1. Introduction

The circular economy is a model of production and consumption, which involves sharing, leasing, reusing, repairing, refurbishing and recycling existing materials and products for as long as possible. In this way, the life cycle of products is extended resulting in less raw materials, fewer emissions and less waste. Several regulations and legislative frameworks are driving the shift towards circular and recyclable materials. These regulations are designed to promote sustainability, reduce waste, and encourage the use of recycled and recyclable materials. They include: the EU Circular Economy Action Plan [

1] which aims to transition the EU towards a circular economy by promoting sustainable product design, reducing waste, and fostering the use of secondary raw materials including plastics and textiles; the draft EU Ecodesign for Sustainable Products Regulation (ESPR) [

2], which focuses on improving the environmental performance of products by establishing requirements for product design that enhance durability, reparability, recyclability, and the use of recycled content and; the Waste Framework Directive (2008/98/EC) [

3] which establishes a waste hierarchy prioritizing prevention, reuse, recycling, and recovery of waste.

Natural materials, such as leather, wool and cotton should be well-placed to meet the needs of the circular economy. Leather manufacture utilises raw hides and skins obtained as by-products of meat production that would otherwise require disposal. Leather is also long-lasting, readily repairable and understood to be biodegradable at end of life. However, concerns over sustainability of leather and consumer demand for substitutes for leather has resulted in the development of a range of plant-based âtrendyâ materials,. These materials are usually based on mycelium, such as the Bolt Threads product, Mylo®, or plant materials, such as Desserto® (cactus) or Piñatex® (pineapple) and are normally comprised of the plant material and a synthetic, such as polyurethane. These materials are often presented as a more sustainable and functional alternative to leather. However, there is little evidence to support this assertion, and the veracity of some of these claims has been examined.

Meyer

et al. (2021) used a number of standard physical tests to evaluate the functional performance characteristics of nine of alternatives to leather [

4]. The results showed none of these âtrendyâ materials could match leather in all the measures evaluated and that many lacked wear performance indicating that they would be short-lived in use. Carcione

et al. (2023) examined the biogenic content of the same leather alternatives and showed that most had a high content of fossil-fuel based materials, and that only a minority had a high biogenic content [

5]. Combined, these areas of research highlight the uncertainty surrounding the sustainability of trendy materials as they offer poor performance characteristics, and are often based on fossil-carbon.

In addition to its performance characteristics and composition, the capacity of a material to be composted or to biodegrade at the end of its life will greatly influence its potential to be part of a circular economic model. Sardroudi

et al. (2024) investigated the disintegration of leather and some of the alternatives, with a focus on their break down and suitability for the biocircular economy [

6]. Their research showed that the leathers assessed were highly suitable for compostability, while the alternatives showed little or no disintegration.

This research seeks to further assess the compostability of leather and trendy alternatives and evaluates the use of compost produced using leathers tanned with the three main leather tanning chemistry’s for plant growth and ecotoxicological profile. The results will further contribute to the understanding of the compatibility of leather and some of the alternatives to leather with ambitions of the circular economy.

2. Materials and Methods

Test pieces of leather and several alternatives (

Table 1) were assessed for their disintegration and biodegradability. Furthermore, the three unfinished leathers (K, L and M) were then further tested in plant response and ecotoxin screening to evaluate the relative ecotoxicity of composts produced with leathers tanned with different primary tannages.

All materials were received from suppliers of the material where possible. Some of the materials were sampled from final articles, through deconstruction and separation. All test pieces were measured for thickness, gently dried and cut or ground to meet the requirements of the test method. Materials were characterised (as per compostability requirements) to meet the metal and fluorine requirements of EN 13432 and EN 14995 [

7,

8]. All materials (except the Leather J and K) were within the metals and fluorine thresholds specified by Annex A (of both) compostability specifications.

To eliminate confounding influences, leathers K, L, and M were sourced as tanned leathers that had not undergone any further chemical processing, e.g. retanning, dyeing, and fatliquoring.

2.1. Assessment of Disintegration

The disintegration of the test materials was assessed using a modified version of ISO 20200: 2023 [

9]. All materials that had not reached 100% disintegration after the initial thermophilic test phase were taken into the mesophilic phase. The inoculum for the thermophilic phase was fresh municipal compost, and the inoculum for the mesophilic phase was unsterilised topsoil.

There is no specified requirement for controls in ISO 20200 but for the purposes of this study, positive controls were used. The expected time of the disintegration of these products is known by the laboratory and any deviation from that time is recorded. After the composting period, the test pieces were cleared of compost debris, and were gently dried until there was no longer any change of mass.

2.2. Determination of Biodegradability

The biodegradability of the test pieces was determined in accordance with ISO 20136: 2020 [

10]. The carbon content (

ms) of the materials tested was measured using ISO 8245: 1999 [

11]. The result was then converted into the theoretical CO

2 (

mTCO2) that could be released using the amount of dry-matter added to the reactor, using the formulae (1 and 2) given below:

Equipment used for the biodegradability reaction was an EGA 61 multi-sample CO2/H2O respirometer (AD Scientific, Hertfordshire, UK), pump flow maximum 340 mol/sec, with flow meter scale of 680 mol/sec (accuracy 1.5% of reading and 0.5% of scale). The resolution of the instrument is 1 ppm of CO2.

The airtight reactors were 2 dm3 glassware, connected to a CO2-free air supply. The inoculum used was domestic sewage activated sludge. Atmospheric barometric measurements, pump pressure, and flow rate corrections were recorded by the equipment and were used in the final calculations of the evolved amount of gas. All CO2 production of the controls and the test reactors were corrected to remove CO2 generated by the activated sludge. The tests were run in the case of this study for 28-days.

The final cumulative CO2 value at the end of the test is known as the absolute biodegradability. The absolute biodegradability of the collagen control is then adjusted to achieve a relative biodegradability of 100%. The same adjustment factor used in the control is then used to determine the relative biodegradability of the other test materials.

2.3. Plant Response Testing

The plant response of leather composts was assessed to understand the growth of plants in biogenic-based substrates to show compatibility with pre-composting requirements, in particular any phytotoxic effects the leathers might have. Three leather intermediates: a chromium-free, a chromium-tanned, and a vegetable-tanned intermediate were shredded and composted for 84 days (1:5 material to compost ratio), as was a negative control compost with no materials.

The methods described in REAL CCS 3.1 were followed using sphagnum moss peat only as a plant growth substrate (blank); a negative control compost containing no test materials; and the test composts made from the leathers listed [

12]. The peat was an H3 to H6 (von Post scale) peat with a conductivity (measured with BS EN 13038: 2011) within the specified range of 4 to 12 mS/m [

13]. The plant trays consisted of:

100% plant growth substrate (the blank);

the negative control plant trays consisted of material-free compost and peat (1:3); and

the test plant trays consisted of material composts and peat (1:3).

The pH of the plant growth substrate was adjusted to be between 5.5 and 7.5 using magnesium limestone, CaMg(CO

3)

2, supplied by Omya Solutions, North Ferriby, UK. The nitrogen-phosphorous-potassium (NPK) ratio was adjusted using an NPK fertiliser (14-16-18) supplied by Yara Ltd, Oslo, Norway to give a K

2O: N ratio of the substrate of ≤1.33:1. Nitrogen was measured using BS EN 13654-2: 2001, phosphorous and potassium by BS EN 13650: 2001 [

14,

15].

The plants tested were tomato Shirley F1 (Solanum lycopersicum), supplied by Moles Seeds, Colchester, UK. The testing was carried out in a phytotron with lighting luminance, temperature, and light cycle as specified in the method. Watering was done using a capillary matting and wicking from a reservoir. Germination rate and plant anomalies were monitored throughout growth. At 28 days, the plants were photographed, measured and harvested to determine the wet biomass weight and plant height.

2.4. Compost Toxicity Levels

Composts were manufactured using the same regime and concentration as the plant response test. The composts were screened for 200 compounds that are common soil contaminants. Contaminating metals were measured using inductively coupled plasma with mass spectroscopy in accordance with BS EN 17294-2: 2016 [

16]. Gas chromatography mass spectrometry, following the Eurofins W6331 method, was used to determine detectable levels of polycyclic aromatic hydrocarbons, volatile halogenated hydrocarbons, chlorophenols, organic chlorinated pesticides, and phthalates. Detectable levels of petroleum hydrocarbons were determined using gas chromatography with flame ionisation detection using the W0202 Eurofins method.

3. Results

3.1. Assessment of Disintegration

The disintegration levels of the various materials can be seen in

Table 2. Test pieces B (kombucha) and M (chromium-free leather) had fully disintegrated during the thermophilic test phase. The other materials had disintegrated to varying degrees under thermophilic test conditions and were continued into the mesophilic phase.

Overall, the leather test pieces disintegrated to a greater degree than the alternatives with test pieces K and M achieving relative disintegration of 84.42% and 100%, respectively. The shoe upper leather test piece also showed extensive disintegration (64.49%). The notable exception was the test piece L, vegetable-tanned leather, which showed limited disintegration (39.63%) over the test period. The alternative materials showed considerably reduced levels of disintegration, for example, test piece H showed only 0.78% relative disintegration. However, some of the alternatives showed high levels of disintegration, notably test piece B and G.

The PU-coated textile had the lowest levels of disintegration of the materials tested. A small amount of material warping was seen, due to thermal abiotic effects, but the surface showed no pitting or discoloration.

Disintegration continued to a reduced degree during the mesophilic phase, with most materials showing limited further breakdown. Muskin®, (I) chromium-tanned leather (K) and SnapPap® (D) showed more extensive degradation during the mesophilic phase, of 4.48%, 4.94% and 7.11% respectively, while the most marked increase, 13.36%, was seen for the shoe upper leather (J).

Overall, the leather test pieces (J-M) showed a greater propensity for disintegration than the synthetic materials (A-I). The exceptions were the limited degradation observed for the vegetable-tanned leather and extensive degradation seen with kombucha and Piñatex®.

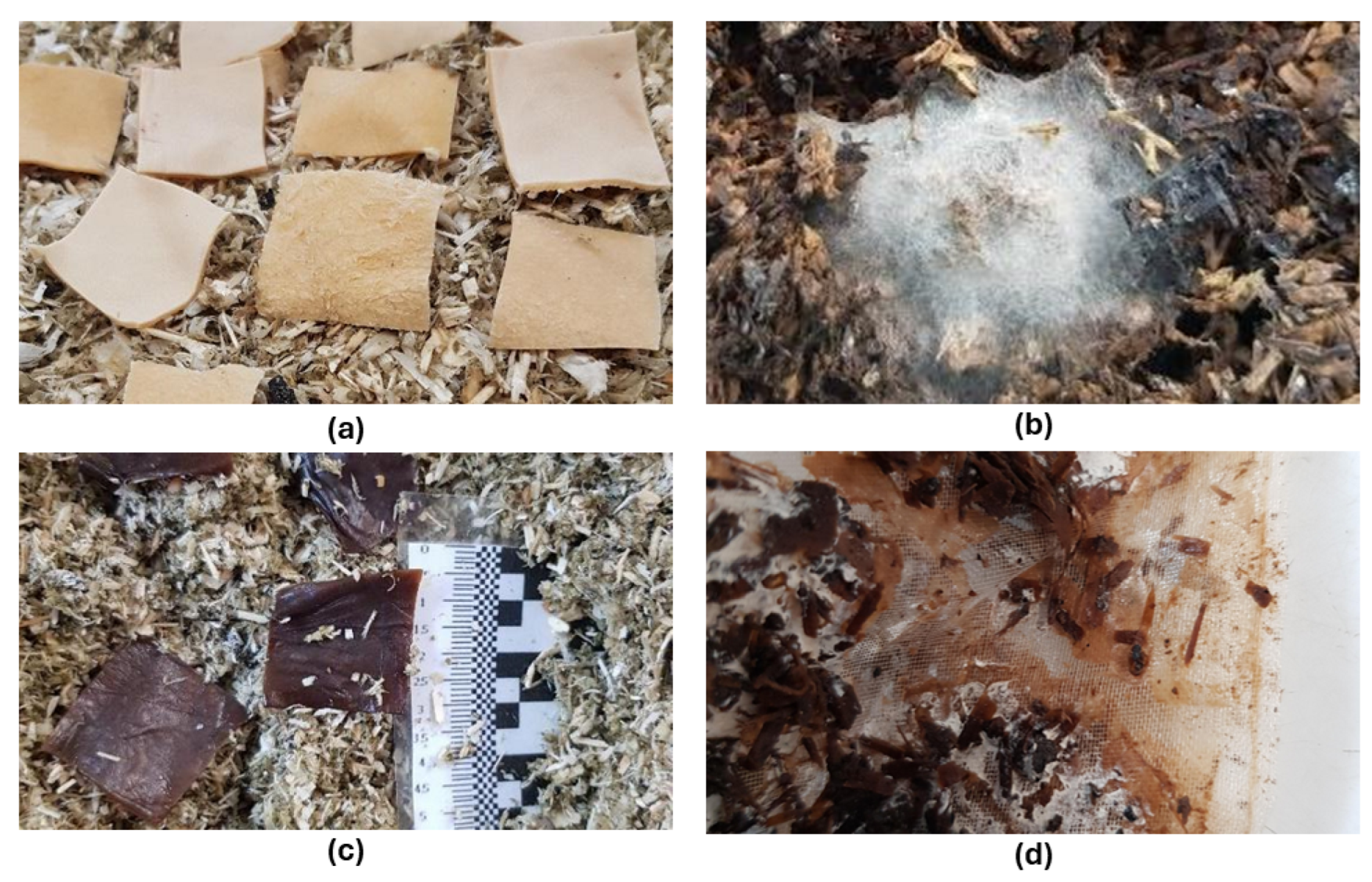

Figure 1 and

Figure 2 show the difference in the extent of disintegration between materials that disintegrated rapidly (B and M) and those that disintegrated more slowly (G and H).

Figure 1b and

Figure 1d show the material was overwhelmed by fungal mycelium and the skeletal fibrous material had been dissolved by abiotic and biotic effects.

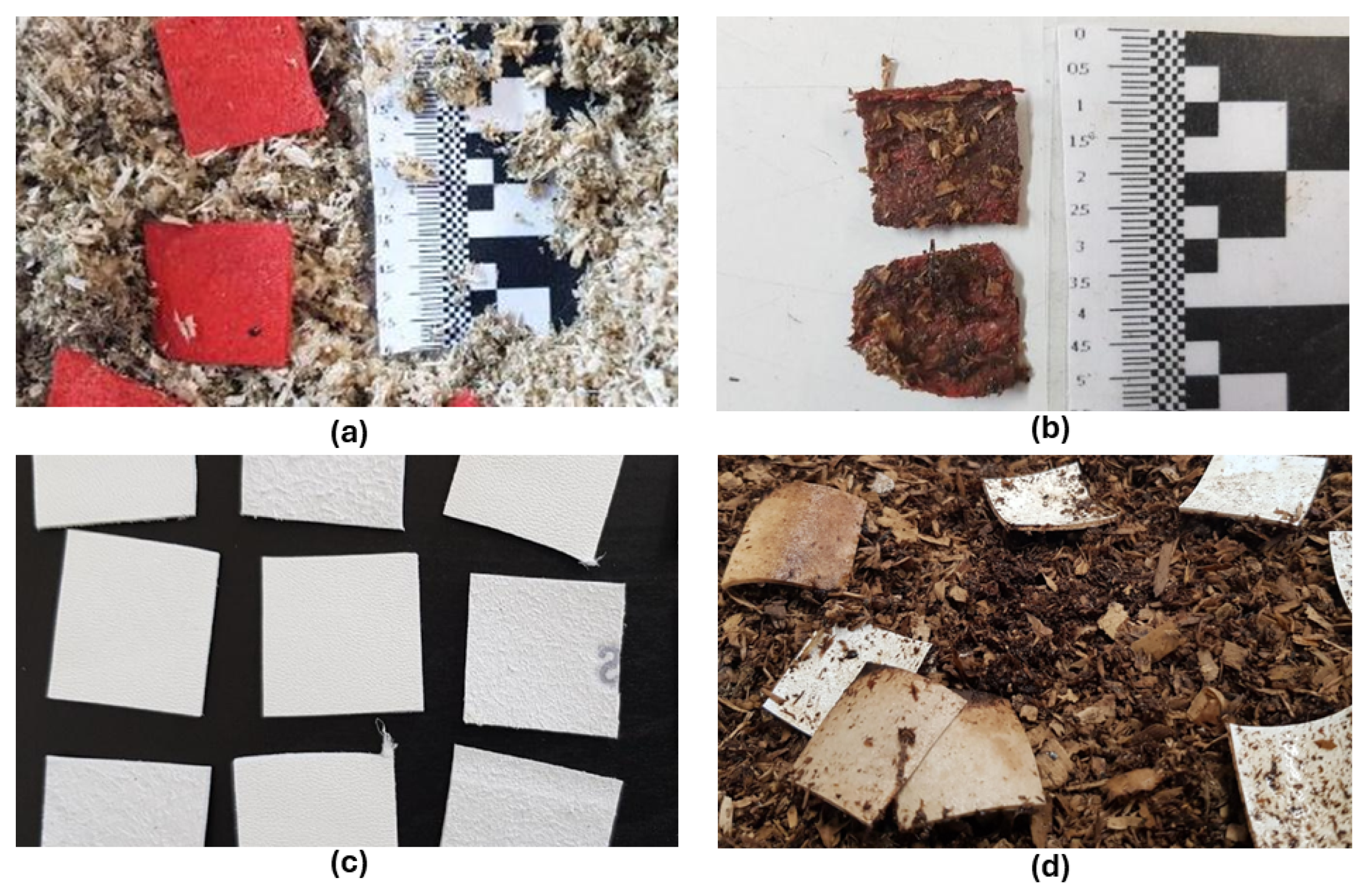

Figure 2 shows Piñatex® and the PU coated textile do not disintegrate as rapidly as those given in

Figure 1. After 84 days in thermophilic conditions both materials were fully intact. Piñatex® showed a similar breakdown to the cellulosic material used in the positive control; plant celluloses and hemicelluloses are typically slow to degrade. Piñatex® contains high melting point polylactic acid which could explain its resistance to thermophilic degradation.

Several of the alternative materials showed extensive biodegradation albeit reduced compared to the leather test pieces (excluding L). Desserto® (E), SnapPap® (D), and Piñatex® (G) biodegraded by 48.17%, 51.35% and 59.84%, respectively. However, the other alternative materials showed limited biodegradability, with the textile-coated PU (H) almost entirely unchanged over the test period with only 0.94% relative biodegradation.

3.2. Determination of Biodegradability

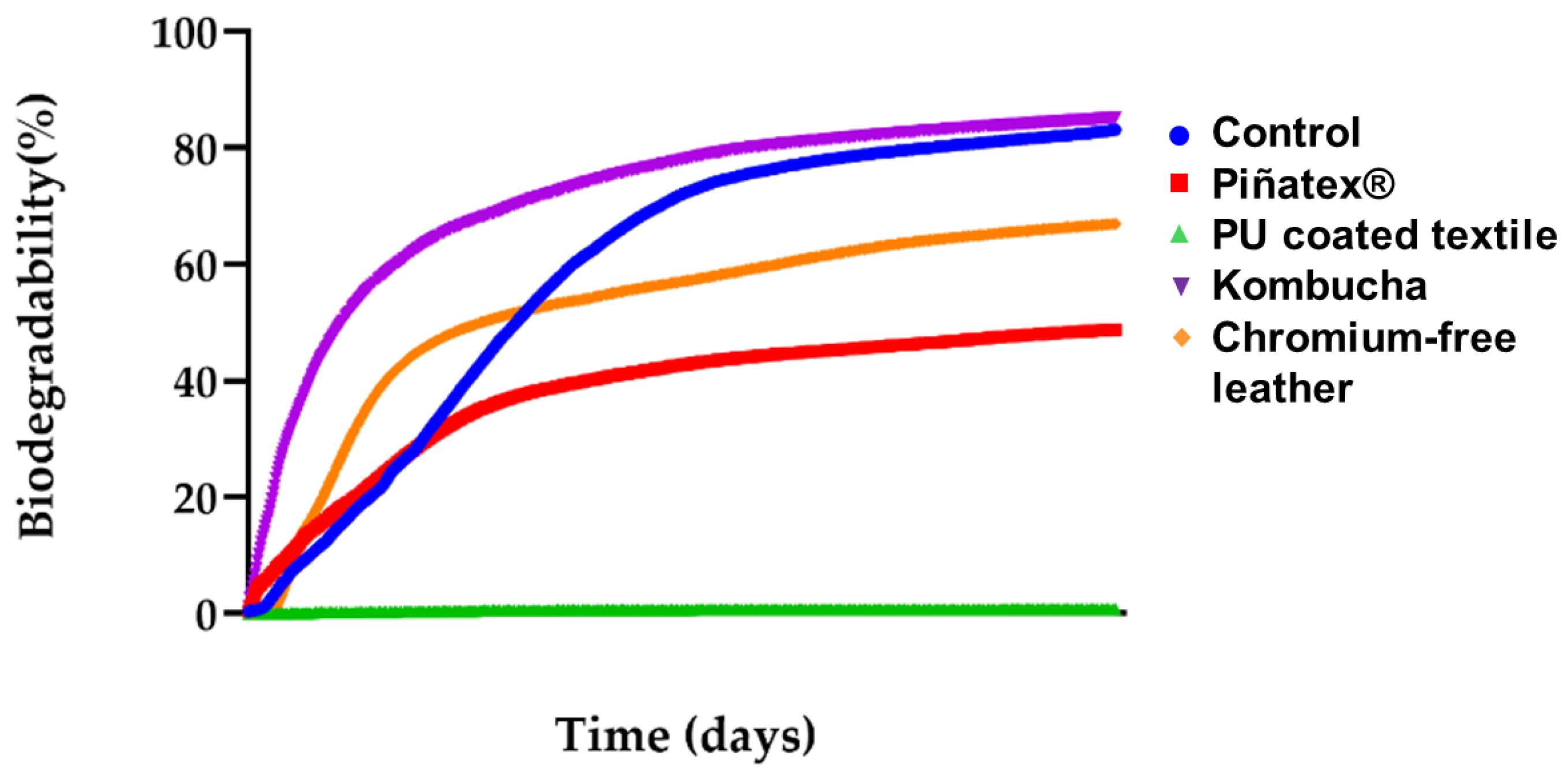

The determinations of biodegradability of the test materials using ISO 20136 were deemed to be viable. The results are shown in

Table 3 and

Figure 3.

The degradation profiles were very similar to those observed in the assessment of disintegration. Kombucha (B) showed the highest degree of biodegradation and exceeded the control collagen specimen in terms of absolute biodegradation. As previously observed, the vegetable-tanned leather (L) showed limited biodegradability of 26.19% relative to the control. However, the trend noted in the disintegration trial was repeated here, with the other leather test pieces (J, K, and M), showing higher potential for biodegradation than the alternative materials. The chromium-free leather (M) biodegraded by over 80% and notably, the shoe upper leather (J) showed a slightly higher degree of biodegradation than the chromium-tanned leather (K); 66.64% versus 64.25%.

The biodegradation profiles of some the test materials are shown in

Figure 3. Notably, the rate of biodegradation of kombucha was much higher than the collagen control up to day 7, and then slowed. All the described materials showed a common profile of rapid initial biodegradation followed by slowing to a plateau. As noted, almost no biodegradation of the PU-coated textile was recorded.

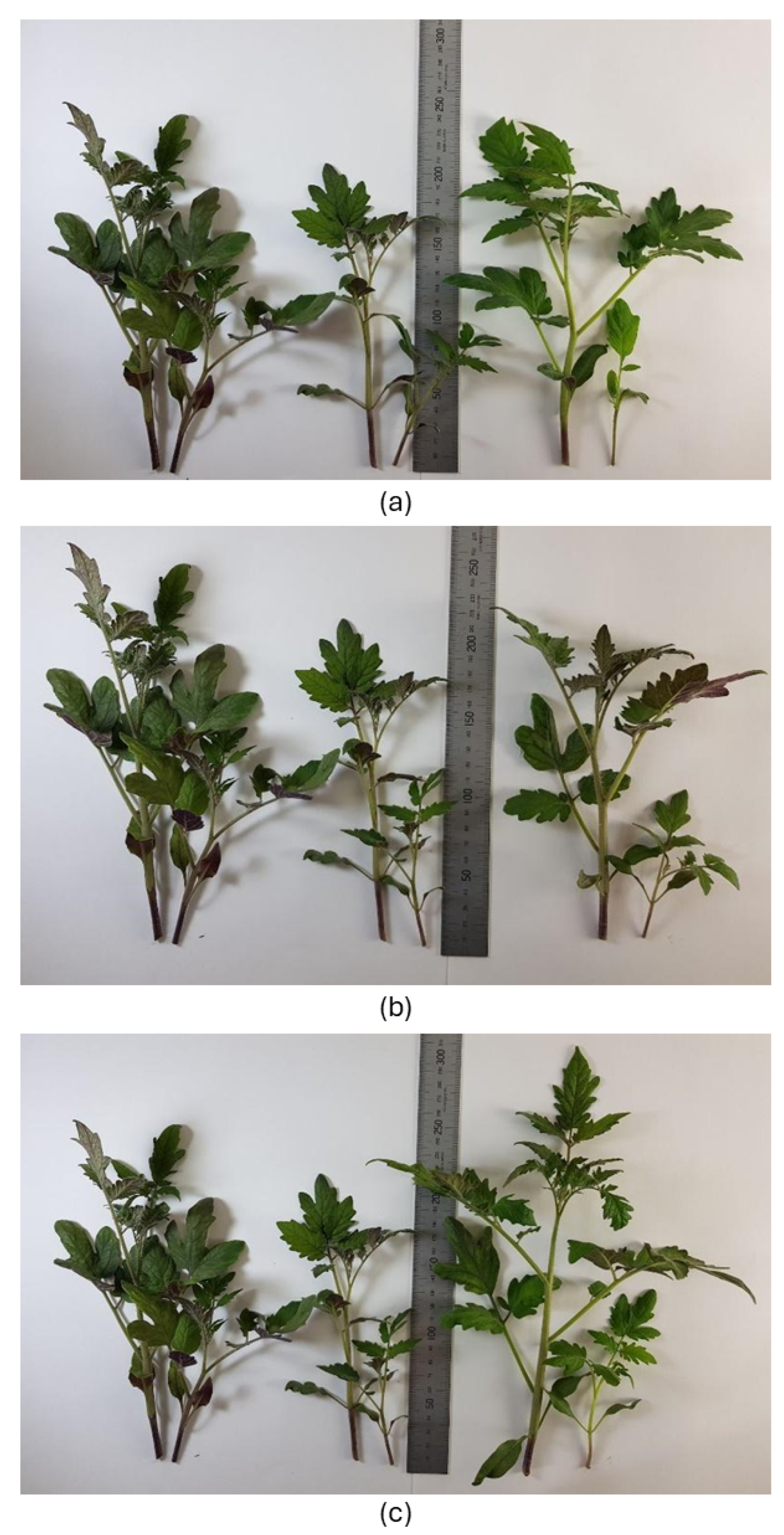

3.3. Plant Response Test

The plants in the blank substrate grew and germinated more than the minimum required, allowing the test to be deemed viable. The vitality of the plants grown in all three leather composts were more than the blank and negative control substrates, with a more green colour, and full bushy growth (not shown) being observed in the test plants. No plant anomalies were detected in the test plants or the blank/control, suggesting none of the substrates were causing stunting, necrotic, chlorotic, or other colour anomalies. No leaf or stem deformations were observed. The plant growth for the three leather composts are given in

Figure 4. The test plants are compared against the blank and control in each frame.

The blank, negative, and all three test trays germinated at a 96.67% germination rate. indicating that there was no germination difference between the controls and the test substrates. The test plants grown in the vegetable-tanned and chromium-free leather composts grew more than plants grown in the blank substrate when comparing the mean top growth fresh mass per plant, see

Table 4.

The plants grown in vegetable tanned leather showed the highest rate of additional fresh top mass growth of all of the tests, with 74% additional leaf and stem matter than the control.

3.4. Soil Ecotoxicity

The composts produced from the three leather types were screened for 200 common soil contaminants including:

Contaminating metals;

Polycyclic aromatic hydrocarbons;

Volatile halogenated hydrocarbons;

Chlorophenols;

Pesticides;

Phthalate esters; and

Extractable petroleum hydrocarbons.

Table 5 shows the detectable substances found in the leather composts. Most soil contaminants screened for were below the levels of detection. Of the substances that were detectable, the majority were also present in the control indicating that were associated with the non-leather components of the compost.

The exception was the high levels of chromium detected in the compost made from chromium-tanned leather where concentrations of 5500 ppm of total chromium were detected.

4. Discussion

Growing awareness and emerging regulation are creating ever greater imperatives for the use of materials that can be part of the circular economy and/or will degrade rapidly and harmlessly in the environment. The ability to utilise a material for the production of compost offers one route to circularity. The work presented evaluated the disintegration and biodegradability of leathers tanned using the three most common tanning processes and a range of âtrendyâ alternatives often presented as sustainable alternatives to leather. The results confirm those reported by Sardroudi

et al. (2024) [

6] and expand the scope of materials analysed to include those evaluated by Meyer and Carcione [

4,

5]. The functional perfomance of the same alternatives and their bio-based content were analysed by Meyer

et al. (2021) and Carcione

et al. (2023), respectively, and this work adds to the understanding on relevant factors underlying any claim for the sustainability of those materials.

The analysis revealed a clear trend of leather having a higher propensity for disintegration than the alternatives. This trend was repeated when the test materials were analysed for the aquatic biodegradability. The notable exceptions were kombucha and Piñatex®, which showed high degrees of disintegration and biodegradation, and vegetable tanned leather, which was largely resistant to degradation.

These apparent aberrations are most likely linked to the composition of the materials. The kombucha test piece was unfinished and contained 100% bio-based content (Carcione

et al., 2023) [

5]. However, as shown by Meyer it also lacked any functionality that would allow for its use in products. It would be expected that the addition of the necessary backers and coatings would see the potential for disintegration fall markedly. This would be in line with the high content of fossil fuel-based components in those alternative materials that showed any degree of functional performance (Carcione

et al., 2023). In contrast to this was the very limited disintegration of Muskin®, an untreated mycelium product, which may be connected to the chemical modification to the base natural material

.

The good performance of Piñatex® in both tests was also likely to be a function of its composition of pineapple leaf matter bonded with polylactic acid (PLA). PLA is a bioplastic and reported to biodegrade in industrial composting scenarios (Fogašová

et al., 2022) which would make Piñatex® susceptible to biodegradation [

17].

Both chromium-free and chromium tanned leather showed high degrees of biodegradability and disintegration. The shoe upper leather test piece showed a reduced susceptibility to both processes and this was probably due to the presence of finishing chemicals on the leather. The vegetable tanned leather was largely unaffected by either process which may be due to the nature of the tannins, which are comprised of large polyphenolic compounds which limit access of the microorganisms responsible for composting and biodegradation. These results show that while leather largely outperforms the alternatives, there is scope to increase the compostability and biodegradability of leather. Leather tanned with newer technologies like zeolites, triose, or aluminium silicates and finished with biobased finishing chemicals may prove to be more biodegradable. Indeed, Sardroudi

et al. (2024) found that leathers produced using alginate-based chemicals and zinc oxide composted more quickly than conventionally tanned leathers [

6].

The capacity to form composts has little relevance if they are not appropriate for the use in the enrichment of soils and supporting plant growth. The use of leathers produced using the three main categories of tanning agent was evaluated for both support of plant growth and content of common soil contaminants. The results show that composts produced from a chromium-free leather and vegetable tanned leather enhanced plant growth compared to the control, with the vegetable tanned leather compost increasing growth by over 76% despite showing only limited disintegration over the duration of the test period. Neither of these composts contained significant levels of contaminants, with most measured contaminants below the level of detection. Those that were detected appeared to be largely linked to the non-leather components of the compost as shown by the higher levels in control.

Sardroudi

et al. (2024) also found that vegetable tanned leather showed limited (or slowed rates of) biodegradability as well as disintegration [

6]. It is possible that the compost containing partially degraded vegetable tanned leather acts as a slow-release source of nutrients for plant growth. It may also be that the vegetable tanned leather in the compost acts to retain and control moisture levels. Further research would be necessary to understand the mechanic by which vegetable leather enhances growth. Nonetheless this strongly suggests that these leathers would be appropriate materials to produce commercial composts. However, it must be noted that the leathers used had not been finished and it is possible that the performance of these leathers would be affected by the addition of finishing chemicals, as indicated by the slightly lower degree of disintegration and biodegradation shown by the shoe upper leather test piece.

In contrast levels of 5500 ppm of total chromium were detected in the compost produced using chromium-tanned leather. It is worth noting that the relatively high levels of chromium in the compost was also reflected in the plant growth, with the fresh top mass of the plants grown in chromium-containing compost being 22% less than the control. The extent to which the plants grown in chromium leather compost are reduced suggests that chromium has phytotoxic effects on plant growth. The potential for phytotoxic effects of chromium has been previously reported [

18].

The chromium content of composts is subject to varying requirements. The EU regulation laying down rules on the making available on the market of EU fertilising products (EU 2021/1768) requires that where an EU fertilising product contains total chromium above 200 mg/kg dry matter, information about the maximum quantity and exact source of total chromium must be given [

19]. The EU Ecolabel criteria for growing media and soil improvers ((EU) 2022/1244) limits total chromium content of composts to 100 mg/kg of dry matter [

20]. As such, the use of chromium-containing materials is not prohibited but must be given consideration. However, it is clear that composts with a chromium content of that measured by this work would not be appropriate for use to enhance soils. This suggests that composting would not be a viable option for circularity of chromium-tanned leather, without pretreatment or mixing with other materials.

5. Conclusions

Soil and its fertilisation is central to a healthy bioeconomy, but faces increasing concerns with regard to soil and nutrient depletion [

21,

22,

23]. Nutrient for soils needs to be sought in different places and the use of composts from a variety of sources should be part of the potential offer.

The data presented here has shown that vegetable tanned, and non-chrome tanned leather are suitable for composting and integration into the biocircular economy with good disintegration and biodegradability performance. Furthermore, both leather types supported greater plant growth compared to the control. In contrast, while chromium-tanned leather was readily disintegrated, the chromium content of the resulting compost was found to impede plant growth.

Similarly, some trendy materials also showed good potential for disintegration albeit that for the most readily degradable, kombucha, was in an unfinished, native state that would not be appropriate for use in products. It is likely that the use of the necessary binders and finishing chemicals would negatively impact on its degradability. Overall, the other trendy materials tested showed poor biodegradation rates. Furthermore, they may pose potential microplastics risks when they do disintegrate due to the fossil carbon embedded within their constituents.

Materials like Noani®, Teak Leaf®, Desserto®, Appleskin®, and Muskin® would pose serious problems for composting systems and were found to have low breakdown rates in biodegradability testing, suggesting that they would persist in the environment. Many of these materials in this study have been made into composites with polyurethanes which has negatively affected their disintegration and biodegradability.

The results show that through its capacity to produce useful composts, leather has the potential to contribute to the circular economy. In contrast, the trendy alternatives had a very limited capacity for biodegradation and would create further waste issues at the end of their life.

Author Contributions

Conceptualization, K. Flowers; Methodology, K. Flowers and I. Flowers; Formal analysis, K. Flowers and I. Flowers; writing—original draft preparation, K. Flowers .; writing—review and editing, I. Flowers. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

We thank all the material suppliers and supporters of this project.

Conflicts of Interest

The authors declare no conflict of interest

References

- European Commission, Directorate-General for Communication. Circular economy action plan : for a cleaner and more competitive Europe. Publications Office of the European Union. Available online: https://data.europa.eu/doi/10.2779/05068 (accessed on 15 February 2024).

- European Commission. Council Regulation (EU) 2024/1781 of the European Parliament and of the Council of 13 June 2024 establishing a framework for the setting of ecodesign requirements for sustainable products, amending Directive (EU) 2020/1828 and Regulation (EU) 2023/1542 and repealing Directive (EU) 2009/125. OJEU 2024, L 2024/1781, 1–89.

- European Commission, Council directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on waste and repealing certain Directives. OJEU 2024, L312, 3–30.

- Meyer, M., Dietrich, S, Schulz, H., and Mondschein, A. Comparison of the technical performance of leather, artificial leather, and trendy alternatives. Coatings 2021, 11, 226-240.

- Carcione, F., Defeo, G.A., Galli, I., Bartalini, S., and Mazzotti, D. Material Circularity: A novel method for biobased quantification of leather, artificial leather, and trendy alternatives. Coatings 2023, 13, 892-903.

- Sardroudi, N.P., Sorolla, S., Casas, C., and Bacardit, A. A study of the composting capacity of different kinds of leathers, leatherette and alternative materials. Sustainability-Basel 2024, 16, 2324-2335.

- CEN. BS EN 13432: 2000. Packaging. Requirements for packaging recoverable through composting and biodegradation. Test scheme and evaluation criteria for the final acceptance of packaging; CEN-CENELEC: Brussels, Belgium, 2000.

- CEN. BS EN 14995: 2006. Plastics. Evaluation of compostability. Test scheme and specifications; CEN-CENELEC: Brussels, Belgium, 2006.

- CEN. BS EN ISO 20200: 2023. Plastics. Determination of the degree of disintegration of plastic materials under composting conditions in a laboratory-scale test; CEN-CENELEC: Brussels, Belgium, 2023.

- CEN. BS EN ISO 20136: 2020. Leather. Determination of degradability by micro-organisms; CEN-CENELEC: Brussels, Belgium, 2020.

- ISO. ISO 8245:1999. Water quality â Guidelines for the determination of total organic carbon (TOC) and dissolved organic carbon (DOC);International Standards Organisation: Geneva, Switzerland, 1999.

- REAL. REAL CCS 3.1:2015. Methods for testing plant response to composted material and its contamination by weed seeds and propagules. October 2015. Method code: OFW004-006;Renewable Energy Assurance Limited (REAL): London, UK, 2015.

- CEN. BS EN 13038:2011. Soil improvers and growing media - Determination of electrical conductivity;CEN-CENELEC: Brussels, Belgium, 2011.

- CEN. BS EN 13654-2:2001. Soil improvers and growing media. Determination of nitrogen - Dumas method;CEN-CENELEC: Brussels, Belgium, 2001.

- CEN. BS EN 13650:2001. Soil improvers and growing media. Extraction of aqua regia soluble elements;CEN-CENELEC: Brussels, Belgium, 2001.

- CEN. BS EN ISO 17294-2:2016. Water quality. Application of inductively coupled plasma mass spectrometry (ICP-MS);CEN-CENELEC: Brussels, Belgium, 2016.

- FogaÅ¡ová, M., Figalla, S., DaniÅ¡ová, L., Medlenová, E., HlaváÄiková, S., VanovÄanová, Z., Omanà ková, L., Baco, A., Horváth, V., Mikolajová, M., Feranc, J., BoÄkaj, J., Plavec, R., Alexy, P., Repiská, M., PÅikryl, R., Kontárová, S., Báreková, A., Sláviková, M., Koutný, M., Fayyazbakhsh, A., and KadleÄková, M. M. PLA/PHB-based materials fully biodegradable under both industrial and home-composting conditions. Polymers-Basel 2022, 14, 4113–4133.

- Dey, S.R., Sharma, M., and Kumar, P. Effects and responses of chromium on plants. In Chromium in plants and environment; Kumar, N., Walther, C., , and Gupta, D.K. Eds.; Springer Cham: Cham, Switzerland, 2023; pp. 385-427.

- European Commission. Commission Delegated Regulation (EU) 2021/1768 of the European Parliament and of the Council of 23 June 2021 amending, for the purpose of its adaptation to technical progress, annexes I, II, II, and IV to regulation (EU) 2019/1009 of the European Parliament and of the Council laying down rules on the making available on the market of EU fertilising products. OJEU 2021, L 356, 8–23.

- European Commission, Commission Decision (EU) 2022/1244 of the European Parliament and of the Council of 13 July 2022 establishing the EU ecolabelling criteria for growing media and soil improvers. OJEU 2022, L 190, 141–165.

- Wassen, M.J., Schrader, J., Eppinga, M.B., Sardans, J., Berendse, F., Beunen, R., Peñuelas, J., and van Dijk, J. The EU needs a nutrient directive. Nat. Rev. Earth Environ. 2022, 14, 287-288. [CrossRef]

- Panagos, P., Köningner, J., Ballabio, C., Liakos, L., Muntwyler, A., Borrelli, P., and Lugato, E. The EU needs a nutrient directive. Sci. Total Environ. 2022, 853, 158706-158723.

- Panagos, P., Montanarella, L., Barbero, M., Schneegans, A., Aguglia, L., and Jones, A. The EU needs a nutrient directive. Geoderma Regional 2022, 29, 510-513.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).