1. Introduction

1.1. Environmental Issues: Current Overview

There is a global concern, from international agencies to society in general, about many different environmental issues that question the sustainability of our current industrial network. Thus, the use of petrol-based products, from their extraction, production or refining to their energy use, have provoked many different environmental problems, like a considerable contribution to greenhouse gas emissions, water and soil pollution, among others [

1,

2]. These effects are due to the direct use of these compounds, but there are other indirect consequences that are equally important, such as the economic dependence and the subsequent political instability as well as the requirement of shipment or transportation of petrol-based fuels or products [

3,

4,

5]. Therefore, it is not only a matter of sustainability, but a matter of economic survival, which has provoked the increasing interest in sustainable practices such as the implementation of green policies, including circular economy and sustainable development of certain areas [

6], especially in Africa, where the sustainable development of different countries or regions is essential, along with the efforts by the rest of developed countries (some of them more engaged than others), to safeguard the environment [

7,

8]. Therefore, there are plenty of actions, from local to global, from institutions (such as the European Union or the United Nations) to individuals, focused on the sustainability of every aspect in our lives [

9,

10]. The clearest example of this fact are the sustainable development goals (SDGs) [

11], which try to foster equality, zero hunger, sustainability and the protection of soil and water resources.

There are many different technologies that can be implemented to foster sustainability, circular economy and green chemistry. Thus, biogas production (normally through anaerobic digestion (AD) from different wastes, such as sewage sludge (SS), agricultural waste or their combination [

12]), is the perfect example for this purpose, with plenty of possibilities to obtain interesting products like hydrogen through reforming processes [

13]. In that sense, hydrogen is one of the most valuable energy vectors, with the subsequent valorization of wastes implied in its generation [

14]

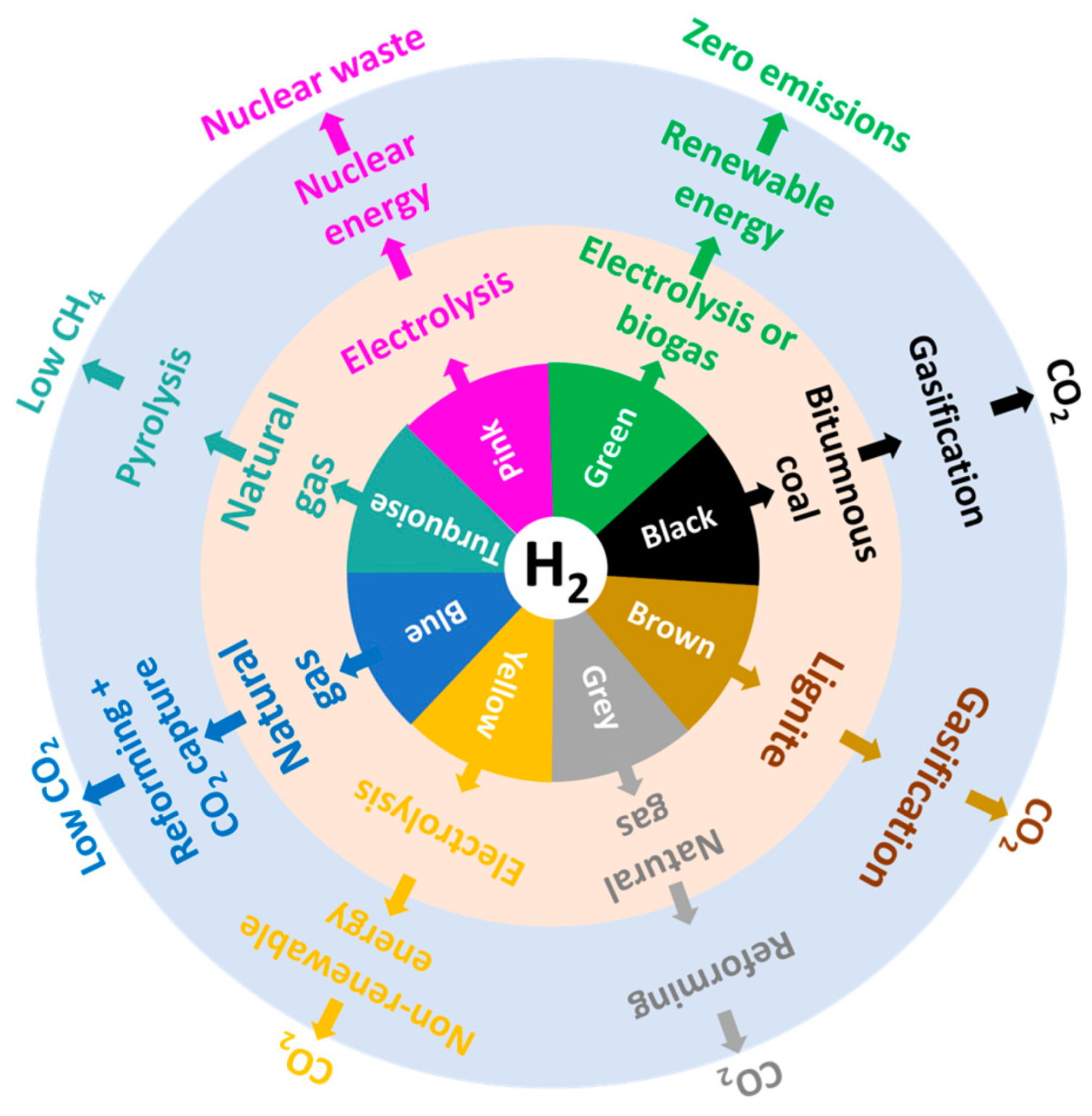

However, hydrogen production and quality depend on different factors, such as the kind of source, process and further treatments to obtain high-purity hydrogen. With this regard, hydrogen can be classified by colors, according to the cleanliness of the whole production [

15], as observed in

Figure 1.

In a sense, hydrogen can be sorted by color according to the environmental cleanliness and sustainability of the process and the subsequent emissions. Thus, these colors go from black and brown (the most polluting processes) to blue, turquoise or green (the most sustainable and less polluting ones). As explained y previous works, turquoise hydrogen performs better than grey hydrogen, playing an important role in green transition [

16]. It should be noted that there are processes that can be ranked in a certain color depending on specific factors like the use of CO

2 capture techniques. Thus, the presence or absence of CO

2 capture could imply blue or grey hydrogen production from natural gas. Also, the use of a certain raw material is vital, as biogas is highly related to green hydrogen processes whereas coal is linked to black hydrogen. Finally, another determining aspect is the use of green energy for an industry. This way, when electrolysis is used to produce hydrogen, renewable energies assure the production of green energy, whereas the use of nuclear energy is linked to pink hydrogen (due to the management of nuclear waste). Within the same color, for instance in the case of green or blue hydrogen, there might be different emission levels according to the technologies used [

17]. In this sense, CO

2 capture can be highly effective, achieving zero or low CO

2 emissions.

Basically, hydrogen color is related to many aspects of hydrogen production. This simple and intuitive labelling points out relevant aspects that are highly esteemed in environmental assessment tools like life cycle assessment (as explained in following sections), like the following:

Nature of the raw material used. Thus, hydrogen obtained from natural gas is not considered as clean as hydrogen obtained from water through hydrolysis, as the source by itself implies certain environmental impacts.

Origin of energy used in the process. Depending on the energy used for a specific process to obtain hydrogen, its color might vary. This way, reforming of biogas can be considered green if renewable energy is used in this process, whereas it can be considered blue if other energy sources are used. The same happens to hydrogen obtained through electrolysis, whose color might vary from pink (if nuclear energy is selected) to green (if renewable energies are chosen).

Pollution (including evolved gases, but also water and soil pollution) and its management. This is one of the most determining aspects to rate hydrogen in a certain color. For instance, if CO2 is released to the atmosphere, it is common to consider the hydrogen produced as black, brown or grey.

In this work, green hydrogen produced through biogas reforming is considered, which could be of a different color depending on CO2 management. Indeed, it is assumed that the direct release of carbon dioxide to the atmosphere would downgrade this process to grey hydrogen.

1.2. Assessment of Environmental Impact and Sustainability

As previously mentioned, these concerns by international and local authorities, along with society in general, make the search for sustainable processes essential. Furthermore, it is important not only to choose green industries, but also to confirm that their performance is environmentally friendly [

18]. This way, any technological solution should be available, with the possibility of choosing different solutions option to their environmental efficiency, cost and resulting economic constraints, optimizing any action to reduce impacts as much as possible [

19].

For this purpose, there are plenty of methods to determine the suitability of a process, especially at industrial scale, from an environmental point of view [

20,

21]. This is a very interesting point, as there are countless research works including emerging green technologies, which should be proven at industrial scale in terms of efficiency and sustainability as an essential step to compete with traditional industries, especially those based on petrol. In this sense, there are several tools or indicators to assess the environmental impact of a certain industry or process. For instance, carbon footprint is an interesting indicator that assess the global greenhouse gas emissions related to an industry or activity. It should be noted that these emissions can be directly or indirectly generated, and it can be considered a part of a LCA, as it is usually included in these kinds of assessments. Another interesting indicator is the atom economy, whose main philosophy is indicated in

Figure 2.

Thus, atom economy would be given by Equation 1:

According to this equation, atom economy ranges from 0 to 100 %, with high atom economy values indicating that there is a low percentage of evolved compounds that are undesirable and, therefore, with polluting potential. However, the energy costs (which could be translated into a considerable carbon footprint) as well as the environmental impact of further treatments to increase atom economy are not covered, which could present a challenge for this tool. Nevertheless, it can be a good indicator to be used as a complement of other methods in order to determine the environmental impact of processes.

In a similar way, carbon and greenhouse gas footprint is an index that indicates the contribution of an industrial activity or production to the levels of these emissions to the atmosphere, normally expressed as kg or tons of CO

2 per a specific unit of production or consumption (that could be equivalent to the functional unit used in LCA, as explained in the following section) [

22]. It should be noted that, for a certain process, there might be direct or indirect carbon dioxide emissions, which can be globally considered in this index.

Derived from the abovementioned index, another interesting assessment of the environmental impact of a certain company or entity is the concept of carbon credit (or offset credit), which is commonly defined as the capability of reduction of carbon emissions (or equivalent emissions), normally expressed as metric tons of CO

2. As explained in the following section, LCA assess CO

2 emissions, providing this interesting information that allows companies to offset greenhouse gas emissions due to their typical activities by introducing new, alternative and green technologies that contribute to the global CO

2 emission reduction. Again, LCA can play an important role, as it is possible the comparison of the contribution of innovative technologies to reduce carbon dioxide emissions to check the real carbon credits achieved by implementing them. For instance, biochar production in some stages included during biogas production or reforming could contribute to increase carbon credits with the subsequent mitigation of environmental consequences [

23].

Finally, another environmental index is water footprint, which can be defined in the context of this review as the amount of water consumed or polluted during industrial activities to produce goods, energy and services, normally expressed in volumetric flow rate units [

24]. As explained in further sections, LCA covers this aspect, especially in some processes included in this review such as biogas or methane steam reforming, where the consumption of water can be a challenge due to the energy costs to generate steam and the subsequent water consumption. It should be noted that water footprint pays attention to different aspects, such as the sphere of influence for the assessment of this indicator, which is an important point in common with LCA, where the delimitation of the process is vital to understand the environmental impact of a certain process (or technology).

It should be noted that there are other indicators or assessment methods, including atmospheric temperature, ozone levels or different chemical and biological measurements, which are highly related to the abovementioned concepts. In any case, life cycle assessment can cover or contribute to many of these indicators, as in the case of water or carbon footprints and carbon credits, which have to do with the abovementioned SDGs. In the following section, the foundations of LCA, which are essential to understand the contribution of catalysts to a positive environmental assessment, are briefly explained.

1.3. Life Cycle Assessment: Foundations

Thus, compared to the abovementioned approaches, LCA is a complete and thorough methodology to assess the environmental balance of a certain technology or industry, including different biofuels or bioproducts [

25]. It allows to make decisions about the right selection of a certain technological solution among different possibilities [

19].

LCA is an extremely useful tool to cover different aspects in industrial production, like the following [

19]:

Corporate strategy. The use of LCA is linked to a thorough analysis of the environmental impact related to industrial products and processes, which is an essential strategy for many companies in strategic sectors such as energy, with the subsequent prestige and good branding.

Research and development. As explained in this review, many research lines are devoted to the improvement of the environmental impact of some steps related to different technologies, and LCA can be a good way to assess the progress of a certain research project or line.

Design of products or processes. The role of LCA at this point is vital, as the production of items imply multiple previous steps, along with further post-treatments, when necessary, that should be assessed.

Education. LCA has such a great significance that it can be taught at different educational levels, as it is currently considered an important step in the design of products or services.

Labeling and description of products. There are plenty of rankings of products. For instance, regarding food, according to their nutritional value. In this sense, products can be also labeled according to their impact during production, usage or disposal. For this purpose, LCA is useful to rank these processes and products.

Performance of meta-analyses, including the review of LCAs about a certain process or product. These studies could present a global perspective of a specific technology, which usually presents some particularities that can be encompassed by using LCA applied to these variations.

In addition, there are also different applications according to the kind of industry. Indeed, many studies about mature technologies, as well as emerging ones, have included LCA as the main subject, as in the case of microalgal biorefineries[

26], biodiesel production from jatropha or waste cooking oil [

27,

28], bioethanol production [

29,

30], glycerol reforming to produce H

2 [

31] or waste biorefineries [

32], among others. In general, LCA covers different aspects of a product, process, or service. On the one hand, it tries to consider all the components implied in the production system, including reagents, products, by-products, but also other less evident factors such as energy used, efficiency of the process, shipment of goods or the use of fungible materials or catalysts, which will be a determining point in this work. On the other hand, LCA is focused on the process, but also on the previous steps to carry out every stage and the consequences of industrial activity. As typically said, this method goes from “cradle to grave”, indicating that every aspect (from extraction, production, manufacture, distribution, use and postreatment) of every component of the process should be considered or, at least most of it. Thus, the more stages and compounds are considered in a LCA, the more complete it is, offering more reliable results [

19]. In other words, this tool is suitable to determine which step (or steps) deserves more attention to be optimized from an environmental point of view.

In this sense, LCA is a very adaptable method, with multiple applications in industry depending on the process. Also, as observed in

Figure 3, there are some representative connections between LCA and the so-called Sustainable Development Goals [

11], which can be explained as follows:

As observed in this figure, LCA has to do with many aspects covered in the SDGs, which are the most representative objectives at international level. For instance, the following are perfect examples of the adjustment of LCA to SDGs:

One of the main aims of LCA is to protect the environment and, subsequently, the good health and well-being of citizens.

Another interesting aspect is the assessment of pollutants on water, trying to obtain clean water and allowing life in aquatic ecosystems.

The production and use of affordable and clean energy is another important factor, where LCA has an important role as energy consumption or production in a certain industry is highly related to CO2 emissions, for instance.

Regarding industry innovation and infrastructure, the production of industrial goods and services is going to be more and more controlled from an environmental point of view, whose assessment could be carried out by using LCA to promote clean and green technologies for these purposes.

Equally, sustainable cities and communities are based on every detail that contribute to environmental conservation, including transportation or shipment of goods, industrial production, etc. Transportation, among other factors, are normally included in LCA.

Obviously, responsible consumption and production is the cornerstone of LCA, where terms such as durability, reusability or recycling are essential to consider a certain process sustainable or not.

Concerning climate action, life below water and life on land, the quantity of pollutants (such as some evolved gases, liquids or solids) could be a challenge that should be managed, which is an important area of knowledge in LCA. Normally, the lower emissions there are (or the better management is carried out), the lower environmental impact on land, water or climate is found.

As observed, LCA and SDGs share many points, guided by their philosophy of going from start to end, pointing out critical aspects such as water, CO2 or energy management. Equally, the requirements to assess different environmental impacts, including emissions to air, water or soil, makes LCA a suitable tool highly linked to the abovementioned SDGs.

In this sense, there are different standards which are highly related to LCA, like those included in

Table 1. As observed, the ISO 14000 series is a set of standards focused on different environmental aspects, including environmental management, performance evaluation, life cycle assessment, water footprint, etc. These are the foundation for an appropriate LCA, offering a wide range of possibilities of adaptation to each specific case. Consequently, most of these standards can be applicable to assess the environmental impact of technologies such as biogas reforming.

As observed, the different series included in this table cover diverse aspects of environmental management, from foundations of LCA to specific aspects such as labeling, vocabulary or even examples to clarify the different aspects included in these norms. Equally, different guidelines for interesting aspects such as life or eco-efficiency assessment of product systems are covered. In general, these standards are mainly focused on good practices when applying LCA in every aspect related to a process or product, including the main steps that should be accomplished to carry out a complete LCA. Thus, according to

Table 2, the main stages in a life cycle assessment are the following:

As in the case of other assessments, the boundaries of the system, that is, the limits within which the environmental impact of a process or production is going to be considered, is an assumption that can simplify the study. However, some valuable information might be missed or ignored. On the other hand, the concept of functional unit (FU) is very interesting, as it will facilitate the comparison of different LCAs about similar subjects. Thus, it is the quantified performance of a product system for use as a reference unit. In other words, it is a quantifiable and additive reference, like kg of hydrogen in the case of biogas or natural gas reforming [

52]. Thus, if hydrogen production is doubled according to this unit, the environmental impact related to the LCA linked to 1 kg of produced hydrogen would be increased 100 %.

As it can be inferred from the above, LCA can be easily implemented to a wide range of green technologies, such as biogas reforming. The following sections will deal with the real possibility of LCA applied to this case, including specific cases from which different conclusions can be made.

1.4. Biogas Reforming: Possibilities for LCA

On the other hand, the other aspect of this review, that is, biogas reforming, is equally highly related to these SDGs, which makes its combination with LCA interesting when it comes to sustainability. Thus, some SDG, such as “Affordable and Clean Energy” or “Climate Action”, among others, are especially linked to LCA and biogas reforming. Therefore, LCA applied to biogas reforming, offers endless opportunities for the improvement of sustainable development. In this sense, this technology offers a great opportunity to the development of sustainable regions, as multiple wastes can provide biogas through anaerobic digestion that can be used in reforming to produce hydrogen. In this context, it should be noted the relevance of wastewater treatment plants, which contributes to the preservation of aquatic ecosystems and the sanitation of water supply. Equally, sewage sludge obtained during anaerobic digestion could present interesting properties once it is treated through hydrothermal carbonization or pyrolysis, obtaining a product with high porosity that presents a wide range of possibilities, like its use as activated carbons for catalyst support or gas adsorption. In other words, reusability, which is in accordance with SDG 12, is another aspect related to biogas reforming, at least at initial stages (that is, biogas production).

However, there are other SDGs that are linked to biogas reforming rather than LCA, like SDG 1 or SDG 8, as the implementation of this technology in rural areas or developing countries could represent a great contribution to the economic growth of these regions, offering an alternative to other energy sources and decreasing energy dependence (which should be combined with LCA to assess the sustainability of these processes, especially managing wastes to produce energy) [

53]. This way, green technologies are relevant in current geopolitical scenarios, as petrol-based industry is usually used as an economic weapon to penalize commercial agreements when there are political tensions between countries.

Concerning biogas, it presents significant differences with natural gas (whose compositions are relatively similar, with methane as the main compound to be upgraded in further processes). On the one hand, biogas is obtained in AD processes, from natural wastes such as SS or agricultural waste, considering biogas as a renewable energy. On the other hand, natural gas is obtained in geological processes that break down organic material. Consequently, biogas has some interesting advantages, such as the valorization of the abovementioned wastes and, if the suitable technology is used, the production of valuable energy vectors (such as hydrogen) that, along with the control of other by-products such as CO2 (through its capture or upgrading), could imply a promising energy source.

As previously explained, biogas reforming could be an interesting area of study for LCA, as it presents interesting challenges like the following (which will be thoroughly studied in further sections):

The characteristics of biogas play an important role in its reforming. Thorough LCA could consider biogas production through AD depending on the kind of waste considered. Consequently, studies from the origin can be carried out.

Energy consumption and its origin is equally relevant, improving or worsening the environmental performance of biogas reforming.

Depending on the kind of reforming process, some particularities can be present, such as water consumption in the case of biogas (or methane) steam reforming.

Apart from that, there are different factors that should be considered, like the use of catalysts, that could improve the catalytic performance of the process as well as it can present an additional environmental impact due to its production.

Thus, depending on the kind of process, the main environmental challenges could be the following: carbon dioxide emissions and their subsequent treatment; methane emissions and their reduction through higher efficiency; catalyst waste and its management; etc.

Accordingly, new studies about the environmental impact of biogas reforming have been conducted, some of them focused on LCA applied to specific processes where biogas (or methane, its majority compound) have been upgraded to hydrogen or syngas. In this sense, the role of different aspects in environmental performance have been covered, with special attention to the most determining pollutants (like CO2) but also considering the role of catalysts (from their production to their management after use, as well as the positive effect in biogas reforming. In this sense, LCA offers different approaches or possibilities in biogas production and its reforming, like the following:

Influence of different wastes and AD conditions on biogas production and their effect on reforming.

Comparison of different operating conditions during biogas reforming, including the use of various catalysts. Indeed, different technologies based on hydrogen production could be compared under these circumstances in order to select the most suitable process [

54].

Assessment of the positive effect of the implementation of technologies for pollutant upgrade or capture.

Recommendations for the improvement of the efficiency and environmental impact of biogas reforming, including the implementation of renewable energies for energy supply in the process.

Etc.

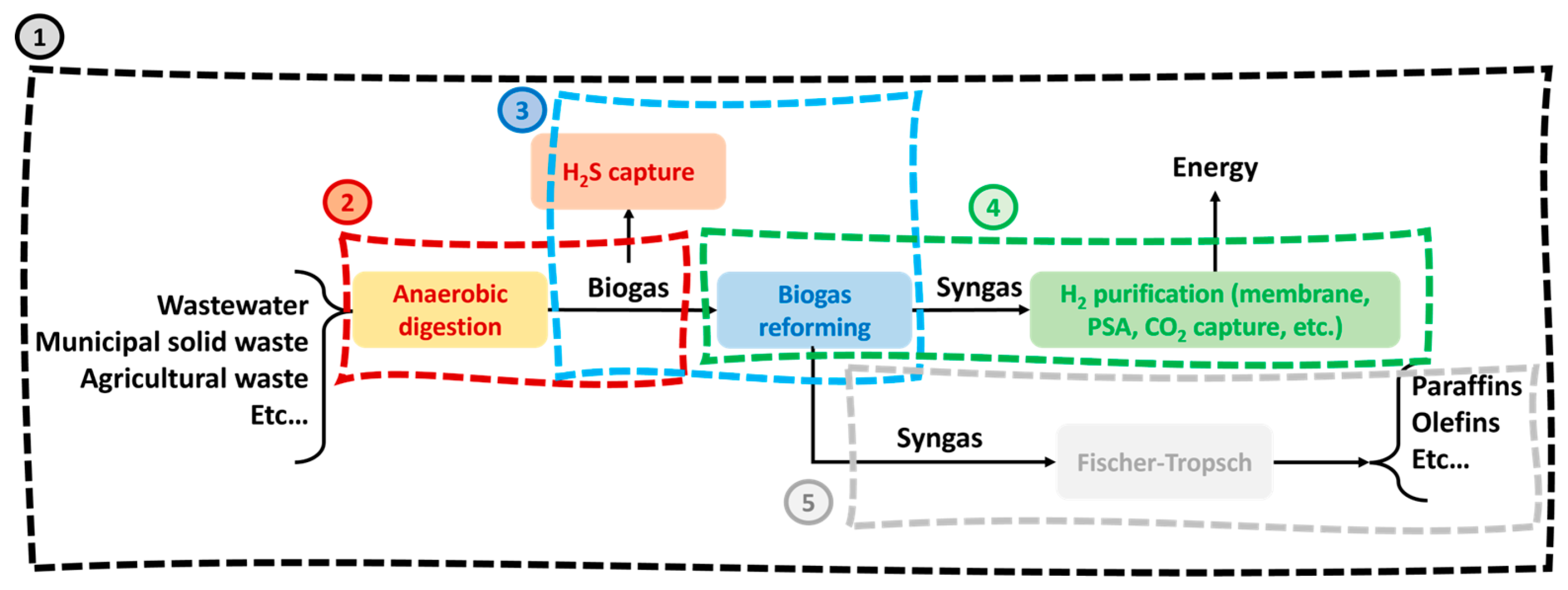

As previously explained, the boundaries of a LCA are essential to establish the objective for a certain evaluation of the environmental impact by using this tool. According to the main steps that could be implied in biogas reforming,

Figure 4 shows possible boundaries for LCA in this context:

Thus, according to this figure, it could be inferred the following:

It should be noted that boundaries should be perfectly established and sized if different technologies are compared. Thus, a global LCA can reflect a more realistic environmental impact compared to boundary 5, related to Fischer-Tropsch, where the context of syngas production is not covered. In any case, different technologies applied to Fischer-Tropsch could be compared by establishing the same boundary in all cases.

Different boundaries can be overlapped. For instance, boundaries 2 and 3 (AD and biogas reforming) can be combined if these steps are available for a LCA.

This way,

Figure 4 points out different boundaries, like Boundary 1, which includes all the aspects related to the possible use of biogas, apart from biogas reforming. Obviously, this one would be the most complex LCA, but also could be the most complete one to consider the global environmental impact of the process. Boundary 2 shows aspects related to anaerobic digestion, including the selection and pre-treatment of wastes, the possibility of co-digestion, and the possibility of biogas purification by removing H

2S, among others. Boundaries 3 and 4 cover biogas reforming from different perspectives, with the different possibilities explained in this work and product purification (normally biogas, a combination of hydrogen and carbon monoxide). Finally, Boundary 5 shows a possibility to upgrade biogas through Fischer-Tropsch to produce different waxes and biofuels.

As it will be explained in this work, the role of catalysts is present in most of the boundaries included in this figure. For example, catalysts are essential in biogas steam reforming and Fischer-Tropsch, with an influence in operating conditions (including energy consumption) or selectivity, whereas their durability and efficiency depend on many factors. In essence, these circumstances are normally included in LCA, both in general and specific terms. Thus, the implementation of a certain technology to improve the environmental impact of a process is normally related to the use of specific catalysts.

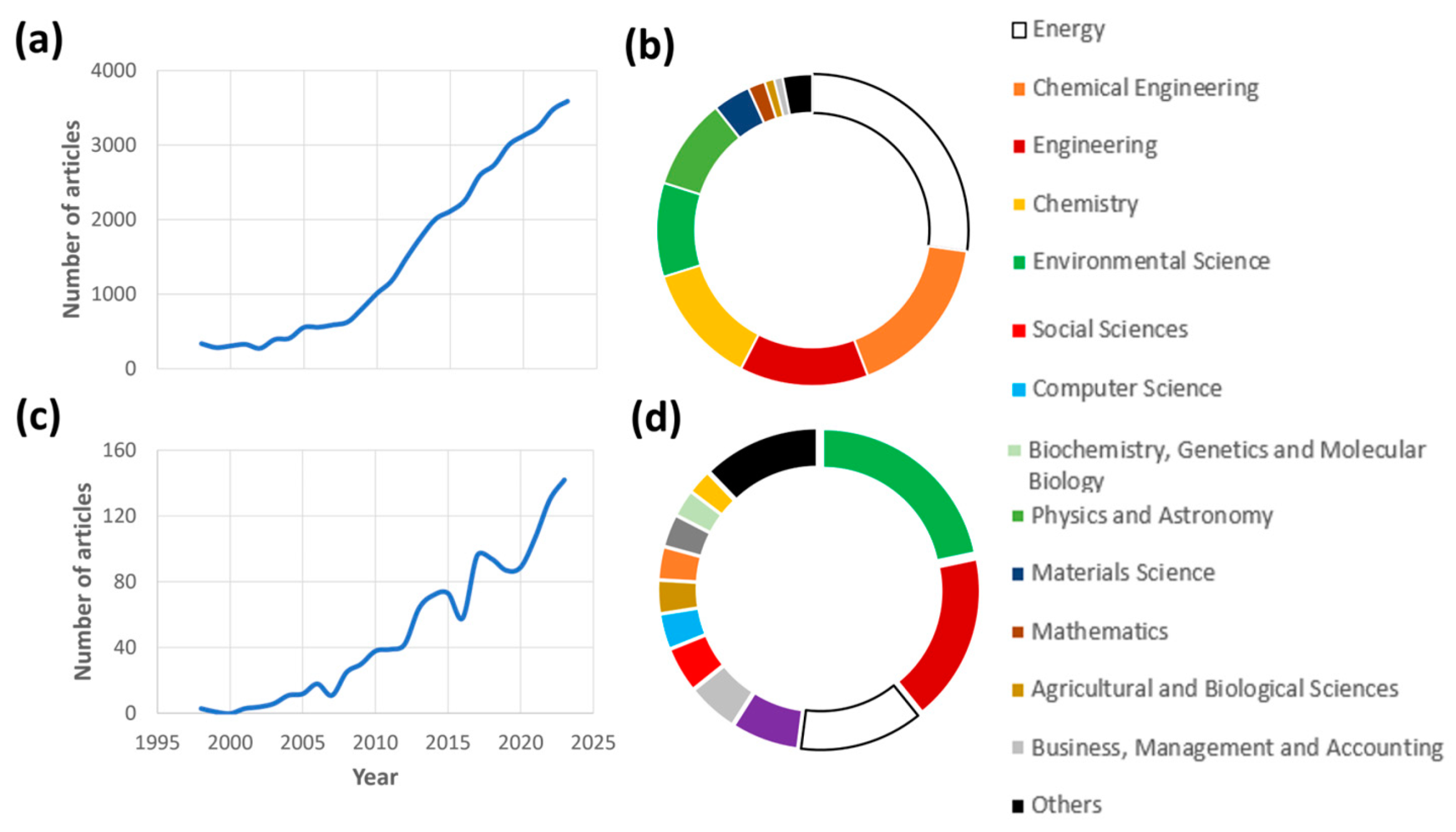

1.5. Scientific Interest

Considering the previous ideas, it is no wonder that the interest in environmental issues and sustainable development of industries translates in an increasing interest by the scientific community. Thus,

Figure 5 shows the evolution of the number of scientific papers over time about the subjects included in this review, and their distribution according to their main research field.

According to this figure, there was a continuous increase in research works related to LCA applications, especially from 2010, which proves the constant interest in this field. On the other hand, it presents a multidisciplinary profile, as these works are framed in several and different research areas like Environmental Science (22 %), Engineering (17 %) or Energy (13 %), among others. In other words, LCA is a tool that can be easily used by a wide range of scientists and technicians to assess the sustainability of multiple processes, as the study of the environmental impact of these processes can be easily adapted to each specific case, being useful for the industrial implementation of a mature technology. In this case, since LCA is a tool devoted to the assessment of environmental impact, it is no wonder that Environmental Science is the majority field where these works are published.

Regarding biogas reforming, the interest in this research line has considerably increased since 2005, equally presenting a considerable variety of fields interested, such as Energy (27 %), Chemical Engineering (17 %), Engineering (13 %), Chemistry (13 %) or Environmental Science (10 %). Also, the role of catalysts is represented in these subjects.

As observed, LCA and biogas reforming share some research areas, especially concerning Energy and Environmental Science, which predict a promising research line when both concepts are combined. An example of this interconnection could be CO2 and CH4 management. As explained in following sections, this could be a relevant point in LCA applied to biogas reforming, as these compounds present a high environmental impact, especially regarding greenhouse gas effect.

1.6. Aim of This Work

Considering the above, the aim of this review was to carry out a state-of-the-art analysis of works focused on LCA applied to biogas reforming, paying special attention to the most recent developments about the following research fields:

Findings about the application of LCA in biogas reforming in general.

The role of catalysts on LCA, considering their catalytic performance and influence on biogas reforming and taking into account their environmental impact during extraction, production, use and management once their useful life is over.

The influence of operating conditions or other factors related to biogas reforming on the performance of catalysts and, therefore, on their impact on LCA.

General outlook about the main advantages and challenges about catalytic biogas reforming.

1.7. Scope and Bibliometric Analysis

To carry out this review, Clarivate’s Web of Science (WoS) was investigated for all entries in the literature on the topics of life cycle assessment applied to biogas reforming (main entries: “life cycle assessment” and “biogas” and “reforming”; “life cycle assessment” and “biogas”; “biogas” and “reforming”) for the last 10 years (as the research interest in this field has considerably increased for 10 years), with special attention to the last 5-year period (2019-2024) to trace most recent research works about this subject. The search, which was made from January to June 2024, returned 3683 results, from which up to 209 articles were considered for their inclusion in this work, including information about 124 published works (mainly research works or proceeding papers) in this paper.

2. Biogas and Methane Reforming and Its Key Factors in LCA

Apart from the different environmental aspects related to biogas production through AD (which could be equally considered in LCA), and assuming that biogas composition presents high percentages of CH4 (which would make this process similar to methane reforming), different treatments to upgrade biogas can be found to produce H2 or syngas (H2 + CO), such as steam reforming or dry reforming, among others. Hereon, according to the majority content in CH4, the chemical routes explained for each biogas upgrade process will be simplified to methane reforming, using both terms (biogas and methane) interchangeably.

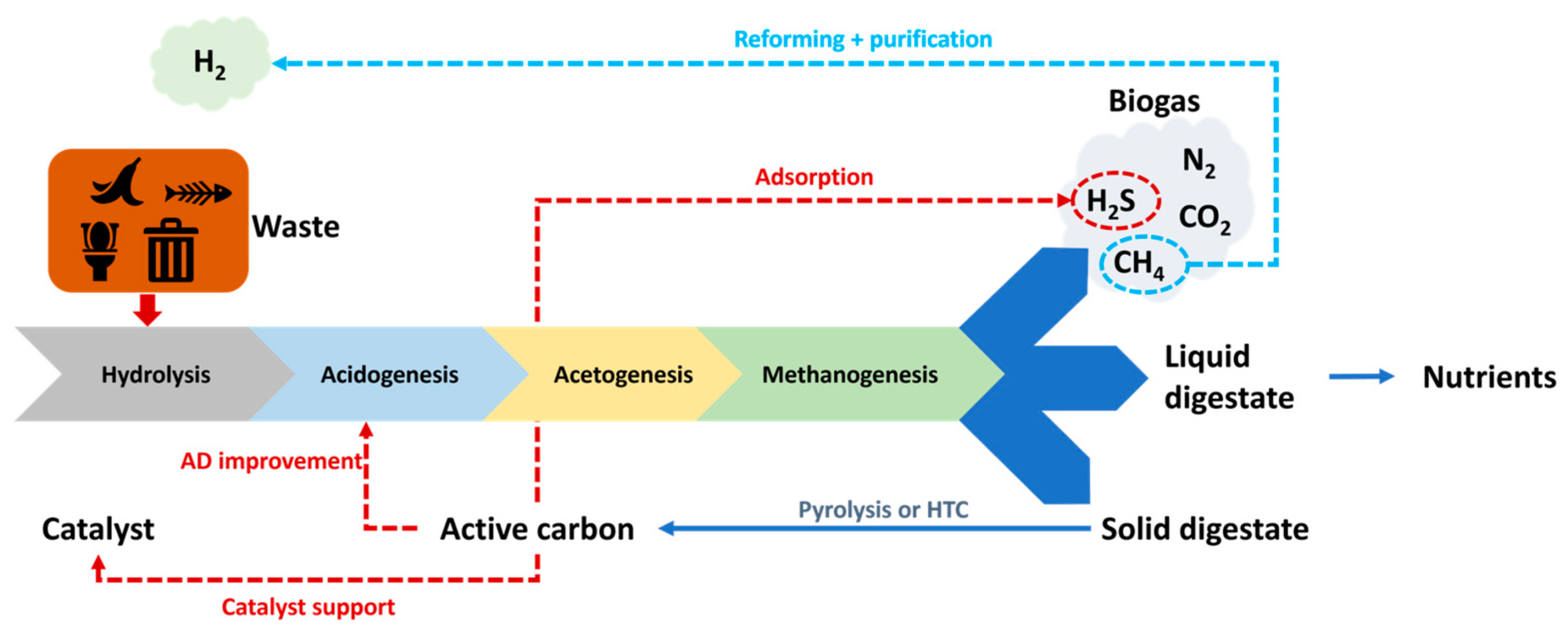

2.1. Anaerobic Digestion

Before explaining the main steps in different steam reforming processes, and following the philosophy of LCA (that is, “from cradle to grave”), biogas production through anaerobic digestion, as well as the main nature and composition of biogas, should be commented. Even though this work is devoted to the processes after biogas production, it should be noted that many factors related to biogas can present a considerable influence on its reforming and, especially, in its catalytic performance. According to

Table 3, there are many different raw materials that can be used to obtain biogas, such as municipal solid waste [

56], wastewater [

57,

58], food waste [

59,

60], animal manure [

61] or agricultural waste [

62], among others. This versatility of raw materials points out the relevance of anaerobic digestion for biogas production, with a positive impact on LCA because most wastes used in this process are valorized during their management.

Thus, AD is essentially a process where microorganisms convert organic matter into biogas (a mixture of CH

4 and CO

2, in general) under anaerobic conditions [

63]. Different efficiency rates (from 47 to 70%) can be obtained in this process depending on many factors, such as the method, pH or microorganisms selected [

60,

64]. Although there are some specific requirements regarding the kind of waste used in anaerobic digestion, some coincidences or general steps are usually present (see

Figure 6), like the following [

65]:

Hydrolysis. This is the first stage in AD, where organic matter and polymers (such as carbohydrates, lipids or proteins) are decomposed in mono and oligomers (such as glucose, glycerol or purines among others) by hydrolytic bacteria (through the action of extracellular enzymes).

Acidogenesis. In this stage, the abovementioned soluble monomers are converted by acidogenic bacteria to smaller organic compounds such as volatile acids, ketones or alcohols. In this step, the majority compounds obtained are acetate, CO2 and H2.

Acetogenesis. In this step, acetogenic bacteria convert the previous acidogenic compounds into hydrogen, CO2 and acetate, reducing the medium’s pH due to the increase in hydrogen ions, even jeopardizing the performance of acetogenic bacteria when pH is below 6, which depends on the nature of organic matter, load and environmental factors when acetic and propionic acids are produced.

Methanogenesis. This is the crucial step to obtain the highest amount of CH4 during the whole process. Thus, methane is obtained through the conversion of hydrogen and carbon dioxide by CO2-reducing and H2-oxidizing methanogens, whereas acetolactic methanogens use acetate to produce methane.

At this point, it is interesting to spotlight some aspects of LCA related to the role of catalysts in biogas production and its corresponding reforming, which are also included in

Figure 6:

First, and as explained in the following subsection in more detail, hydrogen sulfide is generated to a greater or lesser extent depending on the waste and AD conditions. The presence of traces of this compound can hinder catalytic biogas reforming, with the negative consequences in the global efficiency of the process (and, therefore, the corresponding negative LCA, as different pollutants such as methane or carbon dioxide can be released to the atmosphere in excess).

Secondly, different digestate phases, apart from biogas, are obtained [

66], which should be properly managed or reused to improve LCA at this point. Thus, liquid digestate is an interesting source of nutrients, whereas solid digestate can be transformed into active carbon through different methods like pyrolysis or hydrothermal carbonization (HTC). Thus, biochar could be an interesting way to offset CO

2 emissions, improving the carbon credits of the process [

23]. The upgrading of the latter offers different and interesting possibilities due to the versatility of pyrolysis and HTC to obtain products with different porosities (combined with different components such as agricultural waste) [

63], being used as adsorbents (which could be a determining solution for H

2S capture), catalyst support for certain processes where relatively low temperatures (below 600 °C) are achieved, or even as improver of AD process, due to the fact that these solids can serve as pollutant adsorbers in AD medium or as host for microorganisms.

Finally, biogas can be an important source of hydrogen if the suitable reforming process (along with the corresponding separation technique, like the use of PSA or membrane reactors) is used.

As a result, it is important the correct management of digestates and biogas to improve LCA in this stage. Additionally, as it happens in many aspects considered in biogas reforming when the philosophy “from cradle to grave” (the gist of every LCA) is considered, there are important details that will present a determining effect on catalytic biogas reforming and its LCA. Thus, as explained in further sections, the quality of biogas is essential to carry out sustainable processes, and the role of solid digestate seems to improve this fact by offering the possibility of increasing methane percentage in biogas (which is highly desirable) and reducing hydrogen sulfide content (which is mandatory for a suitable catalytic performance to avoid catalytic poisoning).

Another interesting aspect (regarding LCA) concerning the valorization of solid digestate would be the question about which method would be more adequate according to the kind of waste generated. Taking into account that solid digestate usually present high moisture, the use of pyrolysis would be undesirable, as it requires drying processes which usually implies high energy consumption (apart from the pyrolytic process). On the contrary, HTC, where water plays an important role, does not require this step (with mild reaction conditions) [

67], making this process interesting for a positive LCA.

Therefore, the perfect knowledge of all the process concerning biogas production is essential to understand and improve reforming conditions and the environmental impact of the process. This includes the perfect characterization of biogas, which will be covered in the following subsection. Additionally, in order to obtain a wide framework of the sustainability assessment of biogas systems, different information should be included such as environmental, geographic or socio-economic data, among others, to develop a complete and multi-criteria decision-making tool [

61].

2.2. Biogas Characteristics and Its Influence on Reforming

As a result of the above, biogas is produced, with around 50-75 % CH

4, 25-50 % CO

2 and lower amounts of N

2, H

2 and H

2S. This way, one of the great benefits of AD is the possibility to capture and use methane (one of the most problematic greenhouse gases), which can be the starting point for hydrogen production. Moreover, AD seems to be a very resourceful technology to valorize wastes with a difficult environmental management and continuous increase, like wastewater [

65,

68]. As explained in further sections, the efficiency of AD is vital to understand the catalytic performance of different biogas reforming processes, which will have a great influence on LCA. In short, the following conditions would be desirable from both points of view:

Higher CH4 composition. Considering that this is the most important component in biogas to obtain hydrogen, the ideal situation would be a methane composition near 100 %, to avoid the presence of impurities that should be separated or treated in different ways according to their nature and possibilities. However, in further reforming processes, the conversion of methane should be as high as possible to avoid its release to the atmosphere, as it is a greenhouse gas that would penalize LCA of biogas reforming (specifically) and the corresponding waste management through biogas production and hydrogen production (in general).

Lower CO2 composition. Even though CO2 takes part in some reaction routes to obtain H2 from CH4, as explained in further sections, it should be noted that it is one of the typical by-products generated in methane reforming, which should be separated from final hydrogen with additional separation or capture techniques. This is one of the most representative greenhouse gases, avoiding its release to the atmosphere as much as possible.

Lower N2 composition. As explained in the case of methane, CH4 purity is desirable, and nitrogen does not take part in any reforming reaction. Therefore, its minimization in favor of CH4, when possible, is recommended.

Zero H2S composition. The presence of hydrogen sulfide is undesired due to the negative effect at different levels. First, it causes health problems even at low concentrations (ppm); second, it can cause corrosion in facilities; and finally, it provokes poisoning in many typical catalysts (especially Ni-based ones), with the negative consequences related to a poor methane conversion (with methane release to the atmosphere).

It should be noted that some wastes derived from this process, such as sewage sludge, can be valorized and reused in the system. For instance, hydrothermal carbonization could be an interesting process to obtain hydrochar, which could be inserted in AD to host specific microorganisms taking part in the abovementioned steps, as well as assuring a suitable growing medium through pollutant capture [

68]. Consequently, the impact in LCA would be lower, avoiding the release of a waste with a difficult management.

Concerning biogas composition found in the literature, as observed in

Table 3, due to the heterogeneous composition of raw materials used for biogas production through anaerobic digestion, a wide range of biogas composition can be found, especially concerning key factors such as methane composition (from 18 to 75 %) and hydrogen sulfide (from nearly 0 to around 4000 ppm). Even for a certain kind of raw material where biogas is obtained, the composition ranges might vary considerably. As a consequence, this initial information is essential to determine further treatment of biogas (purification and upgrading, mainly), with the subsequent changes in LCA according to these changes, which can introduce new processes to be considered in the corresponding assessment. Moreover, considering the heterogeneity of biogas composition depending on pre-anaerobic digestion conditions (for instance, the presence of certain amino acids like methionine or cysteine in agricultural waste or sewage sludge), reforming systems or at least some components such as H

2S traps should be well dimensioned, considering the worst-case scenario possible.

Considering a biogas suitable for its reforming, that is, with a high CH

4 percentage and low levels of H

2S, there are several processes to produce hydrogen, with the most representative ones being briefly explained in further subsections: steam reforming, dry reforming and tri-reforming. It should be noted that, apart from biogas composition, every technology applied to its reforming will determine LCA, with some parameters that will be adjusted by using catalysts and, at the same time, will influence the service life and catalytic performance of these heterogeneous catalysts. That is the reason why the main inlets and outlets for each process should be, at least briefly, explained (see

Figure 7 for a general overview in the case of biogas reforming). In addition, particularities and parts in common will be explained.

2.3. Biogas Steam Reforming

Concerning biogas or methane steam reforming (see Equation (2)), it is an endothermic reaction that takes place at high temperatures, between 700 and 950 °C and pressure values between 5 and 20 bar.

CO

2 in biogas takes part in a second reaction, as observed in Equation (3).

The simultaneous methane conversion through these chemical routes can lead to biogas bi-reforming or simply biogas steam reforming [

44]. Additionally, the water–gas shift reaction (WGS), as observed in Equation (4), can take place. Both reactions contribute to a higher yield towards hydrogen production and, consequently, higher hydrogen concentrations as a product.

The combination of Equations (2) and (4) gives, as a result, Equation (5):

There are different challenges in biogas or methane reforming that need to be overcome, which usually represent a problem regarding LCA, as these problems are highly related to efficiency, maintenance, durability and by-product management, among others. According to the abovementioned equations, the main products obtained in methane steam reforming are H2, CO2 (also included in biogas, if biogas steam reforming is carried out), CO and unreacted CH4 and H2O. In these cases, different factors should be considered to optimize LCA applied to biogas steam reforming, like the following:

High conversions are desired to decrease unreacted CH4, which would be released to the atmosphere or should be reintroduced in the system through separation technologies.

S/C ratio optimization is essential to avoid extra energy costs and water consumption. On the other hand, low S/C ratios could promote coke deposition, with the subsequent deactivation of the catalysts and decrease in efficiency of facilities, as explained in following sections.

CO2 management is required, mainly through capture or conversion.

Selectivity towards hydrogen production is recommended, to avoid or reduce the amount of the rest of undesired products, which could imply separation stages with their corresponding environmental assessment.

Nevertheless, many of these concerns can be mitigated thanks to the use of catalysts, as explained in further sections with specific examples or the application of LCA to biogas reforming. With this regard, high conversions of methane are achieved by using different catalysts, increasing its conversion above 95 % in many cases [

77,

78]. On the other hand, steam to carbon optimization is important to increase the useful life of a catalyst, especially concerning coke deposition, reducing their environmental impact and increasing their life cycle. Regarding carbon dioxide capture or conversion, there are some catalytic processes where CO

2 can be valorized thanks to the use of catalysts. Finally, different catalysts have been proven as a suitable way to improve the selectivity towards desired products (in this case, hydrogen), consequently decreasing the amount of undesired products released to the environment [

79,

80,

81].

2.4. Biogas Dry Reforming

The main difference, compared to SR, is the absence of steam during methane decomposition, as shown in Equation (6):

As observed, methane and carbon dioxide included in biogas composition react to obtain syngas with different CO/H

2 ratios, which could be an interesting point to obtain pure hydrogen through membrane separation or the starting points for further processes such as Fischer-Tropsch synthesis [

82]. On the other hand, lower conversions of methane (below 90 %) are obtained, with the subsequent release of unreacted CH

4 and CO

2 (whose conversion in this process is higher, up to 95 %) if further treatments are not carried out. Therefore, LCA would present this negative aspect in these cases.

Obviously, the environmental impact related to water consumption, as well as the energy required to vaporize water to provide a constant steam flow, is omitted in this case, which would simplify LCA. Thus, this reaction normally takes place at lower temperatures compared to steam reforming (from 700 to 800 °C) [

73], which could favor a positive LCA. However, this initial advantage compared to the previous reforming process could be neutralized by different factors such as a decrease in efficiency. Also, the absence of steam could favor coke deposition or Boudouard reaction, as observed in Equation (7):

The details about the decrease in catalytic performance due to coke deposition (along with other factors) will be discussed in further sections.

2.5. Biogas Tri-Reforming

In this process, the reaction of the combination of steam and oxygen with biogas takes place. Thus, some reactions (like the ones described in Equations 2 and 6) are involved, as well as catalytic partial oxidation and reverse water-gas shift (see Equations 8 and 9) [

77,

83]:

Equally, as in the case of the previous reforming processes, coke deposition can take place, according to Boudouard reaction (Equation 7) as well as methane decomposition (Equation 10) and carbon monoxide reduction (Equation 11):

It should be noted that these reactions contribute to the decrease in activity of catalysts, with the subsequent decrease in its service life (and the negative impact in LCA). As observed, this method presents, from an LCA perspective, challenges shared with the previous reforming processes, which will be discussed in the following subsection. Basically, the knowledge of these particularities will be essential to understand and apply suitable technical solutions to improve LCA, with many of them having to do with catalysts.

To sum up,

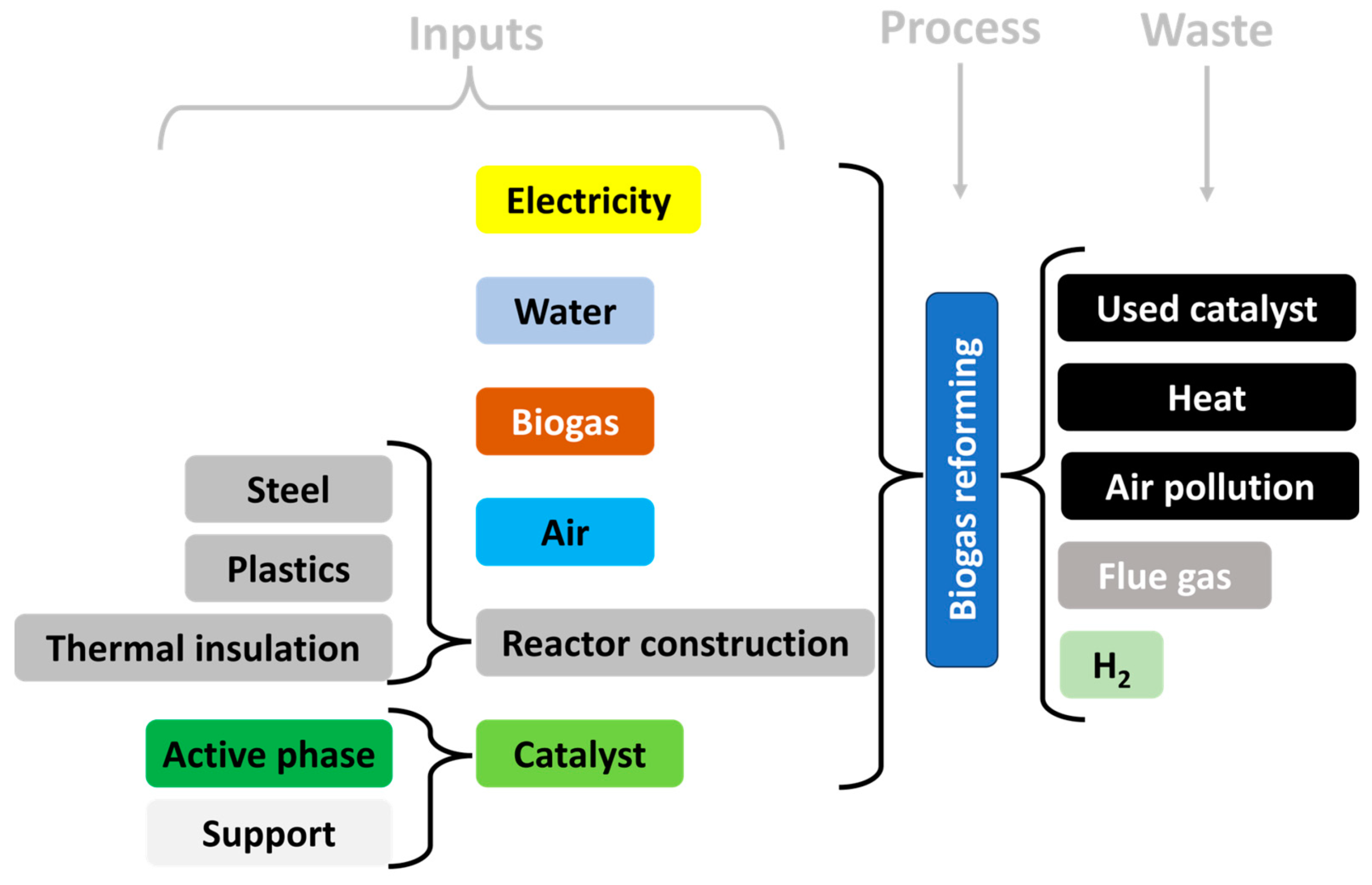

Figure 7 shows, for this specific boundary, the main inputs and wastes generated during biogas reforming in general. As explained in the following subsection, there are some challenges related to LCA applied to this technology, many of them having to do with the use of catalysts. In this sense, there are different aspects related to the environmental impact of the process that should be controlled or assessed, like the electricity consumed for the production of a certain FU, the amount of water required (especially in SR, where steam is required), the quality of biogas, the use of air, the construction of the facilities (including the reactor construction, where different materials such as steel, plastics or compounds to carry out thermal insulation are required), and catalyst production (with the two main components playing an important role, that is, the active phase and the support, along with the corresponding synthesis method). On the other hand, waste generation, including the catalysts, heat generated and pollutants that are evolved to the atmosphere, should be taken into account in LCA.

As in the case of other hydrogen production pathways, there are different aspects that can be covered in a LCA based on biogas reforming, like ecotoxicity, land use, water use, energy resources, ozone depletion or global warming potential (GWP), among others [

84]. The main challenges related to LCA in this context are highly related to the impact in these categories, as explained in the following subsection.

2.6. Main Challenges in LCA Applied to Biogas Reforming

To sum up, and according to the previous subsections, the main challenges regarding LCA applied to biogas reforming are the following:

Characteristics of biogas. As previously mentioned, the ideal composition of a certain biogas should include high concentrations of CH4 and, especially, the absence of H2S to avoid catalytic poisoning and the subsequent decrease in CH4 conversion to H2. As explained in following sections, the upgrading of biogas could imply further steps that should be equally taken into account in LCA, with a positive or negative response depending on the benefits or problems added to the system.

Kind of reforming/operating conditions. As previously explained, and depending on the kind of biogas reforming selected, positive and negative contributions to key aspects of LCA can be obtained. For instance, steam reforming presents higher coke resistance (with longer catalyst’s service life), whereas its vapor consumption (with the subsequent energy cost) is increased. On the contrary, dry reforming seems to be more energy intensive, but the removal of CO

2 is not required, with the positive impact in LCA of biogas reforming. On the other hand, different operating conditions (such as S/C ratio, pressure or temperature), as explained in further sections, can determine different factors such as coke deposition or hydrogen selectivity, which will determine LCA [

15].

GHG emissions. Depending on the process, variable amounts of CH

4 and CO

2, the two main GHG involved in this process (and two of the most polluting GHGs [

22,

85]), are released to the environment due to different factors. On the one hand, high methane conversions are desired, whereas carbon dioxide capture/management is usually required after biogas reforming to improve the atom economy of the process. In any case, the reduction of these concentrations is essential to obtain a positive LCA.

Water consumption. In the case of SR of biogas, water consumption should be considered in LCA, achieving the optimum S/C ratio for this process in order to avoid excess energy use (when there is excessive steam) or low efficiency due to coke deposition (when S/C ratio is not enough to avoid this phenomenon).

Energy consumption. As in every LCA, energy footprint is essential to positively assess a specific process. Thus, excess energy consumption would penalize biogas reforming due to different factors, especially focused on high temperature of the process (which can range from 750 to 900 °C) and steam generation. Also, further steps to separate different gases obtained after biogas reforming (such as PSA) or to upgrade the resulting gas (such as FT) usually imply an increase in energy costs.

Efficiency of the process. Because of the previous point, efficiency of the process is fundamental to obtain a positive LCA. Thus, a high efficiency implies lower consumption of biogas, water or energy per FU, with the subsequent positive impact in the environment. As explained in the following point, the role of catalysts is important to improve the efficiency in catalytic reforming of methane or biogas.

Equipment wear. Due to different factors, some components of the facility, such as reactors, resistances or heat insulation, among others, could be deteriorated over the useful life of the equipment. As a result, certain operating conditions usually become more difficult to keep, like set temperature in reforming reactor. This fact results in an increase in energy consumption due to heat loss (among other factors) or even the replacement of certain components, with the negative impact in LCA. In general, it is assumed that the efficiency of a process decreases at a certain annual percentage rate, with further decrease due to the use of extreme operating conditions (high temperatures, pressure, biogas with a certain quantity of H2S which could promote corrosion, etc.). Additionally, this wear provokes the replacement of these components in shorter periods of time, with the subsequent negative impact in LCA. Mild reaction conditions due to catalysts could partially alleviate this inconvenient.

Catalyst production and use. The use of catalytic routes in biogas reforming has a strong influence on many different aspects, such as an improvement of its efficiency and the subsequent use of milder reaction conditions, which usually reduces energy and reagent consumption. In turn, methane conversion is improved, with the subsequent decrease in CH4 emissions to the atmosphere. Regarding CO2, its concentration would be increased, requiring the use of technologies to capture this GHG. Accordingly, the direct use of catalysts presents a positive contribution to LCA, considering other factors such as their production to obtain a global assessment of the process.

Hydrogen leaks or emissions to the atmosphere. Even though it is assumed that hydrogen production technology, compared to fossil fuel technologies, can present a clear advantage with lower environmental impacts, it should be considered the fact that the permeability of hydrogen is extremely high, which involves losses in hydrogen production systems. In this sense, quantification of hydrogen leak is important to completely assess the benefits of LCA, specifically in biogas reforming systems. Thus, considerable emissions of hydrogen to the atmosphere could provoke its reaction with tropospheric hydroxyl radicals, with the subsequent inefficiency in oxidation of anthropogenic hydrocarbons like methane. With this regard, depending on the control of permeability and efficiency process where hydrogen is used to obtain energy, these technologies can present positive or negative LCA compared to traditional ones [

86].

In this sense, the role of catalysts in LCA is relevant, which should be considered in every LCA applied to biogas reforming from different points of view, as explained in the following section in more detail.

3. Influence of Catalysts on Biogas Reforming in General and LCA in Particular

The role of catalysts in many processes (at laboratory or industrial scale) is essential, as it allows the completion of a certain chemical reaction at milder reaction conditions, with the subsequent benefits related to energy or time savings, among others. In any case, as previous studies about different processes have pointed out, the role of catalysts in LCA is considerable, paying special attention to different inventory items such as catalyst preparation and reuse, where the main components to produce the catalyst should be included, as observed in the case of biodiesel production from

Prunus Armeniaca seeds, where SrO-La

2O

3 catalyst was used [

87] or the comparison between a metal and a biochar-based catalyst for biomass gasification, where there were clear and positive differences for the latter, with 93 % decrease in GHG emissions, requiring around 96 % less energy [

88].

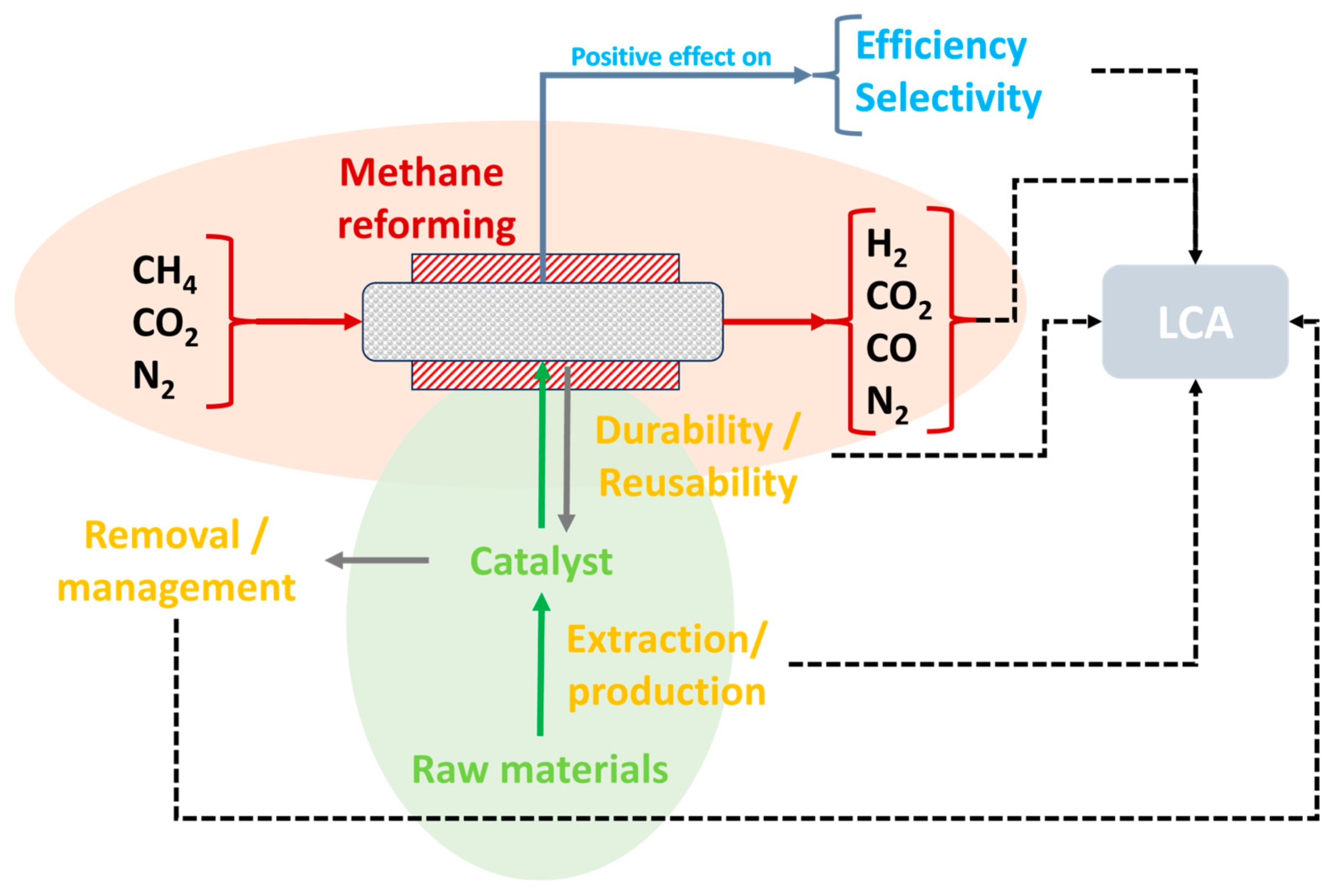

Concerning biogas reforming, there are works where the direct and specific impact of catalysts is clearly explained, showing a positive impact during catalytic performance for hydrogen production from methane through steam reforming, for instance. Thus,

Figure 8 shows the influence of catalysts on LCA steam reforming.

In general, there is a pattern that is relatively shared by many processes, with the main advantages of the use of catalysts, that can be perfectly applied to biogas reforming, like the following:

Increase in yield/performance. In general, hydrogen production is the aim of biogas reforming. Thus, an increase in the yield in hydrogen production and a high percentage of methane conversion is a key point to avoid the presence of byproducts in the final gas. Therefore, to obtain high-purity hydrogen, apart from the fact that further technology (like membrane reactors) is required, the absence of by-products or non-reacted methane is desirable to reduce the environmental impact or their further management.

Use of milder reaction conditions, to avoid the continuous wear and tear in equipment due to extreme operating conditions such as high temperature and pressure. It is well known that the use of catalysts in reforming can considerably reduce the operating temperature and pressure. Thus, even a decrease in 100 °C or 1-2 bar can imply a considerable extension of the useful life of reforming facilities, with the subsequent maintenance of efficiency to keep specific operating conditions. This fact is not only interesting, from a LCA point of view, on account of a lower contribution to environmental impacts due to the fabrication of different components. Also, a higher efficiency to keep operating conditions imply a global lower energy consumption to produce a certain FU in biogas reforming.

Higher selectivity towards hydrogen production. As in the previous case, the production of the desired products is a required situation, avoiding the generation of by-products that should be purified with the subsequent addition of further steps that can present their own environmental impact (related to production, performance and management after use, for instance).

Ability to adapt other processes for waste/bioproduct management. This is a key point on account of the fact that it could allow the valorization of undesired compounds, with the subsequent environmental impact reduction. For instance, if syngas is obtained, catalysts used for Fischer-Tropsch could be useful to adapt this technology to CO valorization with the subsequent environmental benefits [

89].

In a sense, these advantages normally imply a positive answer in LCA, as lower amounts of wastes with difficult management are obtained, increasing efficiency and reducing energy costs (and the subsequent CO2 emissions related to energy consumption).

However, the requirement of catalyst production or purification techniques contributes to the complexity of LCA, not necessarily implying that the use of catalysts reduces the environmental impact of the process. There are catalysts based on different active phases (mainly metals such as Ni, Co, Cu, La, etc.), many of them obtained through calcination from their corresponding salts, like nitrates, which could determine a negative environmental impact on their production. Also, the catalyst support could play an important role, even their shape, porosity, etc., which could vary the environmental impact per production unit [

90,

91]. Regarding one of the most recurring catalysts, that is, Ni-based catalysts, their synthesis processes have been thoroughly covered in previous studies, including impregnation, precipitation or co-precipitation, among others (see

Table 4). In this context, there are different points to consider, like the high environmental impact associated with energy consumption or the possible use of palladium (II) chloride to synthesize Ni-Pd/Al

2O

3 catalysts, which is the most dominant environmental impact in this case [

92]. Consequently, the typical beneficial effect of bimetallic catalysts should be considered along with these eventualities during their synthesis.

Equally, there are other novel processes such as microemulsion (where oil-water routes are mainly followed), with promising results but only applied to tri-reforming and dry-reforming, requiring further research. In any case, most of the abovementioned synthesis methods have some relevant and common points regarding LCA:

Depending on the kind of preparation technique, dispersion of the active phase is important to determine the resistance of the catalyst to deactivation processes (explained in further sections) and its effectiveness during reforming, with the subsequent influence on the release of non-desired products to the environment.

The possibility of combination of the original active phase with promoter addition to improve some characteristics of the final catalyst.

The use of calcination processes at high temperatures (from 500 to 800 °C, normally), with the subsequent energy consumption for a variable range of time (between 2 or 3 to up to 5 or 6, in most cases).

The products obtained in these processes (normally metal oxides) imply the generation of some problematic compounds that could be evolved to the atmosphere, such as NOx, with the corresponding negative environmental impact.

Finally, many of these catalysts require an activation process, usually through heterogeneous reactions with gas like H2, at high temperatures (500-700 °C.

This way, these factors should be equally considered in LCA, not only due to the direct environmental impact of the production process, but also on account of the characteristics of the methods selected, which will determine the quality of the catalysts, especially regarding particle dispersion through the support. As explained in following sections, these factors have a strong influence on catalyst durability and reusability, which in turn is highly related to the positive LCA when the catalyst can be reused during longer periods of time.

In this sense, the use of Nickel-based catalysts is common for different reforming processes, mainly due to its low price, searching for alternatives such as the use of noble metals such as Rh, Pt, Pd or Ru in order to improve some properties of synthetic catalysts, such as resistance to sintering or coke deposition [

95,

97].

Another factor to be considered is the possibility of reactivation or reutilization of catalysts, or its management after use. In this sense, it should be noted that these steps would be another aspect to be considered in LCA, assessing their suitability according to energy required and emissions generated.

In the case of the synthesis of catalysts, the role of the support is essential (see

Table 5 for some examples), whose interaction with the active phase and the acidic/basic nature will be important to understand the durability of a specific catalyst. Moreover, the scarcity of some supports, apart from the different production system (including the shape of the final catalyst in spherical or rings, which will determine the bulk density of the final catalysts) are factors that should be considered in LCA.

However, the environmental impact for their extraction/production should be taken into account in LCA. For instance, in the case of alumina, there are studies about LCA applied to its production through several methods (like Bayer process and others, such as smelting reduction, reduction roasting, sub-molten salt, or acid leaching, among others), obtaining that the red mud generated in the alumina-industry process is a real challenge, requiring environmental processes and changes in the existing technical framework (including low consumption) [

101,

102].

Regarding the use of bi or trimetallic catalysts, along with the addition of promoters,

Table 6 shows the main active phases for biogas reforming. In this sense, the use of these combinations could be interesting in order to obtain high-durability catalysts, reducing the effect of different adverse effects such as coke deposition, sintering or poisoning.

This way, the use of nickel along with different promoters or metallic active phases present a positive effect on the catalytic performance of the corresponding reforming process, whereas their extraction methods (which can be difficult depending on the nature of the element, as in the case of rare earth production) include processes such as mining, grinding, flotation, solvent extraction, crushing, magnetic separation, precipitation or electrolysis (among others) [

104]. Consequently, these processes have an impact in land use or pollution, as well as the corresponding impact due to the consumption of multiple resources, like large quantities of chemicals [

105], depending on the kind of metal or mineral that is extracted [

106]. In the case of nickel products, the most relevant stage (demanding considerable energy) is the primary extraction and refining, with the highest global warming potential [

107].

On the other hand, the use of catalysts has a positive effect in the reforming process. Specifically, many components of reforming facilities can extend their service life thanks to the use of milder reaction conditions. For instance, the use of purification techniques like the use of membrane reactors or pressure swing adsorption could present different impacts, as the former use specific materials for the membrane preparation (such as gold) and the second could contribute to the higher energy consumption of the process. Thus, the role of catalysts, fostering the useful life of membranes or reducing the cycles to separate product gas could be positive in that sense [

108,

109].

In other words, the positive effect of catalysts in a certain process (with the subsequent positive effect on LCA of this specific process) should be differentiated from its contribution to LCA, where different factors such as catalyst preparation, durability, reusability and management after use should be taken into account. Therefore, for the implementation of a sustainable process like biogas reforming, concerning the use of catalysts, the industrial design should strike a balance between the positive contribution of the use of catalysts to the process and the environmental impact of catalyst production, use and management by itself.

The main challenges of catalytic performance during biogas reforming, according to typical catalysts such as nickel-based ones, have a strong connection to LCA, as these factors could contribute to penalize a positive assessment of the global process. This way, their relationships with LCA are the following [

68,

110]:

Sintering: Due to the use of high temperatures (which equally implies higher energy consumption, with the subsequent negative effect in LCA), the active phase of the catalysts that is homogeneously distributed on support’s surface can be reunited in bigger clusters or particles, with the subsequent blockage of pores or the decrease in active surface for biogas reforming. As a consequence, the useful life of the catalyst might be considerably reduced, increasing the effects related to their production per unit of mass on LCA [

111].

Poisoning: The presence of H

2S, apart from the obvious health effects and corrosion in industrial facilities, can provoke the deactivation of the catalyst through poisoning, with the subsequent inefficiency of the catalyst and its continuous replacement, which would multiply the negative impact on LCA per unit of amount of catalyst [

112].

Coke deposition: The continuous conversion of methane implies the adsorption and desorption on the catalytic surface, which implies the accumulation of coke that can block pores [

113]. Therefore, the activity of the catalyst decrease, with the same effects commented in the case of sintering and poisoning.

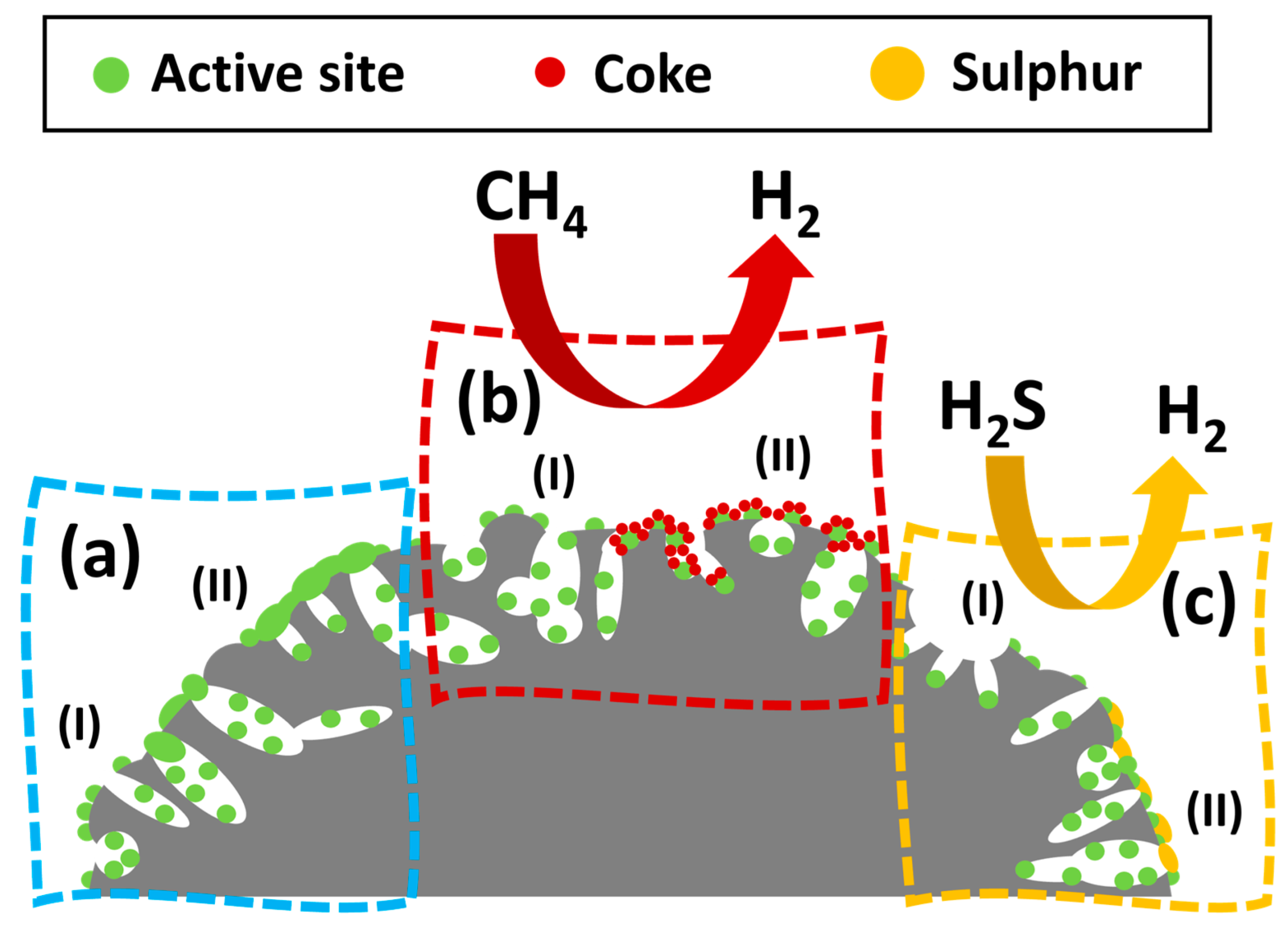

These factors can be observed in

Figure 9:

As observed in

Figure 9a for the case of sintering (at high temperatures), active sites interact with each other to obtain bigger particles that can block pores with available active sites, whereas these bigger particles present lower surface area compared to the previous state, with the subsequent decrease in available active sites. Regarding coke deposition (

Figure 9b), carbon on active sites block them, as well as many pores with available active sites. Finally, in

Figure 9c, it can be noted the blockage of active sites and pores through the permanent interaction of sulphur with active phase. These events usually imply the same consequences: lower catalytic efficiency and durability, increasing the environmental impact in two main aspects: release of unreacted methane and further environmental impact of catalyst production and management after its use.

In this sense, a key point for the suitability according to LCA of a certain catalyst for this process is its durability and reusability, which could considerably decrease the environmental impact (per unit of production) of its production, exploitation and management after its use. Another interesting factor could be the use of active phase, which should be as reduced as possible in the final catalyst. Nevertheless, some measures can be taken to increase the useful life of a catalyst, like the following:

Pre-treatments to remove H

2S from the original biogas (through adsorption, absorption, etc.) [

112,

114]. As previously explained, the own AD process to produce biogas might offer an interesting solution to this challenge, as solid digestate can generate adsorbents (that is, active carbons through pyrolysis or HTC) that can act traps in H

2S capture units. In this sense, a double solution is offered: first, a waste with difficult environmental management is valorized; second, this valuable product is used in the same system to avoid a poor catalytic performance, improving different LCA parameters. In addition, different H

2S valorization technologies could be used in this context, such as thermocatalytic decomposition or H

2S methane reformation, which could solve the abovementioned problem [

115].

Use of modifiers or promoters to improve the performance and durability of traditional catalysts (for instance, La or Mg addition), as previously commented [

90,

111,

116].

Selection of optimum conditions. When possible, the use of low temperatures to avoid or slow down sintering (trying to select temperatures below ½ or 1/3 of the melting point of the metal taking part in the active phase, when the process makes it possible), as well as a good S/C ratio in the case of steam reforming of biogas (normally above 2.5-3.0) to reduce the negative effect of coke deposition on efficiency decrease.

Implementation of purification techniques that allow an increase in hydrogen production yield, such as the use of membrane reactors, that would allow the decrease in temperature (avoiding some problems such as sintering) [

108,

117]. Also, these purification techniques usually allow the capture of problematic pollutants such as CO

2, offering a double positive effect in LCA. In this sense, the use of different compounds such as Mg-based or Ca-based sorbents could be an alternative [

118].

Possibility of regeneration of spent catalyst. Depending on the deactivation processes previously commented and observed in

Figure 9, the possibility of regeneration of catalysts, once they are deactivated, will depend on the reversible nature of the deactivation process. This way, catalysts affected by sintering processes seem to be difficult to regenerate, whereas regeneration due to coke deposition seems feasible, especially using heat treatment and oxidation with air, CO

2, O

2 or steam, among others [

82]. Again, it is a matter of assessing if this regeneration process, where energy costs and gaseous compounds are required, offset the removal and posttreatment of spent catalysts.

This way, factors such as durability, reusability or efficiency would be improved in the case of catalytic performance. However, the contribution of these upgrades to LCA should be also considered, only accepting those steps that clearly improve the overall assessment.

In this section, the main aspects related to catalytic biogas reforming have been covered, but it should be recalled that there are other steps included in the abovementioned boundaries included in

Figure 4 that can also contribute to the improvement of global LCA related to biogas reforming. This way, some transition metals such as cobalt, iron, nickel and ruthenium could be interesting alternatives for a Fischer-Tropsch synthesis if syngas obtained in biogas reforming is not separated to obtain pure hydrogen [

119]. Thus, different fractions of biofuels (like Diesel Fraction) could be obtained [

120], enhancing the syngas obtained during biogas reforming and, subsequently, improving LCA of the whole process. That is the reason why the interconnection of different technologies is important to obtain synergistic and positive effects in LCA, as well as a global point of view to assess the real environmental impact of a certain technology. Otherwise, a certain process could present negative LCA by observing a very limiting boundary, preventing from a sustainable and feasible alternative by combining pre-existing technologies, some of them with a relatively technological maturity.