1. Introduction

Forests represent a public good, with multiple benefits for society, be they economic, ecological or even social [

1,

2]. At the Romania’s level, forests occupy a significant area of approximately 6.9 million hectares [

3], being mostly located in the mountain regions [

4]. The great geomorphologic and climatic diversity of the country’s territories leads to a wide variety of compositions in terms of tree species from forests. All of these involve different management works, as best suited to the various types of forests that, in Romania, have either protection or production functions, or protection and production functions [

3,

5].

Since the superior utilization of all forest products [

6,

7] contributes to Romania’s GDP by approximately 4% [

3], the designing and construction of forest roads is imperative [

4,

5], especially since the long-term storage of wood in improper conditions leads to its downgrading and quality reduction [

8,

9,

10,

11], with financial losses. Unfortunately, the accessibility of the national forest fund is below the optimal level [

3,

4,

12,

13,

14], so the Romanian forests are accessible in proportion to 65% [

4,

5,

15], which leads to a density index far below the level of other countries with similar terrain and relief [

5], at large distances to logging [

4] and repercussions on the final cost of the wood [

6,

14,

16,

17].

Even though, over the time the means of transport have varied a lot [

18,

19], currently the transport of forest products being carried out almost entirely on forest roads (over 90% [

5,

12,

20]), a similar situation being encountered in Finland [

9,

21,

22]. The use of forest roads as the main transport routes is due to several factors [

12,

13,

23,

24,

25]. Thus, forest roads penetrate deeper into the forest [

26], which leads to a more uniform opening of the forest stands [

5,

10]. In addition, forest roads can accommodate a wide range of transport vehicles, safely and at steeper gradients than railways [

26,

27]. On the other hand, the forest roads network can ensure access to the forest both for all those involved in forest management [

5,

18,

29], as well as for those who need to reach some isolated areas, either because they live there [

30], whether they have to carry out their professional activities there or they just want to escape from the daily tumult [

1]. In addition, forest roads can also provide transportation needs for other sectors of the economy [

1,

18].

To fulfill all these functions, forest roads must be designed and built to withstand the traffic of various means of transport [

4,

28], in safety and comfort conditions [

1,

10,

14,

18], especially since the length and distribution of the transport network, its structure and condition can directly influence the activity of forest transport, especially the transport of wood [

31,

32], it being known that the biggest impact on wood costs is given by transport [

10,

11,

16,

17,

24,

33].

Wood, as the main product of the forest [

24], must be brought from the forest to various beneficiaries [

1,

3,

16,

29,

34] with the help of different vehicles [

10,

26,

35,

36], which differ a lot, with different brands and models on the market [

12,

16,

24,

27]. The choice of a certain type of vehicle depends on a number of factors related to: the nature of the work performed in the forest [

20,

33]; the types of wood that have to be transported [

6,

10,

11,

12,

20]; the category of the road used and the transport distances from the forest to the beneficiaries [

9,

24,

32]; the constructive characteristics of vehicles and their loading capacity [

10,

20,

22,

26], as well as the distribution of loadings on axles [

12,

17,

28,

31,

35].

Thus, when transporting wood, it can be used trucks, with or without a trailer, forestry platforms, with or without a semi-trailer, container trucks, all used for transporting wood over long distances [

1,

6,

9,

17,

20,

26,

33,

35,

37], but also tractors with trailers or even animal-drawn vehicles, in the case of short transport distances [

1,

26]. Transport vehicles intended for round wood are usually equipped with their own loading systems [

16,

27,

36], either of the type of hydraulic cranes or of the type of cable loading systems [

18,

20,

24,

26], but there are also vehicles that do not have these features. The choice of a particular type takes into account the characteristics of the area from which the wood is loaded [

10], of the wood storage where the wood reaches [

10,

20], but also the availability of a certain model [

10,

33].

For the efficiency of transport, it has to be mentioned that the organization of transport activities, as well as the scheduling of the vehicles fleet, are of particular importance [

6,

17,

19,

33,

38]. These aspects take into account, above all, the quantities and types of wood to be transported, but also the main characteristics of forest road transport, which consist in the fact that transport activities have a periodic character [

14,

28,

34,

39], depending on the type of cuts and the restrictions related to the harvesting areas [

20], differentiating an “empty transport” - to the forest, and a “full transport” - to the beneficiary [

6,

23,

25], but also by the fact that the harvested wood is temporarily stored in the harvesting area located, in most cases, along a forest road [

1,

10,

20].

The assortments and quantities of wood to be transported dictate, to a large extent, the type of transport vehicle [

6,

10,

20,

37], with consequences on the efficiency and productivity of work [

21,

33]. Currently, the constructive characteristics of vehicles have been greatly improved and adapted to the need to ensure economical transport [

14,

15,

16,

32], vehicles with 2 to 6 axles being available [

24] or even 9 axes [

17] which ensures a better distribution of the loading on the wheel-road contact surface [

12,

22,

23,

35] and high loading capacities [

13,

29,

33,

37].

However, the use of vehicles of transport at maximum capacity is not always possible due to the regulations regarding the circulation on forest roads and public roads, related to the allowable gross vehicle weight [

9,

10,

17,

21,

23,

24,

26,

31]. Thus, in Romania, vehicles transporting wood must be 2.5 m wide, 4.0 m high and 18 m long [

26,

31]. Regarding the allowable gross vehicle weight this is 38 t [

23,

28,

32], but a number of remarks are made regarding the distribution of the loading on the axles [

23,

24,

31]. Since these regulations must be respected in order not to end up with penalties or traffic restrictions [

24], the only available method for the efficiency of wood transport consists in evaluating all the work phases corresponding to this process [

10,

16,

21]. In this sense, time studies can be used which, even if they involve a large consumption of time for their application [

10,

16], they can highlight the aspects that can be improved, so as to reach a better productivity of the transport activity [

19] and to reduce interruptions or delays due to adjacent factors [

6,

10,

16].

The aim of the paper was to evaluate the wood loading process in various types of transport vehicles in terms of the time consumption for each working phases and the factors that can affect productivity. Thus, the following objectives were settled:

To evaluate the transport distances when the wood has to be transported to locals or to economic agents;

To evaluate the productivity when loading round wood in forestry trucks (ATF) and forestry platforms (APF) either in the harvesting area or from a wood storage;

To analyze the working time and the phases of wood loading in forestry trucks;

To highlight the factors that can influence the productivity at wood loading in different vehicles.

4. Discussion

The need for wood at the level of society is constantly increasing, which requires efficiency of the transport process [

6,

9,

13,

17,

24]. Mainly, the transport of wood from the forest to various beneficiaries is carried out with vehicles of different capacities and types [

9,

17,

24,

26,

27,

37,

40], which allow different payloads on the vehicle, but also lower or higher demands on the transport routes [

1,

35,

41]. Thus, roads can condition the use of heavy vehicles, through the constructive characteristics, the area in which they are built, but also the condition in which they are [

10,

16,

17,

42]. On the other hand, the transport distances and the types of transported wood are directly influenced by the type of cutting, the type of stand, but also by the way the forest administrator chooses to sell the wood [

1,

3,

10].

In Romania, in the situation of some compartments administered by state through the National Forest Administration [

13,

32,

43] or forest districts that manage the forests of the local public authorities (U.A.T.s), part of the harvested wood is sold to the locals near the forested areas [

32]. This means that the timber is sold directly from the harvesting area and the buyers have to provide their own transport [

26]. Because the wood is sold to locals, the volumes are reduced and in accordance with the needs of each individual family and the means of transport must be chosen accordingly [

1,

32,

37]. Thus, analyzing the volumes of wood transported between the years 2014 and 2019 on a forest road in Romania, located near a town, Bitir et al. [

32] mentions that small capacity means of transport were used, which had loadings of up to 5 m

3, including animal traction. Even if these kinds of transports were numerous, they represented only 2% of the total volume transported during the analyzed period and it was consisted of 90% of firewood. In another study made by Potocnik and his collaborators [

1], which assesses the impact of traffic characteristics on forest roads in Slovenia, it is mentioned that 15% of the wood was transported by tractors with trailers, being intended for domestic needs. A similar situation also appears in the present research, when the transport distances vary between 3 and 16 km for the wood sold to locals, near the Codrii Cetăților Forest District. Conversely, it has been found that when was transported working wood of one or related species, the distances increase, sometimes considerably, which means that the wood was sold to economic agents. These situations appeared when the wood was transported to a local contractor 63 km away, and when the pulpwood was transported 232 km away. In a study of Mușat and his collaborators [

40], which analyzes the transport distances of a factory that purchases wood for the production of oriented stand boards (OSB), it is mentioned that the transports were made with high-capacity vehicles, which traveled between 50 and 370 km from the place of loading to the destination. Also related to transport distances, Kärhä and his collaborators [

17] mention that in some countries such as Bulgaria, Poland, Turkey and Uruguay transport distances exceed 200 km, and in others they are at most 60 km (Denmark, Estonia, Japan and Slovenia).

In contrast, in the case of private forest districts as was the case of Lignum Forest District, the wood was no longer delivered from the harvesting area, but from its own wood storages area. For this reason, when transporting the wood from the harvesting area to the storage area, different types of high-capacity transport vehicles were used, some of which were held by the forest district, an aspect also mentioned by Acuna [

6] who states that the wood is transported mainly by trucks either held by the company, either rented. In this regard, Mousavi and Naghdi [

10] mention that the wood from the harvesting area must be transported to a storage area at the right time, because otherwise its quality is reduced due to the attack of insects and fungi [

36]. In the storage area, the wood is sorted and delivered to various beneficiaries or to processing companies, which requires large distances and specialized vehicles for transport [

10,

22,

40], such as forestry trucks with or without trailers.

In Romania, although the vehicles used to transport wood are very varied, forestry trucks (ATF) and forestry platforms (APF) predominate [

20,

26,

28,

43]. The type of vehicle used to transport wood can greatly influence the loaded volume [

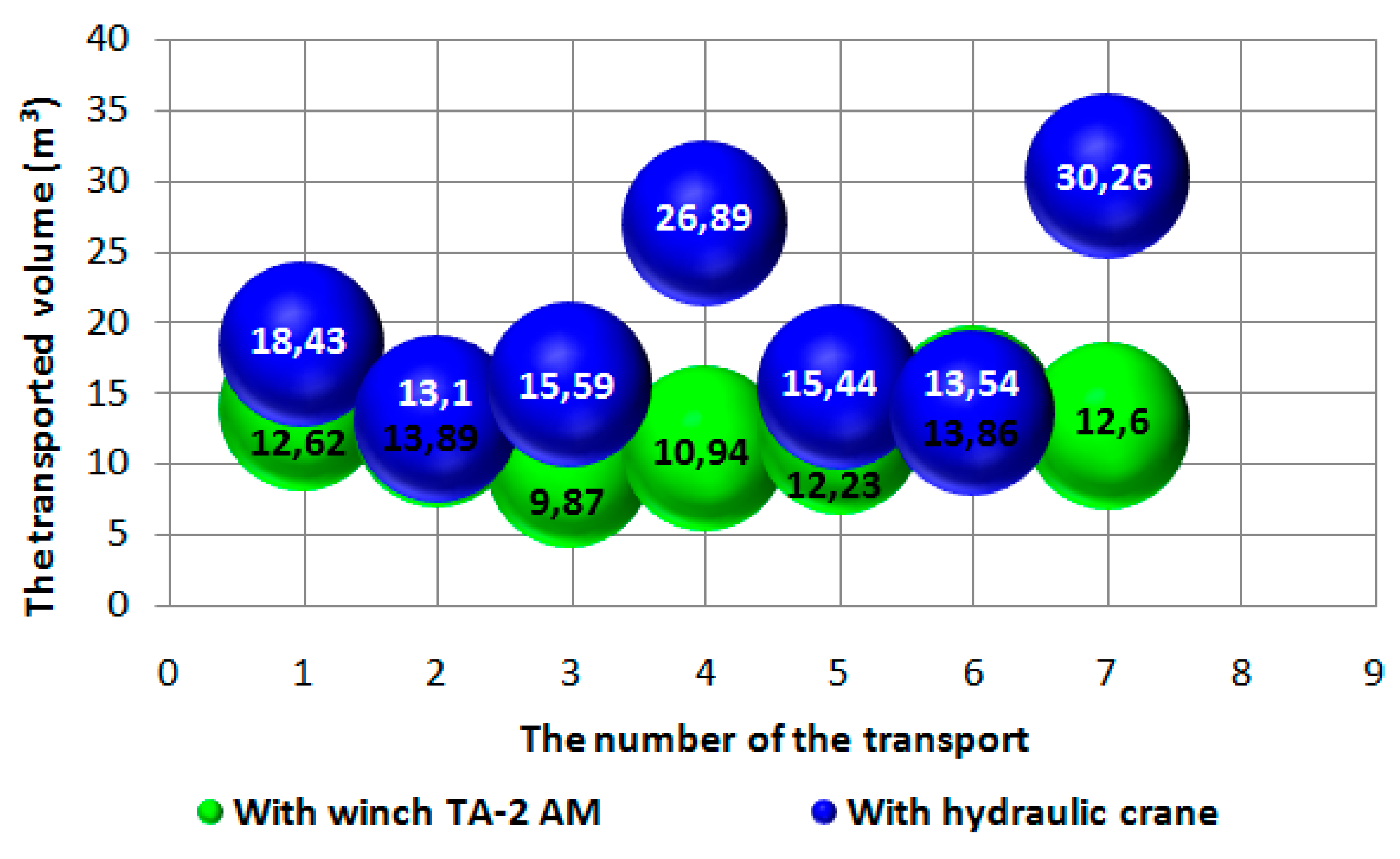

17,

37]. Thus, the field investigations carried out in the forests managed by the Caraș-Severin Forest District indicated that smaller wood volumes were loaded in the forestry platforms (APF) compared to the forestry trucks (ATF).

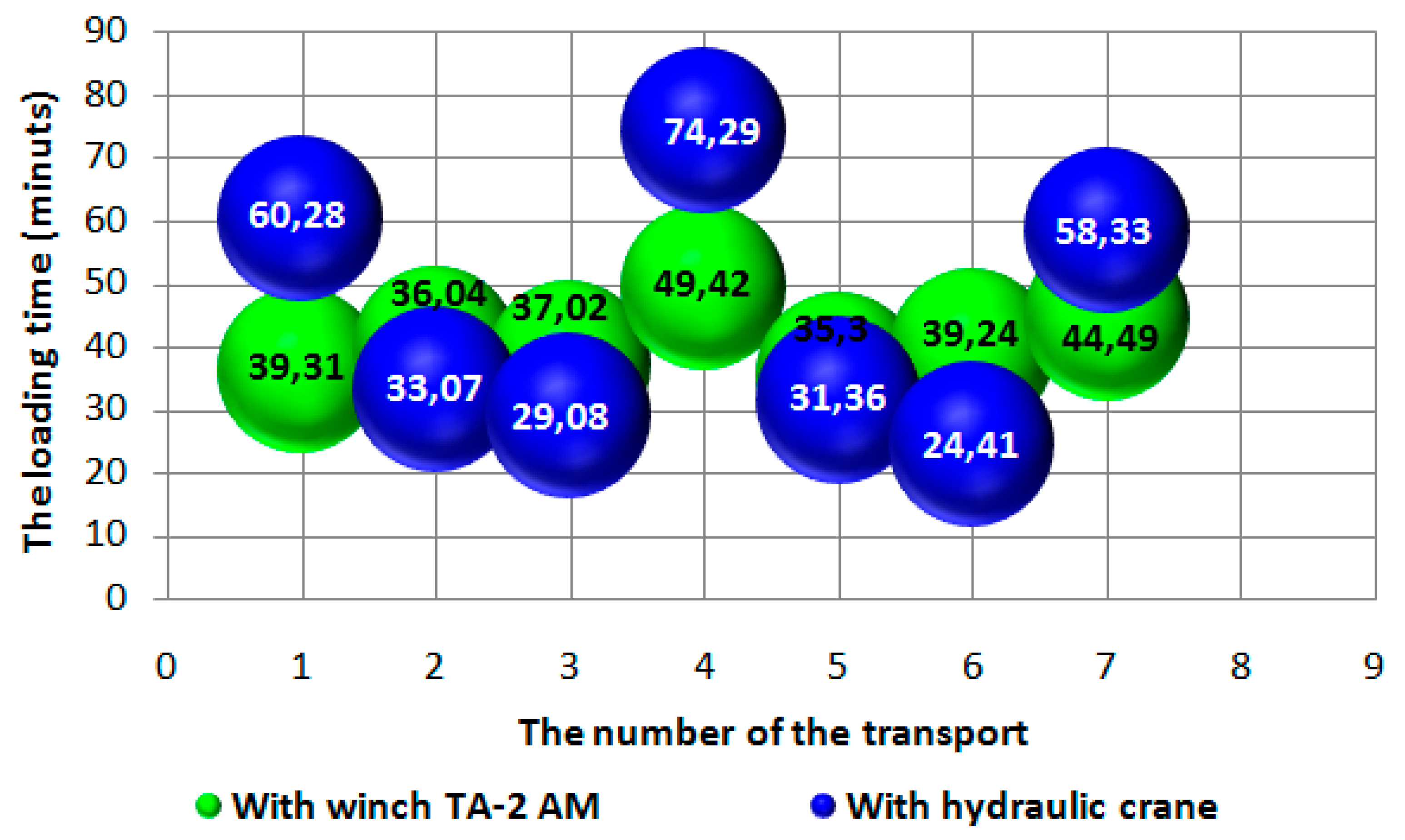

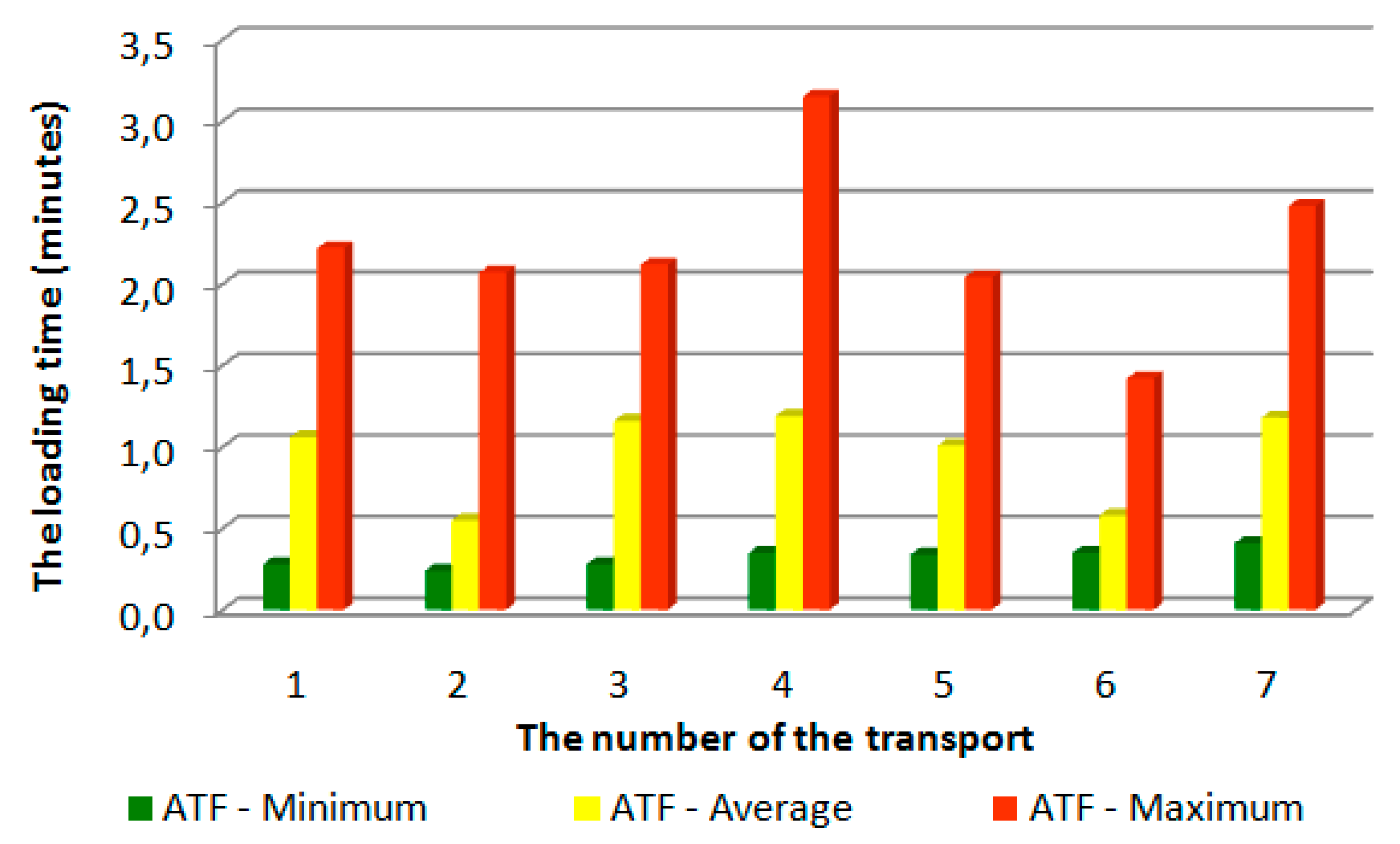

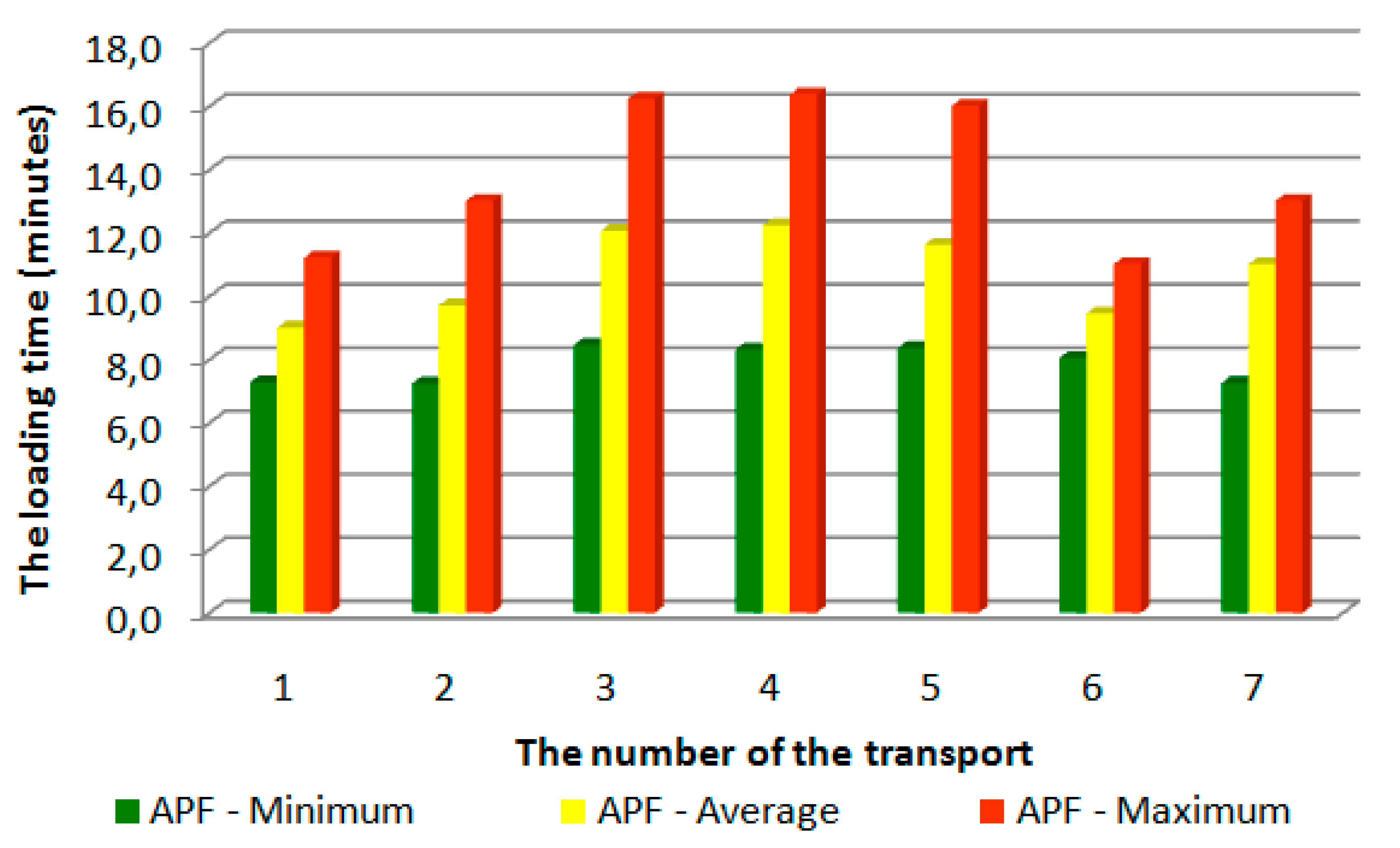

Due to the loading method, in the two studied cases both the loaded volumes and the loading times varied. For the considered forestry platforms (APF), the number of logs loaded at the same time influenced the loading time, which was bigger than at forestry trucks (ATF), but the same happen with the volumes of each loading (they were bigger at forestry platforms). According to Kärhä et al. [

17], the higher the gross vehicle weight and the loaded volume for a transport, the lower the long-distance transport costs for round wood. However, trucks with or without their own loading systems are the main transport vehicle for wood from the forest to the beneficiaries also in other countries, such as Slovenia [

1], Austria [

16], Iran [

10], Ireland [

24], Australia [

33].

The loading method can also influence the volume loaded at the same time. Thus, in the case of forestry platforms (APF), loading involved a variable number of logs that were loaded at the same time, by cables [

20,

26]. In the case of forestry trucks (ATF), the loading was carried out with the help of the hydraulic crane (arm and grapple) of the truck [

20,

26]. This allows loads to be made up of one or more logs (6 in the present case), depending on them diameter and length. In this regard, thick logs are loaded successively, and thin logs can be loaded more at the same time, depending on the capacity of the hydraulic crane. All these aspects also influenced the time of a loading, which means that in the present situation the durations were minimal for forestry trucks (ATF) and longer for forestry platforms (APF).

Forestry trucks (ATF) through the way of loading allow an optimal arrangement of the logs in the truck or in the trailer, which leads to reaching the maximum loading capacity of the vehicle [

20,

26,

36]. In addition, with the grapple and the hydraulic arm, the logs can be better handled to be placed in the truck/trailer, which leads to a stabilization of the load during transport [

26]. On the other hand, at forestry platforms (ATF) the logs must be arranged by the workers before the cables were stretched [

26], which means more time consumption, increased risk of injury [

44,

45] and great physic effort on the part of the workers [

46].

Sometimes loading of vehicles without their own loading systems requires another means of loading, such as a front loader or other tractors equipped with loading equipment [

10,

26]. All these aspects influence the productivity of wood transport by trucks, especially the working phases that involve loading and unloading the wood [

17]. In addition, vehicle configuration can have a major impact on loading potential through the vehicle design and the equipments on it [

16,

31,

33]. In this regard, Sosa and his collaborators [

24] mention that there is an inverse relationship between the variability of the gross vehicle mass and the average net load, which means that the less the gross weight varies, the higher the net load.

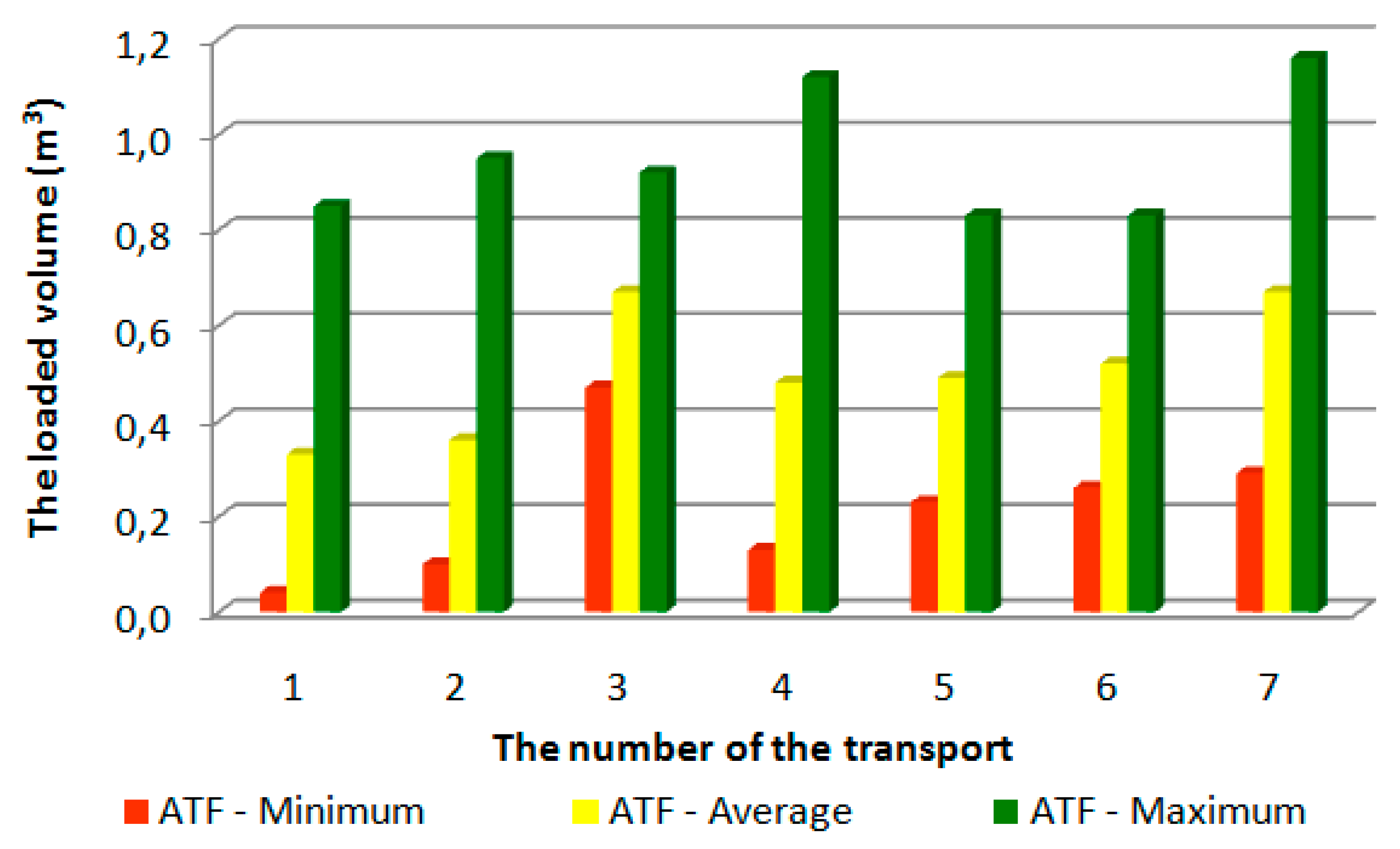

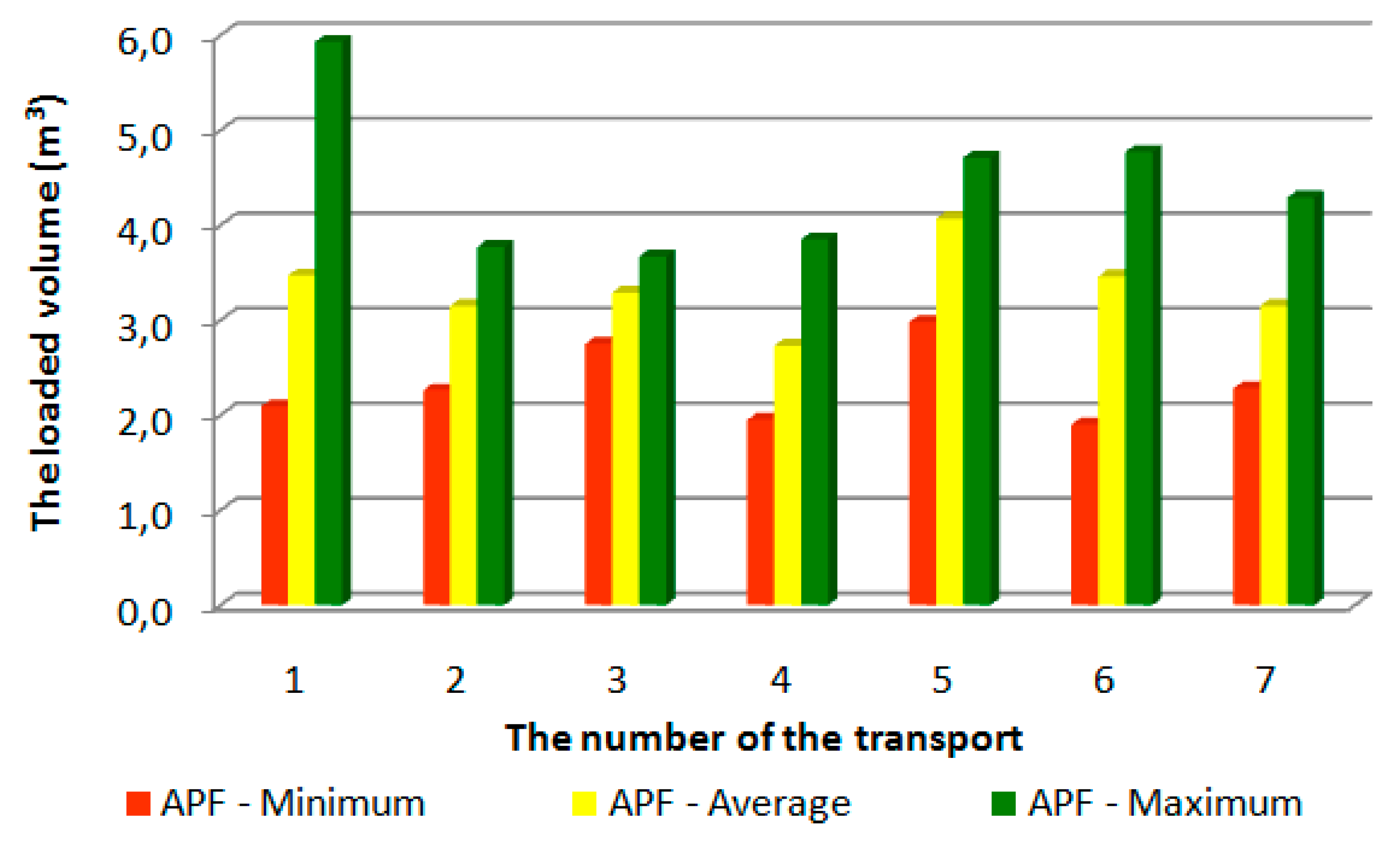

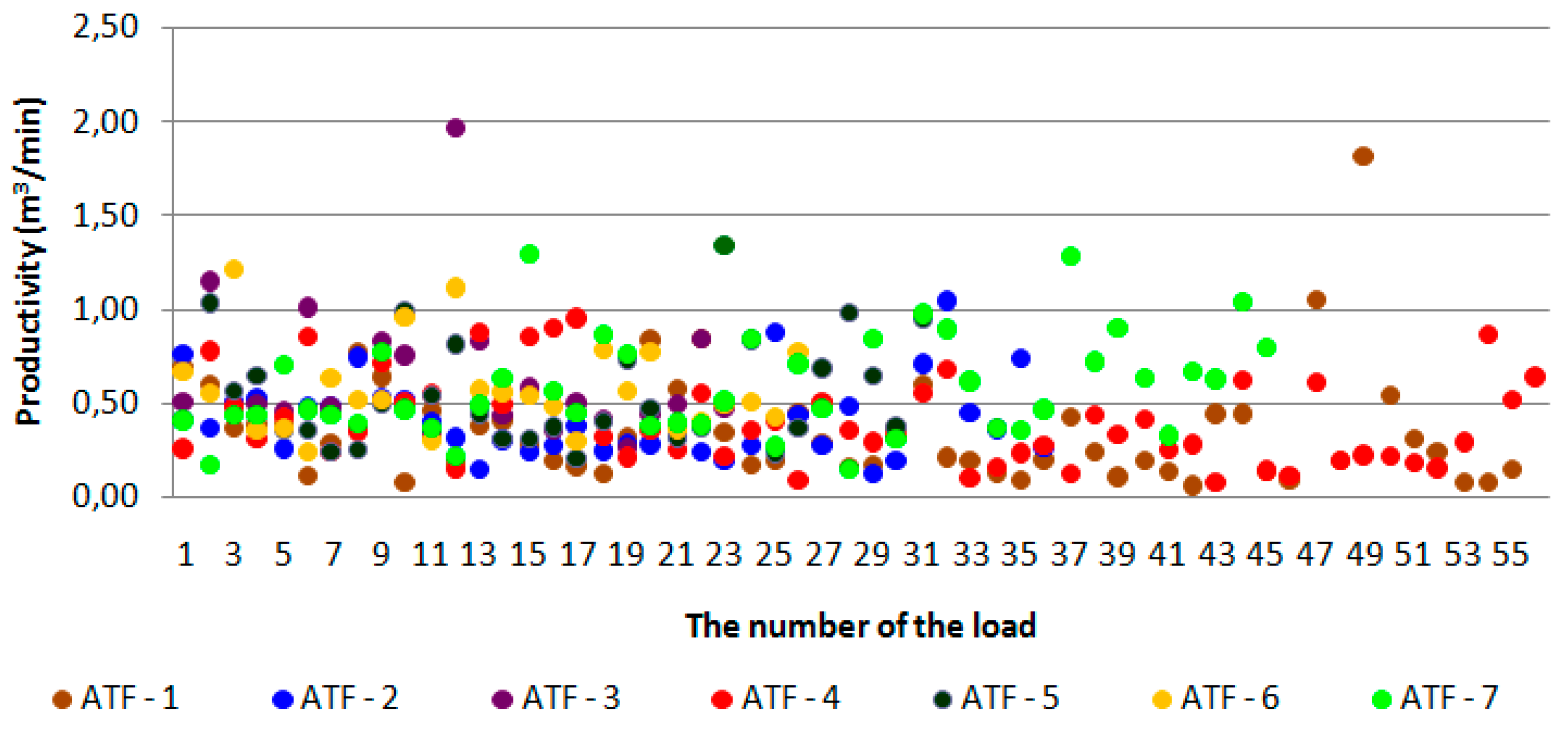

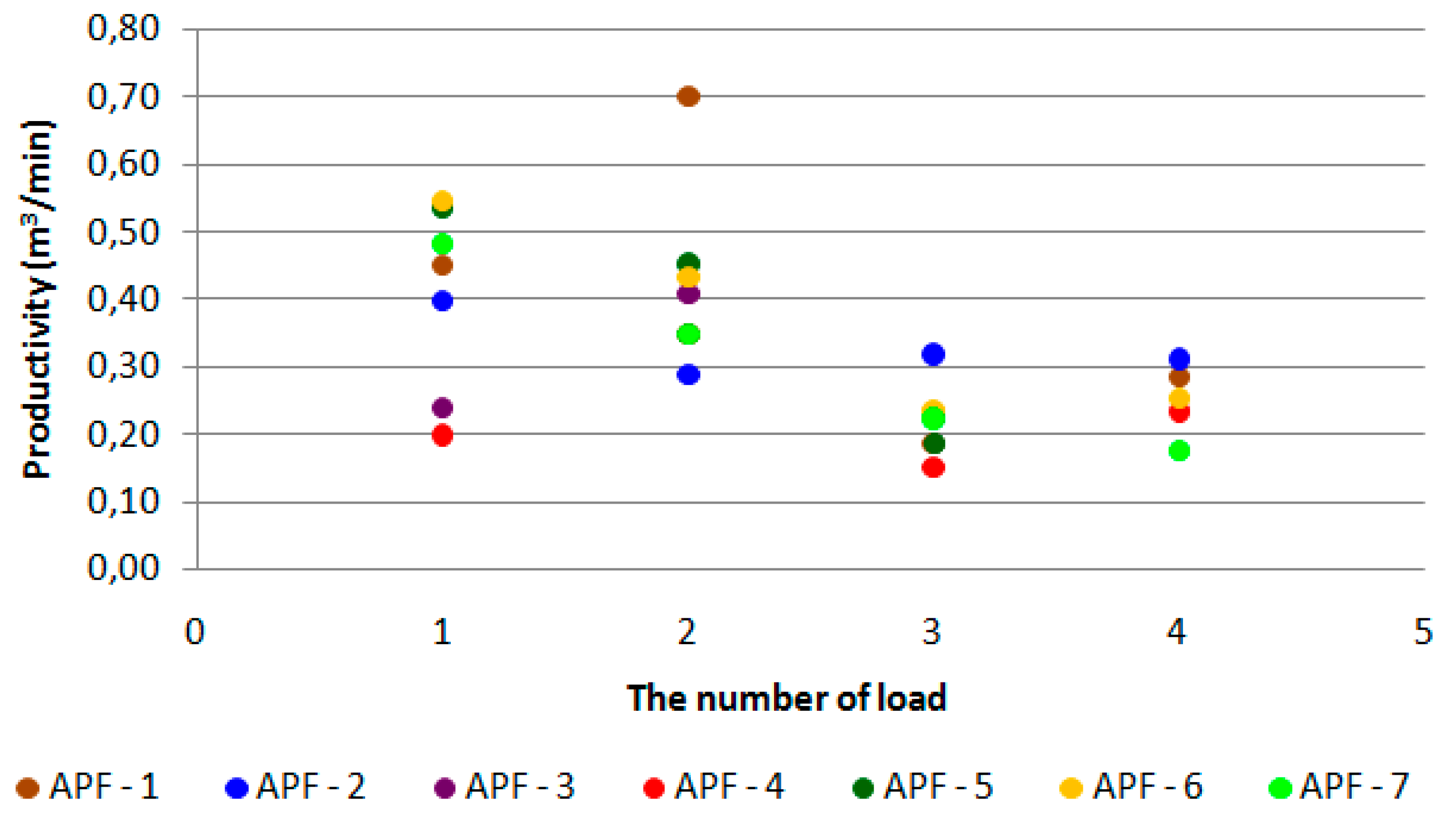

Within the studied working processes, it was found that the productivity at loading wood in forestry trucks (ATF) was somewhat uniform, of 0.5 m

3/loading, while at forestry platforms (APF) it varied a lot, according to the number of loaded loadings (0.2 – 0.6 m

3/loading). Thus, the volume loaded at the same time decreased from the first to the last loading, the first one being the most voluminous and made in the shortest time [

20,

26]. In other words, the equipment of the vehicle played a particularly important role in increasing productivity, along with the type of loaded wood and the experience of the driver [

17,

47,

48].

In addition to the type of vehicle used for transport, the type of loaded wood, and the place where the loading is carried out can have a special importance on productivity [

17]. Thus, if the loading was carried out in the harvesting area, the working process was more difficult because, most of the time, the wood was not initially cut to length and measured, which imposed a series of breaks in the working process, for carrying out these activities. When the loading was carried out in wood storage areas, productivity was higher because the logs were already cut to the dimensions desired by the beneficiary and were placed in stacks. These details ensured that the loading process was not interrupted, thus ensuring greater efficiency.

On the other hand, forestry platforms (APF) required more maneuvering space for loading wood compared to forestry trucks (ATF) ([

20,

26], for stretching cables and manually arranging logs for loading, which required a significant amount of physical effort [

46]. A recommendation in this regard is rendered by Mousavi and Naghdi [

10] which recommend that harvesting areas to be placed on both sides of the road, so that the wood loading in vehicles to be easier and possible from both sides of the truck. In addition, the productivity at loading wood in forestry platforms (APF) could be also conditioned by placing the logs directly on the ground and not on some crossbars, which could help during the stretching of cables [

20,

26]. Thus, with the logs placed directly on the ground, additional activities were required to allow the loading cables to be inserted under the pieces of wood in order to be loaded, including a manual rolling of the logs, which involves a high demand on the workers.

From another perspective, productivity in wood transport is also conditioned by delays [

6,

16] due to factors related to the organization of transport and to the reception of the wood at the factories [

17,

49]. Reducing loading and waiting times can have important effects on the duration of a complete transport [

50]. In Romania, the average duration of a transport is 3.5 - 4 hours [

28,

34], which means that is possible to make two transports per day. This duration includes the rest times for drivers, the loading and unloading times, and the effective moving. Thus, the loading time of high-capacity vehicle is on average one hour per transport, and the unloading time is 0.5 hours [

34]. In the analyzed vehicles, the loading times varied greatly, mainly in relation to the type of loaded wood, between 25 and 75 minutes for the forestry trucks (ATF) and between 35 and 50 minutes for the forestry platforms (APF), respectively.

As for the loaded volumes, they varied in the given situations between 10 and 30 m

3 for forestry trucks (ATF) and between 10 and 14 m

3 for the forestry platforms (APF), the regulations regarding the payload allowed of 38 tons being respected [51]. This limit varies from country to country [

9,

10,

24,

35], depending on the road category, so that in some countries the allowable gross vehicle weight is less than 35 tons, and in others it reaches double values [

17].

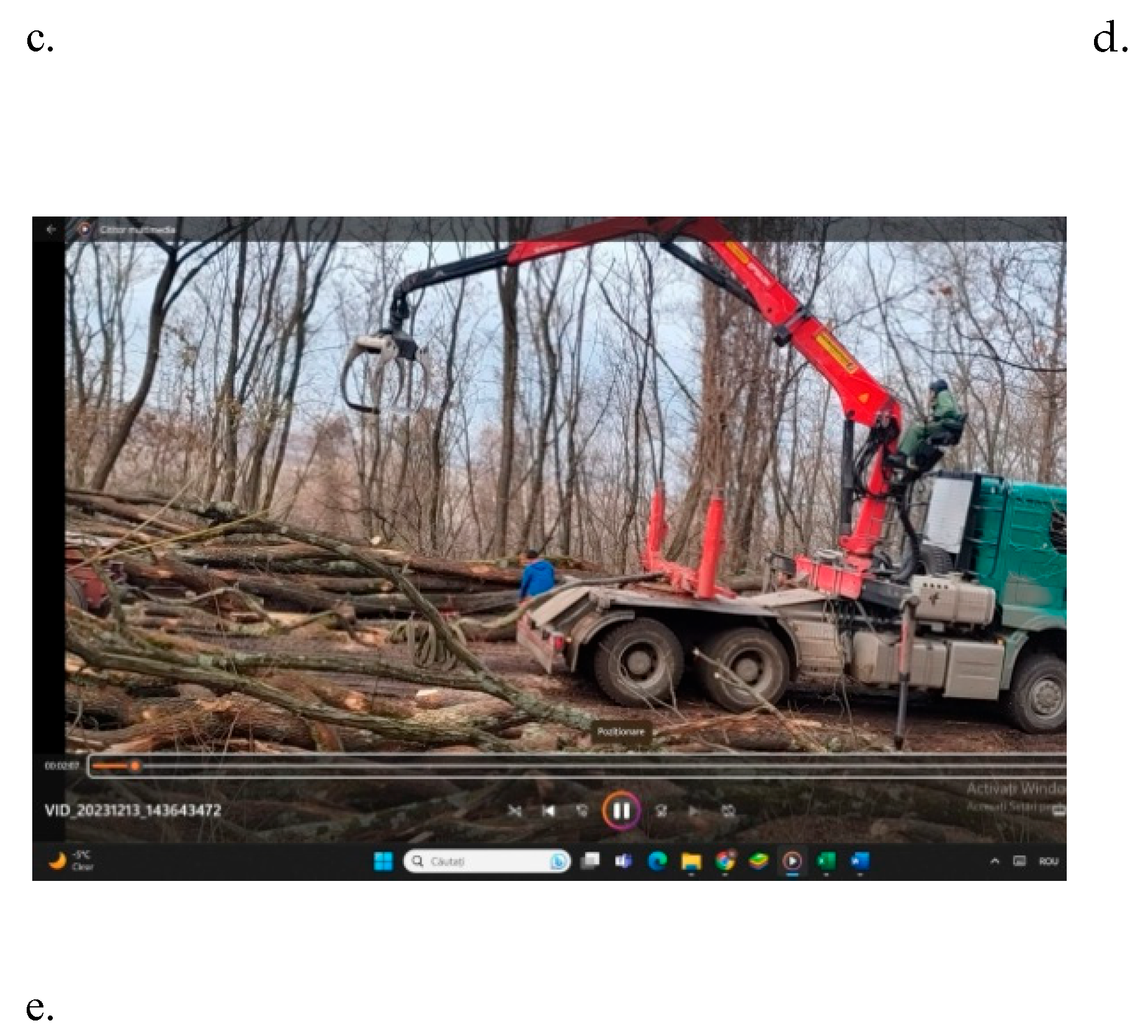

The analysis of the case study carried out for the forestry truck MAN TGS 33.510 with the aim of highlighting the working phases specific to wood loading indicated the predominance of productive activities, of which the most common involved the effective loading of logs. This can be attributed to the fact that the number of loaded logs was large, and the loading of the vehicle involved repetitive activities through which the logs were brought into the truck/trailer and the hydraulic arm was brought back from the truck/trailer to the logs that must be loaded. On the other hand, the non-productive times are greatly influenced by the working phases in which the logs were cut to lengths imposed by the vehicle and/or by the beneficiary. In addition, each transport must be accompanied by a series of transport documents certifying both the origin of the material, the species and the type of material, in the qualitative sense (round wood - working wood - firewood), and quantitative (dimensions and volume). For the drawing up of the transport documents, which accompanying the transport from the place of loading to the place of unloading, the dimensions of the logs are needed. As they were not prepared prior to the transport, and were cut to length just before being loaded, each log was measured and the data were entered into a specific program. All these working phases, considered unproductive for loading, imposed interruptions in the working process. In addition, carrying out these activities at the time of loading involved a very high degree of risk for the workers who made them [

44,

45], as they moved among the logs and very close to the vehicle while uploading the wood.

5. Conclusions

From the forests managed by the state and from the forests owned by the local public administrations, the fuelwood reach, mainly, at locals, and the working wood at some wood processing companies.

Transports with low volumes of wood from several species involve short distances from loading point to the first or to the only unloading point.

The type of vehicle used to transport wood can greatly influence the volume of loaded wood.

At forestry platforms (APF) the loading process is done with cables, which allows loading several pieces at the same time, but this leads to longer durations related to each loaded loading, and also to a lower volume loaded in the vehicle.

At forestry trucks (ATF) the loading capacity can be achieved relatively easily by loading logs one by one, and they can be properly placed to ensure stability during transport and its efficiency.

At forestry trucks (ATF) the loading time of a single load is somewhat constant, while at forestry platforms (APF) it varies a lot, with differences observed from the first to the last loading.

Forestry platforms (APF) require more available space for loading wood compared to forestry trucks (ATF).

The working process of loading forestry platforms is more laborious and requires more physical labor and a larger number of workers compared to forestry trucks where loading is done only by the operator of the vehicle, by acting commands that involve attention and concentration, but not physical effort.

Loading wood from the storage areas is more efficient than loading wood from the harvesting areas, where the logs must be measured and sometimes cut to length.

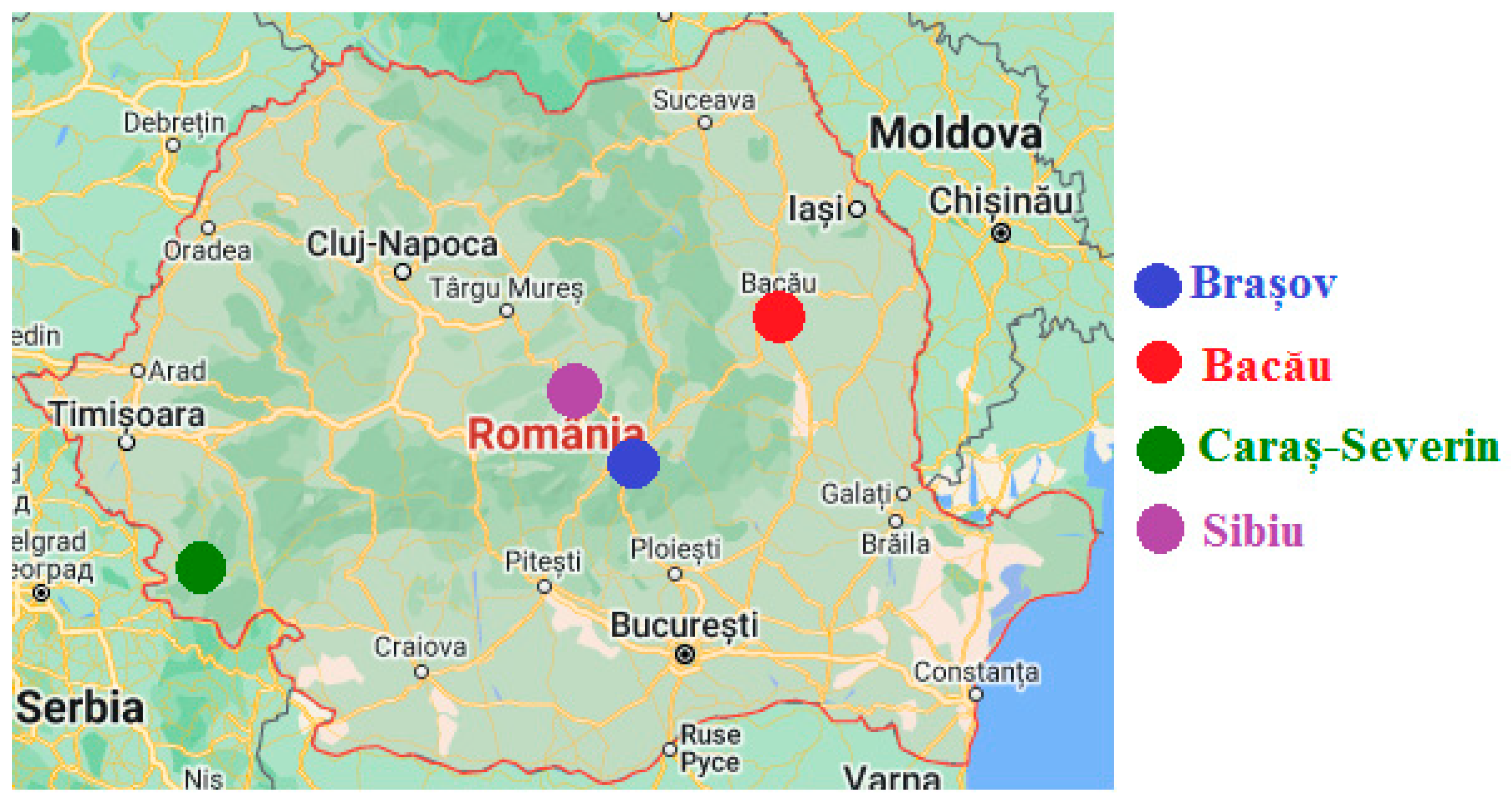

Figure 1.

The study areas.

Figure 1.

The study areas.

Figure 2.

Vehicles used for wood transport in Lignum Forest District: a. Mercedes Actros 3348; b. MAN TGS 33.480 with tipper c. MAN TGS 33.480 with semi-trailer for logs.

Figure 2.

Vehicles used for wood transport in Lignum Forest District: a. Mercedes Actros 3348; b. MAN TGS 33.480 with tipper c. MAN TGS 33.480 with semi-trailer for logs.

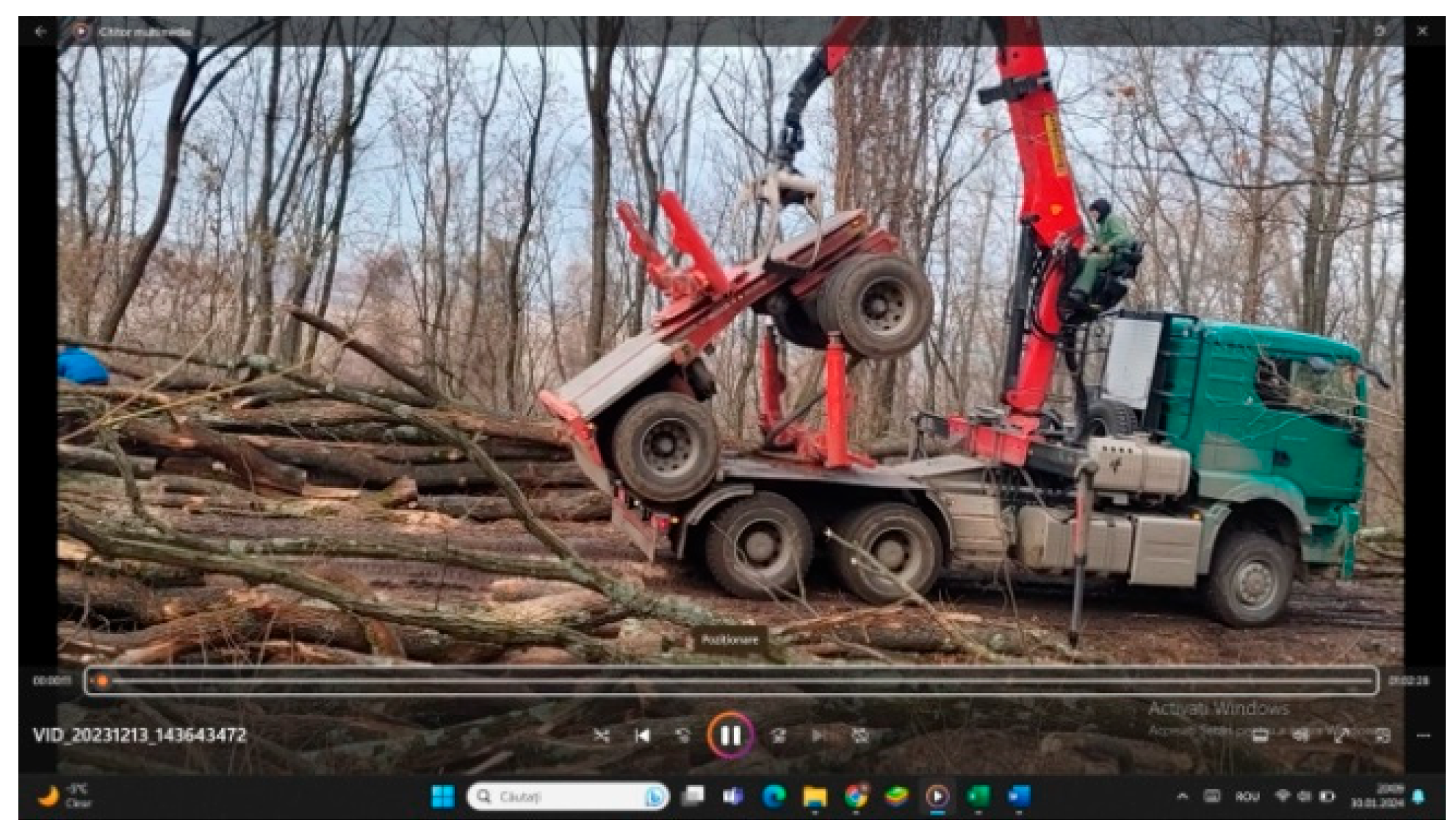

Figure 3.

Loading wood from the harvesting area (Lignum Forest District).

Figure 3.

Loading wood from the harvesting area (Lignum Forest District).

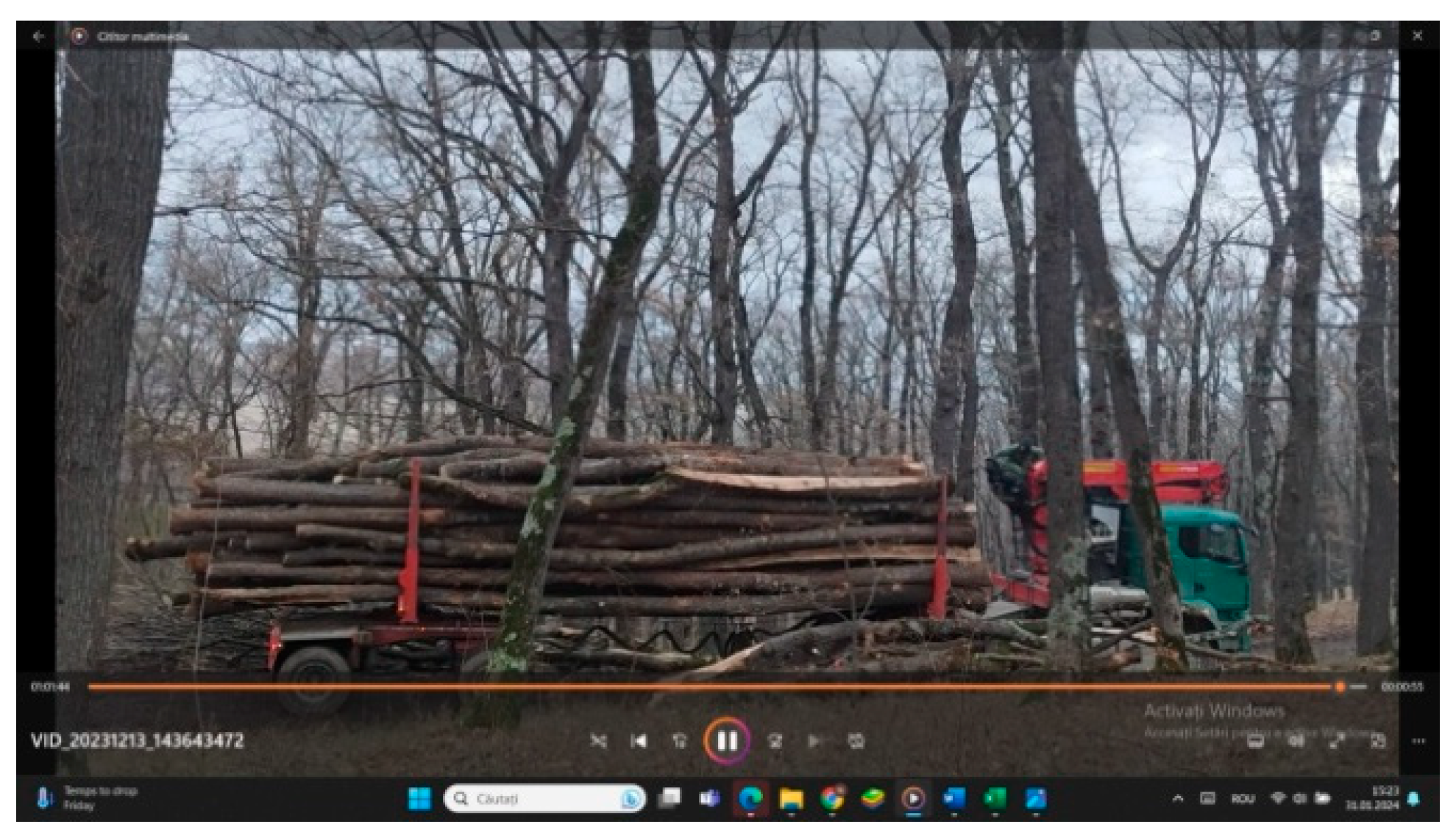

Figure 4.

Loading wood from the wood storage area (Lignum Forest District).

Figure 4.

Loading wood from the wood storage area (Lignum Forest District).

Figure 5.

Forestry truck (ATF) equipped with hydraulic crane.

Figure 5.

Forestry truck (ATF) equipped with hydraulic crane.

Figure 6.

Forestry platform (APF) equipped with TA-2 AM winch.

Figure 6.

Forestry platform (APF) equipped with TA-2 AM winch.

Figure 7.

Vehicle preparation (PA).

Figure 7.

Vehicle preparation (PA).

Figure 8.

Getting off the crane (CM) after loading.

Figure 8.

Getting off the crane (CM) after loading.

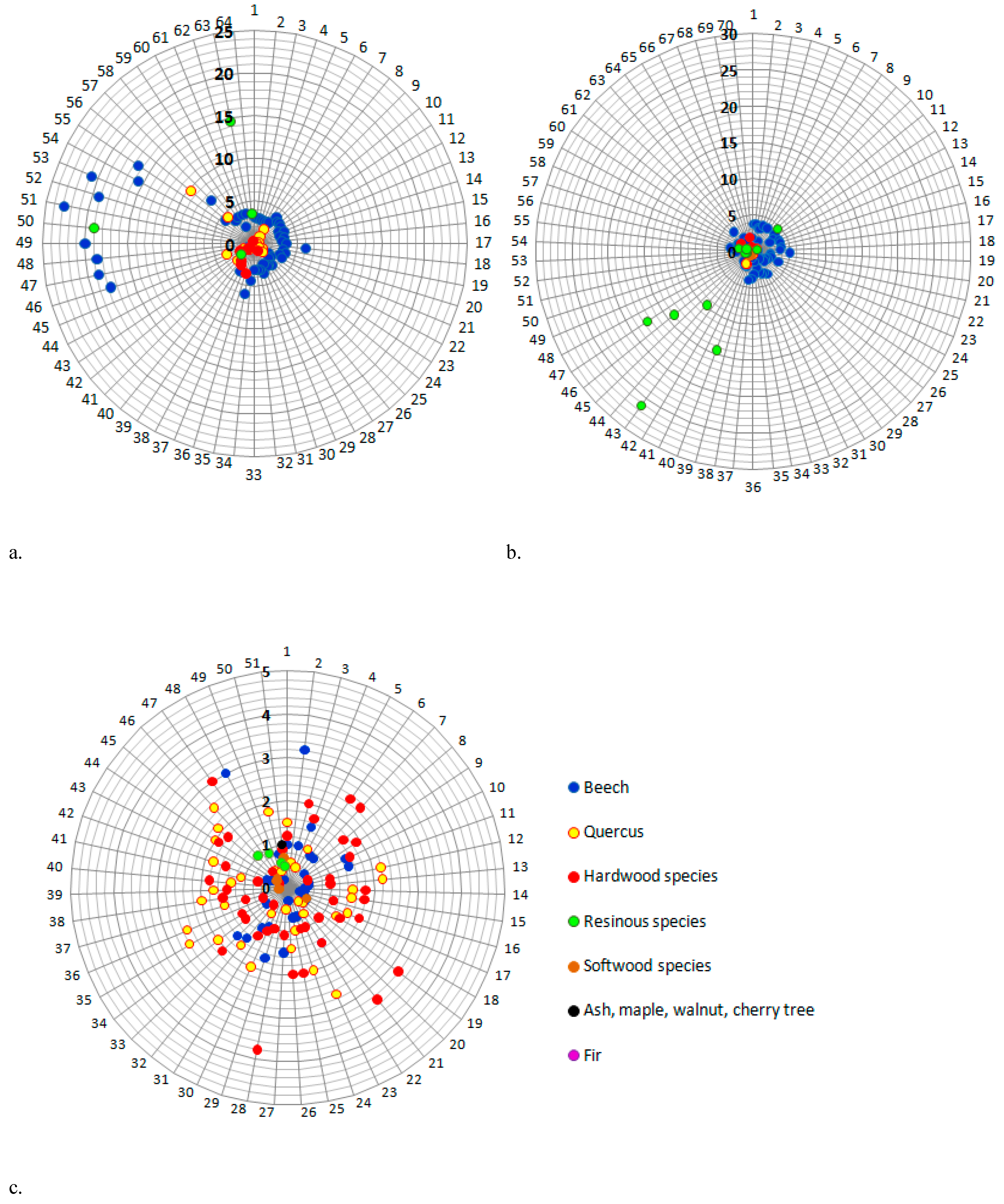

Figure 9.

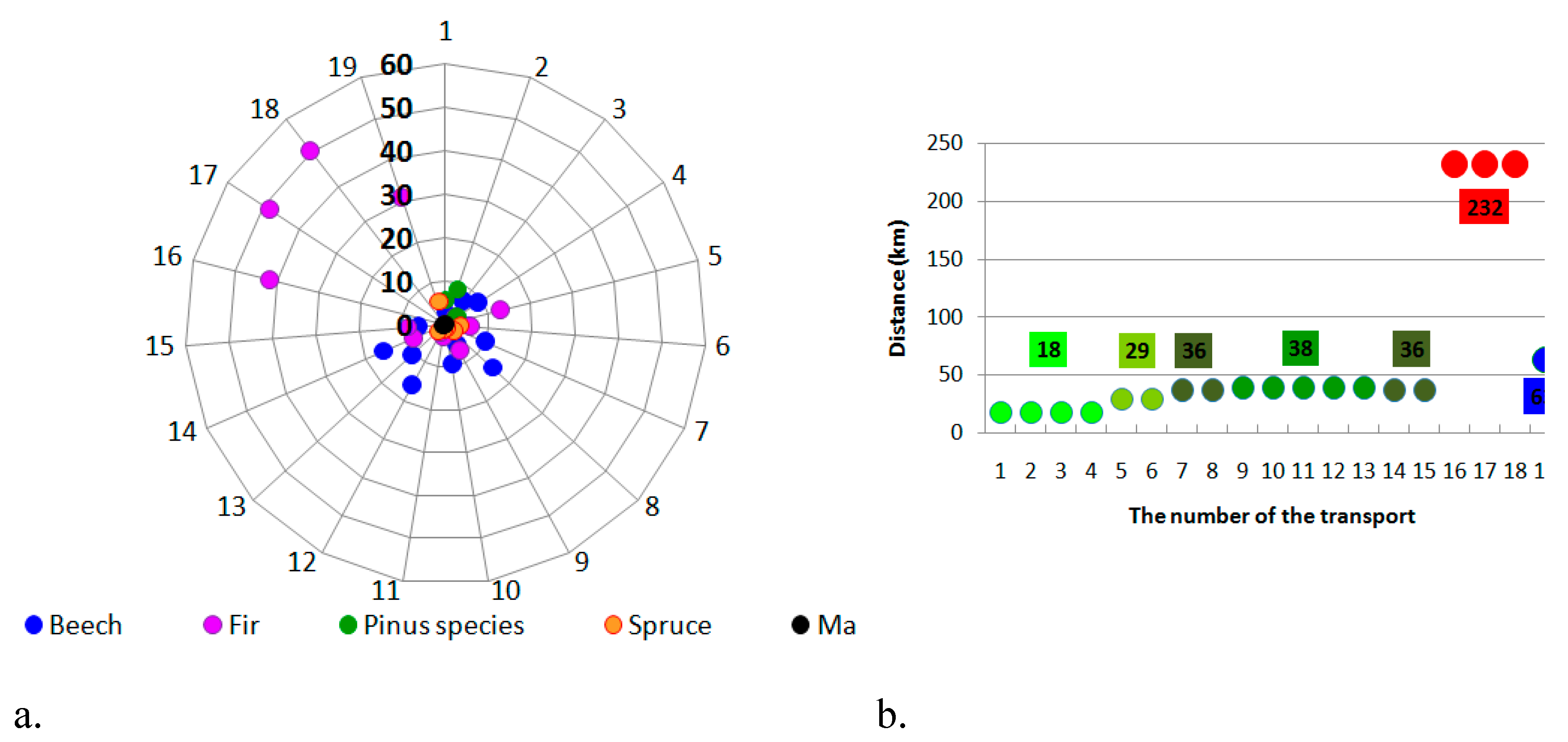

The volumes by species from each transport carried out at Codrii Cetăților Forest District: a. compartment 18B; b. compartments 86B, 87 and 88); c. compartment 22A.

Figure 9.

The volumes by species from each transport carried out at Codrii Cetăților Forest District: a. compartment 18B; b. compartments 86B, 87 and 88); c. compartment 22A.

Figure 10.

The volumes by species from each transport carried out at Lignum Forest District (a.) and the transport distances (b.).

Figure 10.

The volumes by species from each transport carried out at Lignum Forest District (a.) and the transport distances (b.).

Figure 11.

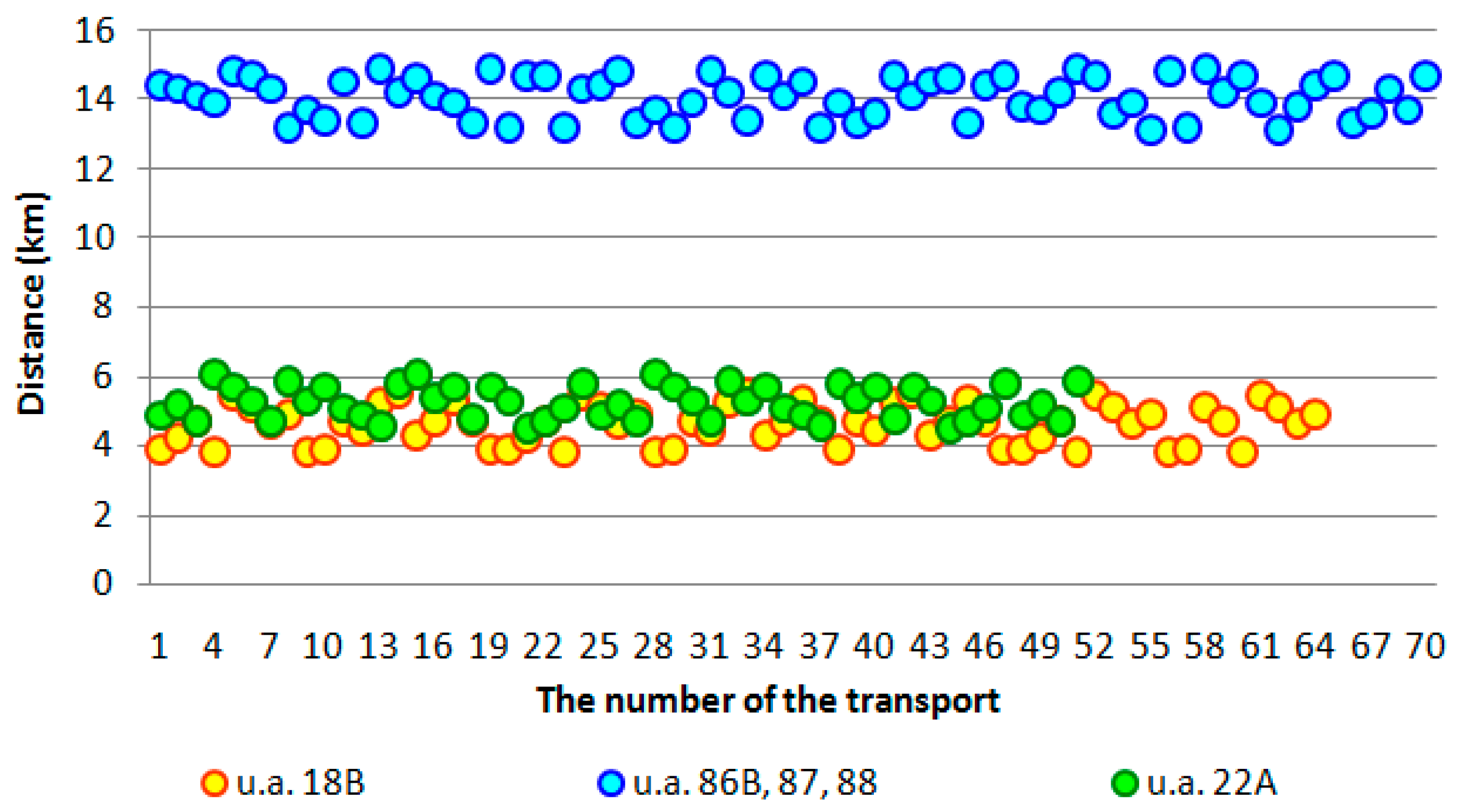

Transport distances specific to Codrii Cetăților Forestry District.

Figure 11.

Transport distances specific to Codrii Cetăților Forestry District.

Figure 12.

The volumes transported by forestry trucks (ATF) and forestry platforms (ATF) in Boșca Montană and Bocșa Română forest districts.

Figure 12.

The volumes transported by forestry trucks (ATF) and forestry platforms (ATF) in Boșca Montană and Bocșa Română forest districts.

Figure 13.

The overall time of loading wood in forestry trucks (ATF) and forestry autoplatforms (APF) in Boșca Montană and Boșca Română forestry districts.

Figure 13.

The overall time of loading wood in forestry trucks (ATF) and forestry autoplatforms (APF) in Boșca Montană and Boșca Română forestry districts.

Figure 14.

Descriptive statistical indicators for loading times of each loading in forestry trucks (ATF).

Figure 14.

Descriptive statistical indicators for loading times of each loading in forestry trucks (ATF).

Figure 15.

Descriptive statistical indicators for loading times of each loading in forestry platforms (APF).

Figure 15.

Descriptive statistical indicators for loading times of each loading in forestry platforms (APF).

Figure 16.

Descriptive statistical indicators regarding the volumes for each loading in the case of forestry trucks (ATF).

Figure 16.

Descriptive statistical indicators regarding the volumes for each loading in the case of forestry trucks (ATF).

Figure 17.

Descriptive statistical indicators regarding the volumes for each loading in the case of forestry platforms (APF).

Figure 17.

Descriptive statistical indicators regarding the volumes for each loading in the case of forestry platforms (APF).

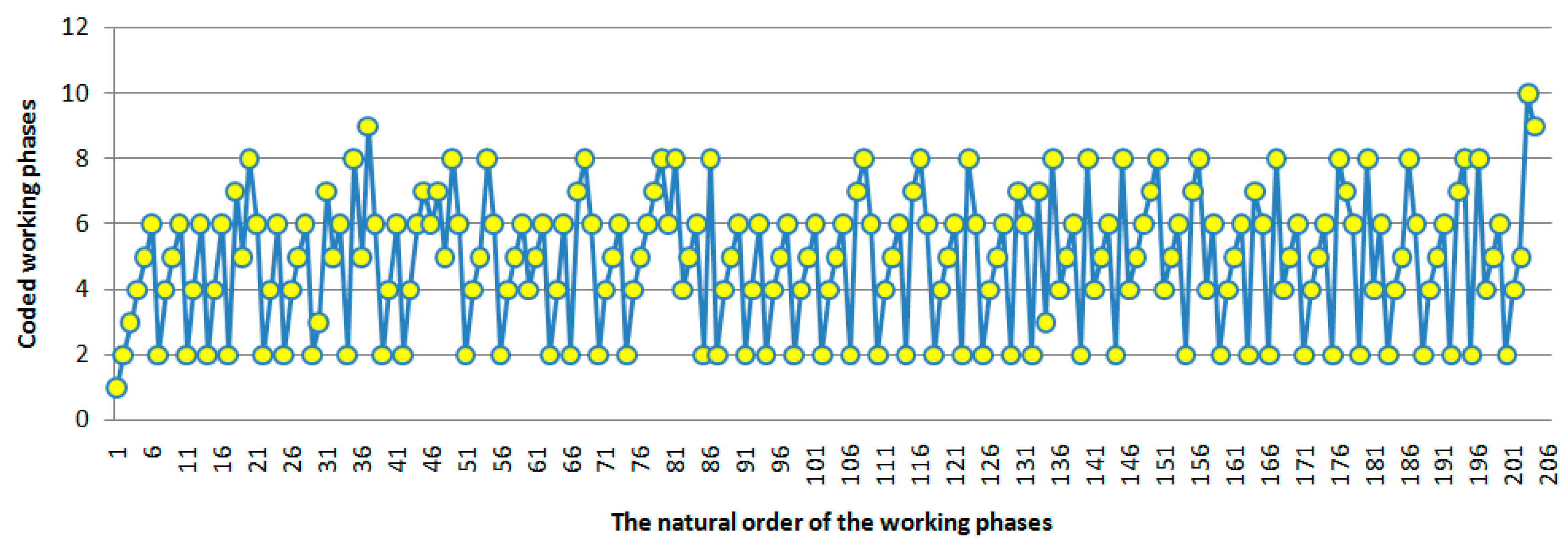

Figure 18.

The sequence of working phases from loading wood into a forestry truck: 1 - vehicle preparation (PA); 2 – actuation of the levers that activate the hydraulic arm and the grapple (IPZ); 3 – log measurement (CL); 4 – transfer of the log to the truck/trailer (TBC); 5 – placement/arrangement of log in truck/trailer (AABC); 6 – returning the hydraulic arm and grapple from the truck/trailer to the log (RB); 7 – other activities (AA); 8 – cross-cut technical break (PTS); 9 – getting off the crane after loading (CM); 10 – stop loading by placing the hydraulic arm in the transport position (II).

Figure 18.

The sequence of working phases from loading wood into a forestry truck: 1 - vehicle preparation (PA); 2 – actuation of the levers that activate the hydraulic arm and the grapple (IPZ); 3 – log measurement (CL); 4 – transfer of the log to the truck/trailer (TBC); 5 – placement/arrangement of log in truck/trailer (AABC); 6 – returning the hydraulic arm and grapple from the truck/trailer to the log (RB); 7 – other activities (AA); 8 – cross-cut technical break (PTS); 9 – getting off the crane after loading (CM); 10 – stop loading by placing the hydraulic arm in the transport position (II).

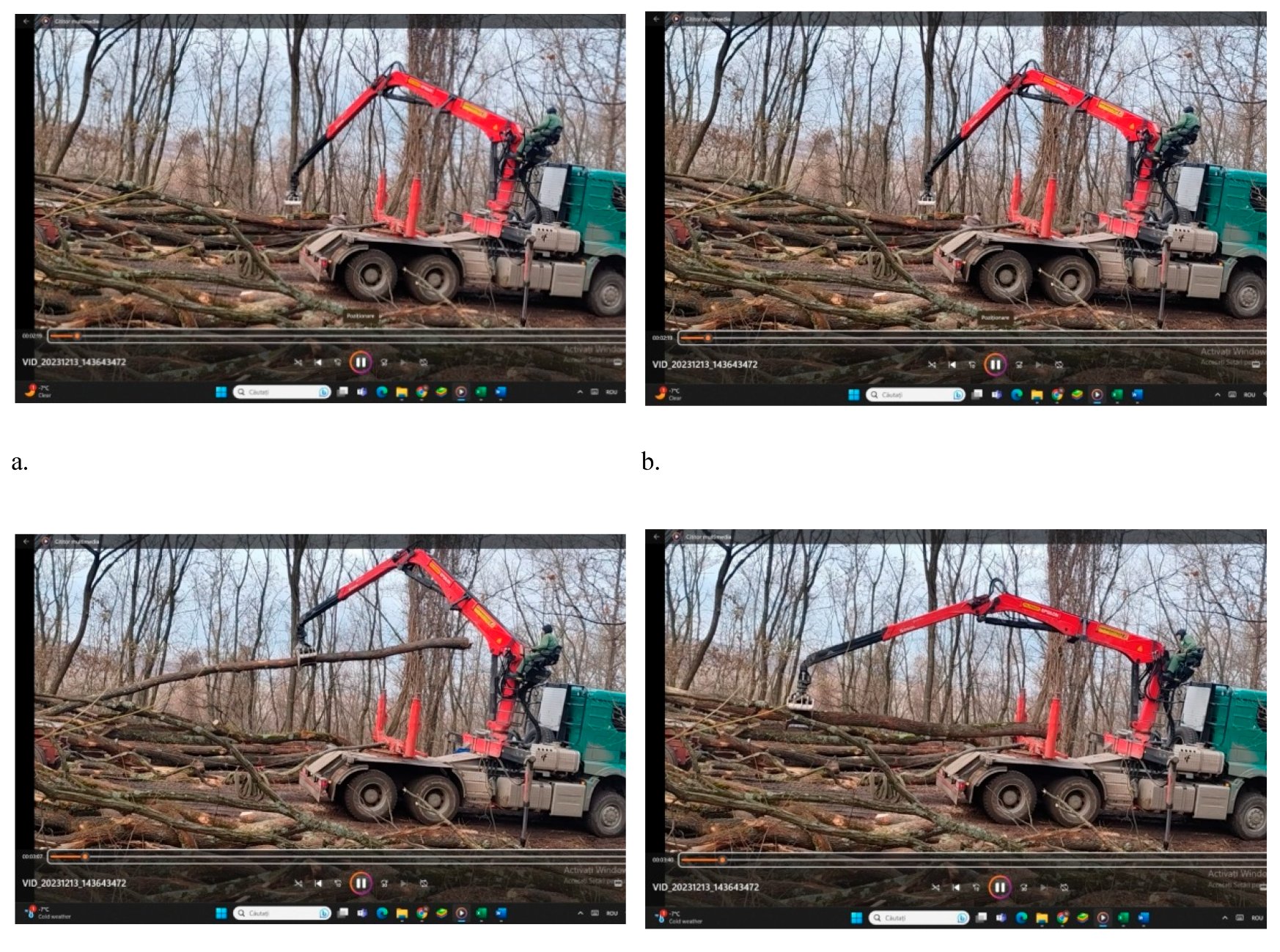

Figure 19.

The working phases of the loading process: a. actuation of the levers that activate the hydraulic arm and the grapple (IPZ); b. log measurement (CL); c. transfer of the log to the truck/trailer (TBC); d. placement/arrangement of log in truck/trailer (AABC); e. returning the hydraulic arm and grapple from the truck/trailer to the log (RB).

Figure 19.

The working phases of the loading process: a. actuation of the levers that activate the hydraulic arm and the grapple (IPZ); b. log measurement (CL); c. transfer of the log to the truck/trailer (TBC); d. placement/arrangement of log in truck/trailer (AABC); e. returning the hydraulic arm and grapple from the truck/trailer to the log (RB).

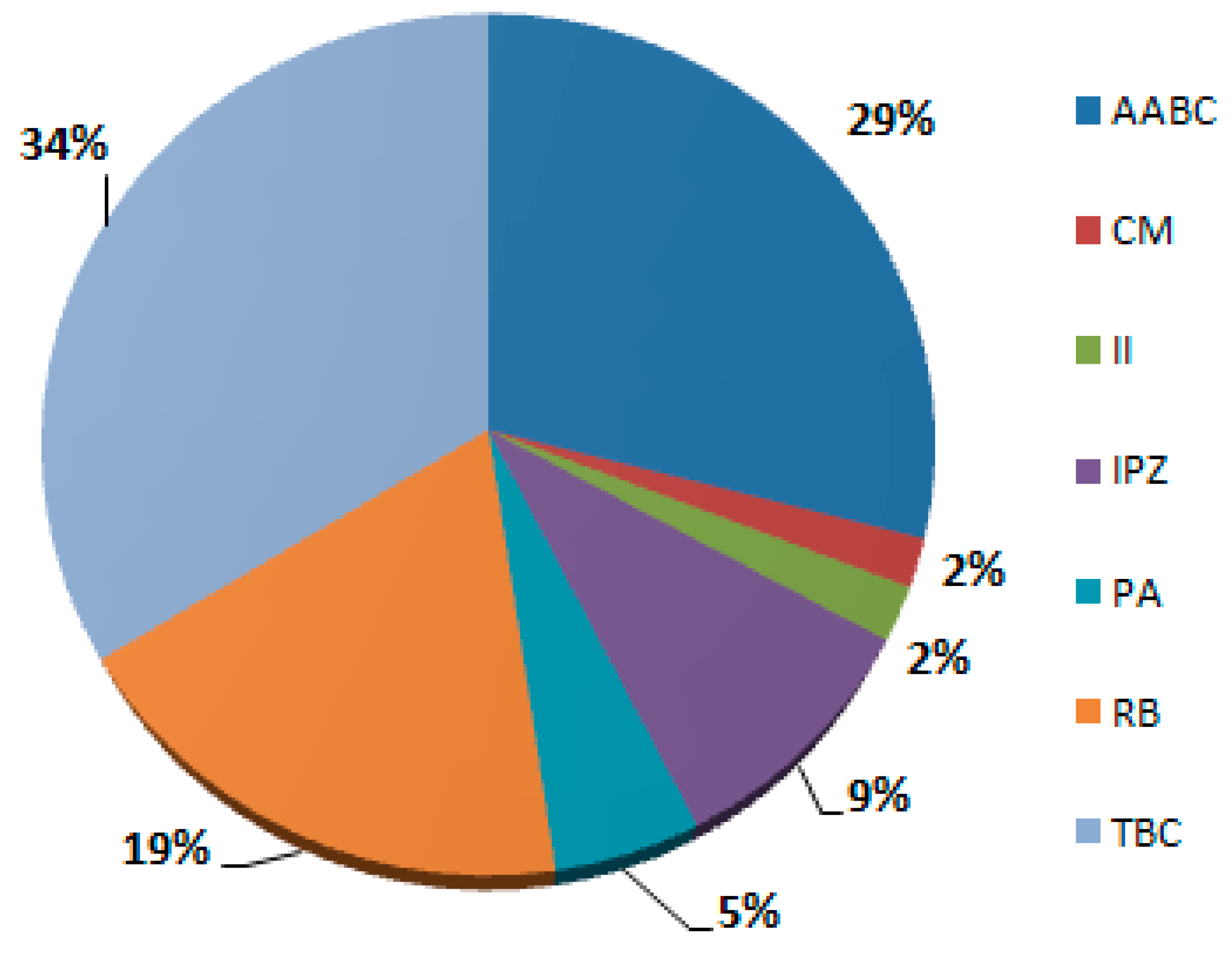

Figure 20.

The weight of working phases from the wood loading in the TG 33.510 forestry truck: PA – vehicle preparation; UM – climbing the crane; IPZ – actuation of the levers that activate the hydraulic arm and the grapple; TBC – transfer of the log to the truck/trailer; AABC – placement/arrangement of log in truck/trailer; RB – returning the hydraulic arm and grapple from the truck/trailer to the log; II – stop loading by placing the hydraulic arm in the transport position; CM – getting off the crane after loading; CL – log measurement; PTS – cross-cut technical break; AA – other activities.

Figure 20.

The weight of working phases from the wood loading in the TG 33.510 forestry truck: PA – vehicle preparation; UM – climbing the crane; IPZ – actuation of the levers that activate the hydraulic arm and the grapple; TBC – transfer of the log to the truck/trailer; AABC – placement/arrangement of log in truck/trailer; RB – returning the hydraulic arm and grapple from the truck/trailer to the log; II – stop loading by placing the hydraulic arm in the transport position; CM – getting off the crane after loading; CL – log measurement; PTS – cross-cut technical break; AA – other activities.

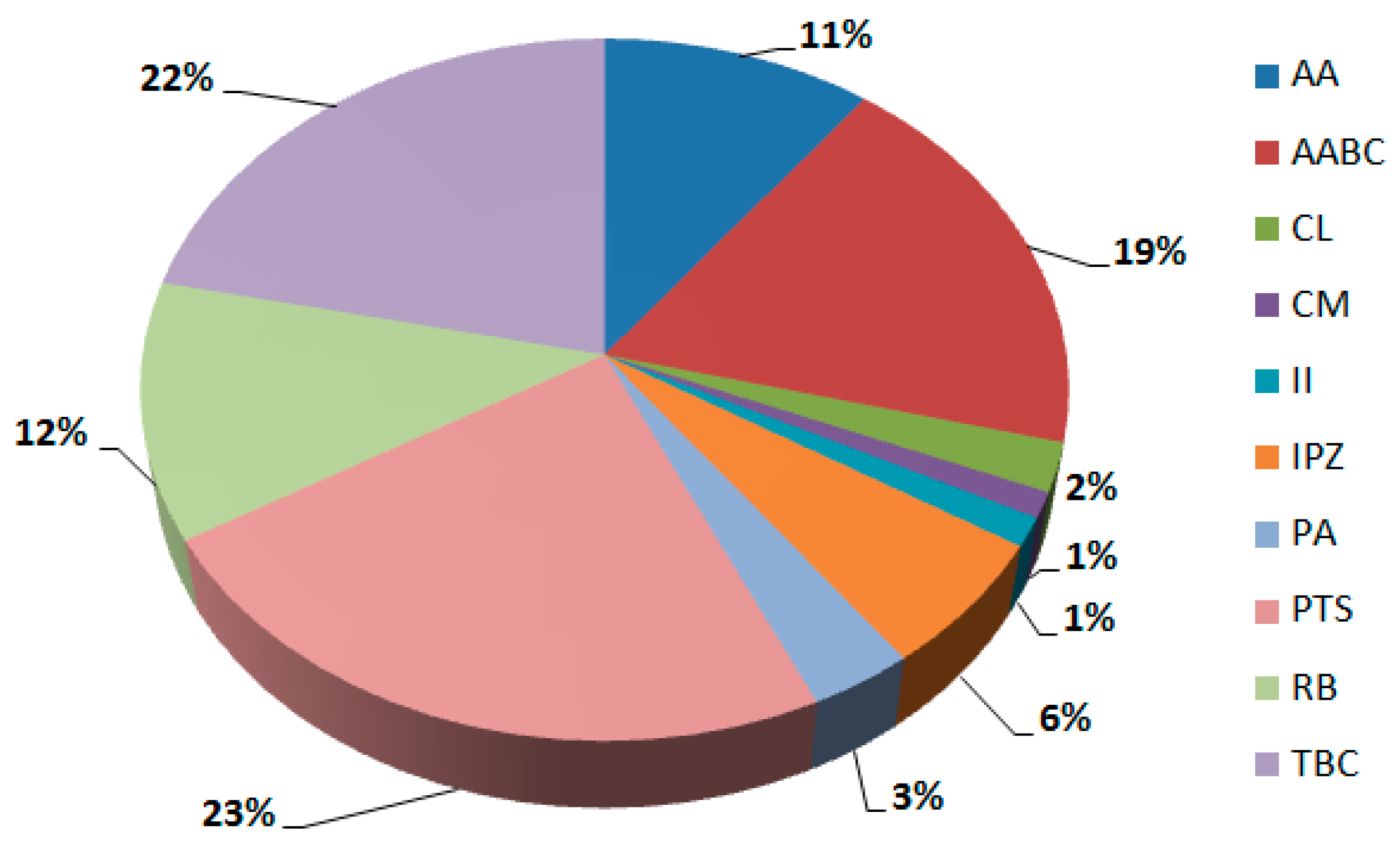

Figure 21.

The weight of working phases from the wood loading in the TG 33.510 forestry truck, as productive times: AABC – placement/arrangement of log in truck/trailer; CM – getting off the crane after loading; II – stop loading by placing the hydraulic arm in the transport position; IPZ – actuation of the levers that activate the hydraulic arm and the grapple; PA – vehicle preparation; RB – returning the hydraulic arm and grapple from the truck/trailer to the log; TBC – transfer of the log to the truck/trailer.

Figure 21.

The weight of working phases from the wood loading in the TG 33.510 forestry truck, as productive times: AABC – placement/arrangement of log in truck/trailer; CM – getting off the crane after loading; II – stop loading by placing the hydraulic arm in the transport position; IPZ – actuation of the levers that activate the hydraulic arm and the grapple; PA – vehicle preparation; RB – returning the hydraulic arm and grapple from the truck/trailer to the log; TBC – transfer of the log to the truck/trailer.

Figure 22.

Productivity of wood loading in forestry trucks (ATF).

Figure 22.

Productivity of wood loading in forestry trucks (ATF).

Figure 23.

Productivity of wood loading in forestry platforms (APF).

Figure 23.

Productivity of wood loading in forestry platforms (APF).