Submitted:

02 August 2024

Posted:

03 August 2024

You are already at the latest version

Abstract

Keywords:

Introduction

Literature Review

IR4.0 Overview

SMEs in IR4.0

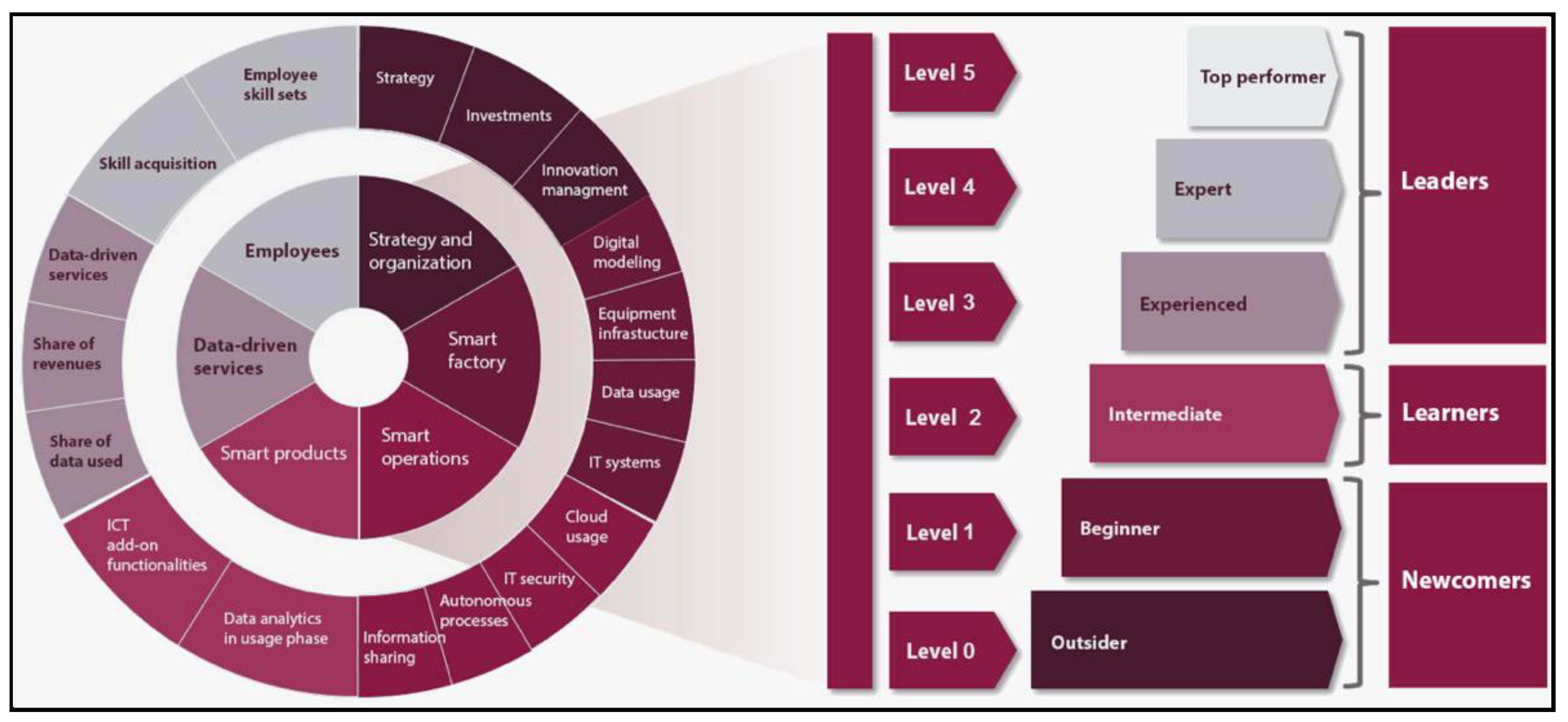

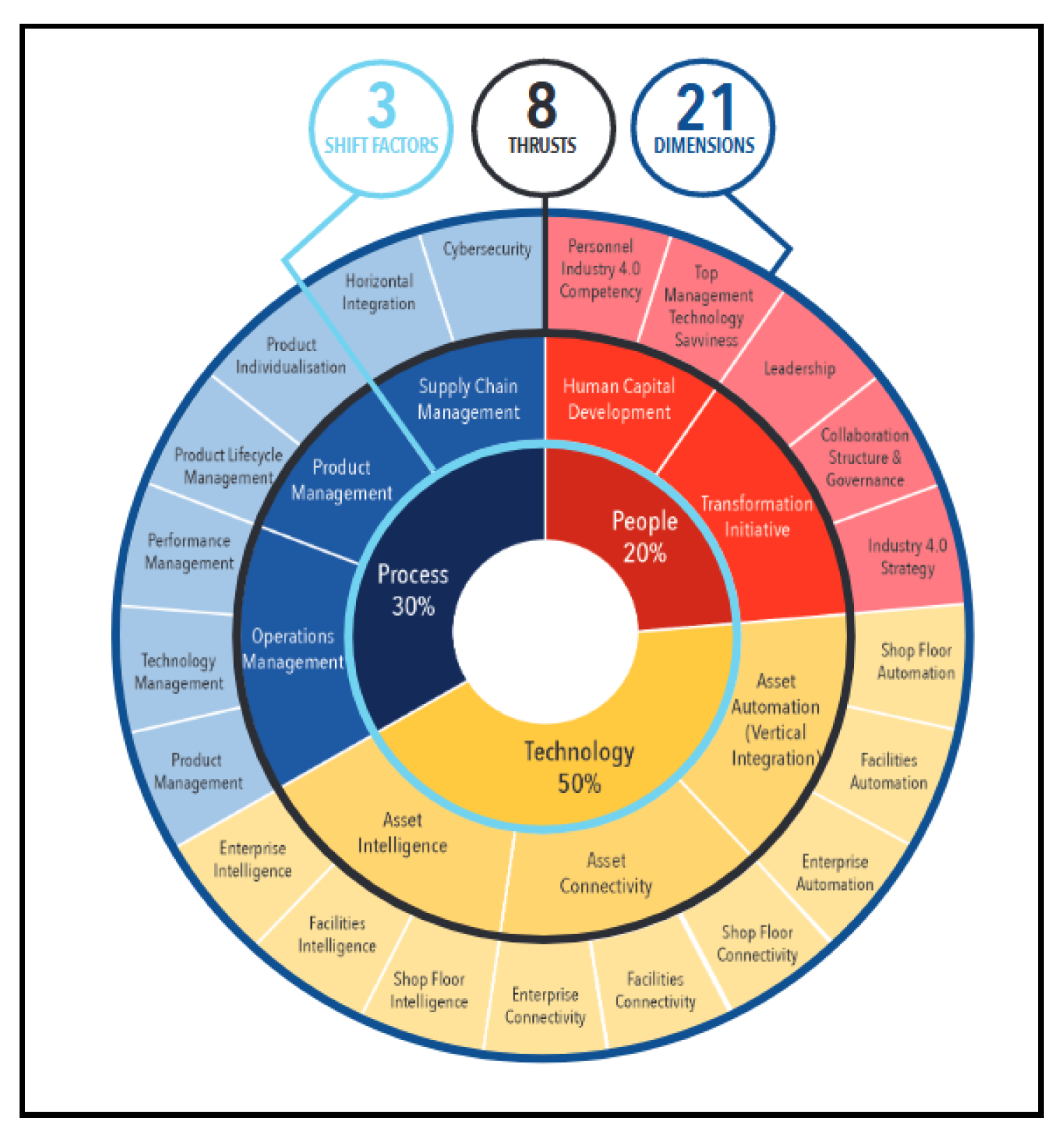

IR4.0 Readiness

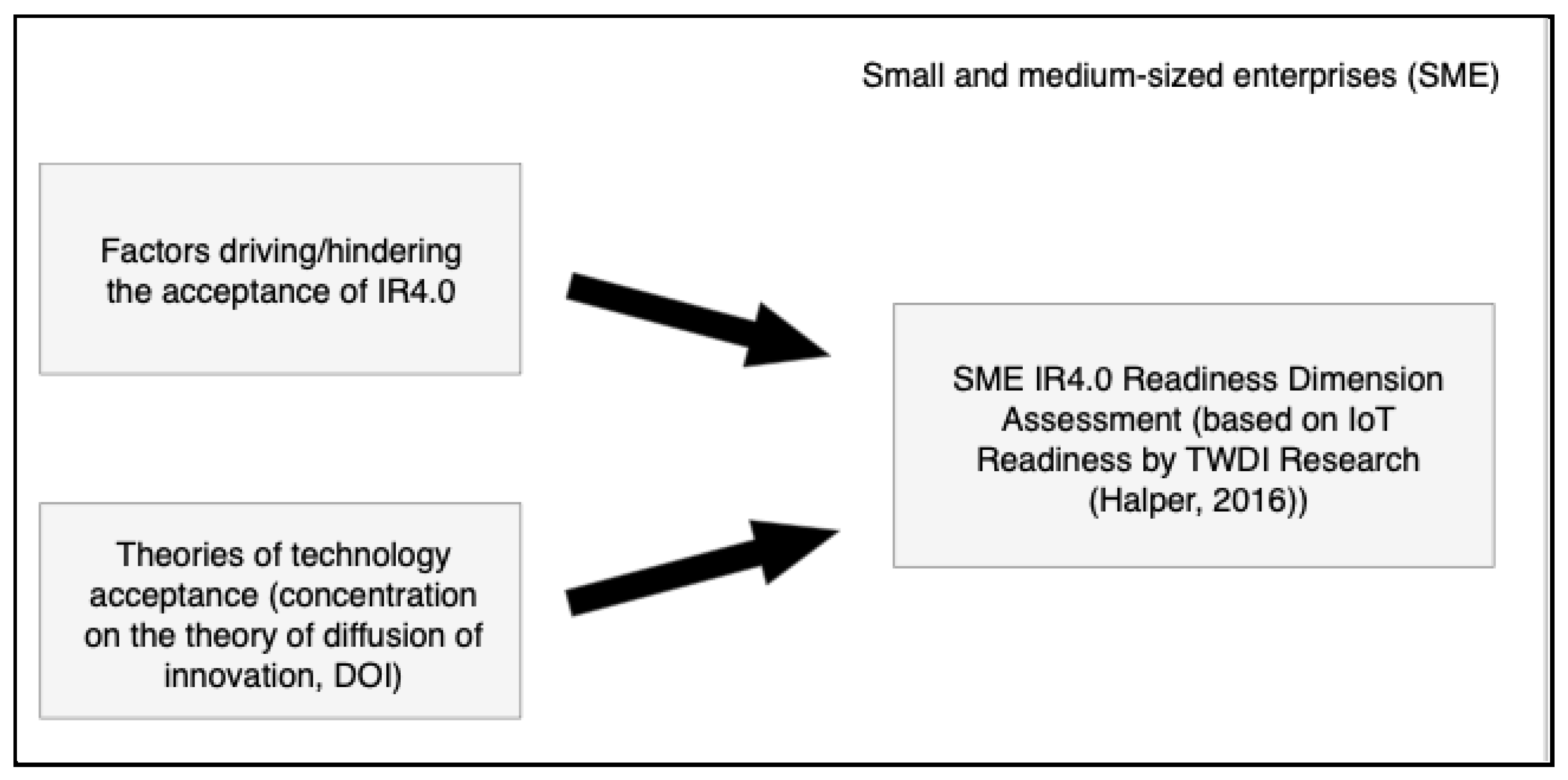

Theories of IR4.0 Adoption

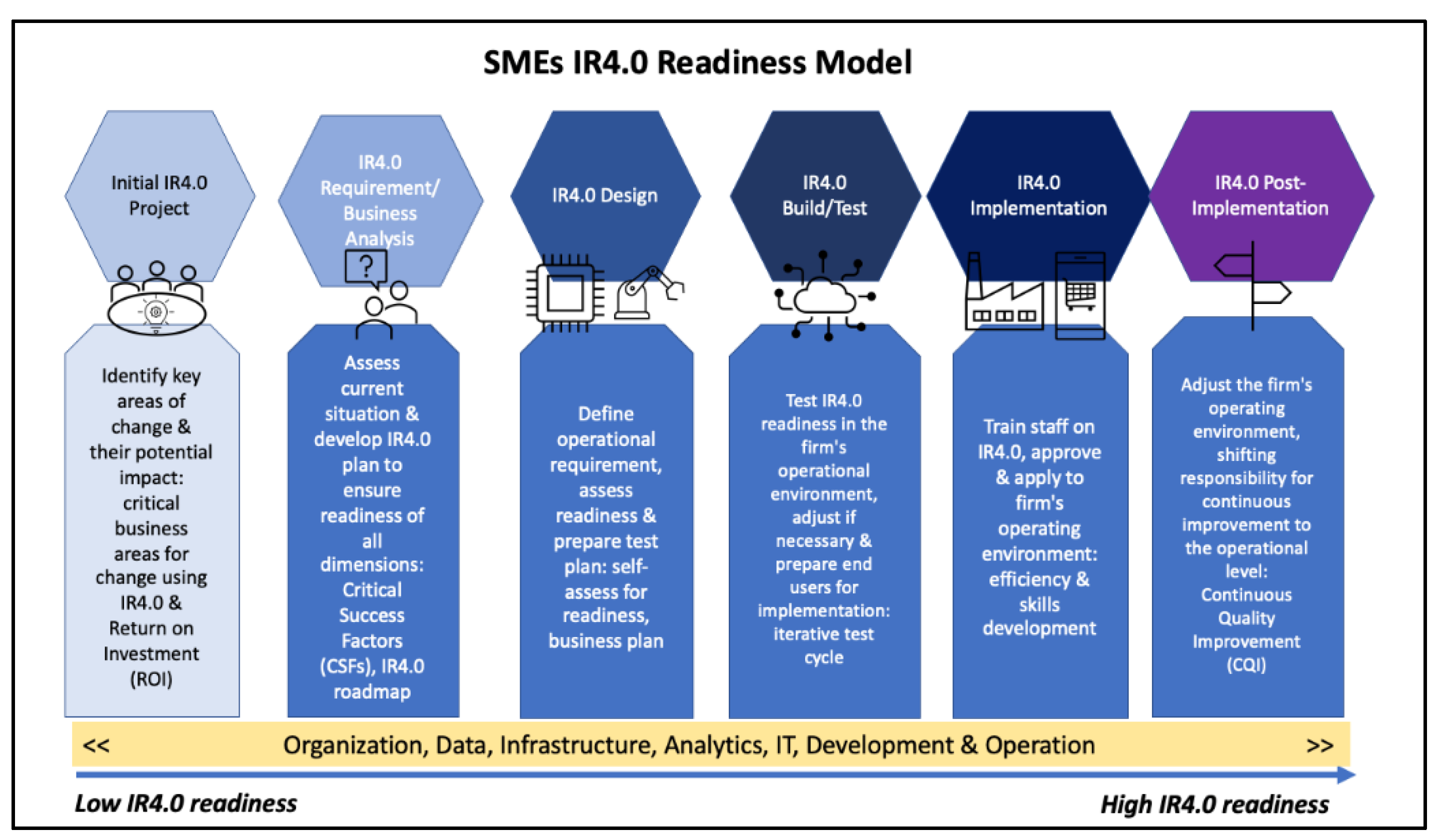

IR4.0 Readiness Model

Methodology

Phase 1: Preliminary Study

- a.

- Systematic Literature Review (SLR)

| Inclusion Criteria | - Directly or indirectly address any one or more research questions. - Focus on the development of IR4.0 readiness assessment models. - Published between 2017 and 2021. |

| Exclusion Criteria | Exclude books, articles unrelated to the research field, articles containing only abstracts with no full text available, and those not meeting the inclusion criteria. |

- b.

- Data Collection

Phase 2: Development Of IR4.0 Readiness Model for SMEs

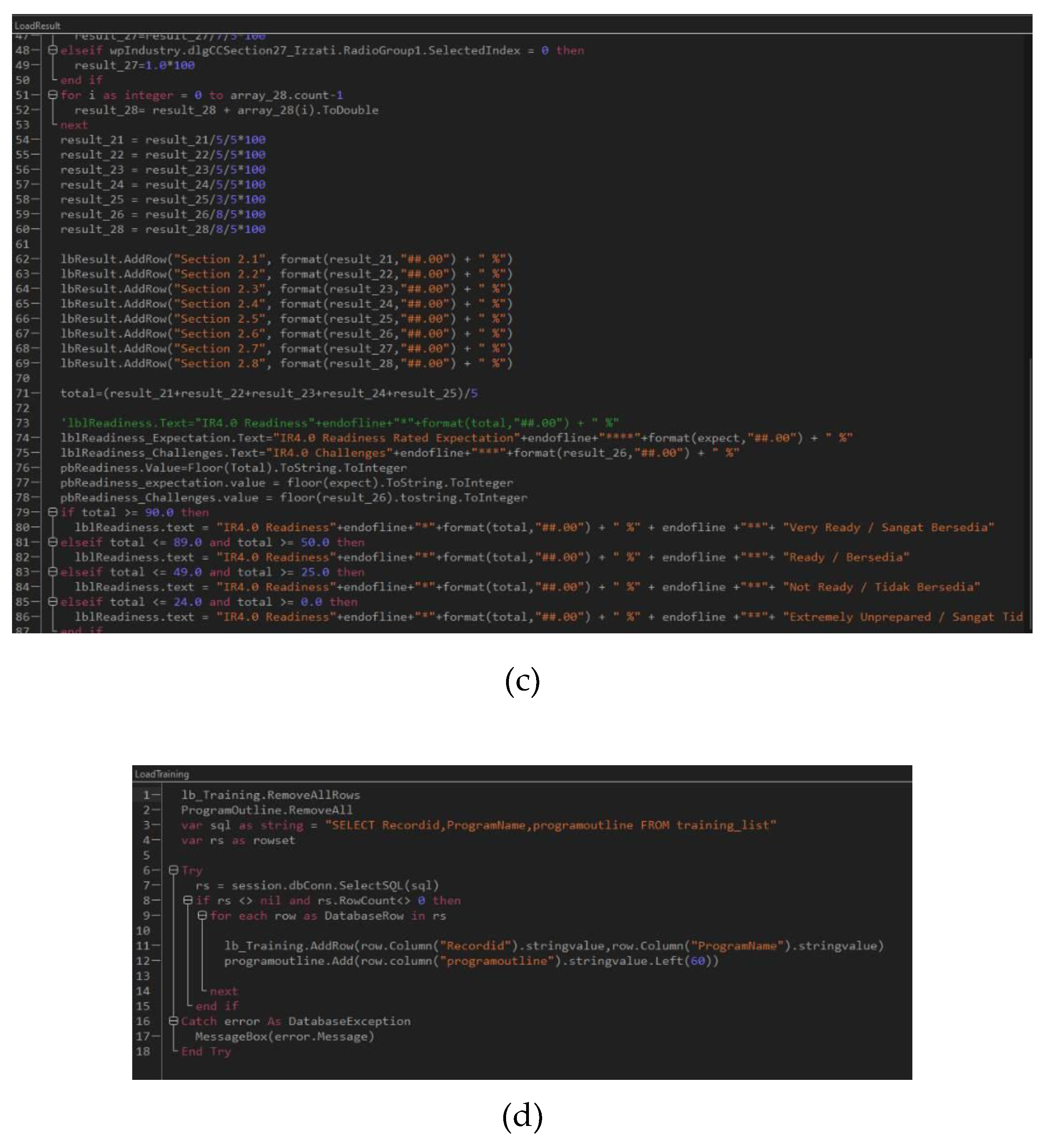

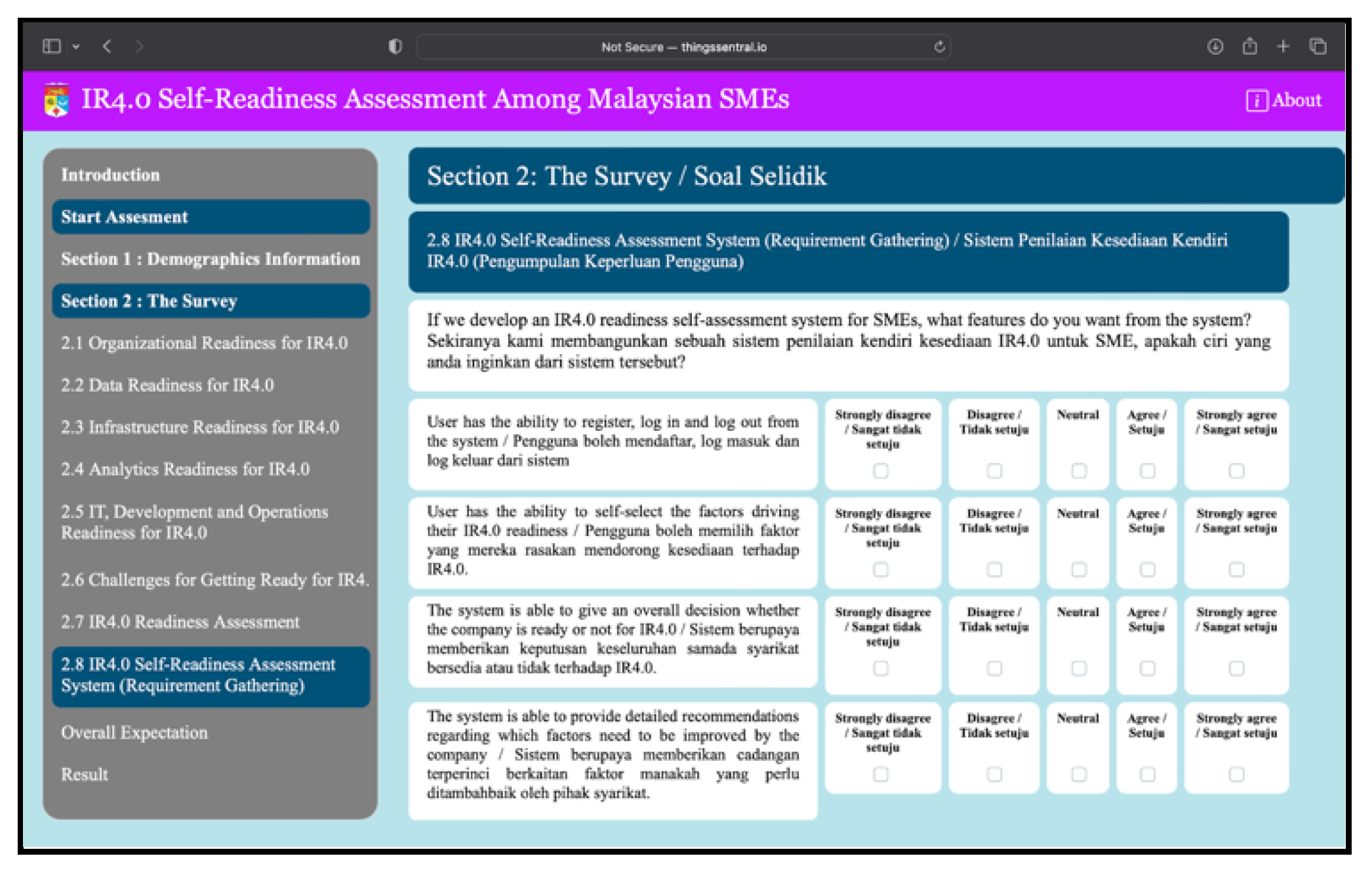

Phase 3: Development of System for the IR4.0 Readiness Model

Phase 4: IR4.0 Readiness Model and System Validation

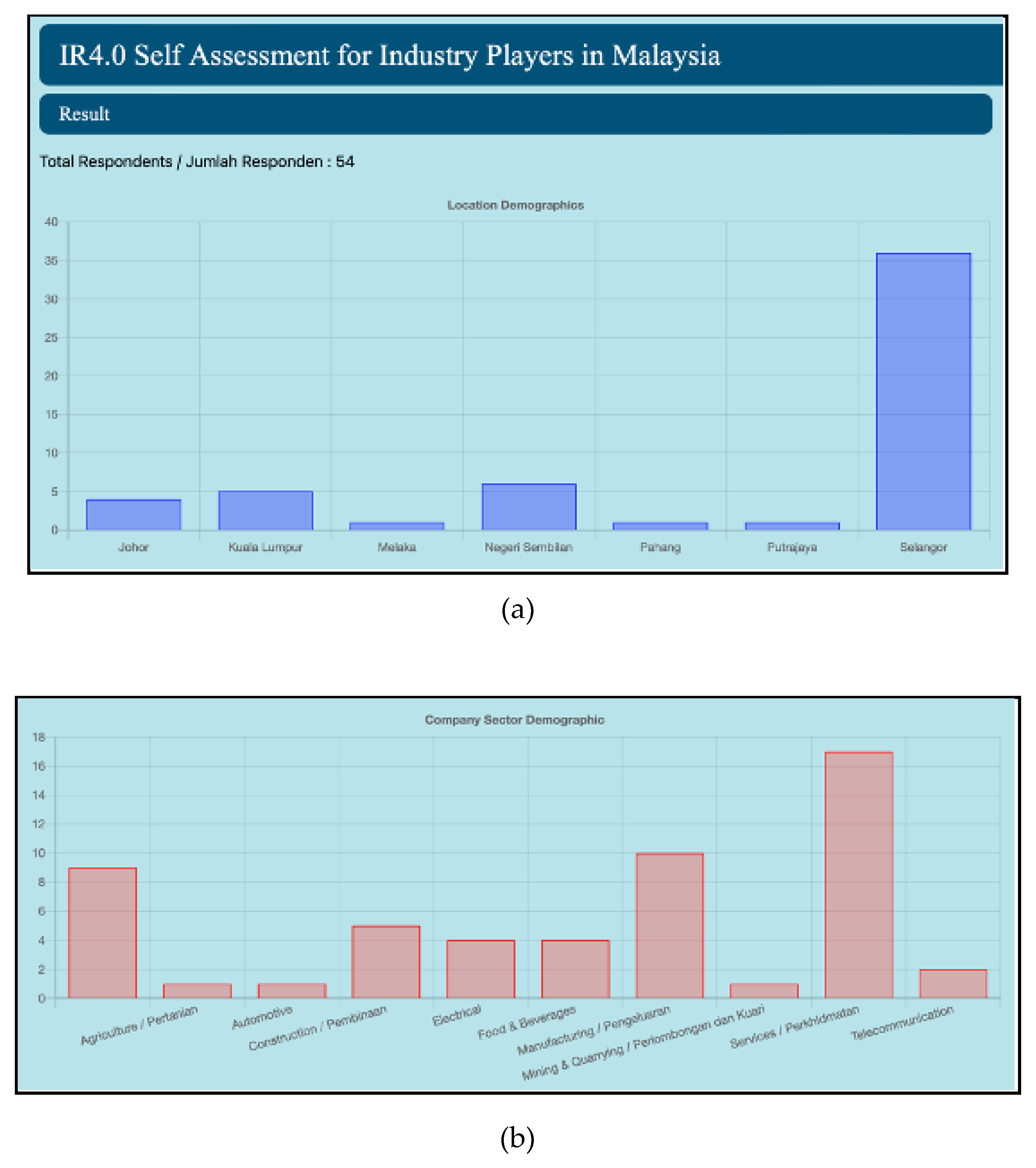

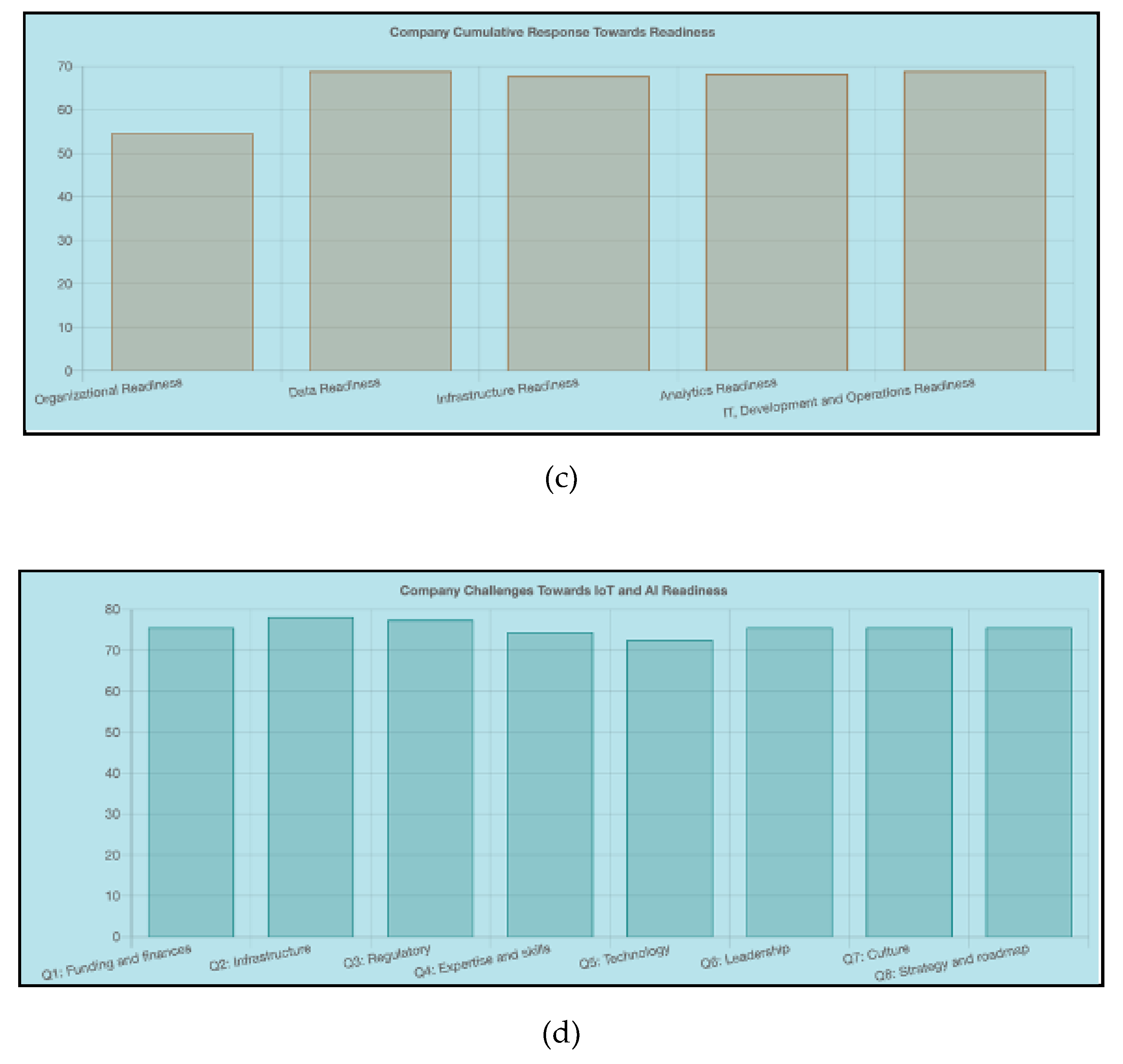

Results and Discussion

IR4.0 Readiness Model For SMEs

Factors For SMEs Adopting IR4.0

Initiative Factor

IR4.0 Readiness Dimension for SMEs

SMEs Readiness Towards IR4.0

Final Research Model

Conclusion

References

- Abd Shukor, R. Abd Shukor, R., Mooi, W. K., & Ibrahim, J. A. (2023). The Future of Malaysian SMEs in the Digital Economy. Qeios.

- Adamik, A. (2020). SMEs on the Way to the Smart World of Industry 4.0. In Eurasian Business Perspectives: Proceedings of the 25th Eurasia Business and Economics Society Conference (pp. 139-156). Springer International Publishing.

- Ahmad, N. H.; Iqbal, Q.; Halim, H. A. Challenges and Opportunities for SMEs in Industry 4.0. 2020. [Google Scholar]

- Alam, I. S. M., & Zakuan, N. A. The impact of industry 4.0 on manufacturing SMEs: A systematic review and future research agenda. International Journal of Industrial Engineering and Management 2020, 11, 5–19. [Google Scholar]

- Alazab, M., & Alhyari, S. Industry 4.0 Innovation: A Systematic Literature Review on the Role of Blockchain Technology in Creating Smart and Sustainable Manufacturing Facilities. Information 2024, 15, 78. [Google Scholar] [CrossRef]

- Alcácer, V., Rodrigues, C., Carvalho, H., & Cruz-Machado, V. Tracking the maturity of industry 4.0: the perspective of a real scenario. The International Journal of Advanced Manufacturing Technology 2021, 116, 2161–2181. [Google Scholar] [CrossRef] [PubMed]

- Ali, S., & Xie, Y. The impact of Industry 4.0 on organizational performance: the case of Pakistan's retail industry. European Journal of Management Studies 26, 63–86. [CrossRef]

- Ali, S. S., Kaur, R., Gupta, H., Ahmad, Z., & Elnaggar, G. Determinants of an organization's readiness for drone technologies adoption. IEEE transactions on engineering management 2021. [Google Scholar]

- Ali, M. H., Suleiman, N., Khalid, N., Tan, K. H., Tseng, M. L., & Kumar, M. Supply chain resilience reactive strategies for food SMEs in coping to COVID-19 crisis. Trends in food science & technology 2021, 109, 94–102. [Google Scholar]

- Ali, S. Data-Driven Decision Support: Leveraging Analytics for Business Success. 2023. [Google Scholar]

- Ali, K., & Johl, S. K. Impact of total quality management on industry 4.0 readiness and practices: does firm size matter? International Journal of Computer Integrated Manufacturing 2023, 36, 567–589. [Google Scholar] [CrossRef]

- Amer, M., Radwhi, A., Ali, A., & Ali, A. (2022, February). An Integrated Digital Collaborative Work Environment for Drilling. In International Petroleum Technology Conference (p. D031S084R003). IPTC.

- Amini, M., & Jahanbakhsh Javid, N. A Multi-Perspective Framework Established on Diffusion of Innovation (DOI) Theory and Technology, Organization and Environment (TOE) Framework Toward Supply Chain Management System Based on Cloud Computing Technology for Small and Medium Enterprises. Organization and Environment (TOE) Framework Toward Supply Chain Management System Based on Cloud Computing Technology for Small and Medium Enterprises (January 2023). International Journal of Information Technology and Innovation Adoption 11, 1217–1234.

- Ariffin, K. A. Z., & Ahmad, F. H. Indicators for maturity and readiness for digital forensic investigation in era of industrial revolution 4.0. Computers & Security 105, 102237.

- Arthur, J. P., Jr., & Bennett, A. W. The impact of training on employee performance: A meta-analysis. Journal of Applied Psychology 1995, 74, 353–361. [Google Scholar] [CrossRef]

- Ashley, K. D. (1990). Modeling Legal Argument. MIT Press: Cambridge, MA.

- Awang, Y., Shuhidan, S. M., Taib, A., Rashid, N., & Hasan, M. S. Digitalization of Accounting Profession: An Opportunity or a Risk for Future Accountants? Proceedings 2022, 82, 93. [Google Scholar] [CrossRef]

- Azevedo, S. G., & de Sousa Jabbour, A. B. L. The role of SMEs in the Industry 4.0 revolution: A systematic review of the literature. Journal of Manufacturing Technology Management 2023, 34, 94–118. [Google Scholar]

- Bahri, E. N. A., & Min, W. (2023). Job Creation vs Job Destruction Following Industrial Revolution 4.0. In Digital Transformation for Business and Society (pp. 1-22). Routledge.

- Balakrishnan, B., Othman, Z., & Zaidi, M. F. A. Review of IR4. 0 readiness and adoption in Malaysian manufacturing sector. International Journal of Business and Economy 2021, 3, 24–35. [Google Scholar]

- Bandari, V. The Impact of Artificial Intelligence on the Revenue Growth of Small Businesses in Developing Countries: An Empirical Study. Reviews of Contemporary Business Analytics 2019, 2, 33–44. [Google Scholar]

- Bernama. 2022. T-Robot Bantu Kelangsungan PKS Harungi Getir Pandemik. Malaysia.

- BH Online. 2023. FMM gesa sistem lebih baik mohon dana, geran dan insentif berkaitan IR4.0. Malaysia.

- Bhatti, A., Akram, H., Basit, H. M., Khan, A. U., Raza, S. M., & Naqvi, M. B. E-commerce trends during COVID-19 Pandemic. International Journal of Future Generation Communication and Networking 2020, 13, 1449–1452. [Google Scholar]

- Bockstaller, C., & Girardin, P. How to validate environmental indicators. Agricultural systems 2003, 76, 639–653. [Google Scholar] [CrossRef]

- Boschmann, S., & Schneck, M. Industry 4.0 for SMEs: Bridging the gap between adoption and implementation. Technological Forecasting and Social Change 2019, 143, 130–142. [Google Scholar]

- Brozzi, R., D’amico, R. D., Pasetti Monizza, G., Marcher, C., Riedl, M., & Matt, D. (2018). Design of Self-assessment Tools to measure Industry 4.0 readiness: A methodological approach for craftsmanship SMEs. In Product Lifecycle Management to Support Industry 4.0: 15th IFIP WG 5.1 International Conference, PLM 2018, Turin, Italy, July 2-4, 2018, Proceedings 15 (pp. 566-578). Springer International Publishing.

- Caballero-Morales, S. O. Innovation as recovery strategy for SMEs in emerging economies during the COVID-19 pandemic. Research in international business and finance 2021, 57, 101396. [Google Scholar] [CrossRef] [PubMed]

- Caiado, R. G. G., Scavarda, L. F., Nascimento, D. L. D. M., Ivson, P., & Cunha, V. H. C. (2020). A maturity model for manufacturing 4.0 in emerging countries. In Operations Management for Social Good: 2018 POMS International Conference in Rio (pp. 393-402). Springer International Publishing.

- Chan, P. K. P., Leung, A. M. Y., & Li, K. T. The impact of big data on small and medium-sized enterprises. International Journal of Information Management 2020, 40, 102348. [Google Scholar] [CrossRef]

- Chatterjee, S., Chaudhuri, R., Shah, M., & Maheshwari, P. Big data driven innovation for sustaining SME supply chain operation in post COVID-19 scenario: Moderating role of SME technology leadership. Computers & Industrial Engineering 2022, 168, 108058. [Google Scholar]

- Chege, S. M., & Wang, D. Information technology innovation and its impact on job creation by SMEs in developing countries: an analysis of the literature review. Technology Analysis & Strategic Management 2020, 32, 256–271. [Google Scholar]

- Chen, J., Wang, T., Fang, Z., & Wang, H. Research on elderly users' intentions to accept wearable devices based on the improved UTAUT model. Frontiers in Public Health 10, 1035398. [CrossRef] [PubMed]

- Chen, X., Chang-Richards, A., Ling, F. Y. Y., Yiu, T. W., Pelosi, A., & Yang, N. Developing a readiness model and a self-assessment tool for adopting digital technologies in construction organizations. Building Research & Information 2023, 51, 241–256. [Google Scholar]

- Cheng, E. C., & Lander, B. (Eds.). (2024). Implementing a 21st Century Competency-Based Curriculum Through Lesson Study: Teacher Learning About Cross-Curricular and Online Pedagogy. Taylor & Francis.

- Choi, S., Wuest, T., & Kulvatunyou, B. S. (2018). Towards a platform for smart manufacturing improvement planning. In IFIP international conference on advances in production management systems (pp. 378–385).

- Çınar, Z. M., Abdussalam Nuhu, A., Zeeshan, Q., Korhan, O., Asmael, M., & Safaei, B. Machine learning in predictive maintenance towards sustainable smart manufacturing in industry 4.0. Sustainability 2020, 12, 8211. [Google Scholar] [CrossRef]

- Cockburn, T. Cockburn, T. (2021). Reflections on emerging digital technologies’ impact on leadership models and decision-making. Available at SSRN 3889464.

- Crnovrsanin, T., Di Bartolomeo, S., Wilson, C., & Dunne, C. (2023). Indy Survey Tool: A framework to unearth correlations in survey data. 2023 IEEE Visualization and Visual Analytics (VIS), 146-150.

- Dalenogare, L. S., Benitez, G. B., Ayala, N. F., & Frank, A. G. The expected contribution of Industry 4.0 technologies for industrial performance. International Journal of production economics 204, 383–394. [CrossRef]

- Das, S. Digital Twin Technology: Enhancing Efficiency and Decision-Making in Industry 4.0. 2023. [Google Scholar]

- De Carolis, A., Macchi, M., Kulvatunyou, B., Brundage, M. P., & Terzi, S. (2017). Maturity models and tools for enabling smart manufacturing systems: comparison and reflections for future developments. In Product Lifecycle Management and the Industry of the Future: 14th IFIP WG 5.1 International Conference, PLM 2017, Seville, Spain, July 10-12, 2017, Revised Selected Papers 14 (pp. 23-35). Springer International Publishing.

- Demong, N. A. R., Shahrom, M., Omar, E. N., Rahim, R. A., & Yahya, M. Industry 4.0 readiness assessment tool: a conceptual framework from social well-being perspective. Romanian Journal of Information Technology and Automatic Control 31, 53–64.

- DiMaggio, P.J., Powell, W. The iron cage revisited: Institutional isomorphism and collective rationality in organizational fields. Am. Sociol. Rev. 1983, 147–160. [Google Scholar]

- Dixon, B. E., Staes, C., Acharya, J., Allen, K. S., Hartsell, J., Cullen, T.,... & Lehmann, H. Enhancing the nation’s public health information infrastructure: a report from the ACMI symposium. Journal of the American Medical Informatics Association, 30, 1000–1005.

- Dobson, D. Big change programmes: Increasing the likelihood of success. Journal of Change Management 2, 7–22. [CrossRef]

- Drzensky, F., Egold, N., & van Dick, R. Ready for a change? A longitudinal study of antecedents, consequences and contingencies of readiness for change. Journal of Change Management 12, 95–111. [CrossRef]

- Economic Planning Unit (ECP). (2021). National Fourth Industrial Revolution (4IR) Policy. Selangor, Malaysia: Ministry of Finance. Retrieved from https://www.ekonomi.gov.my/sites/default/files/2021-07/National-4IR-Policy.pdf.

- European Commision. 2017. Digital Transformation Monitor Germany: Industrie 4.0.

- Eljasik-Swoboda, T., Rathgeber, C. and Hasenauer, R. 2019. Artificial Intelligence for Innovation Readiness Assessment. In 2019 IEEE International Symposium on Innovation and Entrepreneurship (TEMS-ISIE) (pp. 1-6). IEEE.

- Galipeau, D. How Industry 4.0 Influences Our Work Environment. In Digital Project Practice for New Work and Industry 4.0 (pp. 75-98). Auerbach Publications. 2023. [Google Scholar]

- Ganapathy, S. Are Malaysians SMEs ready for Industry 4.0; Digital News Asia: Malaysia, 2018. [Google Scholar]

- García-Peñalvo, F; a graphical platform for building machine learning pipelines adapted to health professionals: , Vázquez-Ingelmo, A., García-Holgado, A., Sampedro-Gómez, J., Sánchez-Puente, A., Vicente-Palacios, V.,... & Sánchez, P. L. (2023). KoopaML.

- Geissbauer, R., Vedso, J., & Schrauf, S. (2016). Industry 4.0: Building the digital enterprise.

- Ghobakhloo, M., Iranmanesh, M., Vilkas, M., & Grybauskas, A. Drivers and barriers of industry 4.0 technology adoption among manufacturing SMEs: A systematic review and transformation roadmap. Journal of Manufacturing Technology Management 2022, 33, 1029–1058. [Google Scholar] [CrossRef]

- Gomes, M. A. S., Kovaleski, J. L., Pagani, R. N., da Silva, V. L., & Pasquini, T. C. D. S. Transforming healthcare with big data analytics: technologies, techniques and prospects. Journal of Medical Engineering & Technology 47, 1–11.

- Guillet, B. D. Online upselling: Moving beyond offline upselling in the hotel industry. International Journal of Hospitality Management 84, 102322. [CrossRef]

- Halili, S. H., Fathima, N., & Razak, R. Exploring Relevant Employability Skills 4.0 For University Students’ Readiness in The Work-Based Learning Program. Journal of Technical Education and Training 14, 68–78.

- Halper, F. (2016). TDWI IoT Readiness Guide: Interpreting Your Assessment Score. TDWI.

- Halse, L. L., & Ullern, E. F. 2017. Getting ready for the fourth industrial revolution: innovation in small and medium sized companies. In Advances in Production Management Systems. The Path to Intelligent, Collaborative and Sustainable Manufacturing: IFIP WG 5.7 International Conference, APMS 2017, Hamburg, Germany, September 3-7, 2017, Proceedings, Part I (pp. 247-254). Springer International Publishing.

- Hang, N. T. Educating and training labor force under Covid 19: Impacts to meet market demand in Vietnam during globalization and integration era. JETT 12, 179–184.

- Harmoko, H. Industry 4.0 readiness assessment: Comparison of tools and introduction of new tool for SME. Tehnički glasnik 2020, 14, 212–217. [Google Scholar]

- Haseeb, S. M. R., Khan, H. A., & Khan, B. B. A. 2019. The role of digital competence in SME innovation: A conceptual framework. Journal of Business Research, 100, 128-138. [CrossRef]

- Hasim, H., & Sherlina, L. Tiktok Social Media as a Means of Small and Medium Business Promotion. Journal of World Science 2022, 1, 1–14. [Google Scholar] [CrossRef]

- Hassan, H., Hsbollah, H. M., & Mohamad, R. Investigating Factors Affecting Solar Photovoltaic (PV) Adoption among Malaysian SMEs. Journal of Advanced Research in Applied Sciences and Engineering Technology 32, 289–313.

- Hermann, M., Pentek, T., & Otto, B. 2016. Design principles for industrie 4.0 scenarios. In 2016 49th Hawaii international conference on system sciences (HICSS) (pp. 3928-3937). IEEE.

- Hernandez-de-Menendez, M., Morales-Menendez, R., Escobar, C. A., & McGovern, M. Competencies for industry 4.0. International Journal on Interactive Design and Manufacturing (IJIDeM) 2020, 14, 1511–1524. [Google Scholar] [CrossRef]

- Hetzner, S., Heid, H., & Gruber, H. Change at work and professional learning: How readiness to change, self-determination and personal initiative affect individual learning through reflection. European Journal of Psychology of Education 2012, 27, 539–555. [Google Scholar] [CrossRef]

- Hindarto, D. The Management of Projects is Improved Through Enterprise Architecture on Project Management Application Systems. International Journal Software Engineering and Computer Science (IJSECS) 3, 151–161. [CrossRef]

- Hizam-Hanafiah, M., Soomro, M. A., & Abdullah, N. L. Industry 4.0 readiness models: a systematic literature review of model dimensions. Information 11, 364. [CrossRef]

- Horvat, D., Stahlecker, T., Zenker, A., Lerch, C. & Mladineo, M. A conceptual approach to analysing manufacturing companies’ profiles concerning Industry 4.0 in emerging economies. Procedia Manufacturing 2018, 17, 419–426. [Google Scholar] [CrossRef]

- Hurst, A. Participant observation. Introduction to Qualitative Research Methods, 2023. [Google Scholar]

- Ismail Albalushi, K., & Naqshbandi, M. M. Factors affecting success and survival of small and medium enterprises in the middle east. Knowledge 2, 525–538. [CrossRef]

- Ismail, S. N. A., Mohamed, W. N., Omar, K., Mat, N. H. N., & Saputra, J. A Conceptual Analysis of the Technology, Organisation, Environment, Readiness and Industry 4.0 Adoption in Malaysia Small and Medium Enterprises. Theoretical and Practical Research in Economic Fields 14, 175–185. [CrossRef]

- Jamilah, L. Smart Farming with IoT and Cloud in Malaysia. Malaysia. 2021. [Google Scholar]

- Jayashree, S., Malarvizhi, C. A. N., & Hassan Reza, M. N. The Impact of Organizational Readiness on IR 4.0 and Sustainability-A Conceptual Framework for SMEs in Malaysia. 2019. [Google Scholar]

- Kaur, B. (2019), Malaysia falls behind in IR4.0 migration, The New Straits Times, https://www.nst.com.my/news/nation/2019/08/514242/malaysia-falls-behind-ir40-migration.

- Kaur, K., Kedia, H., & Rasiah, R. (2023). Ecosystem Supporting Industry 4.0 Technologies in Textile and Clothing Manufacturing. In Digitalization and Development (pp. 68-95). Routledge.

- Kawulich, B. B. (2005, May). Participant observation as a data collection method. In Forum qualitative sozialforschung/forum: Qualitative social research (Vol. 6, No. 2).

- Keefe, E. M., Naumann, R. B., Evenson, K. R., LaJeunesse, S., Heiny, S., & Lich, K. H. Using an adapted community readiness assessment to inform Vision Zero and safe systems action. Transportation research interdisciplinary perspectives 23, 100992. [CrossRef]

- Kim, D. W., Sung, Y. H., Jeung, G.W., Jung, S. S., Kim, H. J., & Kim, D. H. (2012, January 1). Reliability Assessment on Different Designs of a SMES System Based on the Reliability Index Approach. Journal of Electrical Engineering and Technology. The Korean Institute of Electrical Engineers.

- Kirk, S. F. Kirk, S. F., Salas, X. R., Alberga, A. S., & Russell-Mayhew, S. (2020). Reducing weight bias in obesity management, practice and policy.

- Klein, V. B., & Todesco, J. L. COVID-19 crisis and SMEs responses: The role of digital transformation. Knowledge and Process Management 28, 117–133. [CrossRef]

- Kraut, E. (2024). Sustainability Transformation Journey of Small-and Medium-Sized Enterprises: The Path of a Design Company. In DIGITAL TRANSFORMATION FOR ENTREPRENEURSHIP (pp. 215-241).

- Kshetri, N. Industry 4.0 and SMEs: Challenges and opportunities. Technological Forecasting and Social Chang 2019, 143, 107–117. [Google Scholar]

- Latif, A.; Saari, &. Government Initiatives to Promote Adoption of IR4. 0 Technologies in Manufacturing. In Digitalization and Development (pp. 228-242). Routledge. 2023. [Google Scholar]

- Leang, Y. K., & Rasiah, R. (2023). Diffusion of IR4. 0 Technologies in Electronics Manufacturing: The Role of the Embedding Ecosystem. In Digitalization and Development (pp. 49-67). Routledge.

- Liao, Y., Deschamps, F., Loures, E. D. F. R., & Ramos, L. F. P. (2017). Past, present and future of Industry 4.0-a systematic literature review and research agenda proposal. International journal of production research, 55(12), 3609-3629.

- Lim, M. L. W., Wong, S. Y., & Ding, C. S. Challenges of industrial revolution 4.0: quantity surveying students' perspectives. Engineering, Construction and Architectural Management. 2023. [Google Scholar]

- Logan, P., & Angel, L. (2014). Exploring Australian undergraduate pre-registration nursing curricula: where do science subjects fit?. Journal of Learning Design, 7(2), 62-84.

- Lok, C. L., Chuah, S. F., & Hooy, C. W. The Impacts of Data-Driven Leadership in IR4. 0 adoption on firm performance in Malaysia. Annals of Financial Economics, 17(03), 2250023. 2022. [Google Scholar]

- Lucato, W. C., Pacchini, A. P. T., Facchini, F., & Mummolo, G. (2019). Model to evaluate the Industry 4.0 readiness degree in Industrial Companies. IFAC-PapersOnLine, 52(13), 1808-1813.

- Mahidin, D. S. D. M. U. 2019. Department of Statistics Malaysia Press Release. Department of Statistics Malaysia: Putrajaya, Malaysia, 5-9.

- Maskun, R., Musa, R., & Saidon, J. Are malaysian organizations ready to be digitalize? Lesson learned on digital resources implementation. Malaysian Journal of Consumer and Family Economics, 24, 89-103. 2020. [Google Scholar]

- McKinsey & Co, 2022. What are Industry 4.0, The Fourth Industrial Revolution, and 4IR?. https://www.mckinsey.com/featured-insights/mckinsey-explainers/what-are-industry-4-0-the-fourth-industrial-revolution-and-4ir.

- Ministry of International Trade and Industry Malaysia (MITI); National Policy On Industry 4.0: (2018). Industry 4WRD.

- MITI. (2021). National Fourth Industrial Revolution (4IR) Policy.

- Ministry of Science, Technology and Innovation (MOSTI). (2023). Aplikasi Robotik dan Kecerdasan Buatan (AI) di Pasar Amanjaya, Ipoh. Retrieved from https://www.mosti.gov.my/perkongsian-maklumat/aplikasi-robotik-dan-kecerdasan-buatan-ai-di-pasar-amanjaya-ipoh/.

- Mohd F. S., Jaffar; Nor, & Mohd; S, A. Integrate the adoption and readiness of digital technologies amongst accounting professionals towards the fourth industrial revolution. Cogent Business & Management, 9(1), 2122160. 2022. [Google Scholar]

- Muhamad, M. Q. B., Mohamad, S. J. A. N. S., & Nor, N. M. (2023). Influence of Government Intervention towards Industry 4.0 Adoption among Service Sector SMEs: Perspective from an emerging economy. Environment-Behaviour Proceedings Journal, 8(SI15), 47-54.

- Mulu, E. Mulu, E., M'Arimi, M. M., & Ramkat, R. C. (2021). A review of recent developments in application of low cost natural materials in purification and upgrade of biogas. Renewable and Sustainable Energy Reviews.

- Müller, J. M., Buliga, O., & Voigt, K. I. (2018). Fortune favors the prepared: How SMEs approach business model innovations in Industry 4.0. Technological forecasting and social change, 132, 2-17.

- Musyarofah, S. A., Tontowi, A. E., Masruroh, N. A., & Wibowo, B. S. (2022). Comparative Study of Industry 4.0 Readiness Measurement of Indonesian Companies: INDI 4.0, IMPULS and SIRI. In Proceedings of the 1st Australian Conference on Industrial Engineering and Operations Management, Sydney, Australia.

- Nair, A.; illai; V, S.; Kumar, & Senthil; A, S. Towards emerging Industry 5.0–a review-based framework. Journal of Strategy and Management, 2024. [Google Scholar]

- Nick, G., Szaller, Á., Bergmann, J., & Várgedő, T. 2019. Industry 4.0 readiness in Hungary: model, and the first results in connection to data application. IFAC-PapersOnLine, 52(13), 289-294.

- Nirmalarajah Asokan. 2023. Understanding Small and Medium-sized Enterprises (SMEs).

- O'Keefe, R. M.; O'Leary, &; E, D. Expert system verification and validation: a survey and tutorial. Artificial Intelligence Review, 7, 3-42. 1993. [Google Scholar]

- Oleśków-Szłapka, J. Oleśków-Szłapka, J., & Stachowiak, A. (2019). The framework of logistics 4.0 maturity model. In Intelligent systems in production engineering and maintenance (pp. 771-781). Springer International Publishing.

- Organisation for Economic Co-operation and Development (OECD); text=In%20small%20and%20medium%2Dsized: (2023). Enterprises by Business Size. Retrieved from https://data.oecd.org/entrepreneur/enterprises-by-business-size.htm#:~.

- Osterrieder, P.; udde; Friedli, &. The smart factory as a key construct of industry 4.0: A systematic literature review. International Journal of Production Economics, 221, 107476. 2020. [Google Scholar]

- Othman, Z., Zaidi, M. F. A., & Yahaya, W. A. J. W. (2022). Adoption Strategy for Electrical and Electronics (E&E) Small and Medium-Sized Enterprises (SMEs): Malaysia IR4. 0 Perspective. Journal of Advanced Research in Applied Sciences and Engineering Technology, 28(3), 27-38.

- Oztemel, E.; Gursev, &. Literature review of Industry 4.0 and related technologies. Journal of intelligent manufacturing, 31, 127-182. 2020. [Google Scholar]

- Ozturan, M., Atasu, I. and Soydan, H., 2019. Assessment of blockchain technology readiness level of banking industry: Case of Turkey. International Journal of Business Marketing and Management (IJBMM), 4(12), pp.01-13.

- Pandey, A. Diffusion and Adoption of Technology amongst Small and Medium enterprises during COVID-19 with a focus on Internet of Things. 2022. [Google Scholar]

- Peña-Ayala, A., & Ortiz-de-Mandojana, J. A. 2020. Barriers to the adoption of Industry 4.0 in SMEs: A systematic review. Journal of Manufacturing Technology Management, 31(7), 1009-1030.

- Phillipson, J.; iwasing; orton; aioli; ewbery; Turner, &. Shining a spotlight on small rural businesses: How does their performance compare with urban?. Journal of Rural Studies, 68, 230-239. 2019. [Google Scholar]

- Pirola, F.; imini; Pinto, &. Digital readiness assessment of Italian SMEs: a case-study research. Journal of Manufacturing Technology Management, 31(5), 1045-1083. 2020. [Google Scholar]

- Pratiwi, T. W. Firms’ Technological Capabilities Toward the Introduction of Industry 4.0: The Case of Supplier Firms in the Indonesian Automotive Industries. The Indonesian Journal of Development Planning, 2021. [Google Scholar]

- Qatawneh, A; Technology: , & Al-Okaily, M. (2024). The Mediating Role of Technological Vigilance between IT Infrastructure and AIS Efficiency. Journal of Open Innovation.

- Rahamaddulla, S. R. B.; eman; aharudin; B, B. H. T.; Ahmad, &; A, S. Conceptualizing smart manufacturing readiness-maturity model for small and medium enterprise (SME) in Malaysia. Sustainability, 13(17), 9793. 2021. [Google Scholar]

- Rafikov, I., & Ansary, R. (2020). Industrial Revolution 4.0: Risks, Sustainability, and Implications for OIC States. ICR Journal, 11(2), 298-324.

- Rahim, Z. A., Rahman, N. A. A., & Iqbal, M. S. 2021. The National Industry 4.0 Policy Performance Review Based on Industry4WRD Readiness Assessment and Intervention Program. In International Conference of Reliable Information and Communication Technology (pp. 688-696). Cham: Springer International Publishing.

- Rao, P., Kumar, S., Chavan, M., & Lim, W. M. (2023). A systematic literature review on SME financing: Trends and future directions. Journal of Small Business Management, 61(3), 1247-1277.

- Ratanova, I., & Voroncuka, I. 2021. The Aspects of Entrepreneurship and Innovation Development of SMEs. In Proceedings of the 11th Annual International Conference on Industrial Engineering and Operations Management, Singapore (pp. 7-11).

- Ritter, T., & Lettl, C. 2019. Industry 4.0 in SMEs: Assessing the challenges and opportunities. Technology Innovation Management Review, 9(6), 15-22.

- Ronaghi, M. H. Ronaghi, M. H. (2024). Toward a model for assessing smart hospital readiness within the Industry 4.0 paradigm. Journal of Science and Technology Policy Management.

- Sánchez-Báez, E. A. Sánchez-Báez, E. A., Fernández-Serrano, J., & Romero, I. (2020). Organizational culture and innovation in small businesses in Paraguay. Regional science policy & practice.

- Saad, S. M.; ahadori; Jafarnejad, &. The smart SME technology readiness assessment methodology in the context of industry 4.0. Journal of Manufacturing Technology Management. 2021. [Google Scholar]

- Sabo, A. U.; Rahim, bin Abdul; Z, M.; wadabe; M, U.; ahaya; S, I.; Yusuf, &; M, M. The Effect of Individual Entrepreneurial Orientation and the Fourth Industrial Revolution 4.0 On Women Business Venturing Survival in Nigeria. 2024. [Google Scholar]

- Sadin, S. R. Sadin, S. R., Povinelli, F. P., & Rosen, R. (1989). The NASA technology push towards future space mission systems. In Space and Humanity (pp. 73-77). Pergamon.

- Saleh, N. I. Saleh, N. I., Ijab, M. T., & Hashim, N. (2022, December). A Review on Industrial Revolution 4.0 (IR4. 0) Readiness Among Industry Players. In International Conference on Computer, Information Technology and Intelligent Computing (CITIC 2022) (pp. 216-231). Atlantis Press.

- Saleh, N. I., & Ijab, M. T. (2023). Industrial Revolution 4.0 (IR4. 0) Readiness Among Industry Players: A Systematic Literature Review. In Artificial Intelligence and Applications (Vol. 1, No. 2, pp. 70-85).

- Sari, E. T.; Vitalli, &. Comparative Analysis of SMEs Intensity in Ukraine and Indonesia Using FIS Approach. Contemporary Economics, 17(1), 58-76. 2023. [Google Scholar]

- Sario, N. What lies 4WRD for IR4.0 in Malaysia. Malaysia. 2019. [Google Scholar]

- Schiffer, M., Wiendahl, H. H., & Saretz, B. (2019). Self-assessment of Industry 4.0 Technologies in Intralogistics for SME’s. In Advances in Production Management Systems. Towards Smart Production Management Systems: IFIP WG 5.7 International Conference, APMS 2019, Austin, TX, USA, September 1–5, 2019, Proceedings, Part II (pp. 339-346). Springer International Publishing.

- Schumacher, A. Schumacher, A., Erol, S., & Sihn, W. (2016). A maturity model for assessing Industry 4.0 readiness and maturity of manufacturing enterprises. Procedia Cirp.

- Schwab, K. (2017). The fourth industrial revolution. Currency.

- Shahzad, A. Shahzad, A., bin Zakaria, M. S. A., Kotzab, H., Makki, M. A. M., Hussain, A., & Fischer, J. (2023). Adoption of fourth industrial revolution 4.0 among Malaysian small and medium enterprises (SMEs). Humanities and Social Sciences Communications.

- Shaikh, I; Extending Diffusion Theory Of Innovation: M., Amin, H., Noordin, K., & Shaikh, J. M. (2023). Islamic Bank Customers’ Adoption of Digital Banking Services.

- Silva, M. C. R.; Sousa, de; M, J. C.; Silva, & da; G, A. M. The impact of Industry 4. 0 on SMEs: A review of the literature. Journal of Industrial Engineering and Management, 14(2), 631-647 2021. [Google Scholar] [CrossRef]

- Sima, V., Gheorghe, I.G., Subi ́c, J., & Nancu. 2020. Influences of the Industry 4.0 Revolution on the Human Capital Development and Consumer Behavior: A Systematic Review. Sustainability, 12, 4035.

- Singaram, L. R.; akaria; unikanan; ahi; minudin; ahamir; Khalid, S. R.,... &. Pre-investigation on adaptation of construction 4.0 multi criteria business model by SME contractors in Malaysia. Cleaner Engineering and Technology, 15, 100662. 2023. [Google Scholar]

- SME Corp Malaysia. 2022. SME Annual Report 2021. Malaysia.

- SME Corp Malaysia. (2024). Definisi PKS. Retrieved from https://www.smecorp.gov.my/index.php/my/polisi/2020-02-11-08-01-24/sme-definition.

- Sony, M.; Naik, &. Key ingredients for evaluating Industry 4; An International Journal: 0 readiness for organizations: a literature review. Benchmarking, 2020. [Google Scholar]

- Soomro, M. A.; izam-Hanafiah; bdullah; L, N.; li; H, M.; Jusoh, &; S, M. Embracing Industry 4.0: Empirical insights from Malaysia. Informatics, 8, 30. 2021. [Google Scholar]

- Tay, S. I.; lipal; Lee, &; C, T. Industry 4.0: Current practice and challenges in Malaysian manufacturing firms. Technology in Society, 67, 101749. 2021. [Google Scholar]

- Teichmann, F. Teichmann, F., Boticiu, S., & Sergi, B. S. (2023). RegTech–Potential benefits and challenges for businesses. Technology in Society.

- Telukdarie, A. Telukdarie, A., Dube, T., Matjuta, P., & Philbin, S. (2023). The opportunities and challenges of digitalization for SME's. Procedia Computer Science.

- Thakur, J.; Kumar, &. Industry 4.0: Challenges and opportunities for SMEs. International Journal of Production Research, 57(18), 5458-5477. 2019. [Google Scholar]

- Tinholt, D., van Niel, E., van Kraaji, C., Knödler, M. Artificial intelligence benchmark. 2019. [Google Scholar]

- TMEF. 2024. Are Malaysian SMEs falling behind in the digital age?. Malaysia.

- Tortora, A. M.; aria; annone; Pianese, &. A survey study on Industry 4. 0 readiness level of Italian small and medium enterprises. Procedia Computer Science, 180, 744–753 2021. [Google Scholar] [CrossRef]

- Vasudevan, A.; ubramaniam; Hai, &; T, S. The Influence of Organizational Culture on Innovation Management of Malaysian Small and Medium Enterprises (SMEs) towards Industry 4.0. Asian Journal of Entrepreneurship, 2(2), 1-8. 2021. [Google Scholar]

- Vaittinen, E. Vaittinen, E., & Martinsuo, M. (2019). Industrial customers’ organizational readiness for new advanced services. Journal of Manufacturing Technology Management, 1096. [Google Scholar]

- VDMA. (2021). Industrie 4.0 Readiness Assessment. Retrieved from https://www.industrie40-readiness.de/?lang=en.

- Venkatesh, V.; orris; G, M.; avis; B, G.; Davis, &; D, F. User acceptance of information technology: Toward a unified view. MIS quarterly, 425-478. 2003. [Google Scholar]

- Vuong, T. K.; Mansori, &. An Analysis of the Effects of the Fourth Industrial Revolution on Vietnamese Enterprises. Management dynamics in the knowledge economy, 9(4), 447-459. 2021. [Google Scholar]

- Wang, L.; Wang, &. Challenges for SMEs in adopting Industry 4.0: A capability-based perspective. Journal of Manufacturing Technology Management, 30(4), 509-529. 2019. [Google Scholar]

- Weiner, B. J. Weiner, B. J. (2020). A theory of organizational readiness for change. In Handbook on implementation science (pp. 215-232). Edward Elgar Publishing.

- Wippel, M. Wippel, M., Lucke, D., & Jooste, J. L. (2021). An industry 4.0 technology implementation model for rolling stock maintenance. Procedia CIRP.

- Wolf, M.; emm; Erfurth, &. Digital transformation in companies–Challenges and success factors. In International Conference on Innovations for Community Services (pp. 178–193). 2018. [Google Scholar]

- World Bank. 2023. Small and Medium Enterprises (SMEs) Finance.

- Yezhebay, A. Yezhebay, A., Sengirova, V., Igali, D., Abdallah, Y. O., & Shehab, E. (2021). Digital maturity and readiness model for Kazakhstan SMEs. 2021 IEEE International Conference on Smart Information Systems and Technologies (SIST) (pp. 1-6).

- Yin, R. K.; ang; Zhang, &. The impact of data analytics on small and medium-sized enterprises: A conceptual framework. International Journal of Information Management, 46(2), 102-113 2019. [Google Scholar] [CrossRef]

- Yong, S. M. Yong, S. M. (2023). 4th Industry Revolution Digital Marketing Adoption Challenges in SMEs and its Effect on Customer Responsiveness. Information Management and Business Review.

- Yuik, C. J. Yuik, C. J., & Puvanasvaran, P. (2020). Development of lean manufacturing implementation framework in machinery and equipment SMEs. International Journal of Industrial Engineering and Management.

- Zaidi, I. Zaidi, I., Nazmudeen, M. S., & Mohiddin, F. (2021). A Comparative Study on IR4. 0 Technologies and its Maturity Level on Small, Medium Enterprises in Developed and Developing Countries. In 2021 5th International Conference on Business and Information Management (pp. 1-8).

- Zeller, V., Hocken, C., & Stich, V. (2018). Acatech Industrie 4.0 maturity index–a multidimensional maturity model. In Advances in Production Management Systems; IFIP WG 5: Smart Manufacturing for Industry 4.0.

- Zhong, C.; ang; Liu, &. Industry 4.0 adoption challenges and strategies for SMEs in China. Technological Forecasting and Social Change, 143, 118-129. 2019. [Google Scholar]

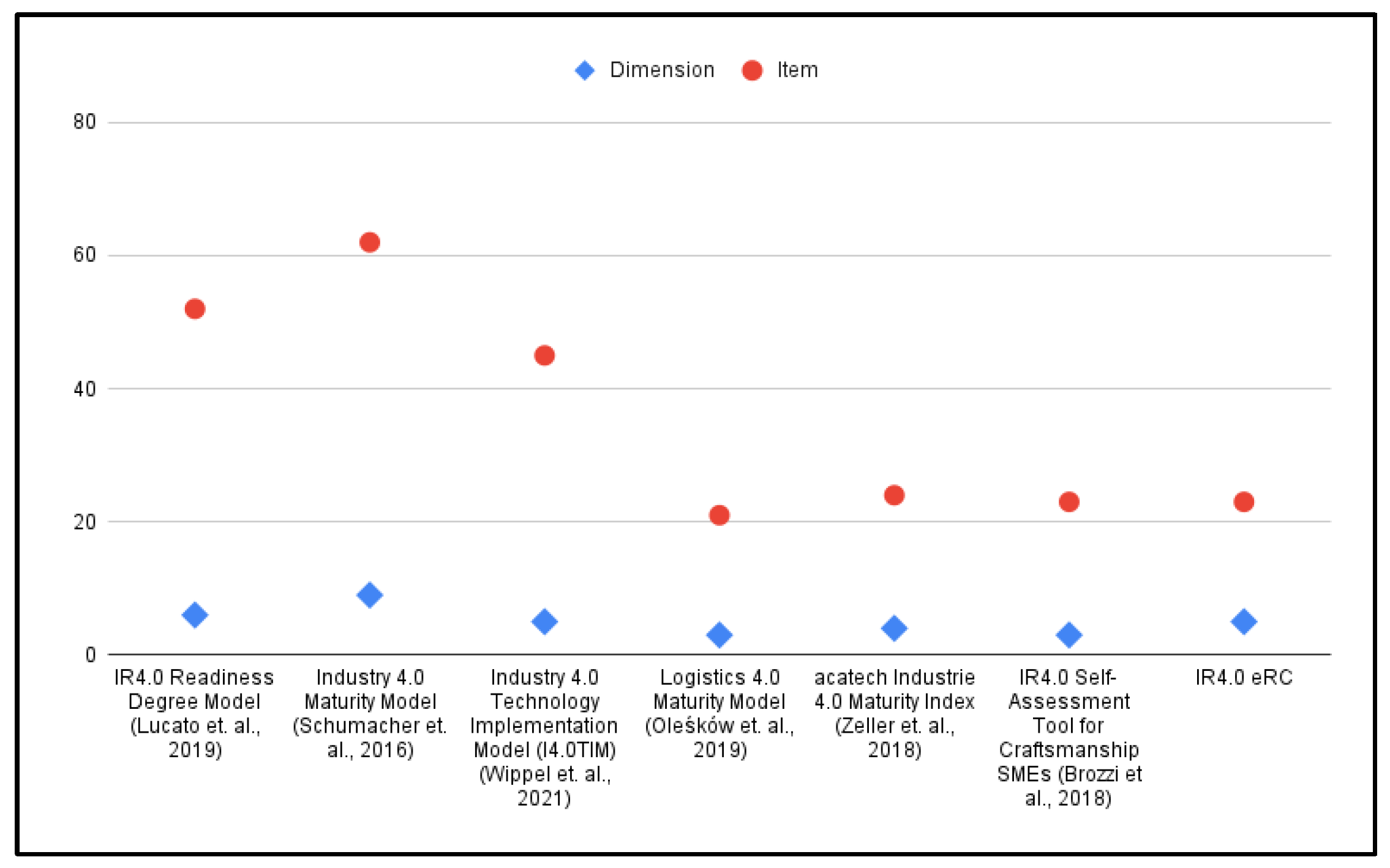

| Model Name | Model Development Phase | Model Features |

|---|---|---|

| IR4.0 Readiness Degree Model (Lucato et al., 2019) |

|

Sector: Manufacturing Dimension: 6 Item: 52 Readiness level: Likert scale (0 – 3) Scoring: Readiness degree |

| Industry 4.0 Maturity Model (Schumacher et al., 2016) |

|

Sector: Manufacturing Dimension: 9 Item: 62 Readiness level: Likert scale (1 – 5) Scoring: Formula define |

| Industry 4.0 Technology Implementation Model (I4.0TIM) (Wippel et al., 2021) |

|

Sector: Railway Dimension: 5 Item: 45 Readiness level: Likert scale (1 – 5) Scoring: Weightage |

| Logistics 4.0 Maturity Model (Oleśków et al., 2019) |

|

Sector: Logistic Dimension: 3 Item: 21 Maturity level: 5 (Ignoring, Defining, Adopting, Managing, Integrated) |

| acatech Industrie 4.0 Maturity Index (Zeller et al., 2018) |

|

Sector: Manufacturing Dimension: 4 Item: 24 Maturity level: 1-6 |

| IR4.0 Self-Assessment Tool for Craftsmanship SMEs (Brozzi et al., 2018) |

|

Sector: Carpentry Dimension: 3 Readiness level: Likert scale (1-5) |

| IR4.0 readiness factors | Author |

|---|---|

| Source | Wippel et al. (2021), Zeller et al. (2019) |

| Infrastructure & Technology | Alcácer et al. (2021), Ali et. al. (2021), Caiado et al. (2020), Horvat et al. (2018), Lucato et al. (2019), Schumacher et. al. (2016), Soomro et al. (2021), Wippel et al. (2021), Brozzi et al. (2018) |

| Awareness | Halse et al. (2017), Tortora et al. (2021), Caiado et al. (2020) |

| Skilled workforce | Caiado et al. (2020), Alcácer et al. (2021), Wippel et al. (2021) |

| Culture | Schumacher et. al. (2016), Zeller et al. (2019), Horvat et al. (2018) |

| Strategy | Alcácer et al. (2021), Ali et. al. (2021), Schumacher et. al. (2016), Soomro et al. (2021), Tortora et al. (2021), Wippel et al. (2021), Horvat et al. (2018) |

| Innovation | Halse et al. (2017), Soomro et al. (2021), Tortora et al. (2021) |

| Organization | Soomro et al. (2021), Zeller et al. (2019), Horvat et al. (2018) |

| Management | Caiado et al. (2020), Horvat et al. (2018), Oleśków et. al. (2019) |

| Product & Operation | Brozzi et al. (2018), Alcácer et al. (2021), Schumacher et. al. (2016), Zeller et al. (2019), Oleśków et. al. (2019) |

| Collaboration | Halse et al. (2017), Horvat et al. (2018) |

| Learning Aspects | Content |

|---|---|

| Insights and skills on how IR4.0 works in a company's operations or the production process of goods or services | Derived from research at SHRDC, where 99% of program participants had never used IoT and simulation applications such as NodeRED, FactoryIO, SFCEDIT, and Jaamsim before. However, the learning process is easy because the participants are engineering graduates who are used to using development applications. These applications are important in developing automation in factories. |

| SME readiness towards IR4.0 | Low, obtained from SHRDC instructor exposure. Other challenges include the small size of the sector and few training program participants attending individually, indicating challenges in employee awareness versus superiors. |

| Funding for IR4.0 | SMEs have little capital to change old machines to new ones. They apply for grants or funds offered by government and private agencies such as Digital Transformation Acceleration Programme (DTAP), Applied Innovation Fund (AIF) Malaysia, and Venture Investment Programme (VIP) to access new technology. The application process is not easy because of the strict requirements. |

| IR4.0 training program at SHRDC | The training program is well organized and relevant to the current needs of the IR4.0 industry. The smart factory exhibition that the researchers participated in was easy to understand because 100% of the technology on display was that which had been learned at the training. |

| Data analytics skills | New skills to handle large volumes of data through data analytics workshops using IBM-SPSS applications. This reinforces the view that SMEs can also analyse data easily without having to know a programming language. |

| Funding and Guidance Program | This program provides financing opportunities and other resources to SMEs that want to develop technologies and projects relevant to IR4.0. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).