Submitted:

12 August 2024

Posted:

13 August 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Chemicals

2.2. Hop sample analysis

2.3. Brewing test

2.4. Beer sample analysis

2.5. Sensory analysis of beer

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

References

- Vent, L. Osvaldův odkaz. Chmelařství 1999, 72, 13–15. [Google Scholar]

- Mikyška, A.; Slabý, M.; Jurková, M.; Krofta, K.; Patzak, J.; Nesvadba, V. Saaz Late - The Czech Hop Variety Recommended for Czech Beer. Kvasny Prum. 2013, 59, 296–305. [Google Scholar] [CrossRef]

- Nesvadba, V.; Charvátová, J. New fine aroma varieties of hops (Humulus lupulus L.) Saaz Brilliant, Saaz Comfort, Saaz Shine and Mimosa. Kvasny Prum 2020, 66, 320–330. [Google Scholar] [CrossRef]

- Olšovská, J.; Straková, L.; Nesvadba, V.; Vrzal, T.; Malečková, M.; Patzak, J.; Donner, P.; Cerkal, R. Saaz – fine aroma hop pedigree. A review of current knowledge. A review of current knowledge. Beverages 2024, submitted.

- Eyres, G.T.; Marriott, P.J.; Dufour, J.P. Comparison of odor-active compounds in the spicy fraction of hop (Humulus lupulus L.) essential oil from four different varieties. J. Agric. Food Chem. 2007, 55, 6252–6261. [Google Scholar] [CrossRef]

- Goncalves, J.; Figueira, J.; Rodrigues, F.; Camara, J.S. Headspace solid-phase microextraction combined with mass spectrometry as a powerful analytical tool for profiling the terpenoid metabolomic pattern of hop-essential oil derived from Saaz variety. J. Sep. Sci. 2012, 35, 2282–2296. [Google Scholar] [CrossRef] [PubMed]

- Kishimoto, T.; Wanikawa, A.; Kono, K.; Shibata, K. Comparison of the odor-active compounds in unhopped beer and beers hopped with different hop varieties. J. Agric. Food Chem. 2006, 54, 8855–8861. [Google Scholar] [CrossRef] [PubMed]

- Lermusieau, G.; Bulens, M.; Collin, S. Use of GC-olfactometry to identify the hop aromatic compounds in beer. J. Agric. Food Chem. 2001, 49, 3867–3874. [Google Scholar] [CrossRef]

- Mikyška, A.; Olšovská, J.; Slabý, M.; Štěrba, K.; Čerenak, A.; Košir, I.J.; Pavlovič, M.; Kolenc, Z.; Krofta, K. Analytical and sensory profiles of Slovenian and Czech hop genotypes in single hopped beers. J. Inst. Brew. 2018, 124, 209–221. [Google Scholar] [CrossRef]

- Mikyška, A.; Štěrba, K.; Slabý, M.; Nesvadba, V.; Charvátová, J. Brewing tests of new fine aroma hop varieties (Humulus lupulus L.) Saaz Brilliant, Saaz Comfort and Saaz Shine. Kvasny Prum. 2021, 67, 464–473. [Google Scholar] [CrossRef]

- Štěrba, K.; Čejka, P.; Čulík, J.; Jurková, M.; Krofta, K.; Pavlovič, M.; Mikyška, A.; Olšovská, J. Determination of Linalool in Different Hop Varieties Using a New Method Based on Fluidized-Bed Extraction with Gas Chromatographic-Mass Spectrometric Detection. J. Am. Soc. Brew. Chem. 2015, 73, 151–158. [Google Scholar] [CrossRef]

- Analytica EBC. 7.7 – α- and β-Acids in Hops and Hop Products by HPLC. Available online: https://brewup.eu/ebc-analytica/hops-and-hop-products/and-acids-in-hops-and-hop-products-by-hplc7/7.7 (accessed on 12 July 2024).

- Analytica EBC. 9.2.6 – Alcohol in Beer by Near Infrared Spectroscopy. Available online: https://brewup.eu/ebc-analytica/beer/alcohol-in-beer-by-near-infrared-spectroscopy/9.2.6 (accessed on 12 July 2024).

- Analytica EBC. 9.4 – Original, Real and Apparent Extract and Original Gravity of Beer. Available online: https://brewup.eu/ebc-analytica/beer/original-real-and-apparent-extract-and-original-gravity-of-beer/9.4 (accessed on 12 July 2024).

- Analytica EBC. 9.6 – Colour of beer: Spectrophotometric Method. Available online: https://brewup.eu/ebc-analytica/beer/colour-of-beer-spectrophotometric-method-im/9.6 (accessed on 12 July 2024).

- Analytica EBC. 9.8 – Bitterness of Beer. Available online: https://brewup.eu/ebc-analytica/beer/bitterness-of-beer-im/9.8 (accessed on 12 July 2024).

- Sparkman, O.D.; Penton, Z.; Kitson, F.G. Gas Chromatography and Mass Spectrometry: A Practical Guide, 2nd ed.; Academic Press: Cambridge, MA, USA, 2011. [Google Scholar]

- Rigby, F.L.A. Theory on the Hop Flavor of Beer. Proc. Am. Soc. Brew. Chem. 1972, 30, 46–50. [Google Scholar] [CrossRef]

- Ono, M.; Kakudo, Y.; Yamamoto, Y.; Nagami, K.; Kumada, J. Quantitative Analysis of Hop Bittering Components and its Application to Hop Evaluation. J. Am. Soc. Brew. Chem. 1984, 42, 167–172. [Google Scholar] [CrossRef]

- Irwin, A.J.; Murray, C.R.; Thompson, D.J. An Investigation of the Relationships between Hopping Rate, Time of Boil, and Individual Alpha-Acid Utilization. J. Am. Soc. Brew. Chem. 1985, 43, 145–152. [Google Scholar] [CrossRef]

- Jacobsen, T.; Hage, T.; Kristensen, R.; Malterud, K.E. Hop Utilization in the Brewery—An Interbrewery Comparison. J. Am. Soc. Brew. Chem. 1989, 47, 62–67. [Google Scholar] [CrossRef]

- Jaskula, B.; Kafarski, P.; Aerts, G.; De Cooman, L. A kinetic study on the isomerization of hop alpha-acids. J. Agric. Food Chem. 2008, 56, 6408–6415. [Google Scholar] [CrossRef] [PubMed]

- Protsenko, L.; Ryzhuk, S.; Liashenko, M.; Shevchenko, O.; Litvynchuk, S.; Yanse, L.; Milosta, H. Influence of alpha acids hop homologues of bitter and aromatic varieties on beer quality. Ukr. Food J. 2020, 9, 425–436. [Google Scholar] [CrossRef]

- Rettberg, N.; Biendl, M.; Garbe, L.A. Hop Aroma and Hoppy Beer Flavor: Chemical Backgrounds and Analytical Tools-A Review. J. Am. Soc. Brew. Chem. 2018, 76, 1–20. [Google Scholar] [CrossRef]

- Lermusieau, G.; Collin, S. Varietal discrimination of hop pellets. II. Comparison between fresh and aged samples. J. Am. Soc. Brew. Chem. 2001, 59, 39–43. [Google Scholar] [CrossRef]

- Jaskula-Goiris, B.; Aerts, G.; De Cooman, L. Hop α-acids isomerisation and utilisation: an experimental review. Cerevisia 2010, 35, 57–70. [Google Scholar] [CrossRef]

- Haley, J.; Peppard, T.L. Differences in Utilization of the Essential Oil of Hops during the Production of Dry-Hopped and Late-Hopped Beers. J. Inst. Brew. 1983, 89, 87–91. [Google Scholar] [CrossRef]

- Fritsch, H.T.; Schieberle, P. Identification based on quantitative measurements and aroma recombination of the character impact odorants in a Bavarian Pilsner-type beer. J. Agric. Food Chem. 2005, 53, 7544–7551. [Google Scholar] [CrossRef] [PubMed]

- Peppard, T.L.; Ramus, S.A.; Witt, C.A.; Siebert, K.J. Correlation of Sensory and Instrumental Data in Elucidating the Effect of Varietal Differences on Hop Flavor in Beer. J. Am. Soc. Brew. Chem. 1989, 47, 18–26. [Google Scholar] [CrossRef]

- Liu, Z.C.; Liu, Y.M.; Wang, L.P. Investigation of Stereoisomer Distribution and Thermochemical Conversion of Eight Terpene Alcohols Derived from Different Varieties of Chinese Hops (Humulus lupulus L.). J. Am. Soc. Brew. Chem. 2020, 78, 185–194. [Google Scholar] [CrossRef]

- Muramatsu, M.; Ohto, C.; Obata, S.; Sakuradani, E.; Shimizu, S. Alkaline pH enhances farnesol production by Saccharomyces cerevisiae. J. Biosci. Bioeng. 2009, 108, 52–55. [Google Scholar] [CrossRef]

- Foster, R.T.; Nickerson, G.B. Changes in Hop Oil Content and Hoppiness Potential (Sigma) during Hop Aging. J. Am. Soc. Brew. Chem. 1985, 43, 127–135. [Google Scholar] [CrossRef]

- Forster, A.; Gahr, A.; Van Opstaele, F. On the Transfer Rate of Geraniol with Dry Hopping. Brew. Sci. 2014, 67, 60–62. [Google Scholar]

- Kollmannsberger, H.; Biendl, M.; Nitz, S. Occurrence of glycosidically bound flavour compounds in hops, hop products and beer. Monatsschr. Brauwiss. 2006, 59, 83–89. [Google Scholar]

- Biendl, M.; Engelhard, B.; Forster, A.; Gahr, A.; Lutz, A.; Mitter, W.; Sch, R. Hops – Their Cultivation, Composition and Usage, 1st ed.; Fachverlag Hans Carl: Nürnberg, Germany, 2015. [Google Scholar]

| Essential oil | Absolute Recovery | Correction Factor | LOD | LOQ | Relative Uncertainty |

|---|---|---|---|---|---|

| (%) | (mg/kg) | (mg/kg) | (%) | ||

| Isobutyl isobutyrate | 87.3 | - | 0.98 | 3.25 | 20.0 |

| Methyl hexanoate | 87.7 | - | 0.16 | 0.54 | 25.0 |

| α-Pinene | 78.9 | - | 1.42 | 4.75 | 25.0 |

| Isoamyl isobutyrate | 98.6 | - | 0.30 | 1.01 | 25.0 |

| Methyl heptanoate | 96.0 | - | 0.60 | 2.00 | 25.0 |

| 2-Nonanone | 157.3 | 0.64 | 0.70 | 2.34 | 25.0 |

| Linalool | 166.8 | 0.60 | 0.94 | 3.13 | 15.0 |

| Methyl octanoate | 93.9 | - | 0.79 | 2.64 | 25.0 |

| Methyl nonanoate | 88.9 | - | 1.02 | 3.41 | 25.0 |

| (Z)-Geraniol (Nerol) | 101.7 | - | 1.48 | 4.92 | 25.0 |

| (Z)-Methyl geranate | 96.5 | - | 0.88 | 2.94 | 10.0 |

| 2-Undecanone | 94.0 | - | 2.29 | 7.64 | 10.0 |

| Geranyl acetate | 96.7 | - | 1.92 | 6.39 | 25.0 |

| 2-Dodecanone | 105.8 | - | 0.96 | 3.20 | 15.0 |

| α-Ionone | 107.7 | - | 2.23 | 7.42 | 25.0 |

| β-Caryophyllene | 70.0 | 1.43 | 1.73 | 5.76 | 10.0 |

| (E)-β-Farnesene | 82.0 | - | 1.76 | 5.86 | 10.0 |

| α-Irone | 116.0 | - | 0.53 | 1.77 | 25.0 |

| β-Caryophyllene oxide | 96.8 | - | 1.78 | 5.92 | 25.0 |

| Farnesole | 91.4 | - | 0.55 | 1.83 | 15.0 |

| β-Pinene | 51.4 | 1.94 | 1.38 | 4.59 | 20.0 |

| Myrcene | 73.7 | 1.36 | 0.71 | 2.38 | 25.0 |

| Limonene | 80.5 | - | 0.52 | 1.74 | 25.0 |

| (E)-β-Ocimene | 81.1 | - | 0.30 | 1.00 | 25.0 |

| 2-Decanone | 119.5 | - | 2.53 | 8.45 | 10.0 |

| Terpinen-4-ol | 100.4 | - | 1.29 | 4.30 | 25.0 |

| α-Terpineol | 96.1 | - | 1.61 | 5.35 | 25.0 |

| Methyl decanoate | 98.4 | - | 0.62 | 2.07 | 10.0 |

| (E)-Methyl geranate | 98.6 | - | 0.67 | 2.22 | 15.0 |

| α-Humulene | 86.5 | - | 0.52 | 1.74 | 20.0 |

| 2-Tridecanone | 101.6 | - | 1.51 | 5.03 | 25.0 |

| β-Ionone | 102.3 | - | 0.85 | 2.85 | 25.0 |

| Variety | Cohumulone (% rel.) | Colupulone (% rel.) | α-acids (wt%) | β-acids (wt%) | α/β | X (wt%) | DMX (wt%) |

|---|---|---|---|---|---|---|---|

| Saaz | 20.59 | 40.66 | 3.84 | 3.94 | 0.97 | 0.34 | 0.06 |

| S. Late | 22.93 | 40.18 | 2.64 | 4.22 | 0.63 | 0.30 | 0.03 |

| S. Brilliant | 21.01 | 42.62 | 3.42 | 2.30 | 1.49 | 0.09 | 0.02 |

| S. Comfort | 18.94 | 42.91 | 3.95 | 3.49 | 1.13 | 0.35 | 0.08 |

| S. Shine | 20.92 | 46.79 | 3.42 | 2.73 | 1.26 | 0.33 | 0.02 |

| Saaz | S. Late | S. Brilliant | S. Comfort | S. Shine | Saaz | |

|---|---|---|---|---|---|---|

| Original extract (% w/w) | 12.6 ± 0.2 | 12.4 ± 0.1 | 12.5 ± 0.0 | 12.3 ± 0.1 | 12.6 ± 0.1 | 12.6 ± 0.2 |

| Alcohol (% v/w) | 5.0 ± 0.2 | 5.0 ± 0.2 | 5.1 ± 0.0 | 5.0 ± 0.1 | 5.1 ± 0.2 | 5.0 ± 0.2 |

| Alcohol (% w/w) | 3.9 ±0.2 | 3.9 ± 0.1 | 4.0 ± 0.0 | 3.9 ± 0.1 | 3.9 ± 0.2 | 3.9 ±0.2 |

| Apparent Extract (% w/w) | 3.2 ± 0.2 | 3.0 ± 0.2 | 2.9 ± 0.0 | 3.0 ± 0.1 | 3.2 ± 0.4 | 3.2 ± 0.2 |

| Real Extract (% w/w) | 5.0 ± 0.1 | 4.8 ± 0.1 | 4.8 ± 0.0 | 4.8 ± 0.1 | 5.0 ± 0.3 | 5.0 ± 0.1 |

| Apparent Attenuation (%) | 74.4 ± 2.0 | 75.5 ± 1.7 | 76.6 ± 0.1 | 75.8 ± 0.1 | 74.7 ± 3.1 | 74.4 ± 2.0 |

| Real Attenuation (%) | 60.1 ± 1.6 | 61.0 ± 1.4 | 62.0 ± 0.0 | 61.0 ± 0.5 | 60.0 ± 2.5 | 60.1 ± 1.6 |

| Bitterness (BU) | 39 ± 1 | 41 ± 1 | 37 ± 1 | 36 ± 1 | 37 ± 2 | 39 ± 1 |

| Color (u. EBC) | 8.9 ± 0.4 | 9.5 ± 0.1 | 9.2 ± 0,0 | 8.5 ± 0.1 | 9.4 ± 0.3 | 8.9 ± 0.4 |

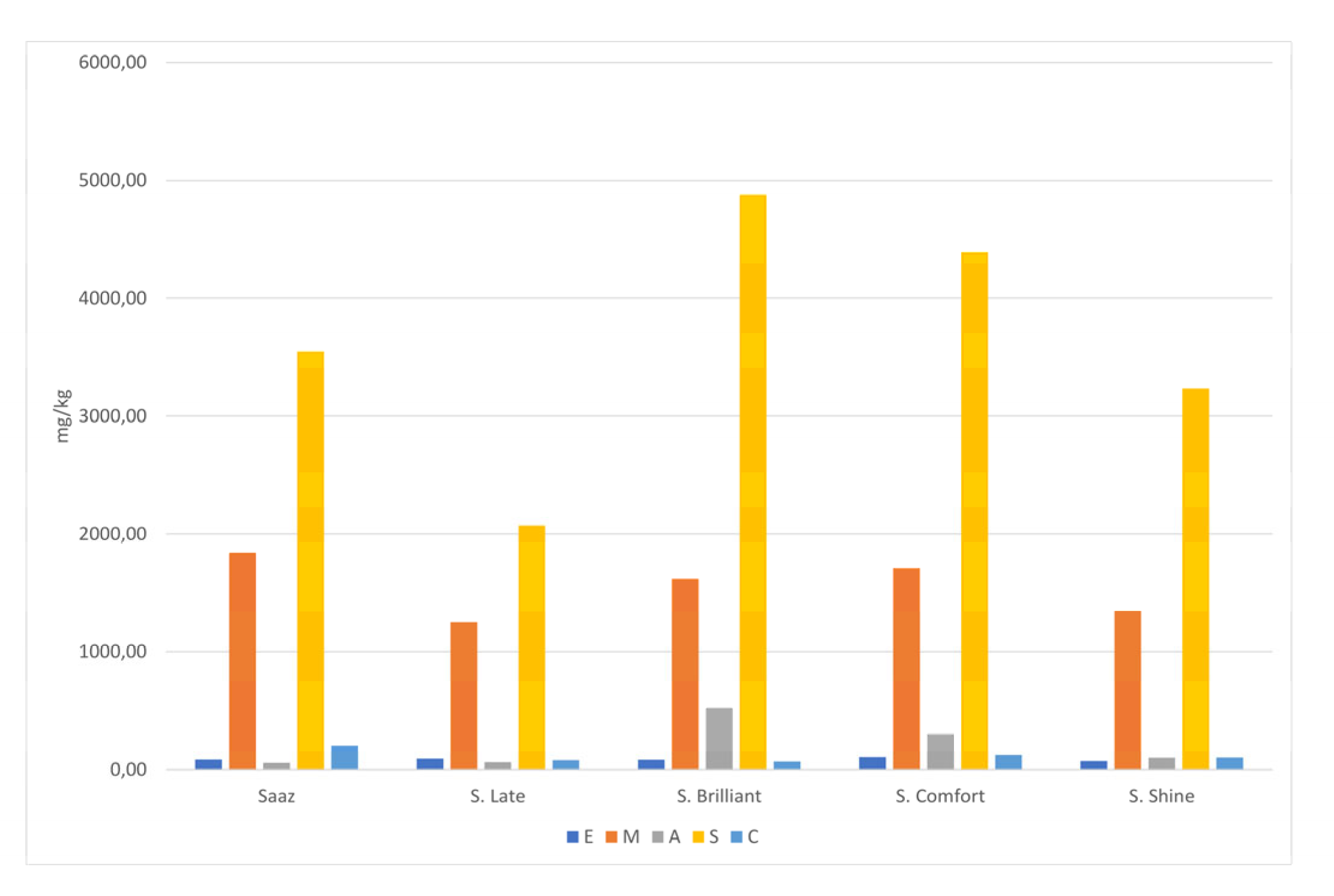

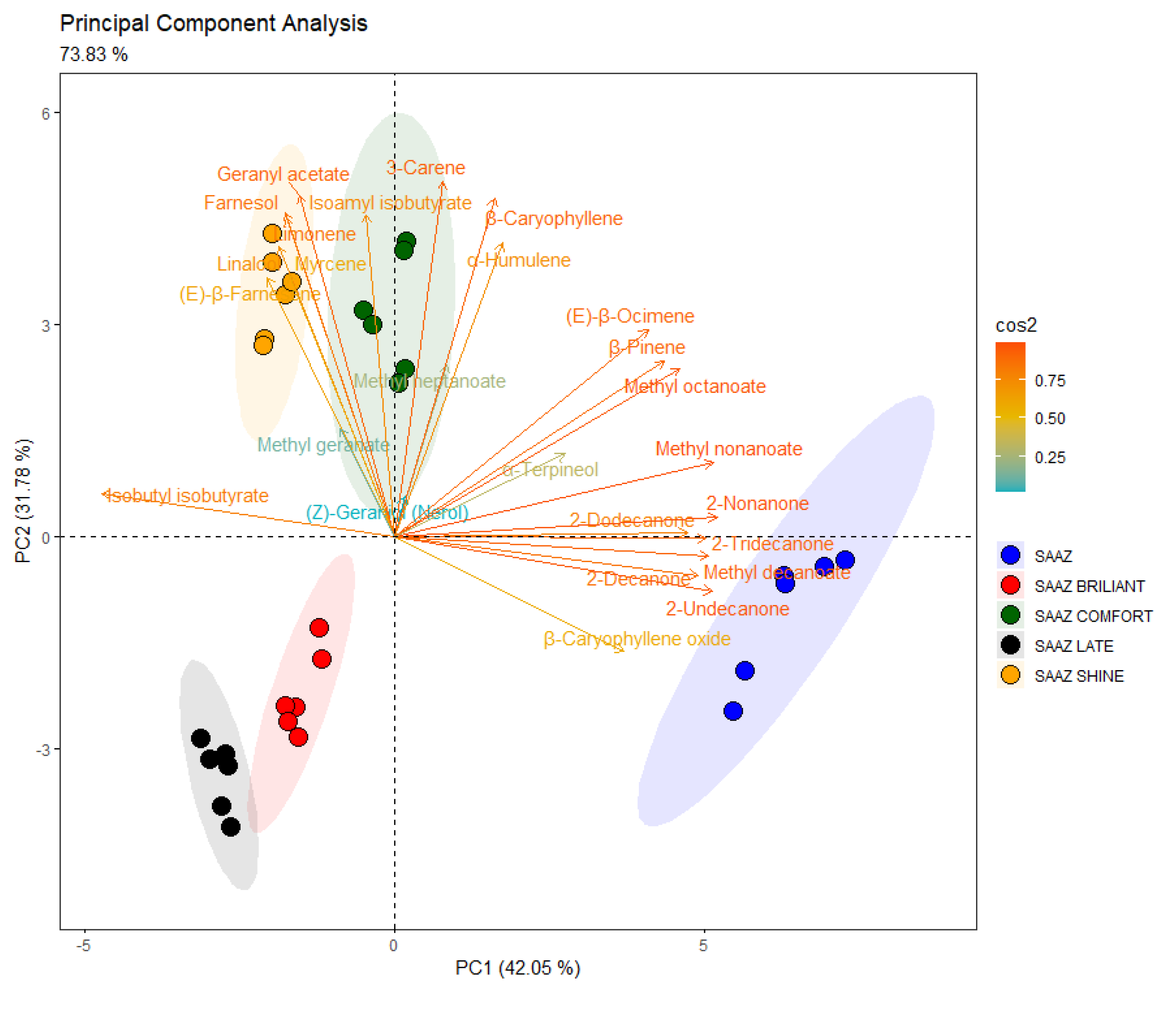

| Saaz | S. Late | S. Brilliant | S. Comfort | S. Shine | |

|---|---|---|---|---|---|

| mg/kg | mg/kg | mg/kg | mg/kg | mg/kg | |

| Isobutyl isobutyrate | 2.04 ± 0.18 | 3.26 ± 0.11 | 3.27 ± 0.15 | 3.16 ± 0.27 | 3.13 ± 0.15 |

| Methyl hexanoate | <0.5 | <0.5 | <0.5 | <0.5 | <0.5 |

| (Z)-Methyl geranate | 3.31 ± 0.08 | 4.93 ± 0.06 | 3.63 ± 0.03 | 3.61 ± 0.11 | 2.65 ± 0.05 |

| Isoamyl isobutyrate | <1.0 | <1.0 | <1.0 | <1.0 | 1.38 ± 0.25 |

| Methyl heptanoate | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 |

| Methyl decanoate | 6.80 ± 0.52 | 3.48 ± 0.35 | 3.25 ± 0.26 | 4.42 ± 0.19 | 3.07 ± 0.24 |

| (E)-Methyl geranate | 65.64 ± 5.16 | 79.71 ± 1.37 | 57.21 ± 1.35 | 87.73 ± 4.54 | 67.50 ± 1.62 |

| Methyl octanoate | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 |

| Methyl nonanoate | <3.0 | <3.0 | <3.0 | <3.0 | <3.0 |

| Geranyl acetate | <3.0 | <3.0 | <3.0 | <3.0 | <3.0 |

| Sum of esters | 75.75 | 91.38 | 67.36 | 98.92 | 77.73 |

| % of esters | 1.3 | 2.6 | 1.4 | 1.5 | 1.1 |

| β-Pinene | 1384.54 ± 170.13 | 778.83 ± 46.80 | 904.48 ± 34.42 | 1138.58 ± 78.01 | 1101.61 ± 83.69 |

| Myrcene | 353.21 ± 32.95 | 398.93 ± 16.31 | 363.21 ± 18.07 | 466.83 ± 33.00 | 418.31 ± 20.25 |

| Limonene | 5.76 ± 0.5 | 6.35 ± 0.54 | 6.03 ± 0.29 | 8.40 ± 1.06 | 8.28 ± 0.53 |

| (E)-β-Ocimene | 61.53 ± 5.73 | 39.26 ± 1.13 | 38.10 ± 2.69 | 55.02 ± 4.50 | 50.44 ± 1.36 |

| 3-Carene | 34.89 ± 2.23 | 27.44 ± 1.83 | 32.37 ± 2.03 | 40.64 ± 2.91 | 41.24 ± 1.01 |

| α-Pinene | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 |

| Sum of monoterpens | 1839.93 | 1250.81 | 1344.19 | 1709.47 | 1619.88 |

| % of monoterpens | 32.1 | 35.2 | 27.7 | 25.8 | 22.6 |

| Terpinen-4-ol | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 |

| α-Terpineol | 5.23 ± 0.63 | 4.00 ± 0.14 | 2.43 ± 0.47 | 3.34 ± 0.48 | 4.74 ± 0.43 |

| (Z)-Geraniol (Nerol) | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 |

| Linalool | 25.33 ± 1.05 | 33.98 ± 0.74 | 22.24 ± 0.71 | 46.35 ± 1.21 | 42.94 ± 0.46 |

| Farnesol | 25.94 ± 8.97 | 23.73 ± 1.38 | 75.97 ± 2.57 | 249.63 ± 6.10 | 472.46 ±12.96 |

| β-Caryophyllene oxide | 55.40 ± 9.57 | 37.89 ± 2.29 | 12.65 ± 0.48 | 26.98 ± 1.44 | 19.28 ± 1.39 |

| Sum of alcohols | 111.90 | 99.60 | 113.29 | 326.30 | 539.42 |

| % of alcohols | 2.0 | 2.8 | 2.3 | 4.9 | 7.5 |

| (E)-β-Farnesene | 611.99 ± 71.65 | 743.19 ± 10.85 | 1174.97 ± 21.24 | 1645.14 ± 62.96 | 1196.47 ± 32.28 |

| β-Caryophyllene | 771.26 ± 101.62 | 394.79 ± 7.34 | 598.57 ± 12.58 | 887.71 ± 27.36 | 941.03 ± 28.82 |

| α-Humulene | 2112.50 ± 249.88 | 897.23 ± 30.83 | 1448.47 ± 49.22 | 1833.86 ± 115.25 | 2722.25 ± 81.06 |

| Sum of sesquiterpens | 3495.75 | 2035.21 | 3222.01 | 4366.71 | 4859.75 |

| % of sesquiterpens | 61.1 | 57.2 | 66.5 | 65.9 | 67.8 |

| 2-Decanone | 14.59 ± 0.42 | 3.86 ± 0.63 | 8.13 ± 0.25 | 8.69 ± 0.58 | 3.44 ± 0.63 |

| 2-Undecanone | 101.46 ± 4.97 | 41.36 ± 0.59 | 49.30 ± 0.47 | 59.11 ± 1.27 | 32.59 ± 1.25 |

| 2-Dodecanone | 11.64 ± 0.2 | 4.38 ± 0.06 | 7.34 ± 0.11 | 8.94 ± 0.35 | 4.35 ± 0.09 |

| 2-Tridecanone | 67.72 ± 7.36 | 29.39 ± 1.18 | 34.56 ± 1.19 | 45.03 ± 4.73 | 26.95 ± 2.52 |

| β-Ionone | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 |

| α-Ionone | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 |

| 2-Nonanone | 6.37 ± 0.56 | <2.0 | 2.27 ± 0.35 | 3.12 ± 0.22 | 1.72 ± 0.19 |

| α-Irone | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 |

| Sum of carbonyls | 201.78 | 78.99 | 101.60 | 124.89 | 69.05 |

| % of carbonyls | 3.5 | 2.2 | 2.1 | 1.9 | 1.0 |

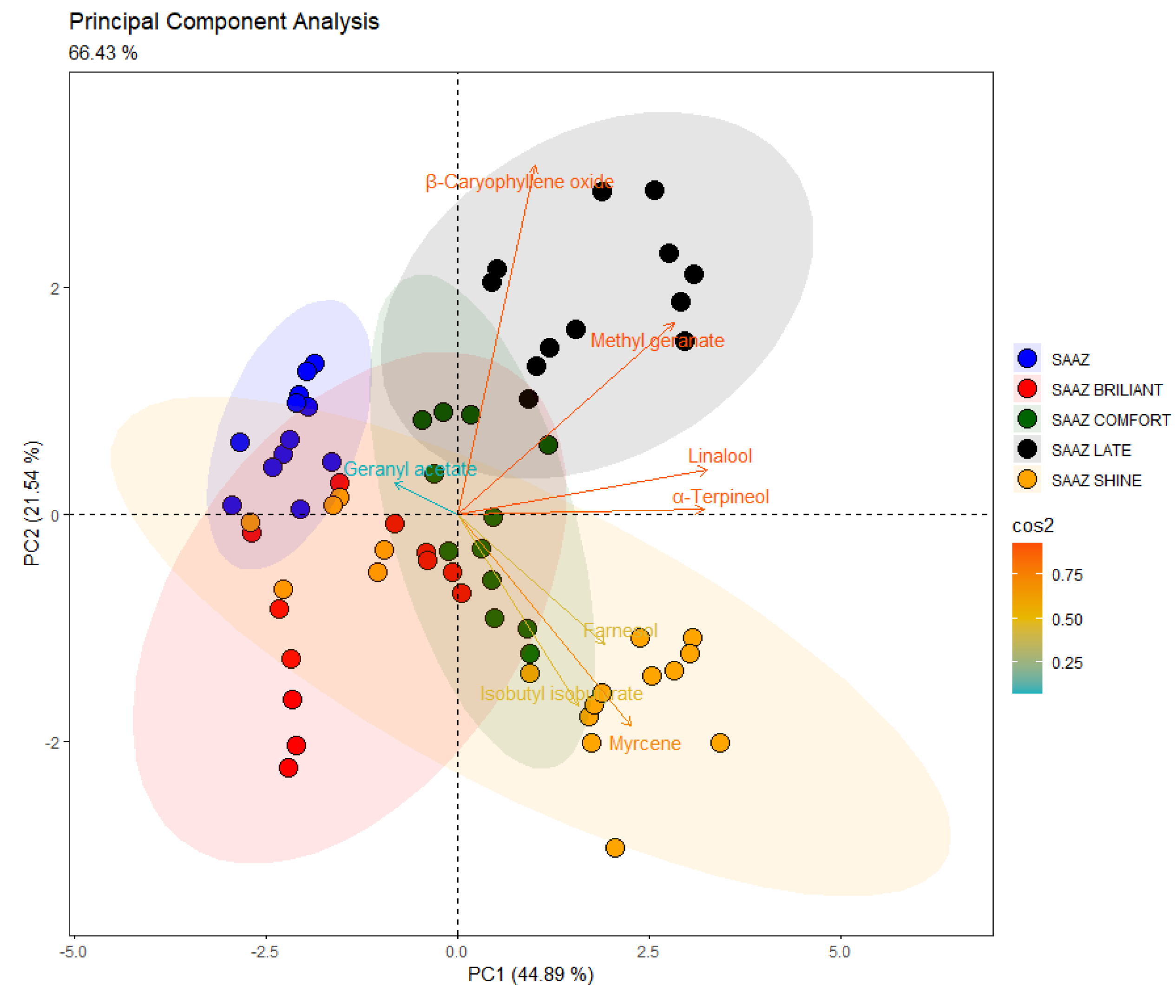

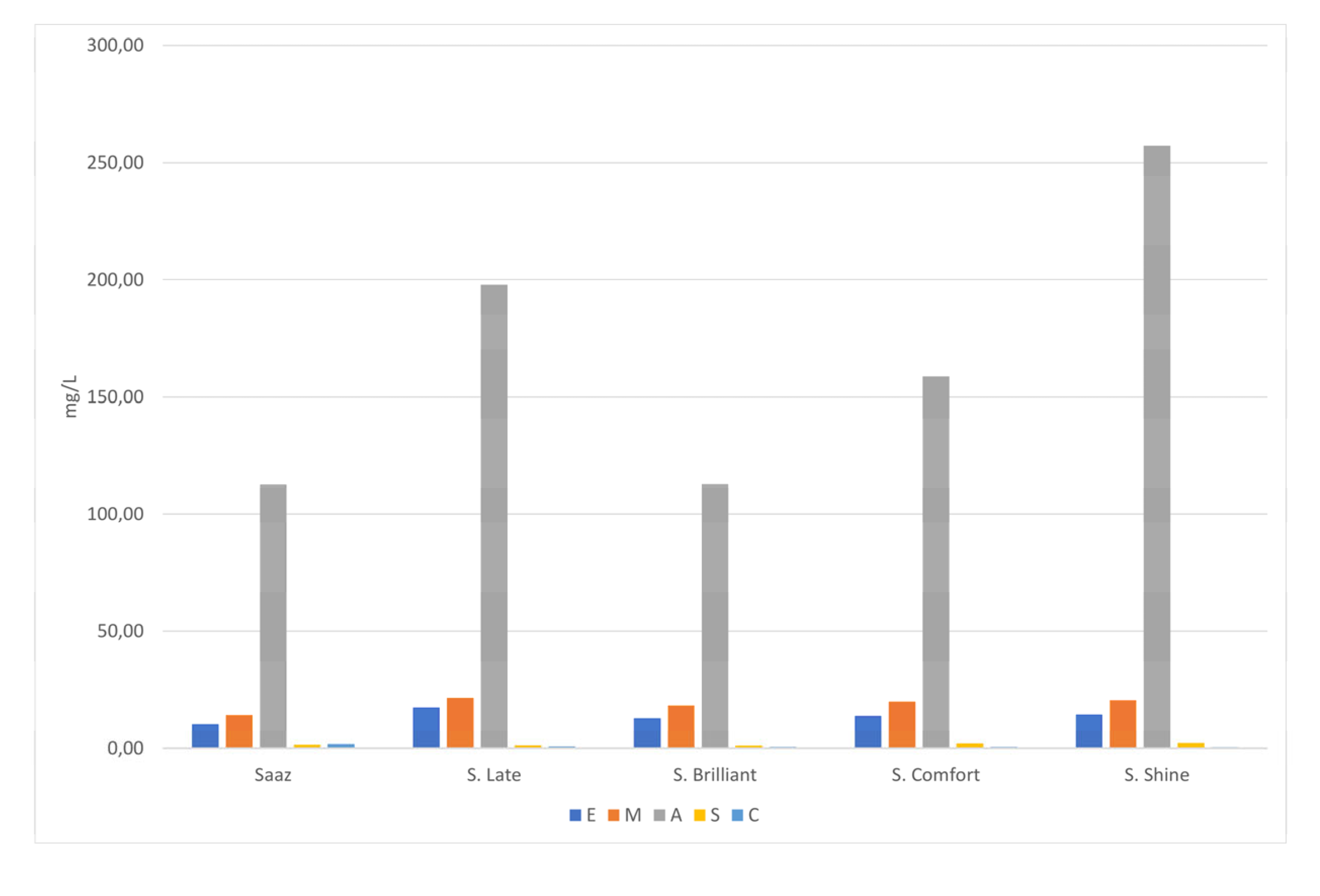

| Saaz | S. Late | S. Brilliant | S. Comfort | S. Shine | |

|---|---|---|---|---|---|

| mg/L | mg/L | mg/L | mg/L | mg/L | |

| Isobutyl isobutyrate | <1.00 | 1.34 ± 0.61 | 1.67 ± 0.61 | 1.06 ± 0.44 | 1.46 ± 0.52 |

| Methyl hexanoate | <0.50 | <0.50 | <0.50 | <0.50 | <0.50 |

| (Z)-Methyl geranate | 8.48 ± 0.67 | 14.42 ± 2.32 | 8.49 ± 1.72 | 10.92 ± 1.07 | 10.48 ± 1.72 |

| Isoamyl isobutyrate | <1.00 | <1.00 | <1.00 | <1.00 | <1.00 |

| Methyl heptanoate | <0.50 | <0.50 | <0.50 | <0.50 | <0.50 |

| Methyl decanoate | <0.50 | <0.50 | <0.50 | <0.50 | <0.50 |

| (E)-Methyl geranate | <1.00 | <1.00 | <1.00 | <1.00 | <1.00 |

| Methyl octanoate | <0.50 | <0.50 | <0.50 | <0.50 | <0.50 |

| Methyl nonanoate | <0.50 | <0.50 | <0.50 | <0.50 | <0.50 |

| Geranyl acetate | 1.30 ± 0.38 | 1.71 ± 0.63 | 2.71 ± 1.46 | 2.01 ± 0.63 | 2.46 ± 1.98 |

| Sum of esters | 9.78 | 17.47 | 12.87 | 13.99 | 14.54 |

| % of esters | 7.7 | 8.0 | 9.8 | 7.8 | 6.2 |

| β-Pinene | <0.5 | <0.5 | <0.5 | <0.5 | <0.5 |

| Myrcene | 2.71 ± 0.51 | 3.22 ± 0.85 | 3.37 ± 0.59 | 4.71 ± 1.17 | 5.05 ± 1.99 |

| Limonene | <0.5 | <0.5 | <0.5 | <0.5 | <0.5 |

| (E)-β-Ocimene | <1.00 | <1.00 | <1.00 | <1.00 | <1.00 |

| 3-Carene | 1.59 ± 1.79 | 1.05 ± 1.61 | 1.98 ± 2.81 | 1.18 ± 1.38 | 1.05 ± 1.93 |

| α-Pinene | <1.00 | <1.00 | <1.00 | <1.00 | <1.00 |

| Sum of monoterpens | 4.30 | 4.27 | 5.35 | 5.89 | 6.10 |

| % of monoterpens | 3.4 | 1.9 | 4.1 | 3.3 | 2.6 |

| Terpinen-4-ol | 0.46 ± 0.26 | 0.78 ± 0.35 | 0.61 ± 0.27 | 0.64 ± 0.23 | 0.55 ± 0.32 |

| α-Terpineol | 3.24 ± 0.25 | 5.12 ± 0.36 | 4.01 ± 0.78 | 4.41 ± 0.15 | 4.74 ± 0.84 |

| (Z)-Geraniol (Nerol) | 3.14 ± 0.38 | 2.04 ± 0.53 | 2.72 ± 0.16 | 1.90 ± 0.12 | 2.09 ± 0.25 |

| Linalool | 17.25 ± 1.46 | 32.11 ± 2.60 | 19.31 ± 3.43 | 28.82 ± 2.51 | 27.76 ± 7.50 |

| Farnesol | 86.98 ± 30.04 | 155.34 ± 6.80 | 85.54 ± 31.24 | 122.00 ± 21.82 | 179.58 ± 10.00 |

| β-Caryophyllene oxide | 1.49 ± 0.29 | 2.53 ± 0.22 | 0.64 ± 0.16 | 1.10 ± 0.13 | 0.80 ± 0.14 |

| Sum of alcohol | 112.57 | 197.92 | 112.83 | 158.87 | 215.52 |

| % of alcohol | 88.5 | 90.1 | 86.1 | 88.6 | 91.3 |

| (E)-β-Farnesene | <2.00 | <2.00 | <2.00 | <2.00 | <2.00 |

| β-Caryophyllene | <0.50 | <0.50 | <0.50 | <0.50 | <0.50 |

| α-Humulene | 0.50 ± 0.23 | <0.50 | <0.50 | 0.55 ± 0.30 | <0.50 |

| Sum of sesquiterpens | 0.50 | 0.00 | 0.00 | 0.55 | 0.00 |

| % of sesquiterpens | 0.4 | 0.0 | 0.0 | 0.3 | 0.0 |

| 2-Decanone | <1.00 | <1.00 | <1.00 | <1.00 | <1.00 |

| 2-Undecanone | <1.00 | <1.00 | <1.00 | <1.00 | <1.00 |

| 2-Dodecanone | <1.00 | <1.00 | <1.00 | <1.00 | <1.00 |

| 2-Tridecanone | <1.00 | <1.00 | <1.00 | <1.00 | <1.00 |

| β-Ionone | <0.50 | <0.50 | <0.50 | <0.50 | <0.50 |

| α-Ionone | <0.50 | <0.50 | <0.50 | <0.50 | <0.50 |

| 2-Nonanone | <1.00 | <1.00 | <1.00 | <1.00 | <1.00 |

| α-Irone | <0.50 | <0.50 | <0.50 | <0.50 | <0.50 |

| Sum of carbonyls | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| % of carbonyls | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| Saaz | S. Late | S. Brilliant | S. Comfort | S. Shine | Saaz | |

|---|---|---|---|---|---|---|

| Fullness | 3.0 | 2.7 | 2.9 | 3.0 | 3.0 | 3.0 |

| Bitterness | 2.1 | 2.2 | 1.8 | 1.9 | 1.9 | 2.1 |

| Astringency | 1.2 | 1.2 | 1.2 | 1.1 | 1.2 | 1.2 |

| Sourness | 1.4 | 1.5 | 1.3 | 1.5 | 1.6 | 1.4 |

| Sweetness | 1.5 | 1.5 | 1.5 | 1.6 | 1.6 | 1.5 |

| Hoppy (overall) | 2.0 | 2.1 | 2.3 | 2.3 | 2.1 | 2.0 |

| Estery | 1.3 | 1.2 | 1.2 | 1.2 | 1.4 | 1.3 |

| Yeasty | 1.0 | 1.3 | 1.2 | 1.0 | 1.0 | 1.0 |

| Hop aroma (in detail) | hoppy, herbal, floral, spicy | hoppy, floral, fruity, woody, spicy | hoppy, fruity, herbal, floral, woody | hoppy, fruity, herbal, spicy | hoppy, fruity, floral, herbal, spicy | hoppy, herbal, floral, spicy |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).