Submitted:

31 July 2024

Posted:

05 August 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Materials

- Native: the powder has been sieved, and the fraction below 0.25 mm has been used in the research.

- Chemically modified: the hazelnut flour has been subjected to chemical components amount characterization according to the following methods: cellulose content - Seifert method, lignin content by TAPPI method, holocellulose content with sodium chlorite. The following results were achieved: 42.7% lignin, 28.8% cellulose, and 30.6% hemicellulose. The two-hour delignification process has been done according to [46]. The final lignin content was 2.6%.

- Carbonized: the hazelnut shells flour has been subjected to heating in a laboratory prototype furnace under the following parameters: heating to 150 °C at 10 °C ramp, heating to 300 °C with a temp. ramp 2 °C, storing at a constant temp. 300 °C for 15 min and cool down to room temperature. The fraction below 0.25 mm has been used in the research.

2.2. Preparation of Panels

2.3. Characterization of the Elaborated Panels

2.4. Statistical Analysis

3. Results and Discussion

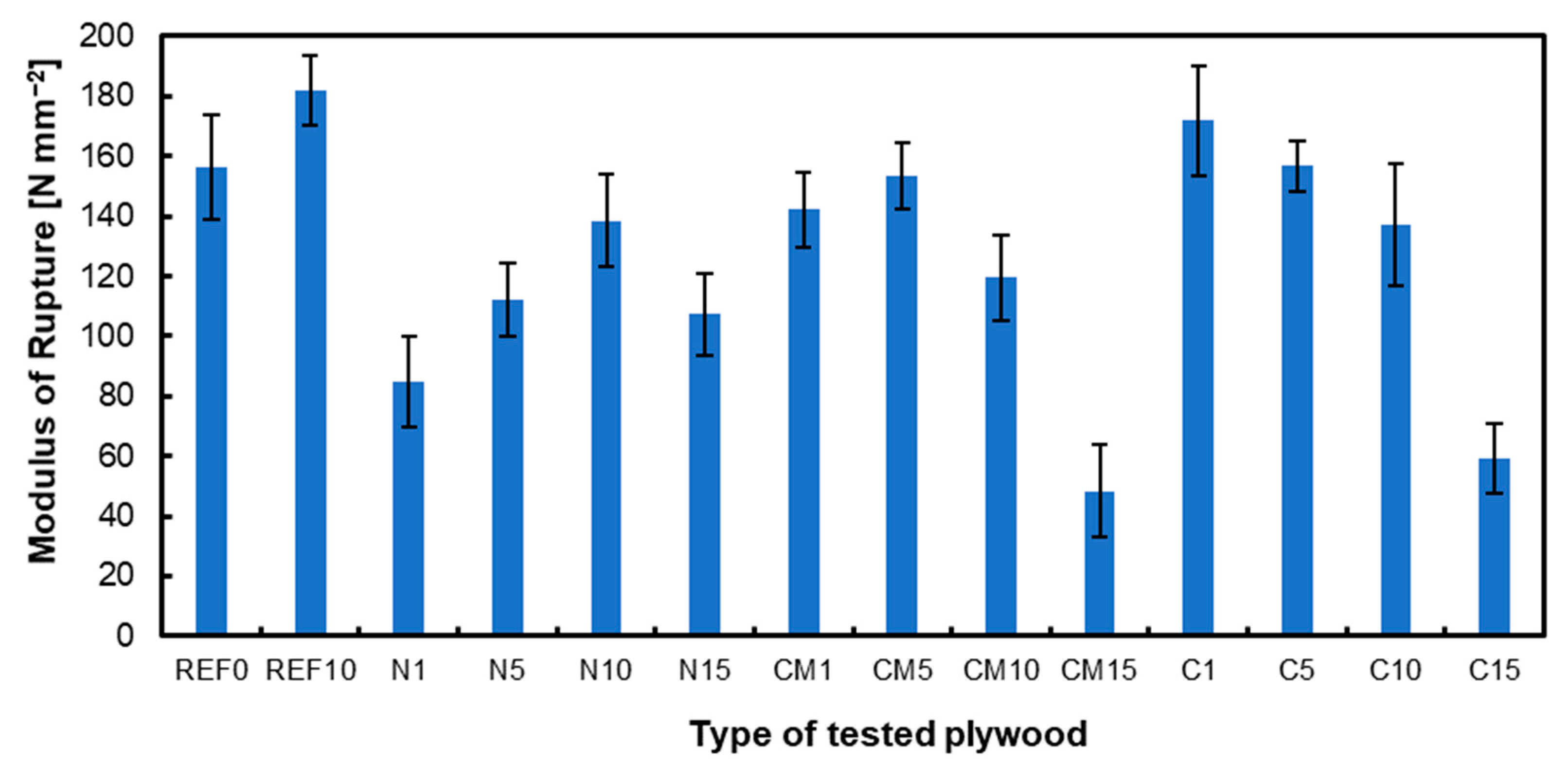

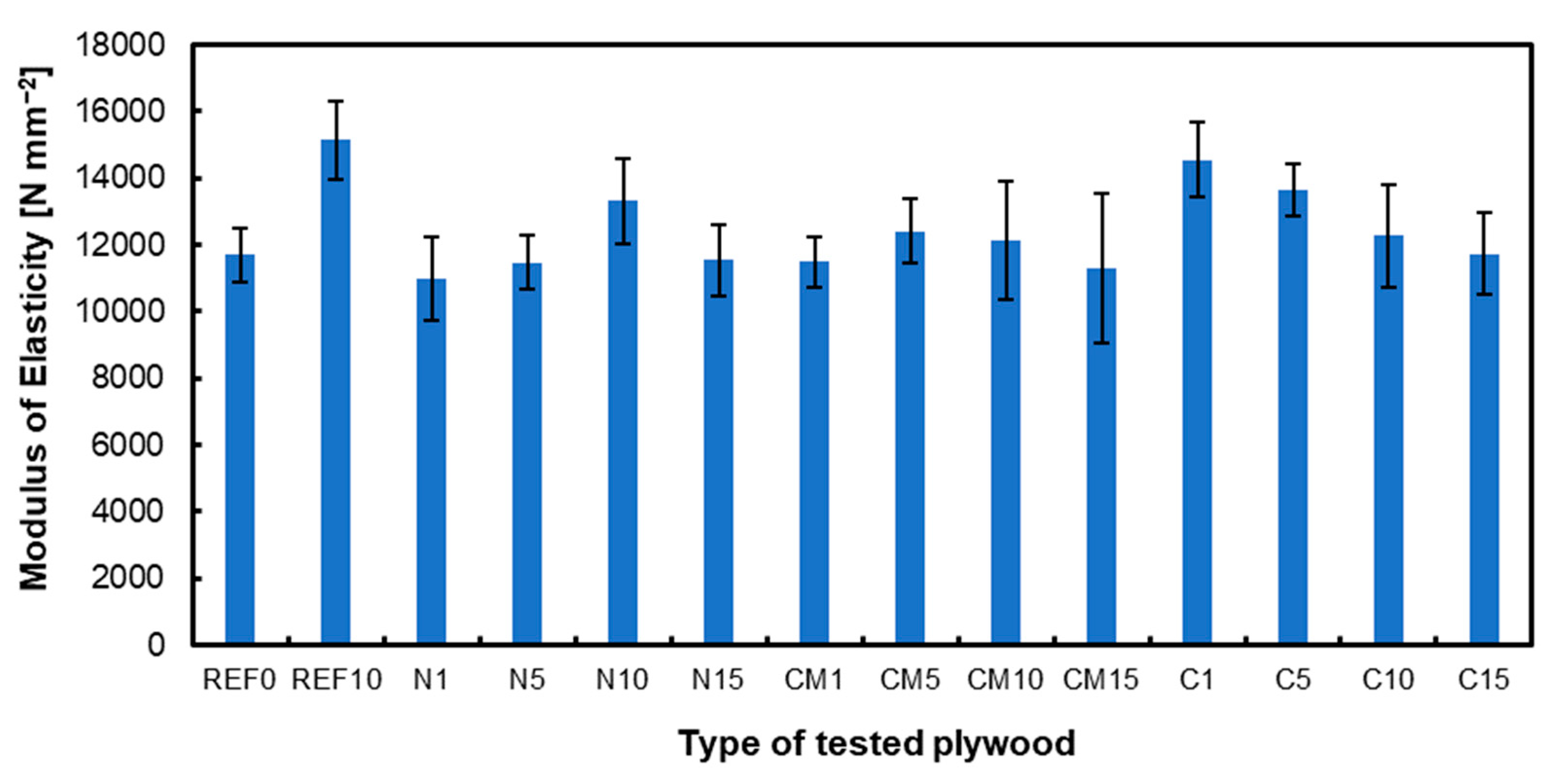

3.1. Modulus of Rupture and Modulus of Elasticity

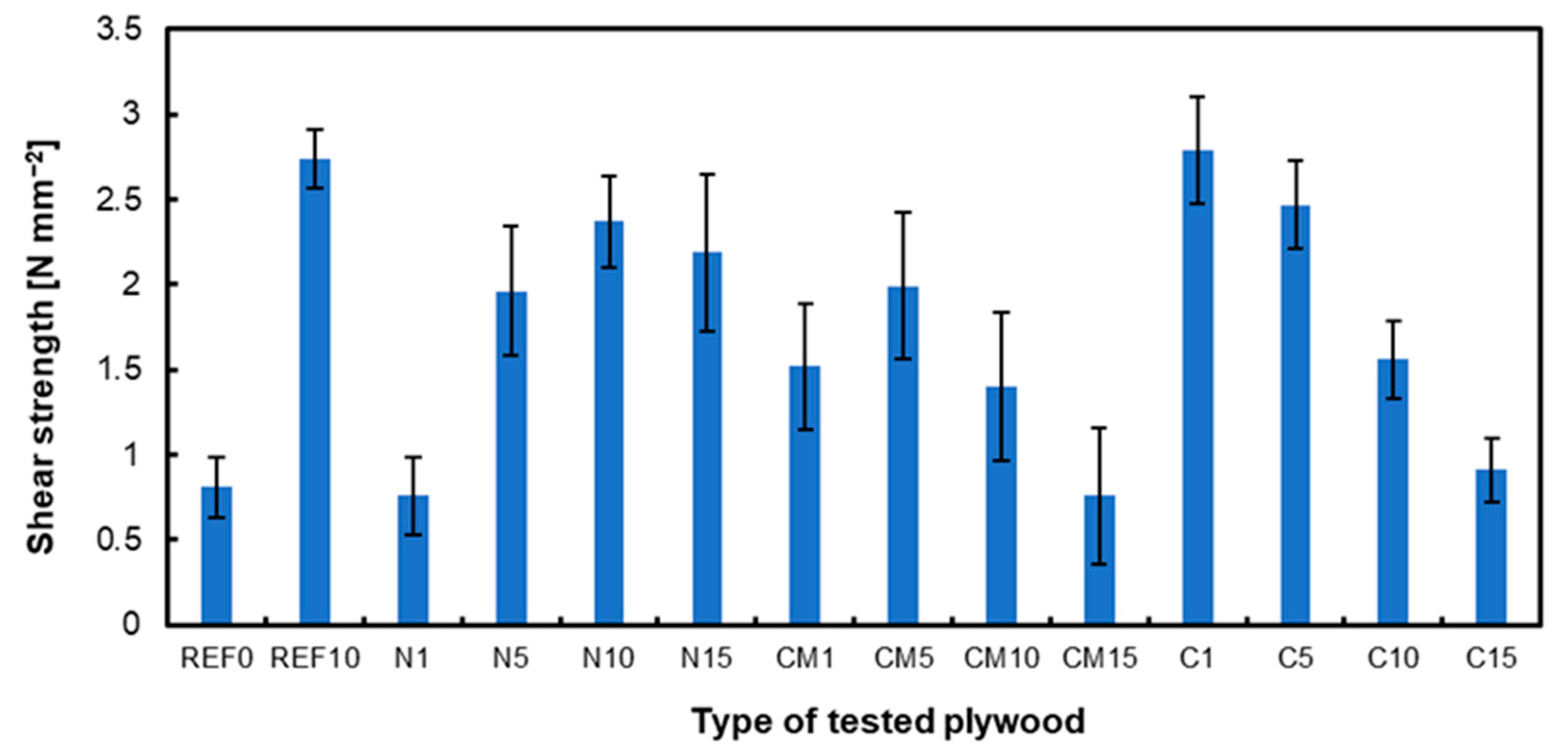

3.2. Shear Strength

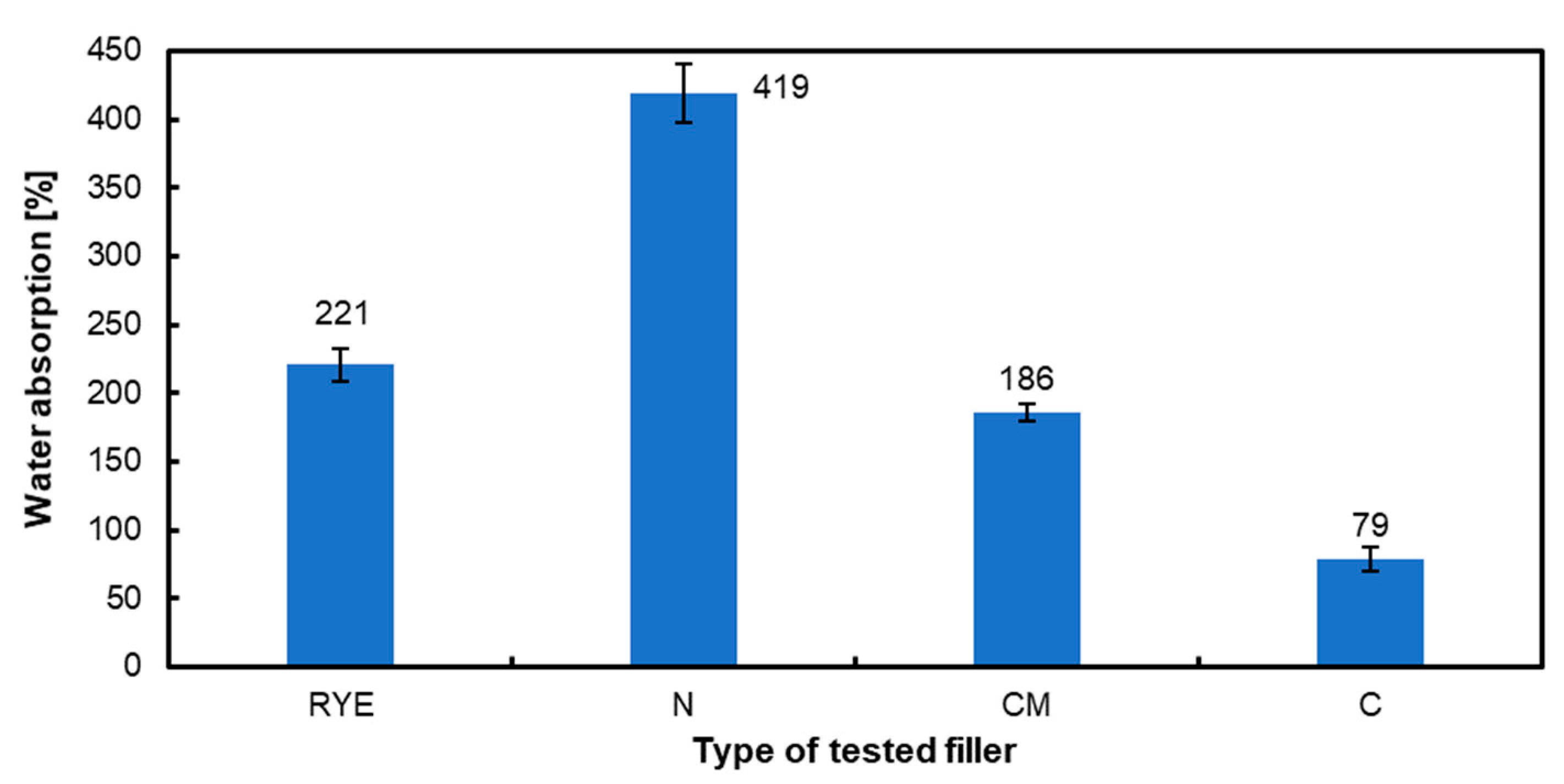

3.3. Water Absorption

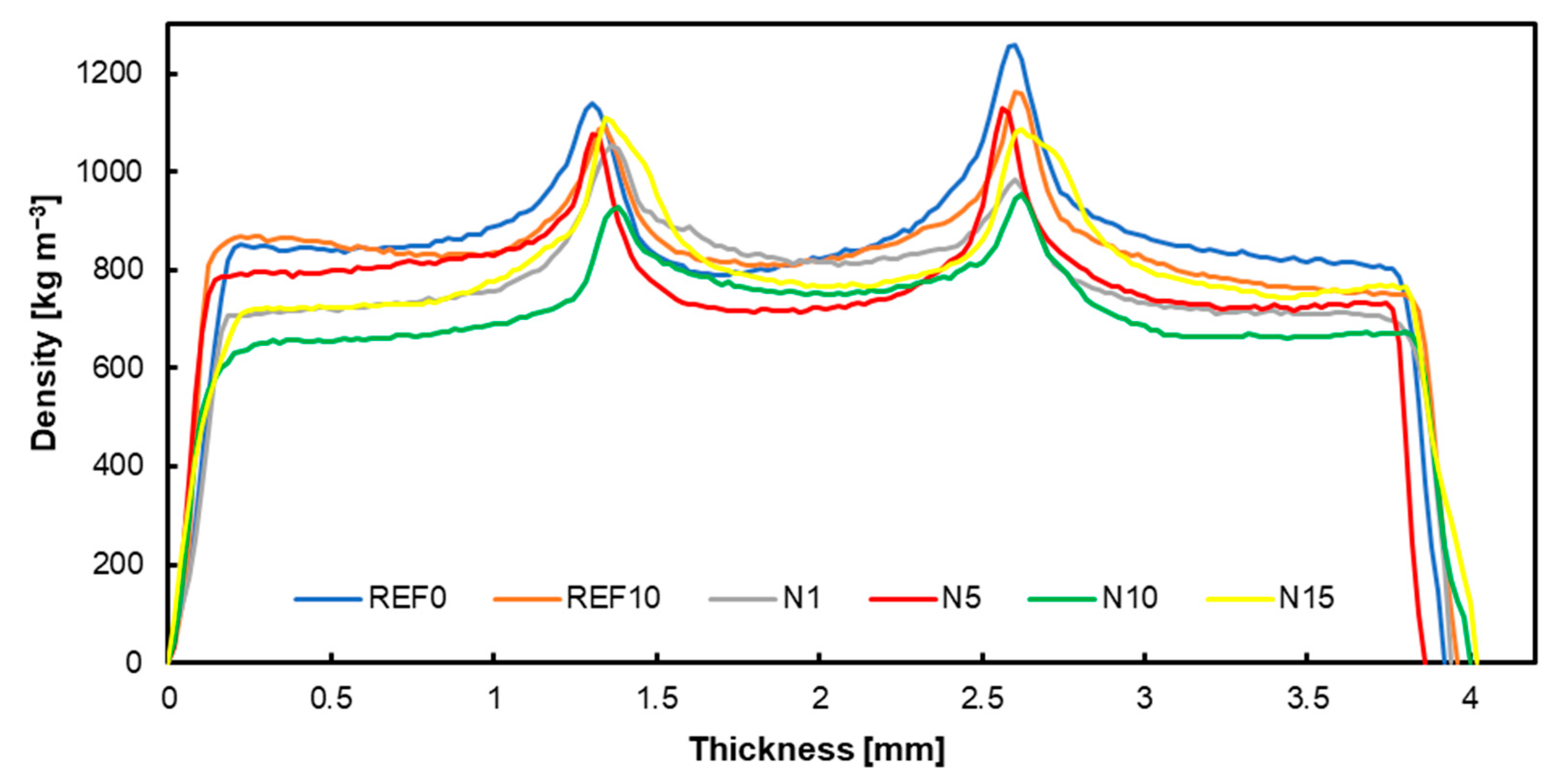

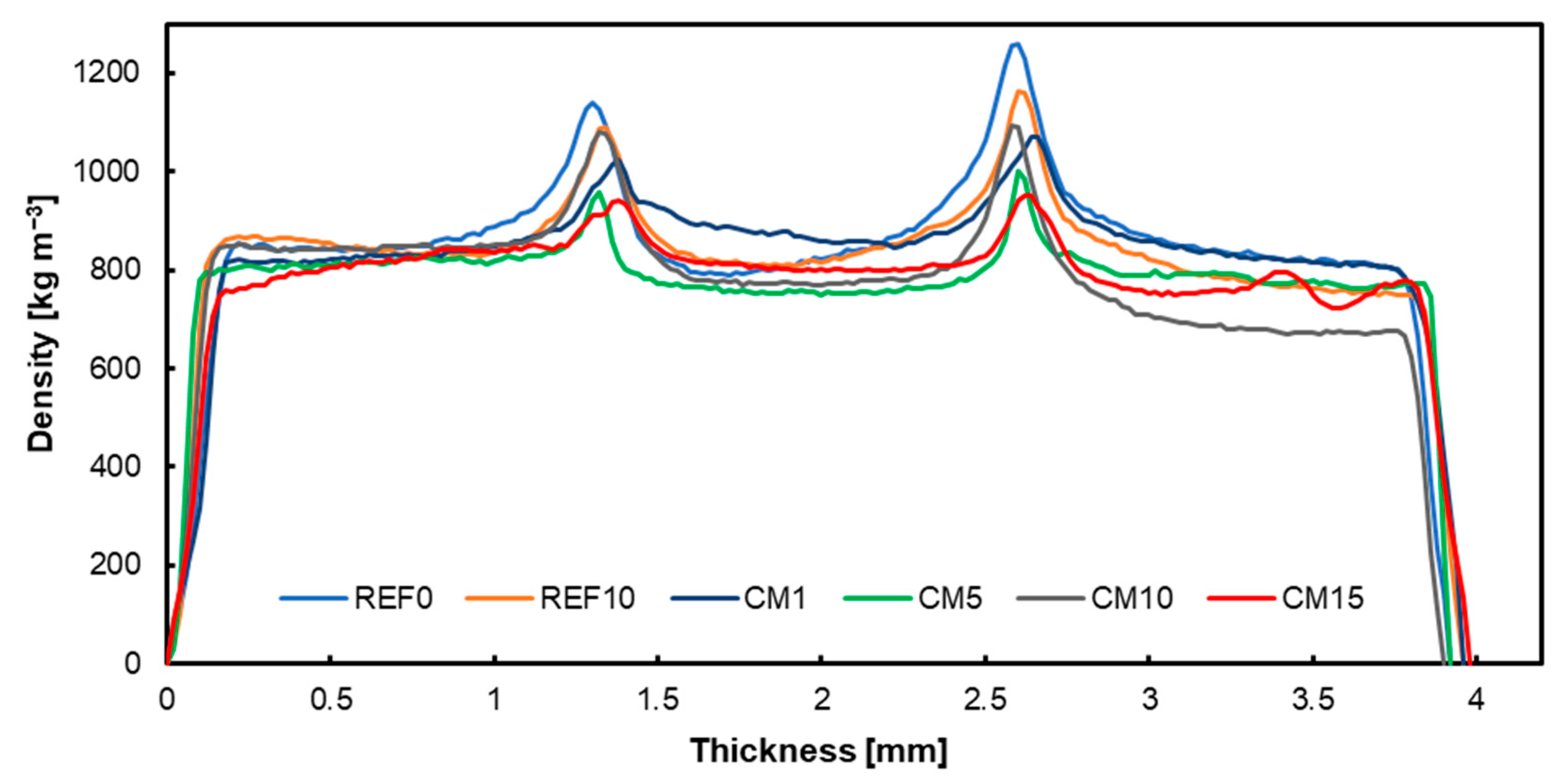

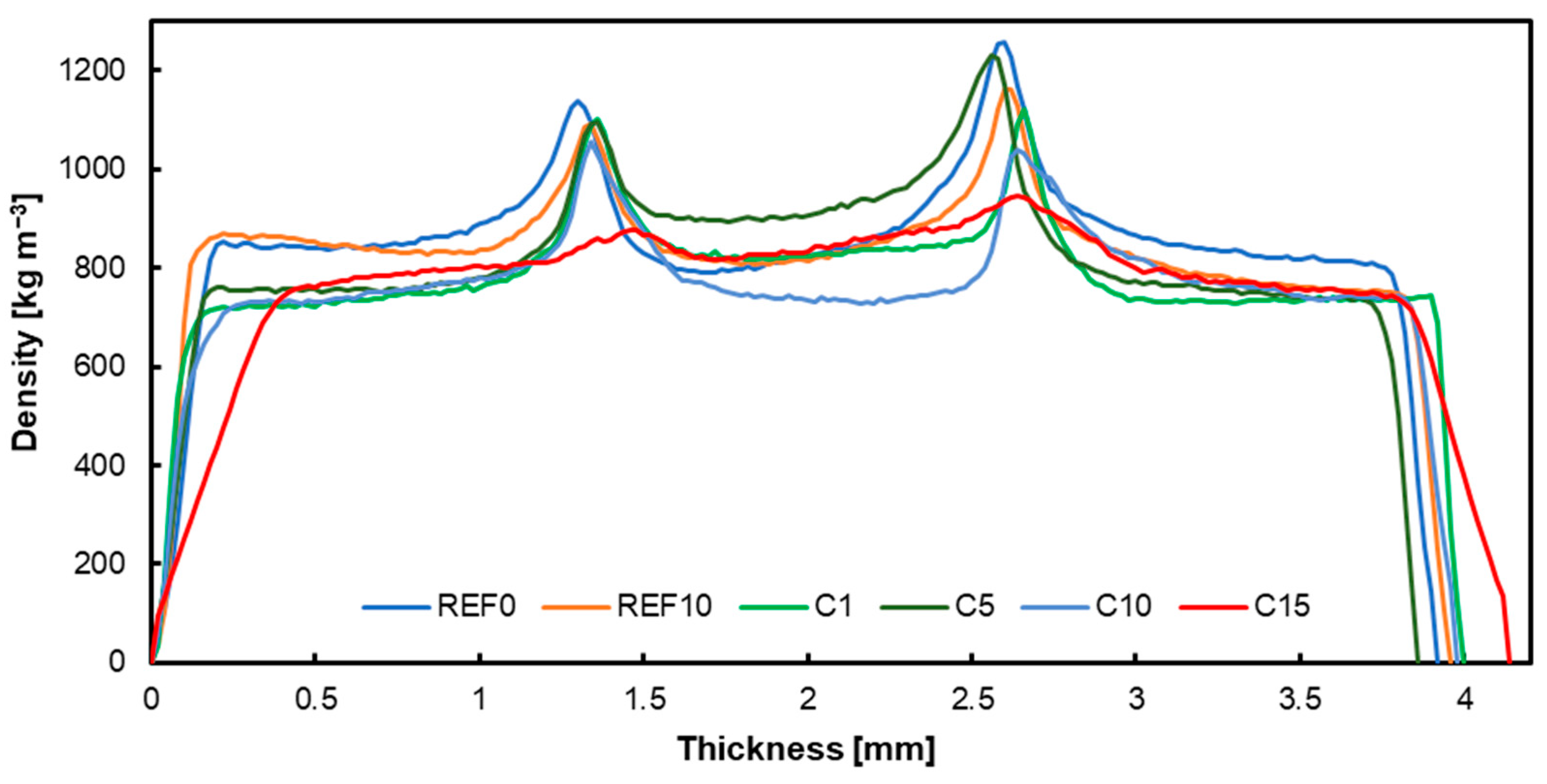

3.4. Density Profiles

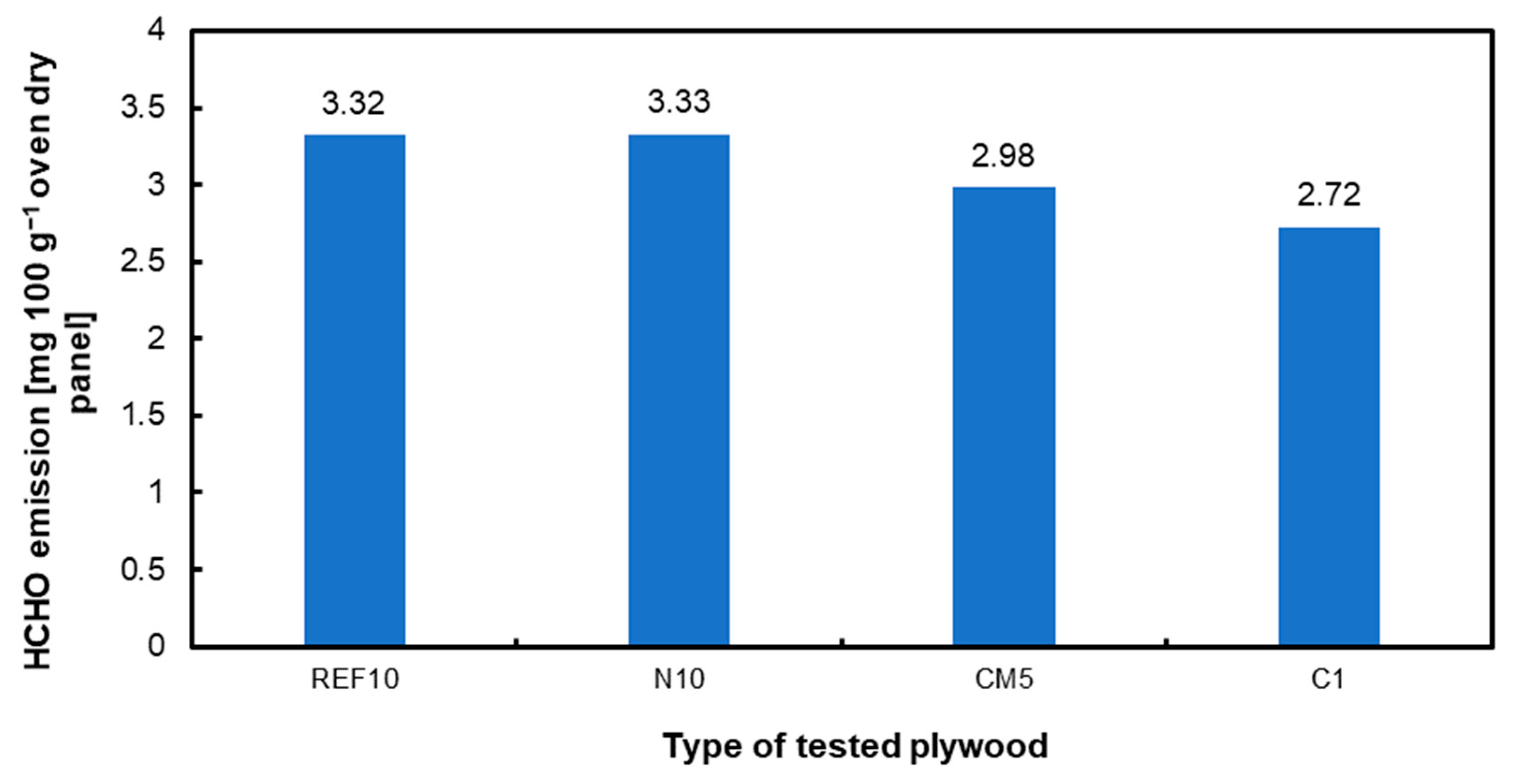

3.5. Formaldehyde Emission

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mohd Yunus, N.Y. 6 - Nonformaldehyde-Based Adhesives Used for Bonding Oil Palm Biomass (OPB). In Oil Palm Biomass for Composite Panels; Sapuan, S.M., Paridah, M.T., SaifulAzry, S.O.A., Lee, S.H., Eds.; Elsevier, 2022; pp. 99–110 ISBN 978-0-12-823852-3.

- Ong, H.R.; Reddy Prasad, D.M.; Khan, M.M.R. Optimization of Preparation Conditions for Melamine Urea Formaldehyde Based Adhesive for Plywood Application Using Response Surface Methodology. Indian J. Chem. Technol. 2016, 23, 39–46. [Google Scholar]

- Thapliyal, P.C. Organic Nanofillers and Their Classification Employed in Polymers; 2023.

- Mazitova, A.K.; Zaripov, I.I.; Aminova, G.K.; Ovod, M. V; Suntsova, N.L. Fillers for Polymer Composite Materials. Nanotechnologies Constr. 2022, 14, 294–299. [Google Scholar] [CrossRef]

- Esposito, N.; Bernai, Y.; Goss, G.R. Inorganic Powders Used in Agricultural Formulations. In Proceedings of the ASTM Special Technical Publication; 2015; Vol. STP 1579, pp. 23 – 35.

- Baek, C.S.; Cho, K.H.; Ahn, J.-W. Effect of Grain Size and Replacement Ratio on the Plastic Properties of Precipitated Calcium Carbonate Using Limestone as Raw Material. J. Korean Ceram. Soc. 2014, 51, 127–131. [Google Scholar] [CrossRef]

- Astuti, P.; Erprihana, A.A. Antimicrobial Edible Film from Banana Peels as Food Packaging. 2014, 2, 65–70.

- Trivedi, D.N.; Munezero, F.; Rachchh, N. Mechanical Characterization of Hybrid Bagasse/Eggshell/E-Glass Fiber-Based Polyester Composite. Period. Polytech. Mech. Eng. 2024, 68, 130–140. [Google Scholar] [CrossRef]

- Hayajneh, M.T.; Al-Oqla, F.M.; Al-Shrida, M.M. Hybrid Green Organic/Inorganic Filler Polypropylene Composites: Morphological Study and Mechanical Performance Investigations. E-Polymers 2021, 21, 710–721. [Google Scholar] [CrossRef]

- Grząbka-Zasadzińska, A.; Klapiszewski, Ł.; Jesionowski, T.; Borysiak, S. Functional MgO–Lignin Hybrids and Their Application as Fillers for Polypropylene Composites. Molecules 2020, 25. [Google Scholar] [CrossRef] [PubMed]

- Reh, R.; Kristak, L.; Sedliacik, J.; Bekhta, P.; Wronka, A.; Kowaluk, G. Molded Plywood with Proportions of Beech Bark in Adhesive Mixtures: Production on an Industrial Scale. Polymers (Basel). 2024, 16, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Réh, R.; Igaz, R.; Krišt’ák, L.; Ružiak, I.; Gajtanska, M.; Božíková, M.; Kučerka, M. Functionality of Beech Bark in Adhesive Mixtures Used in Plywood and Its Effect on the Stability Associated with Material Systems. Materials (Basel). 2019, 12. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Quan, H.; Ji, J.; Zhang, H.; Sun, F. Research on the Preparation of Wood Adhesive Active Fillers from Tannin-/Bentonite-Modified Corn Cob. Forests 2024, 15. [Google Scholar] [CrossRef]

- Mirski, R.; Kawalerczyk, J.; Dziurka, D.; Siuda, J.; Wieruszewski, M. The Application of Oak Bark Powder as a Filler for Melamine-Urea-Formaldehyde Adhesive in Plywood Manufacturing. Forests 2020, 11, 1–12. [Google Scholar] [CrossRef]

- Sabirova, G.A.; Safin, R.R.; Galyavetdinov, N.R. Effect of Wood Filler Concentration on Physical and Mechanical Properties of Pla-Based Composites. Key Eng. Mater. 2021, 887 KEM, 110–115. [CrossRef]

- Walkiewicz, J.; Kawalerczyk, J.; Mirski, R.; Dziurka, D. The Application of Various Bark Species as a Fillers for UF Resin in Plywood Manufacturing. Materials (Basel). 2022, 15, 7201. [Google Scholar] [CrossRef] [PubMed]

- Jeżo, A.; Wronka, A.; Dębiński, A.; Kristak, L.; Reh, R.; Rizhikovs, J.; Kowaluk, G. Influence of Upcycled Post-Treatment Bark Biomass Addition to the Binder on Produced Plywood Properties. Forests 2023, 14(1), 1–14. [Google Scholar] [CrossRef]

- Liu, J.; Li, Y.; Mo, H.; Xie, E.; Fang, J.; Gan, W. Current Utilization of Waste Biomass as Filler for Wood Adhesives: A Review. J. Ind. Eng. Chem. 2022, 115, 48–61. [Google Scholar] [CrossRef]

- Civancik-Uslu, D.; Ferrer, L.; Puig, R.; Fullana-i-Palmer, P. Are Functional Fillers Improving Environmental Behavior of Plastics? A Review on LCA Studies. Sci. Total Environ. 2018, 626, 927–940. [Google Scholar] [CrossRef] [PubMed]

- Mirski, R.; Kawalerczyk, J.; Dziurka, D.; Wieruszewski, M.; Trociński, A. Effects of Using Bark Particles with Various Dimensions as a Filler for Urea-Formaldehyde Resin in Plywood. BioResources 2020, 15, 1692–1701. [Google Scholar] [CrossRef]

- Haylock, R.; Rosentrater, K.A. Cradle-to-Grave Life Cycle Assessment and Techno-Economic Analysis of Polylactic Acid Composites with Traditional and Bio-Based Fillers. J. Polym. Environ. 2018, 26, 1484–1503. [Google Scholar] [CrossRef]

- Oh, Y.-S. Evaluation of Chestnut Shell and Coffee Waste with Phenol-Formaldehyde Resin for Plywood Filler. Ciência Florest. 2021, 31, 1991–2001. [Google Scholar] [CrossRef]

- Anas, M.; Jahiding, M.; Ratna; Sudiana, I.N. Production and Characterization of Activated Carbon from Cashew Nut Shell Using N2 as Activation Agent. In Proceedings of the IOP Conference Series: Materials Science and Engineering; 2019; Vol. 550.

- Shirbhate, V.A.; Gulwade, D.P.; Bhandarkar, S.E.; Narsing, S. V Preparation and Spectroscopic Characterization of Pistachio Nut Shell’s Activated Carbon Using ZnCl2 for Removal of Transition Metal Ions. In Proceedings of the Materials Today: Proceedings; 2020; Vol. 29, pp. 1259 – 1264.

- Buah, W.K.; Williams, P.T. Granular Activated Carbons from Palm Nut Shells for Gold Di-Cyanide Adsorption. Int. J. Miner. Metall. Mater. 2013, 20, 172–179. [Google Scholar] [CrossRef]

- De Castro, P.M.; Ferrarini, S.R.; Rimoli, M.D.S.F.; Merlo, A.A.; Nogueira, R.M.; Pires, E.M. Preparation and Characterization of Steam and Co2 Activated Carbon From Brazil Nut Shell. Biosci. J. 2023, 39, 1–10. [Google Scholar] [CrossRef]

- Kumar, J.; Sivakumar, S.; Prasanth, D.; Guhanesh, B.; Ahamed, A. A Review on the Synthesis of Activated Carbon from Natural Resources for Mechanical Applications. In; 2021; pp. 1013–1025 ISBN 978-981-15-4744-7.

- Wong, J. Introduction to Carbon Sorbents for Pollution Control; 2014.

- Reza, M.S.; Hasan, A.K.; Afroze, S.; Bakar, M.S.A.; Taweekun, J.; Azad, A.K. Analysis on Preparation, Application, and Recycling of Activated Carbon to Aid in COVID-19 Protection. Int. J. Integr. Eng. 2020, 12, 233–244. [Google Scholar] [CrossRef]

- Bergna, D.; Romar, H.; Tuomikoski, S.; Runtti, H.; Kangas, T.; Tynjälä, P.; Lassi, U. Activated Carbon from Renewable Sources: Thermochemical Conversion and Activation of Biomass and Carbon Residues from Biomass Gasification; 2017.

- Kumar, J.A.; Amarnath, D.J.; Renita, A.A.; Babu, G. Activated Carbon Production from Biowaste Materials - Properties and Applications: A Review. Indian J. Environ. Prot. 2020, 40, 507–511. [Google Scholar]

- Raut, E.R.; Thakur, M.A.B.; Chaudhari, A.R. A Review on Activated Carbon Preparation from Natural and Eco-Friendly Raw Materials. In Proceedings of the AIP Conference Proceedings; 2021; Vol. 2417.

- Mukhin, V.M.; Korolev, N. V Active Carbons as an Important Factor in the Sustainable Development of the Economy and the Quality of Life of the Population. Theor. Appl. Ecol. 2021, 2021, 210–217. [Google Scholar] [CrossRef]

- Wang, J.; Wu, Z.; Niu, Q.; Liu, L.; Yang, L.; Fu, M.; Ye, D.; Chen, P. Highly Efficient Adsorptive Removal of Toluene Using Silicon-Modified Activated Carbon with Improved Fire Resistance. J. Hazard. Mater. 2021, 415, 125753. [Google Scholar] [CrossRef] [PubMed]

- Yu, K.; Li, B.; Zhang, H.; Wang, Z.; Zhang, W.; Wang, D.; Xu, H.; Harbottle, D.; Wang, J.; Pan, J. Critical Role of Nanocomposites at Air–Water Interface: From Aqueous Foams to Foam-Based Lightweight Functional Materials. Chem. Eng. J. 2021, 416, 129121. [Google Scholar] [CrossRef]

- Ergun, M.E.; Özlüsoylu, İ.; İstek, A.; Can, A. Analysis and Impact of Activated Carbon Incorporation into Urea-Formaldehyde Adhesive on the Properties of Particleboard. Coatings 2023, 13. [Google Scholar] [CrossRef]

- Himarosa, R.A.; Ramadhan, M.A.; Muflikhun, M.A. Influence of Adding Activated Carbon Filler on Sandpaper-Treated Epoxy Resin Surface. In Proceedings of the AIP Conference Proceedings; 2022; Vol. 2499.

- Kumar, A.; Gupta, A.; Sharma, K. V.; Nasir, M.; Khan, T.A. Influence of Activated Charcoal as Filler on the Properties of Wood Composites. Int. J. Adhes. Adhes. 2013. [Google Scholar] [CrossRef]

- Zamani, R.; Kazemi Najafi, S.; Younesi, H. Utilization of Activated Carbon as an Additive for Urea-Formaldehyde Resin in Medium Density Fiberboard (MDF) Manufacturing. J. Adhes. Sci. Technol. 2022, 36, 2285–2296. [Google Scholar] [CrossRef]

- Li, J.; Xu, S.; Zhang, J.; Luo, X.; Jiang, K.; He, X.; Chen, Y.; Xiao, H. The Effect of Walnut Processing By-Product Filler on Properties of Plywood. In Proceedings of the IOP Conference Series: Materials Science and Engineering; 2019; Vol. 612.

- Jeżo, A.; Wronka, A.; Wang, W.; Zammarano, M.; Shields, J.R.; Knowlton, E.D.; Kim, I.; Gales, J.A.; Hoehler, M.S.; Li, J.; et al. Palm Kernel Meal as a Melamine Urea Formaldehyde Adhesive Filler for Plywood Applications. Int. J. Adhes. Adhes. 2018, 14, 93–98. [Google Scholar] [CrossRef]

- Kawalerczyk, J.; Siuda, J.; Mirski, R.; Dziurka, D. Hemp Flour as a Formaldehyde Scavenger for Melamine-Urea-Formaldehyde Adhesive in Plywood Production. BioResources 2020, 15, 4052–4064. [Google Scholar] [CrossRef]

- Alhababy, A.M. Hazelnut Production Sector In Georgia. 2016, 14, 1–23.

- Fuso, A.; Risso, D.; Rosso, G.; Rosso, F.; Manini, F.; Manera, I.; Caligiani, A. Potential Valorization of Hazelnut Shells through Extraction, Purification and Structural Characterization of Prebiotic Compounds: A Critical Review. Foods 2021, 10. [Google Scholar] [CrossRef] [PubMed]

- EN 827 Adhesives - Determination of Conventional Solids Content and Constant Mass Solids Content; European Committee for Standardization, Brussels, Belgium, 2005.

- Li, H.; Guo, X.; He, Y.; Zheng, R. A Green Steam-Modified Delignification Method to Prepare Low-Lignin Delignified Wood for Thick, Large Highly Transparent Wood Composites. J. Mater. Res. 2019, 34, 932–940. [Google Scholar] [CrossRef]

- EN 326-2:2010+A1 Wood-Based Panels. Sampling, Cutting and Inspection. Initial Type Testing and Factory Production Control; European Committee for Standardization, Brussels, Belgium, 2014.

- EN 326-1 Wood-Based Panels. Sampling, Cutting and Inspection. Sampling and Cutting of Test Pieces and Expression of Test Results; European Committee for Standardization, Brussels, Belgium, 1993.

- EN 310 Wood-Based Panels. Determination of Modulus of Elasticity in Bending and of Bending Strength; European Committee for Standardization, Brussels, Belgium, 1993.

- EN 314-1 Plywood – Bonding Quality – Part 1: Test Methods; European Committee for Standardization, Brussels, Belgium, 2004.

- Dasiewicz, J.; Kowaluk, G. Selected Aspects of Production and Characterization of Layered Biopolymer Composite Bonded with a Cellulose-Based Binder. Ann. WULS - SGGW. For. Wood Technol. 2022, 119, 24–34. [Google Scholar] [CrossRef]

- Dasiewicz, J.; Wronka, A. Influence of the Use of Chestnut Starch as a Binder Filler in Plywood Technology. Ann. Warsaw Univ. Life Sci. SGGW For. Wood Technol. 2023, 148, 137–148. [Google Scholar] [CrossRef]

- Kawalerczyk, J.; Dziurka, D.; Mirski, R.; Siuda, J.; Babicka, M. Possibility of Use of NCC-Reinforced Melamine-Urea- Formaldehyde Adhesive in Plywood Manufacturing. Drv. Ind. 2021, 72, 279–289. [Google Scholar] [CrossRef]

- Kawalerczyk, J.; Dukarska, D.; Antov, P.; Stuper-Szablewska, K.; Dziurka, D.; Mirski, R. Activated Carbon from Coconut Shells as a Modifier of Urea–Formaldehyde Resin in Particleboard Production. Appl. Sci. 2024, 14. [Google Scholar] [CrossRef]

- Oubagaranadin, J.U.K.; Murthy, Z.V.P. Activated Carbons: Classifications, Properties and Applications; 2011.

- Wirts-Rütters, M.; Heimann, M.; Kolbe, J.; Wolter, K.-J. Carbon Nanotube (CNT) Filled Adhesives for Microelectronic Packaging. In Proceedings of the Proceedings - 2008 2nd Electronics Systemintegration Technology Conference, ESTC; 2008; pp. 1057 – 1062.

- Karaman, A.; Nuri̇ Yildirim, M. EFFECT OF MATERIAL, ADHESIVE AND LOADING ON THE STIFFNESS OF WOODEN DOWEL JOINTS. Wood Res. 2023, 68, 768–780. [Google Scholar] [CrossRef]

- Nazerian, M.; Ghalehno, M.D.; Farrokhpayam, S.R. Effect of Wood Species and Veneer Arrangement on Swelling and Strength Properties of Laminated Veneer Lumber (LVL). Eur. J. Sci. Res. 2011, 50, 173–178. [Google Scholar]

- Xu, J.Y.; Niu, Q.; Liao, R.; Zhong, Z. Study on the Bonding Characteristics and Mechanism of Plant-Based Powder. Proc. 2012 Int. Conf. Biobase Mater. Sci. Eng. BMSE 2012 2012, 28–31. [Google Scholar] [CrossRef]

- Atikah, N.; Aziz, A.; Mohamed, T.D.M.; Mohamad, M.; Hazim, M.; Mohamad Amini, M.H.; Abdul Aziz, M.S.; Yusoff, H.; Rizman, Z. INFLUENCE OF ACTIVATED CARBON FILLER ON THE MECHANICAL PROPERTIES OF WOOD COMPOSITES. J. Eng. Appl. Sci. 2015, 10, 376–386. [Google Scholar]

- Jin, F.; Wang, S.; Duan, H.; Xia, Y.; Yang, T.; Yang, D. Study on the Water Absorption Characteristics of Anthracite Particles after Immersion in Water. ACS Omega 2024, 9, 28841–28851. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, S.; Romanias, M.N.; Alleman, L.Y.; Zeineddine, M.N.; Angeli, G.K.; Trikalitis, P.N.; Thevenet, F. Water Interaction with Mineral Dust Aerosol: Particle Size and Hygroscopic Properties of Dust. ACS Earth Sp. Chem. 2018, 2, 376–386. [Google Scholar] [CrossRef]

- Wang, N.; Tan, Y.; Du, X.; Yin, Q. Study on the Difference in Adsorption Thermodynamics for Water on Swelling and Non-Swelling Clays with Implications for Prevention and Treatment of Pneumoconiosis. Arab. J. Chem. 2022, 15. [Google Scholar] [CrossRef]

- Gabelman, A. Adsorption Basics: Part 2. Chem. Eng. Prog. 2017, 113. [Google Scholar]

- Zhong, L.; Zhang, Y.; Ji, Y.; Norris, P.; Pan, W.-P. Synthesis of Activated Carbon from Coal Pitch for Mercury Removal in Coal-Fired Power Plants. J. Therm. Anal. Calorim. 2016, 123, 851–860. [Google Scholar] [CrossRef]

- Mariana, M.; Mulana, F.; Sofyana, S.; Dian, N.P.; Lubis, M.R. Characterization of Adsorbent Derived from Coconut Husk and Silica (SiO2). In Proceedings of the IOP Conference Series: Materials Science and Engineering; 2019; Vol. 523.

- Henning, K.-D.; von Kienle, H. Activated Carbon; 2021; Vol. 1–2;

- Dukarska, D.; Kawalerczyk, J.; Kmieciak, J. Modified Pine Needles as a Formaldehyde Scavenger for Urea-Formaldehyde Resin in Plywood Production. Eur. J. Wood Wood Prod. 2023, Preprint. [Google Scholar] [CrossRef]

- Wronka, A.; Kowaluk, G. Upcycling of Wood Dust from Particleboard Recycling as a Filler in Lignocellulosic Layered Composite Technology. Materials (Basel). 2023, 16, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Ren, H.; Wang, Y. Study of Properties and Mechanism of Bonding Line in Three-Layer Hybrid Cross-Laminated Timber. J. Mater. Civ. Eng. 2022, 34. [Google Scholar] [CrossRef]

- Król, P.; Borysiuk, P.; Mamiński, M. Comparison of Methodologies for Acid Buffering Capacity Determination—Empirical Verification of Models. Appl. Sci. 2019. [Google Scholar] [CrossRef]

- Aydin, I.; Demirkir, C.; Colak, S.; Colakoglu, G. Utilization of Bark Flours as Additive in Plywood Manufacturing. Eur. J. Wood Wood Prod. 2017, 75, 63–69. [Google Scholar] [CrossRef]

- Ružiak, I.; Igaz, R.; Krišták, L.; Réh, R.; Mitterpach, J.; Očkajová, A.; Kučerka, M. Influence of Urea-Formaldehyde Adhesive Modification with Beech Bark on Chosen Properties of Plywood. BioResources 2017, 12, 3250–3264. [Google Scholar] [CrossRef]

- Duan, C.; Meng, M.; Huang, H.; Wang, H.; Zhang, Q.; Gan, W.; Ding, H.; Zhang, J.; Tang, X.; Pan, C. Performance and Characterization of Bamboo-Based Activated Carbon Prepared by Boric Acid Activation. Mater. Chem. Phys. 2023, 295. [Google Scholar] [CrossRef]

- Margiana, R.; Solanki, R.; Lin, Y.-C.; Altimari, U.S.; Alnassar, Y.S.; Mohammed, B.M.; Ibrahim, A.I.; Shams, M.A.; Surendar, A.; Kzar, H.H.; et al. Removal of Formaldehyde from Aqueous Solution Using Low-Cost and Reusable Adsorbents. Phys. Chem. Res. 2023, 11, 853–864. [Google Scholar] [CrossRef]

- Rengga, W.D.P.; Wahyuni, S.; Feinnudin, A. Thermodynamics of Formaldehyde Removal by Adsorption onto Nanosilver Loaded Bamboo-Based Activated Carbon. Mater. Sci. Forum, 2017, 890 MSF, 93–97. [CrossRef]

- Isinkaralar, K.; Gullu, G.; Turkyilmaz, A. Experimental Study of Formaldehyde and BTEX Adsorption onto Activated Carbon from Lignocellulosic Biomass. Biomass Convers. Biorefinery 2023, 13, 4279–4289. [Google Scholar] [CrossRef]

| Variant Label | Filler type | Filler Content | Curing time [s] |

|---|---|---|---|

| [pbw 1 per 100 pbw of Resin] | |||

| REF0 | - | 0 | 88 |

| REF10 | Rye flour | 10 | 86 |

| N1 | Native hazelnut shell flour | 1 | 88 |

| N5 | 5 | 88 | |

| N10 | 10 | 86 | |

| N15 | 15 | 84 | |

| CM1 | Chemically modified hazelnut shell flour | 1 | 87 |

| CM5 | 5 | 85 | |

| CM10 | 10 | 84 | |

| CM15 | 15 | 82 | |

| C1 | Carbonized hazelnut shell flour | 1 | 86 |

| C5 | 5 | 82 | |

| C10 | 10 | 80 | |

| C15 | 15 | 76 |

| Test type | Type of tested plywood | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| REF0 | REF10 | N1 | N5 | N10 | N15 | CM1 | CM5 | CM10 | CM15 | C1 | C5 | C10 | C15 | |

| MOE | a 1 | b | a | a | a, b | a | a | a | a | a | b | b | a, b | a |

| MOR | a | a, b | c | d | a | d | a | a | d | e | a, b | a | a | e |

| Shear strength | a | b | a | c | c | c | c | c | c | a, c | b | b, c | c | a, c |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).