1. Introduction

For several indigenous communities and colonists in the North Ecuadorian Amazon, the cultivation and trade of coffee and cocoa constitute important income sources which, above all, are not linked with work in extractive activities such as oil and mining [

1]. However, coffee and cocoa cultivation may be of concern considering that the highest rates of forest losses in South America are linked with farming, especially large-scale monoculture [

2]. It is believed that the production rationale of transnational agribusiness that promotes monoculture and large-scale farming schemes significantly differs from the rationale of local communities using small-scale agroforestry systems [

3]. In fact, at the level of smallholders of the Amazon region, it is known that deforestation processes are linked to poverty [

4]. Accordingly, cooperatives of small-scale farmers who grow coffee and cocoa in agroforestry systems were promoted in the last decade by government and non-government institutions as an attempt to improve the socio-economic conditions of local communities and as a model to prevent deforestation [

5]. Beyond discouraging deforestation, the role of cooperatives could go towards the positioning of alternative sources of income in a region traditionally dedicated to oil extraction, and prone to the deployment of large-scale farming schemes.

The empirical evidence shows that farmers´ cooperatives in the cocoa and coffee sectors are not necessarily a synonym for poverty alleviation or sustainable supply chains [

6,

7]. A closer look at the agro-industrial processes carried out within farmer cooperatives in the north Ecuadorian Amazon shows that the consumption of fossil fuels to supply the thermal energy required by the drying processes and the accumulation and open-air decomposition of agro-residues generated during threshing has significant environmental impacts, namely: methane emissions, groundwater contamination, and soil acidification [

8]. Following the notions of bioeconomy [

9], the agro-residues generated during the post-harvesting processes can be turned into value-added goods such as biofuels and bioproducts. Thus, beyond placating the environmental impacts caused by the agro-residues the implementation of the bioeconomy could support farmers’ cooperatives in the identification of new income and job sources not linked with oil extraction.

In this regard, the use of coffee husks as solid fuel is probably the first alternative, in the context of farmers' cooperatives, to add value to this agro-residue, reducing the environmental impacts linked with poor waste management practices, avoiding the consumption of fossil fuels, and reducing the drying costs. The use of coffee husks as solid fuel in farmers ‘cooperatives has been linked with the release of large amounts of atmospheric pollutants (often referred to as smoke by the local communities) which can be a sign of inefficient combustion processes [

10]. The atmospheric pollutants released during the incomplete combustion of coffee husks are reported as unburned hydrocarbons, carbon monoxide, and nitrogen-derived compounds such as NO and NO

x [

11]. Furthermore, during coffee husk combustion in mechanical dryers, ash accumulation in the combustion bed and slagging issues at the furnace level have been reported which prevents steady-state drying conditions from being achieved [

12].

As an alternative, the use of pyrolysis processes to reduce smoke emissions and convert coffee husks into biochar while still producing thermal energy that can be supplied to the drying processes has been proposed [

13,

14]. The cited authors state, without experimental evidence, that a pyrolysis process would avoid the release of atmospheric pollutants while reducing local air pollution. There is experimental evidence at the level of thermogravimetric studies about the carbonization process of coffee husks [

15,

16]. Nonetheless, at the farm scale, and up to our best knowledge, there are no experimental studies regarding the gaseous emissions during the carbonization of coffee husks nor regarding those from coffee husks combustion furnaces.

This study provides an experimental analysis -at the farm scale- on the use of coffee husks as feedstock for combustion and pyrolysis processes. Therefore, this study provides an analytical framework based on experimental data to discuss whether the thermochemical conversion of coffee husks could be a paradigm for the adoption of the bioeconomy in farmers´ cooperatives of the north Ecuadorian Amazon, also revealing income and job sources not linked to oil extraction. A retort burner already implemented in a farmers´ cooperative, and a pilot-scale auger-type pyrolysis reactor were used to monitor operating conditions and corresponding flue gas emissions. To compare the flue gas emissions of both technologies during coffee husk valorization, the European eco-design standard for fixed combustion sources was used as a reference due to local standards are not yet available for this purpose [

17]. Concerning the pyrolysis process, this study also reports and discusses the physical-chemical properties of the carbonized coffee husk considering its use as biochar for soil amendment and carbon sequestration. Finally, a comparative SWOT analysis based on participant observations guides a discussion on the role of combustion and pyrolysis as processes to generate added value from coffee husks and thus, advance the implementation of the bioeconomy in farmers´ cooperatives of the north Ecuadorian Amazon.

2. Materials and Methods

2.1. Study Site and Collection of Coffee Husks

The coffee husks used in the combustion and pyrolysis experiments were collected following a participant observation method. The principal author of this work (Mario Heredia) was received by the farmers´ cooperative APROCEL located in the province of Sucumbíos (0°09'21.1"N 76°50'47.8"W) to participate in the post-harvesting processes. APROCEL groups 400 small-scale farmers that grow coffee and cocoa in the north Ecuadorian Amazon. The post-harvesting processes of red coffee cherries in APROCEL followed the dry method as already described by [

8]. Thus, after threshing, a batch of the coffee husks was saved in a jute sack of 30 kg following the norm UNE-CEN/TS 14778-1:EX. This batch was used to determine the proximal and elemental composition of coffee husks. The moisture, ash, and volatile matter content were determined following the standards BS EN 14774-3:2009, BS EN 14775:2009, BS EN 15148:2009, respectively. The heating value and the C-H-N-S-O composition of the coffee husks were determined following the standards ASTM D 1989-96 and BS EN 15104:2011, respectively.

2.2. Thermochemical Conversion Processes

2.2.1. Combustion Process: Retort Burner

The combustion experiments used an industrial dryer of 12 tons capacity per batch already implemented in APROCEL. This dryer includes a single-pass tubular heat exchanger (finned type) that transfers the thermal energy generated by the combustion process toward the drying air. The thermal energy generated in the combustion chamber, located within the heat exchanger, can be provided from two sources, namely a diesel burner or a retort burner that uses raw coffee husks as solid fuel. The retort burner used in the experiments has a nominal thermal power of 100 kWth and is fed with raw coffee husks from a hopper with a capacity of 300 kg that includes an agitator with 4 blades.

Following the recommendations of not increasing the drying air temperature over 45°C to prevent damage to the grain organoleptic quality [

18], the feeding rate of coffee husks implemented in the retort burner during the experiments was 7 kg/h. The ash accumulated in the combustion bed is removed manually after 60 minutes of operation. Accordingly, the monitoring period of flue gas and combustion temperatures is one hour. The sampling of the flue gas was performed during periods of steady-state combustion, that is when constant temperatures were observed in the monitoring sites.

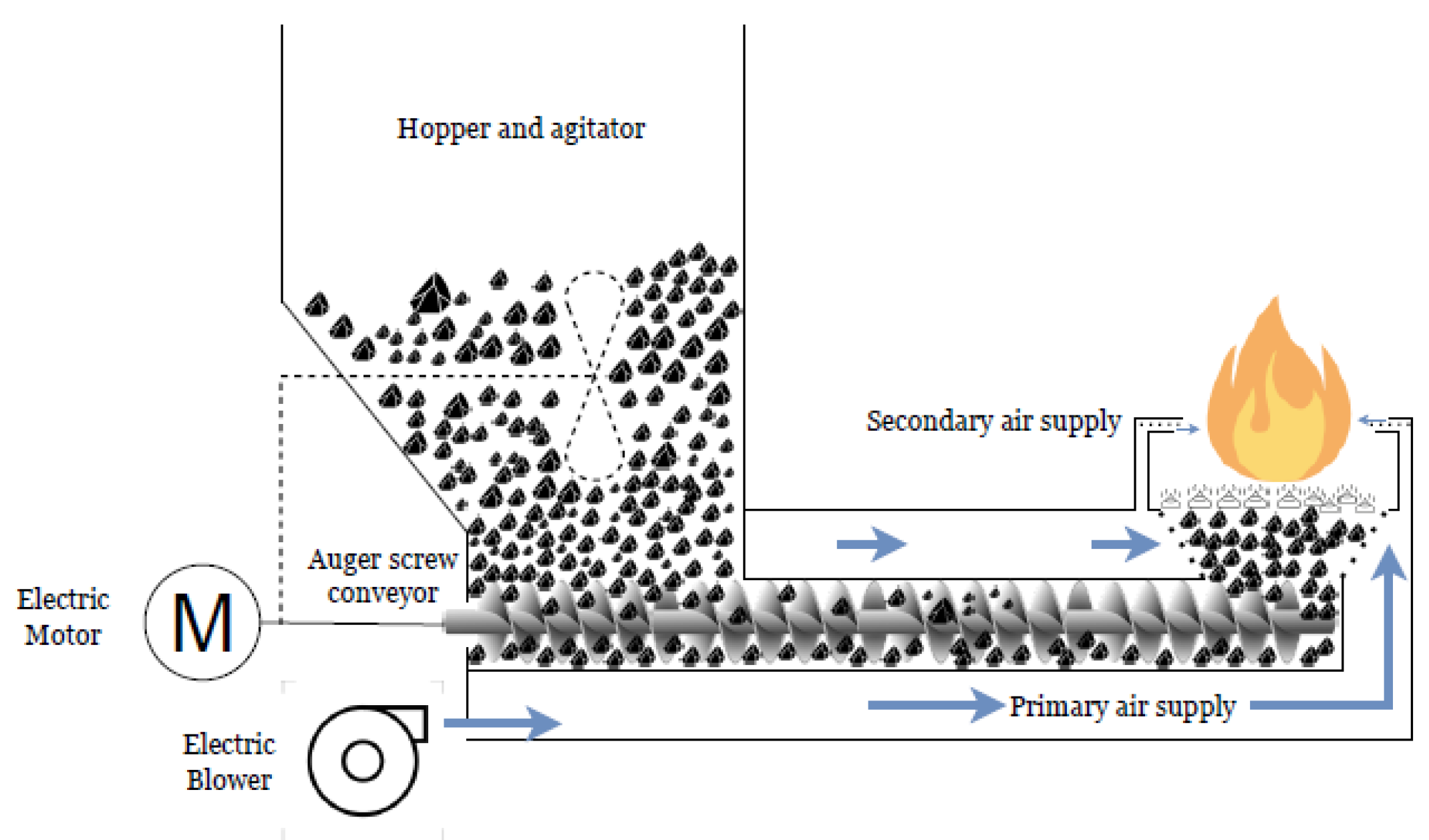

Figure 1 shows the field implementation of the retort burner used in the combustion experiments of coffee husks along with its schematic representation.

The air for the combustion process is supplied by an axial-type electric blower of 0.11 kW coupled to the retort frame. The primary air is supplied through a set of boreholes distributed over the surface of the combustion bed (cone-type) while the secondary air is supplied through two vent tubes located 750 mm above the surface of the combustion bed as shown in the scheme of

Figure 1. The vent tubes for the secondary air supply are placed in parallel (side to side) and each has 6 vertical slots with 45° inclination, 35 mm length, and 2 mm thickness constituting a curtain of cross-flow with 12 air streams projected over the combustion bed (see scheme in

Figure 1).

2.2.2. Pyrolysis Process: Pilot-Scale Auger-Type Pyrolysis Reactor

The coffee husks were pyrolyzed using a pilot-scale auger-type pyrolysis reactor that has been used in previous studies for the conversion of tropical and Andean agro-residues into solid carbonaceous materials [

19]. The pilot-scale auger-type pyrolysis reactor does not use external energy sources such as fossil fuels neither for initial heating or operation. The thermal energy required for the initial heating process and that supplied for the carbonization process is produced through the combustion of agro-residues and also by the combustion of vapors from pyrolysis of agro-residues, respectively. No additional gases are required to promote an inert atmosphere in the pyrolysis reactor or to drag the pyrolytic vapors. Additional details concerning the pilot-scale auger-type pyrolysis reactor are extensively described elsewhere [

20]. The feed rate of coffee husks implemented in the carbonization experiments was 30 kg/h.

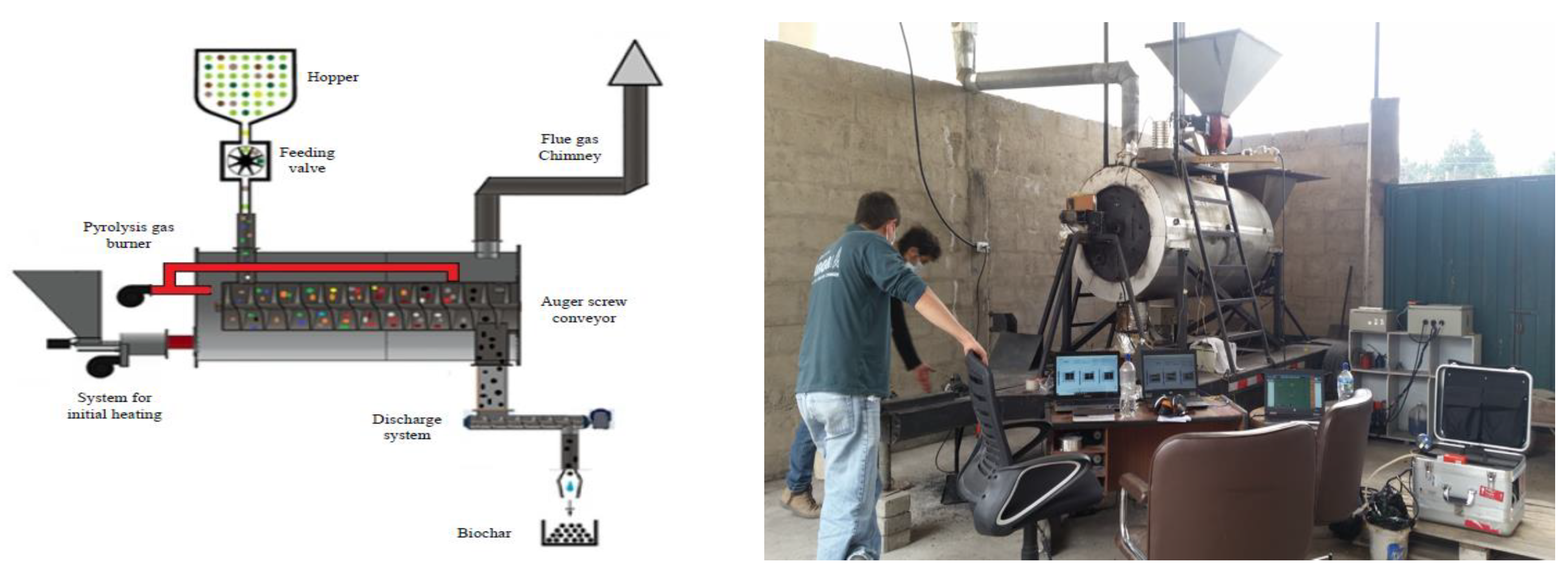

Figure 2 shows a schematic representation of the pilot-scale auger-type pyrolysis reactor used in the pyrolysis experiments of coffee husk and its field implementation for experimental studies.

2.3. Sampling, Proximal and Elemental Characterization of Carbonized Coffee Husks

During the pyrolysis experiments, samples of 3.5 kilograms of carbonized coffee husks were collected from the discharge port of the pilot-scale auger-type pyrolysis reactor following the norm UNE-CEN/TS 14778-1:EX. The proximal and elemental composition of the carbonized coffee husks, namely moisture, ash, and volatile matter content as well as the heating value and the composition of C-H-N-S-O were determined following the same standards used for physic-chemical characterization of raw coffee husks disclosed in

Section 2.1. The quality of the carbonized coffee husks as a soil amendment, namely its stability in the soil (molar ratio O/C

org), carbon content, and degree of carbonization (molar ratio H/C

org) were assessed following the European guidelines for the sustainable production of biochar [

21]. All the samples of carbonized coffee husks were collected during the periods of operation in steady-state. Therefore, the carbonized coffee husks were collected when constant temperatures were observed in the pilot-scale auger-type pyrolysis reactor along with a steady composition of the flue gas.

2.4. Process Monitoring: Flue Gas Composition and Temperature Profiles

The composition of the flue gas during the combustion and pyrolysis experiments was monitored using an AU Mobile Brain Bee infrared online analyzer. The gas analyzer monitors CO (0 to 9.99%vol), CO

2 (0 to 19.9%vol), HC (0 to 13999 ppm, expressed as hexane), and O

2 (0 to 24.99%vol). The gas analyzer resolution is 0.01%vol for CO and O

2, 0.1%vol for CO

2, and 1ppm for HC. A particle matter filter followed by a gas condenser submerged in liquid water in equilibrium with solid water at atmospheric pressure was used for moisture and condensable material removal and to remove particles from the flue gas. Before the flue gas analyzer, a sintered bronze filter was also installed followed by a coalescent filter and a dual particle filter.

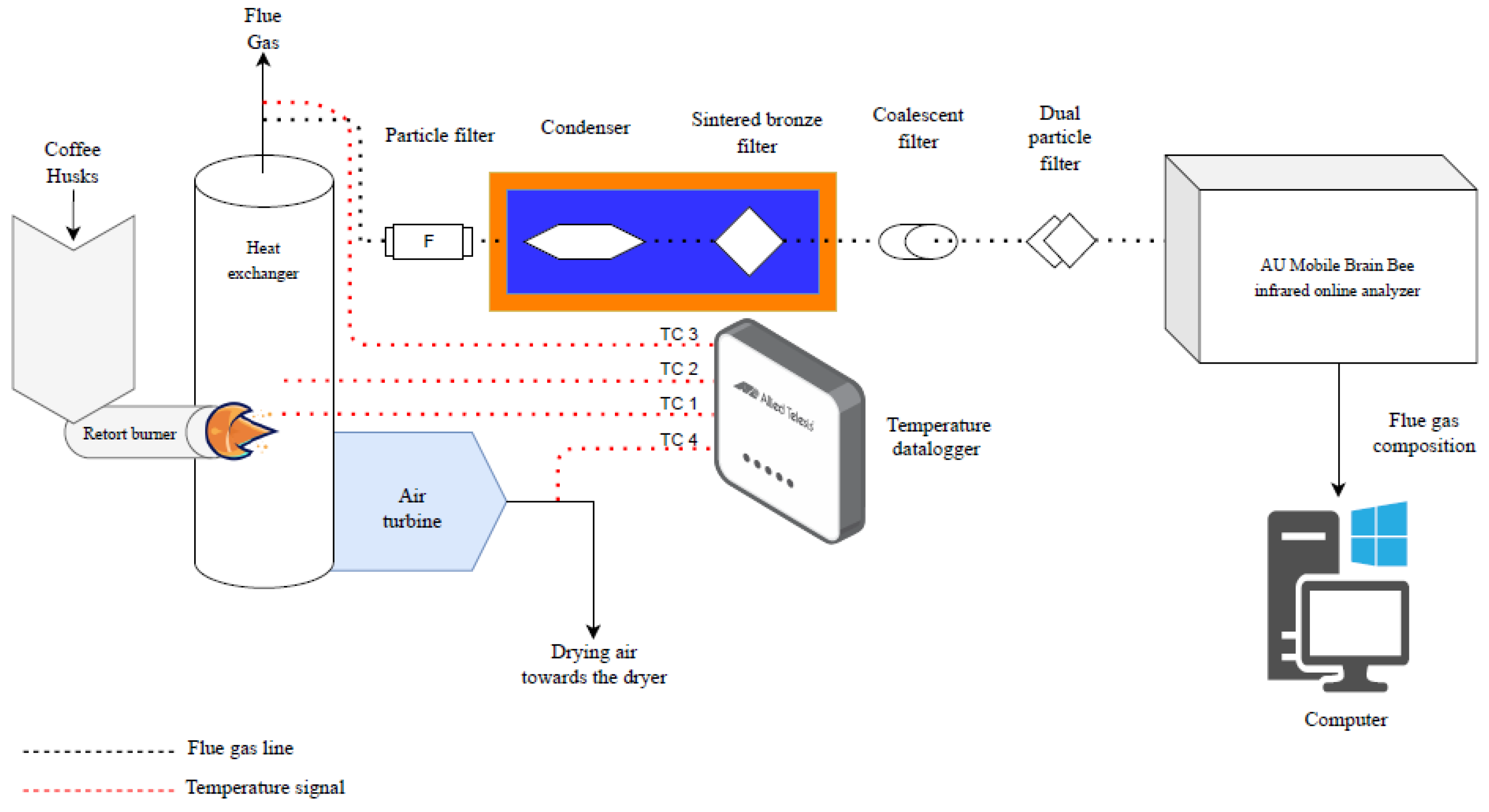

Figure 3 shows the flue gas conditioning process implemented for the experiments. The conversion efficiency of the combustion processes was assessed by monitoring the CO concentration in the flue gas following the European emissions standards for fixed combustion sources [

17]. Accordingly, the CO concentration in the flue gas was corrected to an O

2 concentration of 11%vol O

2 dry gas following the numerical procedure described in previous work [

22].

Concerning the monitoring of temperature profiles during the pyrolysis process of coffee husks, seven thermocouples were distributed along several sections of the pilot-scale auger-type pyrolysis reactor. Three thermocouples were installed to monitor the temperature in the combustion chamber of the pyrolysis reactor (TP 1, TP 2, and TP 3), and one thermocouple to monitor the flue gas temperature (TP 4). Furthermore, the temperature at the outlet (TP 5) and inlet (TP 6) of the pyrolysis chamber and the pyrolysis gas temperature (TP 7) were monitored. The location details and individual characteristics of each thermocouple used in the pyrolysis experiments were similar to those used in previous studies in the same reactor [

19,

23].

Concerning the monitoring of temperature profiles during the combustion of coffee husks in the retort burner, four K-type thermocouples were used as shown in

Figure 3. The thermocouples have a measurement range of 95 to 1260 °C and an accuracy of 2.2 °C. Two thermocouples were installed in the combustion chamber, one at the level of the combustion bed (TC 1 in

Figure 3) and the second 450 mm over the combustion bed straight in the flame region (TC 2 in

Figure 3). The flue gas temperature (TC 3 in

Figure 3) was also monitored together with the temperature of the air supplied to the dryer (TC 4 in

Figure 3). For the acquisition of temperature data, a four-channel datalogger (model Logger 88598 4chK SD) was used. The data logger records the temperature at each measurement point in intervals of fifteen seconds.

2.5. Comparative SWOT Analysis: Combustion and Pyrolysis Processes

This SWOT analysis aims to understand the restrictions and opportunities linked to the implementation of coffee husk combustion and pyrolysis processes in farmers´ cooperatives of the North Ecuadorian Amazon and discuss how these technological alternatives contribute to the implementation of the bioeconomy. This SWOT analysis relies on the experimental evidence generated in the present study together with the participant observations made by the principal author (Mario Heredia) while participating in the post-harvesting processes in APROCEL. Identification of new income and job sources in the farmers´ cooperatives linked to the implementation of pyrolysis and combustion processes is of major interest. Thus, following a previously published work in which four farmers´ cooperatives in the same region were involved [

8] this SWOT analysis guides the identification of alternative economic activities not linked with the ongoing oil extraction activities in this region.

3. Results and Discussion

3.1. Combustion and Pyrolysis Processes in the Context of Farmers´Cooperatives

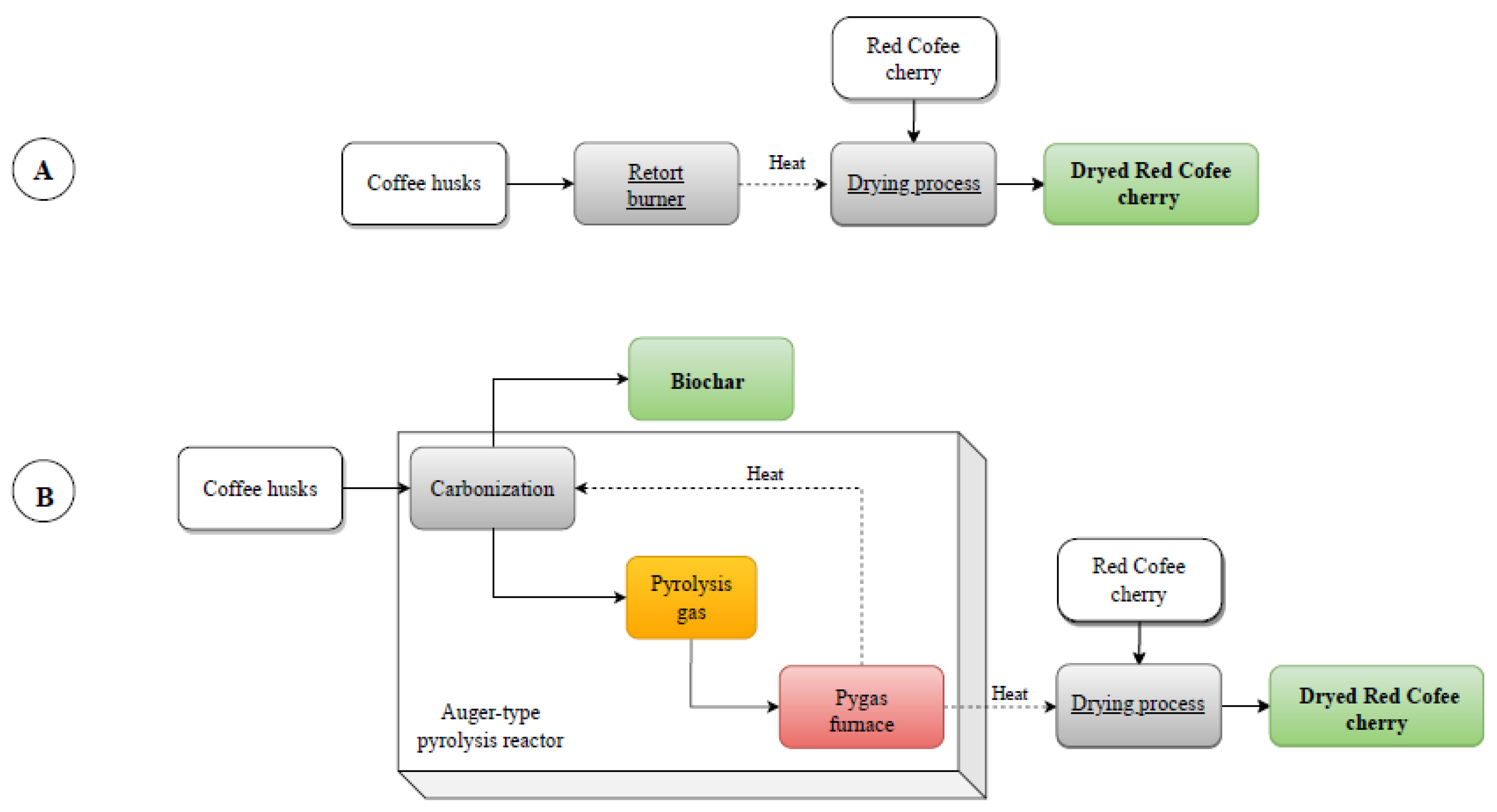

As

Figure 4 shows, two thermochemical conversion processes were identified to add value to the coffee husks generated in the farmer cooperative APROCEL, namely combustion, and pyrolysis processes. The combustion of coffee husks was implemented in APROCEL in 2018 as part of a technology transfer program. In this case, the raw coffee husks are used as solid biofuel to supply the thermal energy required by a mechanical dryer of 12 tons capacity per batch (see A in

Figure 4). Before 2018, APROCEL used subsidized diesel to supply the thermal energy consumed by this dryer. Currently, the implementation of the retort burner that uses coffee husks as solid biofuel avoids the expenses of diesel. In fact, since the implementation of the retort burner, the cooperative has not renewed the permission given by the “Agencia de Control y Regulación Hidrocarburífero (ARCH)” that allows the acquisition of subsidized diesel in local gas stations. Following the notions of [

9], the use of coffee husks as solid biofuel to replace fossil fuel in a productive process could be a kind of biomass-based bioeconomy in which value is generated from a residual biomass source that has been an environmental and economic liability for the cooperative. In this case, diesel, a fossil energy source that in Ecuador, besides subsidized, is 60% imported [

22], is replaced by a renewable energy source which is available right in the consumption site.

It was observed that after the implementation of the retort burner, the analyzed cooperative became self-sufficient in terms of thermal energy as the mechanical drying process is currently driven using biofuels. In the energy subject, the operation of the cooperative has been strengthened as it is now independent of the government subsidies to fossil fuels, a policy whose constant revision constituted a threat to users that benefit from these subsidies to access fossil fuels with preferential prices. From the government side, once the cooperative uses raw coffee husks as biofuel, an implicit subsidy removal has been operated without affecting production costs for the final energy user (i.e., the cooperative) as well as the citizen´s right to access energy. Strategies concerning the implementation of energy reforms in Latin America to remove incentives for the use of fossil fuels e.g., subsidies, is a topic of major relevance in the literature [

24]. Hence, it is extremely important to advance studies to determine if government support for schemes of biofuel utilization, as the one analyzed in this work but deployed on a larger scale, can constitute a successful strategy to deploy the urgently needed energy reform.

An alternative for improving the already implemented bioeconomic system in APROCEL can be the integration of a pyrolysis process in which the raw coffee husks are converted into biochar while the energy required by the drying process still can be supplied by the excess thermal energy of the pyrolysis process (B in

Figure 4). In the context of the rural and urban sectors of the Amazon Region, biochar can be used in applications concerning soil amendment, environmental remediation of contaminated water sources, animal husbandry, green and grey infrastructure, and carbon sequestration [

8]. Accordingly, the production of biochar in farmers´ cooperatives as APROCEL and its subsequent sales and distribution can represent a new source of income and thus, foster an economically and environmentally sustainable valorization of residual biomass. It must not be lost sight that besides the opportunities around biochar, the implementation of pyrolysis technology in a rural context would also generate new job opportunities as operation and maintenance services, as well as general management and logistics services would be required [

25].This section may be divided by subheadings. It should provide a concise and precise description of the experimental results, their interpretation, as well as the experimental conclusions that can be drawn.

3.2. Proximal and Elemental Characterization of Carbonized Coffee Husks

This study demonstrates that raw coffee husks directly collected from the threshing machine can be carbonized using a pilot-scale auger-type pyrolysis reactor.

Table 1 shows the proximate and elemental composition of the raw coffee husks generated in the threshing process in APROCEL along with the proximal and elemental composition of the carbonized coffee husks produced in the pyrolysis experiments. The carbonized coffee husks have a carbon content higher than 50 wt%, an O/C

org ratio lower than 0.4, and an H/C

org ratio lower than 0.7. Likewise, the content of volatile matter is 13.0 wt% and the ash content is 15.0 wt%, both on a wet basis (

Table 1). These indicators show that the coffee husks have a proper degree of carbonization, low aromaticity, and therefore stability in the soil. Accordingly, the coffee husks carbonized in this experiment can be regarded as biochar following the European Standard [

21]. In this respect, future studies to determine the content of heavy metals, pH value, bulk density, and surface area are also relevant to advance the understanding and characterization of this carbonaceous material and to provide insights that guide its safe utilization while opening further application opportunities.

To further support the categorization of the carbonized coffee husks produced in the experiment as biochar,

Table 3 provides the mean temperatures recorded during the carbonization experiments in seven locations along the auger-type pyrolysis reactor. The location of the thermocouples in the auger-type pyrolysis reactor can be consulted elsewhere [

19]. The highest temperature observed at the outlet of the carbonization chamber (TP5) was 436.2 °C which follows the typical temperatures for biochar production by pyrolysis, which depending on the feedstock, is suggested to be at least 400 °C [

26]. High pyrolysis temperatures as those observed in the analyzed experiments guarantee the production of biochar with high content of carbon and with low content of volatile matter (

Table 1).

Following the European Guidelines, the producing device, in this case, the auger-type pyrolysis reactor must have a proper system for temperature monitoring and recording. Furthermore, temperatures should not have fluctuated more than 20% during the carbonization process. In all cases, the standard deviation of the pyrolysis temperatures (

Table 3) is far below the maximum temperature fluctuation tolerance. It is worth noting that thermocouples referred to in

Table 1 as TP1 to TP3 are located in the combustion chamber of pyrolysis vapours. This combustion chamber, which is where the pyrolysis vapours are converted into thermal energy surrounds the pyrolysis chamber. Thus, the auger is housed within the pyrolysis chamber (

Figure 2). Accordingly, the temperatures that specifically concern the carbonization process are those corresponding to thermocouples TP4 to TP7 in which case, the standard deviation magnitude is even lower than that observed in the thermocouples TP1 to TP3. The location of the thermocouples in the auger-type pyrolysis reactor can be consulted elsewhere [

19].

During the experiments, monitoring the combustion flue gas temperature was of major importance as it guided the quantification of excess thermal energy generated in the reactor and that could be recovered to supply the heat required by the mechanical dryer of red coffee cherries. While the temperature of the combustion flue gas in a typical thermal energy system (e.g., a boiler) is typically around 150 °C to 180 °C, the observed combustion flue gas temperature during the pyrolysis experiments was 422.6 °C (see TP4 in

Table 3). Accordingly, it is confirmed the availability of excess thermal energy during the pyrolysis of coffee husks. In this case, the integration of a heat exchanger to recover the thermal energy available in the combustion flue gas stream would make it possible to produce hot air and then supply it to the cooperative industrial dryer. Thereby, the integration of a pyrolysis process in the cooperative would also avoid the use of diesel for the drying processes along with the disclosed benefits of replacing a fossil energy source with a renewable source whether from the perspective of the cooperative and that of the government and its subsidies policy.

3.3. Flue Gas Composition Observed during the Experiments

From the flue gas monitoring emerges the first concerns regarding the use of coffee husks as solid biofuel to supply the thermal energy required by the mechanical dryer. Considering the alternative A in

Figure 4, during the combustion experiment, steady temperatures were observed within the heat exchanger reflecting a steady state energy conversion process. Likewise, air with a steady temperature of 40°C was supplied to the dryer. Nonetheless, under these conditions, the average CO concentration in the combustion flue gas was 11029.4 mg/Nm

3, at 11%v O

2, and dry gas (see

Table 4) which is 22 times higher than the European eco-design standard of 500 mg/Nm

3, at 11%v O

2, and dry gas. The combustion flue gas temperature corresponding to this observation was 146.1 °C.

The attempt to increase the drying air temperature from 40 °C to 45 °C by increasing the biomass feeding rate of the retort burner from 7 kg/h to 15 kg/h resulted in an increase of the CO concentration in the combustion flue gas from 11029.4 to 27650.6 mg/Nm

3, at 11%v O

2, and dry gas. Although complex air stagging techniques are implemented in the retort biomass burner, namely independent vent tubes to supply secondary air over the combustion bed zone, the high CO and HC concentration (67.7 and up to 100.5 ppm, at 11%v O

2, and dry gas) along with the low CO

2 concentration (7.6 %vol, dry gas) is showing that the efficiency of combustion process of coffee husks is yet lower than that observed in similar combustion furnaces using raw agro-residues as a solid fuel [

27].

Considering that the moisture content of the coffee husks used in the combustion experiments is relatively low (9.4 wt%, wet basis,

Table 1), the low conversion rate of CO into CO

2 observed in the combustion experiments is likely associated with the high ash content of the coffee husks used as feedstock. As

Table 1 shows, the ash content of the coffee husks used in the experiments is 7.1 wt%, wet basis, which is more than seven times higher than the ash content of a standardized pellet used in combustion appliances in Europe [

28]. As the combustion process unfolds, it was observed that ash starts accumulating over the combustion bed and around the primary air supply boreholes. The ash is manually removed from the combustion bed for periods of 60 minutes (see

Section 2.2.1). Nonetheless, the progressive ash accumulation affects the efficiency of the combustion process, because it influences the hydrodynamics of the combustion process, namely, a proper air-fuel mixture in the combustion bed. Large pieces of sintered material were observed during the ash removal process (

Figure 5). Thus, ash accumulation and ash sintering can be regarded as fundamental constraints towards an efficient combustion process.

Conversely, the CO concentration in the combustion flue gas from the pyrolysis unit was lower than that observed during the experiments of combustion of raw coffee husks (

Table 4), especially during the co-combustion regime in the pyrolysis unit. The pilot-scale auger-type pyrolysis reactor (

Figure 2) has a supporting biomass combustion system for initial heating and operation and a gas burner for the energetic conversion, through combustion, of the pyrolysis vapors once the carbonization process has started. During the period in which the supporting biomass combustion system for initial heating and the pyrolysis gas burner operates simultaneously, referred to in

Table 4 as the co-combustion regime, the CO concentration in the flue gas (458 mg/Nm

3, at 11%v O

2, and dry gas) is below the eco-design standard of 500 mg/Nm

3, at 11%v O

2, and dry gas. In this case, the CO concentration in the flue gas was 24 times lower than that observed during the combustion experiments of coffee husks in the retort burner.

It was observed that when the pilot-scale auger-type pyrolysis reactor shifted from the co-combustion regime towards the auto-thermal regime, there was an increase in the CO concentration in the flue gas (

Table 4). The auto-thermal regime is the operating state in which all the thermal energy required by the carbonization process is generated exclusively by the combustion of the pyrolysis vapors. Thus, the average CO concentration in the combustion flue gas observed during the auto-thermal operation regime was 1912.6 mg/Nm

3, at 11%v O

2, and dry gas. This increase of the CO concentration in the combustion flue gas, is of course, followed by an increase of the HC concentration from 3.3 to 9.2 ppm, and a decrease of the CO

2 concentration from 14.8 to 10.7 mg/Nm

3, both measured at 11%v O

2, and dry gas. One of the few technical reports regarding the pyrolysis of coffee husks at pilot-scale [

29], refers to this phenomenon in which lower CO emissions correspond to a combustion situation in which a supporting fuel (i.e. pilot flame) is used to achieve proper combustion conditions for the pyrolysis vapours. As a concluding remark, regardless of the operation regime of the auger-type pyrolysis reactor tested in our study, the CO concentration in the combustion flue gas observed during the carbonization of coffee husks was always lower than those observed during the combustion of raw coffee husks in the retort burner.

3.4. Comparative SWOT Analysis of Combustion and Pyrolysis Processes: a Paradigm for the Early Adoption of the Bioeconomy in Farmers´Cooperatives?

Since 1960, the main economic activity in the Ecuadorian Amazon had to do with oil extraction which in the local literature is referred to as extractivism [

30]. Currently, in the Ecuadorian Amazon and particularly in the north, an urgent transition from this extractivist economy towards new forms of generating social and economic value is required. This transition is demanded from an environmental conservation perspective and as a central aim of the climate change agenda. Nonetheless, it is also relevant from a vision of strategic planning of the economy in which the exclusive dependence of the region on the income linked to non-renewable resource extraction constitutes an undeniable weakness. In Ecuador, rather than a process by design, it is thought that the reduction of the economic dependence on oil extraction would be linked to the depletion of oil resources [

31] or driven by social resistance of local communities affected by the development of new extractive projects [

32,

33].

In this context, it is of crucial relevance a discussion on the emergence of bioeconomic activities that do not require non-renewable resources extraction, but rather aim to add value to the residual biomass already available, for example, the agro-residues in the farmers’ cooperatives that grow cocoa and coffee. The operation of cooperatives may become a source of concern if one considers that this activity must be held on the territory, demanding energy, and generating agro-residues. Thus, the combustion of raw agro-residues available in the analyzed farmer cooperative represents an opportunity aligned with the bioeconomy, as the fossil fuels used for thermal energy production can be replaced by a local energy source (the coffee husks) while reducing the drying costs and getting independence on government subsidies for thermal energy generation (see opportunities in

Table 5). Undoubtedly, further technological development is still required to improve the combustion process and reduce emissions. Filling this technological gap may aid the emergence of new bioeconomic activities. For instance, an alternative to improve the observed combustion efficiency has to do with the implementation of leaching processes to reduce the ash content of coffee husks [

34]. In turn, leachate rich in nutrients such as calcium, potassium, and silica could also be transformed into a valuable agricultural input (see opportunities in

Table 5). Processes at the level of farm scale in a rural context for this purpose are somehow documented in the literature [

35]. Nevertheless, technology upgrades and knowledge transfer processes are still required (see weaknesses in

Table 5).

Another alternative to improve combustion efficiency is the implementation of pelletization processes to increase the coffee husks bulk and energy density. In this case, other agro-residues available in the region, e.g., palm oil wastes, could also be considered to formulate mixtures of agro-residues resulting in pelletized solid fuels with balanced physical and chemical properties for their use as a solid fuel for thermal energy production. From a medium-scale perspective, the production, sales, and distribution of pelletized solid biofuels may become a relevant bioeconomic activity in the upcoming years as the demand for this type of renewable energy vector is on the rise, for instance, in the local cement production sector [

36]. Nevertheless, the energy demand and costs related to proper pelletization need to be addressed.

Concerning the implementation of pyrolysis as a process to add value to coffee husks and create new products and services aligned with the bioeconomy, probably the production, sales, and distribution of biochar is the first option. Besides the use of biochar as an amendment its application in soils is linked with the provision of carbon sequestration services. Considering that the price of organic soil amendments in Ecuador is low, the income that could come from claiming the financial compensation corresponding to the amount of carbon sequestered in soils through farming activities is of major interest. The current price per ton of CO

2 sequestered in soils paid to small-scale farmers in a rural context is between 110 – 165 USD [

37]. Depending on the considered boundary conditions and externalities, a ton of biochar can be worth 2 to 3.2 tons of CO

2 equivalent [

38]. Of course, to access this financial compensation, a proper measure, report, and verification protocol must be rigorously applied in the field (see weaknesses in

Table 5). The most recent artisanal C-sink standard released for this purpose can be found elsewhere [

39]. It is worth mentioning that at the local level, there is a standard issued by the Ecuadorian Environmental Ministry that regulates the provision of carbon sequestration services [

40]. Following this standard, the provision and trade of carbon sequestration services that use technology and that are not linked with ecosystem services is subject to appropriation and titularity (see strengths in

Table 5). Accordingly, carbon removal certificates generated through the application of biochar to soils could be traded freely, considering that the Ecuadorian standard allows one unique transaction directly from the company interested in neutralizing their emissions and the project implementer. Thus, stock of carbon removal certificates to speculate on its price is not allowed following the Ecuadorian standard.

Regarding the artisanal C-sink standard used in the voluntary market which claims to be adapted for small-scale farmers, we observed that biochar production is tied to the use of low-cost, low-complexity, and low-efficiency technologies, for instance, Kon-tiki and brick kilns. However, neither Kon-tiki kilns nor brick kilns have been proven effective in converting coffee husks into biochar on a scale larger than a farm which may not be enough for the quantity of agro-residues available in the cooperative studied in this work. A commercial reactor to implement the pyrolysis process in the scale of the farmer cooperative studied, e.g., PYREG 500 kW, with a processing capacity of 1000 t/y, would have a capital and operational expenditure per ton of feedstock processed of 696 and 285 USD, respectively [

41]. A technical report concerning a commercial updraft gasifier (PPV300, processing capacity 750 t/y) that produces thermal energy and biochar as a byproduct from coffee husks has a capital and operational expenditure per ton of coffee husk processed of 164 USD and 50 USD, respectively [

42]. In this last case, the reference considers a lifespan of only 5 years while the lifespan referred to the PYREG 500 kW reactor is at least 10 years. Furthermore, the PPV300 machine only provides operating expenditure concerning energy and maintenance costs, therefore, ignoring labor costs.

As reported in

Table 5 (see weaknesses), there is a high level of uncertainty regarding the cost structure of a pyrolysis facility, and thus, about the opportunity to implement a bioeconomic activity from it. Hence, financial studies are required to determine if the cashflows linked to biochar sales and the carbon credits compensate the capital and operational expenditures linked to the pyrolysis technology along with those required for carbon credits issuance and the platforms for measurement, report, and verification. Such studies are relevant as will also provide details about the amount and type of jobs created and other externalities such as the financial value of the thermal energy used to replace fossil fuels in the drying process along with a government perspective about the fossil fuel subsidies that can be avoided.

4. Conclusions

In the Ecuadorian Amazon, a transition from the current extractivist model towards a more equilibrated socio-economic and environmental model is, by far, a subject of superlative complexity. Nevertheless, this complex arrangement of new bioeconomic activities that do not rely on resource extraction, but on the creative use of already available residual biomass will not emerge without pilot-scale or demonstration studies at the farm level as the one presented in this work. In the analyzed farmers´ cooperative, the integration of thermochemical conversion processes that use raw coffee husks as feedstock, namely, combustion and pyrolysis, allows the replacement of fossil fuels consumed in the drying process, potentially reducing drying costs, decreasing environmental impacts linked to agro-residues accumulation and making the cooperative independent from the government subsidies policy.

Although the integration of the coffee husks combustion process makes the cooperative self-sufficient in terms of thermal energy, the CO concentration in the flue gas (11029.4 mg/Nm3, at 11%v O2, and dry gas) is higher than the eco-design standard of 500 mg/Nm3, at 11%v O2, and dry gas. The high ash content of the coffee husks (7.6 wt%, dry basis) causes ash accumulation in the combustion bed and later sintering issues, that can further influence negatively the conversion rate of CO into CO2. For the case of coffee husks pyrolysis, the CO concentration in the combustion flue gas was lower (458 mg/Nm3, at 11%v O2, and dry gas) than the eco-design standard of 500 mg/Nm3, at 11%v O2, and dry gas, and always lower than that observed during the combustion of coffee husks in the retort burner. Furthermore, the analysis of the proximal and elemental composition of the carbonized coffee husks shows that it can be classified as biochar following the European standard and thus, be used as a high-quality product for soil amendment and carbon sequestration.

It can be argued whether the production, sales, and distribution of biochar or the associated provision of carbon sequestration services by farmers' cooperatives is an activity related to the bioeconomy, and indeed whether this is an activity to promote a transition to a post-extractivist economy in the Ecuadorian Amazon. However, access to the income streams that would offer the proposed pyrolysis technology is still uncertain, especially the one coming from the trade of carbon credits. As usual, farmers will have to struggle with high auditing and management costs linked to certifications and standards, even though these claim to be designed to help them prosper. Alike the technology demonstration at the pilot-scale deployed and analyzed in this study, a demonstration of the scheme that allows cooperatives to generate and trade carbon credits is currently required, so that, necessary intermediaries and their role can be identified as well as concrete benefits for farmers. One should not lose sight that to overcome the current extractivist model, these bioeconomic activities, at some point, should be more profitable than resource extraction or deforestation.

Author Contributions

Conceptualization, MAHS; methodology, MAHS; software, MAHS; validation, MAHS, LT, and IS.; formal analysis, MAHS, LT, and IS; investigation, AHS; resources, MAHS, LT, and IS; data curation, MAHS; writing—original draft preparation, MAHS; writing—review and editing, MAHS, LT, and IS; visualization, MAHS; supervision LT, and IS X.X.; project administration, MAHS.; funding acquisition, MAHS. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

The authors acknowledge the European Committee for Training and Agriculture CEFA that facilitated the contact with the farmers' cooperative APROCEL and thank the farmers for the invitation that allowed our first author to join, observe, and understand the cooperative activities and tasks. It is acknowledged the Project BioValChar - Sustainable valorization of residual biomass for biochar, PCIF-GVB-0034-2019, funded by the Portuguese Foundation for Science and Technology (FCT). It is acknowledged by the Portuguese Foundation for Science and Technology (FCT)/Ministry of Science, Technology and Higher Education (MCTES), Portugal, for the financial support to CESAM (UIDP/50017/2020+UIDB/50017/2020+LA/P/0094/2020), through national funds.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Viteri, O.; Ramos-martín, J.; Lomas, P.L. Livelihood Sustainability Assessment of Coffee and Cocoa Producers in the Amazon Region of Ecuador Using Household Types. J. Rural Stud. 2018, 62, 1–9. [Google Scholar] [CrossRef]

- Branthomme, A.; Merle, C.; Kindgard, A.; Lourenço, A.; Ng, W.-T.; D´Annunzio, R.; Shapiro, A. How Much Do Large-Scale and Small-Scale Farming Contribute to Global Deforestation? Results from a Remote Sensing Approach; FAO: Italy, Rome, 2023; ISBN 9789251378427. [Google Scholar]

- Somarriba, E.; Lopez, A. Coffee and Cocoa Agroforestry Systems: Pathways to Deforestation, Reforestation, and Tree Cover Change, 1st ed.; PROFOR: Costa Rica, 2018. [Google Scholar]

- Vasco, C.; Torres, B.; Pacheco, P.; Griess, V. The Socioeconomic Determinants of Legal and Illegal Smallholder Logging: Evidence from the Ecuadorian Amazon. For. Policy Econ. 2017, 78, 133–140. [Google Scholar] [CrossRef]

- Salazar, O.V.; Ramos-Martín, J. Organizational Structure and Commercialization of Coffee and Cocoa in the Northern Amazon Region of Ecuador. Revista NERA 2017, 35, 266–287. [Google Scholar] [CrossRef]

- Bacon, C.M.; Sundstrom, W.A.; Flores Gómez, M.E.; Ernesto Méndez, V.; Santos, R.; Goldoftas, B.; Dougherty, I. Explaining the “Hungry Farmer Paradox”: Smallholders and Fair Trade Cooperatives Navigate Seasonality and Change in Nicaragua’s Corn and Coffee Markets. Glob. Environ. Chang. 2014, 25, 133–149. [Google Scholar] [CrossRef]

- Tennhardt, L.; Lazzarini, G.; Weisshaidinger, R.; Schader, C. Do Environmentally-Friendly Cocoa Farms Yield Social and Economic Co-Benefits? Ecol. Econ. 2022, 197, 107428. [Google Scholar] [CrossRef]

- Mario A. Heredia, Salgado; Säumel, I.; Cianferoni, A.; Tarelho, L.A.C. Potential for Farmers’ Cooperatives to Convert Coffee Husks into Biochar and Promote the Bioeconomy in the North Ecuadorian Amazon. Appl. Sci. 2021, 11. [Google Scholar] [CrossRef]

- Vivien, F.D.; Nieddu, M.; Befort, N.; Debref, R.; Giampietro, M. The Hijacking of the Bioeconomy. Ecol. Econ. 2019, 159, 189–197. [Google Scholar] [CrossRef]

- Franca, A.S.; Oliveira, L.S. Coffee Processing Solid Wastes: Current Uses and Future Perspectives; 2009; ISBN 9781607413059.

- Oliveira, L.S.; Franca, A.S. An Overview of the Potential Uses for Coffee Husks. In Coffee in Health and Disease Prevention; Elsevier Inc., 2015; pp. 281–291. ISBN 9780124095175. [Google Scholar]

- Saenger, M.; Hartge, E.; Werther, J. Combustion of Coffee Husks. Renew Energy 2001, 23, 103–121. [Google Scholar] [CrossRef]

- Flammini, A.; Brundin, E.; Grill, R.; Zellweger, H. Supply Chain Uncertainties of Small-Scale Coffee Husk-Biochar Production for Activated Carbon in Vietnam. Sustainability 2020, 12, 1–27. [Google Scholar] [CrossRef]

- Draper, K. The Potential for Biochar to Improve Sustainability in Coffee Cultivation and Processing: A White Paper; Freiburg, 2018.

- Setter, C.; Silva, F.T.M.; Assis, M.R.; Ataíde, C.H.; Trugilho, P.F.; Oliveira, T.J.P. Slow Pyrolysis of Coffee Husk Briquettes: Characterization of the Solid and Liquid Fractions. Fuel 2020, 261. [Google Scholar] [CrossRef]

- Afessa, M.M.; Debiagi, P.; Ferreiro, A.I.; Mendes, M.A.A.; Faravelli, T.; Ramayya, A.V. Experimental and Modeling Investigation on Pyrolysis of Agricultural Biomass Residues: Khat Stem and Coffee Husk for Bio-Oil Application. J. Anal. Appl. Pyrolysis 2022, 162, 105435. [Google Scholar] [CrossRef]

- The European Commission COMMISSION REGULATION (EU) 2015/1189: Implementing Directive 2009/125/EC of the European Parliament and of the Council with Regard to Ecodesign Requirements for Solid Fuel Burners. Off. J. Eur. Union 2015, L193/100, 8–15.

- Sandeep, T.N.; Channabasamma, B.B.; Gopinandhan, T.N.; Nagaraja, J.S. The Effect of Drying Temperature on Cup Quality of Coffee Subjected to Mechanical Drying. J. Plant. Crops 2021, 49, 35–41. [Google Scholar] [CrossRef]

- Heredia Salgado, M.A.; Coba S, J.A.; Cianferoni, A.; Säumel, I.; Tarelho, L.A.C. Conversion of Quinoa and Lupin Agro-Residues into Biochar in the Andes: An Experimental Study in a Pilot-Scale Auger-Type Reactor. Front. Bioeng. Biotechnol. 2022, 10, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Heredia Salgado, M.A. Biomass Thermochemical Conversion in Small Scale Facilities, Aveiro University, 2020.

- European Biochar Foundation Guidelines for a Sustainable Production of Biochar v4.5E. European Biochar Foundation (EBC) 2018, v4.5, 1–22. [CrossRef]

- Heredia Salgado, M.A.; Tarelho, L.A.C.; Matos, M.A.A.; Rivadeneira, D.; Narváez C, R.A. Palm Oil Kernel Shell as Solid Fuel for the Commercial and Industrial Sector in Ecuador: Tax Incentive Impact and Performance of a Prototype Burner. J. Clean Prod. 2019, 213, 104–113. [Google Scholar] [CrossRef]

- Heredia Salgado, M.A.; Coba S, J.A.; Tarelho, L.A.C. Simultaneous Production of Biochar and Thermal Energy Using Palm Oil Residual Biomass as Feedstock in an Auto-Thermal Prototype Reactor. J. Clean Prod. 2020, 266, 121804. [Google Scholar] [CrossRef]

- Vieites, Y.; Andretti, B.; Weiss, M.; Jacob, J.; Hallack, M. Effectively Communicating the Removal of Fossil Energy Subsidies: Evidence from Latin America. Glob. Environ. Chang. 2023, 81, 102690. [Google Scholar] [CrossRef]

- Garcia-Nunez, J.A.; Rodriguez, D.T.; Fontanilla, C.A.; Ramirez, N.E.; Silva Lora, E.E.; Frear, C.S.; Stockle, C.; Amonette, J.; Garcia-Perez, M. Evaluation of Alternatives for the Evolution of Palm Oil Mills into Biorefineries. Biomass Bioenergy 2016, 95, 310–329. [Google Scholar] [CrossRef]

- Tomczyk, A.; Sokołowska, Z.; Boguta, P. Biochar Physicochemical Properties: Pyrolysis Temperature and Feedstock Kind Effects. Rev. Environ. Sci. Biotechnol. 2020, 19, 191–215. [Google Scholar] [CrossRef]

- Qiu, G. Testing of Flue Gas Emissions of a Biomass Pellet Boiler and Abatement of Particle Emissions. Renew Energy 2013, 50, 94–102. [Google Scholar] [CrossRef]

- Pio, D.T.; Tarelho, L.A.C.; Matos, M.A.A. Characteristics of the Gas Produced during Biomass Direct Gasification in an Autothermal Pilot-Scale Bubbling Fluidized Bed Reactor. Energy 2017, 120, 915–928. [Google Scholar] [CrossRef]

- Bieri, L.; Classen, M.; Gutzwiller, S.; Lukacs, A.; Schmid, M. Pulpa Pyro Peru Generacion de Biocarbono y Energia de Pulpa de Cafe En Peru; Zurich, 2012. [Google Scholar]

- Chagnon, C.W.; Durante, F.; Gills, B.K.; Sophia, E.; Hokkanen, S.; Kangasluoma, S.M.J.; Konttinen, H.; Kröger, M.; Lafleur, W.; Ollinaho, O.; et al. From Extractivism to Global Extractivism : The Evolution of an Organizing Concept. J. Peasant Stud. 2022, 49, 760–792. [Google Scholar] [CrossRef]

- Espinoza, V.S.; Fontalvo, J.; Martí-Herrero, J.; Miguel, L.J.; Mediavilla, M. Analysis of Energy Future Pathways for Ecuador Facing the Prospects of Oil Availability Using a System Dynamics Model. Is Degrowth Inevitable? Energy 2022, 259, 124963. [Google Scholar] [CrossRef]

- Avcı, D.; Fernández-Salvador, C. Territorial Dynamics and Local Resistance: Two Mining Conflicts in Ecuador Compared. Extr. Ind. Soc. 2016, 3, 912–921. [Google Scholar] [CrossRef]

- Valladares, C.; Boelens, R. Mining for Mother Earth. Governmentalities, Sacred Waters and Nature’s Rights in Ecuador. Geoforum 2019, 100, 68–79. [Google Scholar] [CrossRef]

- Chin, K.L.; H’ng, P.S.; Paridah, M.T.; Szymona, K.; Maminski, M.; Lee, S.H.; Lum, W.C.; Nurliyana, M.Y.; Chow, M.J.; Go, W.Z. Reducing Ash Related Operation Problems of Fast Growing Timber Species and Oil Palm Biomass for Combustion Applications Using Leaching Techniques. Energy 2015, 90, 622–630. [Google Scholar] [CrossRef]

- Babayemi, J.O.; Adewuyi, G.O.; Dauda, K.T.; Kayode, A.A.A. The Ancient Alkali Production Technology and the Modern Improvement: A Review. Asian J. Appl. Sci. 2011, 4, 22–29. [Google Scholar] [CrossRef]

- Kusuma, R.T.; Hiremath, R.B.; Rajesh, P.; Kumar, B.; Renukappa, S. Sustainable Transition towards Biomass-Based Cement Industry: A Review. Renew. Sustain. Energy Rev. 2022, 163, 112503. [Google Scholar] [CrossRef]

- Ithaka Institute Removing Carbon and Empowering Local Biochar Projects for Win of Artisanal Communities: The Win- CDR Buyers; Berlin, 2023.

- Schmidt, H.-P.; Kammann, C.; Hagemann, N. EBC-Guidelines for the Certification of Biochar Based Carbon Sinks V2.1; Arbaz, Switzerland, 2020.

- Ithaka Institute Global Artisan C-Sink: Guidelines for Carbon Sink Certification for Artisan Biochar Production; Switzerland, 2022; Vol. 1.

-

Ministerio del Ambiente Agua y Transición Ecológica Esquema de Compensación de Emisiones de Gases de Efecto Invernadero Del Ecuador; Acuerdo Ministerial 053: Ecuador, 2023.

- Forte, B.; Coleman, M.; Metcalfe, P.; Weaver, M. The Case for the PYREG Slow Pyrolysis Process in Improving the Efficiency and Profitability of Anaerobic Digestion Plants in the UK. Available online: http://www.wrap.org.uk/sites/files/wrap/DIAD I NeueAg feasibility report.pdf.

- UNIDO Supporting Adopters of the PPV300 PYROLYSIS Technology Strengthen Their Business Cases; Vienna, 2021.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).