3.1. Dispersion Assessment

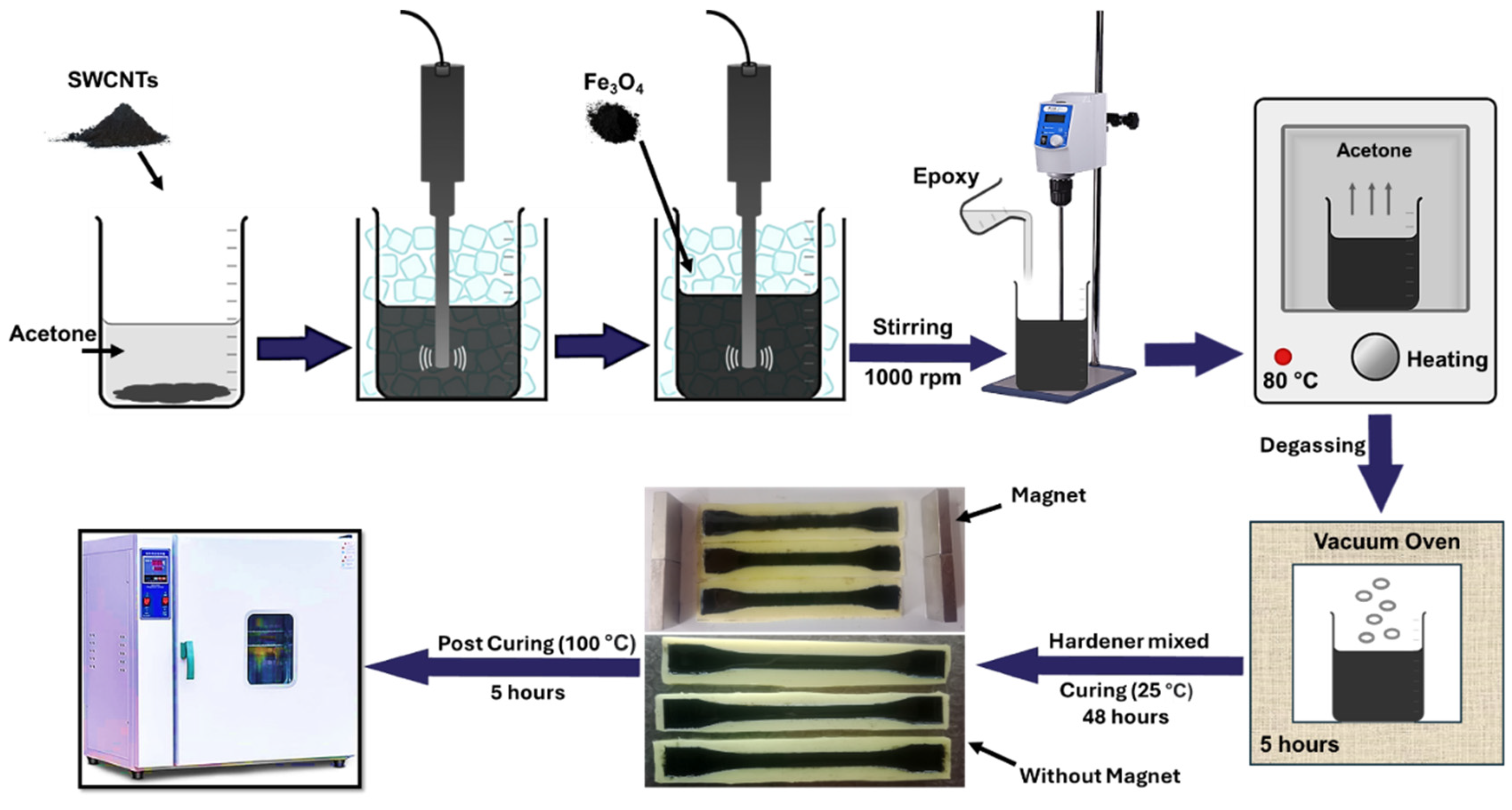

In this study, SWCNTs/Fe₃O₄ epoxy composite solutions were prepared using sonication and stirring processes to ensure proper mixing of the constituents prepared with a constant concentration of SWCNT at 0.03 Vol.% while varying the Fe₃O₄ content at 0.1 Vol.%, 0.5 Vol.%, and 1 Vol.%. Meanwhile, these prepared solutions were analyzed under an optical microscope to assess the homogeneity and dispersion of the components.

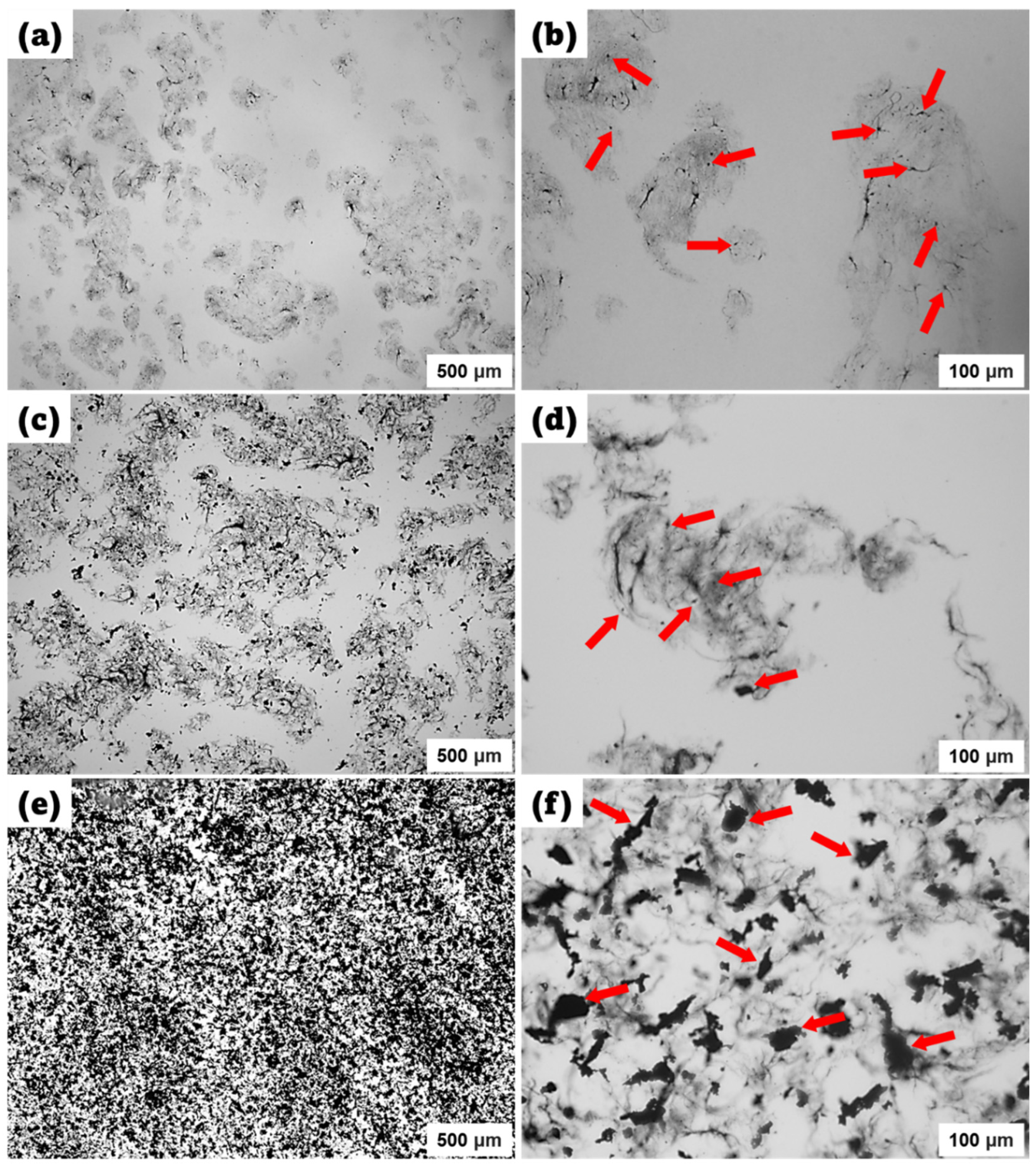

Figure 2 (a) and (b) represent the dispersion quality of the composite with 0.1 Vol.% Fe₃O₄ content observed at 500 μm and 100 μm, respectively. In

Figure 2 (a), at a larger scale (500 μm), the dispersion appears quite good, indicating that the Fe₃O₄ nanoparticles are well distributed throughout the epoxy matrix. However, upon closer inspection at 100 μm in

Figure 2 (b), it becomes evident that while the Fe₃O₄ nanoparticles are indeed well dispersed, they are not sufficiently interacting with the SWCNTs to form a connected network structure. The red arrows in

Figure 2 (b) highlight the presence of Fe₃O₄ nanoparticles, highlighting their distribution. Despite the excellent dispersion, the low concentration of Fe₃O₄ does not facilitate enough interaction with SWCNTs to enhance the composite’s performance significantly. On the other hand,

Figure 2 (c) and (d) illustrate the dispersion quality at 0.5 Vol.% Fe₃O₄, observed at 500 μm and 100 μm, respectively. At 500 μm in

Figure 2 (c), the composite shows a good dispersion of Fe₃O₄ nanoparticles similar to the 0.1 Vol.% sample, but with a denser distribution. A closer look in

Figure 2 (d), observed at 100 μm, shows the interaction between Fe₃O₄ nanoparticles and SWCNTs. The red arrows indicate regions where Fe₃O₄ nanoparticles act as connecting points, forming connected structures with the SWCNTs. This intermediate concentration allows for better interaction between the components, leading to fewer agglomerations and a more homogeneous composite. The improved dispersion and interaction suggest an optimal balance for enhancing the composite’s properties at this concentration. However,

Figure 2 (e) and (f) depict the dispersion at the highest Fe₃O₄ content of 1 Vol.%, observed at 500 μm and 100 μm, respectively. At the larger scale (

Figure 2 (e)), the dispersion appears dense, indicating a high concentration of Fe₃O₄ nanoparticles. However, closer inspection at 100 μm in

Figure 2 (f) reveals significant agglomeration. The red arrows point to regions where Fe₃O₄ nanoparticle clusters, forming large agglomerates. These clusters hinder the dispersion quality and negatively impact the composite’s performance. The high concentration of Fe₃O₄ leads to excessive particle-particle interactions rather than interactions with SWCNTs, causing these undesirable clusters.

3.2. Magnetically Induced Alignment of SWCNTs/Fe₃O₄ Epoxy Composites

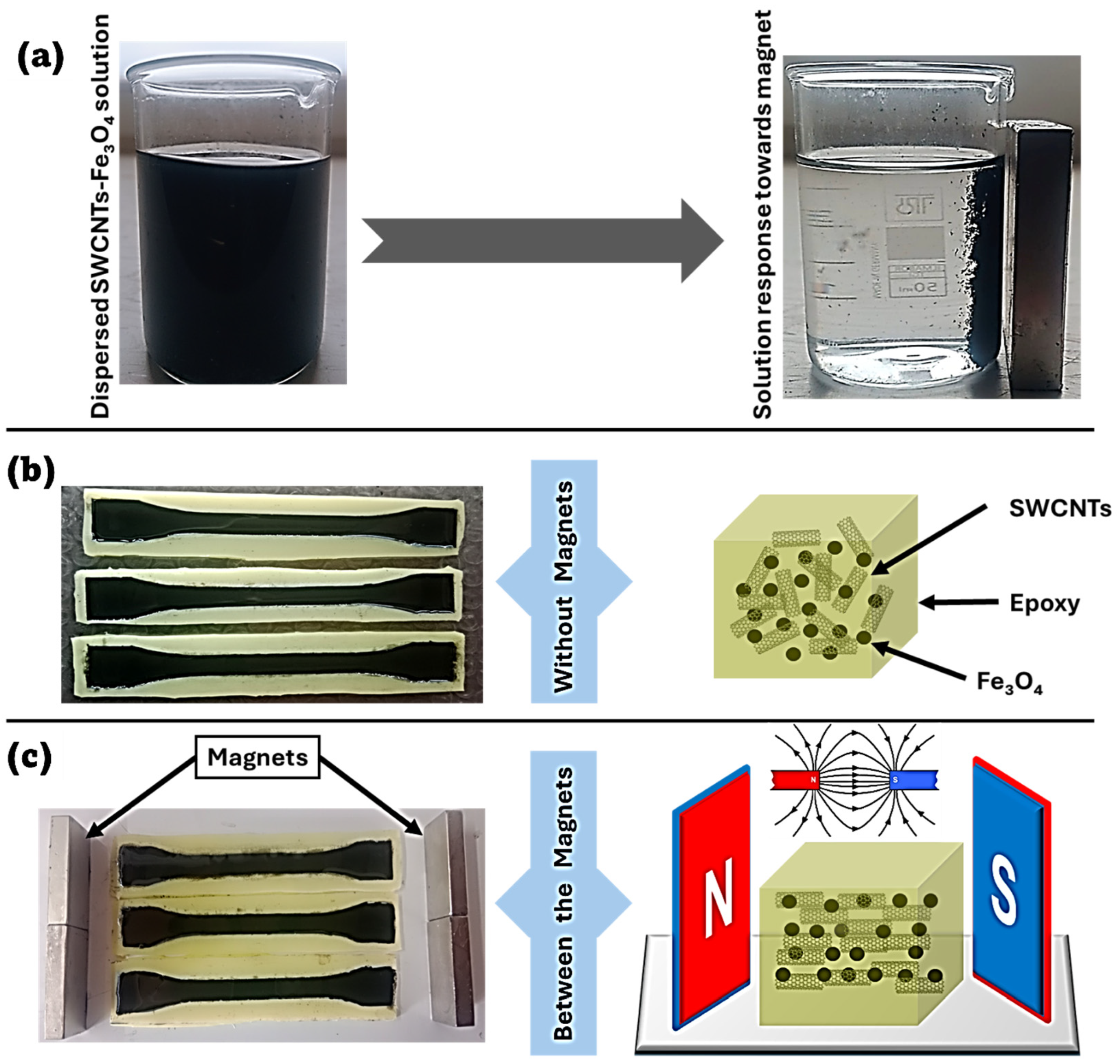

The preparation of SWCNTs/Fe₃O₄ epoxy composites was systematically explored to examine the effects of magnetic fields on the alignment of these constituents during the curing process. As shown in

Figure 3 (a), a homogeneous dispersion of SWCNTs and Fe₃O₄ nanoparticles in acetone was initially achieved. As evidenced by the response of the dispersed solution to an external magnet, the Fe₃O₄ particles demonstrated significant magnetic susceptibility, confirming their ferromagnetic nature. This behavior suggests the potential for controlling the spatial orientation of the Fe₃O₄ nanoparticles and the attached SWCNTs within the epoxy matrix through the application of an external magnetic field. The homogeneous solution was subsequently divided into two parts for curing: one cured in the absence of a magnetic field, resulting in a random orientation of the SWCNTs and Fe₃O₄ particles (

Figure 3 (b)), and the other cured in the presence of a magnetic field, leading to the alignment of Fe₃O₄ particles along the field lines and, consequently, the SWCNTs as well (

Figure 3 (c)). This alignment produced a composite with anisotropic properties, enhancing specific physical characteristics such as electrical conductivity and mechanical strength in the direction of alignment.

Several studies support the alignment of CNTs using magnetic fields. For instance, research has shown that strong magnetic fields can align CNTs at a macroscopic scale, forming long wires parallel to the magnetic field lines [

11]. This alignment technique is advantageous for creating composites with enhanced directional properties. Additionally, modulated magnetic fields have been demonstrated to achieve simultaneous alignment and micropatterning of CNTs within polymer composites2. This method leverages the magnetic anisotropy of CNTs to control their orientation and patterning within the composite matrix [

12]. Recent advancements in the field have further explored the dynamic alignment of single-walled carbon nanotubes in pulsed magnetic fields, highlighting the potential for precise control over CNT orientation [

13].

Moreover, several theoretical frameworks support the observed alignment of magnetic nanoparticles under an external magnetic field well. The principles of magnetostatics describe the magnetic force, F, on a magnetic dipole, m, in a magnetic field, B, as

indicating that a magnetic dipole in a non-uniform field experiences a force that aligns it along the field gradient [

14]. For ferromagnetic materials, the Weiss theory of ferromagnetism provides a critical understanding. This theory introduces the concept of internal molecular fields, represented by the equation:

, where H

eff is the effective magnetic field, H is the applied magnetic field, λ is the Weiss constant, and M is the magnetization. The spontaneous alignment of magnetic moments in ferromagnetic materials is attributed to these internal fields, which are significantly strong, causing a parallel alignment even in the absence of an external field [

15]. Furthermore, Maxwell’s equations, specifically Gauss’s law for magnetism

and the Ampère-Maxwell law, describes the behavior of the magnetic field, ensuring that the field lines guide the alignment of Fe₃O₄ particles and the attached SWCNTs [

16]. When preparing A- SWCNTs/Fe₃O₄ epoxy composites under a magnetic field, the concept of magnetic anisotropy helps explain why Fe₃O₄ particles align in a specific direction. Magnetic anisotropy refers to the tendency of a material to prefer magnetization in certain directions, with the easy axis being the direction where this magnetization occurs most naturally. The anisotropy energy

(with K

u being the anisotropy constant that measures how strongly the material prefers this direction and θ the angle between the magnetization direction and the easy axis i.e., the direction where this magnetization occurs most naturally) indicates that the energy is minimized when the magnetization aligns with the easy axis (where θ = 0). When a magnetic field is applied during the preparation of the composites, the Fe₃O₄ particles tend to align their magnetization along the field direction because it corresponds to the direction of the lowest anisotropy energy. This alignment occurs because the system naturally seeks to minimize its energy, leading to the aligned structure of the SWCNTs/Fe₃O₄ composites within the epoxy matrix [

17,

18]. These studies underscore the importance of magnetic alignment techniques in fabricating high-performance nanocomposites with tailored properties. The strategic alignment of SWCNTs and Fe₃O₄ nanoparticles within an epoxy matrix under magnetic fields opens numerous avenues for advanced material design. Aligned SWCNT composites are particularly promising in electronics, where directional electrical conductivity is crucial, and in structural materials, where directional mechanical properties can significantly enhance performance. This study effectively demonstrates the significant influence of magnetic fields on the alignment of SWCNTs and Fe₃O₄ nanoparticles within an epoxy composite, supported by theoretical principles and recent advancements in the field, highlighting the potential for developing high-performance anisotropic materials.

3.3. Tensile Testing

Due to the exceptional characteristics of the fillers, epoxy composites reinforced with SWCNTs and Fe₃O₄ nanoparticles exhibit significantly enhanced mechanical properties, including increased tensile strength, modulus, toughness, and hardness. With their high tensile strength and modulus, SWCNTs significantly improve load transfer and resistance to crack propagation, while Fe₃O₄ nanoparticles add rigidity and create additional barriers to crack growth, contributing to overall toughness and hardness. The orientation of these fillers within the epoxy matrix is crucial; aligned SWCNTs provide superior mechanical properties in the direction of alignment, leading to anisotropic behavior, while random orientations reduce these enhancements due to less effective load transfer and energy dissipation. Similarly, the orientation of Fe₃O₄ particles, particularly when aligned using magnetic fields, can influence the composite’s stiffness and strength anisotropically. When combined, the fillers’ orientations offer tailored mechanical properties depending on application needs. However, random orientation generally decreases the mechanical advantages these fillers offer, making the composite less effective than when the fillers are strategically aligned [

19,

20].

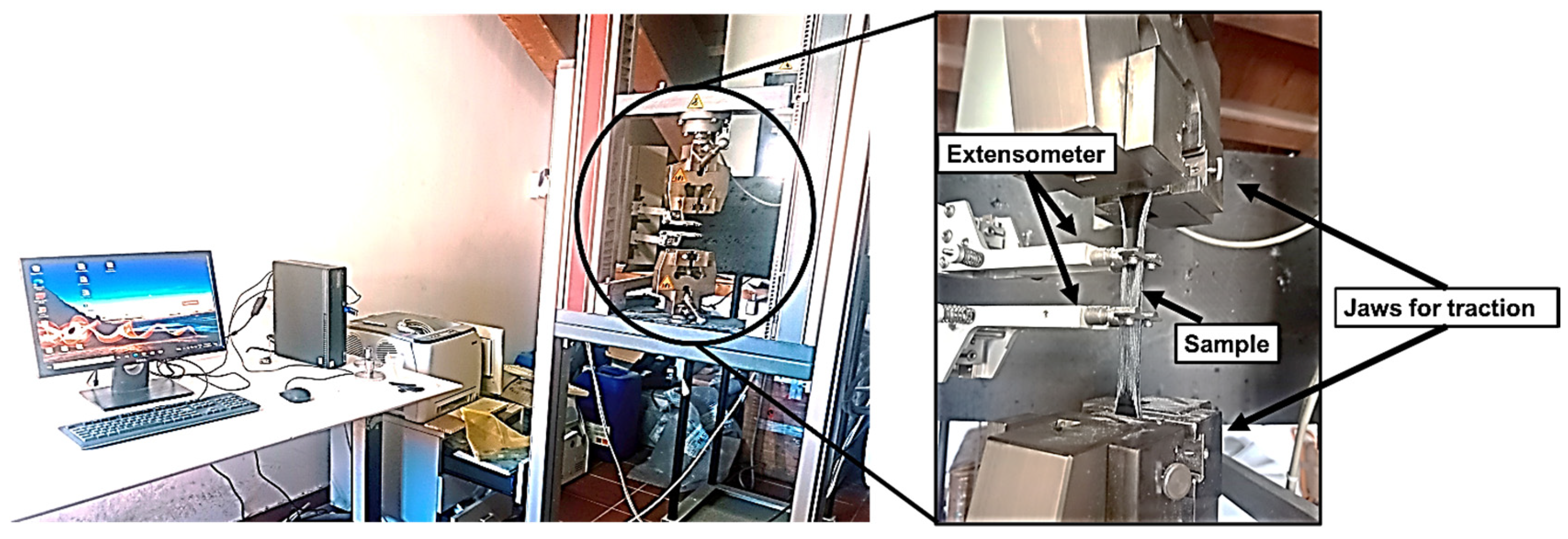

Figure 4 depicts a tensile testing setup using a Zwick-Roell universal testing machine. The setup consists of a computer connected to the machine for data acquisition and control. The highlighted area shows the critical components of the tensile test, including the jaws that securely hold the sample and apply traction and an extensometer that measures the deformation of the sample during the test. The sample, positioned between the jaws, is subjected to tensile forces, and the extensometer records the elongation, providing data to evaluate the material’s mechanical properties.

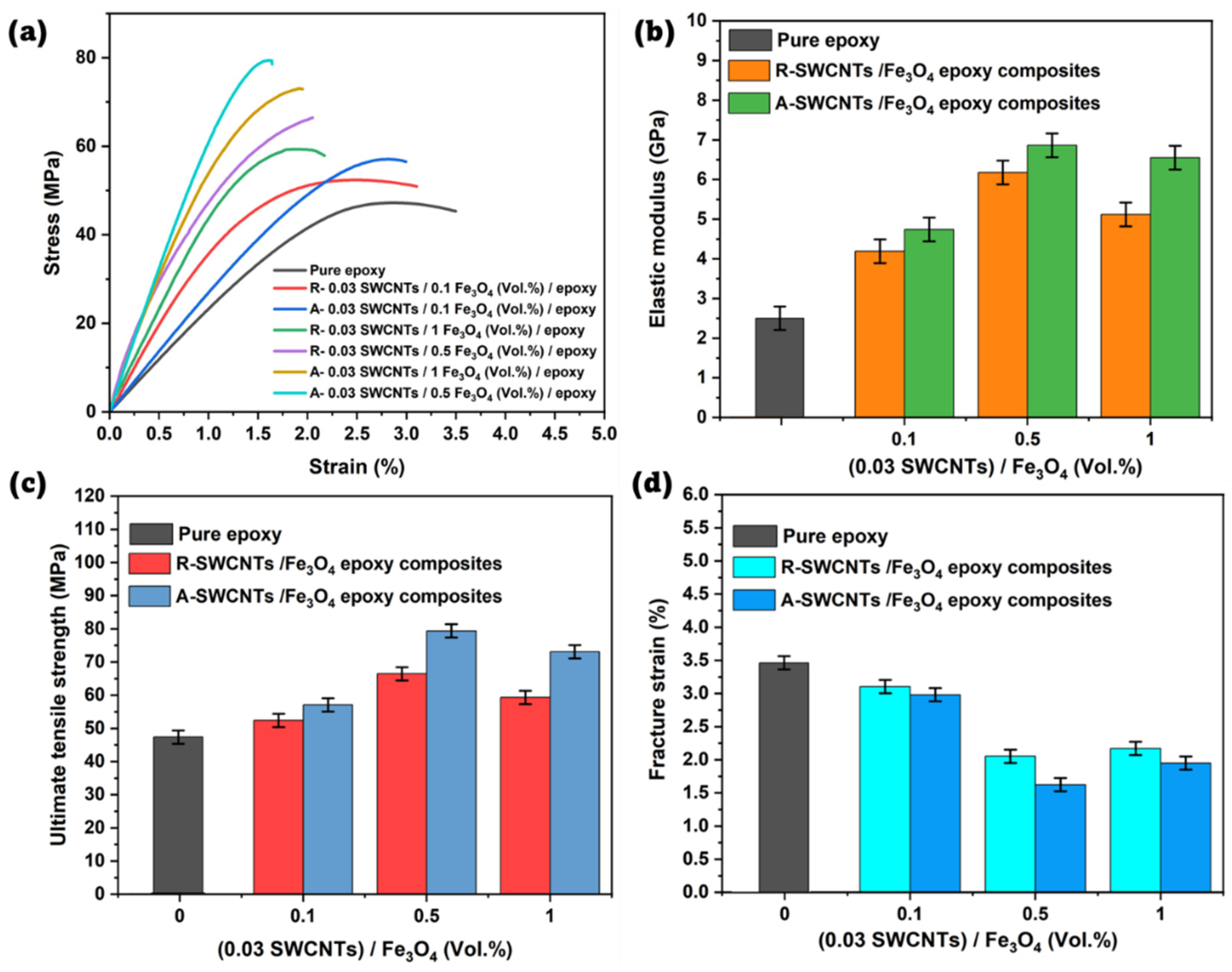

Figure 5(a) presents stress-strain curves for R- and A- SWCNTs/Fe₃O₄ epoxy composites compared with pure epoxy. Pure epoxy shows the lowest stress at any given strain, indicating the inherent limitations in its load-bearing capacity. Introducing SWCNTs and Fe₃O₄ into the epoxy matrix significantly enhances its mechanical properties due to the superior load transfer capability of the SWCNTs and the reinforcing effect of Fe₃O₄ nanoparticles.

Among the composites, the A-0.03 SWCNTs/0.5 Fe₃O₄ epoxy composite exhibits the highest stress values, suggesting the optimal synergy between SWCNT alignment and Fe₃O₄ content, which maximizes the load transfer efficiency and enhances the tensile strength. The enhanced performance of the A- SWCNTs/Fe₃O₄ epoxy composites compared to the R- SWCNTs/Fe₃O₄ epoxy composites can be attributed to the more efficient load transfer provided by the horizontally aligned SWCNTs/Fe₃O₄. In the aligned composites, a more coherent network is formed that better supports the load and transmits stress throughout the matrix, improving the overall mechanical response.

However, at higher Fe₃O₄ concentrations (1 Vol.%), a decline in stress is observed, likely due to nanoparticle agglomeration, which creates stress concentration points and impairs the uniform dispersion of the reinforcing phases, thus reducing the composite’s overall mechanical performance. Additionally, the reduction in strain at higher stress levels across the composites indicates the materials’ increasing brittleness, where the enhanced stiffness due to the reinforcement limits the composite’s ability to undergo plastic deformation, leading to earlier fracture. This behavior is more pronounced in the A- SWCNTs/Fe₃O₄ epoxy composites.

Figure 5(b) illustrates the comparison of elastic modulus of pure epoxy, R- SWCNTs/Fe₃O₄ epoxy composites, and A- SWCNTs/Fe₃O₄ epoxy composites, each with a fixed SWCNTs content of 0.03 Vol.% and varying Fe₃O₄ content of 0.1, 0.5, and 1 Vol.%. The results demonstrate that the elastic modulus increases with the addition of both R- SWCNTs/Fe₃O₄ and A- SWCNTs/Fe₃O₄ as compared to pure epoxy, indicating enhanced mechanical properties. Furthermore, A- SWCNTs/Fe₃O₄ epoxy composites consistently exhibit higher elastic modulus values than those R- SWCNTs/Fe₃O₄ epoxy composites at all Fe₃O₄ concentrations, suggesting that the alignment of SWCNTs/Fe₃O₄ under a magnetic field significantly improves the stiffness of the composite. Specifically, at 0.1 Vol.% Fe₃O₄, the elastic modulus for R- SWCNTs/Fe₃O₄ is 4.19 GPa, while for A- SWCNTs/Fe₃O₄ it is 4.74 GPa. At 0.5 Vol.% Fe₃O₄, the values are 6.18 GPa for R- SWCNTs/Fe₃O₄ and 6.86 GPa for A- SWCNTs/Fe₃O₄. At 1 Vol.% Fe₃O₄, the modulus slightly decreases for both composites but remains higher in the A-SWCNTs/Fe₃O₄ composite (6.55 GPa) compared to the R- SWCNTs/Fe₃O₄ composite (5.12 GPa). This trend suggests that increasing the Fe₃O₄ content up to 0.5 Vol.% improves the stiffness of the composite, but further increase to 1 Vol.% results in a slight reduction in the elastic modulus, possibly due to the agglomeration of nanoparticles, which might disrupt the continuity. The overall enhancement in elastic modulus, especially in A- SWCNTs/Fe₃O₄ composites, underscores the importance of nanotube alignment in maximizing mechanical reinforcement in such nanocomposites.

Figure 5(c) compares the ultimate tensile strength (UTS) of pure epoxy and R-, A- SWCNTs/Fe₃O₄ epoxy composites. Pure epoxy serves as a baseline with a UTS of 47.246 MPa. Upon incorporating 0.1 Vol.% Fe₃O₄ into the epoxy with R- SWCNTs, the UTS increases to 52.405 MPa, indicating a modest enhancement. The corresponding A- SWCNTs/Fe₃O₄ epoxy composite shows a more significant increase in UTS to 57.087 MPa, suggesting that the alignment of SWCNTs/Fe₃O₄ contributes to better load transfer and composite reinforcement. As the Fe₃O₄ content increases to 0.5 Vol.%, the UTS of the R- SWCNTs/Fe₃O₄ composite jumps to 66.439 MPa, while the A-SWCNTs/Fe₃O₄ composite reaches 79.378 MPa, highlighting a substantial improvement due to the combined effects of Fe₃O₄ and SWCNT alignment. At the highest Fe₃O₄ content (1 Vol.%), the UTS slightly decreases to 59.313 MPa for the R- SWCNTs/Fe₃O₄ composite, whereas the A- SWCNTs/Fe₃O₄ composite maintains a high UTS of 73.068 MPa. This trend suggests that while Fe₃O₄ content enhances UTS up to a certain threshold, the alignment of SWCNTs/Fe₃O₄ is crucial in maximizing the tensile strength, particularly at higher filler concentrations. Overall, both Fe₃O₄ content and SWCNT/Fe₃O₄ alignment significantly influence the tensile strength of the epoxy composites, with aligned SWCNTs/Fe₃O₄ providing superior reinforcement.

Figure 5(d) shows the variations in fracture strain (%) of R- and A- SWCNTs/Fe₃O₄ epoxy composites at different Fe₃O₄ loadings in comparison to pure epoxy with a fracture strain of 3.498%. With the introduction of SWCNTs/Fe₃O₄, the fracture strain decreases across all composites, reducing the material’s ability to withstand deformation before breaking. For R- SWCNTs/Fe₃O₄ composites, the fracture strain decreases from 3.104% at 0.1 Vol.% Fe₃O₄ to 2.053% at 0.5 Vol.% and further to 2.171% at 1 Vol.%. Similarly, the fracture strains of A- SWCNTs/Fe₃O₄ composites decrease from 2.981% at 0.1 Vol.% to 1.624% at 0.5 Vol.% and 1.95% at 1 Vol.%. Notably, the A- SWCNTs/Fe₃O₄ composites consistently exhibit lower fracture strain values compared to the R- SWCNTs/Fe₃O₄ composites at the same Fe₃O₄ content, indicating that the alignment of SWCNTs/Fe₃O₄ under a magnetic field further reduces the material’s ductility. This trend suggests that while adding Fe₃O₄ and aligning SWCNTs may improve specific properties like stiffness or strength, it compromises the material’s fracture strain, making it more brittle.

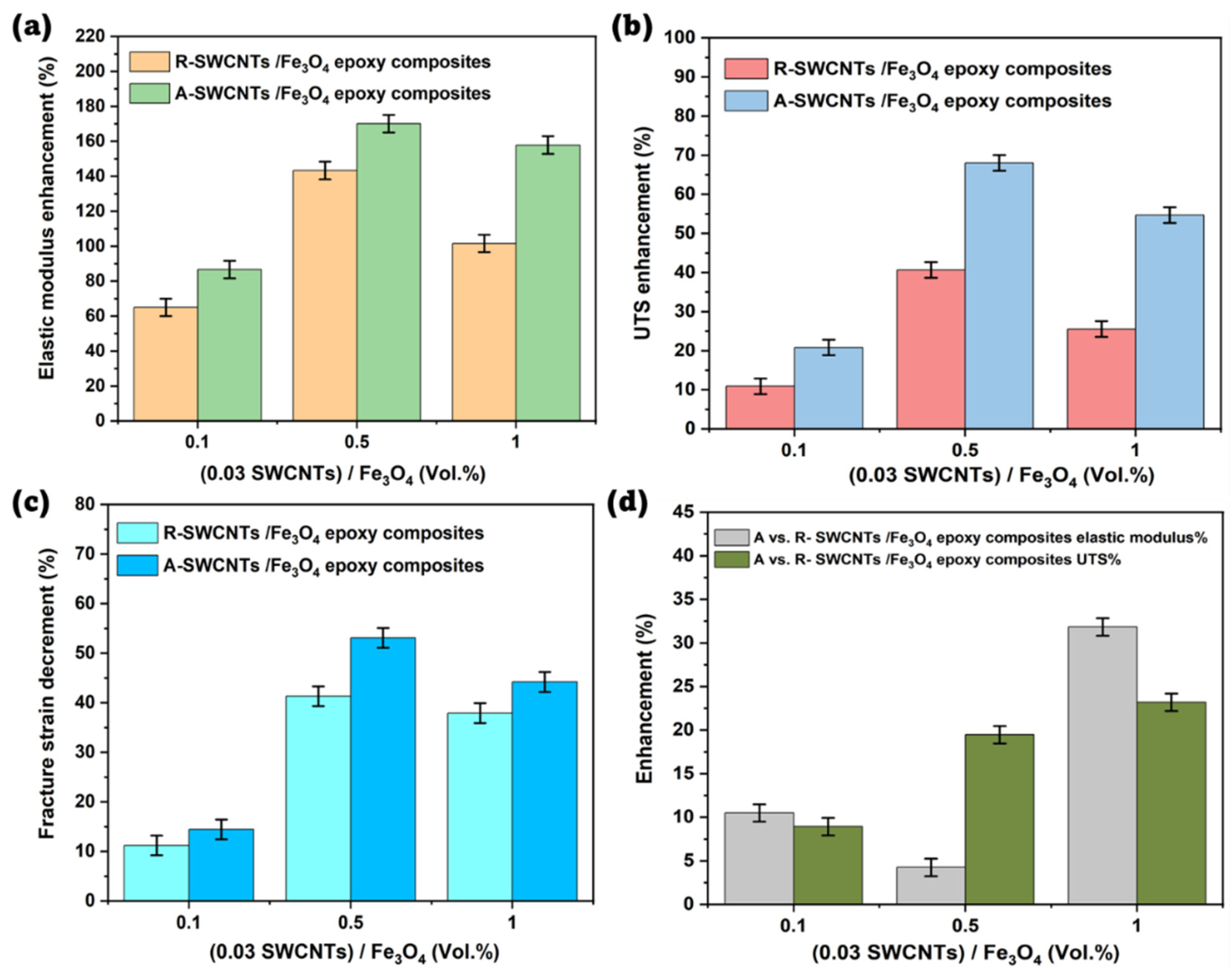

Figure 6(a) demonstrates the percentage (%) enhancement in the elastic modulus of SWCNTs/Fe₃O₄ epoxy composites, comparing two configurations: R- and A- SWCNTs/Fe₃O₄ epoxy composites. The percentage (%) enhancement for both composite configurations is calculated relative to pure epoxy using the formula:

where E

c, is the elastic modulus of the SWCNTs/Fe₃O₄ epoxy composite and E

e is the elastic modulus of the pure epoxy.

The results show that A- SWCNTs/Fe₃O₄ epoxy composites consistently exhibit higher elastic modulus enhancements than R- SWCNTs/Fe₃O₄ epoxy composites at all Fe₃O₄ concentrations. Specifically, at 0.1 Vol.% Fe₃O₄, the R- SWCNTs composite shows a 64.96% enhancement, while the A- SWCNTs composite shows an 86.61% enhancement. At 0.5 Vol.% Fe₃O₄, the enhancements increase to 143.31% for R- SWCNTs and 170.08% for A- SWCNTs. At 1 Vol.% Fe₃O₄, the enhancements are 101.57% for R- SWCNTs and 157.87% for A- SWCNTs. These findings highlight that the alignment of SWCNTs/Fe₃O₄ significantly improves the elastic modulus, likely due to better load transfer and a more efficient reinforcing network. Both R- SWCNTs and A- SWCNTs composites exhibit substantial improvements in elastic modulus compared to pure epoxy, confirming the reinforcing effect of SWCNTs and Fe₃O₄, with alignment providing additional benefits. extensometer.

Figure 6(b) presents the UTS enhancement (%) of SWCNTs/Fe₃O₄ epoxy composites, and the data show that at all Fe₃O₄ concentrations, the A- SWCNTs/Fe₃O₄ composites exhibit significantly higher UTS enhancement compared to the R- SWCNTs/Fe₃O₄ composites, indicating that the alignment of SWCNTs/Fe₃O₄ under a low magnetic field improves the tensile strength of the composites. Specifically, at 0.1 Vol.% Fe₃O₄, the UTS enhancement for A- SWCNTs is 20.83%, compared to 10.92% for R- SWCNTs. At 0.5 Vol.% Fe₃O₄, the A- SWCNTs show a substantial enhancement of 68.01%, whereas R- SWCNTs exhibit 40.64%. Finally, at 1 Vol.% Fe₃O₄, the UTS enhancement for A- SWCNTs is 54.67%, compared to 25.54% for R- SWCNTs. The trend clearly illustrates that the alignment of SWCNTs/Fe₃O₄ results in a more significant improvement in tensile strength across all Fe₃O₄ concentrations, with the maximum enhancement observed at 0.5 Vol.% Fe₃O₄ for A- SWCNTs.

Figure 6(c) shows the fracture strain % decrement for SWCNTs/Fe₃O₄ epoxy composites using the formula:

Here , and represent the fracture strains of pure epoxy and composite, respectively.

It is evident that as the Fe₃O₄ content increases from 0.1 to 1 Vol.%, there is a significant increase in the fracture strain decrement for both R- SWCNTs/Fe₃O₄ and A- SWCNTs/Fe₃O₄ epoxy composites. Specifically, at 0.1 Vol.% Fe₃O₄, the A- SWCNTs/Fe₃O₄ composite shows a fracture strain decrement of 14.45%, which is slightly higher than the 11.24% observed for the R- SWCNTs/Fe₃O₄ composite. As the Fe₃O₄ content increases to 0.5 Vol.%, the decrement rises significantly to 53.1% for the A- SWCNTs/Fe₃O₄ composite, compared to 41.32% for the R- SWCNTs/Fe₃O₄ composite. At 1 Vol.% Fe₃O₄, the fracture strain decrement reaches 44.2% for the A- SWCNTs/Fe₃O₄ composite and 37.9% for the R- SWCNTs/Fe₃O₄ composite. This trend suggests that the alignment of SWCNTs/Fe₃O₄ under a magnetic field leads to a more pronounced reduction in the material’s ductility.

Figure 6(d) presents % enhancement elastic modulus and UTS of A- SWCNTs/Fe₃O₄ epoxy composites as compared to R- SWCNTs/Fe₃O₄ epoxy composites. The graph reveals that A- SWCNTs composites presented a 10.49%, 4.25%, and 31.84% higher elastic modulus at 0.1, 0.5, and 1 Vol.% Fe₃O₄, respectively as compared to R- SWCNTs/Fe₃O₄ epoxy composites. On the other hand, the UTS of A- SWCNTs composites was 8.93%, 19.47%, and 23.19% higher than R- SWCNTs/Fe₃O₄ epoxy composites at 0.1, 0.5, and 1 Vol.% Fe₃O₄, respectively. This data underscores the superior mechanical performance of A- SWCNT composites.

3.4. Electrical Conductivity Analysis

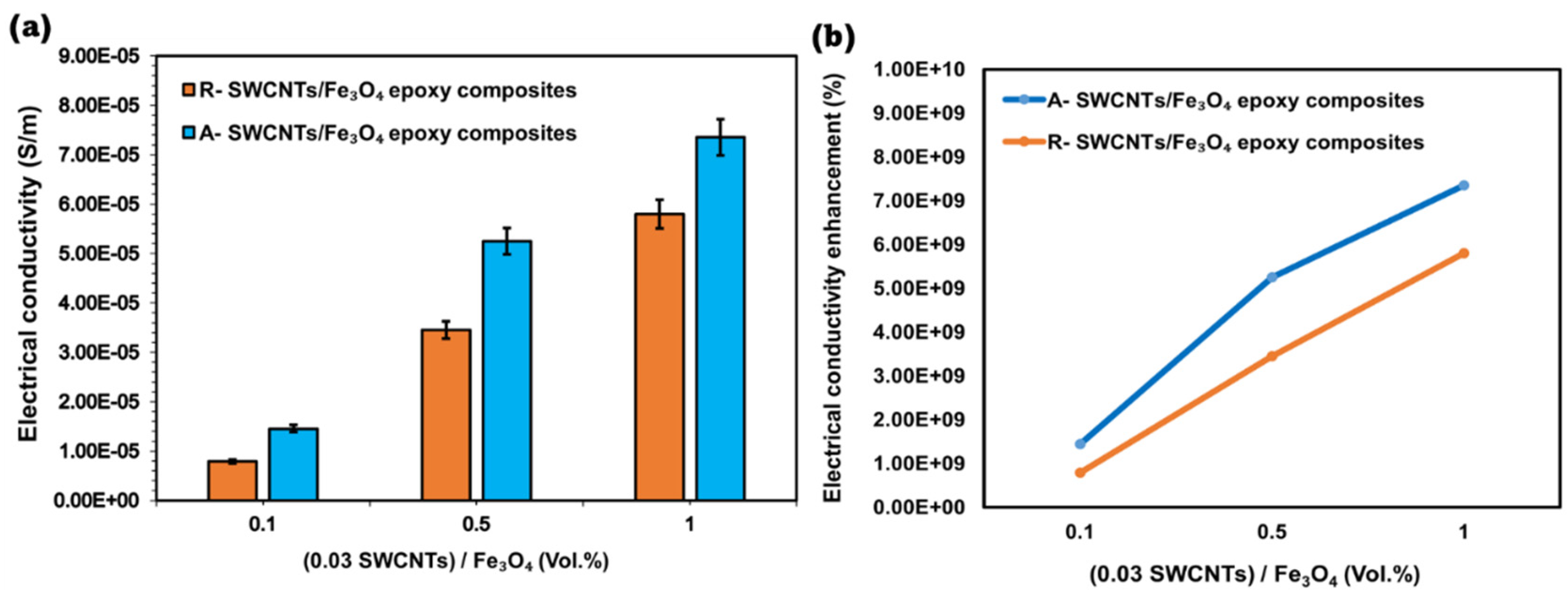

Pure epoxy typically exhibits very low electrical conductivity (10−9 S/m) due to its insulating nature, which arises from the absence of free charge carriers within its molecular structure. However, SWCNTs, known for their excellent electrical properties, form conductive pathways within the composite, while Fe₃O₄ nanoparticles enhance the overall network connectivity and potentially facilitate electron transfer. The alignment of SWCNTs under a magnetic field further optimizes these pathways, resulting in even higher conductivity than randomly oriented composites.

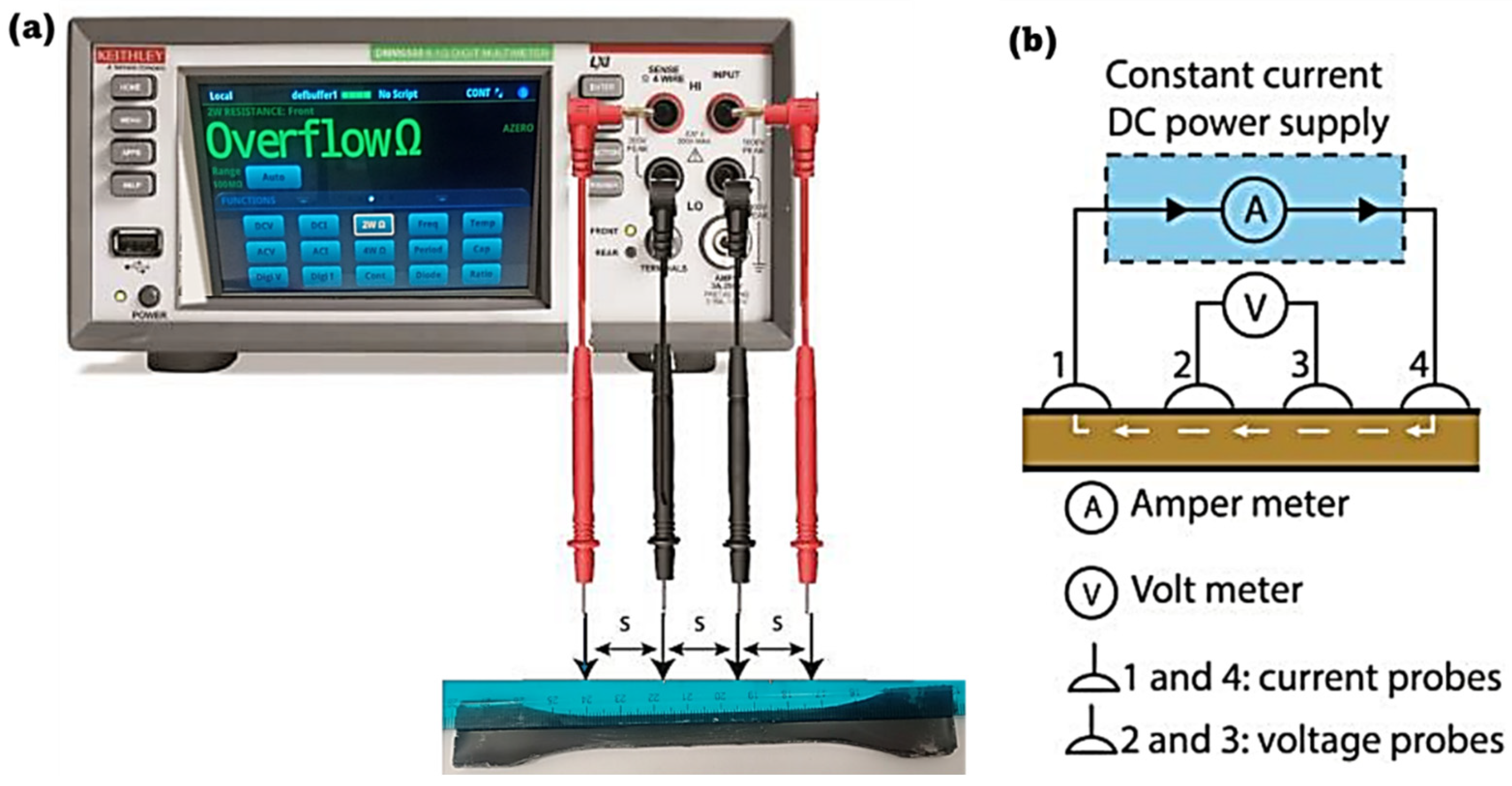

Figure 7(a) illustrates the four-probe technique setup for measuring the electrical resistivity,

ρ, to determine the electrical conductivity “σ” of SWCNTs/Fe

3O

4 epoxy composites where a digital multimeter (a Keithley model) is connected to the sample via four probes. These probes are aligned along the sample’s surface with equal spacing, s.

Figure 7(b) outlines the circuit setup for the four-probe method. A constant current DC power supply injects current through the outer two probes (labeled 1 and 4), while the voltage drop is measured across the inner two probes (labeled 2 and 3). This configuration minimizes contact resistance effects, providing a more accurate resistance measurement.

Figure 8(a) presents the measured electrical conductivity for the R- and A- SWCNTs/Fe₃O₄ epoxy composites. The electrical conductivity increases with increasing Fe₃O₄ content for both types of composites, but the A- SWCNTs/Fe₃O₄ composites exhibit significantly higher conductivity than their random counterparts. For example, the conductivity for R- SWCNTs/Fe₃O₄ composites rises from 7.89E-06 S/m at 0.1 Vol.% to 5.80E-05 S/m at 1 Vol.%, while for the A- SWCNTs/Fe₃O₄ composites, it increases from 1.45E-05 S/m to 7.35E-05 S/m over the same range. This enhanced conductivity in A- SWCNTs/Fe₃O₄ composites is attributed to the better alignment of SWCNTs/Fe₃O₄ within the epoxy matrix, facilitated by the magnetic field, which promotes more effective charge carrier pathways. The increased alignment leads to a higher probability of electron transport along the conductive SWCNTs/Fe₃O₄ network, thereby boosting overall conductivity.

Figure 8(b) compares the % enhancement in electrical conductivity for both composites relative to pure epoxy, which serves as the baseline. The A- SWCNTs/Fe₃O₄ composites consistently demonstrate a higher enhancement across all Fe₃O₄ concentrations. For instance, at 1 Vol.% Fe₃O₄, the A- SWCNTs/Fe₃O₄ composite shows an enhancement of 7.35E+09%, whereas the R- SWCNTs/Fe₃O₄ composite achieves only 5.80E+09%. This dramatic difference underscores the critical role of SWCNT/Fe₃O₄ alignment in optimizing electrical properties. The magnetic alignment likely results in a more interconnected network of SWCNTs, which, combined with the conductive Fe₃O₄ nanoparticles, creates efficient pathways for electron flow. In contrast, the random orientation of SWCNTs in the R- SWCNTs/Fe₃O₄ composites leads to less efficient pathways, as the electrons must traverse more tortuous routes, reducing the overall conductivity enhancement. Therefore, applying a magnetic field during composite preparation is a significant factor in maximizing the electrical performance of these nanocomposites.