1. Introduction

Conventional thermal insulation materials have the disadvantage of consuming large amounts of energy during production and releasing pollutants compounds into the environment [

1,

2]. This contributes to the increment of the greenhouse gas emissions of the buildings and can lead to further health problems [

3,

4,

5].

Therefore, there is a need to develop materials that mitigate the environmental impacts generated by traditional panels. The search for new strategies to use renewable feedstocks is one of the main current challenges for the development of new insulation materials. In this way, new ecological alternatives would reduce the environmental impact resulting from the excessive use of materials of fossil origin. In this regard, natural fibers are environmentally friendly resources that have several advantages, such as biodegradability, low density, abundance and low cost, among others. For these and other reasons, the use of natural fibers, biopolymers, biofilms, and biosourced composites have increased significantly in recent years [

6,

7,

8,

9,

10,

11]. The main challenge today is to develop new applications for natural fibers in order to avoid overexploitation of existing sources and thus provide the means to ensure a long-term sustainable market [

10,

12]. Then, to reduce the environmental impact generated by conventional insulating materials, alternatives focussed on bio-based materials are being developed [

3,

5,

10,

13,

14]. Examples of natural sources for these materials are flax [

15,

16], hemp [

17,

18], miscanthus [

19,

20,

21,

22], spruce bark fibers [

23], wheat [

24,

25], wood fiber and chip [

4,

26], cork [

27], camphor branches [

28], kenaf fibers [

29], sugar palm fiber composites [

30], corn cub [

31], and sunflower stalks [

32].

However, low availability and lack of fundamental knowledge regarding the feedstock processing, continue to hinder the ability to scale up these technologies to commercial scale [

33].

Studies have shown that biobased materials made of natural fibers offer good performance in terms of both thermal insulation and hygrometric comfort. In effect, their thermal phase shift, breathability and acoustic insulating properties have been reported [

14,

34,

35,

36,

37]. Studies have been carried out with different sources of naturals fibers to develop materials with thermal insulation capabilities as insulating boards with thermal conductivities ranging from 0.04 to 0.06 W/mK and good mechanical properties [

7,

38,

39,

40,

41].

Furthermore, the use of bio-based materials reduces the environmental impact of a product even before its use phase, i.e., environmental benefits are generated immediately from raw material production and material manufacturing. Ranefjärd et al. [

42] indicate that compared to conventional building materials, bio-based materials tend to have lower greenhouse gas emissions. This generally makes them a more sustainable choice for building materials and reduces the building sector’s environmental impact. This characteristic can be enhanced if the origin of the biological material is not virgin, but instead the feedstock is a waste.

In particular, forestry waste and by-products can be a rich source of useful raw materials [

43,

44]. Currently, Eucalyptus plantations cover large areas worldwide (> 20 million ha) and they are continuously growing; most prominently in Australia, Spain, Portugal, Kenya, Central and South Brazil, Uruguay, and Chile [

45]. The industrial transformation of

Eucalyptus globulus sp. into pulp and solid wood generates high volumes of bark as a by-product.

For instance, in Chile, Eucalyptus is the second commercial species with the largest cultivated area. Its industrial consumption is approximately 11.8 million m

3 per year, being its main use the production of pulp and timber [

46,

47]. The main by-product is the bark, which accounts for 10% of the tree volume, generating 1.5 million m

3 [

48].

E. globulus bark has a lower calorific value than pine bark and is difficult to transport in the boiler conveyor system, making it less attractive as a fuel. This characteristic, combined with a high availability that guarantees a constant supply of the material, has prompted forest industry experts to focus their efforts on developing new applications for

E. globulus bark. For example, several studies have focused on isolating and modifying the extractives in the bark, because of their potential uses as chemicals [

49,

50], metal removers [

51,

52], and biofuel [

53], among others. On the other hand, many researchers have chosen to take advantage of the intrinsic properties of bark, such as its low thermal conductivity [

54]. In this context,

E. globulus bark has a particularly fibrous morphology, making it an ideal candidate for applications in which such structures would benefit the overall performance.

In a recent publication, Casa-Lédon et al. [

55] examined the production of insulation boards from

E. globulus bark. That study reports that eucalyptus bark panels with densities above 50 kg/m

3 have carbon emission of 1.4-2.8 kg CO

2 eq and energy demands between 16.2 and 33.6 MJ. These values contrast with the 9.8 kg CO

2 eq and 229 MJ reported for the traditional glass wool insulation panel and the 10 kg CO

2 eq and 140 MJ reported for the conventional glass fiber insulation panel. Therefore, from an environmental perspective, the

E. globulus bark insulation panel can be a very attractive alternative with less carbon emission and embodied energy in comparison to conventional insulation materials.

Considering the potential benefit of using E. globulus bark fibers as raw material for insulation panels, it is relevant to determine an adequate manufacturing process and to understand the behaviour of the main properties that determine their performance in service. Therefore, the objectives of this study are as follows: (1) to evaluate the feasibility of producing fibers from the bark of Eucalyptus globulus, using a mechanical process; (2) to manufacture insulating panels from these fibers; and (3) to evaluate their performance as cavity wall insulation materials.

2. Materials and Methods

2.1. Eucalyptus Globulus Fibers Production

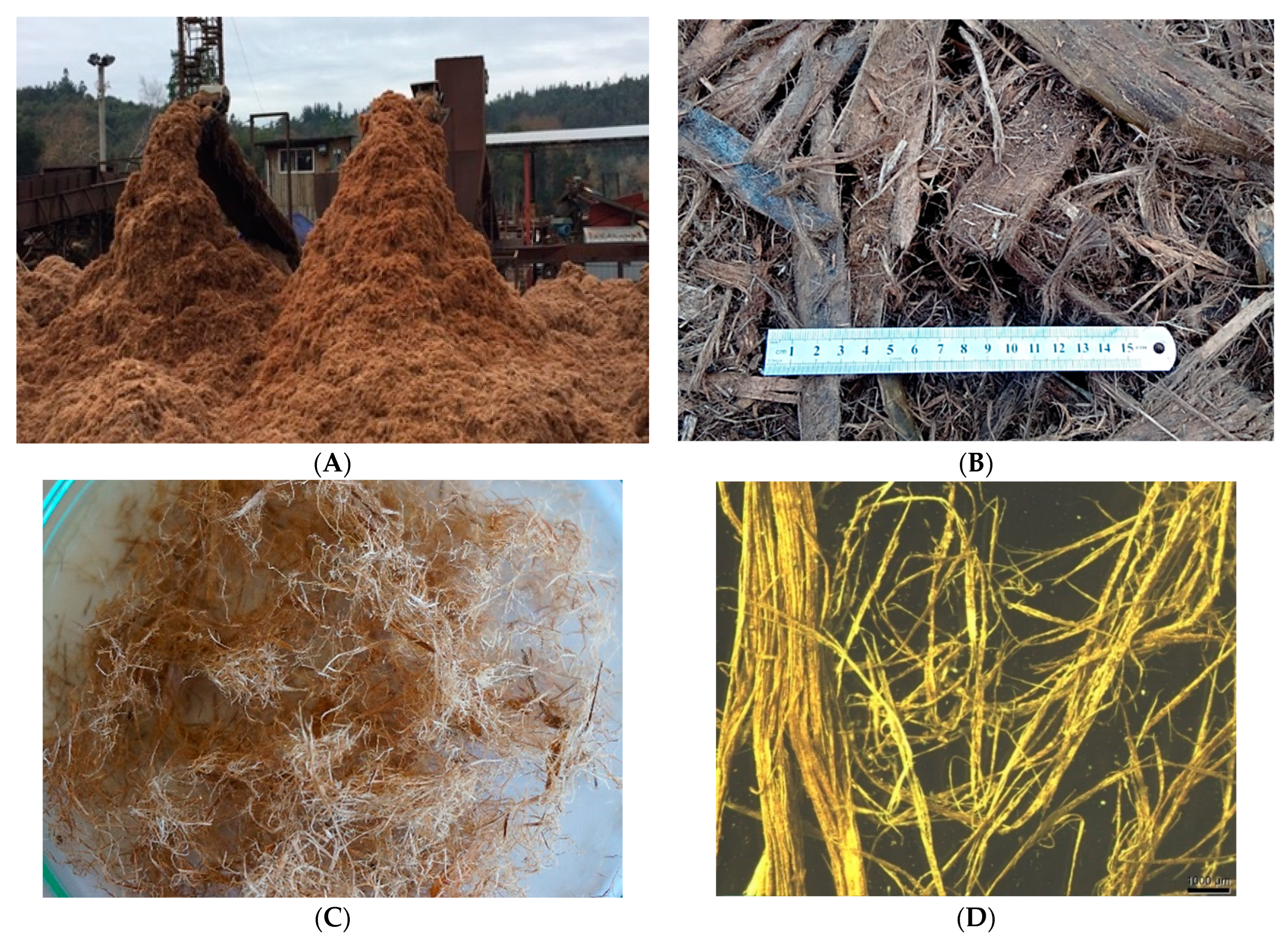

Triturated

E. globulus bark obtained from sawmill placed in the Bio-Bio Region, Chile, was used as a raw material (

Figure 1A,B). The sample was air-dried for 24 hours to adjust its moisture content to 16% (oven dry matter). Afterwards it was mechanically processed in a Peerless hammer mill to obtain

E. globulus fiber bark (EGFB) (

Figure 1C). An optical imaging of EGFB is presented in

Figure 1D, which was captured with an optical microscope system using a 20X and 4X magnifier. The length, diameter and aspect ratio were obtained.

2.2. Chemical Characterization of Eucalyptus Globulus Bark

Particles of Eucalyptus bark were placed in a Soxhlet system with a mixture of ethanol/water to obtain free-extractives bark, according to Sluiter et al. [

56]. A two-step acid hydrolysis was carried out—by following Sluiter et al. [

57]—to fractionate the bark to cellulose, hemicellulose, and lignin. The ash content was determined according to ISO 18122:2016 [

58].

2.3. Morphological Characterization of E. globulus Bark’s Fibers

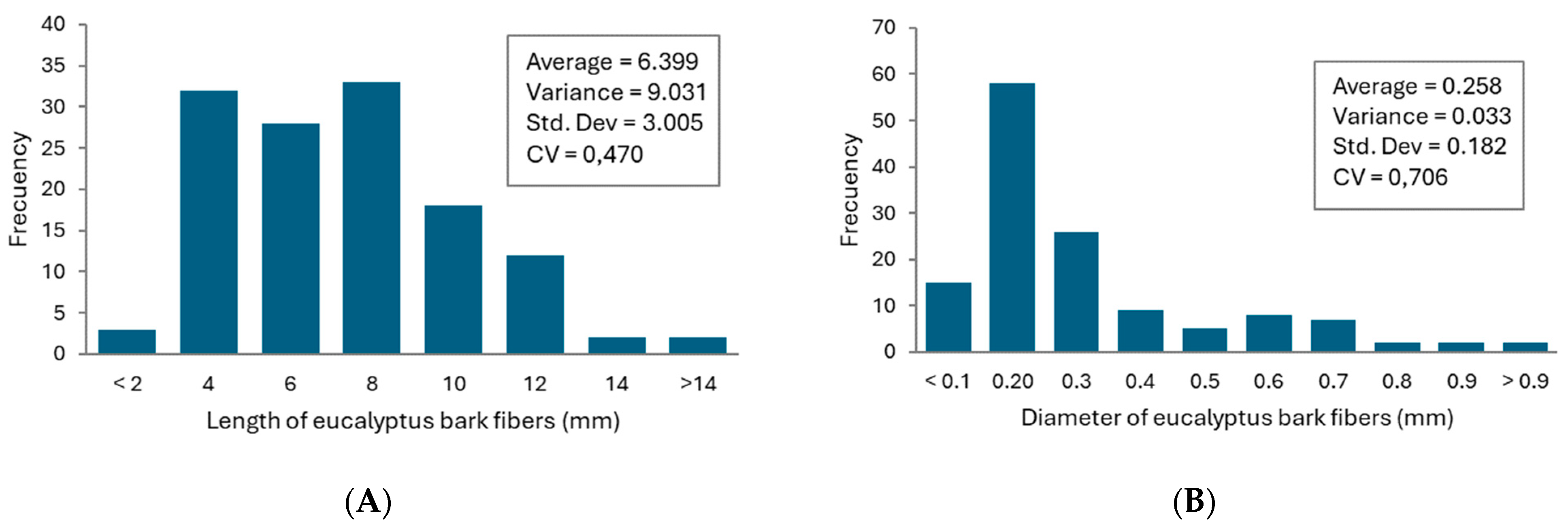

The morphological characterization of E. globulus bark was carried out after mill hammer defibration. Approximately 150 fibers were analyzed using an optical microscope Leica model DM 500 with a 10x Magnifier glass. Several images were taken, which were subsequently processed in a specialized software that sorted them out by length and diameter.

2.4. Production of Thermal Insulation Panel

The panels were manufactured using a commercial phenol-formaldehyde resin (Oxilite 5731

®, solids content 43.01%, a viscosity of 1050 cP and pH 11) as the adhesive. Resin and bark fibers were mixed in a rotatory system. Then, a specific mass of the mixture was moved into a 400x400 mm mold to adjust its theoretical density to a predetermined value (see

Table 1).

Two press systems were tested: (a) hot plates and (b) saturated steam injection at 8 bar. We define the pressing time as the time necessary to reach the curing temperature (110 ° C). Our testing revealed that system (b) required a significantly lower pressing time than system (a): 3 minutes compared with 13 minutes, respectively. Afterwards, the panels were conditioned at 25 °C to reach 65% of moisture.

The parameters to fabricate a rigid insulation panel are shown in

Table 1.

As integral parts of vegetal organisms, EGFB are quite prone to degradation by fungi and are easily flammable materials, just as wood. Therefore, the final product must be adapted to reduce its susceptibility to fire and increase its fungal resistance. To that end, a standard flame retardant and an antifungal solution were incorporated into the panels with density of 100 kg/m3 to evaluate their flame and fungal resistances according to the methodology presented later.

2.5. Determination of Apparent (Bulk) Density

The apparent (bulk) density was calculated according to standard UNE EN 323 [

59], as a ratio between the sample’s mass (with precision of 0.01 g) and its volume. To that end, the standard defines a necessary number of samples and follows the methodology specified in the UNE EN 325 [

60] to determine both the sample’s mass and its dimensions.

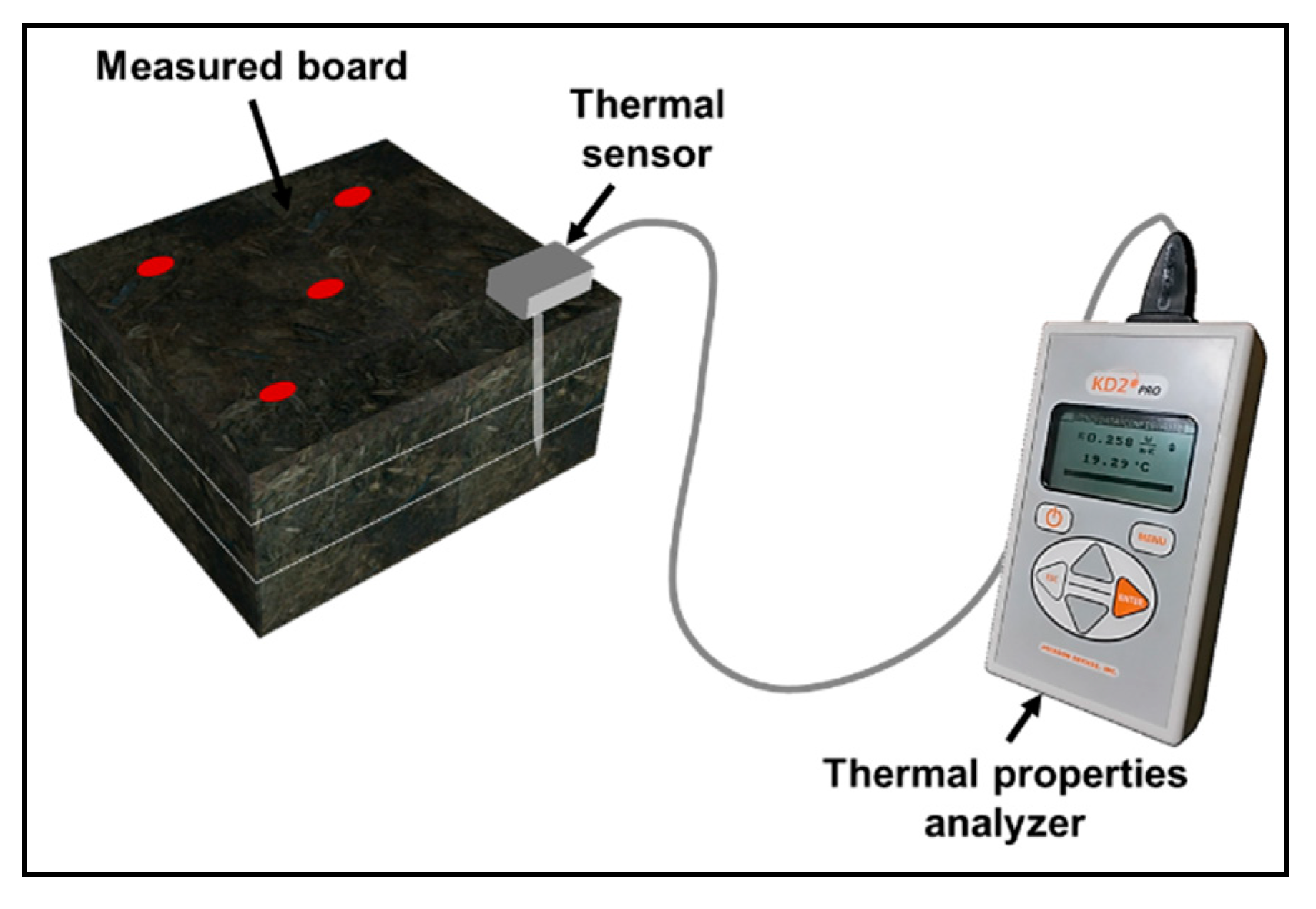

2.6. Determination of Thermal Conductivity

The thermal conductivity of the insulation panels was determined through a transient heat method based on ASTM D5334-08 [

61]. A KD2-Pro Thermal Properties Analyzer with a thermal sensor KS-1 in a range from 0.02 to 2.00 W/mK was used as the measuring device. This sensor incorporates a heater and a thermocouple inside,

Figure 2.

2.7. Thermal Diffusivity Determination

The specific heat of bark fibers and polymerized phenolic resin were determinate by DSC (Differential Scanning Calorimetry) according to Morintale et al. [

62]. A NETZSCH DSC analyzer model 204 F1 Phoenix was used. The heating ratio was 5°C/min within a temperature range of 25 – 250°C, with an inert atmosphere. The specific heat was calculated using equation 1, where c: specific heat (J/kg K); DSC: Differential Scanning Calorimetry (mW/mg); T ̇: heating rate (K/min). The specific heat was calculated as shown in Equation (1).

The specific heat of each constituent of the panel was determined separately, and it was calculated as the average of each value obtained within the temperature range of from 25 to 250°C. Then the global specific heat of the panel was determined as the sum of the contribution of each constituent in the actual formulation (90% w/w of fibrous material, and 10% w/w of curated phenolic resin).

Thermal diffusivity (α, m

2/s) was calculated using Equation (2), where r is density in kg/m3; λ is thermal conductivity in W/m.K; and c is the specific heat in J/kg.K.

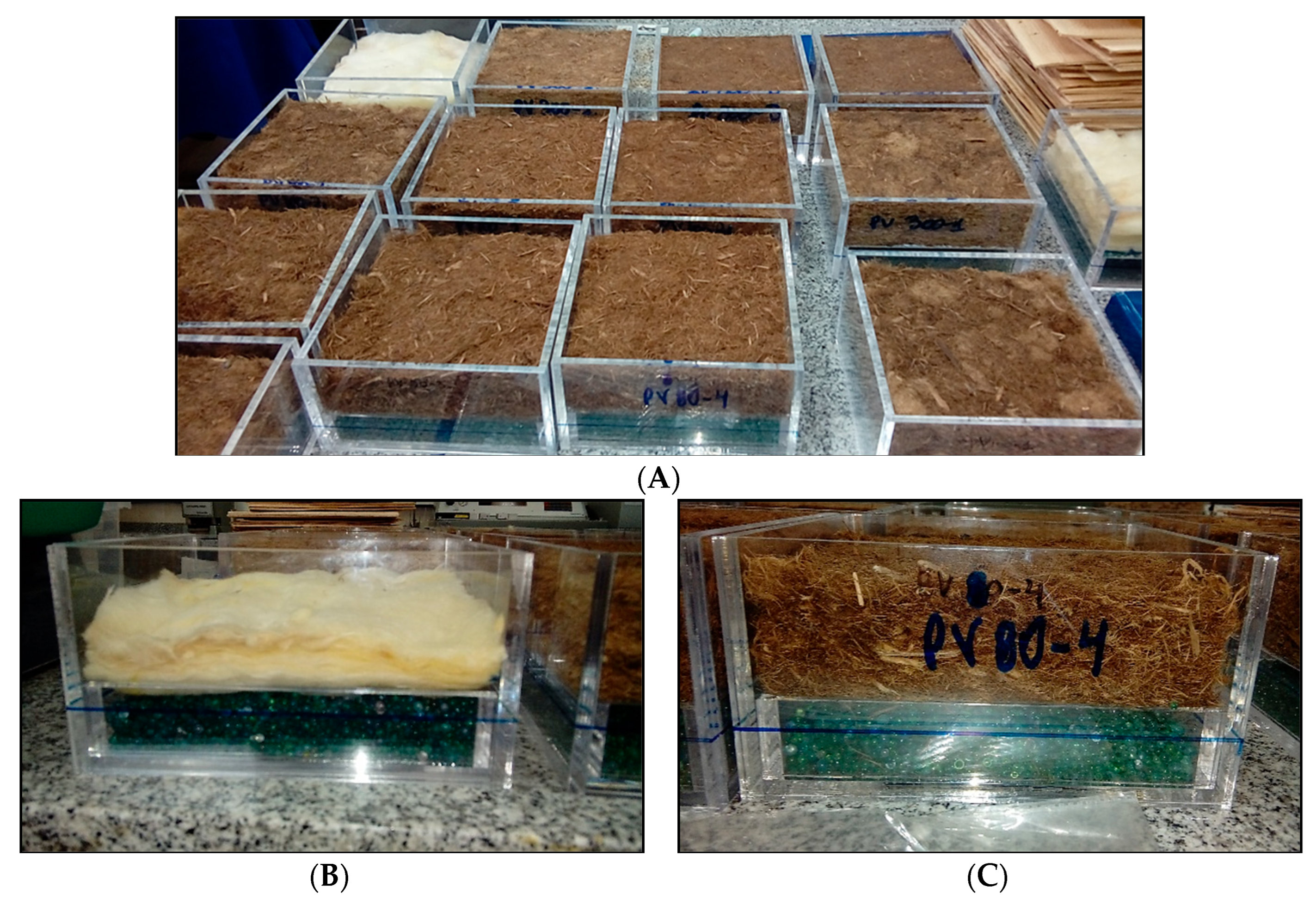

2.8. Determination of the Water Vapor Transmission

Water vapor transmission (WVT) was determined in rigid panels with a theoretical density between 80 – 300 kg/m

3 using the dry cup method described in ASTM E 96-95 [

63]. A glass wool insulation panel was used as the control value, and each measurement was carried out four times. The sample was placed in a recipient with silica gel sealing the contact edges. The system shown in

Figure 3 was kept in a controlled environment at 23 ± 0.5 ° C and 50 ± 3% H.R. for 3 weeks.

The weight of each sample was registered daily to determine the vapor transmission rate across the panel (G, kg/s). With this information, several properties were calculated as follow:

Permeability (δ

MAT, kg m/GN s) as the flow of water vapor (G) that goes through a material of thickness d (m), per unit area (A, m

2), when the difference in vapor pressure between the two faces is ∆p (Pa). It is calculated using Equation (3). Vapor resistivity (GN s/kg m) is the reciprocal value of permeability.

Vapor resistance (R

V, GN s/kg) is calculated by multiplying the value of Vapor resistivity by the thickness of the material (d), according to Equation (4).

Vapor resistance factor (or µ-value) is a dimensionless parameter used to assess vapor permeability relative to air (Equation (5)). The higher the µ-value, the lower the permeability. For calculation purposes, the permeability of the air used was δ

AIR = 0.2 kg m/GN s [

64].

Equivalent air thickness (s

d, m) is the equivalent air thickness that produces the same water vapor diffusion strength as a material of thickness (d,m). It is calculated using Equation (6).

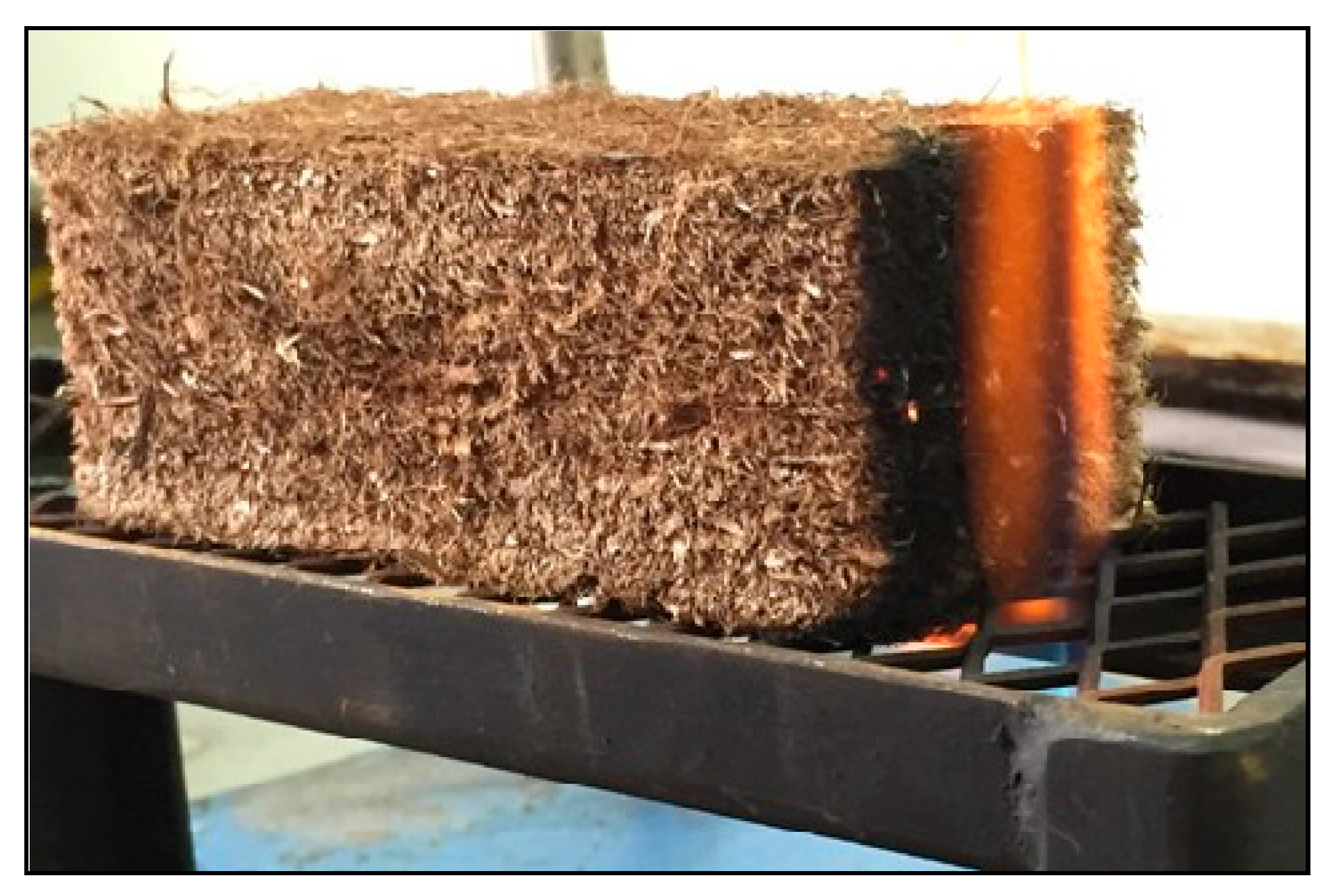

2.9. Determination of Fire-Test Response

Samples obtained from panel with a theoretical density of 100 kg/m

3 were soaked in a commercial flame retardant (AF7000

® AP TX AT) The fire-test-response of these samples was measured following the ASTM D 4986-03 [

65], which describes a small-scale horizontally oriented burning test procedure for comparing the relative rate of burning and the extent and time of burning of cellular polymeric materials having a density less than 250 kg/m

3. Six samples of 50 x 50 x 150 mm were extracted from panels with a theoretical density of 100 kg/m

3, soaked with a commercial flame retardant (AF7000

® AP TX AT) and oven-dried at 40°C for 8 hours. Unsoaked samples of the same density were also tested to compare the results.

Each sample was placed on a metallic support and exposed to a blue flame with equivalent energy to 37 MJ/m

3 for 60 seconds (

Figure 4). Then, the flame was removed, and the time required to consume 125 mm of the panel was recorded.

2.10. Determination of Mold Resistance

Ten samples of 80 x 120 x 50 mm were obtained from EGFB-based panel with a theoretical density of 100 kg/m

3. Then, they were treated with an antifungal (Nipacide

® CO5) and oven-dried at 40°C for 8 hours. In addition, untreated samples and samples without resin were also studied for comparison. A commercial fiberboard (MDF) was used as a control unit. The

Table 2 summarizes the composition of the EGFB-based panel samples.

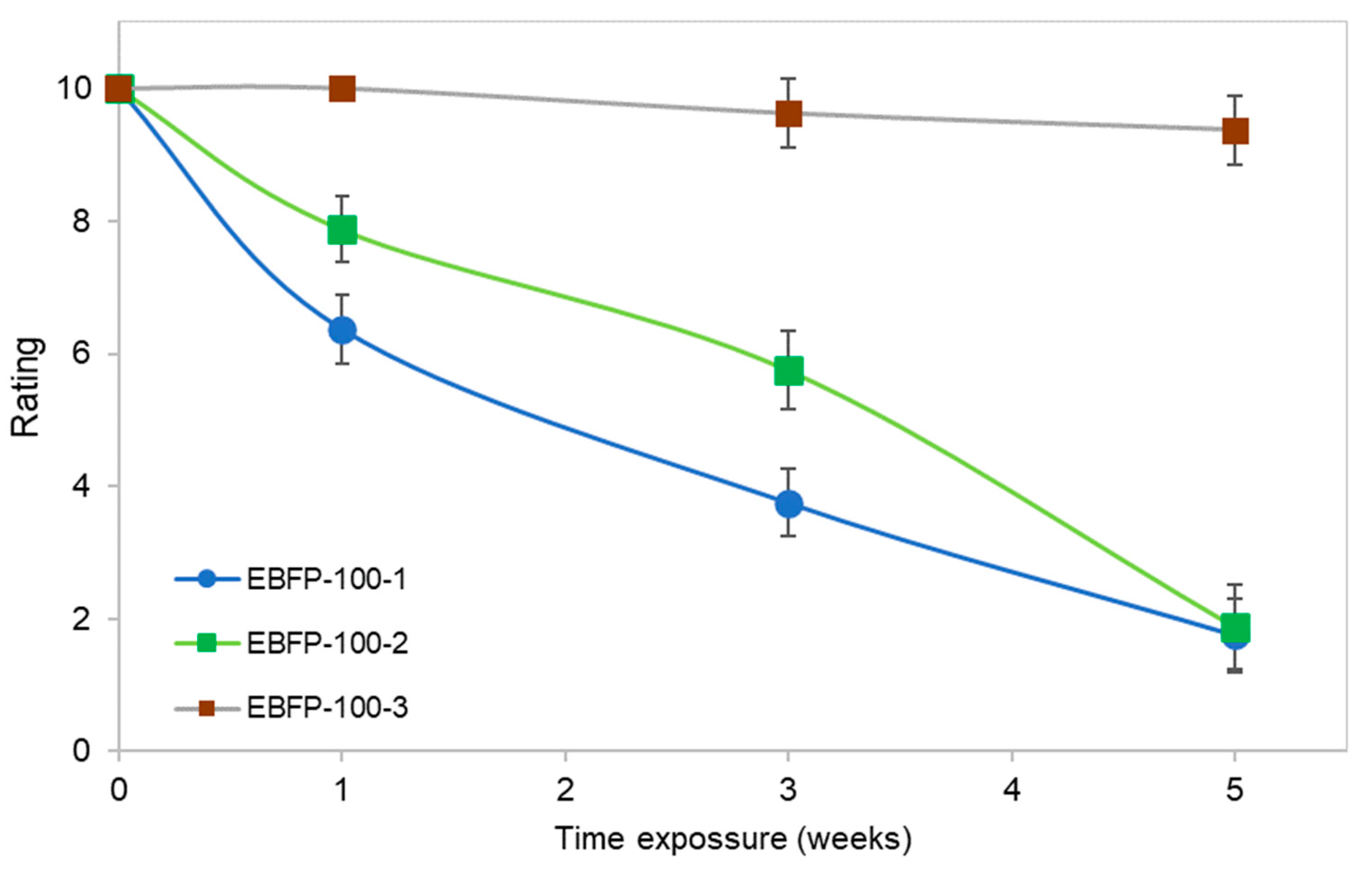

The mold resistance of EGFB-based panel was determined according to ASTM D 3273-12 [

66]. The samples were inoculated with a mold colony arranged in two chambers conditioned at 34 °C of temperature and 95 - 98% of relative humidity, according to the standard. All samples were removed at weeks 1, 3, and 5 and photographed with a digital camera. The images were analyzed and classified visually, according to the size of the surface covered by mycelium molds. A scale of 0 to 10 was used to quantify the visual assessment. The total absence of mold had an evaluation of 10 and the presence of mold on the total surface (equivalent to 91-100% of the surface area) had an evaluation of 0.

3. Results

3.1. Characterization of Eucalyptus Bark Fibers

Pictures of the fibers (EGFB) obtained by milling the

E. globulus bark (

Figure 1A,B) are given in

Figure 1C,D. EGFB composition in terms of extractives, cellulose, hemicellulose, lignin, and ash is shown in

Table 3 in comparison with other raw materials [

67]. The fibrous nature of

E. globulus bark is related to its particularly high cellulose content (≈ 50%).

Figure 5 shows the length and diameter distribution of EGFB. The fibers have an average length of 6.40 mm and an average diameter of 0.26 mm, giving an average aspect ratio of 25.

3.2. Characterization of EGFB-Based Panels

Thermal insulation panels have been prepared using phenol-formaldehyde resin and two press systems (a) Hot plates and (b) saturated steam injection at different densities (see Material & Methods section). The parameters of the pressing conditions, including the pressing time and temperature are given in

Table 1. It should be noted that the saturated steam pressing method leads to a significant reduction in the pressing time required to obtain a panel to the required specifications: 3 minutes compared to the 13 minutes required when using the hot plate system (based on a 50 mm wide panel).

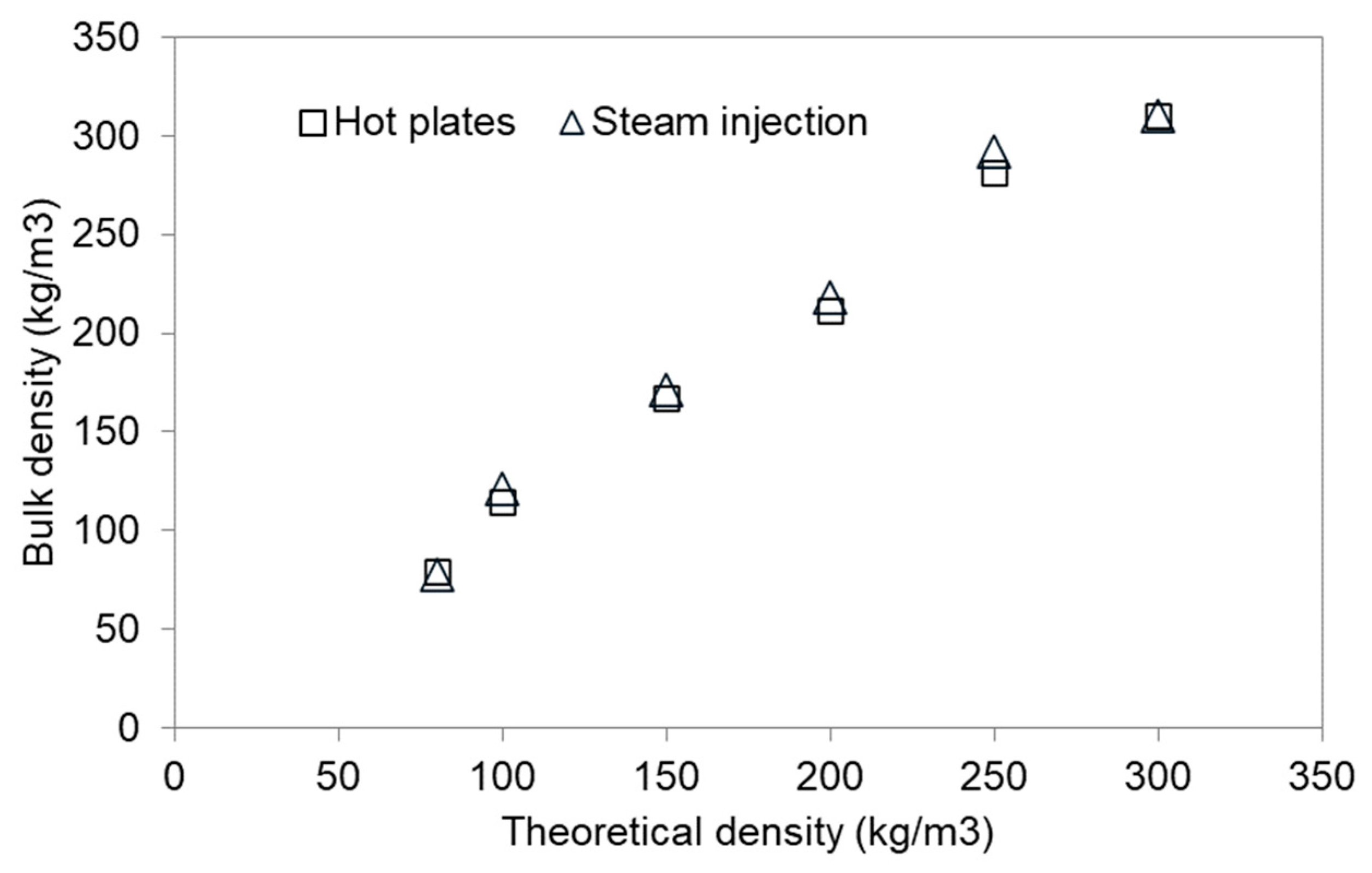

A comparison between the theoretical density and bulk density between the two pressing methods was performed, and the results are presented in

Figure 6. It appeared that both pressing technologies allow to obtain panel with similar densities.

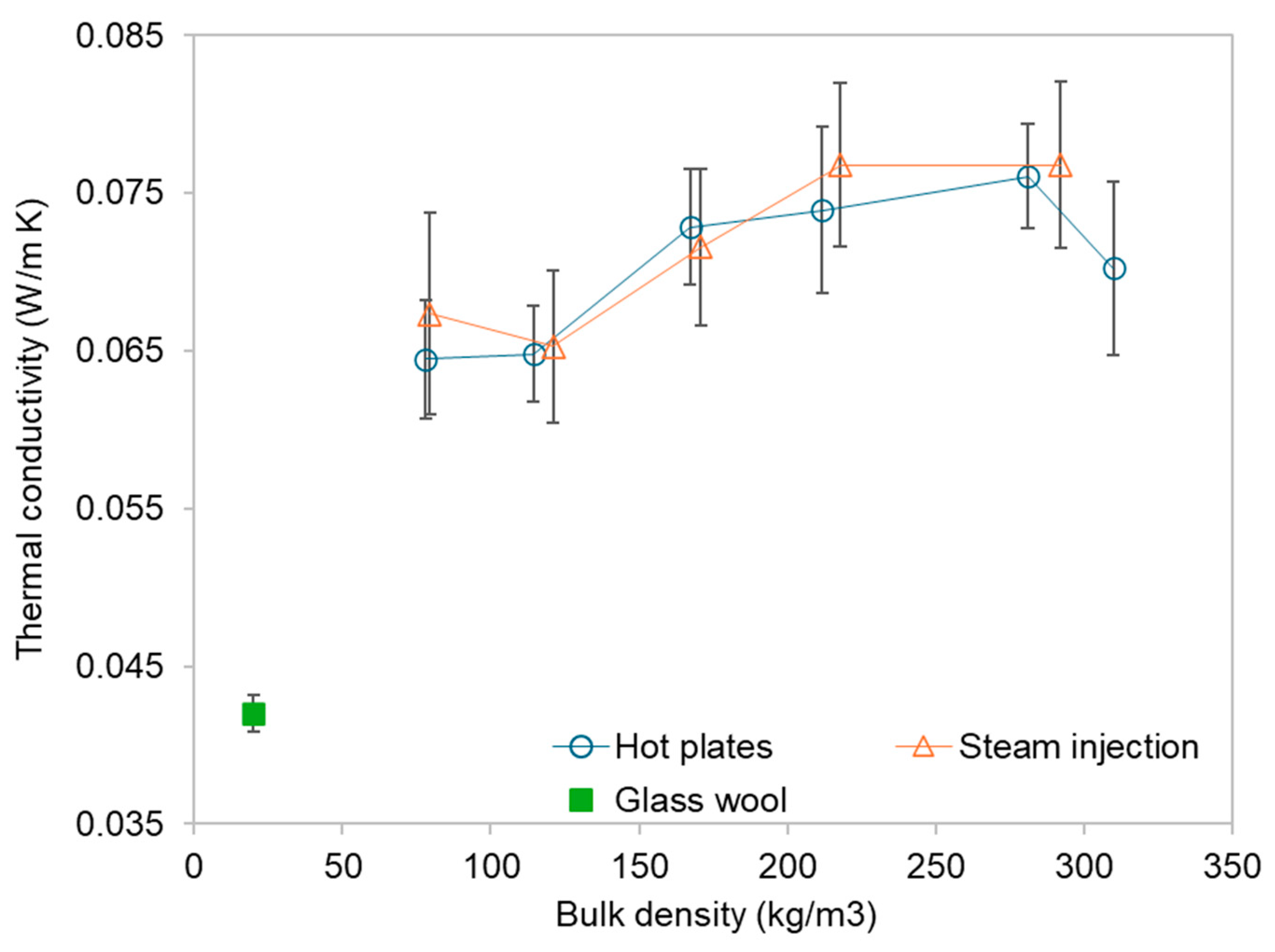

The influence of the final density on the thermal conductivity of the two panels is shown in

Figure 7. It was observed that the thermal conductivity fluctuated between 0.064 and 0.077 W/m.K. According to the DIN 4108-2 [

68], materials with a λ value lower than 0.10 W/m K can be classified as thermal insulating materials. This fact shows the good insulating properties of the materials generated from EGFB. As reference, the thermal conductivity of commercial glass wool with real density 20 kg/m

3, measured with the same method, was 0.042 W/m.K.

As expected, the thermal conductivity increases with the increment of the final density of the panel, regardless of the pressing system used (

Figure 7). This is consistent with the fact that lower density panels have a higher volume of stagnant air (porosity) in their structure, which has a rather low thermal conductivity value of 0.026 W/mK [

69].

Within the framework of our study aiming the design of insulating materials, the manufacture of materials with low density is preferred. However, a balance must be maintained because less homogeneous fiber bonding is generally observed in low density panels. As it is presented in

Figure 7 and like other studies dealing with insulating natural fiber-based panels, the same relationship between thermal conductivity with density can be observed. Korjenic et al. [

70] reported the thermal conductivity of jute, flax, and technical hemp panels with density between 26.1 and 82.1 kg/m

3, obtaining values between 0.0393 and 0.0486 W/mK. Similarly, Khedari et al. [

71] developed insulating panels from durian peel and coconut coir particles with a density between 288 - 234 kg/m

3, showing thermal conductivities between 0.0728 and 0.0788 W/mK.

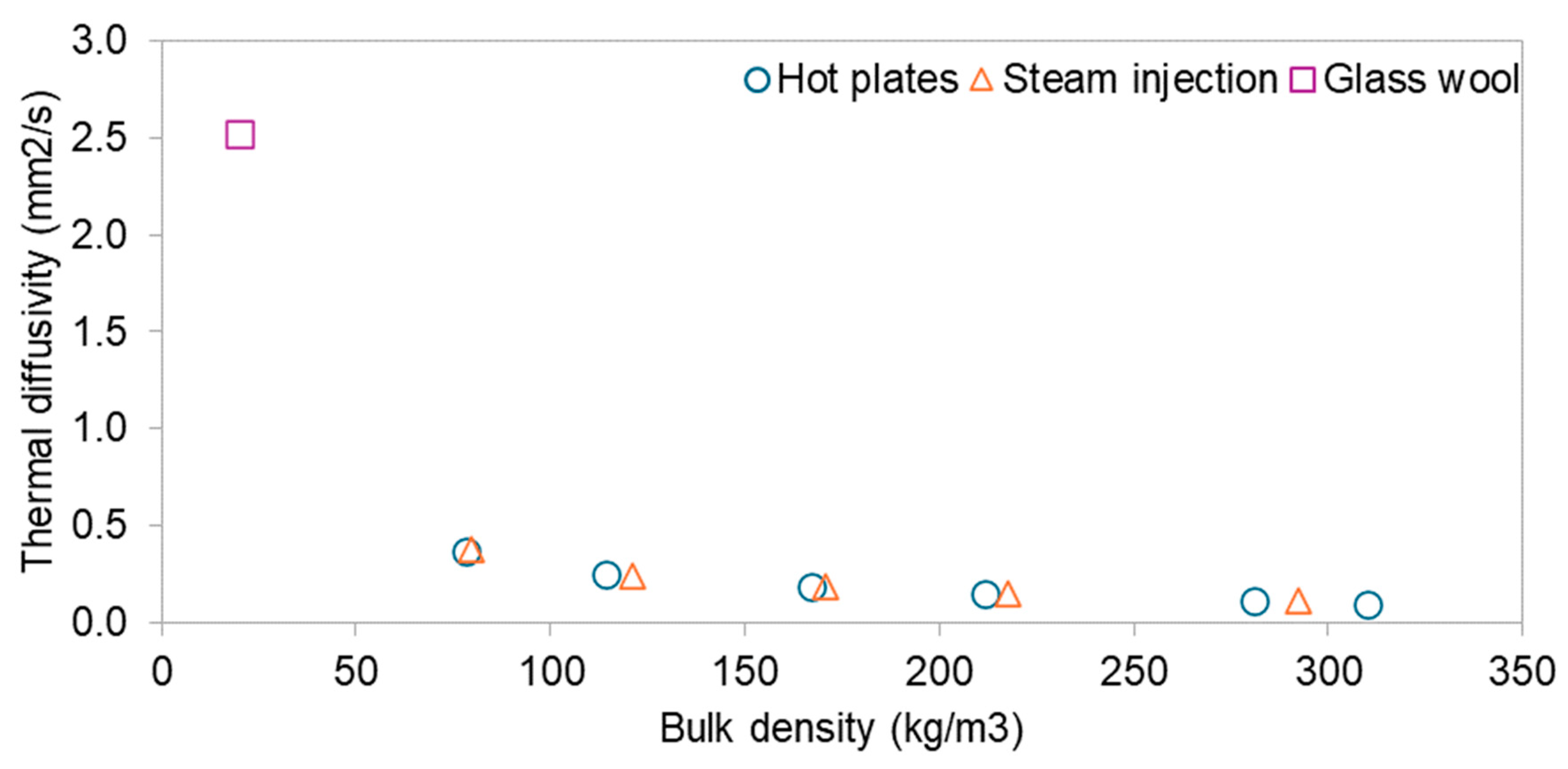

Another important property measured to the EGFB-based panel was the thermal diffusivity that describes how fast the material reacts to a temperature change, being the thermal diffusivity dependent on the thermal conductivity, density, and specific heat of the material. As it was mentioned in the methodology, the specific heat of EGFB-based panel results from the sum of each specific heat of the constituents of the panel and their contribution (90% w/w of fibrous material and 10% w/w of curated phenolic resin).

Table 4 presents the specific heat of EGFB at 12% moisture content, the cured phenolic resin and the EGFB-based panel. The values for commercial wood fiber products and glass wool from literature are presented in

Table 4 as well.

It can be seen that EGFB showed a relatively high specific heat. Compared to wood, the bark has greater thermal insulation and specific heat properties, as it fulfills a protective function in the tree against fire, the weather, among other [

54]. Therefore, compared to commercial products, the EGFB panel has a higher heat storage capacity, which ensures thermal inertia and effective protection against extreme temperature [

75].

Figure 8 shows the thermal diffusivity obtained for all EGFB- based panels as function of density. As is expected there is a direct relationship between density and thermal diffusivity [

76,

77]. The higher the density, the less empty spaces into the material and the thermal diffusivity approaches to the one of the wood (

Table 5). In general, biobased insulation material shows low thermal diffusivity and it will be expected that it responds slower to changes in the thermal environment compared to others material with high thermal diffusivity.

The water vapor permeability of rigid panels with a theoretical density between 80 - 300 kg/m

3 was studied using the dry chamber method.

Table 6 shows the water vapor resistance properties of the panels.

It was observed that water permeability decreased with panel density due to the resistance offered by the mass of the material. The lower density panels showed similar behavior to commercial glass wool.

Both glass wool and eucalyptus fiber insulators have a low equivalent air thickness, S

d < 0.5m, therefore allow water vapor to pass. These values are related to high breathability, a highly desirable property in many building systems, as it allows conditions that prevent condensation, while improving thermal comfort [

79,

80]. Thus, like glass wool, the panels developed in this study will require a vapor barrier in their application. Bark panels of higher density (>100 kg/m

3) have a greater resistance than those of lower density, which is confirmed by the permeability values obtained. The higher the µ value, the lower the water vapor permeability. The results obtained are in accordance with those reported for wood fiber insulating materials, which are in the range of 3 to 7, and are higher than those reported for glass wool [

72,

75]. However, compared to expanded polystyrene (µ=58),

E. globulus bark panels are much more permeable [

81].

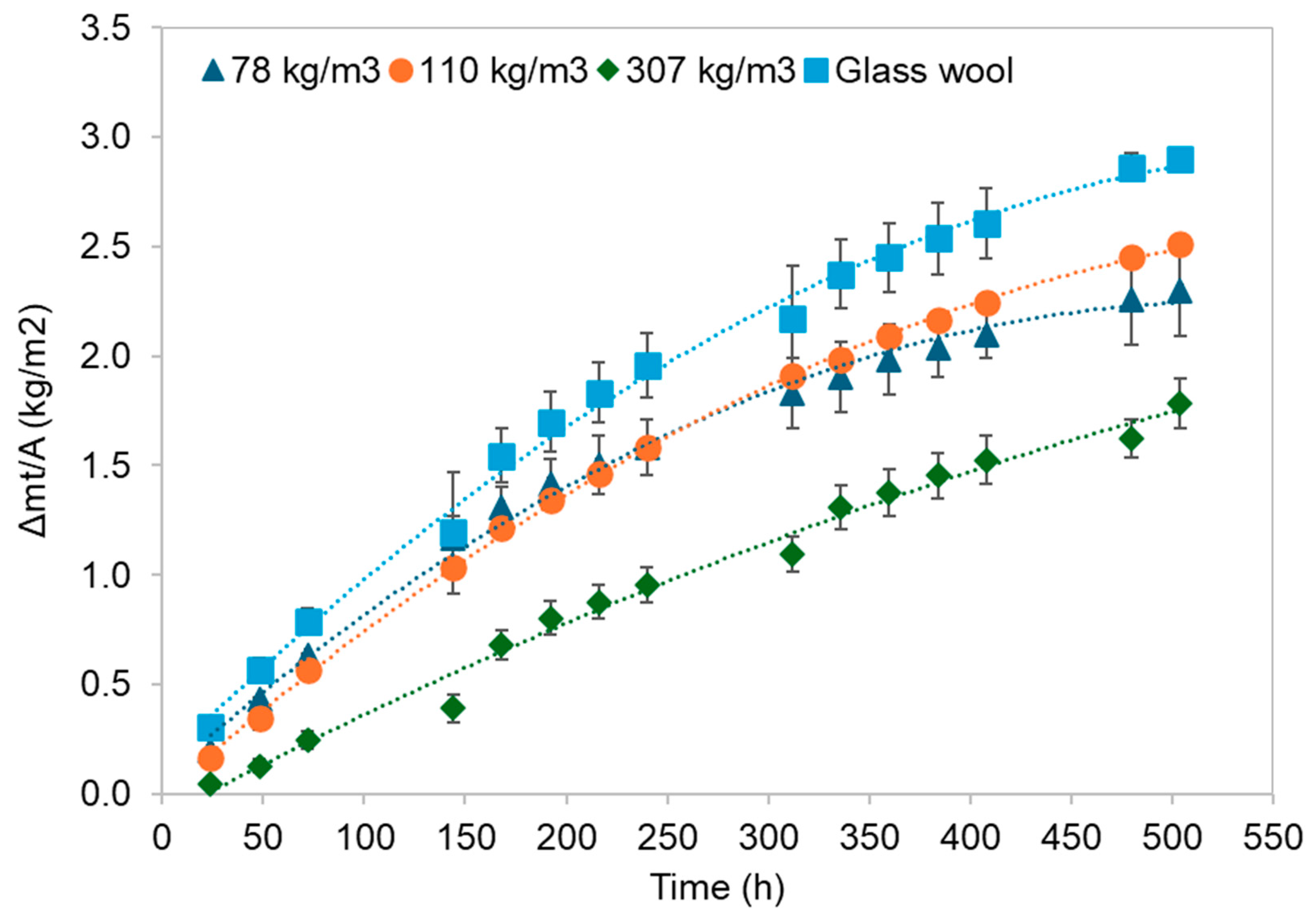

Figure 9 shows the ratio of mass gained per panel area over time. We observed that samples of panels with a density of 78 and 110 kg/m

3 displayed a similar behavior, unlike the sample of density 307 kg/m

3 that showed greater resistance to the passage of vapor per unit of area. The results also show that the bark panels have a lower permeability to the passage of steam than the glass wool sample. In contrast to Cetiner et al. [

82], the higher density samples exhibited greater resistance to vapor passage and showed much lower mass change values in a longer time.

3.3. Fire-Test Response of Eucalyptus Bark Panel

The fire behavior of EGFB-based panels has been examined without and with the addition of 1% w/w of a commercial flame-retardant base on ammonium salts (FR). A rigid panel of theoretical density 100 kg/m3 without adhesive was made, resulting in an easily burnt material, given its fully organic nature. However, after removing the flame we observed that no flame is generated during ignition, but passive combustion in which combustion gases are released (smoke generation). The untreated rigid panel has a burning rate of 2.6 mm/min, independent of the presence of phenolic resin. The incorporation of 1 % flame retardant product grants the material with complete protection against the testing conditions. This result is comparable with commercial insulators from mineral sources, such as glass wool.

3.4. Mold Resistance

The mold resistance of EGFB-based panel has been studied using a standardized method [

66]. The resistance with and without 10% phenolic resin and with a commercial antifungal additive were compared. In

Figure 10 the samples were ranked in terms of resistance against mold.

The commercial antifungal additive incorporated into the EGFB-based panel allowed the protection of the material during the 5 weeks of study, ending with a rank of 9.4 in this period. In contrast, untreated panels, regardless of the phenolic resin content, were affected from the first week by the mold colony reaching the fifth test week with a rank of 1.9, for samples with resin, and 1.8, for plain samples. This may be a result of its sugar-rich chemical composition and the favorable environmental conditions of experimentation. Although the bark plays a protective role against the attack of pathogens in the tree, this protection is limited when temperature and humidity conditions favor the growth of these molds. It is, therefore, necessary to incorporate commercial additives to maximize the durability of the insulating material.

4. Discussion

The results indicate that EGFB-based panels are a viable alternative as a thermal insulation solution. Indeed, the values obtained for thermal diffusivity and water vapor transmission properties are comparable with other commercially available insulation materials. Still, for good in-service performance, the EGFB-based panels need be treated with flame retardant and antifungal additive.

The good performance of the panel is relevant because bio-based eucalyptus bark panels generate less CO

2 eq and require less energy consumption compared to traditional alternatives [

55]. In effect,

E. globulus panels have an immediate reduction in environmental impact, generating benefits from raw material production and product manufacturing [

55], contributing to a more sustainable construction industry and building sustainability.

Furthermore, by taking advantage of a resource generally considered a waste, these panels also contribute to reducing the impact of disposing eucalyptus bark in landfills which is becoming a worldwide problem considering that Eucalyptus plantations have a strong global presence, covering up to 20 million hectares in countries such Australia, Brazil, Chile, Kenya, Portugal, Spain and Uruguay.

Particularly in the case of Chile, approximately 14.4 million m

3 of Eucalyptus is generated per year, generating 1.5 million m3 of bark. And, according to the Camara Chilena de la Construcción [

83], approximately 12.2 million m

2 of houses and buildings are constructed per year. Assuming that all dwellings use insulation materials, as required by the Chilean standards [

84], the demand for insulation would be approximately 12 million m

2. In a conservative scenario, where the demand for a new product represents 5% of the market, 600 000 m

3 of EGFB-based insulation material will be required. For the case of a 50 mm thick

E. globulus bark panel with a density of 100 kg/m

3, the demand would be 3000 tonnes/year of insulation material.

Therefore, the EGFB insulation panel is an important alternative for using a relevant industrial waste and for mitigating the environmental impacts associated to buildings.

5. Conclusions

The present article studied the feasibility of producing E. globulus bark fibers suitable to manufacture insulating panels. Additionally, the performance of panels produced by the hot plate method and by the saturated steam injection method was evaluated through relevant properties

Based on the results of theoretical density and bulk density, it possible to conclude that both methods of panel production yield similar densities. Furthermore, the thermal conductivity fluctuated between 0.064 and 0.077 W/m.K, which indicated that the EGFB-based panels have good insulation properties.

Furthermore, E. globulus fibers panels have low equivalent air thickness (Sd < 0.5 m) and therefore, the panels allow the passage of water vapour and contribute to high breathability, which prevents the generation of condensation and improves thermal comfort.

The higher density panels (>100 kg/m3) showed higher resistivity, which is confirmed by the permeability values obtained. In this respect, increasing the water vapour diffusion resistance factor (µ) decreases the water vapour permeability (δ).

In terms of fire resistance performance, the panels produced without any treatment are easier to burn, with a burning rate of 2.6 mm/min. For the case where 1% of a commercial flame retardant based on ammonium salts (FR) was incorporated, a complete fire resistance is observed, which is similar to the glass wool commercial panels.

The mould resistance results indicate that treating the panels with antifungal additive provided protection to the material during the 5-week test. Indeed, in this case the rank obtained for the samples is 9.4. This contrasts with the panels not treated with antifungal and the panels with 10% phenolic resin. In both cases, significant levels of mould were present from the first week of testing, with a rank lower than 2.0.

Finally, compared to wood fiber and glass wool commercial panels, the EGFB-based panel has a higher heat storage capacity. This fact ensures the protection against extreme temperature changes.

Therefore, based on the results obtained during the tests, the EGFB-based panels present adequate performance to be considered as cavity wall insulation material. However, it is required to treat the panels with flame retardants and antifungal additive to guarantee an adequate performance during their service life.

The results confirm the possibility to reuse a renewable, biodegradable, and locally abundant natural waste. In this regard, the EGFB-based panel can be an alternative to solve the bark disposal problem generated by the forestry industry and the environmental impact generated by the construction industry.

In fact, the use of this bio-based product represents an improvement in the sustainability of buildings, because, compared to traditional panels, EGFB panels present environmental benefits since the beginning, i.e., as early as the procurement of the raw material and the production of the panels. This is reinforced by using as the main raw material a waste of the forestry industry. Finally, considering that insulation panels are a key material to ensure indoor living comfort, the application and benefits of the EGFB-based insulation panels can be a massive sustainable solution.

Author Contributions

Conceptualization, C.F. and M.P-M. and C.S.; methodology, C.F. and C.S.; investigation, C.F., C.S. and M.P-M.; resources, C.F. and C.S.; writing—original draft preparation, C.F., C.S. and M.P-M.; writing—review and editing, M.P-M. and A.C.; visualization, C.F., M.P.-M. and A.C., All authors have read and agreed to the published version of the manuscript.

Funding

The authors acknowledge the funding provided by the Franco-Chilean EcosSud Collaborative Program C18E05, and the support of ANID BASAL FB210015 CENAMAD and Fondef ID14I20081

Data Availability Statement

Data sharing is not applicable to this article.

Acknowledgments

All authors thank to Johana Vega and ANID BASAL FB210015 CENAMAD

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Güereca, L. P.; Jato-Espino, D.; Lizasoain-Arteaga, E. Life-Cycle Assessment of Construction Materials: Analysis of Environmental Impacts and Recommendations of Eco-Efficient Management Practices. In Handbook of Environmental Materials Management; Springer International Publishing: Cham, 2019; pp. 2337–2372. [Google Scholar] [CrossRef]

- Zabalza Bribián, I.; Valero Capilla, A.; Aranda Usón, A. Life Cycle Assessment of Building Materials: Comparative Analysis of Energy and Environmental Impacts and Evaluation of the Eco-Efficiency Improvement Potential. Build Environ 2011, 46, 1133–1140. [Google Scholar] [CrossRef]

- Biyada, S.; Merzouki, M.; Urbonavičius, J. New Resources for Sustainable Thermal Insulation Using Textile and Agricultural Waste in a New Circular Economy Approach: An Overview. Processes 2023, 11, 2683. [Google Scholar] [CrossRef]

- Siciliano, A.; Zhao, X.; Fedderwitz, R.; Ramakrishnan, K.; Dai, J.; Gong, A.; Zhu, J.; Kośny, J.; Hu, L. Sustainable Wood-Waste-Based Thermal Insulation Foam for Building Energy Efficiency. Buildings 2023, 13, 840. [Google Scholar] [CrossRef]

- Petcu, C.; Hegyi, A.; Stoian, V.; Dragomir, C. S.; Ciobanu, A. A.; Lăzărescu, A.-V.; Florean, C. Research on Thermal Insulation Performance and Impact on Indoor Air Quality of Cellulose-Based Thermal Insulation Materials. Materials 2023, 16, 5458. [Google Scholar] [CrossRef] [PubMed]

- Gamon, G.; Evon, Ph.; Rigal, L. Twin-Screw Extrusion Impact on Natural Fibre Morphology and Material Properties in Poly(Lactic Acid) Based Biocomposites. Ind Crops Prod 2013, 46, 173–185. [Google Scholar] [CrossRef]

- Viel, M.; Collet, F.; Lanos, C. Development and Characterization of Thermal Insulation Materials from Renewable Resources. Constr Build Mater 2019, 214, 685–697. [Google Scholar] [CrossRef]

- Liu, W.; Chen, T.; Fei, M.; Qiu, R.; Yu, D.; Fu, T.; Qiu, J. Properties of Natural Fiber-Reinforced Biobased Thermoset Biocomposites: Effects of Fiber Type and Resin Composition. Compos B Eng 2019, 171, 87–95. [Google Scholar] [CrossRef]

- Baley, C.; Gomina, M.; Breard, J.; Bourmaud, A.; Davies, P. Variability of Mechanical Properties of Flax Fibres for Composite Reinforcement. A Review. Ind Crops Prod 2020, 145, 111984. [Google Scholar] [CrossRef]

- Vinod, A.; Sanjay, M. R.; Suchart, S.; Jyotishkumar, P. Renewable and Sustainable Biobased Materials: An Assessment on Biofibers, Biofilms, Biopolymers and Biocomposites. J Clean Prod 2020, 258, 120978. [Google Scholar] [CrossRef]

- Pratheep, V. G.; Priyanka, E. B.; Thangavel, S.; Jason Gousanal, J.; Bijoy Antony, P. T.; Kavin, E. D. Investigation and Analysis of Corn Cob, Coir Pith with Wood Plastic Composites. Mater Today Proc 2021, 45, 549–555. [Google Scholar] [CrossRef]

- Duque Schumacher, A. G.; Pequito, S.; Pazour, J. Industrial Hemp Fiber: A Sustainable and Economical Alternative to Cotton. J Clean Prod 2020, 268, 122180. [Google Scholar] [CrossRef]

- Cosentino, L.; Fernandes, J.; Mateus, R. A Review of Natural Bio-Based Insulation Materials. Energies (Basel) 2023, 16, 4676. [Google Scholar] [CrossRef]

- Liu, L.; Li, H.; Lazzaretto, A.; Manente, G.; Tong, C.; Liu, Q.; Li, N. The Development History and Prospects of Biomass-Based Insulation Materials for Buildings. Renewable and Sustainable Energy Reviews 2017, 69, 912–932. [Google Scholar] [CrossRef]

- Lanting, S. Biobased Materials in the Construction Industry: A Case Study into the Effects of Using Biobased Con-Struction Materials on Life Cycle Costs, University of Twente, Twente, Netherlands, 2023.

- Betts, D.; Sadeghian, P.; Fam, A. Post-Impact Residual Strength and Resilience of Sandwich Panels with Natural Fiber Composite Faces. Journal of Building Engineering 2021, 38, 102184. [Google Scholar] [CrossRef]

- Martínez, B.; Bernat-Maso, E.; Gil, L. Applications and Properties of Hemp Stalk-Based Insulating Biomaterials for Buildings: Review. Materials 2023, 16, 3245. [Google Scholar] [CrossRef] [PubMed]

- Grenon, V.; Maref, W.; Ouellet-Plamondon, C. M. Comparison of Thermal Insulation Proprieties between Glass Wool, Hemp Wool and an Experimental Material Composed of Pleurotus Ostreatus Mycelium and Ash Wood Chips.

- Shavyrkina, N. A.; Budaeva, V. V.; Skiba, E. A.; Gismatulina, Y. A.; Sakovich, G. V. Review of Current Prospects for Using Miscanthus-Based Polymers. Polymers (Basel) 2023, 15, 3097. [Google Scholar] [CrossRef] [PubMed]

- Khalaf, Y.; El Hage, P.; Dimitrova Mihajlova, J.; Bergeret, A.; Lacroix, P.; El Hage, R. Influence of Agricultural Fibers Size on Mechanical and Insulating Properties of Innovative Chitosan-Based Insulators. Constr Build Mater 2021, 287, 123071. [Google Scholar] [CrossRef]

- Masuda, T.; Takano, K.; Hiyama, K. Sound Absorption Performance Test of Grass Compression Board to Promote Resource Circulation. E3S Web of Conferences 2023, 396, 01034. [Google Scholar] [CrossRef]

- Dias, P. P.; Jayasinghe, L. B.; Waldmann, D. Investigation of Mycelium-Miscanthus Composites as Building Insulation Material. Results in Materials 2021, 10, 100189. [Google Scholar] [CrossRef]

- Gößwald, J.; Barbu, M.-C.; Petutschnigg, A.; Tudor, E. M. Binderless Thermal Insulation Panels Made of Spruce Bark Fibres. Polymers (Basel) 2021, 13, 1799. [Google Scholar] [CrossRef]

- Dong, Y.; Kong, J.; Mousavi, S.; Rismanchi, B.; Yap, P.-S. Wall Insulation Materials in Different Climate Zones: A Review on Challenges and Opportunities of Available Alternatives. Thermo 2023, 3, 38–65. [Google Scholar] [CrossRef]

- Soto, M.; Rojas, C.; Cárdenas-Ramírez, J. P. Characterization of a Thermal Insulating Material Based on a Wheat Straw and Recycled Paper Cellulose to Be Applied in Buildings by Blowing Method. Sustainability 2022, 15, 58. [Google Scholar] [CrossRef]

- Schulte, M.; Lewandowski, I.; Pude, R.; Wagner, M. Comparative Life Cycle Assessment of Bio-based Insulation Materials: Environmental and Economic Performances. GCB Bioenergy 2021, 13, 979–998. [Google Scholar] [CrossRef]

- Carabaño Rodríguez, R.; Bedoya Frutos, C.; Galván Martínez, J.; Ruiz Amador, D. La Utilización Del Corcho Como Material de Aislamiento Térmico Para Una Construcción Sostenible. In I Congreso Internacional sobre Investigación en Construcción y Tecnología Arquitectónica; Madrid, 2014.

- Cai, Z.; Song, X.; Wang, X.; Guo, T.; Takahashi, H.; Cai, C. Effect of Applied Pressure on the Performance of Biodegradable Fiber Insulation Board Manufactured from Camphor Branches (Cinnamomum Camphora). Forests 2024, 15, 156. [Google Scholar] [CrossRef]

- Xu, J.; Sugawara, R.; Widyorini, R.; Han, G.; Kawai, S. Manufacture and Properties of Low-Density Binderless Particleboard from Kenaf Core. Journal of Wood Science 2004, 50, 62–67. [Google Scholar] [CrossRef]

- Sahari, J.; Sapuan, S. M.; Zainudin, E. S.; Maleque, M. A. Sugar Palm Tree: A Versatile Plant and Novel Source for Biofibres, Biomatrices, and Biocomposites. Polymers from Renewable Resources 2012, 3, 61–78. [Google Scholar] [CrossRef]

- Pinto, J.; Cruz, D.; Paiva, A.; Pereira, S.; Tavares, P.; Fernandes, L.; Varum, H. Characterization of Corn Cob as a Possible Raw Building Material. Constr Build Mater 2012, 34, 28–33. [Google Scholar] [CrossRef]

- Mati-Baouche, N.; De Baynast, H.; Lebert, A.; Sun, S.; Lopez-Mingo, C. J. S.; Leclaire, P.; Michaud, P. Mechanical, Thermal and Acoustical Characterizations of an Insulating Bio-Based Composite Made from Sunflower Stalks Particles and Chitosan. Ind Crops Prod 2014, 58, 244–250. [Google Scholar] [CrossRef]

- Sanjay, M. R.; Siengchin, S.; Parameswaranpillai, J.; Jawaid, M.; Pruncu, C. I.; Khan, A. A Comprehensive Review of Techniques for Natural Fibers as Reinforcement in Composites: Preparation, Processing and Characterization. Carbohydr Polym 2019, 207, 108–121. [Google Scholar] [CrossRef]

- Papadopoulos, A. M. State of the Art in Thermal Insulation Materials and Aims for Future Developments. Energy Build 2005, 37, 77–86. [Google Scholar] [CrossRef]

- Aly, N. M.; Seddeq, H. S.; Elnagar, Kh.; Hamouda, T. Acoustic and Thermal Performance of Sustainable Fiber Reinforced Thermoplastic Composite Panels for Insulation in Buildings. Journal of Building Engineering 2021, 40, 102747. [Google Scholar] [CrossRef]

- Berardi, U.; Iannace, G. Acoustic Characterization of Natural Fibers for Sound Absorption Applications. Build Environ 2015, 94, 840–852. [Google Scholar] [CrossRef]

- Asdrubali, F.; Pisello, A. L.; Alessandro, F. D.; Bianchi, F.; Cornicchia, M.; Fabiani, C. Innovative Cardboard Based Panels with Recycled Materials from the Packaging Industry: Thermal and Acoustic Performance Analysis. Energy Procedia 2015, 78, 321–326. [Google Scholar] [CrossRef]

- Rojas, C.; Cea, M.; Iriarte, A.; Valdés, G.; Navia, R.; Cárdenas-R, J. P. Thermal Insulation Materials Based on Agricultural Residual Wheat Straw and Corn Husk Biomass, for Application in Sustainable Buildings. Sustainable Materials and Technologies 2019, 20, e00102. [Google Scholar] [CrossRef]

- Pennacchio, R.; Savio, L.; Bosia, D.; Thiebat, F.; Piccablotto, G.; Patrucco, A.; Fantucci, S. Fitness: Sheep-Wool and Hemp Sustainable Insulation Panels. Energy Procedia 2017, 111, 287–297. [Google Scholar] [CrossRef]

- Muthuraj, R.; Lacoste, C.; Lacroix, P.; Bergeret, A. Sustainable Thermal Insulation Biocomposites from Rice Husk, Wheat Husk, Wood Fibers and Textile Waste Fibers: Elaboration and Performances Evaluation. Ind Crops Prod 2019, 135, 238–245. [Google Scholar] [CrossRef]

- Ali, M. E.; Alabdulkarem, A. On Thermal Characteristics and Microstructure of a New Insulation Material Extracted from Date Palm Trees Surface Fibers. Constr Build Mater 2017, 138, 276–284. [Google Scholar] [CrossRef]

- Ranefjärd, O.; Strandberg-de Bruijn, P. B.; Wadsö, L. Hygrothermal Properties and Performance of Bio-Based Insulation Materials Locally Sourced in Sweden. Materials 2024, 17, 2021. [Google Scholar] [CrossRef]

- Brandão, A. S.; Gonçalves, A.; Santos, J. M. R. C. A. Circular Bioeconomy Strategies: From Scientific Research to Commercially Viable Products. J Clean Prod 2021, 295, 126407. [Google Scholar] [CrossRef]

- Gregg, J. S.; Jürgens, J.; Happel, M. K.; Strøm-Andersen, N.; Tanner, A. N.; Bolwig, S.; Klitkou, A. Valorization of Bio-Residuals in the Food and Forestry Sectors in Support of a Circular Bioeconomy: A Review. J Clean Prod 2020, 267, 122093. [Google Scholar] [CrossRef]

- Ferreira, V.; Boyero, L.; Calvo, C.; Correa, F.; Figueroa, R.; Gonçalves, J. F.; Goyenola, G.; Graça, M. A. S.; Hepp, L. U.; Kariuki, S.; López-Rodríguez, A.; Mazzeo, N.; M’Erimba, C.; Monroy, S.; Peil, A.; Pozo, J.; Rezende, R.; Teixeira-de-Mello, F. A Global Assessment of the Effects of Eucalyptus Plantations on Stream Ecosystem Functioning. Ecosystems 2019, 22, 629–642. [Google Scholar] [CrossRef]

- Quilhó, T.; Pereira, H. WITHIN AND BETWEEN-TREE VARIATION OF BARK CONTENT AND WOOD DENSITY OF EUCALYPTUS GLOBULUS IN COMMERCIAL PLANTATIONS. IAWA J 2001, 22, 255–265. [Google Scholar] [CrossRef]

- Ministerio de Agricultura. Anuario Forestal 2023; 2023.

- Sartori, C.; da Silva Mota, G.; Ferreira, J.; Miranda, I.; Mori, F. A.; Pereira, H. Chemical Characterization of the Bark of Eucalyptus Urophylla Hybrids in View of Their Valorization in Biorefineries. Holzforschung 2016, 70, 819–828. [Google Scholar] [CrossRef]

- Neiva, D. M.; Araújo, S.; Gominho, J.; Carneiro, A. de C.; Pereira, H. Potential of Eucalyptus Globulus Industrial Bark as a Biorefinery Feedstock: Chemical and Fuel Characterization. Ind Crops Prod 2018, 123, 262–270. [Google Scholar] [CrossRef]

- Abdelkhalek, A.; Salem, M. Z. M.; Kordy, A. M.; Salem, A. Z. M.; Behiry, S. I. Antiviral, Antifungal, and Insecticidal Activities of Eucalyptus Bark Extract: HPLC Analysis of Polyphenolic Compounds. Microb Pathog 2020, 147, 104383. [Google Scholar] [CrossRef] [PubMed]

- Martini, S.; Afroze, S.; Ahmad Roni, K. Modified Eucalyptus Bark as a Sorbent for Simultaneous Removal of COD, Oil, and Cr(III) from Industrial Wastewater. Alexandria Engineering Journal 2020, 59, 1637–1648. [Google Scholar] [CrossRef]

- Ghodbane, I.; Hamdaoui, O. Removal of Mercury (II) from Aqueous Media Using Eucalyptus Bark: Kinetic and Equilibrium Studies. J Hazard Mater 2008, 160, 301–309. [Google Scholar] [CrossRef] [PubMed]

- Romaní, A.; Larramendi, A.; Yáñez, R.; Cancela, Á.; Sánchez, Á.; Teixeira, J. A.; Domingues, L. Valorization of Eucalyptus Nitens Bark by Organosolv Pretreatment for the Production of Advanced Biofuels. Ind Crops Prod 2019, 132, 327–335. [Google Scholar] [CrossRef]

- Wesolowski, A.; Adams, M. A.; Pfautsch, S. Insulation Capacity of Three Bark Types of Temperate Eucalyptus Species. For Ecol Manage 2014, 313, 224–232. [Google Scholar] [CrossRef]

- Casas-Ledón, Y.; Daza Salgado, K.; Cea, J.; Arteaga-Pérez, L. E.; Fuentealba, C. Life Cycle Assessment of Innovative Insulation Panels Based on Eucalyptus Bark Fibers. J Clean Prod 2020, 249, 119356. [Google Scholar] [CrossRef]

- Sluiter, A.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D. Determination of Extractives in Biomass. Laboratory Analytical Procedure.; 2008.

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D. Determination of Structural Carbohydrates and Lignin in Biomass. Laboratory Analytical Procedure.; 2012.

- International Organization for Standardization (ISO). ISO 18122:2016: Solid Biofuels - Determination of Ash Content.

- The Spanish Association for Standardization. UNE EN 323: Wood-Based Panels - Determination of Density; 1994.

- The Spanish Association for Standardization. UNE EN 325: Wood-Based Panels - Determination of Dimensions of Test Pieces; 2012.

- American Society for Testing and Materials (ASTM). ASTM D 5334: Standard Test Method For Determination Of Thermal Conductivity Of Soil And Soft Rock By Thermal Needle Probe Procedure; 2008.

- Morîntale, E.; Harabor, A.; Constantinescu, C.; Rotaru, P. Use of Heat Flows from DSC Curve for Calculation of Specific Heat of the Solid Materials. Physics AUC 2013, 23, 89–94. [Google Scholar]

- American Society for Testing and Materials (ASTM). ASTM E 95-96: Standard Test Methods for Water Vapor Transmission of Materials; 1995.

- This British Standard (BS). BS 5250:2002 Incorporating Amendment No. 1: Code of Practice for Control of Condensation in BuildingsICS 91.120.99.; 2002.

- American Society for Testing and Materials (ASTM). ASTM D 4986-03: Standard Test Method for Horizontal Burning Characteristics of Cellular Polymeric Materials; 2003.

- American Society for Testing and Materials (ASTM). ASTM D 3273: Standard Test Method for Resistance to Growth of Mold on the Surface of Interior Coatings in an Environmental Chamber; 2021.

- Pereira, H. Variability in the Chemical Composition of Plantation Eucalypts (Eucalyptus Globulus Labill). Wood and Fiber Science 1988, 82–90. [Google Scholar]

- DIN. DIN 4108-2: Thermal Protection and Energy Economy in Buildings - Part 2: Minimum Requirements to Thermal Insulation; Berlin, 2013.

- Ducoulombier, L.; Lafhaj, Z. Comparative Study of Hygrothermal Properties of Five Thermal Insulation Materials. Case Studies in Thermal Engineering 2017, 10, 628–640. [Google Scholar] [CrossRef]

- Korjenic, A.; Petránek, V.; Zach, J.; Hroudová, J. Development and Performance Evaluation of Natural Thermal-Insulation Materials Composed of Renewable Resources. Energy Build 2011, 43, 2518–2523. [Google Scholar] [CrossRef]

- Khedari, J.; Nankongnab, N.; Hirunlabh, J.; Teekasap, S. New Low-Cost Insulation Particleboards from Mixture of Durian Peel and Coconut Coir. Build Environ 2004, 39, 59–65. [Google Scholar] [CrossRef]

- Actis. Wood Fibre Insulation Product Guide Sylvactis 55 FX (Vol. 297).; 2015.

- Hauser, G.; Otto, F.; Ringeler, M. Verbesserung Des Sommerlichen Wärmeverhaltens von Wohngebäuden Durch Holzfaser-Dämmplatten. 2005, 561.

- Neroth, G.; Vollenschaar, D. Wendehorst Baustoffkunde; Neroth, G., Vollenschaar, D., Eds.; Vieweg+Teubner: Wiesbaden, 2011. [CrossRef]

- Fachgentur Nachwachsende Rohstoffe, e.V. Dämmstoffe Aus Nachwachseden Rohstoffen. ; 2016.

- Johra, H. Thermal Properties of Building Materials - Review and Database; Aalborg, 2021. [CrossRef]

- Shakir, M. A.; Ahmad, M. I.; Yusup, Y.; Wabaidur, S. M.; Siddiqui, M. R.; Alam, M.; Rafatullah, M. Sandwich Composite Panel from Spent Mushroom Substrate Fiber and Empty Fruit Bunch Fiber for Potential Green Thermal Insulation. Buildings 2023, 13, 224. [Google Scholar] [CrossRef]

- Božiková, M.; Kotoulek, P.; Bilčík, M.; Kubík, Ľ.; Hlaváčová, Z.; Hlaváč, P. Thermal Properties of Wood and Wood Composites Made from Wood Waste. Int Agrophys 2021, 35, 251–256. [Google Scholar] [CrossRef]

- Torres-Ramo, J.; González-Martínez, P.; Arriazu-Ramos, N.; Sánchez-Ostiz, A. Influence of the Water Vapour Permeability of Airtight Sheets on the Behaviour of Facade. Sustainability 2020, 12, 10480. [Google Scholar] [CrossRef]

- Charvátová, H.; Procházka, A.; Zálešák, M.; Drápela, J.; MAříK, V. Computational Analysis of Indoor Thermal Comfort in a Terraced Family House With Thermal Insulation. IEEE Access 2023, 11, 80822–80834. [Google Scholar] [CrossRef]

- Jerman, M.; Černý, R. Effect of Moisture Content on Heat and Moisture Transport and Storage Properties of Thermal Insulation Materials. Energy Build 2012, 53, 39–46. [Google Scholar] [CrossRef]

- Cetiner, I.; Shea, A. D. Wood Waste as an Alternative Thermal Insulation for Buildings. Energy Build 2018, 168, 374–384. [Google Scholar] [CrossRef]

- Cámara Chilena de la Construcción. Informe MACh 60 Macroeconomía y Construcción; 2022.

- Ordenanza General de Urbanismo y Construcciones (OGUC). Ordenanza General de Urbanismo y Construcciones.; 2017.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).