3.2. Slump Test

The results of the slump test on the different types of concrete made are given in

Table 5.

According to the results in

Table 5, we see that the slump of the reference concrete is 2cm, which suggests that it is a firm concrete, and this even by incorporating the corrosion inhibitor, we can conclude that the sodium benzoate tested in our study does not influence the properties of our concrete in the fresh state.

Although the addition of the adjuvant marks a remarkable jump in slump which goes from 2cm to 19cm, this spreading confirms that our concrete becomes fluid in the presence of adjuvant. This result is logical since it is a new generation superplasticizer.

Also, we remark that the addition of limestone fillers changed the state of the fresh concrete, it went from a firm concrete (concrete + sodium benzoate) to a plastic concrete. According to [

10] The effect of limestone results in greater compactness of the granular skeleton and will therefore have effects on the properties of concrete both in the fresh and hardened states.

However, the addition of superplasticizer adjuvant means to change the state of fresh concrete, it passes from a firm state in the presence of sodium benzoate to a plastic state after addition of limestone fillers to a fluid state, when incorporate the superplasticizer adjuvant; it will be benefic when pouring concrete with dense reinforcements.

3.3. Non-Destructive Testing: Dynamic Auscultation

The results of the dynamic auscultation tests are summarized in

Table 6.

According to the results in

Table 6, we note that the addition of sodium benzoate reduces the compressive strength of concrete at young age by 21%, this result remains to be confirmed by destructive measurements. Whereas for other ready-made concretes, the addition of the inhibitor or adjuvant does not significantly influence the mechanical resistance at 7 days. Furthermore, at 28 days we see that the addition of the inhibitor reduced this resistance by 2.6% when comparing to the reference concrete, although the addition of the adjuvant comes to remedy this problem and it exceeds even that of a reference concrete of 2.35%. At 56 days, these resistances are practically lower than those of a reference concrete, of the order of 18.2% with the addition of sodium benzoate, the contribution of the adjuvant remains beneficial and tends to enhance these resistances. In the longer term 90 days, the compressive strengths of concrete with inhibitors decrease by 9.55%, the adjuvant has no negative effects on the evolution of the strengths according to these results which remain to be confirmed at using destructive testing.

By analyzing the results illustrated in

Figure 2, we note that the resistances recorded using non-destructive methods: ultrasound reach their maximum values at 90d, these resistances are slightly lower compared to the reference concrete not exceeding 10%, the adjuvant used improves workability and does not affect these resistances according to these non-destructive tests. Through these results, we note that the limestone fillers added to the concrete increase its resistance at 28 days, but the presence of corrosion inhibitors at an optimal concentration slightly reduces these resistances, we note that sodium benzoate decreases the resistance when comparing with a Reference concrete even in the presence of limestone fillers. We can see that limestone fillers tends to increase compressive strengths compared to the other formulations. Some authors, such as Campitelli and Florindo [

8] who studied the beneficial effect of fillers on mechanical properties. The addition of filler introduced at the time of grinding would lower the strength performance of cements, even for the optimum SO

3 present in the cement, whatever the percentage of addition or the fineness thereof. Concurrent grinding with fillers does not promote good particle distribution in size. In particular the greater part of clinker in the large particles would not favor the development of resistance in young adulthood [

14].

3.4. Destructive Testing

a- Compression tests

The results of the compressive tests on concrete specimens for different types of concrete made are given in

Table 7.

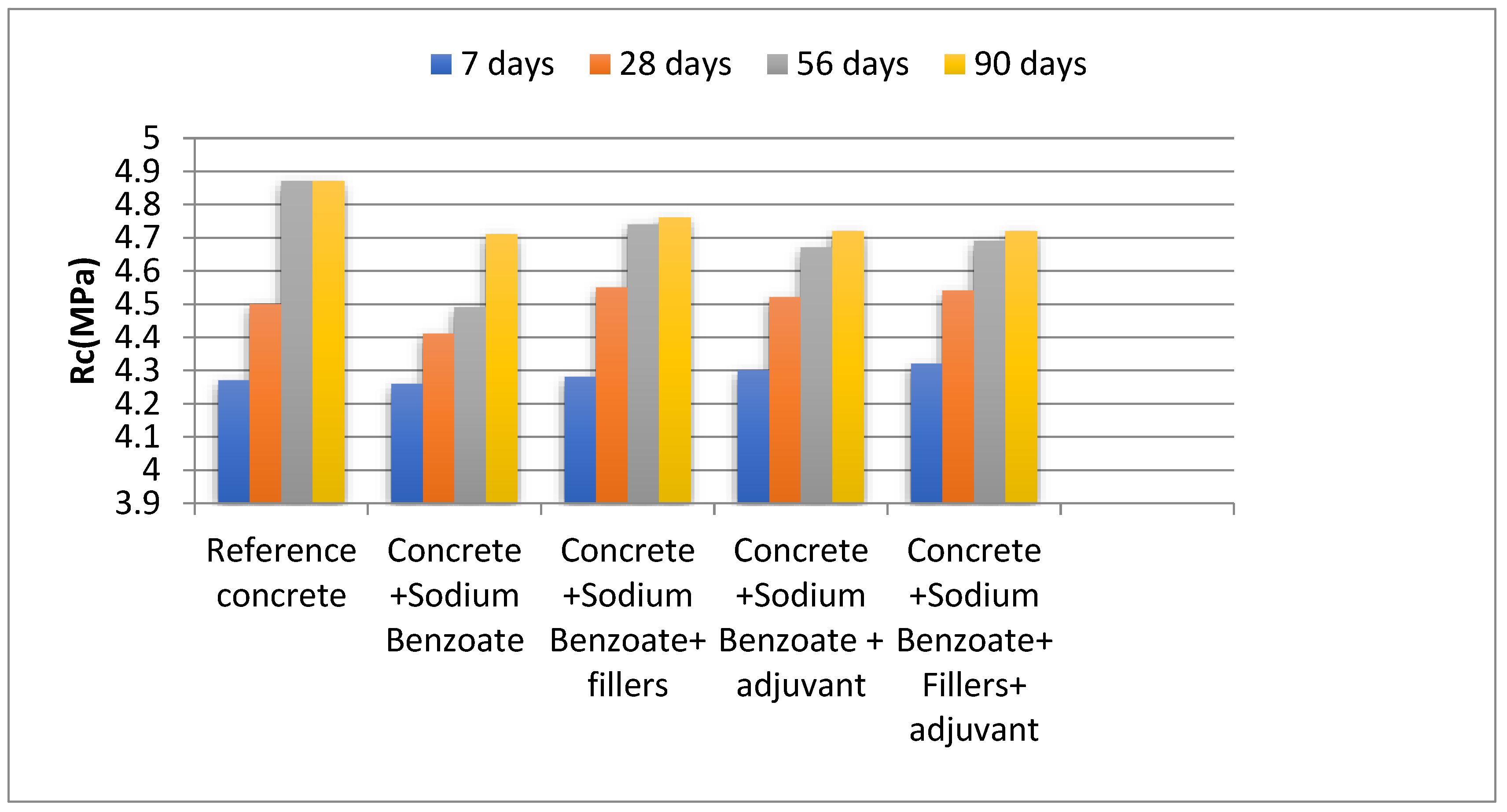

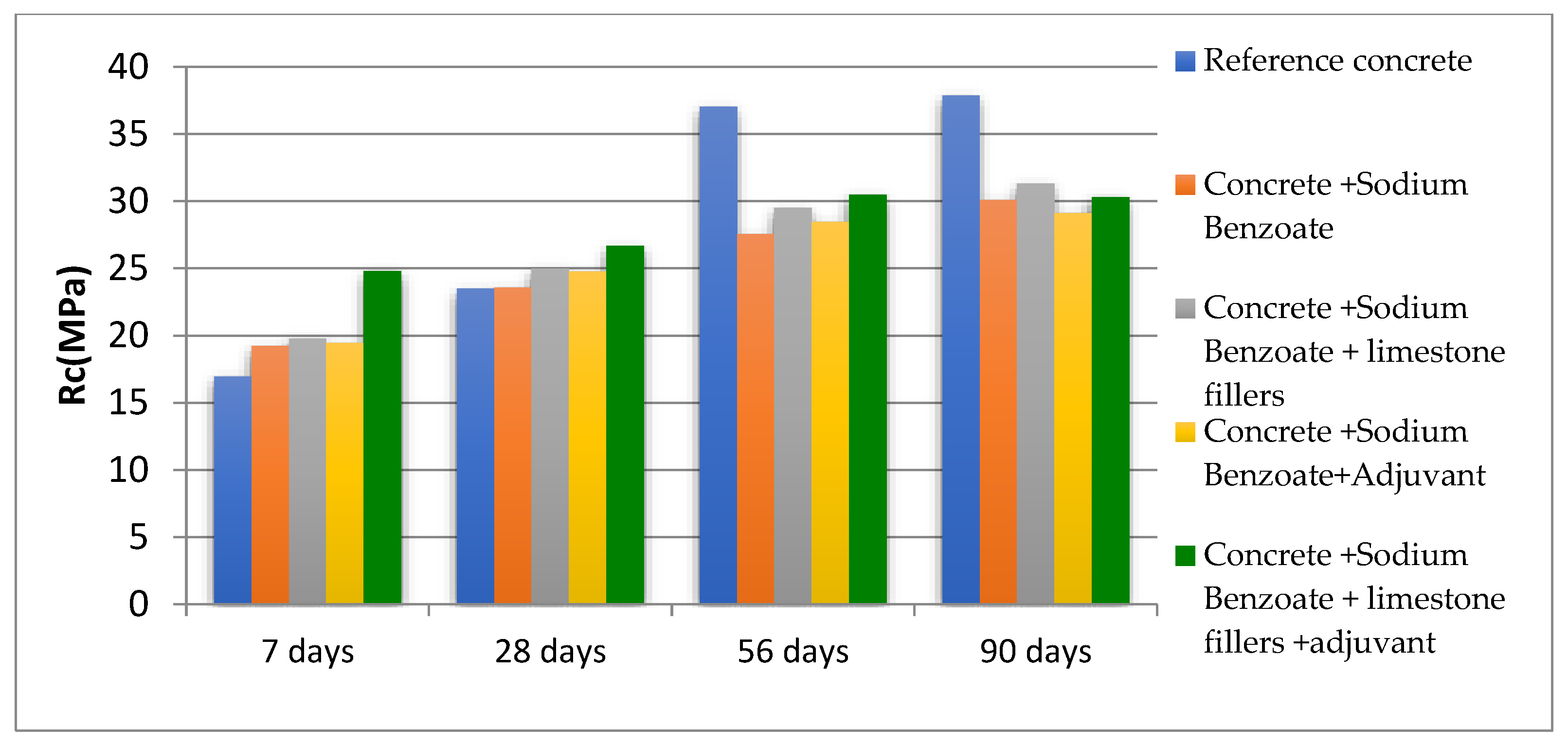

Through results illustrated in

Table 7, we can see that at early age 7 days, of concrete, compressive strength for reference concrete is the lower compared with the other samples, however its better improved for concrete with sodium benzoate+ limestone fillers + adjuvant. It shifts from 31.64% compared to reference concrete. For the same type of concrete, in the long term 56 and 90 days, the compressive strengths decrease when compared with the reference concrete.

In order to better compare the evolution of the compressive strengths for the different concretes made over the time periods studied, we have drawn the histogram illustrated in

Figure 3.

The results in

Figure 3 represent the compressive strengths by destructive measurements for the different concrete compositions at well-specified time periods. We note that for a young concrete “7 Days”, the resistance of a concrete with sodium benzoate is higher than the other ready-made concretes as well as that of the reference concrete by 35.29%. For the latter, its resistance is lower than that of other concretes, we can therefore conclude that sodium benzoate has a positive influence on the mechanical properties of concrete at 7 days.

While at 28 days, we see that the compressive strength of a concrete with sodium benzoate is similar to the resistance for reference concrete, the highest value was recorded for concrete with sodium benzoate, limestone fillers and adjuvants, when comparing with reference concrete, also, the addition of the adjuvant did not considerably improved the mechanical resistance of concrete incorporating corrosion inhibitor.

At 56 Days, we can clearly see that the mechanical resistance of all the concretes produced is slightly lower than that of the reference concrete. Furthermore, at 90 days, the compressive strengths tend to decrease in the presence of sodium benzoate and adjuvant, they remain lower when comparing with a reference concrete. By analyzing the effect of adding limestone fillers and their influence on mechanical resistance at 28 Days, we see that they improve slightly the compressive strength resistances for concretes with sodium benzoate weather for concrete with adjuvants compared to reference concrete. According to the results obtained, the addition of limestone fillers did not really improve the compressive strengths of the concretes studied in the presence of corrosion inhibitors and adjuvants, moreover, their positive effect on flexural strengths was detected for all time periods studied.

Concerning the influence of the adjuvant used on the mechanical performance of concrete, we

We notes that at young ages, compressive strengths are slightly improved, while that at 90 days, these resistances tend to decrease. While the bending resistances in presence of adjuvants and inhibitors are slightly improved.

b- Bending tensile tests

The results obtained relating to bending strengths are presented in

Table 7, they present the effect of the addition of sodium benzoate as corrosion inhibitor, adjuvant and limestone fillers on the compressive strengths for the different concrete compositions.

The results of the tensile bending tests carried out on prismatic specimens are summarized in

Table 8.

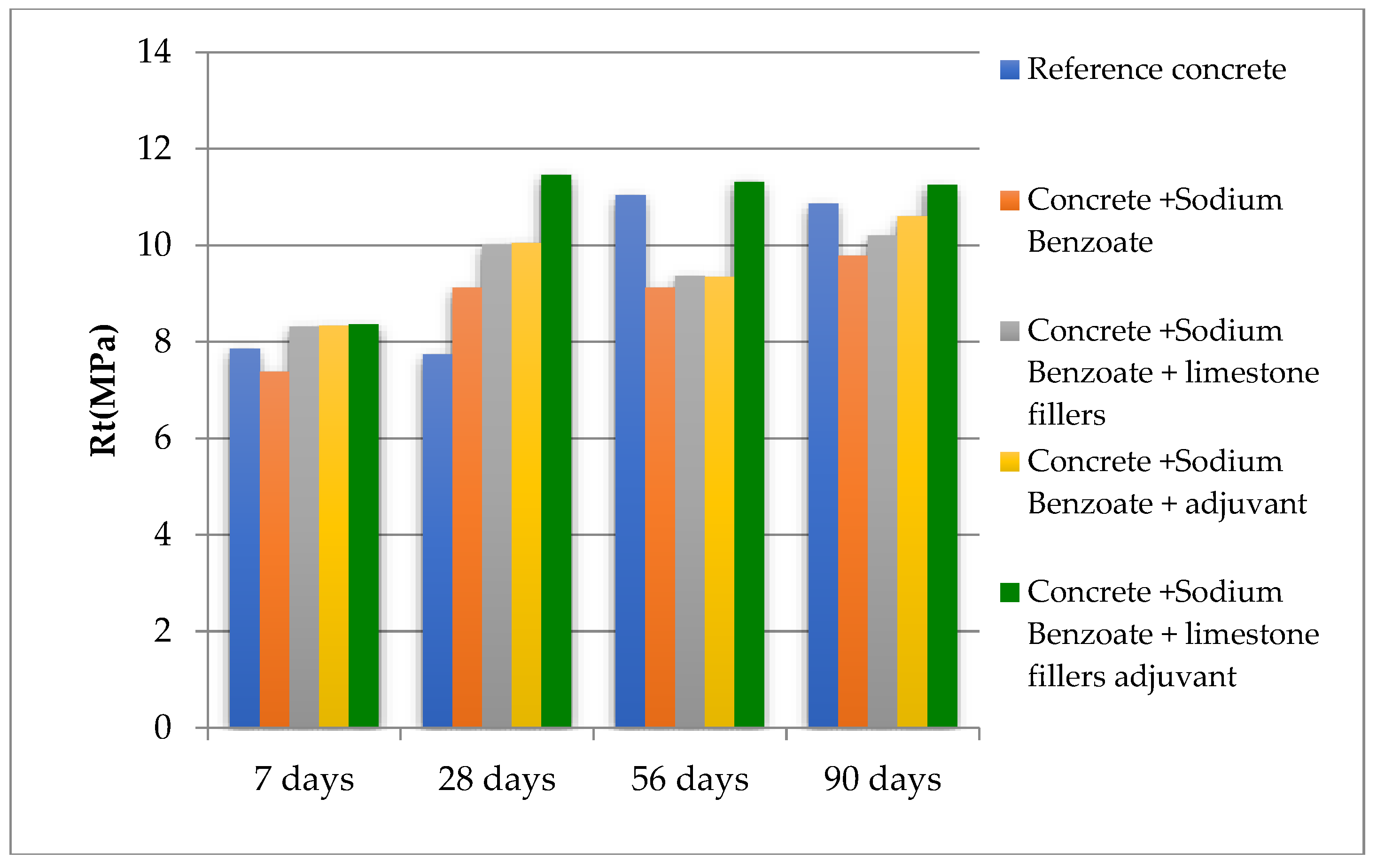

In order to better compare the evolution of the Bending tensile strengths for the different concretes made over the time periods studied, we have drawn the histogram illustrated in

Figure 4.

According to the results illustrated in

Figure 4, we note that for a young concrete “7 Days”, the flexural resistance of a concrete with sodium benzoate and adjuvant is slightly higher than that of other concretes made as well as ‘to that of the reference concrete of 5.41%.

While at 28 days, we see that the flexural resistance of a concrete with sodium benzoate+ limestone fillers +adjuvant is higher when compared with a reference concrete whose resistance remains the lowest when compared with the other compositions of concrete. The addition of the adjuvant improves these flexural strengths for concretes with corrosion inhibitor. However, limestone fillers remain to increase slightly this resistance

At 56 Days, according to the results illustrated in

Figure 3, there is an improvement in the tensile strength for the reference concrete, but, we don’t see any modification in the resistance for samples with sodium benzoate, however, limestone and adjuvant acts to regulate this parameter and increase slightly the resistance by bending of 17.39% recorded for a concrete with sodium benzoate compared to the reference concrete, on the other hand the addition of the adjuvant tends to increase this resistance by 5.97%, when comparing with a reference concrete.

Although at 90 Days, we notice that the tensile strength of the ready-made concretes is slightly lower than that of the reference concrete, in the presence of adjuvant, the resistance values improve by 6.85% compared to concretes without adjuvant.

Grinding the clinker and limestone fillers reduces the proportion of clinker in the mixture and therefore reduces the strength achieved. Finer grinding could be carried out to obtain strengths equivalent to a mixture without addition. But for additions between (5 and 10%), the resistances are not significantly reduced. And more intense grinding is not particularly indicated.