1. Introduction

Mining industry is passing through a phase of major transformation to meet the increasingly tougher environmental standards and the needs of rising world population, as well as demands from various industries, such as technology, construction and energy [

1]. This revolution involves an application of highly automated systems and achieving more sustainable and efficient operations [

1]. In Australia, number of major mining companies, namely Rio Tinto, BHP Billiton and Fortescue Metals Group have been leaders in adopting advanced technologies including autonomous haulage systems (AHS) and autonomous drilling systems (ADS) [

2]. It is worth mentioning that after incorporating these technologies Rio Tinto registered 11% and 26% improvements respectively in operational performance at its Pilbara iron ore mine in Australia [

3]. Similarly, BHP Billiton reported a 25% increase in production, a 40% reduction in drilling costs and an 80% reduction in accidents at its Jimblebar iron ore mine after adopting these technologies [

4]. Fortescue Metals Group's AHS deployment helped to reduce its production cost by half between 2015 and 2019 at Pilbara mine due to using 128 AHS units [

5]. Impressive as these developments are, there is a need for further advancement in mine automation, since current technologies still require considerable human input. The ongoing challenge in achieving complete automation in the mining sector can be seen where engineers and operators remotely steer AHS trucks from their control rooms using joysticks and sophisticated handheld controllers. This dependence must be removed to achieve full automation. Application of swarm robotics in the mining industry, inspired by the collective behavior of ants, honeybees, and fireflies, can offer a novel solution to this issue. These biological systems excel at decentralized decision-making and self-organization, and applications of these models can significantly improve scalability, flexibility, and reliability of automated mining systems. The development of swarm robotics using solutions inspired by nature offers new opportunities for solving complex tasks in a decentralized and adaptive manner, both in practical applications and on research platforms [

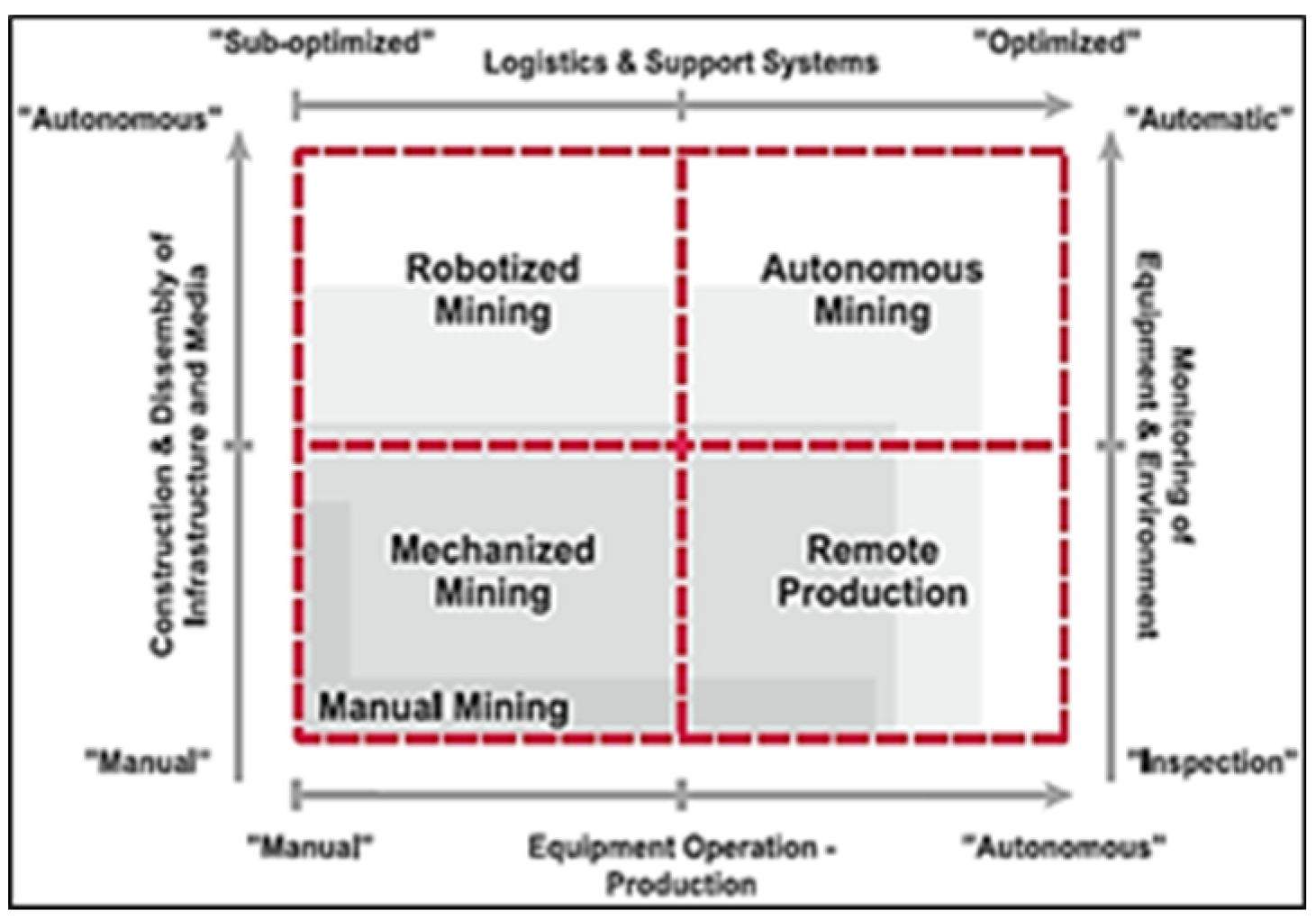

6]. The roadmap proposed by Anderson [

7] envisions fully autonomous mining operations with no human operators on site, focusing on the production, construction, and demolition of infrastructure, monitoring of equipment and the mine environment, and logistics and support systems as a first step towards this future [

8], as shown in

Figure 1.

This study presents a nature-inspired swarm robot model developed based on the behaviors of ants, honeybees, and fireflies through Robot Operating System (ROS) simulation, and its applications to mining operations aimed to improving their autonomy and efficiency. The subsequent sections of this paper are organized as follows:

Section 2 reviews related work,

Section 3 discusses the development of the swarm model, and

Section 4 evaluates the performance of the proposed swarm robot system.

2. Related Work

Swarm robotics, inspired by collective behaviors observed in nature, has found applications across diverse fields. In agriculture, the Swarm Robotics for Agricultural Applications (SAGA) project draws inspiration from honeybee models to optimize farming tasks [26]. Thamrin et al. (2022) reported that a small-scale unmanned vehicle, using an automated navigation system with infrared sensors and Bezier curves, navigates, monitors, and harvests plantations with narrow pathways, thereby reducing the need for manual labor [24,25]. In medicine, millirobots mimic the movements of caterpillars or jellyfish for intricate medical procedures [27]. Construction benefits from Fiber-bots, which utilize the principles of the particle swarm algorithm [28], and KALI, which is modeled after the building structures of termite colonies [29]. Additionally, swarm robotics are utilized in rescue operations, transportation, logistics, and other domains [21]. However, despite its extensive use in agriculture, medicine, and construction, swarm robotics remains underutilized in the mining sector [15].

Swarm robotics has great potential to enhance and optimize mining operations in terms of efficiency, scalability, autonomy, and resilience [14]. Preliminary studies have explored the application of swarm robotics in mining tasks such as ore detection, transportation, and exploration in simulated environments. Subhan et al. (2014) highlighted the benefits of using unmanned vehicles in coal mines, pointing out the advantages of decentralized control and cooperative behavior for ore detection and mining tasks [9]. Similarly, Tan et al. (2021) proposed a swarm robotic system for extraterrestrial mining using the ABCO method, demonstrating how swarm behaviors inspired by nature can improve mining efficiency and reliability [14]. The study of Duarte et al. (2016) further highlighted the applicability of swarm behaviors in mining tasks and large-scale robot swarms for ore detection [23]. Nature-inspired algorithms and their applications in mining have been widely studied and applied to various optimization problems in the industry [13]. Despite these advances, all research remains at the research platform stage and real-world mining applications have yet to fully adopt swarm robotics. The mining industry has made significant progress in automation technology, adopting systems such as the Automated Haulage System (AHS) and the Automated Drilling System (ADS) [2]. Komatsu's FrontRunner AHS and Caterpillar's Command Haulage System have demonstrated the ability to increase productivity and reduce costs. Achieving full automation remains a challenge, but swarm robotics inspired by natural behavior offer a promising solution. The European Space Agency's (ESA) PANGAEA-X event demonstrated how greater autonomy can be achieved through swarm intelligence, leading to more efficient and scalable operations [22]. Despite these technological advances, significant human input is still required, and large-scale implementation of swarm robotics technology in the mining industry remains a distant goal.

Therefore, this paper will focus on the practical implementation and optimization of swarm robots in different mining environments. This includes developing and testing nature-inspired algorithms specifically for mining operations, evaluating their performance in terms of efficiency, scalability, and reliability, and addressing the challenges of integrating these technologies into existing mining infrastructure.

3. Swarm Model Design

This section discusses developing nature-inspired swarm robotics models for mining efficiency and intra-swarm robot interactions based on various swarm behaviors in nature. These models were initially developed from a bottom-up design that was progressively improved and enriched with unique traits specific to various swarm models from nature, such as ant, firefly, and honeybee among others [

13]. Further enhancements have been applied to the swarm robotic systems to optimize their collective behavior and make them better adopted for complex mining environments.

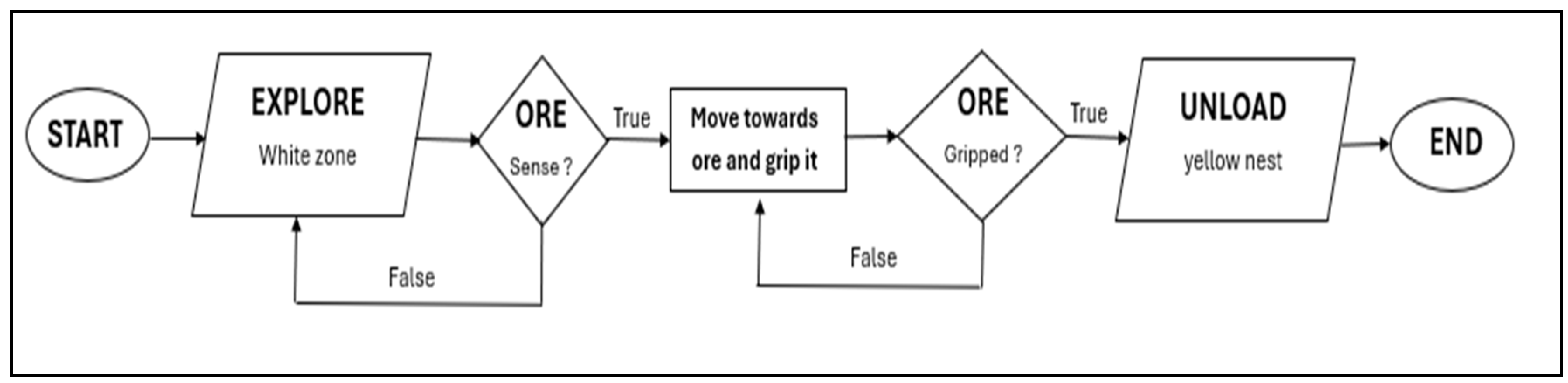

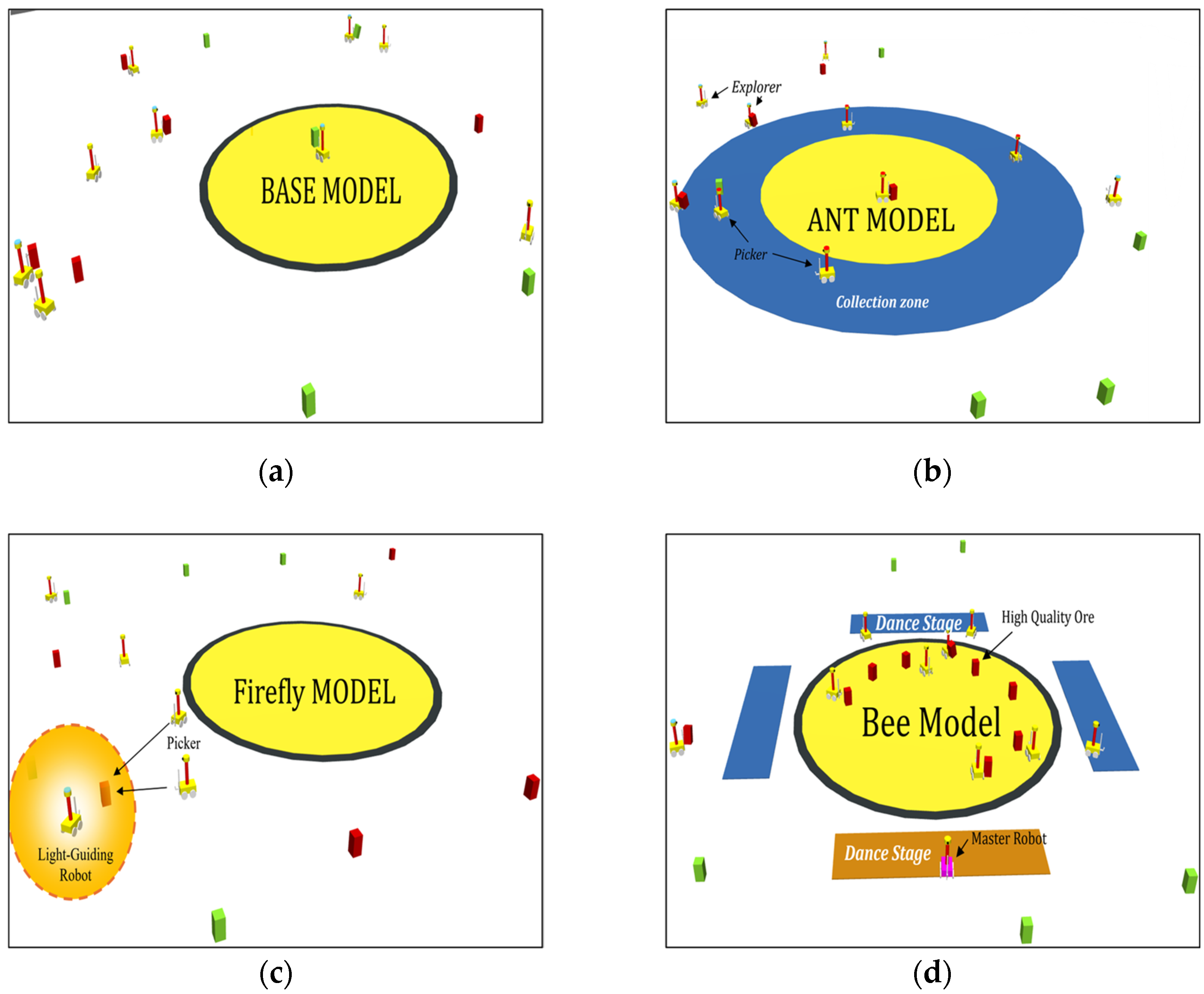

3.1. Baseline Model

The baseline model is used as a comparison standard. It uses a finite state machine (FSM) to implement basic operations such as detection, grasping, and transportation. Each robot can complete all tasks, ensuring flexibility, but lacks the benefits of specialisation. The FSM outlines a simple process where the robots transition from a standby state to a random walk to detect an object. Once an object is detected, robots attempt to grasp it and if successful, they deliver the object to a designated "nest" area. The system loops back to the initial state to continue the operation. The model operates under a decentralized control system, allowing each robot to operate independently without centralized guidance. The FSM outlining the basic operation process is shown in

Figure 2.

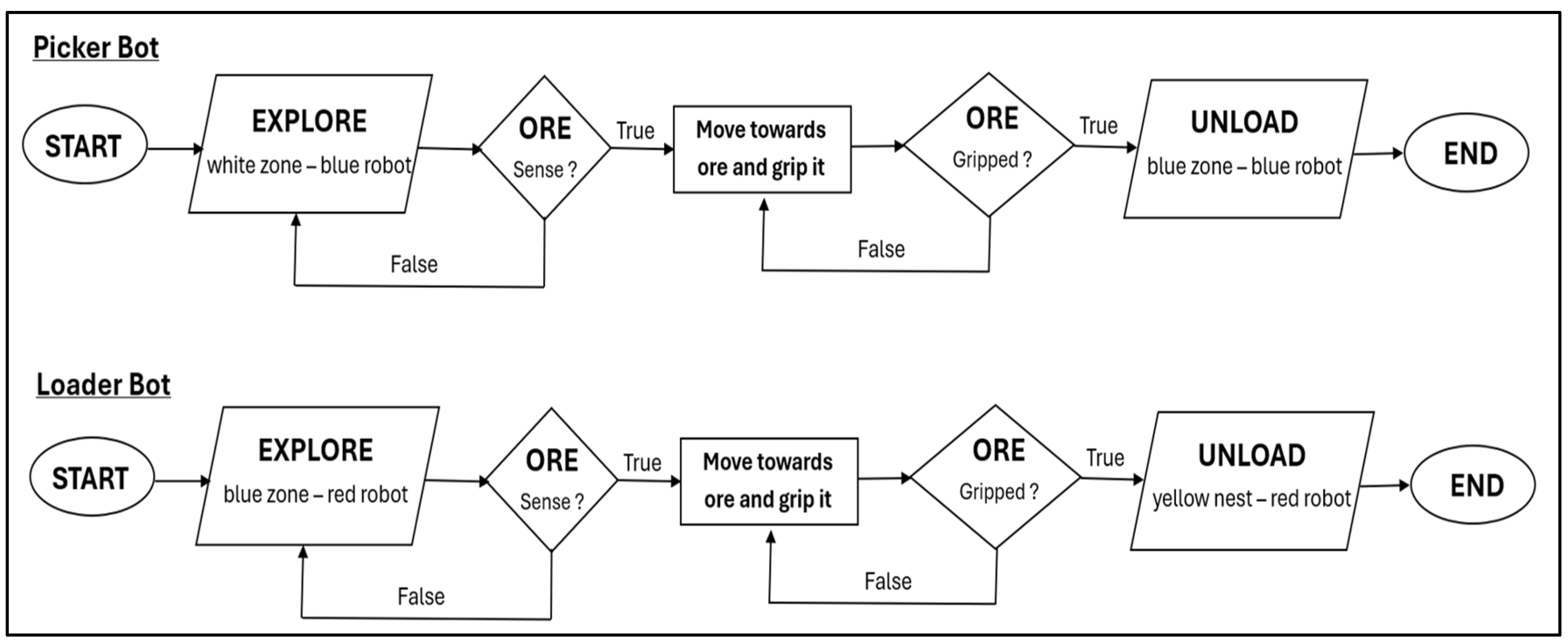

3.2. Ant Model

Starting from the baseline, the ant model introduces role specialization, inspired by the division of labour of leafcutter ants [

10,

18]. It groups the robots into specific tasks: the blue picker robots (similar to leafcutter ants) focus on picking ore, while the red loader robots (similar to porter ants) transport the ore to a central "nest". The model's FSM defines specific states for each role, i.e. "picking" for pickers and "transporting" for loaders, hence improving the efficiency through role specialization [

17]. The model maintains decentralized control allowing the robots to independently perform the designated roles, consequently improving the efficiency through specialization, while following a structured FSM that defines role-specific states and transitions. The FSM for the operational flow of the ant model is shown in

Figure 3.

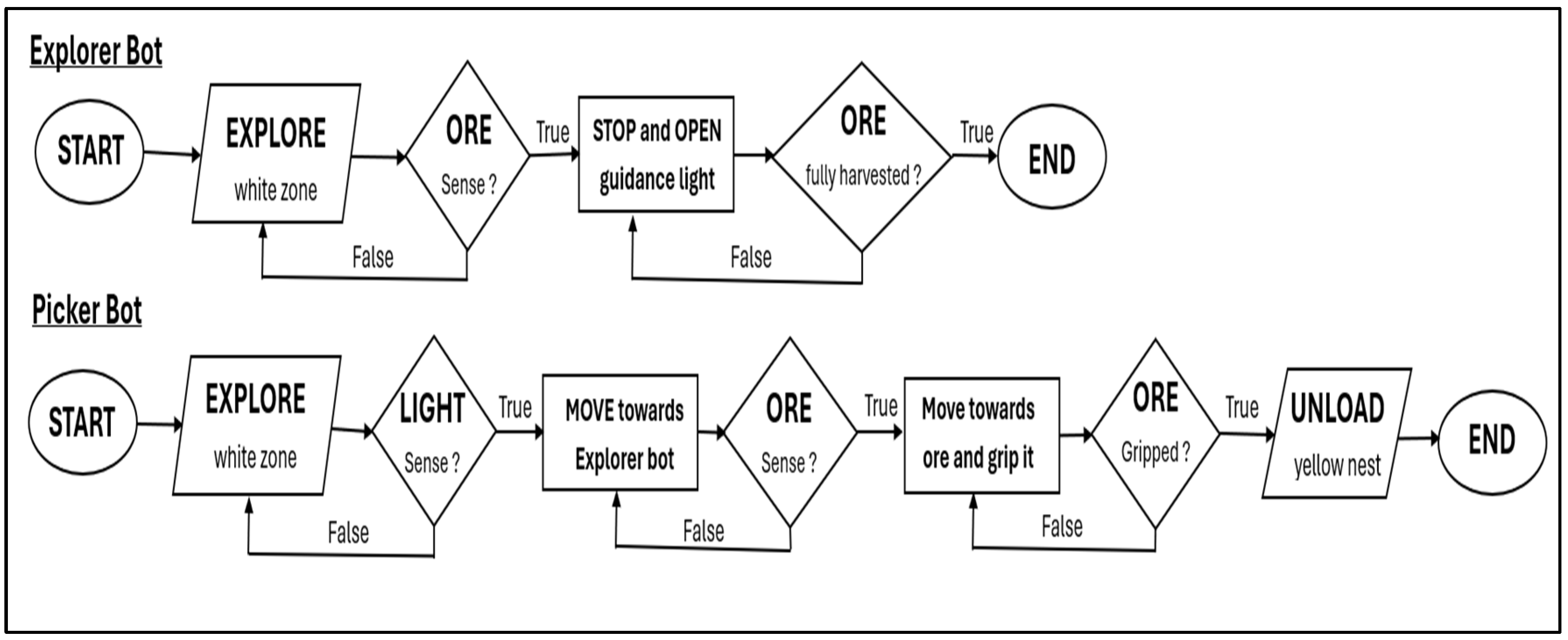

3.3. Firefly Model

The firefly model takes a step further by incorporating communications through mimicking the bioluminescent signals used by fireflies [

11,

19]. This model distinguishes between a guide robot that emits light beam using LEDs and a pick-up robot that responds to this signal. The integration of communications facilitates coordination and improves navigation and task execution in the complex mining environment. The FSM guides the robot through a sequence of exploration, light detection, and movement toward the light, thereby facilitating coordination. The model also operates under a decentralized control system, with the FSM states guiding exploration, light detection, and movement toward light signals. The FSM outlining operational flow of the firefly model, is shown in

Figure 4.

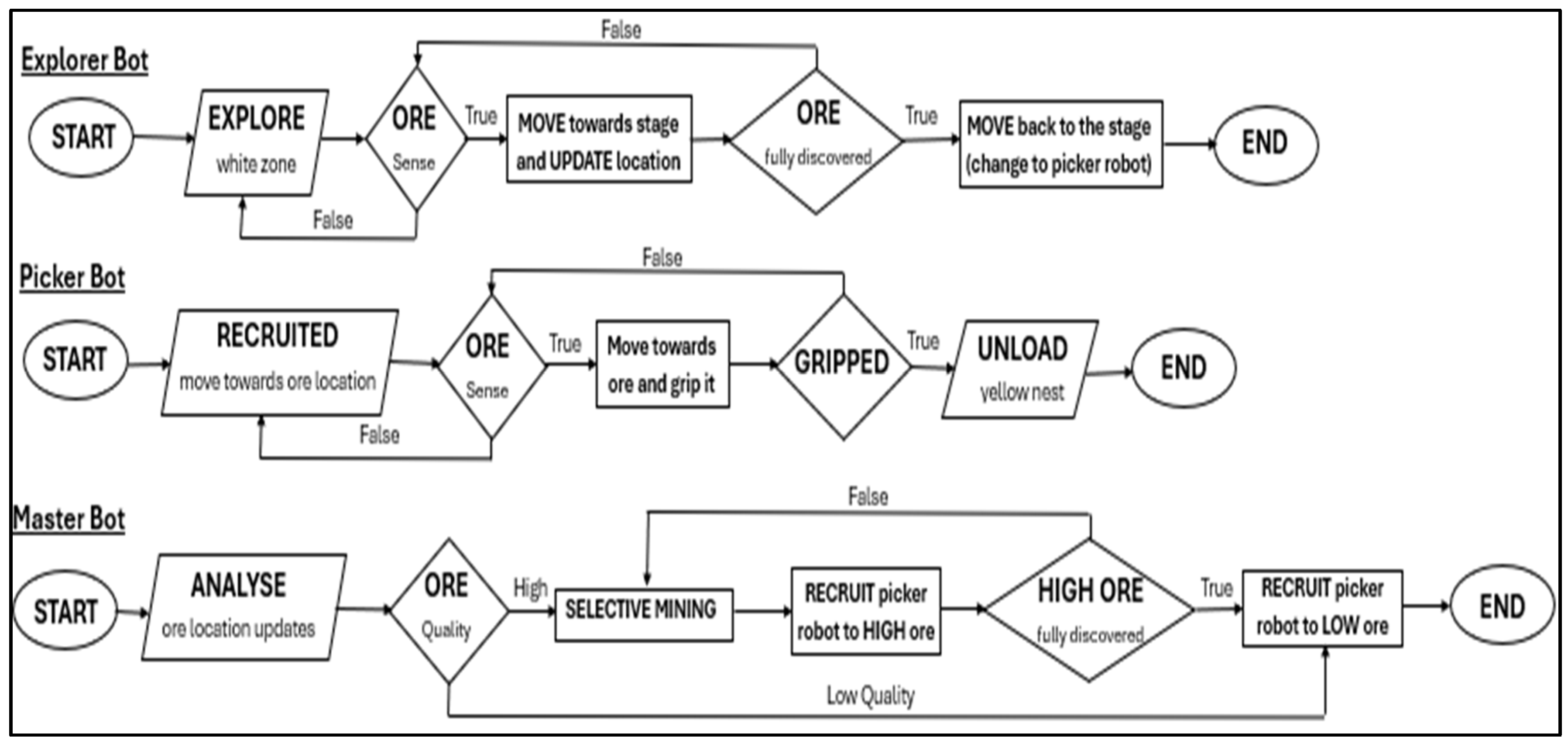

3.4. Honeybee Model

The most complex model is the honeybee model, which has been proposed by introducing a hybrid control system combining the centralized and decentralized controls. It expands on the capabilities of previous models discussed above by adding localization and enhanced communication, mimicking the foraging behavior and structured division of labour of honeybees [

12,

14]. Scout robots identify resource locations and communicate detailed information back to the central “hive” using digital “waggle dances”, while observation robots process this information to precisely locate resources [

20]. The subsequent recruitment and deployment of harvesting robots is optimized through this system by the master robot, reflecting a significant upgrade in role specialization, communication, and localization capabilities.

Figure 5 shows the FSM outlining the operational flow of the honeybee model.

3.5. Swarm Robotics and Formation Control

This section outlines a strategic development approach for swarm robotics applied to mining, where each subsequent model builds on its predecessor by integrating increasingly complex and efficient mechanisms. The process begins with a baseline model that serves as a foundational platform. The subsequent models, i.e. the ant, firefly, and honeybee models are enhancements to this standard, each incorporating specialized roles, enhanced communication capabilities, and precise localization techniques that mimic behaviours observed in nature. The ant and firefly models use decentralized control and behavior-based formation control, that allows the robots to form a network in an ordered manner, where such network interacts with neighbouring agents [

13]. These settings facilitate autonomous collective behavior that is flexible and does not require a centralized supervision. Contrary to this, the honeybee model has a hybrid control system that combines both centralized and decentralized controls with autonomous leader-follower and behaviour-based formation controls. In this configuration, a robot can effectively communicate, share information and accurately interpret data location for optimal performance [

13]. The honeybee model blends centralized coordination with decentralized flexibility making it well suited for dynamic and complex mining environment.

3.6. Swarm Arena Setup

To assess operational efficiency in mining using a simulated environment, we employed nature-inspired behaviours in our swarm robot model. Robot Operating System (ROS) is a full set of software libraries and tools used for creating graphical user interfaces (GUIs) for swarm robotics and simulate environments in Gazebo (Ubuntu Linux 22.04 Focal version). The system specifications are HP Zen2 G5 TWR; Intel Core i7-10700 CPU; 16 GB RAM; 64-bit operating system. The swarm robots are designed using ROS’s Unified Robot Description Format (URDF) and are equipped with advanced LiDAR sensors, automatic control systems, and complex decision-making algorithms. In addition, tools like Rviz, OpenCV are integrated with ROS for real-time monitoring and data visualization enabling individual robots’ tracking within the swarm as well as viewing sensor outputs. Within a 15 m x 15 m area around a “nest” symbolized by a yellow circle of 2 m radius on the Gazebo simulation environment base has been constructed. In the ant model, a larger blue circle with a radius of 4 m is nominated as the collection area/zone. In the honeybee model, four rectangular areas adjacent to the central base are labeled as "dance floors" and will serve to facilitate the report of information and updates with the master robot, imitating the waggle dance of bees in a hive. Mineral-rich areas are represented by the white areas enclosed within the rectangle and interspersed with ore blocks, where green blocks represent low grade ore and red blocks represent high grade ore. Each robot has a sensing area of 0.15 m x 0.1 m and a standard speed of 0.2 m/s. Due to ROS and system limitations, a maximum of 15 robots could be built into the model. The maximum range of the LiDAR sensor integrated in the robot is 1 m, and the optical beacon range can extend up to 1.8 m.

Figure 6 illustrates the setup for the four different models discussed above.

4. Discussions

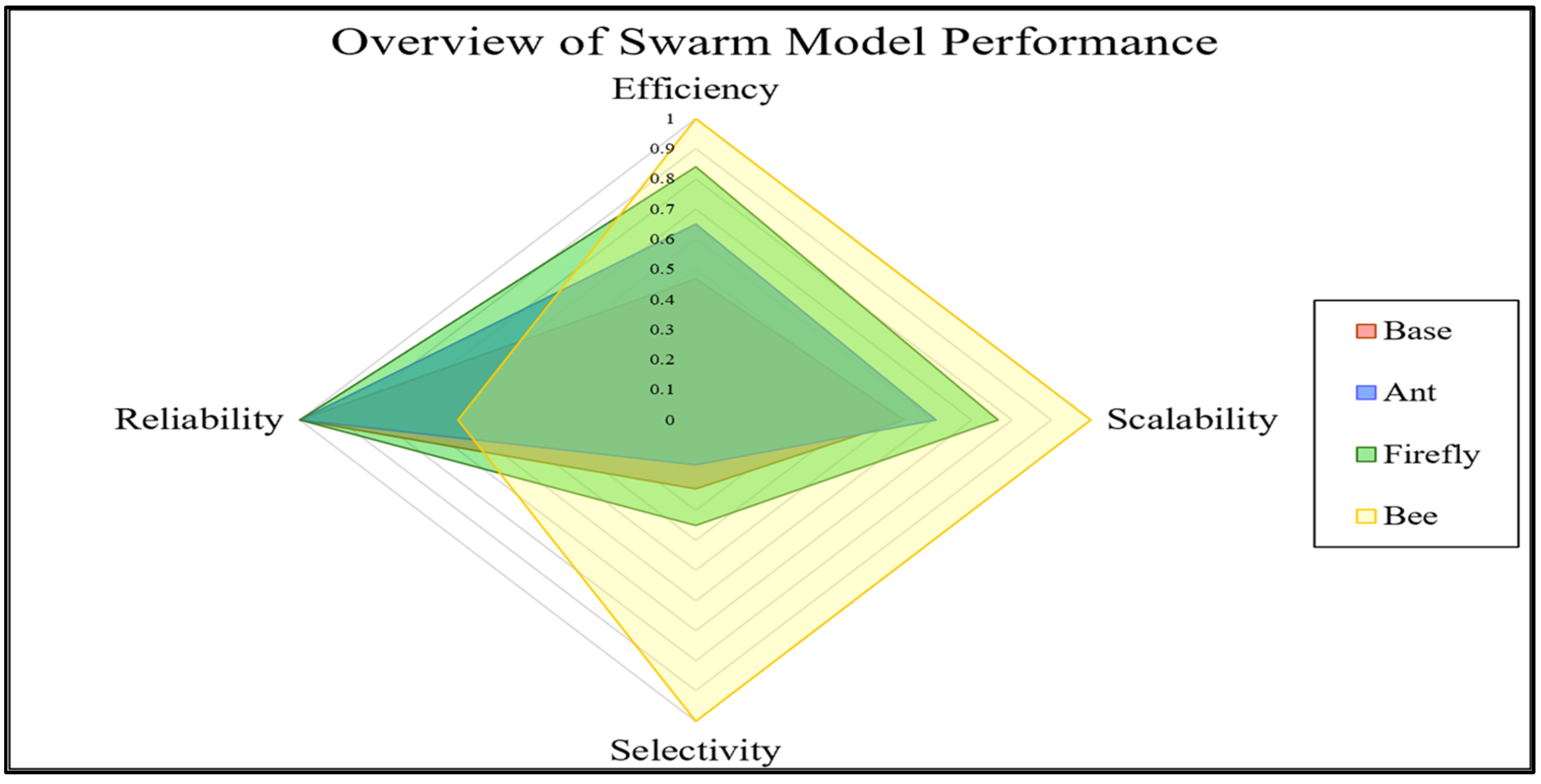

This section evaluates the mining performance of each model along multiple dimensions, namely, mining efficiency and robustness, mining scalability and adaptability, mining reliability, and mining selectivity. The results are summarized in a spider graph analysis that provides insights into the strengths and limitations of each population model, and, hence, allow to identify the models that can be best suited for applications in real-life mining processes and contexts.

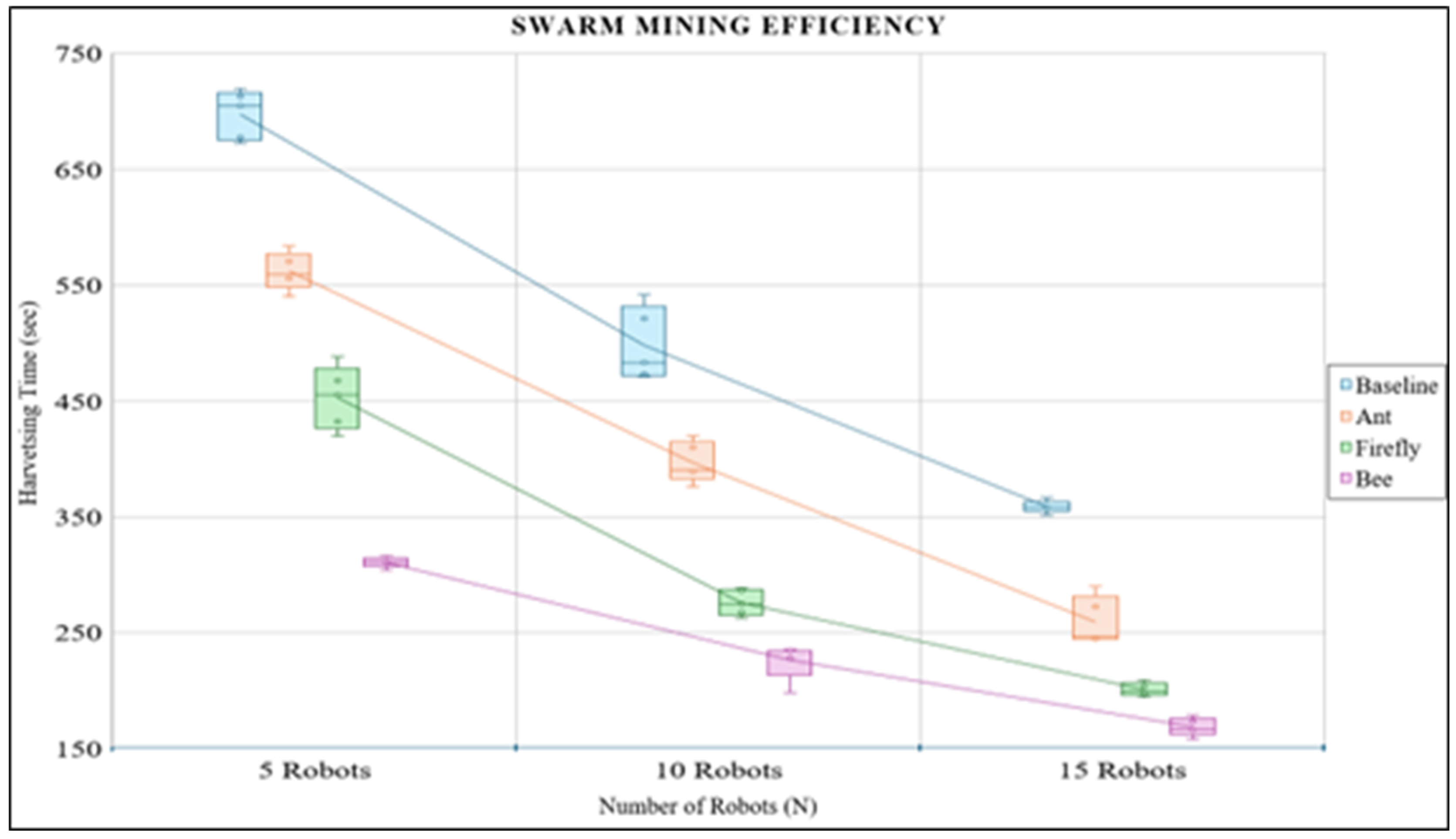

4.1. Mining Efficiency and Robustness

Strengthening of the supply chain operations and improving the profit can be attained through efficient and robust mining aimed at achieving high production. In this study, the performance of each swarm model has been tested using configurations of 5, 10, and 15 robots, and 20 randomly dispersed blocks to evaluate their impact on ore recovery and overall mining efficiency. These test data on mining efficiency and robustness are shown in

Figure 7, illustrating how each one of the models allows to optimize the mining operations.

In terms of the efficiency, the honeybee and firefly models perform better than the ant and baseline models. The total harvesting time when using 5 robots for the honeybee model is 311 seconds which is by 55.4% more efficient than the 698 seconds taken by the baseline model, and that for the firefly model is 453 seconds while the ant model needs 562 seconds, hence the efficiency of the firefly model is better by 35.1% versus the baseline model and by 19.5% versus the ant model. For a simple FSM implementation, the baseline model performs less efficiently than the others due to multiple tasks such as exploration, harvesting and transportation running simultaneously. This requires robots to multitask by continuously switching from one task to another hence becoming inefficient which hampers the workflow. This indicates that the baseline model is better suited for basic less complex mining tasks. On the other hand, the ant model inspired by the leafcutter ants’ division of labour is enhancing the performance of the baseline model through functional separation among robots. However, in the ant model if a group of specialized robots performs poorly, the lack of integrated communication may cause operational delays thus making it necessary to synchronize the activities between specialized units to prevent idleness.

The firefly model draws inspiration from the bioluminescent communication between fireflies, using the light beam emitted by the detection robot to effectively guide the picking robot to the ore location. This feature demonstrates the key role of direct signaling in reducing idle time and enhancing the rapid positioning and coordination of mining tasks. Furthermore, the honeybee model adopts the complex foraging behavior of honeybees, where the scout robot identifies and transmits resource information to the master robot, and the master robot then coordinates the harvesting robot. This model uses a hybrid control system to optimize exploration and harvesting operations through enhanced positioning capabilities, greatly reducing the time required to locate and extract the ore blocks. The integration of role specialization and direct communication strategies in these models could largely contribute to further advancement of current mining practices by making them more efficient and robust.

4.2. Statistical Analysis

To evaluate significant performance differences between the models, an analysis of variance (ANOVA) test was performed. The results are summarized in

Table 1, indicating that there is at least one model for which statistically significant differences in harvesting speed between the different models have been identified.

To further investigate which specific models differed from each other, Tukey honestly significant difference (HSD) post hoc tests were performed.

Table 2 summarizes the results of the Tukey HSD test, showing the mean differences between each pair of models, as well as their corresponding p-values and confidence intervals.

Statistical analysis showed that there were significant differences in the harvesting speeds of the four swarm models. The efficiency of the honeybee model was superior to the other models thanks to the hybrid control system.

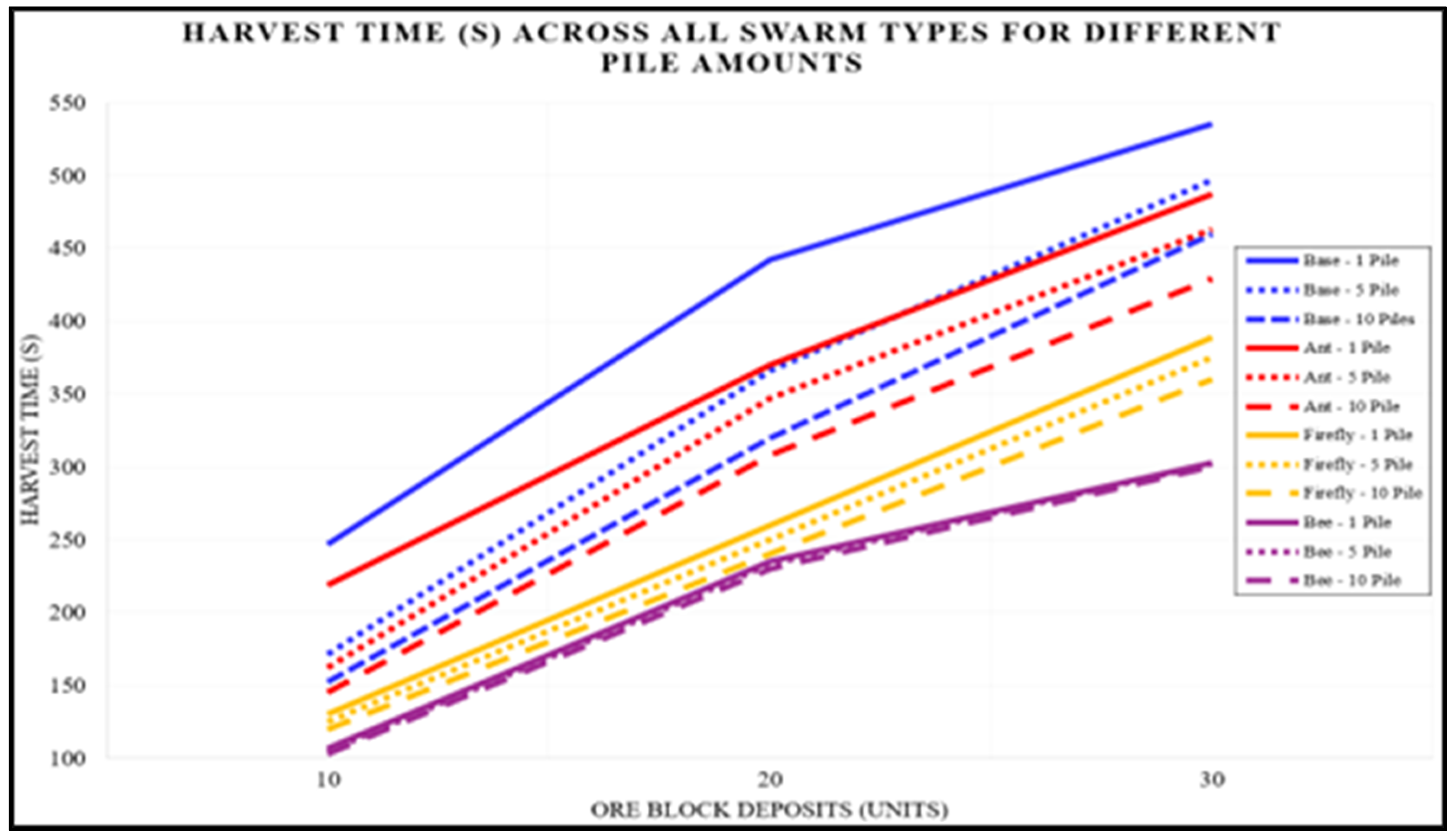

4.3. Mining Scalability and Adaptation

Scalability and adaptability of mining operations are critical, especially given the diversity of geological structures and distributions of mineral deposits, ranging from dispersed deposits typical of placer mines to highly concentrated deposits found in vein mines. This study has quantitatively evaluated the scalability and adaptability of various swarm models by measuring their performance under different food supply levels (from 10 to 30 ore blocks) and different numbers of ore piles (from 1 to 10 ore piles). The design of the simulation environment reflects these different mining environments, with a focus on optimizing and adapting the swarm model to different scenarios.

Figure 8 shows the results from the swarm mining scalability and adaptability tests.

This section evaluates the mining performance of the considered four swarm models from the perspective of scalability and adaptability, focusing on how these models handle changes in the number of piles and block distribution. As shown in

Figure 8, the honeybee model performs well with an efficiency improvement of 39%, followed by the firefly model, then the ant model, and finally the baseline model. When comparing the solid line representing 1 pile and the dashed line representing 10 piles form

Figure 8, it can be observed that the mining time for all considered models is longer for the case of the 1 pile than it is for the case of 10 piles. This is because the more piles there are, the better are the chances of finding minerals when leaving the nest and hence, the exploration area is reduced at a given time. However, as the number of blocks increases further and the complexity in terms of tasks increases accordingly, mining time also tends to increase. This is due increased workload necessitated by handling more tasks and processing more blocks. Consequently, in the baseline model the multitasking becomes a bottleneck thereby leading to inefficiency.

Contrary to the baseline model, the ant, firefly and honeybee models combine role specialization with advanced coordination mechanisms for a better performance. Such combinations allow these models to effectively allocate tasks among robots thus minimizing the idle times and enhancing the overall productivity. In

Figure 8, the honeybee model denoted in purple shows that different pile configurations have high consistency which indicates that this model can adapt well to various mining environments, such as changes in the number and distribution of ore deposits. With this design approach any changes in the piles or ore quantity will not affect the model’s performance, thus making it well suited for efficient mining activities at diverse environments with different geographical locations. This consistency could be achieved because the honeybee model searches throughout the overall area before utilizing a recruitment and coordination system for extracting, rather than searching repeatedly like the other considered models do. This approach allows the honeybee model to maintain consistent performance regardless of the number of piles or ore volume, making it highly adaptive and efficient in diverse mining environments.

The ant model demonstrates greater efficiency in the case of fewer ore piles than for dispersed mining environments, making it better suited for mining areas with concentrated ore deposits like vein mining. In such environments minerals are found in dense geological structures. These concentrated areas can be well developed by the means of work division using the ant model and consequently reduce the time taken to operate in these mining ores.

The firefly model on other hand, demonstrates high versatility in the case of large volumes of ores and achieves the same results despite different numbers of ore piles, as is shown in

Figure 8. This implies that the firefly model has a robust foraging behavior that makes it suitable for complicated situations where resources are scattered as can be the case in open pits or big space mining operations. The search strategy of the firefly model optimizes extraction from these diverse and widespread areas with dispersed deposits.

Overall, the honeybee model was quite consistent over all levels and layouts of ore piles hence it is highly adaptable to dynamic and heterogeneous mineralized sites, for instance placer mines or alluvial mines having varied deposits.

4.4. Mining Reliability

Mining activities are sometimes subjected to unexpected changes, disturbances, unplanned downtimes, equipment failures and difficult operating conditions making the reliability an important aspect in mining. For successful implementation of the considered swarm models in mining, it is important to ensure that they can effectively operate and harvest even in the presence of errors within the swarm. Evaluating the performance of swarm models under different simulated error conditions where error rates vary between 20% and 80%, allows to determine their reliability. In the case of the honeybee model, the master robot interprets data and makes decisions in a hybrid swarm control system that combines centralized and decentralized controls. A disadvantage of this type of a system is in that a breakdown in the master robot will result in the failure of the whole group. Whereas, within a swarm model without a leading or guide robot if number of robots fail for various reasons affected by random errors at rates from 20% to 80%, this will not cause such a serious impact on the operations, as would the failure of a leading or guide robot that would result in the interruption of the harvesting process resulting in the failure in task completion. This shows that the honeybee model has limitations regarding its reliability and fault tolerance, hence it is not well suited for the application to hazardous mining environments and unknown environments such as space mining.

Unlike the honeybee model, the ant and firefly models use a decentralized control system where each agent operates independently and does not rely on a centralized control. These models have demonstrated robust operation performance at all tested error rates and were able to successfully complete harvesting missions even with error rates as high as 80%. The decentralized control approaches have proven to be more resilient and adaptable to uncertainty, making them more suitable for space mining, remote mining, or underground mining, where errors are more likely to occur, and system robustness is critical. The failure of a single agent does not affect the entire operation. The results show that while the centralized control models like the honeybee model have efficiency advantages under controllable conditions due to low-level targeted communication, they are susceptible to single-point failures. The decentralized control models like the ant and firefly ones are more robust and reliable in uncertain environments because the failure of a single agent does not affect their overall performance and the entire operations. This makes decentralized control more promising for use in challenging mining environments.

4.5. Mining Selectivity

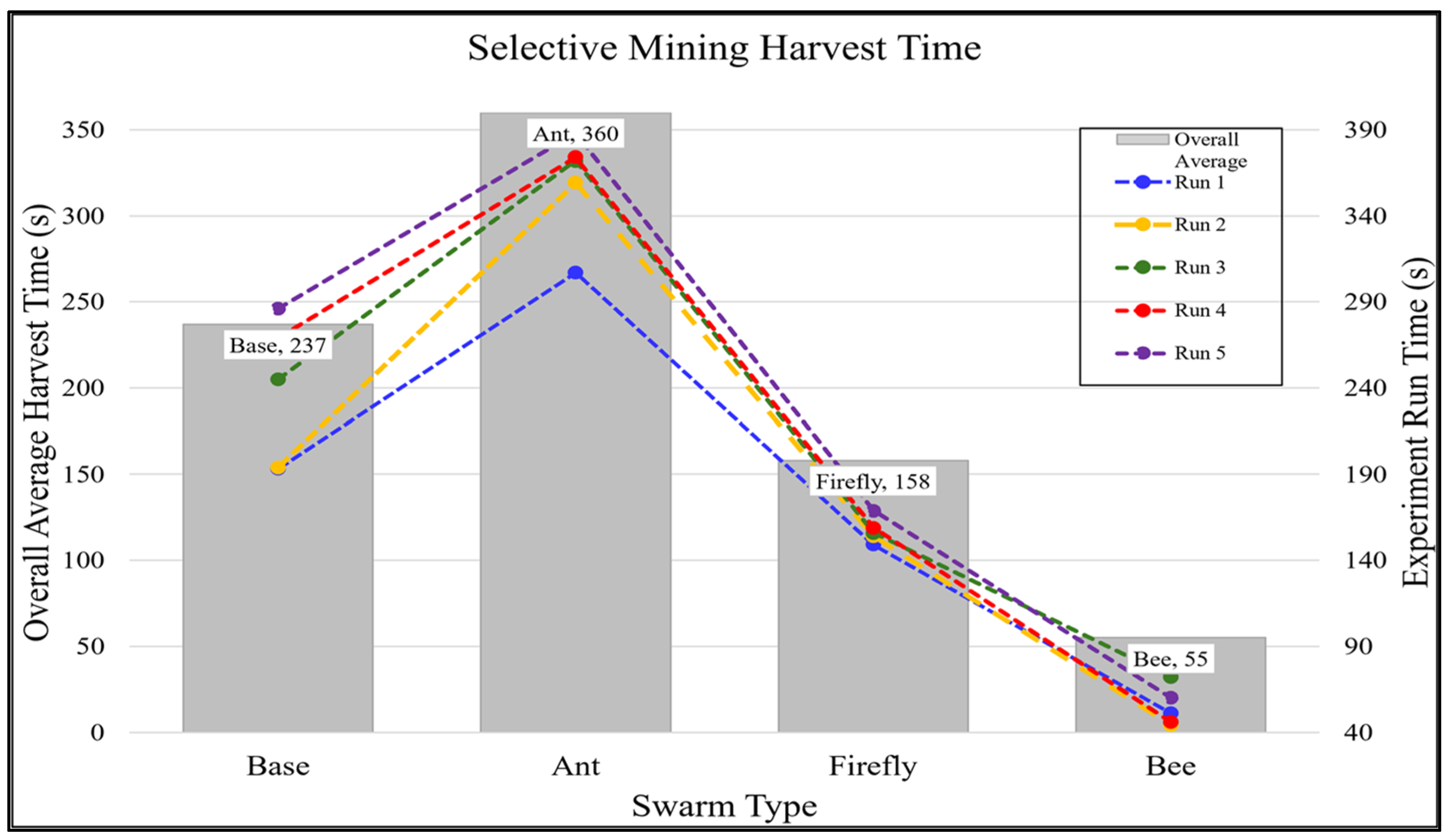

Selective mining is a critical approach in the mining industry, focusing on extracting high-quality minerals to maximize profitability and meet market demands. In mining operations, this method often involves prioritizing high-grade ores and leaving behind low-grade ores unless their extraction becomes economically viable due to market conditions. One common underground mining method is room-and-pillar mining, where low-grade ores are left as pillars to support the roof while rooms are created by extracting the high-grade ore. This approach targets high-grade ores initially, with low-grade ores being mined only when market demand justifies it. Similarly, cut and fill mining involves extracting the ore in horizontal slices, prioritizing high-grade ores and using the extracted low-grade ores as a backfill material. Another technique, longwall mining, involves cutting along the surface of the ore seam to obtain the higher-quality ore, leaving the low-grade ores behind for structural support. In this study, the adaptability of selective mining was evaluated within a swarm model. The experiment deployed 10 robots to process 20 randomly dispersed ore blocks, consisting of 10 high-grade blocks (marked in red) and 10 low-grade blocks (marked in green). Each robot was equipped with a laser radar sensor (LiDAR) to detect the colour of the ore blocks, distinguishing between high and low-grade ores based on colour. This approach is common in simulations of swarm robots to test their capabilities, focusing on the dynamic interactions of swarm models rather than the specific technology used for ore quality detection. The results from these selective mining tests are illustrated in

Figure 9.

This section evaluates the precision and accuracy of the considered swarm models for mining high-grade deposits, focusing on the selective mining protocols used in each model to prioritize the high-quality ore blocks. As is shown in

Figure 9, the honeybee model achieved the best results, with an overall average selective mining time of 55 seconds, compared to 158 seconds, 360 seconds, and 237 seconds for the firefly, ant, and baseline models, respectively. The baseline, ant, and firefly models operate under decentralized and behavior-based formation control, rely primarily on real-time environmental analysis and data sensed during travel to reach consensus. The selective mining protocol did not improve the performance of these models. Each robot's ability to detect ore is limited by its perception radius, causing them to repeatedly explore the same area, resulting in redundant actions and wasted effort. Without centralized control processing, these models lack prior knowledge of the location of high-grade ore and must explore the mining area independently. This implies that the mining operation will take longer and require more robots to search and detect high-grade ores, hence lowering its overall efficiency and speed. Decentralized mechanisms have innate constraints such as many robots traversing the same high-grade ore blocks and coming together at the same place thereby causing congestion and further slowing down mining operations. In addition, for the firefly model to work properly it relies on real-time environmental cues which sometimes may be inconsistent or wrong about the quality of ore. Moreover, each robot in the ant model is operating independently which results in a workload imbalance and idle time. For instance, while others are searching for high-grade ore some robots can be mining low-grade ones leading to inefficient task allocation with reduced overall productivity. The lack of centralized data interpretation and command issuing makes mining operations inefficient where robots must search through mining areas without any coordinated strategy being implemented.

Unlike the decentralized firefly, ant and baseline models, the honeybee model uses centralized control, and this provides unique advantages for selective mining. In this regard, the area under mining is explored by scout robots who relay to the master robot the information on where the ore deposits are found. The master robot would then make selective decisions like the onlooker bee in nature to wisely choose or discard blocks of ore based on the data regarding the mineral quality and resource location given by the scout robot. Then, the mining robots are recruited and organized by the master robot at specific locations of ores. Within an area of decentralized ore deposits in a mine, the honeybee model integrates selective mining protocols which help it deliver an accurate direction to high-grade ore blocks. This process involves utilization of advanced communication and coordination mechanisms that allow for leveraging on the prior knowledge possessed by the master robot regarding the ore locations. Consequently, instead of unproductive searches, a mining robot can be directed straight to high-grade ores via exact positioning thus eliminating redundant operations and speeding up the rate at which minerals are being mined, thereby enhancing overall profitability and efficiency. Through the time-based adjustment according to the mineral quality, this centralized control system works perfectly with its decision-making role as far as real-time selective mining is concerned. This ensures that the honeybee model fully prioritizes the high-grade ore and makes mining operation more selective.

4.6. Classification of Swarm Model

The performance values for the considered models have been determined from simulation results. The lowest harvesting time was used as the standard metric, with the honeybee model showing the highest results for efficiency, scalability and selectivity due to its minimal harvesting time. This standard was then used to scale down the other results accordingly. For example, for the honeybee model it took 55 seconds to complete a task in selectivity, this was set as the highest performance value, i.e. 1.0. If for the ant model it took 360 seconds for the same task, its performance value would be 0.40, i.e. 55/360. This scaling method allowed for a comparative analysis of the models' performance for various aspects such as efficiency, reliability, selectivity, and scalability. The spider graph in

Figure 10 provides a visual representation of these scaled metrics, highlighting the relative strengths and weaknesses of each swarm model.

According to the swarm model performance presented in the spider graph analysis form

Figure 10, the honeybee model exhibits the best capabilities in terms of efficiency, scalability, and selectivity. Meanwhile, the baseline, ant and firefly models exhibit the strongest capabilities in terms of reliability. The excellent performance of the honeybee model stems from its built-in hybrid decentralized-centralized control. This feature provides prior knowledge about the ore deposit, thereby improving mining efficiency and selectivity for precise mining. In addition, environmental changes do not affect the performance of the honeybee model because it does not rely on real-time environmental studies. On the other hand, the firefly and ant models achieve the highest reliability due to their decentralized control systems. These models ensure that each robot is independent of the others and thus, if for instance a robot in the system fails or malfunctions, it will not affect the overall functioning of the process. Moreover, in terms of the efficiency, scalability and selectivity, the firefly model surpasses the ant model. This is because apart from task allocation, the firefly model uses a localization feature, i.e. a guide light and optimizes mining operation.

4.7. Mining Design Applications

From the spider diagram analysis presented in

Figure 10, it is evident that the ant model, firefly model and honeybee model have different strengths and advantages for various mining approaches making them adaptable to several scenarios. The ant model has a task allocation feature with a behavior based decentralized control and a high level of reliability which fit well for such mining operations where valuable minerals are extracted without making a precise target or having defined positions, such as extracting from streams or seabed, hence the ant model could be highly suitable for placer mining and dredging. The ant model could be successfully applied also to block caving method in underground mining since this method does not require targeting high ore grades. The use of task allocation mechanism in the ant model can optimize transportation of ores in block caving as well as hydraulic mining whereby the ore is broken down by gravity or using hydraulic jets. The task allocation feature of the ant model could allow to further be improved the mining efficiency by breaking the tasks into smaller sub-tasks to be carried out by individual robots. Another area where the task allocation feature of the ant model can be of a major advantage is in space exploration technologies such as asteroid mining, planetary mining and mining on the Moon. The ant model allows to break down the whole process into smaller tasks to have each agent in the swarm tasked independently, and thus achieve a more reliable and sustainable production in the harsh space environment without human intervention.

Moreover, the firefly model utilizes a decentralized control behavior-based task allocation and positioning mechanism that has a superior scalability, dependability and effectiveness compared to the ant model. Its positioning feature has the potential to be very useful in open pit and strip surface mining where it can target high grade ore areas and layers. For underground mining the ore position is crucial, and the firefly model would be suitable for room-and-pillar, longwall, cut-and-fill, and stoping mining methods. In harsh underground environments swarm robots with ore detection feature provided by the firefly positioning technology will allow for targeted mining with high confidence. The firefly model can have successful applications in space mining especially asteroid, planetary mining or mining on the Moon, where signal transmissions and remote operations can be hindered due to permanently shadowed regions along with harsh environmental conditions.

The honeybee model employs centralized control strategies which help maximize efficiency, scalability, and selectivity thereby making it suitable for mining techniques that require accurate targeting of high-grade ores. In open pit and strip surface mining methods, the honeybee model can extract minerals effectively from high grade areas while leaving low grade materials behind to increase mining efficiency and profitability. In underground mining, the honeybee model could be suitable for room-and-pillar mining, which selectively mines high-grade ores and leaves low-grade ores as structural pillars. It can be applied also for cut-and-fill mining, which preferentially mines the high-grade ore while backfilling the voids with low grade materials, and longwall mining, which requires precise cutting to target the high-grade ore layers. Methods such as shrinkage stoping mining and sublevel stoping mining further highlight the ability of the honeybee model to focus on high grade ore bodies. The centralized control and advanced communication mechanism of the honeybee model allows the scout robot to explore and pass the information on the ore deposit to the master robot, which then coordinates the mining activities for targeted and efficient mining. In addition, specialized mining techniques such as in-situ leaching, solution mining and heap leaching also could benefit from the high accuracy and selectivity that the honeybee model offers, since it will allow targeting the high-grade ore areas for the leaching process. The summary on applications of swarm models to mining methods is presented in

Table 3.

5. Conclusions

This study proposes and evaluates the performance of three swarm robot models (ants, fireflies, and honeybees) in different mining environments, focusing on mining efficiency, scalability, reliability, and selectivity. The results are presented in the form of spider diagrams, highlighting the strengths and limitations of each model based on its control mechanism and capabilities. The honeybee model is inspired by the foraging behavior of honeybees, and it integrates advanced communication mechanisms and a hybrid centralized-decentralized control system, which allow it to excel in selective mining. To this effect, the honeybee model is most advanced in terms of efficiency, scalability and selectivity for mining that requires precision and targeted extraction of high-grade ores. However, the honeybee model has reliability limitation which can make it vulnerable under unknown and harsh conditions. The ant model was inspired by the leafcutter ants’ task allocation strategy and decentralized control systems, with emphasis on the decentralized control. This model is suitable for mining operations where there is no need for selectivity or strict control of ore grade and efficiency levels are not a matter of concern. Due to its high level of reliability, the ant model is very well suited for applications in space mining where human intervention and maintenance are impossible. Ant model would excel in regolith extraction due to its decentralized control and task allocation features. The firefly model takes motivation from the firefly’s bioluminescence attractive features while employing behavior-based decentralized control, making it superior to the ant model. It also emphasizes on efficiency, scalability, and selectivity while also maximizing the reliability. In underground mines the firefly model could be useful for deposit location search and used in hazardous or unknown environments such as toxic gas mining and space mining. In these harsh environments, decentralized control of swarm robots could allow to locate them which could be more important than signal and data transmission, which could be delayed or non-existent in the space environment. This study shows, that for the successful application of swarm robots in mining, choosing the swarm model with capabilities that suit the best to the specific characteristics and requirements of the mining environment under consideration is decisive. The performance evaluation of the considered swarm models demonstrates that applying the best suited swarm model could ensure further improvements in the operational efficiency in mines whereby further contributing towards sustainability in terms of achieving automated and efficient mining methods. It is recommended that future research considers addressing the limitations of the honeybee model by developing remedial solutions to improve its reliability and sustainability and build on the existing models to develop hybrid models that will combine the inherent strengths from existing ones with enhanced adaptability for various mining environments.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Wellmer, F.W., Buchholz, P., Gutzmer, J., Hagelüken, C., Herzig, P., Littke, R. and Thauer, R.K., 2019. Raw materials for future energy supply. Cham: Springer International Publishing.

- Government of Western Australia., 2019. Western Australia Iron Ore Profile 2019.

- Salisbury, C., 2018. Iron Ore–Delivering value from flexibility and optionality. London, UK: Rio Tinto.

- BHP., 2019. Automation data is making work safer, smarter and faster.

- Jang, H. and Topal, E., 2020. Transformation of the Australian mining industry and future prospects. Mining Technology, 129, pp.120-134.

- Brambilla, M., Ferrante, E., Birattari, M. and Dorigo, M., 2013. Swarm robotics: a review from the swarm engineering perspective. Swarm Intelligence, 7, pp.1-41.

- Andersson et al. 2011. SMIFU WP1, Final report, Nordic Rock Tech Centre.

- LTU,Strategic Research and Innovation Agenda for the Swedish Mining And Metal Produc-ing Industry (Strim), 2013. Available atwww.ltu.se/cms_fs/1.114292!/file/Agenda-STRIM-LTU-Vinnova.

- Subhan, M.A., Bhide, A.S. and SSGB, C., 2014. Study of unmanned vehicle (robot) for coal mines. International Journal of Innovative Research in Advanced Engineering (IJIRAE), 1, pp.116-120.

- Gordon, D.M., 2016. From division of labor to the collective behavior of social insects. Behavioral ecology and sociobiology, 70, pp.1101-1108.

- Fister, I., Fister Jr, I., Yang, X.S. and Brest, J., 2013. A comprehensive review of firefly algorithms. Swarm and evolutionary computation, 13, pp.34-46.

- Karaboga, D., Gorkemli, B., Ozturk, C. and Karaboga, N., 2014. A comprehensive survey: artificial bee colony (ABC) algorithm and applications. Artificial Intelligence Review, 42, pp.21-57.

- Tan, J., Melkoumian, N., Harvey, D., Akmeliawati, R. Classifying Nature-Inspired Swarm Algorithms for Sustainable Autonomous Mining. Insights Min Sci technol.2024, 4, 555636. [CrossRef]

- Tan, J., Melkoumian, N., Akmeliawati, R., & Harvey, D. (2021). Design and application of swarm robotics system using ABCO method for off-Earth mining. Fifth International Future Mining Conference 2021. AusIMM.

- Schranz, M., Umlauft, M., Sende, M. and Elmenreich, W., 2020. Swarm robotic behaviors and current applications. Frontiers in Robotics and AI, 7, p.36.

- Bao, H., Knights, P., Kizil, M. and Nehring, M., 2023. Electrification alternatives for open pit mine haulage. Mining, 3, pp.1-25.

- Di Pietro, V., Govoni, P., Chan, K.H., Oliveira, R.C., Wenseleers, T. and van den Berg, P., 2022. Evolution of self-organised division of labour driven by stigmergy in leaf-cutter ants. Scientific Reports, 12, p.21971.

- Constantino, P.B., Valentinuzzi, V.S. and Helene, A.F., 2021. Division of labor in work shifts by leaf-cutting ants. Scientific Reports, 11, p.8737.

- Palmieri, N. and Marano, S., 2016. Discrete firefly algorithm for recruiting task in a swarm of robots. Nature-Inspired Computation in Engineering, pp.133-150.

- Kiran, M.S., 2014. Improved artificial bee colony algorithm for continuous optimization problems. Journal of Computer and Communications, 2, p.108.

- Sebbane, Y.B., 2018. Intelligent autonomy of UAVs: advanced missions and future use. CRC Press.

- St-Onge, D., Kaufmann, M., Panerati, J., Ramtoula, B., Cao, Y., Coffey, E.B. and Beltrame, G., 2019. Planetary exploration with robot teams: Implementing higher autonomy with swarm intelligence. IEEE Robotics & Automation Magazine, 27, pp.159-168.

- Duarte, M., Costa, V., Gomes, J., Rodrigues, T., Silva, F., Oliveira, S.M. and Christensen, A.L., 2016. Evolution of collective behaviors for a real swarm of aquatic surface robots. PloS one, 11, p.e0151834.

- Thamrin, N.M., Arshad, N.H.M., Adnan, R. and Sam, R., 2022. Forward Navigation for Autonomous Unmanned Vehicle in Inter-Row Planted Agriculture Field. Control Engineering in Robotics and Industrial Automation: Malaysian Society for Automatic Control Engineers (MACE) Technical Series 2018, pp.183-198.

- Mariappan, M., Arshad, M.R., Akmeliawati, R. and Chong, C.S., 2022. Control Engineering in Robotics and Industrial Automation. Springer International Publishing.

- Trianni, V., IJsselmuiden, J. and Haken, R., 2016. The saga concept: swarm robotics for agricultural applications. Technical Report. 2016. Available online: http://laral. istc. cnr. it/saga/wp-content/uploads/2016/09/sagadars2016. pdf (accessed on 23 August 2018).

- Phys.org. 2018. Nature-inspired soft millirobot makes its way through enclosed spaces. [online] Available at: [Accessed 1 June 2021].

- Kayser, M., Cai, L., Bader, C., Falcone, S., Inglessis, N., Darweesh, B., Costa, J. and Oxman, N., 2018, September. Fiberbots: design and digital fabrication of tubular structures using robot swarms. In Robotic Fabrication in Architecture, Art and Design (pp. 285-296). Springer, Cham.

- Petersen, K.H., Nagpal, R. and Werfel, J.K., 2011. Termes: An autonomous robotic system for three-dimensional collective construction. Robotics: science and systems VII.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).