1. Introduction

Synthetic biology is regarded as the third biotechnology revolution after "DNA double helix discovery" and "human genome sequencing". It breaks through the traditional research paradigm of biology which focuses on discovery description and quantitative analysis, and provides a new research idea of quantitative, designable, predictable and engineering for life science [

1]. Using synthetic biology techniques, researchers can re-engineer and synthesize organisms to create simpler and more efficient biological processes, more efficient synthesis of desired target products, more natural medicines to treat complex diseases, and biofuels to secure national energy reserves. In the field of medicine, several strains of high-yield drugs modified by scientists using synthetic biology technology have been put into use; In the field of biofuels, scientists have designed and constructed Escherichia coli for biodiesel production, opening up a new way for microbial engineering to refine energy [

1]. In the process of modifying synthetic organisms, researchers need to redesign, synthesize and clone biological cells, and repeatedly pick and clone biological cells on the basis of continuous experimental trial and error, then finally gradually approach the design goal. Currently, in synthetic biological casting process, the operator often needs to operate and coordinate multiple related instruments, with these devices operate independently. Once the completion of the current instrument operation steps, the sample needs to be manually transferred to the next instrument to continue the workflow. Although these instruments have high efficiency in their respective processes, the flow between processes is cumbersome, time-consuming, and highly repetitive, which largely occupies the time of researchers, in some ways, also reduces the overall research efficiency. In order to accelerate the research of synthetic biology, we need to introduce standardized experimental means, so as to complete the engineering closed-loop R&D of "design-build-test" with high throughput, low cost and multiple cycles. Therefore, it is urgent to establish a professional platform of synthetic biology that can realize the engineering and mass synthesis of living organisms [

2,

3].

In 2019, the "Global Biofoundry Alliance" was established in Japan, which aims to strengthen cooperation and communication between institution, jointly tackle the technical problems of automated synthetic biology research, formulate international unified standards, and introduce the concept of intelligent manufacturing into synthetic biology [

4]. This type of automated facility for synthetic biology research is also called Biofoundry [

5]. In recent years, many international research institutions have built Biofoundry [

6]. Research institutions in the United States, the United Kingdom and other countries have completed the construction of synthetic biology automated infrastructure. For example, iBioFAB(Illinois Biological Foundry for Advanced Biomanufacturing) at the University of Illinois, Agile Biofoundry at the US Department of Energy, and Edinburgh at the University of Edinburgh in the UK Genome Foundry(EGF) et al. [

7,

8,

9]. In the past decade, China has developed rapidly in the field of synthetic biology, and the Tianjin Institute of Industrial Biotechnology of the Chinese Academy of Sciences independently designed China's first set of automated equipment for the field of synthetic biology [

10]. The platform for synthetic biology research, established by Shenzhen Institute of Advanced Technology, Chinese Academy of Sciences, has opened test operation in 2023 [

11].

The scale and functionality of these facilities are designed according to the specific needs of different countries, and the purpose is to help researchers load specific synthetic biological designs into cells and complete a large number of engineering experiments. At present, scientists can realize the design and construction of synthetic biology automated casting platforms. The feasibility of the idea of mass production of biological organisms has been preliminarily verified, but there are still many challenges in the process of specific engineering applications. Many research and development demands remain unfulfilled. It takes time and efforts to explore subdivisions.

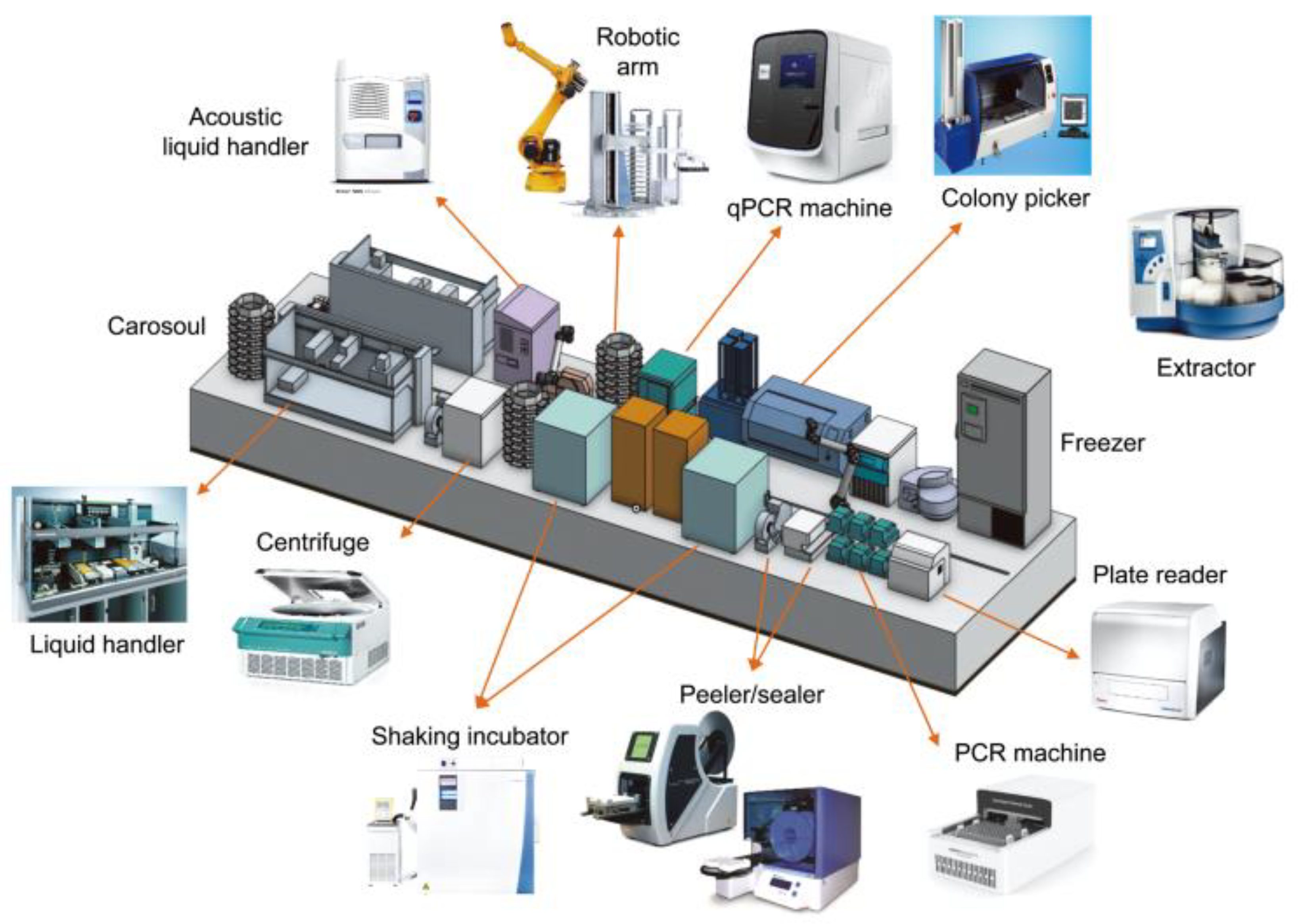

The research and development of synthetic biology automated casting platform involves mechanical engineering, control engineering, biomedical engineering, communication engineering and other related fields. In terms of hardware, it is necessary to ensure that standard experimental vessels such as 96-well plates can be applied on the platform and perform high-throughput operations on the corresponding experimental instruments. Common instruments and equipments for synthetic biology automated casting platforms include, acoustic liquid handler, robotic arm, qPCR machine, colony picker, extractor, freezer, plate reader, PCR machine, peeler, sealer, shaking incubator, centrifuge, liquid handler and so on [

12], are shown in

Figure 1. In terms of software, a set of upper level control software is needed to ensure the integrated control of common instruments and equipment and automatic transfer equipment on the platform. At the same time, it is also necessary to have an information management system that can collect the operation process and experimental data in different equipments. Since most of instruments and equipments used on the platform come from diverse manufacturers, achieving integrated control and information interconnection between different instruments and equipment is a major challenge in current development of the industry.

In practical applications, the synthetic biology automated platform needs to be customized and extended according to the specific case. Therefore, a set of synthetic biology automated casting platform based on automation integration technology is developed to achieve scalability, high throughput and automation, which has great application value for establishing and improving the whole life cycle of synthetic biology research.

In this paper, an extensible automatic casting platform for synthetic biology is constructed. Based on modular equipment design and system software development, a set of synthetic biology automated casting platform integrated system and related methods were proposed to provide intelligent whole-process technical support for synthetic biology and its industrial applications. The main contribution of the paper is to design the system interface based on OPC UA technology, and to enhance the stability of the system through the concept of three-mode redundancy. It effectively solves the bottleneck problem that it is difficult for equipments with different interfaces to access the platform, and preliminarily realizes the interconnection of related synthetic biological equipments on the platform system.

2. Materials and Methods

2.1. System Overview

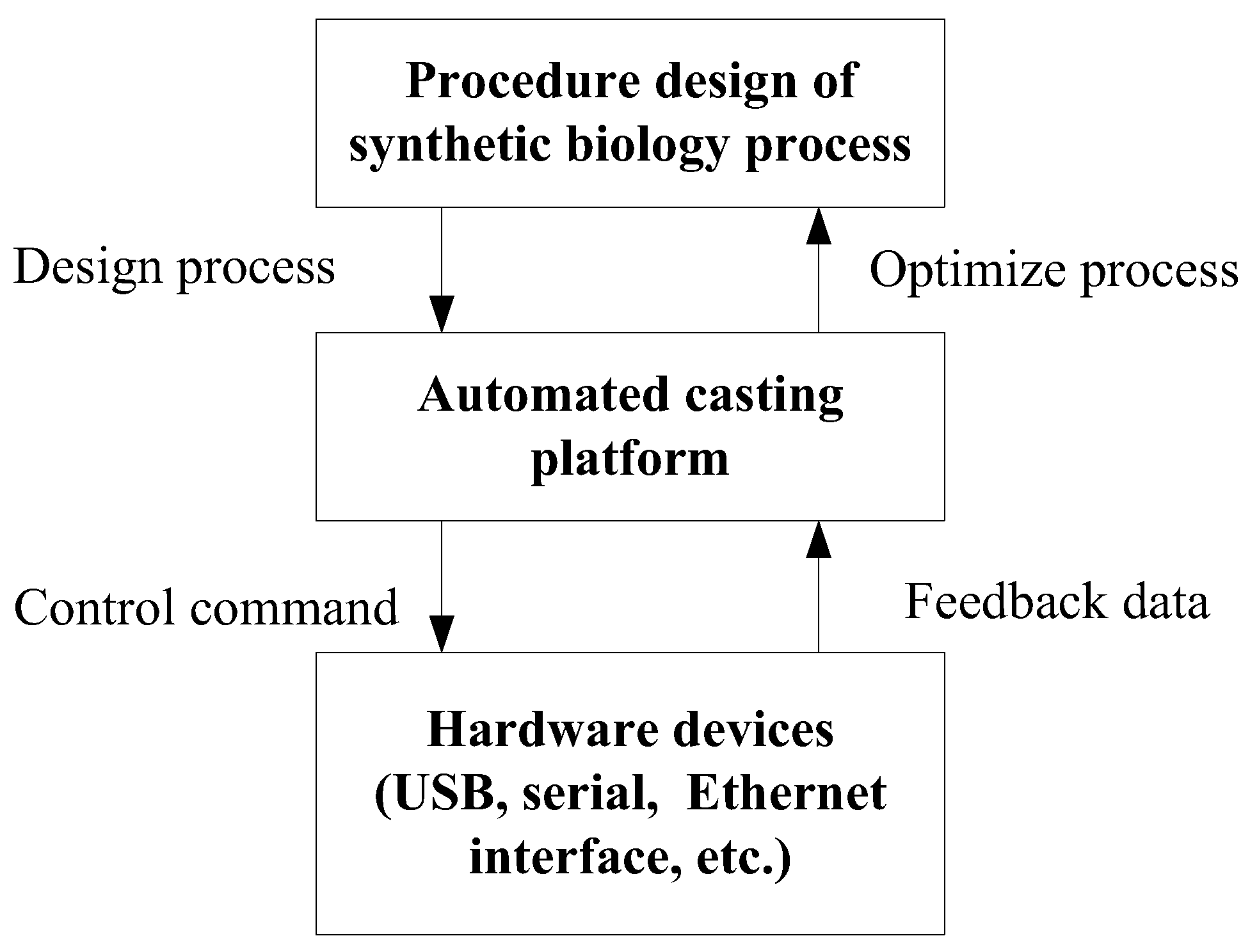

The synthetic biology automatic casting platform proposed in this paper can integrate all synthetic biological equipment in the platform, so that each equipment and the platform can be interconnected. According to the designed synthetic biology process, the operation process is edited on the platform system. The platform system will issue instructions to the subordinate equipment according to the edited operation process, and the equipment will give the data feedback in real time, so as to realize the orderly and controllable overall automatic scheduling, as shown in

Figure 2. The software and hardware modules of the system are designed with reference to the relevant automation integrated control scheme [

13,

14,

15,

16].

The hardware component should include biosynthesis equipment, material transfer equipment, material access equipment, auxiliary feedback equipment, communication equipment, and interactive equipment.

The software part should include the driver protocol module, data transceiver module, data processing module, logic control module, server and client modules.

OPC UA is used to connect and contrl different devices, It is an industrial Internet of things technology with high scalability and security that can solve the problem of interface incompatibility between different hardware and software manufacturers, so that the synthetic biological automatic casting platform can be compatible with serial interface, ethernet interface, USB interface, wireless interface, and achieve cross-platform communication.

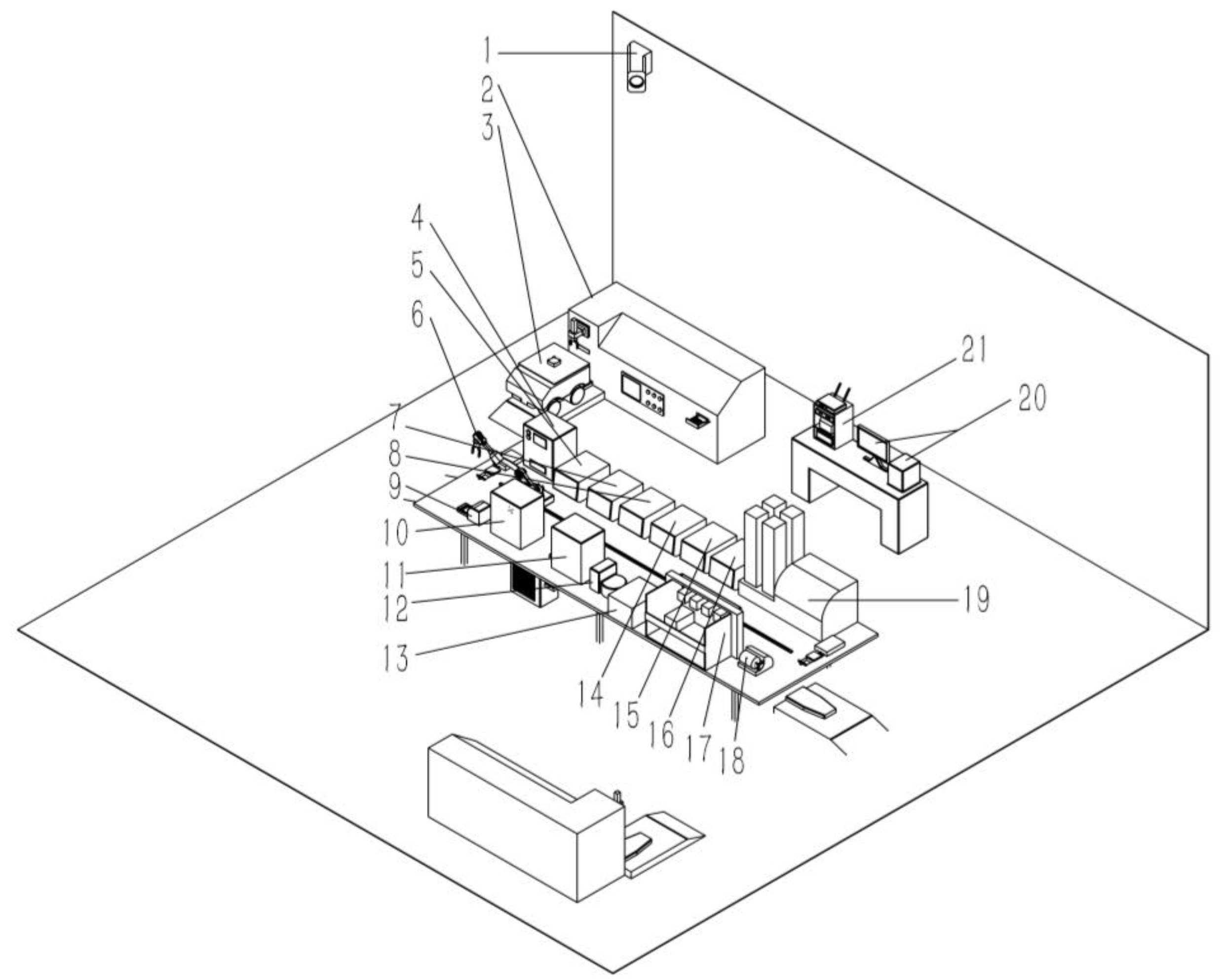

2.2. Hardware Equipment

According to the conventional process of synthetic biology, the instruments with high frequency of use include colony picker, sealer, peeler, code reader, PCR machine, incubator, oscillator, centrifuge, liquid handler, microplate reader and so on. When arranging instruments on the platform, consideration should be given to the sequence of the synthetic biological process and the convenience of the robotic arm in transfering the PCR plate. In addition, the PCR plate may also need to be transfered to other platforms during the experiment, which needs to be completed with the help of AGV. The relevant instruments and equipments involved in the routine process of synthetic biology is listed one by one, as shown in

Table 1. Arrange and plan it, as shown in

Figure 3.

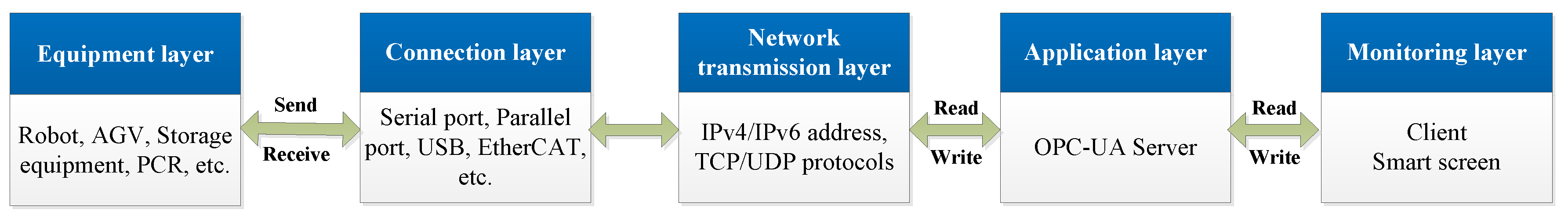

2.3. Communication Framework

The communication between platform system and platform equipment is divided into five different communication layers: equipment layer, connection layer, network transmission layer, application layer and monitoring layer. The five communication layers are adjacent to each other, as shown in

Figure 4. Data is transmitted and exchanged between adjacent layers through encapsulated independent API interfaces, and there is no direct interactive communication relationship between adjacent layers.

The equipment layer refers to all the equipment that provides raw data in the integrated system of synthetic biology automated casting platform. Equipment at the equipment layer provide status data through their own protocol interfaces. This layer provides equipment status data to the system software through cyclic scanning or active upload, and finally issues corresponding equipment instructions according to these states. This layer is not only the source layer of system data, but also the final execution layer of the system.

The connection layer refers to the physical connection between the execution equipment and the communication equipment. For example, serial port, parallel port, CAT-5 cable and so on. By means of physical connection, it effectively avoids the problems such as poor signal stability and poor anti-interference caused by wireless transmission, ensuring the stable transmission of data.

The network transport layer is responsible for managing communication addresses and transport protocols. Its main role is to complete the communication transmission between equipment. And it can provide flow control, error control and other functions for the transmission process.

The application layer is responsible for parsing and using the data. After the data is transmitted from the equipment layer to this layer through the connection layer and the network transport layer, it will be stored in the variable of the server node to provide subscriptions for the client. At the same time, it also analyzes the data, analyzes the status of the equipment, and determines whether to issue the command. In particular, the server of the application layer is the OPC UA server, and there is an independent communication architecture between the OPC UA server and its client.

The monitoring layer is responsible for monitoring the status of the data being read. The client belonging to the monitoring layer will establish a connection with the server belonging to the application layer for data transmission, and the client can subscribe to the value of the equipment node of the equipment layer to understand the status of the equipment in real time, so as to achieve remote monitoring.

2.4. Software Modules and Processes

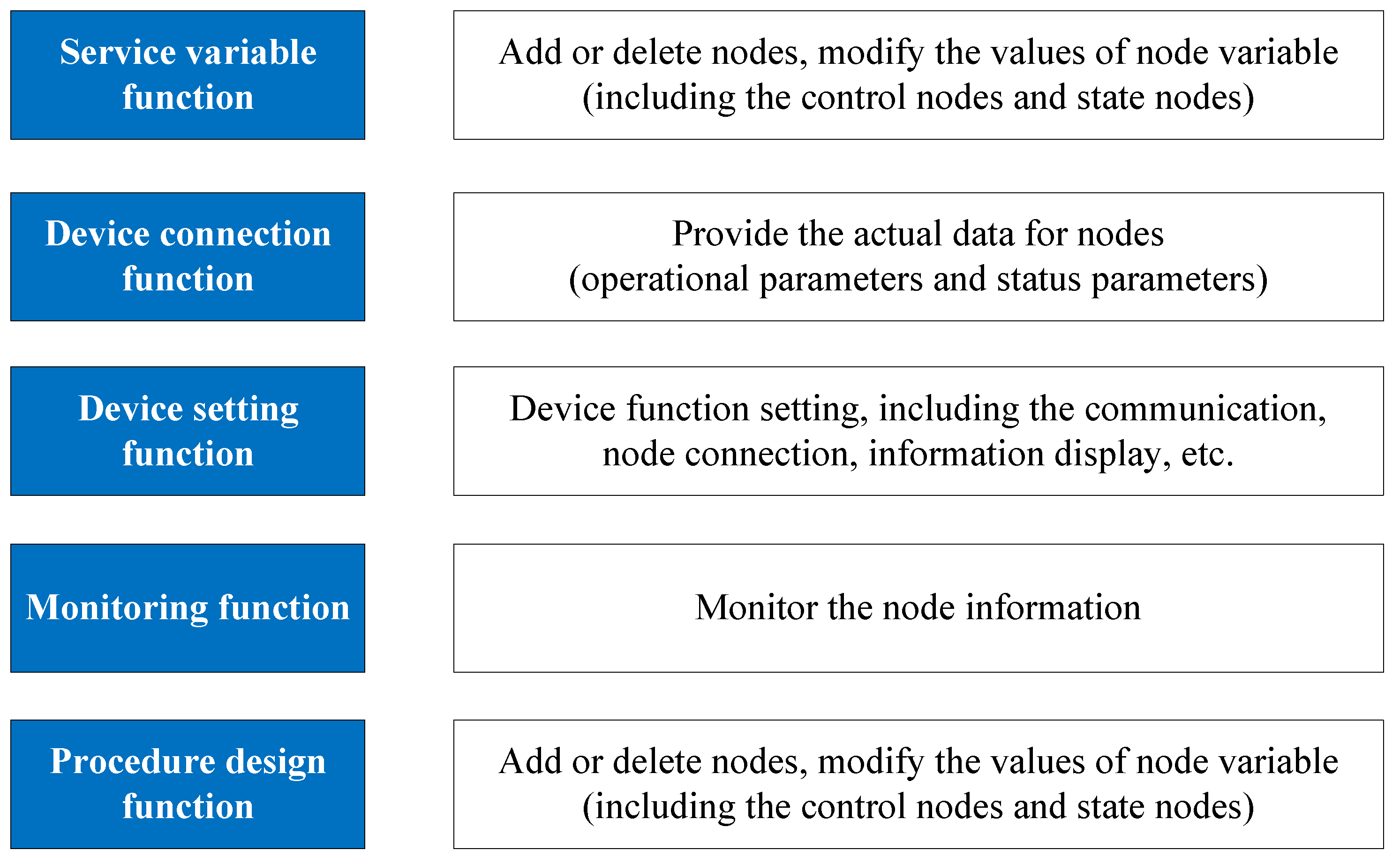

The main functions of automated casting platform include service variable function, device connection function, device setting function, monitoring function, procedure design function, etc. These node variables correspond with the devices. By writing or reading the node variables, we can realize the remote control or status monitoring of the devices.

The implementation of synthetic biology automated casting platform software functions are shown in

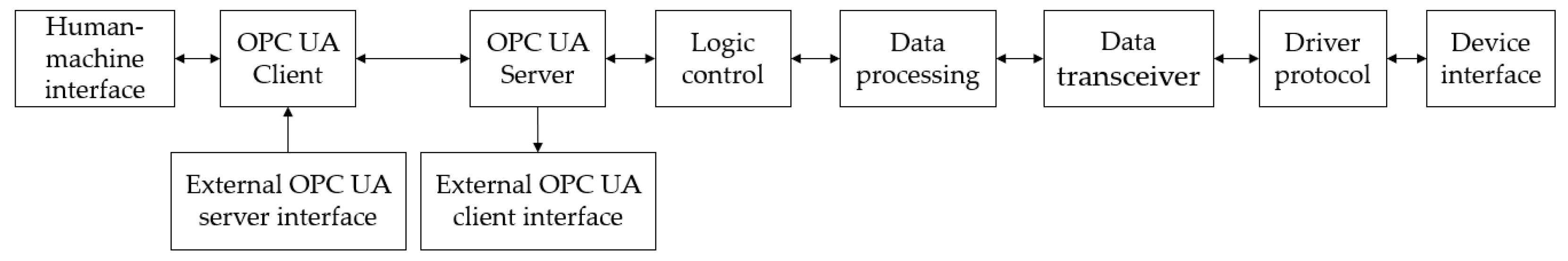

Figure 6. It is composed of ten modules: human-machine interface, OPC UA client, OPC UA server, logic control, data processing, data transceiver, driver protocol, equipment interface, external OPC UA client interface, and external OPC UA server interface. There are two working modes of software design, active triggering and passive backtracking, which can be parallel by multithreading.

Starting from the human-machine interface, from left to right, is the process of the active trigger mode. The operator issues subscription information or control commands to the client through the human-machine interface. The client writes the subscription to the subscription item, and the control command is written to the node in the server where the control instruction is stored. The node value defined as the control is refreshed and sends the node value to the control logic. The control logic determines and arranges the feasibility of the control command value, and finally sends the control command that can make the equipment work normally without conflict to the data processing. Data processing translates control commands into equipment control commands and sends them to data transceiver; Data transceiver sends control instructions to the equipment interface through the driver protocol.

Starting from the human-machine interface, from right to left, is the process of passive backtracking mode. The equipment sends the data information to the equipment interface, and the equipment interface sends the data information to the data transceiver through the driver protocol. Data transceiver transfers data to data processing. The data processing will process the data in a unified structure and update the data to the OPC UA server (if it is the feedback of the control information, it is passed to the control logic). The server returns the subscription node information to the OPC UA client. The client provides the data to the human-machine interface. Human-machine interface is humanized display. OPC UA clients provide extended interfaces for connecting to external OPC UA servers, and OPC UA servers provide extended interfaces for providing services to external OPC UA clients.

2.5. Redundancy Design

In order to improve system reliability, two methods are often used: Fault Avoidance and Fault Tolerance [

17,

18,

19,

20]. Fault avoidance refers to the technology that does not allow errors to creep into the software during the development process. Fault tolerance refers to the technology that minimizes the impact of some unavoidable errors. Reliability design is also needed in the integrated system software of synthetic biology automated casting platform. Considering comprehensively, fault tolerance is more suitable. Fault tolerance methods include structure redundancy, information redundancy, and time redundancy. Structural redundancy can be divided into dynamic redundancy and static redundancy (Triple modular Redundancy). The main way of dynamic redundancy is multi-module standby, when the system detects an error in a working module, it replaces it with a spare module and restarts.

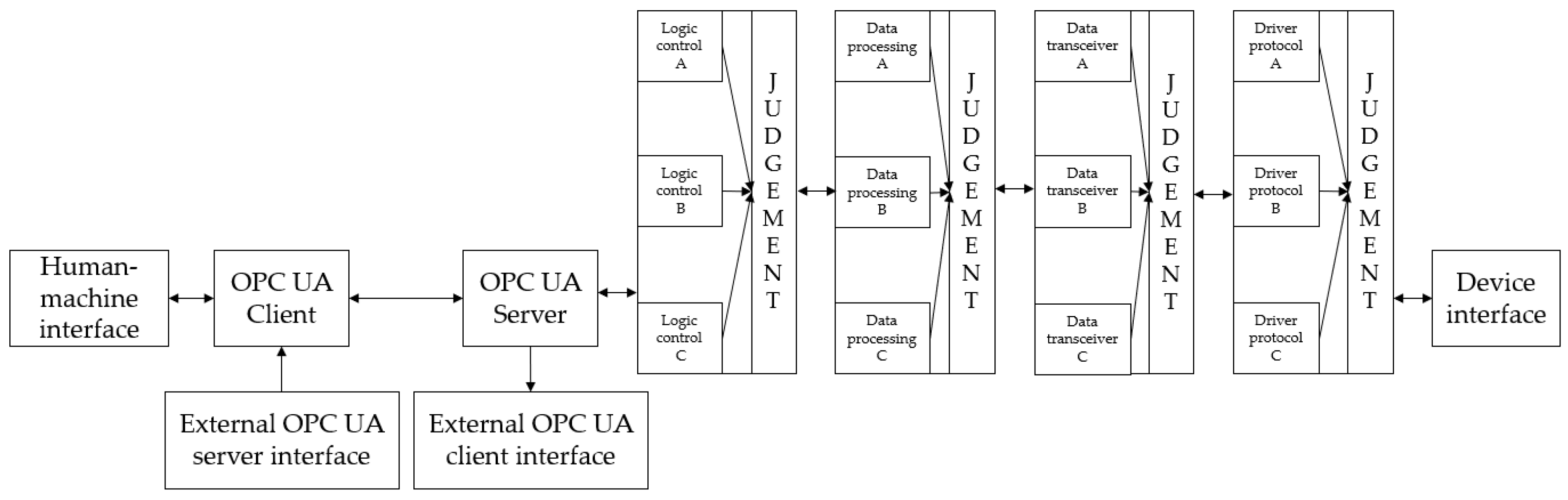

In this paper, triple modular redundancy is used to enhance the reliability of the system software. Triple modular redundancy is achieved by three independent modules performing the same operation at the same time and using a majority voting system to determine the correct output. This design allows the system to work even when no more than two modules have errors, because it is able to compensate for the errors of faulty modules. Triple modular redundancy systems usually follow the "two out of three" rule. If two or more of the three modules provide the same result, then the result is considered the correct output and can improve the confidence of the system [

21]. According to the "two-out-of-three" rule, the data processing, data transceiver, logic control and driving protocols in the system software framework should be further optimized. Because OPC UA already contains redundancy technology [

22], the human-machine interface module and equipment interface module have simple internal structure, so there is no need to do additional redundancy design. The optimized software framework is shown in

Figure 7.

2.6. Software Interface

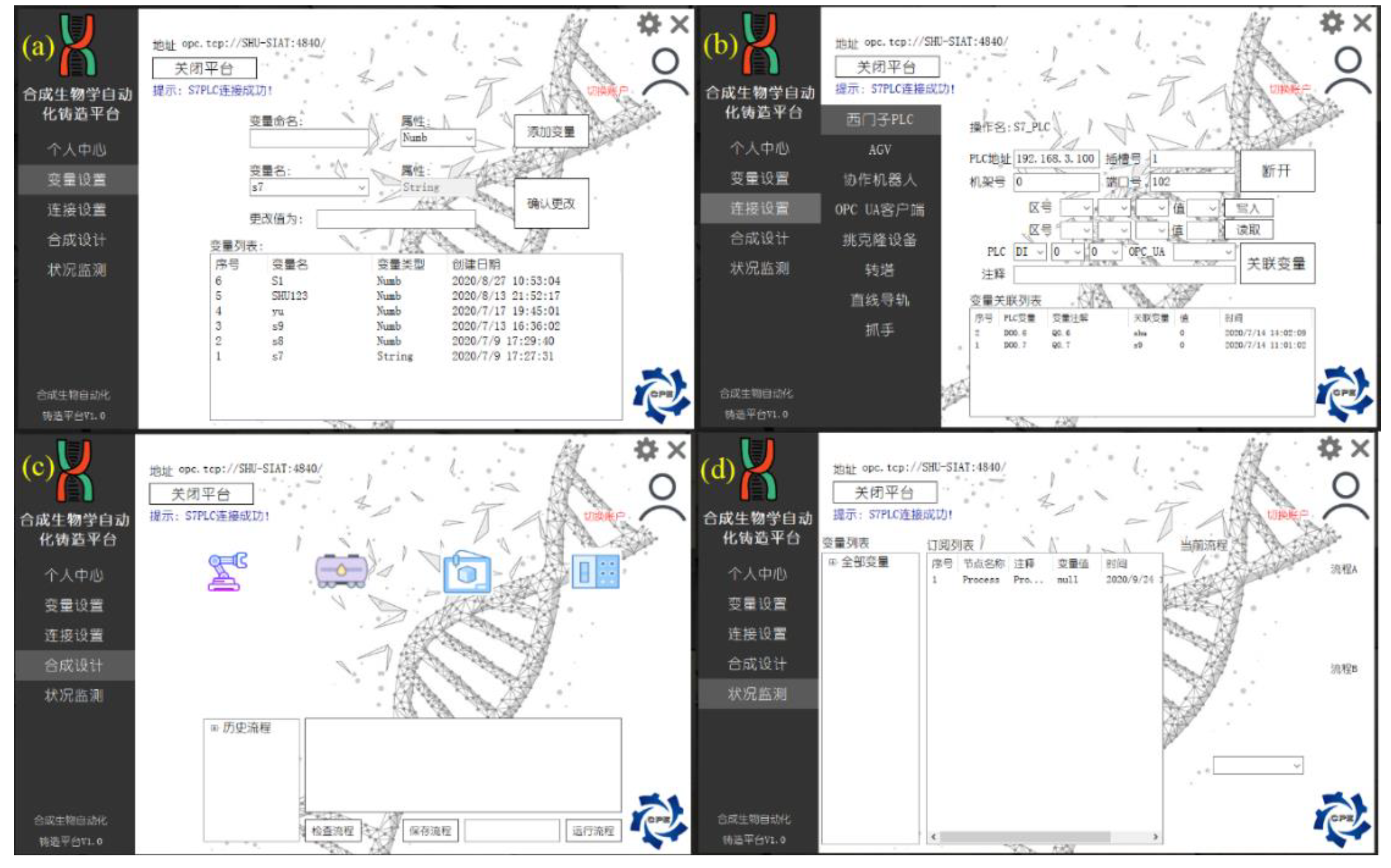

Considering the software framework proposed in the above chapter, the integrated system control software of synthetic biology automated casting platform is designed and developed, as shown in

Figure 8. The variable setting interface, connection setting interface, composition design interface and condition monitoring interface of the software are displayed respectively.

3. Experiment

Escherichia coli, Corynebacterium glutamicum, Bacillus subtilis and Saccharomyces are common industrial microorganisms at present [

23,

24,

25,

26]. Among them, Escherichia coli has the advantage of rapid reproduction, and its physiological and biochemical characteristics have been deeply studied and understood by scientists [

27]. In addition, because of the advantages of clear genetic background and easy genetic manipulation, Escherichia coli is also a model bacterium of molecular biology, which is widely used in the construction of various synthetic organisms[

28,

29,

30].

In this paper, Escherichia coli was used as the experimental bacteria, and batch construction of Escherichia coli was carried out using the project's self-developed synthetic biology automated casting platform.

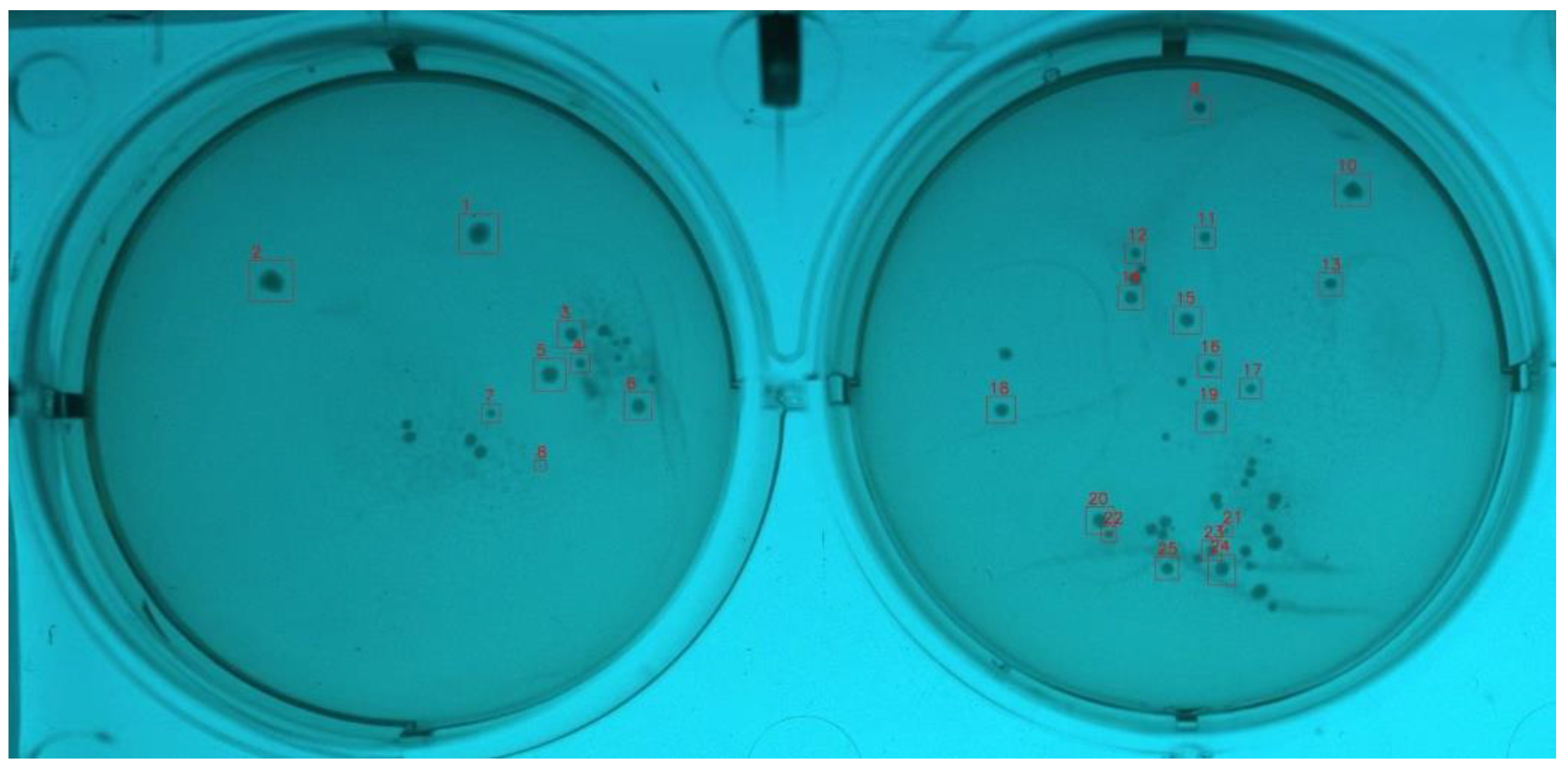

During the whole experiment, the preparation of experimental colonies and the configuration of reaction solution were mainly completed on Liquid Handler. The Manipulator equipped with the seventh axis realized linkage and interaction with other equipment on the platform, integrated all the instruments and equipment that needed manual operation on the platform, completed the operations of liquid configuration, cloning, oscillation, coating and cultivation, realizing the automation of the whole process of synthetic biology. The colonies produced by automated culture are shown in

Figure 9. Under ideal conditions, the platform automated cloning selection efficiency can reach 2,400 colonies/hour.

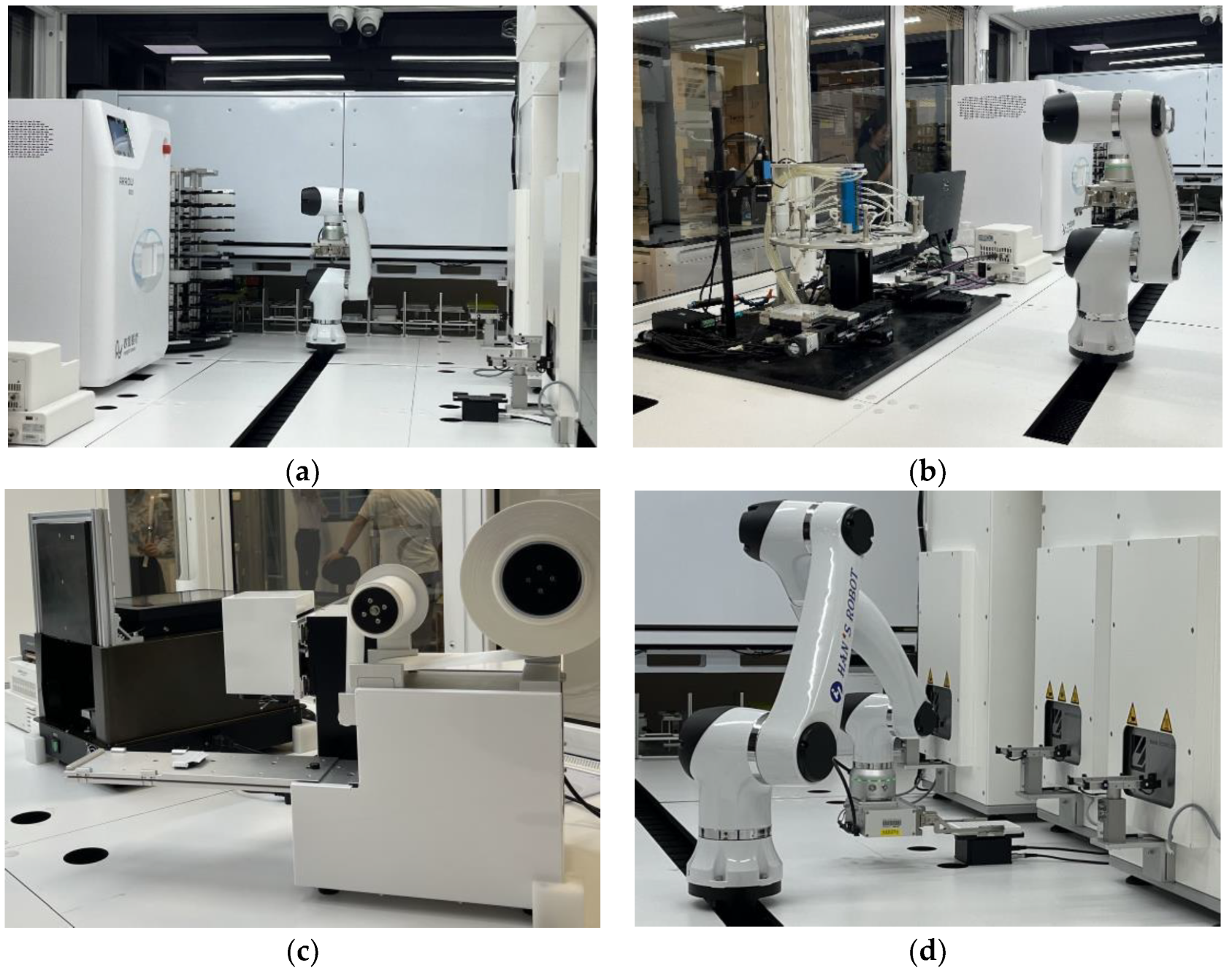

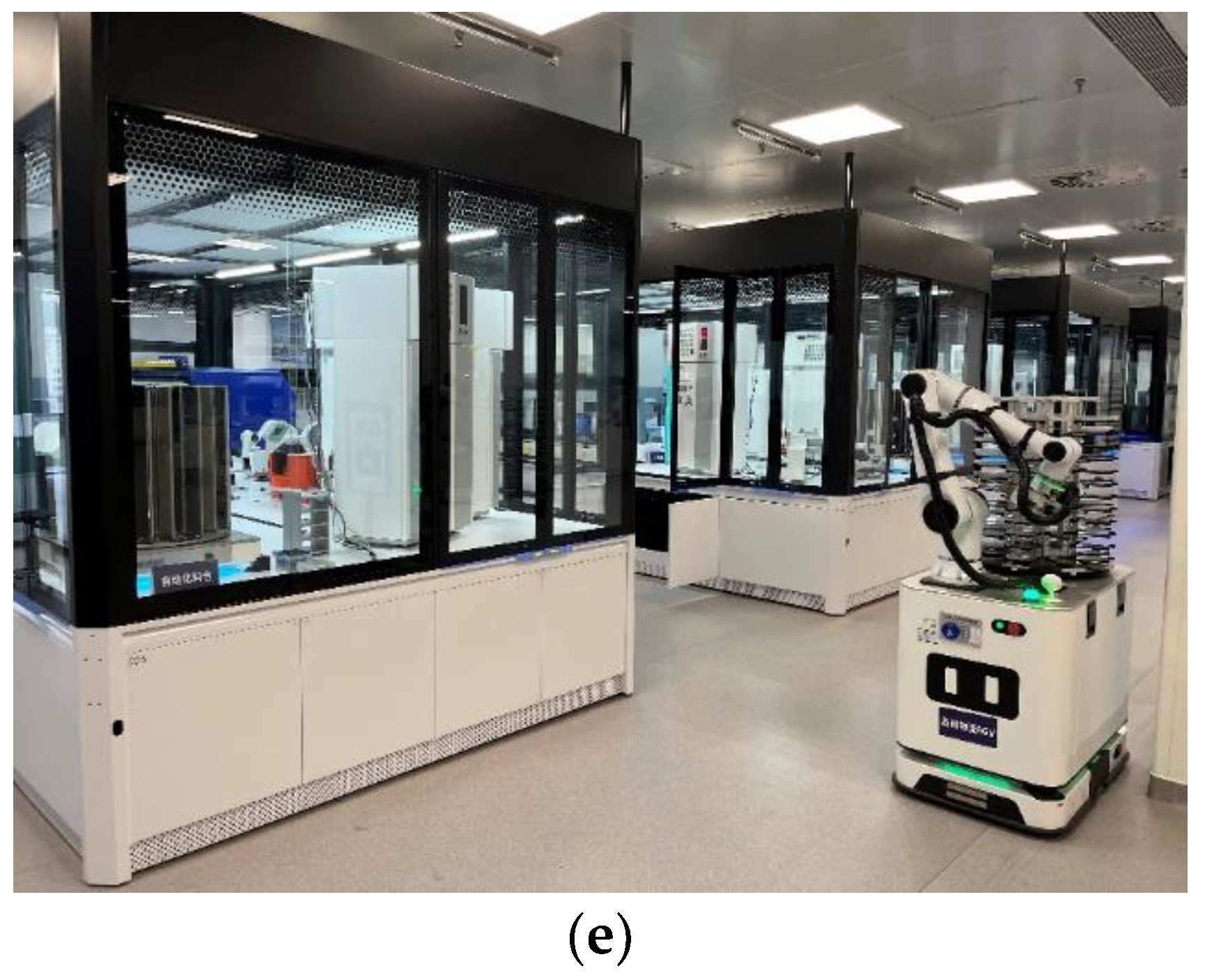

The actual operation of some steps in the above experiment is shown in the

Figure 10. At present, the platform has been gradually applied in the field of synthetic biology, and the relevant automated experimental processes and methods have been jointly developed with cooperative units, and the automatic synthesis of a variety of commonly used organisms has been gradually realized, greatly improving the efficiency of the existing level of synthetic organisms.

In addition to the equipment experiment, we simulated and verified the effect of triple modular redundancy on the system.

After design and optimization with triple modular redundancy, the reliability improvement of the software system was analyzed as follows:

Triple modular redundancy systems usually follow the rule of "two-out-of-three". If two or more of the three modules provide the same result, then this result is considered the correct output.

Ignore modules that do not perform redundancy. The reliability of redundant modules are , , , .

is the reliability probability before two-out-of-three redundancy, expressed as Equation (1).

is the reliability probability after two-out-of-three redundancy, expressed as Equation (2).

In order to express the relationship between the reliability of each module in the redundancy design more directly and simply, the reliability probability of the redundant module is regarded as the same, which makes the Equation (3).

So

and

are equal to the Equation (4) and Equation (5).

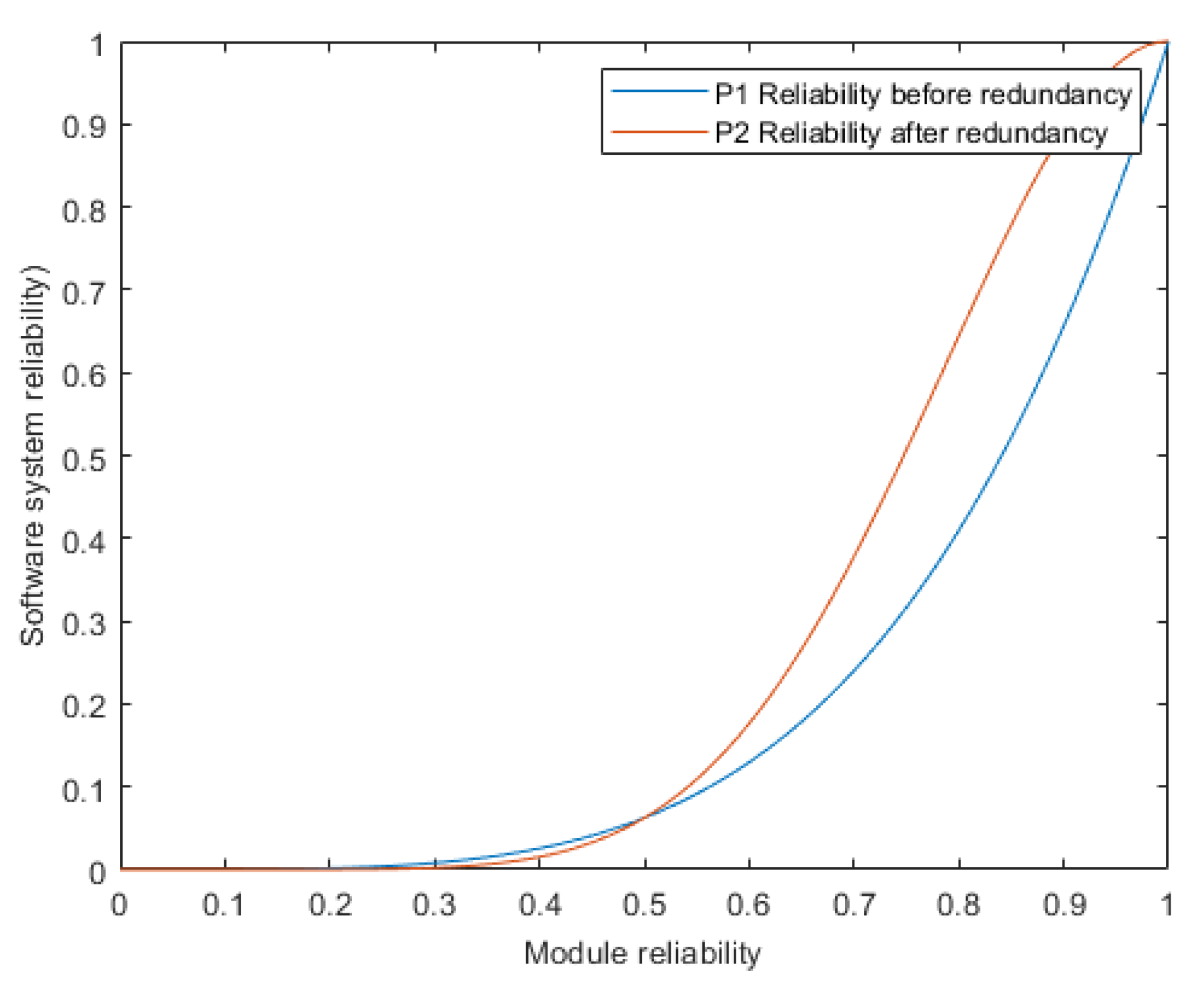

Plot the functional equation.

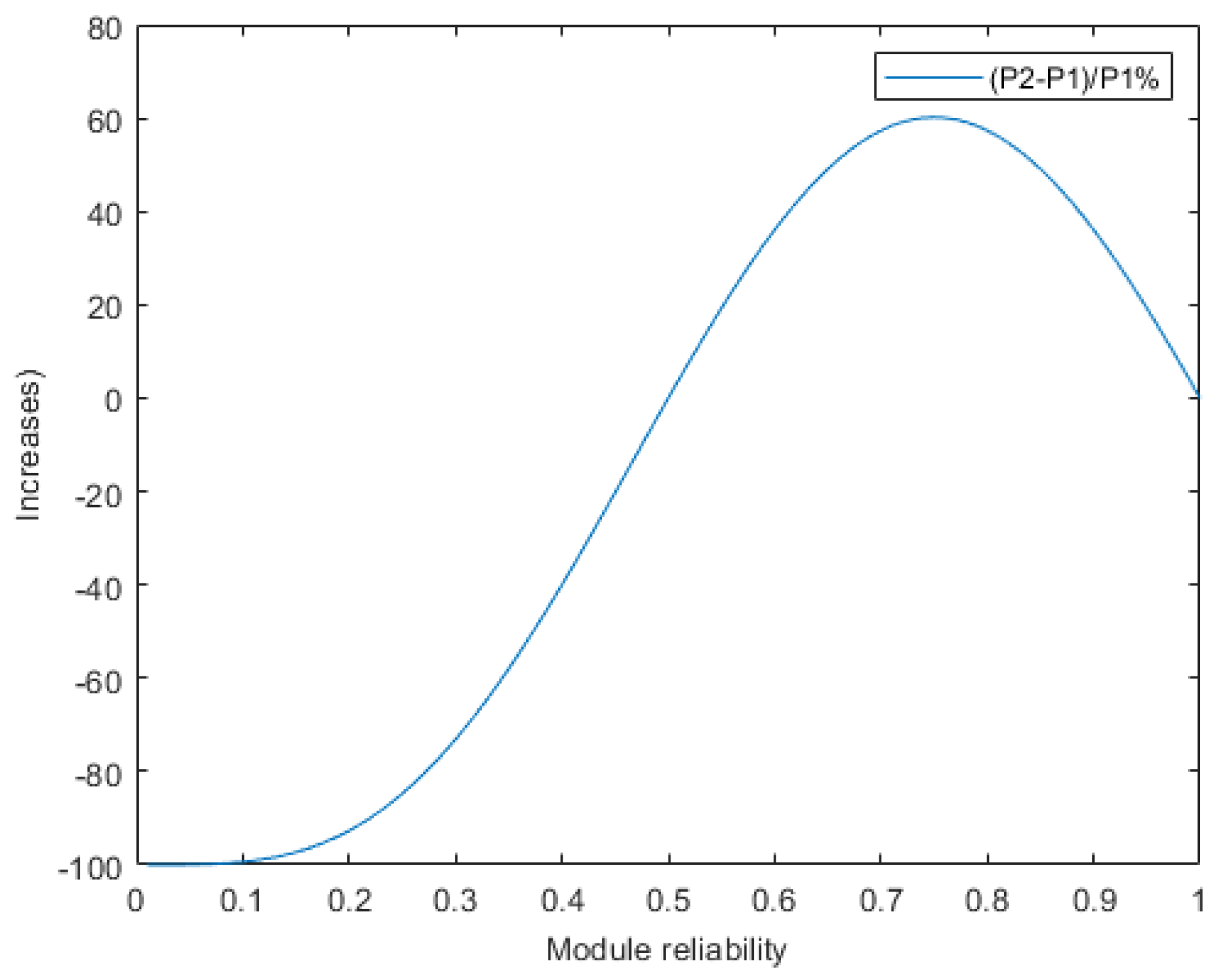

As shown in

Figure 11, when the reliability of the module system is higher than 0.5 (50%), the reliability after redundancy design is obviously improved compared with that before redundancy design. However, when the reliability of the module system is less than 0.5 (50%), redundant design will further reduce the reliability of the system. Therefore, when the reliability of the module system is lower than 0.5 (50%), it is more appropriate to consider improving the design defects of the module itself rather than increasing the redundancy design.

As shown in

Figure 12, when the module reliability is 0.5-0.77 (50%-77%), the positive effect brought by the redundant design increases with the increase of the module reliability. When the reliability is about 0.77 (77%), the positive effect obtained by the redundant design is the best. When the reliability of the modules exceeds 0.77 (77%), the effect of redundant design gradually decreases. Therefore, when the reliability of the modules is above 0.77 (50%-77%), if it is not a particularly high requirement for the reliability of the system, it is not necessary to increase the redundancy design.

4. Conclusions

In this paper, the system integration approach is used to integrate various equipments used in the synthetic biology process into a casting platform, and the automatic casting platform of synthetic biology is built modularized. Based on this platform, a comprehensive system software has been developed to solve the linkage problem among various equipments and system platform. A feasible and practical integrated solution of synthetic biological automation was developed. The main contributions are summarized in the following two aspects:

- (1)

The integration effect of the OPC UA technology for different equipments on the platform was validated. By establishing a synthetic biology automated casting platform and taking the editing protocol experiment of Corynebacterium glutamicum as an example, it was verified that the software developed based on the OPC UA technology enables the platform to integrate various distinct equipments and achieve data interconnection.

- (2)

The influence of triple modular redundancy design on system stability is analyzed. By constructing a mathematical function and calculating the simplified function model, the analysis shows that only when the module reliability is higher than 0.5 (50%), the redundant design has a positive effect.

The synthetic biology automated casting platform system proposed in this research has undergone preliminary verification, and there is still a certain distance compared with mature automation systems in the industrial field. Synthetic biological automated integrated system is a very complex research topic. In the future, with the increasing attention of synthetic biological automation, the research on general synthetic biological automation integrated system will be further deepened.

Author Contributions

S.L. contributed to the methodology, summarizing the key technology and writing the original draft preparation; C.M. provided technical guidance, and reviewed the format of paper; F.Y. helped to test and debug the platform; S.C. built the prototype, software, and validation; K.H. supervised the overall technique and revised the structure of paper. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Key R&D Program of China, grant number 2018YFA0902900.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zhao G, P. Synthetic biology: Unsealing the convergence era of life science research. Bulletin of the Chinese Academy of Sciences (BCAS), 2018, 33, 1135–1149. [Google Scholar]

- Clarke L J, Kitney R I. Synthetic biology in the UK—an outline of plans and progress[J]. Synthetic and Systems Biotechnology, 2016, 1, 243–25. [Google Scholar] [CrossRef] [PubMed]

- Chao R, Yuan Y B, Zhao H M. Building biological foundries for next generation synthetic biology. Sci China Life Sci, 2015, 58, 658–665. [Google Scholar] [CrossRef] [PubMed]

- Hillson N, Caddick M, Cai Y, et al. Building a global alliance of biofoundries. Nat Commun, 2019, 10, 2040. [Google Scholar]

- Le Feuvre R A, Scrutton N S. A living foundry for Synthetic Biological Materials: A synthetic biology roadmap to new advanced materials. Synthetic and Systems Biotechnology, 2018, 3, 105–112. [Google Scholar] [CrossRef] [PubMed]

- Arnold, C. Cloud labs: where robots do the research. Nature, 2022, 606, 612–613. [Google Scholar] [CrossRef] [PubMed]

- Cui J M, Zhang B Z, Ma Y F, et al. Engineering platforms for Synthetic Biology research (in Chinese). Bull. Chin. Acad. Sci., 2018, 33, 1249–1257. [Google Scholar]

- Chao R, Mishra S, Si T, et al. Engineering biological systems using automated biofoundries. Metab. Eng., 2017, 42, 98–108. [Google Scholar] [CrossRef] [PubMed]

- Chao R, Yuan Y B, Zhao H M. Building biological foundries for next-generation synthetic biology (in Chinese). Sci. China Life Sci, 2015, 58, 658–665.

- Tu R, Mao Y F, Liu Y, Cheng H J, Yuan W, Yu S L, Pan W J, An J J, Wang M. Advances in automated high-throughput editing and screening of engineered strains. Chin J Biotech, 2022, 38, 4162–4179. [Google Scholar]

- Zhang T, Leng M T, Jin F, Yuan H. Overview on platform for synthetic biology research at Shenzhen[J]. Synthetic Biology Journal, 2022, 3, 184–194. [Google Scholar]

- Tang T, Fu L H, Guo E P, et al. Automation in synthetic biology using biological foundries (in Chinese). Chin. Sci. Bull., 2021, 66, 300–309. [Google Scholar] [CrossRef]

- Gehrmann C, Gunnarsson M A Digital Twin Based Industrial Automation and Control System Security Architecture. IEEE T Ind Inform 2020, 16, 669–680. [CrossRef]

- Koziolek H, Burger A, Platenius-Mohr M, Jetley R A classification framework for automated control code generation in industrial automation. J Syst Software 2020, 166.

- Quiros G, Cao DS, Canedo A Dispersed Automation for Industrial Internet of Things. IEEE T Autom Sci Eng 2020, 17, 1176–1181. [CrossRef]

- Zissis G Industrial Automation: A Cornerstone Shaping Industry 4. 0. IEEE Ind Appl Mag 2020, 26, 4. [CrossRef]

- Zhao S L, Hao R X The fault tolerance of (n, k)-bubble-sort networks. Discrete Appl Math 2020, 285, 204–211. [CrossRef]

- van den Brand M, Groote JF Software engineering: Redundancy is key. Sci Comput Program 2015, 97, 75–81. [CrossRef]

- Chiang M L, Hsieh H C, Wang C W Improving the Fault-Tolerance Under Software-Defined Network Based on New Sight of Agreement Protocol. IEEE Access 2018, 6, 40898–40908. [CrossRef]

- Zhu M M, Pham H (2020) A generalized multiple environmental factors software reliability model with stochastic fault detection process. Ann Oper Res.

- Yong Y, Yu-Xin H, Hao C Redundancy Mechanism and Reliability Analysis of Trusted Software System Based on Component. 2018, 27, 66-71.

- Mahnke, W. OPC Unified architecture [M]. China Machine Press, 2011, 8-13.

- Becker J, Rohles CM, Wittmann C. Metabolically engineered Corynebacterium glutamicum for bio-based production of chemicals, fuels, materials, and healthcare products. Metab Eng, 2018, 50, 122–141. [Google Scholar] [CrossRef] [PubMed]

- Pan J,Tang Y,Liu J, et al. Reprogramming protein stability in Escherichia coli to improve four-carbon dicarboxylic acids production[J]. Chemical Engineering Journal, 2024, 493152893-.

- Park S A, Bhatia S K, Park H A, et al. Bacillus subtilis as a robust host for biochemical production utilizing biomass. Crit Rev Biotechnol, 2021, 41, 827–848. [Google Scholar] [CrossRef] [PubMed]

- Lian JZ, Mishra S, Zhao HM. Recent advances in metabolic engineering of Saccharomyces cerevisiae: new tools and their applications. Metab Eng, 2018, 50, 85–108. [Google Scholar] [CrossRef] [PubMed]

- Liu X, Wang N, Hao Y, Li Y, Fan X, Xie X. Threonine synthesis under interfered transcriptions of genes involved in central metabolic pathway by CRISPRi [J]. Food and Fermentation Industries. 2019, 45, 1–7. [Google Scholar]

- Gu P, Yang F, Su T, Li F, Li Y, Qi Q. Construction of an L-serine producing Escherichia coli via metabolic engineering[J]. Journal of Industrial Microbiology & Biotechnology, 2014, 41, 1443–1450. [Google Scholar]

- Kruse D, Kramer R, Eggeling L, Rieping M, Pfefferle W, Tchieu J, Chung Y, Saier M, Burkovski A. Influence of threonine exporters on threonine production in Escherichia coli[J]. Applied Microbiology and Biotechnology, 2002, 59, 205–210. [Google Scholar] [CrossRef] [PubMed]

- Kim SH, Schneider BL, Reitzer L. Genetics and regulation of the major enzymes of alanine synthesis in Escherichia coli[J]. Journal of Bacteriology, 2010, 192, 5304–5311. [Google Scholar] [CrossRef] [PubMed]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).