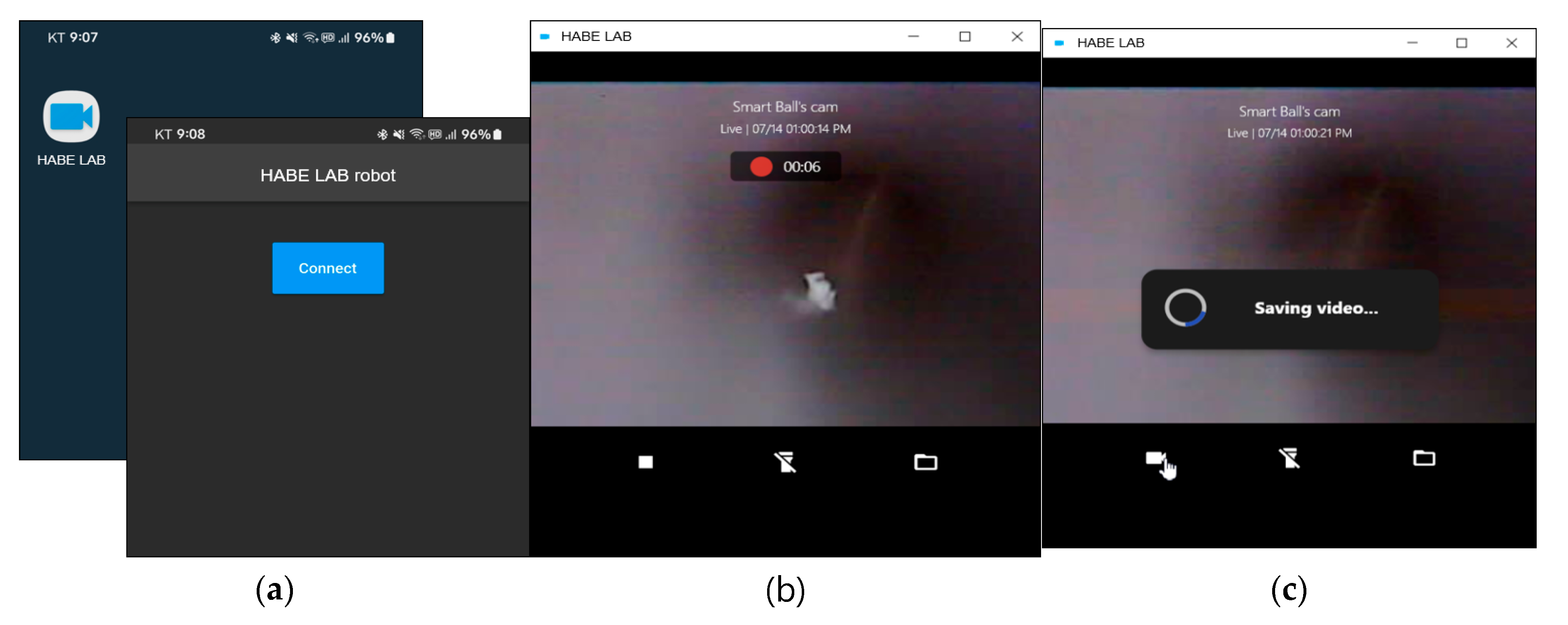

The video captured by the robot as it moves through the pipeline is transmitted in real-time to the monitoring system via wireless communication. This system was developed as an application that can be installed on a laptop, tablet PC, or smartphone. The monitoring system consists of a viewer for the administrator to check the real-time video, a menu for recording and saving, and a function to turn the robot's LED on and off.

Figure 10 below shows the operation of the application installed on a smartphone. As shown in

Figure 10a, the administrator runs the application and connects to the robot inserted into the pipeline.

Figure 10b shows the robot moving inside the pipeline, transmitting real-time video to the smartphone, and recording it in the application. As shown in

Figure 10(c), the recorded video can be saved to a designated path.

4.2. Performance Experiments

To verify the performance of the developed prototype system, a laboratory with actual Ondol piping installed was constructed, and performance verification experiments were conducted. The laboratory constructed for the performance experiment is shown in

Figure 11 below. The experiment was constructed identically to the three patterns seen in

Figure 2. To ensure the field applicability of the developed system, the following verifications are required: first, verification of smooth movement through the straight and curved sections of the piping; second, verification that the video captured by the robot is well transmitted in real-time to the monitoring system and that defects can be clearly identified by the naked eye on the monitoring system; and lastly, verification of wireless communication performance. The verification of communication performance was excluded from this experiment. This is because the movement of the robot cannot be visually confirmed when the piping is embedded in cement mortar, and the performance of wireless communication has already been verified through preliminary research. Therefore, the performance verification focused on the mobility of the robot and the quality test of the detection screen on the monitoring system.

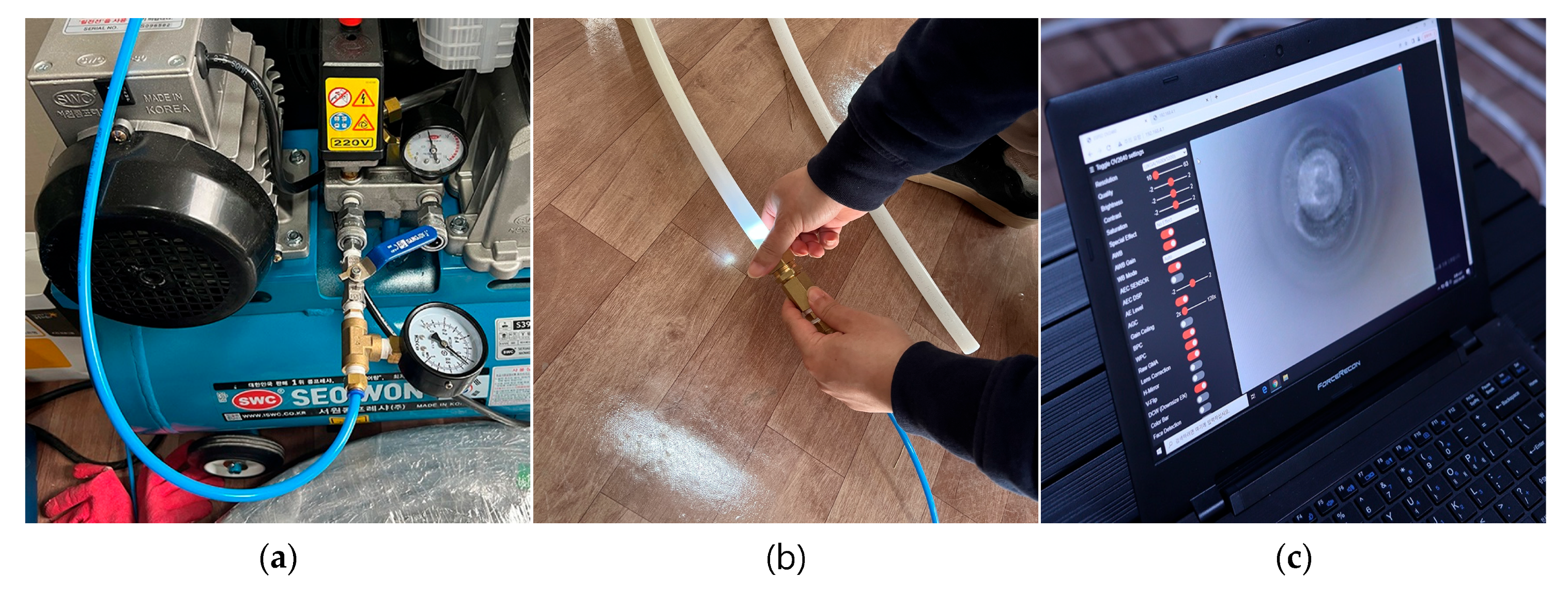

Figure 12 below shows the process of inserting the robot into the piping.

Figure 12a shows the air compressor used for moving the inspection robot inside the piping. The air compressor used in this experiment is an off-the-shelf product with specifications of 3.5 horsepower and 40 liters.

Figure 12b shows the process of inserting the inspection robot into the piping and connecting the air compressor hose to the piping, and

Figure 12c shows the monitoring system confirming the video sent by the inspection robot.

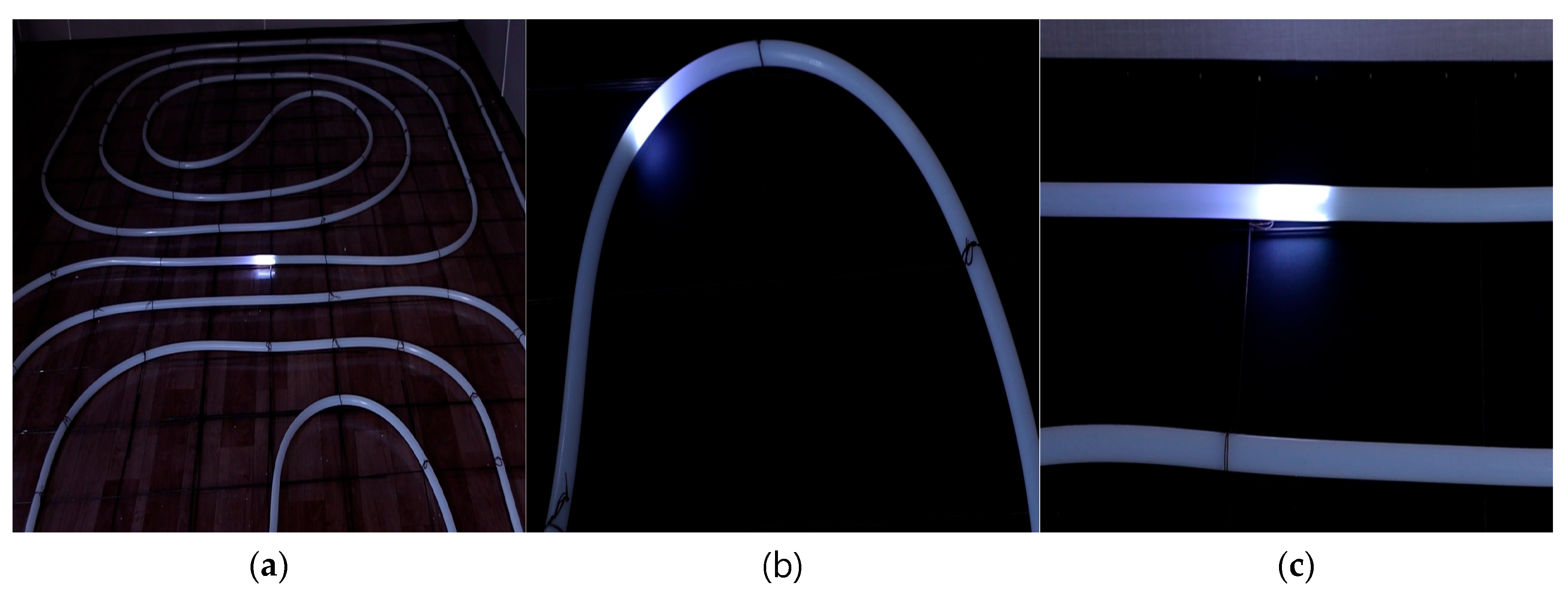

Figure 13 below shows the inspection robot moving. To confirm the moving position, the laboratory lights were turned off, and the robot's LED was turned on. In

Figure 13a, the robot appears as the bright part inside the piping.

Figure 13b shows the curved section, and

Figure 13c shows the straight section. The robot moves through the compressive force of the air introduced into the piping, and the moving speed is adjusted by the compressive force of the air compressor. In the experiment, the robot was moved at an average speed of 350 mm/s, with speed adjustments possible between 200 and 500 mm/s. As a result, it was verified that the robot could move smoothly in both straight and curved sections.

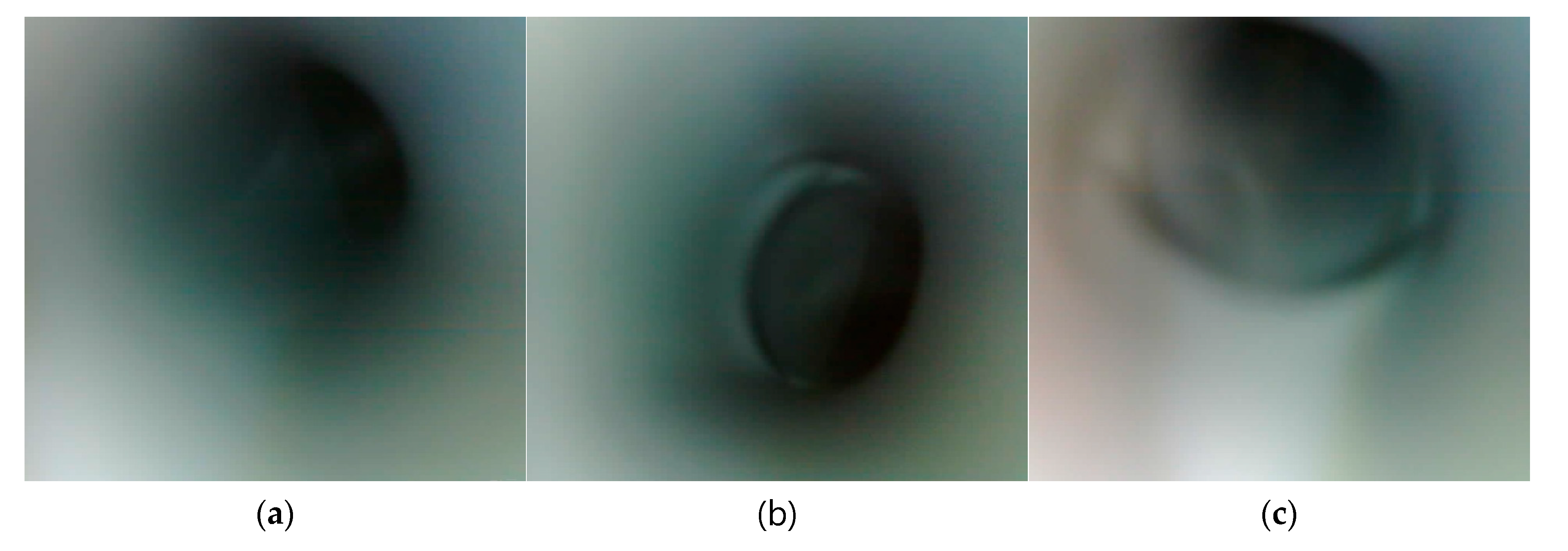

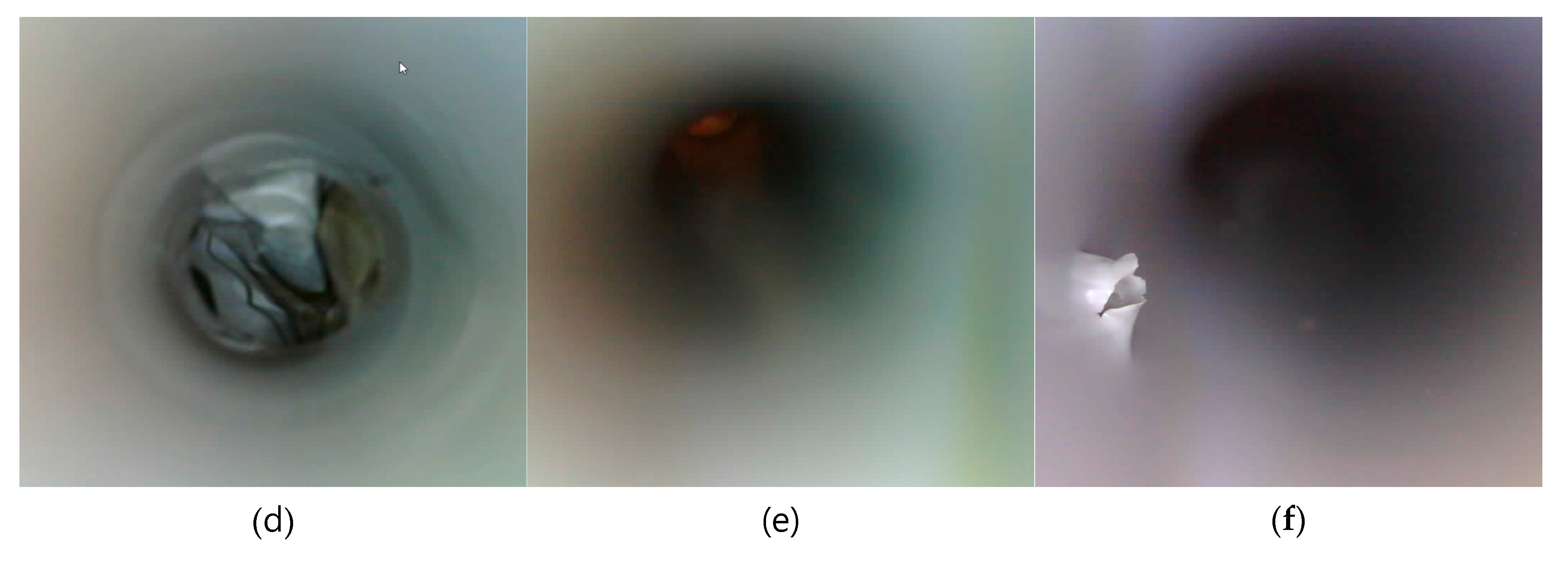

Figure 14 below shows representative images of the video sent by the inspection robot while moving. As the robot moves through the piping, it captures images of the piping, and the administrator should be able to check these images on the monitoring system to assess the condition.

Figure 14a shows the normal interior of the piping.

Figure 14b,c show the formation of wrinkles inside the piping due to bending beyond the elastic limit of the piping at the curved sections. These wrinkles can occur due to the mistakes of workers during the installation of the piping, which weakens the durability of the pipe wall, hinders the flow of hot water, and ultimately becomes a potential cause of leakage.

Figure 14d shows the blockage of the piping. During the installation of the piping, it is common for cement mortar, foreign substances, etc., to enter, and this image shows such a situation.

Figure 14e shows light leaking in due to damage at the pipe connection, and

Figure 14f shows a hole created by a nail used to secure the piping during installation, which punctured the pipe wall due to a worker's mistake. Various situations that can occur during actual installation were set up in the piping to verify whether these situations could be identified through the captured images from the robot.

4.3. Discussion and Further Study

The performance verification experiment confirmed that the developed robot can quickly navigate the narrow inner diameter and curved sections of the piping while maintaining sufficient video quality to identify issues. This validation of mobility and video quality suggests that the robot system proposed in this study is ready for immediate deployment in the field.

Several challenges emerged during the development and experimentation process of the prototype. First, while the use of an air compressor for robot movement ensures speed, it presents limitations in precise forward and backward movement control. To address this, future work will involve developing a segment-type robot by connecting two prototypes to secure space for the drive unit and battery installation.

Additionally, the current requirement for continuous visual inspection of the transmitted video from inside the piping reduces work efficiency. To improve this, future research will focus on transitioning to an AI-based information processing method that can automatically detect issues and incorporate notification and storage functions into the monitoring system.

5. Conclusions

In this study, an inspection robot system was developed to inspect Ondol piping used for residential heating in Korea. The characteristics of Ondol piping were analyzed, and the performance requirements for the inspection robot system were derived based on these characteristics. A prototype was developed reflecting these requirements, and performance experiments were conducted to verify that the system achieved a performance level suitable for field use.

Ondol piping is used for residential heating and is embedded in cement mortar, leading to significant damage when repairs are necessary due to defects. Therefore, it is essential to inspect the piping condition from the installation stage, and regular inspections are required during the maintenance stage. In the case of Korean apartments, there are numerous units, and the piping to be inspected is extensive. Speed and accuracy in inspections are crucial requirements due to the need for regular inspections during both the installation and maintenance stages. The system proposed in this study is considered a customized solution for these needs.

If this system is applied in the field, it will enable visual confirmation of the construction quality of heating pipes that were previously uncheckable and facilitate the early detection of pipe deformation and damage, thereby eliminating potential defect factors. Furthermore, it will allow for the accumulation of data related to Ondol piping, which is used in most Korean residences, and minimize labor and costs through non-destructive inspection technology. Ultimately, it will contribute to reducing maintenance costs and extending the lifespan of buildings. This study can also aid in establishing inspection systems for similar small-diameter piping.

Author Contributions

Conceptualization, Lee. M. and L.U.K.; methodology, Lee. M. and L.U.K.; validation, L.U.K.; formal analysis, Lee. M. and L.U.K.; investigation, Lee. M. and L.U.K.; resources, Lee. M. and L.U.K.; data curation, Lee. M. and L.U.K.; writing—original draft preparation, Lee. M. and L.U.K.; writing—review and editing, Lee. M. and L.U.K.; visualization, Lee. M. and L.U.K.; supervision, L.U.K.; project administration, L.U.K.; funding acquisition, L.U.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education(2020R1I1A3064165).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to privacy.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Ambati, P.; Raj, K.M.; Joshuva, A. A Review on Pipeline Inspection Robot. AIP Conference Proceedings, Chennai, India, 7–9 August 2020.

- Jang, H.; Kim, T.Y.; Lee, Y.C.; Kim, Y.S.; Kim, J.; Lee, H.Y.; Choi, H.R. A Review: Technological Trends and Development Direction of Pipeline Robot Systems. J. Intell. Robot. Syst. 2022, 105, 59. [Google Scholar] [CrossRef]

- John, B.; Shafeek, M. Pipe Inspection Robots: A Review. IOP Conf. Ser.: Mater. Sci. Eng. 2022, 1272, 1–12. [Google Scholar] [CrossRef]

- Kim, S.K.; Lee, D.H.; Hong, H.K. An Energy Saving Technique Using Ondol Heating Schedule Control of Housing Units in Korea. Indoor Built Environ. 2010, 19, 88–93. [Google Scholar] [CrossRef]

- Lee, U.K. An Experimental Analysis of Ultrasonic Cavitation Effect on Ondol Pipeline Management. J. Korea Inst. Build. Constr. 2024, 24, 67–75. [Google Scholar]

- Jo, J.H.; Lee, U.K.; Jeong, J.H.; Lee, S.S. Comparatively Testing Concrete Permeability for Wireless Communications of a Pipe-Cleaning Robot. Int. J. Mech. Eng. 2022, 7, 0974–5823. [Google Scholar]

- Jo, H.J.; Lee, U.K.; Kim, J.Y.; Lee, S. Experiment on the Feasibility of Cleaning Building Pipelines Using Ultrasonic Cavitation. In Proceedings of the The 9th International Conference on Construction Engineering and Project Management, Las Vegas, NV, USA, 20–23 June 2022; pp. 295–303. [Google Scholar]

- Jeong, J.H.; Lee, S.S.; Lee, U.K. Design of Ball-Type Equipment for Pipeline Maintenance. In Proceedings of the International Conference on Next-Generation Convergence Technology, Pusan, Korea, 11–12 January 2021. [Google Scholar]

- Elankavi, R.S.; Dinakaran, D.; Jose, J. Developments in In-Pipe Inspection Robot: A Review. J. Mech. Contin. Math. Sci. 2020, 15, 238–248. [Google Scholar]

- Ab Rashid, M.Z.; Yakub, M.F.M.; Bin Shaikh Salim, S.A.Z.; Mamat, N.; Putra, S.M.; Roslan, S.A. Modeling of the In-Pipe Inspection Robot: A Comprehensive Review. Ocean Eng. 2020, 203, 107206. [Google Scholar] [CrossRef]

- Colvalkar, A.; Nagesh, P.; Sachin, S.; Patle, B.K. A Comprehensive Review on Pipe Inspection Robots. Int. J. Mech. Eng. 2021, 10, 51–66. [Google Scholar]

- Elankavi, R.S.; Dinakaran, D.; Chetty, R.K.; Ramya, M.M.; Samuel, D.H. A Review on Wheeled Type In-Pipe Inspection Robot. Int. J. Mech. Eng. Robot. Res. 2022, 11, 745–754. [Google Scholar] [CrossRef]

- Rusu, C.; Tatar, M.O. Adapting Mechanisms for In-Pipe Inspection Robots: A Review. Appl. Sci. 2022, 12, 6191. [Google Scholar] [CrossRef]

- Verma, A.; Kaiwart, A.; Dubey, N.D.; Naseer, F.; Pradhan, S. A Review on Various Types of In-Pipe Inspection Robot. Mater. Today: Proc. 2022, 50, 1425–1434. [Google Scholar] [CrossRef]

- Kahnamouei, J.T.; Moallem, M. A Comprehensive Review of In-Pipe Robots. Ocean Eng. 2023, 277, 114260. [Google Scholar] [CrossRef]

- Ismail, I.N.; Anuar, A.; Sahari, K.S.M.; Baharuddin, M.Z.; Fairuz, M.; Jalal, A.; Saad, J.M. Development of In-Pipe Inspection Robot: A Review. In Proceedings of the 2012 IEEE Conference on Sustainable Utilization and Development in Engineering and Technology, Kuala Lumpur, Malaysia, 6–9 October 2012; pp. 310–315. [Google Scholar]

- Gargade, A.; Ohol, S. Development of In-Pipe Inspection Robot. IOSR J. Mech. Civ. Eng. 2016, 13, 64–72. [Google Scholar] [CrossRef]

- Song, Z.; Luo, Y. Research Status and Development Trend of Oil and Gas Pipeline Robot. Acad. J. Sci. Technol. 2022, 3, 134–140. [Google Scholar] [CrossRef]

- Mills, G.H.; Jackson, A.E.; Richardson, R.C. Advances in the Inspection of Unpiggable Pipelines. Robotics 2017, 6, 1–13. [Google Scholar] [CrossRef]

- Roslin, N.S.; Anuar, A.; Jalal, M.F.A.; Sahari, K.S.M. A Review: Hybrid Locomotion of In-Pipe Inspection Robot. Procedia Eng. 2012, 41, 1456–1462. [Google Scholar] [CrossRef]

- Blewitt, G.; Cheneler, D.; Andrew, J.; Monk, S. A Review of Worm-Like Pipe Inspection Robots: Research Trends and Challenges. Soft Sci. 2024, 4, 1–26. [Google Scholar] [CrossRef]

- Zhang, Y.; Yan, G. In-Pipe Inspection Robot with Active Pipe-Diameter Adaptability and Automatic Tractive Force Adjusting. Mech. Mach. Theory 2007, 42, 1618–1631. [Google Scholar] [CrossRef]

- Hadi, A.; Hassani, A.; Alipour, K.; Askari Moghadam, R.; Pourakbarian Niaz, P. Developing an Adaptable Pipe Inspection Robot Using Shape Memory Alloy Actuators. J. Intell. Mater. Syst. Struct. 2020, 31, 632–647. [Google Scholar] [CrossRef]

- Cetinsoy, E.; Esgin, H. Design of an Ex-Proof Untethered In-Pipe Inspection Robot. In Proceedings of the 2018 IEEE International Conference on Automation, Cluj-Napoca, Romania, 24–26 May 2018; pp. 1–6. [Google Scholar]

- Kwon, Y.S.; Lee, B.; Whang, I.C.; Kim, W.K.; Yi, B.J. A Flat Pipeline Inspection Robot with Two Wheel Chains. In Proceedings of the 2011 IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011; pp. 5141–5146. [Google Scholar] [CrossRef]

- Jalal, M.A.; Sahari, K.M.; Anuar, A. Development of Magnetic Wheeled Boiler Tube Inspection Robot. J. Teknol. 2015, 76. [Google Scholar]

- Chatzigeorgiou, D.; Youcef-Toumi, K.; Ben-Mansour, R. Design of a Novel In-Pipe Reliable Leak Detector. IEEE/ASME Trans. Mechatron. 2014, 20, 824–833. [Google Scholar] [CrossRef]

- Hirose, S.; Ohno, H.; Mitsui, T.; Suyama, K. Design of In-Pipe Inspection Vehicles for Φ25 Φ50 Φ150 Pipes. In Proceedings of the 1999 IEEE International Conference on Robotics and Automation, Detroit, MI, USA, 10–15 May 1999; pp. 2309–2314. [Google Scholar]

- Elankavi, R.S.; Dinakaran, D.; Doss, A.S.A.; Chetty, R.K.; Ramya, M.M. Design and Motion Planning of a Wheeled Type Pipeline Inspection Robot. J. Robot. Control 2022, 3, 415–430. [Google Scholar] [CrossRef]

- Zheng, D.; Tan, H.; Zhou, F. A Design of Endoscopic Imaging System for Hyper Long Pipeline Based on Wheeled Pipe Robot. In Proceedings of the AIP Conference Proceedings, Wuhan, China, 25–26 February 2017. [Google Scholar]

- Li, H.; Li, R.; Zhang, J.; Zhang, P. Development of a Pipeline Inspection Robot for the Standard Oil Pipeline of China National Petroleum Corporation. Appl. Sci. 2020, 10, 8. [Google Scholar] [CrossRef]

- Ariaratnam, S.T.; Chandrasekaran, M. Development of an Innovative Free-Swimming Device for Detection of Leaks in Oil and Gas Pipelines. In Proceedings of the Construction Research Congress, Banff, Canada, 8–10 May 2010; pp. 588–596. [Google Scholar]

- Chapman, H. Development of a Successful Internal Leak Detection and Pipeline Condition Assessment Technology for Large Diameter Pipes. In Proceedings of the 6th Annual WIOA NSW Water Industry Engineers & Operators Conference, Tamworth, Australia, 27–29 March 2012; pp. 29–37. [Google Scholar]

- Islas-García, E.; Ceccarelli, M.; Tapia-Herrera, R.; Torres-SanMiguel, C.R. Pipeline Inspection Tests Using a Biomimetic Robot. Biomimetics 2021, 6, 17. [Google Scholar] [CrossRef] [PubMed]

- Song, S.J. Development of the Visual Inspection Device with Driving Motors for Non-Destructive Test of Piping from the Inside. J. Korean Soc. Mech. Technol. 2018, 20, 541–547. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).