1. Introduction

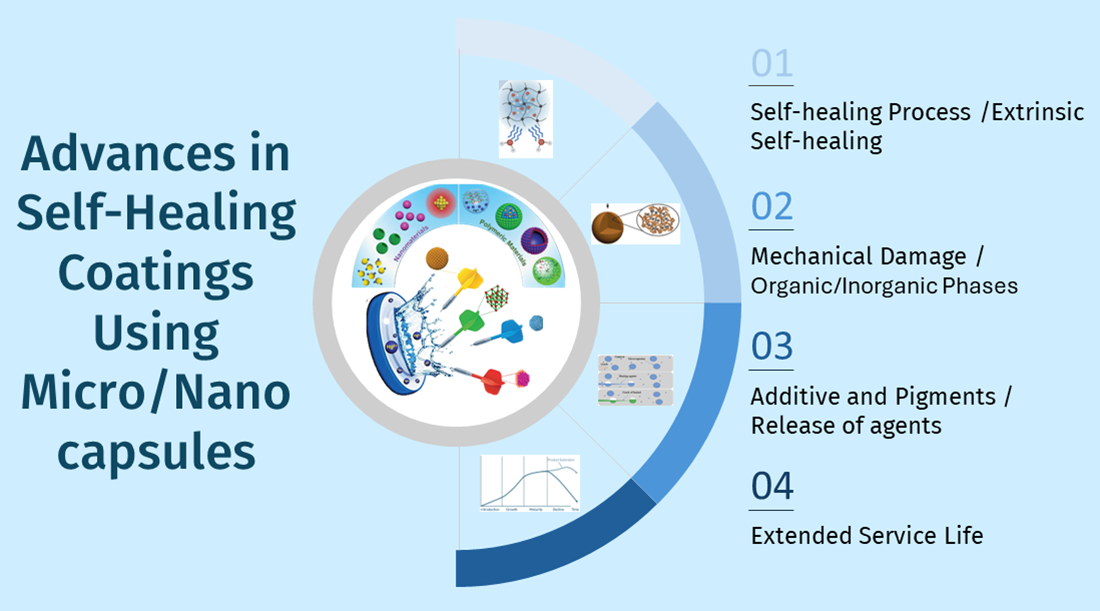

Self-healing coatings are considered as an alternative approach for efficient protection of materials [

1]. These coatings usually embedded microcapsules and nanocontainers that include self-healing agents, catalysts, corrosion inhibitors, monomers and water repellent liquids [

2]. Automatic healing is defined as the self-healing function according to which a structural material is self-repairing its damage and regains its mechanical properties without any external intervention. Self-healing function requires the ability of sensing damage, together with the healing ability. Four different self-healing methods are mentioned namely self-healing using remendable polymers, self-healing using additives and fillers such as microcapsules and nanocontainers, self-healing using solvents and self-healing using thermoplastic polymers [

3,

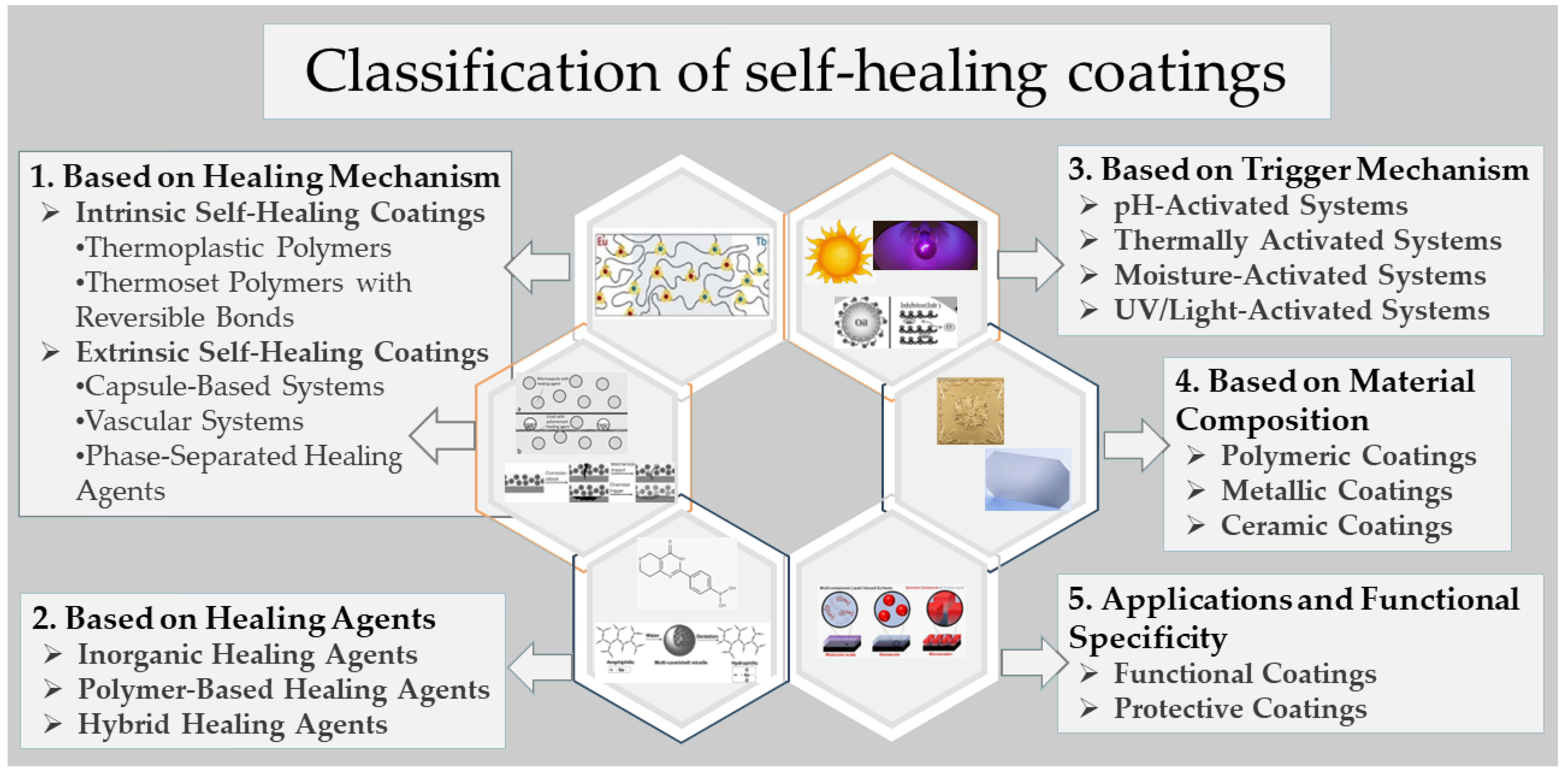

4]. Several criteria can be taken into consideration for the classification of self-healing coatings such as the healing mechanism, the materials used, and the type of damage they address. The main classifications are based on a) the healing mechanism that can be either intrinsic self-healing coatings or extrinsic self-healing coatings, b) the type of damage addressed that can be either scratch-resistant coatings or corrosion-resistant coatings or barrier coatings, c) the materials used that can be either inorganic coatings or polymeric coatings or composite coatings, d) the stimuli-responsive healing triggers that can be either ph-sensitive or thermally activated or moisture-sensitive or light-induced and e) the functional specificity and applications such as protective coatings or functional coatings [

5]. The classification of self-healing coatings is illustrated in

Figure 1.

Application of self-healing coatings addresses the demand for sustainability, service-life extension, low-maintenance surfaces in a range of industrial applications. The principle of self-healing derives inspiration from biological systems, which are endowed with an intrinsic ability to heal themselves, in order to guarantee the long-term reliability and efficiency of the material in the absence of external influence [

6]. These coatings are developed to react to damage by triggering a self-healing process that assists in restoring the integrity of the material [

7]. Including microcapsules and nanocontainers in these coatings is essential because these microscopic containers hold active ingredients like catalysts, repair monomers, and corrosion inhibitors that are released when they are damaged. Because of the flexibility in the production and composition of these micro and nanostructures, customized responses to particular mechanical and environmental problems are possible [

8].

Microcapsules and nanocontainers have attracted the scientific and industrial interest. Their composition can be inorganic oxides and hydroxides, inorganic and organic polymers, natural polymers and hybrid composites. Moreover, their shape can be stable such as spherical, octahedral, cubic, or vary according to the conditions applied and the mechanism of dynamic self-assembly. Therefore, some systems that are discussed in literature are liposomes, micelles, polymersomes, solid nanocapsules, dendrimers, nanoparticles, nanotubes, and nanogels. Moreover, microcapsules and nanocontainers can have either a core-shell structure, or they can be nanofunnels, nanospheres, nanobottles, nanotubes and nanofibers. Microcapsules and nanocontainers can be fabricated via several different synthetic methodologies. Some of them are the self-assembly methods, precipitation-based synthetic methods, layer-by-layer technique, ultrasonic techniques, sol-gel technique and emulsion-based processes [

9,

10,

11].

This review article is focused on the demonstration of the advancements related to self-healing coatings with autonomous ability. Several studies and works are presented with respect to the fabrication of microcapsules and nanocontainers and sequent their incorporation into organic coatings for their corrosion protection improvement as well as their self-healing ability enhancement.

2. Self-Healing Coatings Based on Additives Including Corrosion Inhibitors

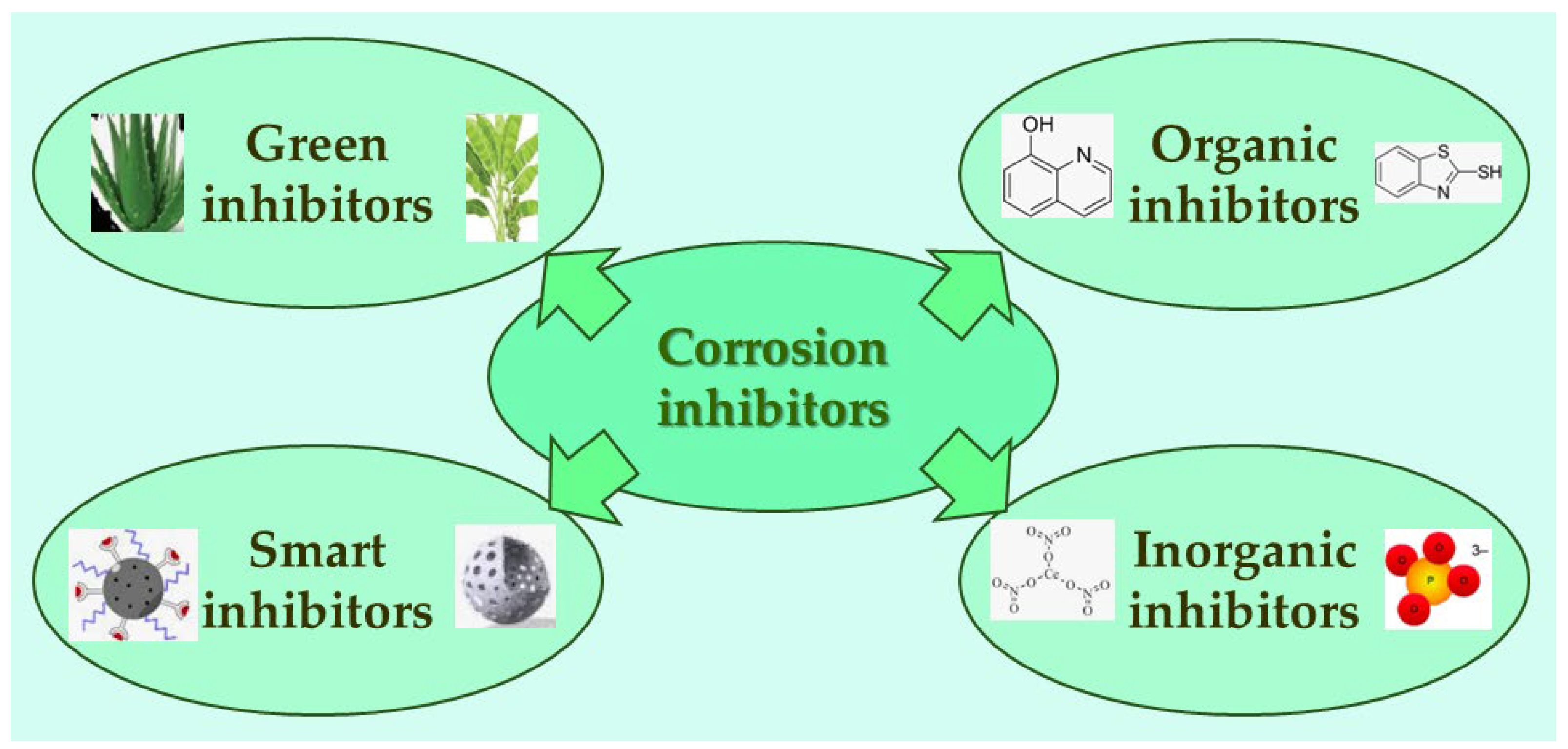

Corrosion inhibitors are chemicals compounds that slow down or prevent the material degradation of metals [

12]. In coatings demonstrating self-healing properties, these inhibitors can be incorporated into the coating. When damage occurs onto the coating due to its interaction with the environment, an exposure of the inhibitors to the environment is created which implies the metal protection through three different procedures. The first one is the cathodic or anodic protection where the metal electrochemical potential is shifted enabling it less prone to oxidation. Another procedure is the formation of a protective layer where a passive layer is created onto the metal surface by the inhibitors preventing further corrosion. A third process is the neutralization of the aggressive agents such as sulfur or chloride compounds.

Several chemical compounds can be used as corrosion inhibitors in self-healing coatings (

Figure 2). One category is the organic inhibitors that can be adsorbed onto the metal surface blocking active corrosion sites [

13]. The effectiveness of an organic inhibitor relies upon the size of the organic molecule, number, and type of groups or bonding atoms in the molecule, aromaticity, nature and surface charge, and the type of aggressive environment. Another type is the inorganic inhibitors that precipitate as insoluble salts or can create protective layers onto the metal substrates [

14]. Green inhibitors are specified as organic and inorganic, demonstrating eco-friendly properties and reduction of adverse effects on the environment [

15]. Another category is the smart inhibitors that are activated only when corrosion process occurs [

16]. Smart inhibitors can be incorporated in microcapsules or embedded in a coating matrix that responds to environmental titillating such as thermal of pH changes. The applications of self-healing coatings including corrosion inhibitors are their utility in a variety of industries, such as marine, aerospace, automotive, and construction. The benefits encompass the reduced maintenance, extended lifespan and the improved safety.

Yeganeh et al. performed experiments on the synthesis of mesoporous silica nanocontainers and functionalized and loaded with the corrosion inhibitor sodium molybdate [

17]. The mesoporous silica nanocontainers were fabricated by mixing cetyltrimethylammonium bromide as a surfactant and tetraethylorthosilicate as a silica precursor. Then, the produced mesoporous silica nanocontainers were functionalized with 1-(2-aminoethyl)-3aminopropyltrimethoxysilane and got a positive charge using anhydrous FeCl

3 in order to accomplishe enhanced adsorption of molybdate (MoO

42−) as a corrosion inhibitor on the functionalized nanocontainers. Epoxy composite coatings incorporating loaded nanocontainers were applied onto mild steel substrates by a film applicator. Evaluation of the produced loaded mesoporous silica nanocontainers displayed the pH-dependence of molybdate release from the epoxy coating. The increase of the pH from 1 to 14, resulted to 160 times increase in the molybdate concentration in the solution. Electrochemical impedance spectroscopy and the electrochemical noise analysis were used for the assessment of the corrosion behavior of the coatings. The results revealed enhanced corrosion resistance of the coatings including the loaded nanocontainers which confirms the proper corrosion inhibiting effect of the released molybdate ions.

In another study, Haddasi et al. evaluated the concentration of 2-mercaptobenzimidazole (MBI) into graphene-based carbon hollow spheres with respect to their active/barrier corrosion protective properties, after their incorporation into epoxy coatings [

18]. Several epoxy coatings including either the loaded with inhibitor or empty hollow spheres, were applied on mild steel plates via a wet film roller applicator. Studies based on the release kinetics of MBI from the CHSs proved that a deposition of released MBI molecules onto the metal substrate can be achieved. The mechanical and electrochemical evaluation of the produced coatings after their exposure onto corrosive environments revealed enhanced active/self-healing/barrier properties as well as wet adhesion strength of the coating onto the metal substrate.

Montemor and her team conducted experiments on the investigation of epoxy coatings self-healing ability after incorporating into them microcapsules loaded with highly reactive isocyanates [

19] and polyethyleneimine [

20]. Calcium carbonate microagglomerates, with an average diameter of 2.5 mm, consisted of several round shaped nanoparticles, were synthesized and loaded with the corrosion inhibitor polyethyleneimine [

20]. The pH-sensitive produced loaded microparticles were utilized as additives into epoxy coatings that were applied onto carbon steel via the dip-coating process. The obtained coatings were characterized with respect to their morphological, structural and corrosion protective properties and the results revealed that the modified coatings imparted enhanced corrosion protection as well as very stable barrier properties as the time elapsed. Moreover, the abovementioned coatings demonstrated improved self-healing properties. The corrosion inhibition effect was based on the calcium carbonate microparticles dissolution due to the pH variation resulting to the subsequent release of the corrosion inhibitor. The release outcome was the formation of a protective film onto the steel surface.

Steel plates corrosion resistance after applying onto them epoxy-based coatings modified with microcapsules loaded with isophorone diisocyanate and with pH-sensitive cerium tri(bis(2-ethylhexyl)phosphate particles serving as inhibitor, was also investigated by Montemor et al. [

19]. The healing effects were assessed by a combination of several electrochemical techniques. The acquired results after the combination of both additives evidenced a multilevel protection effect that is characterized by more stable and enhanced coating barrier properties without any interfacial corrosion activity. The healing mechanism in the coating included the hydroxyl ions accumulation that reinforces significantly the corrosion protection conferred by the epoxy coating providing stable corrosion protection over time.

The work of Habib and his team reports the self-healing properties of epoxy-based polymeric nanocomposite coatings that was applied onto steel substrates [

21]. Both talc nanoparticles (TNPs) modified with sodium nitrate as well as microcapsules of urea-formaldehyde including linseed oil were embedded into these coatings. It was mentioned that the efficient loading of NaNO

3 into TNPs, that can be attributed to the existence of physio-chemical adsorption mechanism, proceeds without affecting the TNPs parent lamellae structure. The conducted characterizations evidenced that the NaNO

3 corrosion inhibitor release from TNPs is influenced by the solution pH variations as well as the immersion time. Additionally, the release of the self-healing agent linseed oil microcapsules in response to the external damage was estimated to be a time-dependent procedure. Promising corrosion inhibition efficiency and self-healing properties were achieved and were ascribed to combinations of inhibitor, nanocontainers, and self-healing agents. In a similar work of the same team, epoxy coatings were reinforced by the incorporation of cerium dioxide nanoparticles loaded with dodecylamine and n-methylthiourea as organic corrosion inhibitors [

22]. The potential self-healing properties of the produced coatings as well as the increase of their lifetime were estimated. The CeO

2 nanoparticles displayed a pH sensitive and self-release behavior of the corrosion inhibitors. The release of the inhibitors resulted to the formation of a protective layer onto defect sites of the steel surface and the corresponding healing effect. The fabricated protective film prevented the aggressiveness of Cl

− in the solution outcoming to the existence of exceptional corrosion inhibition efficiency for the modified coating with the aforementioned loaded microcapsules.

In the study of Wen and his team, an intelligent coating for the mild steel corrosion protection was developed [

23]. Free radical polymerization was used for the synthesis of a hybrid hydrogel based on benzotriazole, polyethyleneimine, hydroxypropyl acrylate and vinyltriethoxysilane. The prepared hydrogel was used of the fabrication of an intelligent coating that was applied onto mild steel. Electrochemical characterizations were conducted for the corrosion protection assessment of the intelligent coating. The obtained results displayed that the increase of the hydrogel into the coatings outcome to the improvement of the anti-corrosion capability the coatings. The corresponding mechanism relies on the formation of inhibitor-adsorptive layer onto the mild steel due to the benzotriazole release.

The development, characterization and validation of self-healing coatings including corrosion inhibitors is an active area of research, that pays attention on enhancing the economic viability, environmental friendliness and effectiveness of these advanced materials.

3. Self-Healing Coatings Based on Additives Including Healing Agents

One effective approach to obtain coatings with self-healing properties is the use of additives, including healing agents. Healing agents refer to substances, compounds or factors that initiate and encourage the healing process in the damaged coatings.

In the study of Neisiany and his team, a self-healing carbon/epoxy composite including healing agent loaded into core-shell nanofibers between carbon fiber fabric layers was fabricated [

24]. A coaxial electrospinning method was used so as healing agents based on low viscosity epoxy resin together with its amine-precursor curing agent to be encapsulated into nanofibers that consist of copolymer of acrylonitrile and styrene. The encapsulation yield reached up to 97%. Mechanical studies confirmed that the core-shell nanofibers incorporation into the epoxy coating did not reduce the overall composite mechanical properties. On the other hand, the embodiment of aforementioned nanofibers between carbon layers imparted a self-healing ability, resulting to self-repairing and restoring of the composite mechanical properties.

Additionally, H. Li and coworkers examined [

25] the efficient and facile encapsulation of a lubricant oil that acts as a core material into microcapsules of SiO

2 shell wrapped with polystyrene. The fabrication of the loaded microcapsules included Triton X-100 together with 3-isocyana-topropyl triethoxysilane and fumed SiO

2 nanoparticles to be used as emulsifiers for the formation of oil/water Pickering emulsions via the Pickering polymerization technique. The produced microcapsules were spheres with an average diameter of 3.3 μm and a shell thickness roughly 900 nm. Moreover, the lubricant oil demonstrated improved thermal stability with a decomposition temperature of 250

oC. The obtained core-shell microcapsules were embedded into an epoxy coating and the final self-lubricating coating was applied onto aluminium substrates. The produced coatings composed of SiO

2 wrapped PS microcapsules/epoxy composites demonstrated improved self-lubricating properties that are ascribed to the synergetic effect between lubricant oil and SiO

2 nanoparticles that made a positive contribution to enhance the polymer coatings tribological properties.

A very interesting concept developed by W. Li and his team [

26]. Solid wastes, such as fluorinated silica gel waste and polystyrene (PS) foam waste were recycled and re-used for the fabrication of a hydrophobic coating with self-healing properties. At first, silica gel waste and PS foam waste were used as raw materials for the superhydrophobic coatings fabrication. Secondly, near infrared-responsive microcapsules were synthesized using fluorinated carbon nanoparticles via the method of electrostatic adsorption onto the surface of microcapsules. Then, the obtained particles were used as fillers with hydrophobic properties together with the polystyrene foam waste that acted as a coating binder. The produced superhydrophobic coating was applied onto several different substrates via a doctor-blade and presented robust durability and enhanced self-healing properties.

Further studies evaluated the mechanism of the microcapsules that are applied to the interlaminar interface during the synthesis of carbon fiber composites [

27]. Microcapsules with enhanced thermal and mechanical properties composed of a high-boiling-point organic solvent and a diglycidyl ether bisphenol A-based epoxy resin were fabricated via in situ polymerization of formaldehyde and urea and applied to carbon fibre composite structural materials in order to improve their self-healing performance. The obtain results evidenced enhanced self-healing properties when the aforementioned microcapsules were used together with Lewis acidic catalysts due to the encapsulated epoxy monomer polymerization.

In a similar study by also Montemor and coworkers, emulsion polymerization followed by interfacial polymerization was used for the fabrication of chemically and thermally stable isophorone diisocyanate microcapsules [

28]. The obtained microcapsules were embedded into an epoxy coating for carbon steel corrosion protection. Electrochemical characterization results proved an increase over time of the modified coatings barrier properties. Moreover, the produced coatings demonstrated self-healing properties that were attributed to the ability of the capsules to heal damaged areas in the coating and the formation of a protective polymeric barrier layer. The healing mechanism encompasses several reactions involving amine group formation due to partial conversion of isocyanate groups in the presence of water, the formation of polyurea due to amine reaction with isocyanates and finally the formation of polyurethane layer.

In another study, Chen et al. reported the preparation of a smart coating with autonomous self-responding and self-healing functions without external intervention, based on a simple integration microcapsule composed of one-component into the matrix [

29]. For this reason, microcapsules were fabricated including a hexamethylene diisocyanate solution under photopolymerization. The formatted coatings were evaluating in respect of their morphology, thermal, corrosion and mechanical resistance. The microcapsule-embedded coatings demonstrated improved self-repairing ability.

Additionally, it the work of Kouhi et al., healing agent-filled capsules with mean diameters as small as 450 nm and as large as 6 μm were fabricated by in situ polymerization [

30]. The produced core-shell micro/nanocapsules consisted of urea–formaldehyde as a shell and drying linseed oil as a core. Then, the micro/nanocapsules were embedded in a polymer in a content range of 91–94%. The obtained coatings were assessed with respect to their mechanical and corrosion behaviour properties and evidenced improved performance in self-healing applications. The outcome of the experiments demonstrated a release of the healing materials form the micro/nanocapsules in paint films when cracks were formatted, resulting to efficiently crack healing with satisfactory protective properties.

In situ polymerization of aniline onto CeO

2 nanoparticles was used for the fabrication of polyaniline/cerium dioxide nanocomposites by Lei and coworkers [

31]. The prepared nanocomposites were embedded into epoxy coatings and applied on carbon steel substrates revealing excellent corrosion resistance. The enhancement of corrosion protection performance of the modified epoxy coatings was correlated to the synergetic protection of the enhancement of the protective barrier and the hindrance of the diffusion of aggressive ions of the nanoparticles. Moreover, the self-healing protection improvement was associated to the redox behavior of polyaniline. Thus, the hybrid polyaniline/CeO

2 nanoparticles are considered as the best route to enhance the protection performance of the epoxy coatings on carbon steel.

A very interesting concept developed by Ma et al. in order for microcapsules with high encapsulating capacity to be obtained [

32]. As a consequence, these microcapsules had enhanced self-healing efficiency. For this reason, graphene oxide (GO)-modified double-walled Polyurea microcapsules were fabricated using 1, 6-Diaminohexane as an inner core and a prepolymer based on isophorone diisocyanate was utilized as the outer core. The synthetic process included as a first step the preparation of GO modified prepolymer emulsion; then, the emulsion of 1, 6-Diaminohexane was prepared; after that initial single walled were fabricated through interfacial polymerization between the two aforementioned emulsions; and finally, double-walled microcapsules and coating of the second core material were developed. The outcome of this study revealed that the microcapsules that had been modified with GO demonstrated a spherical shape with a mean diameter of 0.5 μm. The obtained microcapsules had excellent thermostability as well as good mechanical properties with respect to Young's modulus, hardness and load. Finally, the corresponding epoxy coating including the above microcapsules presented improved anticorrosive self-healing efficiency. The reason of the enhanced anticorrosive and barrier properties was attributed to the GO nanostructure that hinders the penetration of aggressive species though scratches and defects.

Palazzo et al. considered the effect of supercritical emulsions extraction technology in order to fabricate microcapsules based on polymethylmethacrylate/diglycidyl ether of bisphenol A [

33]. These microcapsules were able to act as a health-monitoring element. They had a spherical shape together with a smooth surface and a mean size of 220 nm, with enhanced encapsulation efficiency. The health-monitoring liquid epoxy formulation, using in microcapsules preparation, was accomplished by homogeneously mixing a reactive diluent with a bifunctional epoxy resin. Then, a dye was added into this mixture under stirring. The results revealed that the produced capsules can be broken under stressing, outcoming to the release of the dye from the microcapsules.

Self-healing coatings based on healing agents are considered as a promising route to acquire more reliable and durable surface protection. The technology is still under development, with ongoing research paid attention on improving the effectiveness, efficiency, and economic feasibility of the aforementioned systems.

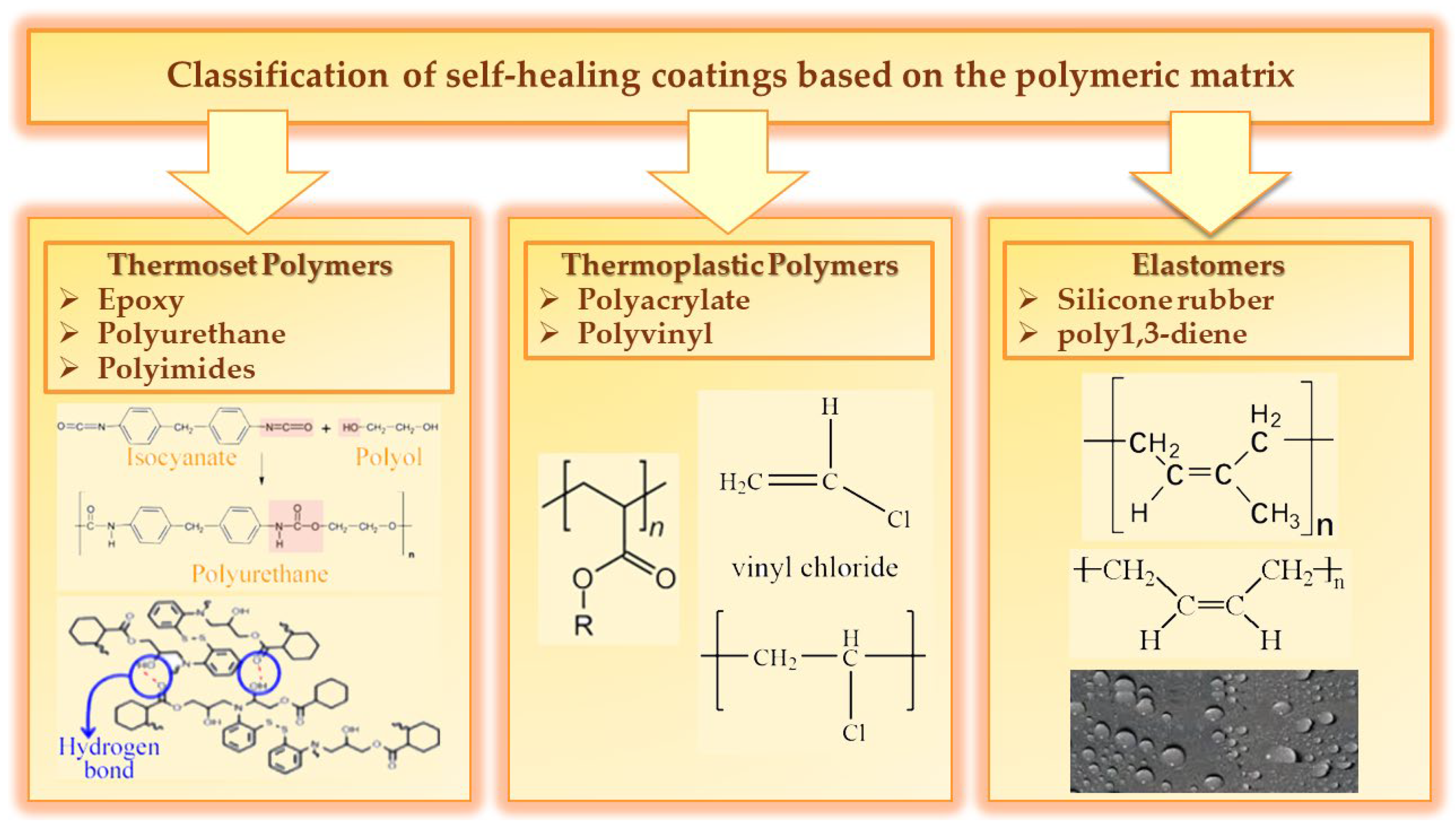

4. Classification of Self-Healing Coatings Based on the Polymeric Matrix

The self-healing coatings are classified into three different categories named thermoset polymers, thermoplastic polymers and elastomers, depending on the polymeric matrix.

Figure 3 illustrates the types of the coatings.

4.1. Thermoset Polymers

The characteristics of thermoset polymers are their ability to harden permanently after curing. In general, this type of polymers cannot be re-melted. The healing mechanism is based on rearrangements or reversible chemical reactions, such as disulfide bonds and diels-alder reactions, hydrogen-bonded connections, ionic polymers where the matrix network can reconstruct bonds upon heating.

4.1.1. Epoxy-Based Self-Healing Coatings

Epoxy stands out as a highly effective and dependable polymer matrix employed in self-healing polymer coatings for several years. Its exceptional thermal, mechanical, and adhesion properties set it apart from other polymer matrices. In the extrinsic self-healing mechanism, healing agents or inhibitors are typically encapsulated within micro/nano carriers alongside the self-healing polymer matrix. When employing this micro/nano encapsulation technique, it is crucial to consider that the self-healing agents or inhibitors should possess low viscosity to facilitate seamless encapsulation and timely release as needed [

34]. Zhang et al. [

35] formulated a multifunctional anticorrosion coating system using waterborne epoxy and nanofillers, specifically vanadium oxide modified by the polyaniline polymer PANI and tannic acid (V2O5@pani@TA-Fe). In this system, the polyaniline-modified vanadium oxide particles played a dual role, providing both corrosion passivation and inhibition effects. Additionally, the tannic acid contributed to the inhibition activity by actively releasing inhibitors in response to pH changes. The combined dual-action capability of the system significantly enhanced its self-healing anti-corrosion properties. The self-healing performance was assessed using electrochemical impedance spectroscopy (EIS) and salt spray tests (SST). The results demonstrated that the inhibition value of the water-based epoxy reinforced with V2O5 modified by polyaniline and tannic acid complexes (WEP/VPC) coating remained higher than 10^8 X/cm² even after 80 days of immersion, surpassing the performance of pure water-based epoxy (WEP) coatings [

36]. Water-based epoxy coatings have been fabricated demonstrating anti-corrosion and self-healing properties by the team of A. Sardari [

37]. These coatings had several additives such as organinc microcapsules including 8-hydroxy quinoline as corrosion inhibitor. Robust superhydrophobic coatings combing chemically reactive epoxy groups and low surface energy materials were produced by Dan Zhang et al. [

38]. In the work of Soares and his group, epoxy coating including montmorillonite modified with ionic liquids and zind based salts acting as anti-corrosion additives were synthesized and applied onto steel substrates [

39]. In this study of Song et al. [

40], a wear-resistant epoxy coating was fabricated that demonstrating self-lubricating properties and displaying self-healing action under photothermal effect.

However, more work needs to be done, including the introduction of novel healing techniques, engineering design optimization, cost reduction, and a faster transition from laboratory work to useable real-world applications in a variety of fields and industries. Additionally, the creation of long-lasting self-healing polymeric coatings is essential for prolonged environmental exposure.

4.1.2. Polyurethane Based Self-Healing Coatings

Polyurethane stands out as the highly sought-after polymer type in the contemporary era due to its versatile characteristics suitable for a wide range of applications, including anti-corrosion coatings. Traditionally, polyurethane has been utilized to enhance the aesthetics, scratch resistance, lifespan, and corrosion resistance of various metallic objects. In the realm of polymeric coating systems, polyurethane (PU) takes a prominent position, thanks to its numerous properties, including being eco-friendly, non-volatile, cost-effective, and sustainable. The utilization of polyurethane (PU) as a polymer matrix for anti-corrosion coatings has advanced through the development of various self-healing systems incorporating PU. In a study by Jinson Wang et al. [

41], a smart-lignin-based green coating was formulated with notable anti-corrosion performance and the capability to swiftly release the corrosion inhibitor (nicotinic acid, a green inhibitor) upon mechanical damage. The assessment of anti-corrosion performance, conducted through electrochemical impedance spectroscopy (EIS), revealed an increase in the corrosion potential value from 481 mV (uncoated sample) to +187 mV. The released corrosion inhibitor facilitated the formation of a passive layer on the metal substrate's surface in response to mechanical damage, underscoring the self-healing ability of the lignin polyurethane (LPU) coatings.

4.1.3. Polyimides Based Self-Healing Coatings

Polyimides are a category of high-performance polymers that demonstrate thermal chemical resistance, mechanical strength, and stability. Nowadays, there is a remarkable interest in synthesizing polyimides based self-healing coatings because of the demand for long lasting and resistant materials that can be used in various applications such as protective coatings, electronics and aerospace.

Yong Chae Jung et al. developed a new type of colorless polyimides with a self-healing function and resolving the trade-off between the functionality and durability. These coatings had the ability of self-healing, rapidly restoring any damage caused by external stress [

42]. The team of Yanlian Xu et al. fabricated two-dimensional lamellar polymer composite coatings based on polyimide/cardanol together with benzoxazine copper. The obtained coatings exhibited excellent anti-corrosion properties and enhanced mechanical performances [

43]. In the work of Kuang-Lieh Lu et al. synthesized durable high-performance materials using polyimides revealing enhanced corrosion resistance properties, anticorrosion effect against high temperature, and long-term robustness [

44]. Joseph Lichtenhan with his team investigated combinations of polyimide-based nanomaterials together with polyhedral oligomeric silsequioxane in order to produce coatings that exhibited improved stability in mechanical properties. The self-healing mechanism was assigned to the creation of a silica thin layer [

45].

4.2. Thermoplastic Polymers

This type of polymers exhibit healing through thermal processes. Thermoplastic polymers are characterized by their ability to be reheated and reprocessed. The healing mechanism is based on the ability that the polymer matrix softens upon heating, allowing the defected areas to flow and merge, resulting to coating recovery.

4.2.1. Polyacrylate Based Self-Healing Coatings

Polyacrylate (PAL) and its derivative-based materials (polymers) have gained widespread recognition in the coating industries due to numerous attributes, including low cost, high transparency, excellent adhesion, processability, and durability, particularly under ambient conditions. One particularly intriguing aspect of PAL (polyacrylate) materials is the ability to tailor their physical properties through the judicious selection of monomers for the formation of the polymer network. Numerous studies have been conducted to enhance the recurrent self-healing characteristics, typically relying on reversible bonds like covalent bonds, hydrogen bonds, coordinate covalent bonds, ionic interactions, and host–guest interactions [

46,

47]. The use of van der Waals interactions aims to eliminate both chemical and physical interactions, allowing for multiple recoveries under mechanical stress without the need for any external triggering agent. Wenpeng Zhao et al. [

48] investigated the mechanical and self-healing characteristics of anisotropic composites by incorporating multiple reversible bonds, specifically strong coordination bonds and weak hydrogen bonds. Through FTIR and combined 2D FTIR analysis, it was determined that the rapid self-healing capability (within 30 seconds with a healing efficiency of approximately 95%) of the designed system was attributed to the weak hydrogen bonds. Meanwhile, the robust mechanical properties (12.6 MPa) were primarily a result of the strong coordinate interactions. Such systems can be utilized as a soft actuator that further employed for the manufacturing of smart self-healing polymer materials for many applications especially in the medical/bio-medical sectors.

4.2.2. Polyvinyl Based Self-Healing Coatings

Self-healing coatings based on polyvinyl pay attention on the fabrication of protective layers enable to automatically damage restore. The utility of these coatings is to enhance the longevity and durability of various surfaces, ranging from plastics to metals, through the incorporation of mechanisms that permit the coating to heal itself after damage such as cracks or scratches. Polyvinyl compounds, like polyvinyl acetate, polyvinyl chloride, and polyvinyl alcohol, are polymers that can be used in several applications. The modification of these materials in self-healing coatings to include healing agents results to the demonstration of self-healing properties.

Kwan-Young Han et al. [

49] synthesized and examined self-healing polyvinyl including functional polymer that reacts to ultraviolet irradiation and thermal energy. The obtained material exhibited improved thermal stability, processability, chemical resistance, and mechanical strength because of the functional molecule introduction at the brush end joined to the polyvinyl chain. In the work of Chun Cheng et al. [

50] high-performance self-healing coatings were prepared from a mixed solution of hydrolyzed poly(styrene-co-maleic anhydride) and polyvinyl alcohol. The coatings revealed enhanced antifogging performance in a humid, warm environment as well as a refrigerator room. An improved self-healing ability was detected that was ascribed to hydrogen bonding self-assembly. Hydrogel coatings based on borax and polyvinyl alcohol were produced and applied in rigid polyurethane foam by Xiaodong Qian et al. [

51]. The fabricated coatings were investigated in respect of their self-healing, fire-retardant and recyclability properties. The reversible and dynamic cross-linked networks based on the hydrogen bonds and borate ester bonds imparted the hydrogels with enhanced recyclability, repairability, and elasticity. Self-healing organic coatings based on polyvinyl butyral formulations were synthesized by Mittal et al. [

52]. Polypyrrole-carbon black additives were incorporated as an inhibiting pigment. The exposure of the composite coatings in aggressive environments imparted self-healing effect that was assigned to diffusion barrier nature and of redox properties polypyrrole. A stable passive layer was created on the metal surface because of the interaction organic sulfonic acid dopant, that was released from the polypyrrole with metal iron oxide. Mai M. Khalaf et al. [

53] prepared via dip-coating process, protective systems with self-healing properties in order to defend carbon steel corrosion in acidic medium environment containing chloride. Polyvinyl chloride was introduced as an organic healing agent into formulations that contained TiO2, ZnO, and ZnO-TiO2 nanocomposites.

4.3. Elastomers

The elastomers are characterised by highly elastic properties indicating their ability to stretch and return to original shape. The healing mechanism is occured through ionic interactions, physical entanglement, or reversible cross-links that can reconstruct after damage.

4.3.1. Silicone Rubber Based Self-Healing Coatings

Coatings that impart self-healing effect based on silicone rubber are a very interested area of material science. Because of the flexibility and durability of silicone rubber, these coatings are able to repair themselves after damage, such as cuts, scratches, or cracks, that enhances their performance and durability in various applications. Briefly, silicone rubber exhibits excellent elasticity and flexibility, even at elevated temperatures, provides good resistance to UV radiation, many chemicals, and weathering, and finally it has thermal stability.

Elastic silicone rubbers based on polydimethylsiloxane-co-nickel(II)-pyridinedicarboxamide copolymers were developed by the team of Islamova et al. [

54]. The self-healing capability was attributed to the reversible metal-ligand interactions, and it was estimated at room temperature. The Ni

2+ ions acted as cross-links between the polydimethylsiloxane chains through the coordination of Ni–O and Ni–Npyridine bonds. Yumin Wu et al. [

55] prepared self-healing silicone rubber cross-linked by the multiple hydrogen bonds with ethylene carbonate and α,ω-aminopropyl poly(dimethylsiloxane) based on the nonisocyanate reaction. The several hydrogen bonds between the imino and carbonyl groups together with the generated hydroxyl groups finally produced a hydrogen bond cross-linked network imparting enhanced thermal-induced self-healing efficiency as well as good cyclic self-healing ability.

Zhang et al. [

56] prepared a self-healing coating consisted of polydimethylsiloxane-based polyurea together with an organic antifouling agent. The coating demonstrated good adhesion to the substrate, that was assigned to the breaking and reorganization of the urea group hydrogen bonds. The coating exhibited enhanced self-healing capability in both artificial seawater and air at room temperature. The team of Lee et al. [

57] synthesized a polysiloxane-based polyurethane elastomer via a triboelectric effect. The elastomer consisted of urea-oxime-carbamate units, in order the molecular chain to present improved fluidity to enhance reconstruction after damage. Reversible dissociation and reconnection occurred, due to imparts high mobility to the molecular chains, revealing self-healing effect. Rao et al. [

58] developed a self-repairing polydimethylsiloxane elastomer based on metal-ligand interaction. The chain of the elastomer had a structure based on 2,2 '-bipyridine-5,5' -dicarboxamide. The metal-ligand interaction created by the addition of Zn

2+ that exhibited kinetic instability, enabling the elastomer with self-healing ability at room temperature.

4.3.2. Poly1,3-diene Based Self-Healing Coatings

Polybutadiene and polyisoprene are both types of synthetic rubbers, with enhanced flexibility and elasticity. Polyisoprene can exhibit self-healing properties that are assigned to reversible covalent bonds such as the incorporation of diels-alder or disulfide bonds, into the polymer structure, physical cross-links such as the presence ionic interactions or hydrogen bonds, and molecular mobility at elevated temperatures promoting healing effect. Polybutadiene self-healing properties are ascribed to microphase separation creating domains that repair damage via the mobility of the rubbery phase, reversible networks metal-ligand interactions or hydrogen bonds, and plasticization [

59,

60,

61].

5. Types of Self-Healing Capsules

The development of self-healing coatings has led to the development of multiple self-healing capsule types, each tailored to meet specific requirements and overcome obstacles in different applications. These capsules are designed to encapsulate healing agents and release them when damaged, thereby enabling the self-healing process [

62]. One of the main types of self-healing capsules is based on microencapsulation technology. Microencapsulation involves encapsulating the core drug in a protective shell distributed throughout the material. If the material is damaged, the capsules rupture and release the healing agent to repair the crack or break. This process not only prevents further damage but also extends the life cycle of the material. Microencapsulation technology has found widespread use in self-healing materials, from concrete to polymers, and offers a promising solution for improving the durability of various structures.

Chemical self-healing capsules play a crucial role in the development of advanced micro/nanocapsules for self-healing coatings [

63]. These capsules are designed to encapsulate various active agents capable of repairing damage within coatings, offering a sustainable solution for enhancing material longevity and performance. The introduction of chemical self-healing capsules marks a significant advancement in the field of materials science, particularly in the realm of protective coatings for various applications. By understanding the mechanism of action of these capsules, researchers and engineers can harness their potential for creating innovative self-healing materials. The mechanism of action of chemical self-healing capsules involves the controlled release of healing agents in response to damage or external stimuli. When a coating containing these capsules experiences a scratch, crack, or other forms of damage, the capsules rupture, releasing the encapsulated healing agents. These agents then react with the surrounding environment to initiate the healing process, effectively repairing the damage and restoring the coating's integrity [

64]. This self-healing mechanism offers a dynamic and autonomous approach to maintaining the functionality and aesthetics of coatings over time, reducing the need for frequent repairs or replacements. Chemical self-healing capsules include urea-formaldehyde (UF) capsules, which have been prepared using an in-situ encapsulation method. These capsules demonstrate a significant size reduction, enhancing their efficiency in delivering healing agents within coatings [

65]. Additionally, organic shell nano/microcapsules such as poly(urea-formaldehyde), polystyrene, and polyurethane have been synthesized for self-healing applications, showcasing the versatility and adaptability of chemical self-healing capsules [

66]. The development of microcapsule-type self-healing coating systems highlights the potential for these capsules to self-heal cracks and maintain the structural integrity of coatings over extended periods [

67]. Through continued research and innovation, the utilization of chemical self-healing capsules is poised to revolutionize the field of protective coatings, offering sustainable and cost-effective solutions for enhanced material performance and longevity.

Biological self-healing capsules are a fascinating innovation in the realm of self-healing coatings, offering a unique approach to repairing damage inspired by natural biological processes. These capsules are designed to encapsulate self-healing agents and release them when needed to repair defects in coatings, such as those used in anti-corrosion applications. The concept of self-healing coatings inspired by biological systems is rooted in the idea of mimicking the regenerative capabilities found in living organisms, enabling materials to repair physical damage autonomously. The introduction of biological self-healing capsules into coatings has opened up new possibilities for enhancing durability and functionality in various industrial applications by harnessing the power of nature for self-repair [

68]. The mechanism of action behind biological self-healing capsules involves a carefully orchestrated process that triggers the release of healing agents upon detecting damage in the coating [

63]. These capsules are designed to respond to specific stimuli, such as changes in pH or temperature, which are indicative of damage or corrosion. Once the capsules rupture or degrade in response to the stimuli, the self-healing agents are released, filling in cracks or gaps in the coating to restore its integrity. This self-healing process not only repairs the visible damage but also helps prevent further deterioration, prolonging the lifespan of the coating and reducing maintenance requirements in various applications. Examples of biological self-healing capsules include micro/nanocapsules fabricated using different types of micro/nanocontainers. These capsules can be loaded with a variety of self-healing agents, such as polymers, resins, or other active materials capable of repairing damage in coatings. The incorporation of biological self-healing capsules into coatings has been shown to enhance their anti-corrosion properties and improve overall performance in harsh environments. By leveraging the versatility and efficacy of these innovative capsules, researchers and engineers are advancing the field of self-healing coatings, paving the way for more durable and sustainable materials in various industries.

Physical self-healing capsules are innovative materials that play a crucial role in the development of self-healing coatings. These capsules are designed to contain healing agents that can be released when damage occurs, promoting the repair of the coating without human intervention. The concept of physical self-healing capsules is inspired by biological systems that possess the remarkable ability to repair themselves in response to damage. By incorporating these capsules into coatings, researchers aim to enhance the durability and longevity of various materials, ranging from automotive paints to protective coatings for infrastructure. The mechanism of action of physical self-healing capsules involves a proactive response to damage, triggered by external stimuli such as mechanical stress or environmental factors. When a coating containing these capsules experiences a crack or scratch, the capsules rupture, releasing the healing agent into the damaged area. The healing agent then interacts with the surrounding material, catalyzing a self-repair process that restores the integrity and functionality of the coating. This autonomous healing process demonstrates the potential of physical self-healing capsules to revolutionize the field of protective coatings and materials engineering.

5.1. Nano-Capsules in Self-Healing Coatings

Nano-capsules play a crucial role in the development of self-healing coatings, offering innovative solutions for enhancing the durability and longevity of various materials. These micro/nanocapsules are designed based on different types of micro/nanocontainers and are at the forefront of cutting-edge research in materials science. The synthesis of micro/nanocapsules involves effective parameters that influence their structure and performance, leading to the fabrication of self-healing coatings that exhibit remarkable capabilities [

69,

70]. By encapsulating active agents within these capsules, such as healing agents or corrosion inhibitors, self-healing coatings can autonomously repair damage and protect surfaces from environmental factors, extending the lifespan of coated materials [

71].

Self-healing capsules play a crucial role in the restoration and maintenance of materials by releasing mending agents upon crack formation. These capsules are evenly dispersed within the material matrix, with the volume fraction typically below 5% of the matrix to ensure effectiveness [

72]. The capsules, assumed to act independently and not cluster, rupture when a microcrack emerges, releasing reactive agents that flow to the fracture plane and form a polymer network, effectively sealing the crack [

7,

73,

74]. Different structures of self-healing capsules have been explored, including micro/nanocapsules embedment, spherical capsules, and storage in polyurethane microcapsules, each designed to enhance the healing process and maintain material integrity [

69,

72,

73]. Additionally, hollow fiber embedment has shown promising results in improving compressive strength and reducing permeability in cement matrices, highlighting the diverse applications of self-healing capsules in various material systems [

69,

72]. Through innovative designs and strategic distribution, these capsules release healing agents efficiently, enhancing the self-healing capabilities of materials and extending their lifespan [

72,

74].

5.2. Mechanisms of Self-Healing Capsules

Self-healing capsules exhibit a variety of release mechanisms based on their design and components. For instance, some capsules release the healing agent upon contact with the matrix itself, while others require contact with a second component present in the matrix to trigger the release. Additionally, self-healing capsules can be engineered to release the healing agent upon exposure to moisture, air, or heat, providing versatility in application based on environmental conditions [

70,

75]. The efficacy of the release mechanism is influenced by factors such as the crack area, capsule concentration, and crack volume relative to the healing agent available in the capsules. Moreover, the shape and size of the capsules play a significant role in the controlled release of the healing agent. Spherical capsules are known to offer a more controlled and enhanced release compared to cylindrical capsules, which suffer from inferior release upon cracking due to suction effects exerted by closed ends [

75]. Furthermore, the reliability of self-healing systems is dependent on the number of capsules included to prevent cracks from propagating and fracturing them, highlighting the importance of proper capsule distribution within the matrix. Overall, the design and deployment of self-healing capsules are critical in ensuring effective healing of cracks and enhancing the durability of cementitious materials.

Categorizing self-healing capsules according to their structure and release mechanisms offers numerous advantages in the field of concrete repair and maintenance. By dispersing healing agents within a matrix or encasing them in matrix aggregates, the capsules can effectively deliver the mending materials where they are needed most. Moreover, integrating self-healing capsules during concrete production streamlines the repair process and enhances the structural integrity of the material [

75]. One key benefit of this classification system is the mitigation of the suction effect caused by sealed cylindrical capsules, thereby improving the overall healing efficiency of the capsules. Encapsulating healing agents within coated hollow plant fibers allows for the controlled release of the mending substances when cracks develop in the concrete, ensuring targeted and efficient repair mechanisms [

75]. Additionally, the systematic categorization of self-healing capsules based on their structure and release mechanisms enables researchers to assess their effectiveness across different structural components, facilitating the development of more resilient and durable concrete structures. This approach not only enhances the practical application of self-healing capsules in the construction industry but also contributes to the advancement of innovative solutions for sustainable infrastructure maintenance.

5.3. Application-Based Classification of Self-Healing Capsules

One of the key factors to consider is the application. Based on their structure, microcapsules can be classified into several categories. For instance, single-walled single nuclei and single-walled multiple nuclei microcapsules offer unique advantages in dual-targeted drug delivery via sonochemical methods [

76]. These innovative structures allow for precise and efficient delivery of healing agents to the damaged areas, enhancing the overall healing process. Moreover, the utilization of microcapsule self-healing technology has shown promising results in the field of cement-based materials [

77]. Researchers are exploring the potential of these capsules for future applications, indicating a growing interest in this advanced technology.

Another crucial aspect of self-healing capsules is the triggering mechanism that initiates the healing process. Extrinsic self-healing composites stand out for their automatic recovery capabilities when damaged, drawing inspiration from biological systems that exhibit natural healing properties [

78]. Within this category, there are two major groups: autonomic and non-autonomic self-healing materials. Autonomic materials, in particular, have the remarkable ability to heal themselves without the need for external intervention [

79]. This self-sustainability makes them highly desirable for various applications where continuous maintenance is impractical. By understanding the different triggering mechanisms, researchers can tailor self-healing capsules to specific requirements, maximizing their effectiveness.

The material compatibility of self-healing capsules plays a significant role in determining their performance and durability. Inorganic capsules, such as those based on magnesium oxide, have shown great promise in enhancing the healing potential of various materials [

80]. Researchers have developed innovative techniques for preparing and encapsulating powder mineral pellets, further expanding the applications of inorganic capsules [

80]. By focusing on the mineralogy of the inner core and granule strength, scientists can optimize the compatibility of these capsules with different matrices, ensuring long-lasting and effective healing properties [

80]. This attention to detail in material compatibility is essential for advancing the field of self-healing technology and unlocking new possibilities for sustainable infrastructure development.

Τhe classification of self-healing capsules based on application method, triggering mechanism, and material compatibility provides a comprehensive framework for understanding their diverse functionalities. By exploring the nuances of each type of self-healing capsule, researchers can continue to innovate and develop cutting-edge solutions for a wide range of industries. The potential of self-healing capsules to revolutionize material maintenance and restoration is vast, making them a vital area of research and development in the modern era.

5.3. Optimization of Micro/Nanocapsule Design for Self-Healing Coatings

To optimize the design of micro/nanocapsules for enhancing the lifespan of self-healing coatings, researchers focus on various factors such as responsive release mechanisms, container size, and encapsulation processes. Microcontainers, typically ranging from 50 to 200 μm, are identified as optimal for self-healing coatings due to their ability to rupture easily under mechanical stress and provide sufficient storage space for healing agents, thus initiating the healing process effectively [

81]. On the other hand, nanocontainers, being smaller in size, are more suitable for carrying corrosion inhibitors in self-healing coatings, thereby enhancing the coatings' protective capabilities. The authors emphasize the importance of maintaining the coating's integrity and long-term corrosion resistance by utilizing the separation provided by micro/nanocontainers between the inhibitors and the coating matrix. Furthermore, the design of micro/nanocapsules can be optimized by incorporating pH- or wettability-responsive properties to enhance the lifespan of self-healing coatings and by developing green and innovative capsules from sustainable energy sources [

63]. By employing kinetic models to understand the release behavior of encapsulated substances, researchers can predict and optimize the release kinetics, ensuring effective deployment of inhibitors for corrosion prevention [

19]. Ultimately, the controlled and targeted release of inhibitors through micro/nanocontainers plays a crucial role in extending the longevity and stability of materials covered with self-healing coatings.

6. Conclusions

This review paper highlights the significant advances in self-healing coatings, especially those containing various types of self-healing capsules. These capsules, including microcapsules, chemical, biological, and physical self-healing capsules, play a vital role in autonomously repairing damage and improving the durability of materials. Incorporating these capsules into coatings has been shown to significantly improve corrosion resistance and perform better, especially in aggressive environments. The mechanism of action, release behavior, and material compatibility of these capsules have been thoroughly studied and provide valuable insights into their effectiveness and potential applications. Despite significant progress, challenges remain in optimizing self-healing technologies, reducing costs, and accelerating the transition from laboratory research to practical applications.

Developing self-healing polymeric coatings that are highly durable and able to resist long-term environmental exposure is the key to widespread adoption. In brief, advancements in self-healing coatings stand as significant achievements in enhancing material functionality to ensure longevity. It is imperative that the advanced studies focus on these technologies, improving methods, exploring new healing agents innovatively and coming up with economically viable solutions to achieve the maximum utilization of self-healing coatings in various industrial fields. The bright future that this field can offer through continuous advancement and no compromise to innovation or optimization which will completely overhaul the traditional approach of material maintenance towards sustainability. It is very important that long-lived self-healing polymer coatings are developed since regular exposure to the environment for a considerable amount of time.

In conclusion, the development of self-healing coatings, especially through the development of micro- and nano-containers, represents a quantum leap forward in improving material performance and durability. Further research into these technologies is imperative, and new treatment approaches must be investigated, while cost-effective applications must not be neglected. In this way, we can realize the full potential of self-healing coatings in various industrial sectors. The prospect of a future revolution in material care through continued dynamic innovation and optimization bodes well for the adoption of sustainable practices in the industry. The development of durable, ageing-resistant polymer coatings that can withstand long-term environmental impacts is suitable for the widespread use of such materials. In conclusion, the development of self-healing coatings - especially through micro- and nano-containers - undoubtedly represents an important step towards improving material performance and extending service life.

In future investigations, these areas are to be brought to perfection new healing agents are to be explored without cost concern so as to find cost-effective solutions that could unleash the full potential of self-healing coatings for all industrial spheres. The dynamics and ongoing fine-tuning within this area promises the transformation of approaches towards maintaining materials, with an eye on green sustainability far into the future.

Author Contributions

Conceptualization, I.K.; methodology, I.K., A.K.; validation, I.K., A.K., I.AK.; formal analysis, I.K., A.K.; investigation, I.K., A.K.; resources, I.K.; writing—original draft preparation, I.A.K., A.K., I.A.K.; writing—review and editing, I.K., A.K., I.A.K.; visualization, I.K.; supervision, I.K.; All authors have read and agreed to the published version of the manuscript.

Funding

This research was not funded.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data sharing is not applicable to this article as no new data were created or analyzed in this study.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ahmad, S.; Habib, S.; Nawaz, M.; Shakoor, R.A.; Kahraman, R.; Mohammed Al Tahtamouni, T. The role of polymeric matrices on the performance of smart self-healing coatings: A review. Journal of Industrial and Engineering Chemistry 2023, 124, 40–67. [Google Scholar] [CrossRef]

- Zehra, S.; Mobin, M.; Aslam, R.; Bhat, S.u.I. Nanocontainers: A comprehensive review on their application in the stimuli-responsive smart functional coatings. Progress in Organic Coatings 2023, 176, 107389. [Google Scholar] [CrossRef]

- Chen, Z.; Scharnagl, N.; Zheludkevich, M.L.; Ying, H.; Yang, W. Micro/nanocontainer-based intelligent coatings: Synthesis, performance and applications – A review. Chemical Engineering Journal 2023, 451, 138582. [Google Scholar] [CrossRef]

- Kayla Lee, C.G.C., Jacob Rouse, Xin Wei, Mei Li, Suying Wei, . Advanced Micro/Nanocapsules for Self-healing Smart Anticorrosion Coatings; 2021.

- Eduok, U.; Ohaeri, E.; Szpunar, J. Self-healing composite coatings with protective and anticorrosion potentials: classification by healing mechanism. 2020, 123–162. [Google Scholar] [CrossRef]

- Xu, J.; Zhu, L.; Nie, Y.; Li, Y.; Wei, S.; Chen, X.; Zhao, W.; Yan, S. Advances and Challenges of Self-Healing Elastomers: A Mini Review. Materials (Basel) 2022, 15. [Google Scholar] [CrossRef] [PubMed]

- Karaxi, E.K.; Kartsonakis, I.A.; Charitidis, C.A. Assessment of Self-Healing Epoxy-Based Coatings Containing Microcapsules Applied on Hot Dipped Galvanized Steel. Frontiers in Materials 2019, 6. [Google Scholar] [CrossRef]

- Sadrabadi, T.E.; Allahkaram, S.R.; Staab, T.; Towhidi, N. Preparation and characterization of durable micro/nanocapsules for use in self-healing anticorrosive coatings. Polymer Science, Series B 2017, 59, 281–291. [Google Scholar] [CrossRef]

- Shi, F.; Wu, J.; Zhao, B. Preparation and Investigation of Intelligent Polymeric Nanocapsule for Enhanced Oil Recovery. Materials (Basel) 2019, 12. [Google Scholar] [CrossRef]

- Malekkhouyan, R.; Nouri Khorasani, S.; Esmaeely Neisiany, R.; Torkaman, R.; Koochaki, M.S.; Das, O. Preparation and Characterization of Electrosprayed Nanocapsules Containing Coconut-Oil-Based Alkyd Resin for the Fabrication of Self-Healing Epoxy Coatings. Applied Sciences 2020, 10, 3171. [Google Scholar] [CrossRef]

- Habib, S.; Khan, A.; Nawaz, M.; Sliem, M.H.; Shakoor, R.A.; Kahraman, R.; Abdullah, A.M.; Zekri, A. Self-Healing Performance of Multifunctional Polymeric Smart Coatings. Polymers (Basel) 2019, 11. [Google Scholar] [CrossRef]

- Shang, Z.; Zhu, J. Overview on plant extracts as green corrosion inhibitors in the oil and gas fields. Journal of Materials Research and Technology 2021, 15, 5078–5094. [Google Scholar] [CrossRef]

- Al-Amiery, A.A.; Isahak, W.N.R.W.; Al-Azzawi, W.K. Corrosion Inhibitors: Natural and Synthetic Organic Inhibitors. Lubricants 2023, 11, 174. [Google Scholar] [CrossRef]

- Al-Amiery, A.; Yousif, E.; Nor Roslam Wan Isahak, W.; Khalid Al-Azzawi, W. A Review of Inorganic Corrosion Inhibitors: Types, Mechanisms, and Applications. Tribology in Industry 2023, 45, 313–339. [Google Scholar] [CrossRef]

- Rani, B.E.A.; Basu, B.B.J. Green Inhibitors for Corrosion Protection of Metals and Alloys: An Overview. International Journal of Corrosion 2012, 2012, 1–15. [Google Scholar] [CrossRef]

- Zhou, X.; Dong, Q.; Wei, D.; Bai, J.; Xue, F.; Zhang, B.; Ba, Z.; Wang, Z. Smart corrosion inhibitors for controlled release: a review. Corrosion Engineering, Science and Technology 2022, 58, 190–204. [Google Scholar] [CrossRef]

- Yeganeh, M.; Omidi, M.; Rabizadeh, T. Anti-corrosion behavior of epoxy composite coatings containing molybdate-loaded mesoporous silica. Progress in Organic Coatings 2019, 126, 18–27. [Google Scholar] [CrossRef]

- Haddadi, S.A.; Ramazani S.A, A.; Mahdavian, M.; Arjmand, M. Epoxy nanocomposite coatings with enhanced dual active/barrier behavior containing graphene-based carbon hollow spheres as corrosion inhibitor nanoreservoirs. Corrosion Science 2021, 185, 109428. [Google Scholar] [CrossRef]

- Attaei, M.; Calado, L.M.; Morozov, Y.; Taryba, M.G.; Shakoor, R.A.; Kahraman, R.; Marques, A.C.; Montemor, M.F. Smart epoxy coating modified with isophorone diisocyanate microcapsules and cerium organophosphate for multilevel corrosion protection of carbon steel. Progress in Organic Coatings 2020, 147, 105864. [Google Scholar] [CrossRef]

- Raj, R.; Morozov, Y.; Calado, L.M.; Taryba, M.G.; Kahraman, R.; Shakoor, A.; Montemor, M. Inhibitor loaded calcium carbonate microparticles for corrosion protection of epoxy-coated carbon steel. Electrochimica Acta 2019, 319, 801–812. [Google Scholar]

- Habib, S.; Fayyed, E.; Shakoor, R.A.; Kahraman, R.; Abdullah, A. Improved self-healing performance of polymeric nanocomposites reinforced with talc nanoparticles (TNPs) and urea-formaldehyde microcapsules (UFMCs). Arabian Journal of Chemistry 2021, 14, 102926. [Google Scholar] [CrossRef]

- Habib, S.; Fayyad, E.; Nawaz, M.; Khan, A.; Shakoor, R.A.; Kahraman, R.; Abdullah, A. Cerium Dioxide Nanoparticles as Smart Carriers for Self-Healing Coatings. Nanomaterials (Basel) 2020, 10. [Google Scholar] [CrossRef] [PubMed]

- Wen, J.; Lei, J.; Chen, J.; Gou, J.; Li, Y.; Li, L. An intelligent coating based on pH-sensitive hybrid hydrogel for corrosion protection of mild steel. Chemical Engineering Journal 2020, 392, 123742. [Google Scholar] [CrossRef]

- Neisiany, R.E.; Lee, J.K.Y.; Khorasani, S.N.; Ramakrishna, S. Towards the development of self-healing carbon/epoxy composites with improved potential provided by efficient encapsulation of healing agents in core-shell nanofibers. Polymer Testing 2017, 62, 79–87. [Google Scholar] [CrossRef]

- Li, H.; Li, S.; Li, F.; Li, Z.; Wang, H. Fabrication of SiO2 wrapped polystyrene microcapsules by Pickering polymerization for self-lubricating coatings. J Colloid Interface Sci 2018, 528, 92–99. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Zhang, X.; Yu, X.; Wu, G.; Lei, Y.; Sun, G.; You, B. Near infrared light responsive self-healing superhydrophobic coating based on solid wastes. J Colloid Interface Sci 2020, 560, 198–207. [Google Scholar] [CrossRef] [PubMed]

- Bolimowski, P.A.; Bond, I.P.; Wass, D.F. Robust synthesis of epoxy resin-filled microcapsules for application to self-healing materials. Philos Trans A Math Phys Eng Sci 2016, 374. [Google Scholar] [CrossRef] [PubMed]

- Attaei, M.; Calado, L.M.; Taryba, M.G.; Morozov, Y.; Shakoor, R.A.; Kahraman, R.; Marques, A.C.; Montemor, M.F. Autonomous self-healing in epoxy coatings provided by high efficiency isophorone diisocyanate (IPDI) microcapsules for protection of carbon steel. Progress in Organic Coatings 2020, 139, 105445. [Google Scholar] [CrossRef]

- Chen, S.; Han, T.; Zhao, Y.; Luo, W.; Zhang, Z.; Su, H.; Tang, B.Z.; Yang, J. A Facile Strategy To Prepare Smart Coatings with Autonomous Self-Healing and Self-Reporting Functions. ACS Appl Mater Interfaces 2020, 12, 4870–4877. [Google Scholar] [CrossRef] [PubMed]

- Kouhi, M.; Mohebbi, A.; Mirzaei, M.; Peikari, M. Optimization of smart self-healing coatings based on micro/nanocapsules in heavy metals emission inhibition. Progress in Organic Coatings 2013, 76, 1006–1015. [Google Scholar] [CrossRef]

- Lei, Y.; Qiu, Z.; Tan, N.; Du, H.; Li, D.; Liu, J.; Liu, T.; Zhang, W.; Chang, X. Polyaniline/CeO2 nanocomposites as corrosion inhibitors for improving the corrosive performance of epoxy coating on carbon steel in 3.5% NaCl solution. Progress in Organic Coatings 2020, 139, 105430. [Google Scholar] [CrossRef]

- Ma, Y.; Zhang, Y.; Liu, J.; Ge, Y.; Yan, X.; Sun, Y.; Wu, J.; Zhang, P. GO-modified double-walled polyurea microcapsules/epoxy composites for marine anticorrosive self-healing coating. Materials & Design 2020, 189, 108547. [Google Scholar] [CrossRef]

- Palazzo, I.; Raimondo, M.; Della Porta, G.; Guadagno, L.; Reverchon, E. Encapsulation of health-monitoring agent in poly-methyl-methacrylate microcapsules using supercritical emulsion extraction. Journal of Industrial and Engineering Chemistry 2020, 90, 287–299. [Google Scholar] [CrossRef]

- Kartsonakis, I.A.; Balaskas, A.C.; Koumoulos, E.P.; Charitidis, C.A.; Kordas, G. ORMOSIL-epoxy coatings with ceramic containers for corrosion protection of magnesium alloys ZK10. Progress in Organic Coatings 2013, 76, 459–470. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, L.; He, Y.; Chen, C.; Wu, Y.; Zhong, F.; Li, H.; Xie, P.; Guo, X. Designing a high-performance waterborne epoxy coating with passive/active dual self-healing properties by synergistic effect of V2O5@polyaniline-tannic acid inhibitors. Progress in Organic Coatings 2021, 151, 106036. [Google Scholar] [CrossRef]

- Kartsonakis, I.A.; Athanasopoulou, E.; Snihirova, D.; Martins, B.; Koklioti, M.A.; Montemor, M.F.; Kordas, G.; Charitidis, C.A. Multifunctional epoxy coatings combining a mixture of traps and inhibitor loaded nanocontainers for corrosion protection of AA2024-T3. Corrosion Science 2014, 85, 147–159. [Google Scholar] [CrossRef]

- Alizadegan, F.; Eivaz Mohammadloo, H.; Mirabedini, S.M.; Asemabadi, Z.; Sardari, A. Preparation of self-healing water-based epoxy coatings containing microcapsules, treated CeO2 particles and 8HQS corrosion inhibitor, and study of their anti-corrosion properties. Progress in Organic Coatings 2024, 195, 108660. [Google Scholar] [CrossRef]

- Zhao, Z.; Liu, S.; Sun, C.; Wu, Y.; Zhang, D. A novel epoxy-based self-healing robust superhydrophobic coatings for oil/water separation. Progress in Organic Coatings 2024, 194, 108574. [Google Scholar] [CrossRef]

- Henriques, R.R.; Carelo, J.C.; Soares, B.G. Anti-corrosive and self-healing properties of epoxy coatings loaded with montmorillonite modified with zinc-based ionic liquid. Progress in Organic Coatings 2024, 187, 108185. [Google Scholar] [CrossRef]

- Shan, Z.; Jia, X.; Li, S.; Li, Y.; Yang, J.; Fan, H.; Song, H. Self-lubricating and wear-resistant epoxy resin coatings based on the “soft-hard” synergistic mechanism for rapid self-healing under photo-thermal conditions. Chemical Engineering Journal 2024, 481, 148664. [Google Scholar] [CrossRef]

- Wang, J.; Seidi, F.; Huang, Y.; Xiao, H. Smart lignin-based polyurethane conjugated with corrosion inhibitor as bio-based anticorrosive sublayer coating. Industrial Crops and Products 2022, 188, 115719. [Google Scholar] [CrossRef]

- Kim, Y.N.; Lee, J.; Kim, Y.-O.; Kim, J.; Han, H.; Jung, Y.C. Colorless polyimides with excellent optical transparency and self-healing properties based on multi-exchange dynamic network. Applied Materials Today 2021, 25, 101226. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, X.; Chen, J.; Bai, W.; Zheng, X.; Lin, Q.; Lin, F.; Xu, Y. Two-dimensional lamellar polyimide/cardanol-based benzoxazine copper polymer composite coatings with excellent anti-corrosion performance. RSC Adv 2022, 12, 10766–10777. [Google Scholar] [CrossRef] [PubMed]

- Lin, X.-Y.; Yu, Y.-H.; Tse, M.-M.; Cheng, S.-H.; Liu, Y.-H.; Lu, K.-L. Semiconductive (Cu–S)n metal–organic framework incorporated polyimide nanocomposite coatings forming an oxide barrier for durable anticorrosion effects. Progress in Organic Coatings 2023, 180, 107562. [Google Scholar] [CrossRef]

- Li, X.; Al-Ostaz, A.; Jaradat, M.; Rahmani, F.; Nouranian, S.; Rushing, G.; Manasrah, A.; Alkhateb, H.; Finckenor, M.; Lichtenhan, J. Substantially enhanced durability of polyhedral oligomeric silsequioxane-polyimide nanocomposites against atomic oxygen erosion. European Polymer Journal 2017, 92, 233–249. [Google Scholar] [CrossRef]

- Burattini, S.; Greenland, B.W.; Merino, D.H.; Weng, W.; Seppala, J.; Colquhoun, H.M.; Hayes, W.; Mackay, M.E.; Hamley, I.W.; Rowan, S.J. A healable supramolecular polymer blend based on aromatic pi-pi stacking and hydrogen-bonding interactions. Journal of the American Chemical Society 2010, 132, 12051–12058. [Google Scholar] [CrossRef]

- Das, A.; Sallat, A.; Bohme, F.; Suckow, M.; Basu, D.; Wiessner, S.; Stockelhuber, K.W.; Voit, B.; Heinrich, G. Ionic Modification Turns Commercial Rubber into a Self-Healing Material. ACS Appl Mater Interfaces 2015, 7, 20623–20630. [Google Scholar] [CrossRef] [PubMed]

- Zhao, W.; Zhang, Z.; Hu, J.; Feng, X.; Xu, J.; Wu, Y.; Yan, S. Robust and ultra-fast self-healing elastomers with hierarchically anisotropic structures and used for wearable sensors. Chemical Engineering Journal 2022, 446, 137305. [Google Scholar] [CrossRef]

- Jang, D.-H.; Park, B.-M.; Kwon, K.H.; Ree, M.; Han, K.-Y. Nanoscratch self-healing characteristics of polyvinyl polymer thin films embedded with Al2O3 nanoparticles with thermal and UV energy reactivity. Materials Today Communications 2020, 25, 101375. [Google Scholar] [CrossRef]

- Luo, S.; Qiao, X.; Wang, Q.-Y.; Zhang, Y.-F.; Fu, P.; Lin, Z.-D.; Du, F.-P.; Cheng, C. Excellent self-healing and antifogging coatings based on polyvinyl alcohol/hydrolyzed poly(styrene-co-maleic anhydride). Journal of Materials Science 2019, 54, 5961–5970. [Google Scholar] [CrossRef]

- Qian, X.; Mu, N.; Zhao, X.; Shi, C.; Jiang, S.; Wan, M.; Yu, B. Novel self-healing and recyclable fire-retardant polyvinyl alcohol/borax hydrogel coatings for the fire safety of rigid polyurethane foam. Soft matter 2023, 19, 6097–6107. [Google Scholar] [CrossRef]

- Niratiwongkorn, T.; Luckachan, G.E.; Mittal, V. Self-healing protective coatings of polyvinyl butyral/polypyrrole-carbon black composite on carbon steel. RSC Advances 2016, 6, 43237–43249. [Google Scholar] [CrossRef]

- Abd El-Lateef, H.M.; Alnajjar, A.O.; Khalaf, M.M. Advanced self-healing coatings based on ZnO, TiO2, and ZnO-TiO2/polyvinyl chloride nanocomposite systems for corrosion protection of carbon steel in acidic solutions containing chloride. Journal of the Taiwan Institute of Chemical Engineers 2020, 116, 286–302. [Google Scholar] [CrossRef]

- Deriabin, K.V.; Ignatova, N.A.; Kirichenko, S.O.; Novikov, A.S.; Islamova, R.M. Nickel(II)-pyridinedicarboxamide-co-polydimethylsiloxane complexes as elastic self-healing silicone materials with reversible coordination. Polymer 2021, 212, 123119. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, K.; Sun, J.; Yuan, J.; Yang, Z.; Gao, C.; Wu, Y. A Type of Hydrogen Bond Cross-Linked Silicone Rubber with the Thermal-Induced Self-Healing Properties Based on the Nonisocyanate Reaction. Industrial & Engineering Chemistry Research 2019, 58, 21452–21458. [Google Scholar] [CrossRef]

- Liu, C.; Ma, C.; Xie, Q.; Zhang, G. Self-repairing silicone coatings for marine anti-biofouling. Journal of Materials Chemistry A 2017, 5, 15855–15861. [Google Scholar] [CrossRef]

- Xiong, J.; Thangavel, G.; Wang, J.; Zhou, X.; Lee, P.S. Self-healable sticky porous elastomer for gas-solid interacted power generation. Science advances 2020, 6, eabb4246. [Google Scholar] [CrossRef]

- Rao, Y.L.; Chortos, A.; Pfattner, R.; Lissel, F.; Chiu, Y.C.; Feig, V.; Xu, J.; Kurosawa, T.; Gu, X.; Wang, C.; et al. Stretchable Self-Healing Polymeric Dielectrics Cross-Linked Through Metal-Ligand Coordination. Journal of the American Chemical Society 2016, 138, 6020–6027. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Tang, Z.; Huang, J.; Guo, B.; Huang, G. Promoted strain-induced-crystallization in synthetic cis-1,4-polyisoprene via constructing sacrificial bonds. Polymer 2016, 97, 580–588. [Google Scholar] [CrossRef]

- Walther, A.; Göldel, A.; Müller, A.H.E. Controlled crosslinking of polybutadiene containing block terpolymer bulk structures: A facile way towards complex and functional nanostructures. Polymer 2008, 49, 3217–3227. [Google Scholar] [CrossRef]

- Tang, F.; Gong, D. Polymerization of butadiene, isoprene and 1-substituted dienes using cobalt catalysts. Inorganica Chimica Acta 2022, 539, 121011. [Google Scholar] [CrossRef]

- Kartsonakis, I.A.; Charitidis, C.A. Corrosion Protection Evaluation of Mild Steel: The Role of Hybrid Materials Loaded with Inhibitors. Applied Sciences 2020, 10, 6594. [Google Scholar] [CrossRef]

- Wei, H.; Wang, Y.; Guo, J.; Shen, N.Z.; Jiang, D.; Zhang, X.; Yan, X.; Zhu, J.; Wang, Q.; Shao, L.; et al. Advanced micro/nanocapsules for self-healing smart anticorrosion coatings. Journal of Materials Chemistry A 2015, 3, 469–480. [Google Scholar] [CrossRef]

- Zhang, F.; Ju, P.; Pan, M.; Zhang, D.; Huang, Y.; Li, G.; Li, X. Self-healing mechanisms in smart protective coatings: A review. Corrosion Science 2018, 144, 74–88. [Google Scholar] [CrossRef]

- Blaiszik, B.J.; Sottos, N.R.; White, S.R. Nanocapsules for self-healing materials. Composites Science and Technology 2008, 68, 978–986. [Google Scholar] [CrossRef]

- Sadabadi, H.; Allahkaram, S.R.; Kordijazi, A.; Rohatgi, P.K. Self-healing Coatings Loaded by Nano/microcapsules: A Review. Protection of Metals and Physical Chemistry of Surfaces 2022, 58, 287–307. [Google Scholar] [CrossRef]

- Lee, J.S.; Kim, H.W.; Lee, J.S.; An, H.S.; Chung, C.M. Microcapsule-Type Self-Healing Protective Coating That Can Maintain Its Healed State upon Crack Expansion. Materials (Basel) 2021, 14. [Google Scholar] [CrossRef] [PubMed]

- Stephenson, A.K.a.L.D. Self Healing Coatings Using Microcapsules and Nanocapsules; 2002. [Google Scholar]

- Samadzadeh, M.; Boura, S.H.; Peikari, M.; Kasiriha, S.M.; Ashrafi, A. A review on self-healing coatings based on micro/nanocapsules. Progress in Organic Coatings 2010, 68, 159–164. [Google Scholar] [CrossRef]

- Krzak, M.; Tabor, Z.; Nowak, P.; Warszyński, P.; Karatzas, A.; Kartsonakis, I.A.; Kordas, G.C. Water diffusion in polymer coatings containing water-trapping particles. Part 2. Experimental verification of the mathematical model. Progress in Organic Coatings 2012, 75, 207–214. [Google Scholar] [CrossRef]

- , doi:10.1016/j.porgcoat.2012.10.028. [CrossRef]

- Lv, Z.; Chen, H. Analytical models for determining the dosage of capsules embedded in self-healing materials. Computational Materials Science 2013, 68, 81–89. [Google Scholar] [CrossRef]

- Lv, Z.; Li, S.; Chen, H. Analytical model for effects of capsule shape on the healing efficiency in self-healing materials. PloS one 2017, 12, e0187299. [Google Scholar] [CrossRef]

- Nesterova, T.; Dam-Johansen, K.; Pedersen, L.T.; Kiil, S. Microcapsule-based self-healing anticorrosive coatings: Capsule size, coating formulation, and exposure testing. Progress in Organic Coatings 2012, 75, 309–318. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; De Belie, N. Self-Healing in Cementitious Materials-A Review. Materials (Basel) 2013, 6, 2182–2217. [Google Scholar] [CrossRef] [PubMed]

- Chang, Y.; Yan, X.; Wu, Z. Application and prospect of self-healing microcapsules in surface coating of wood. Colloid and Interface Science Communications 2023, 56, 100736. [Google Scholar] [CrossRef]

- Liu, B.; Wu, M.; Du, W.; Jiang, L.; Li, H.; Wang, L.; Li, J.; Zuo, D.; Ding, Q. The Application of Self-Healing Microcapsule Technology in the Field of Cement-Based Materials: A Review and Prospect. Polymers (Basel) 2023, 15. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Pham, D.T.; Ji, C. Nanocomposites for Extrinsic Self-healing Polymer Materials. 2017, 243–279. [Google Scholar] [CrossRef]

- Mohonee, V.K.; Lim Goh, K.; Mishnaevsky, L.; Pasbakhsh, P. Capsule based self-healing composites: New insights on mechanical behaviour based on finite element analysis. Computational Materials Science 2021, 192, 110203. [Google Scholar] [CrossRef]

- Li, J.; Guan, X.; Zhang, C. Inorganic capsule based on expansive mineral for self-healing concrete. Cement and Concrete Composites 2023, 144, 105305. [Google Scholar] [CrossRef]