Submitted:

19 August 2024

Posted:

20 August 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Geological Background

3. Samples and Methodology

3.1. Sample Information

3.2. Experiments

3.2.1. XRD

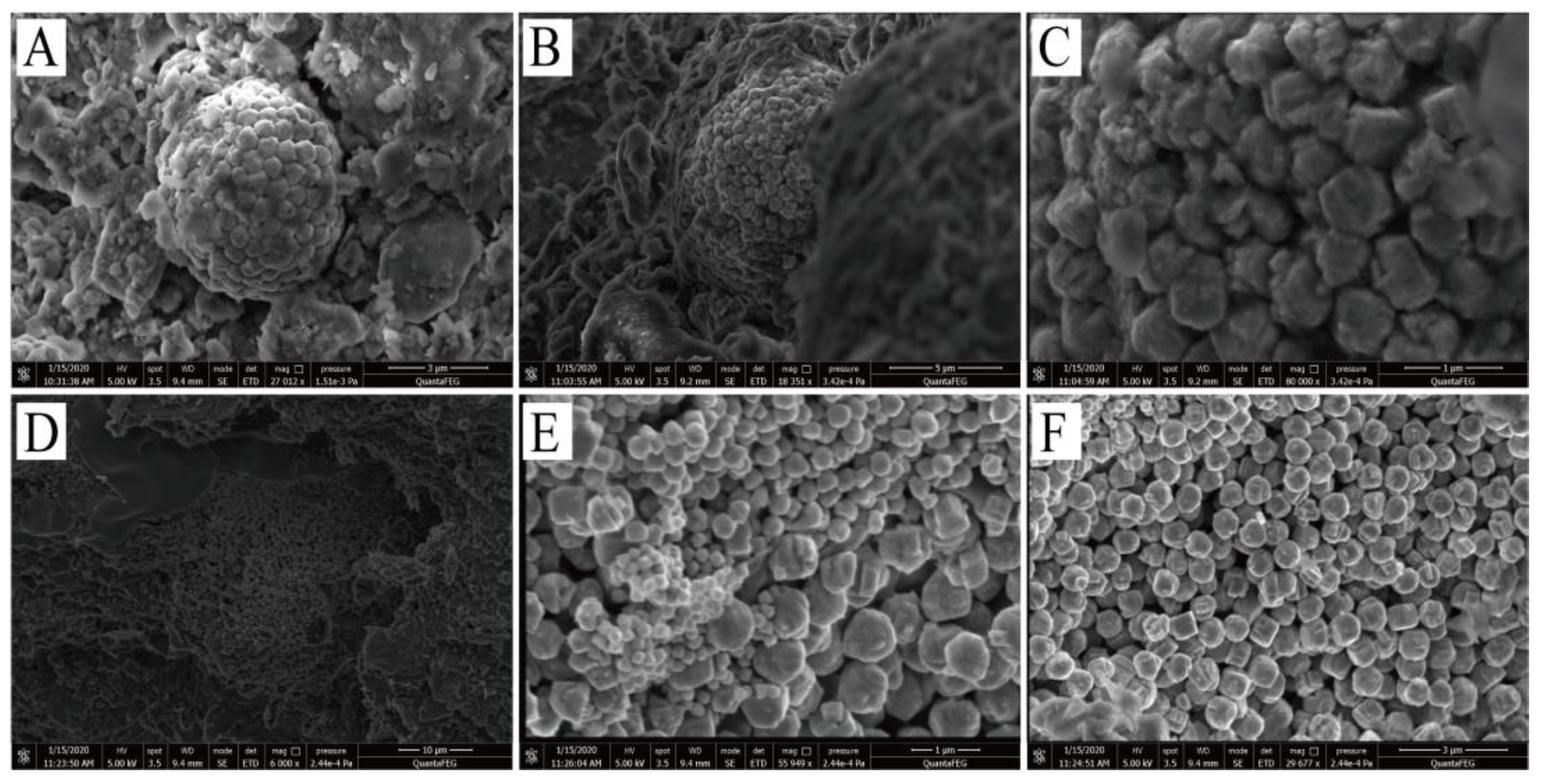

3.2.2. CTS and SEM

3.2.3. NMRC

3.2.4. HPMI

3.2.5. CRMI

3.2.6. LP-N2GA

4. Results and Discussion

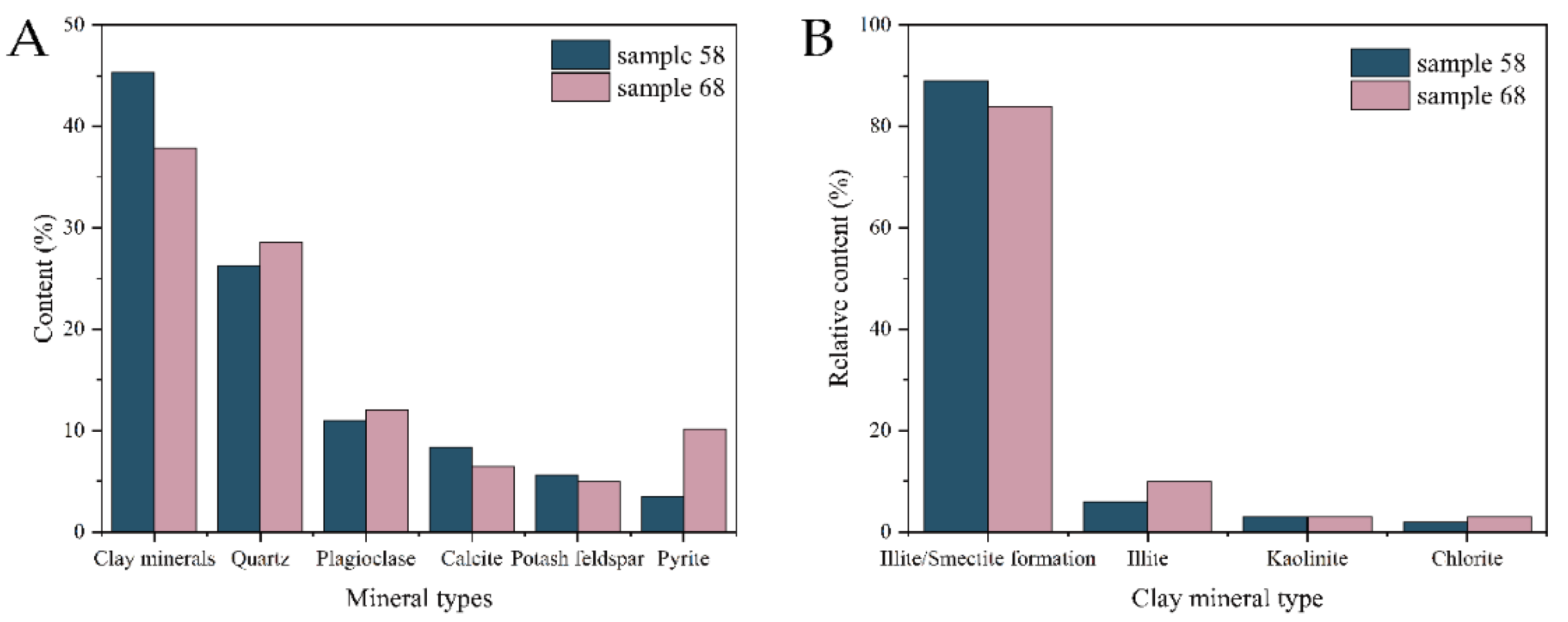

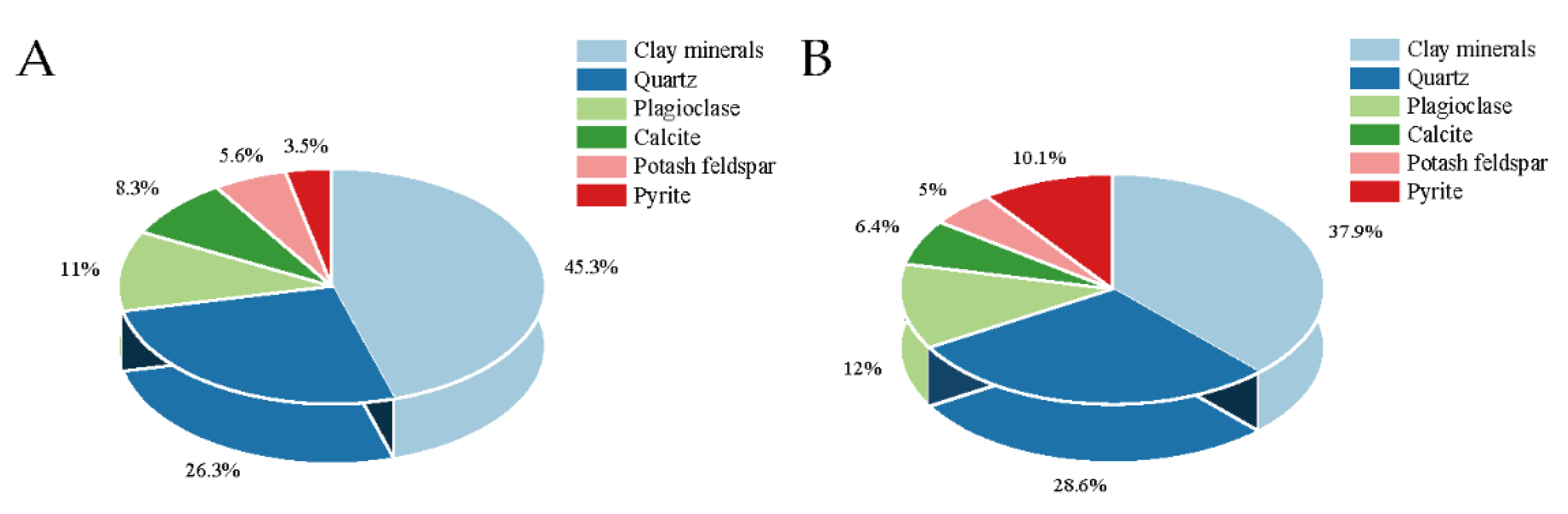

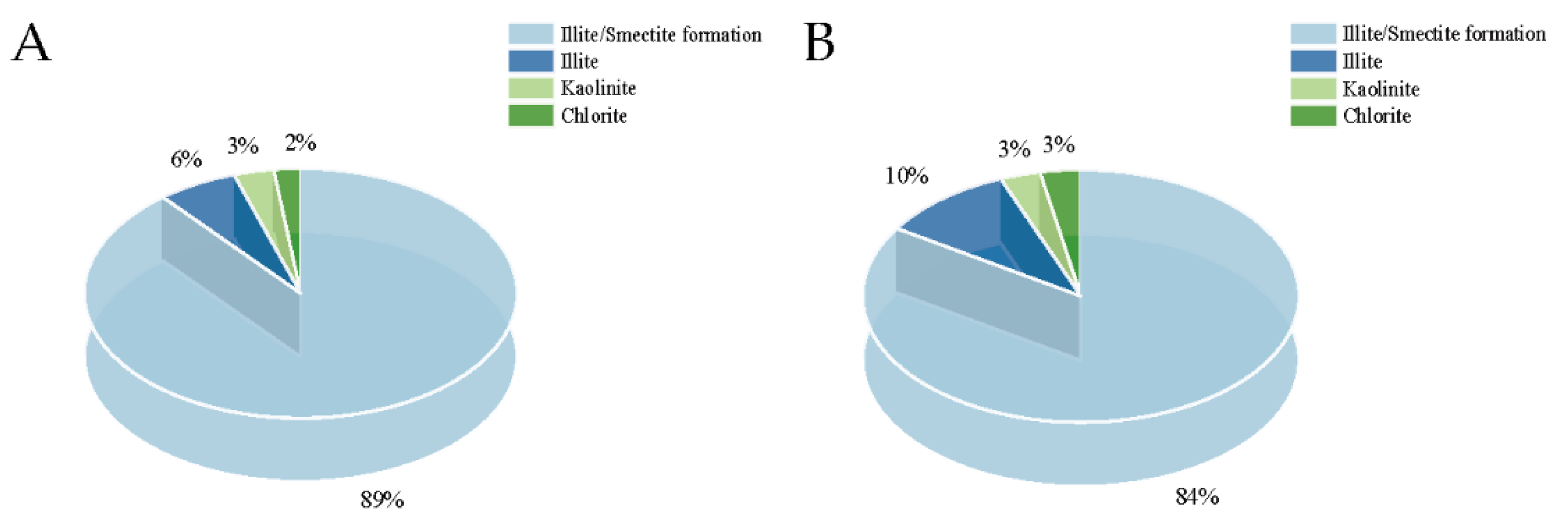

4.1. Mineral Compositions that Make up the Pores

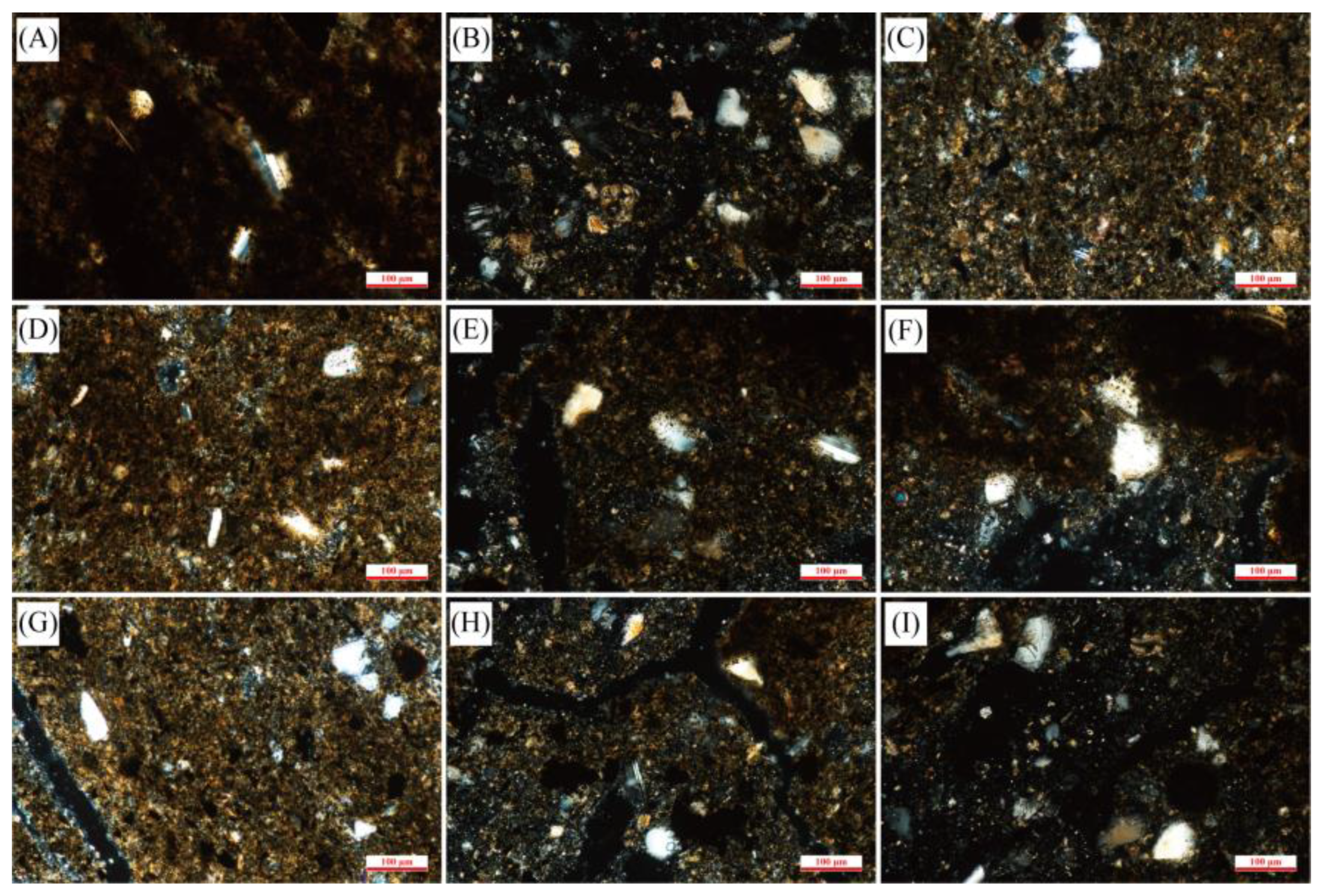

4.2. Pore and Throat Types, Geometry

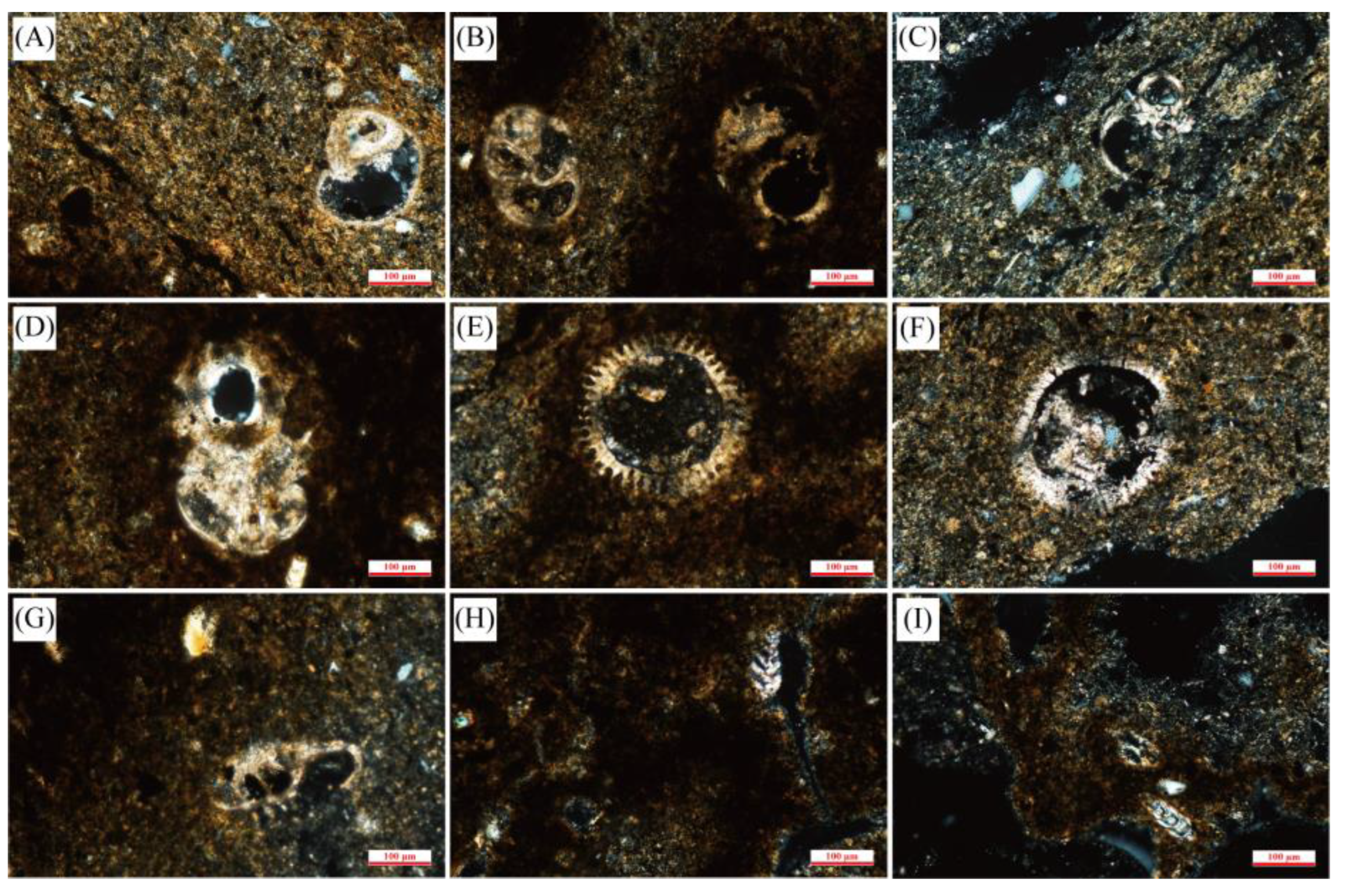

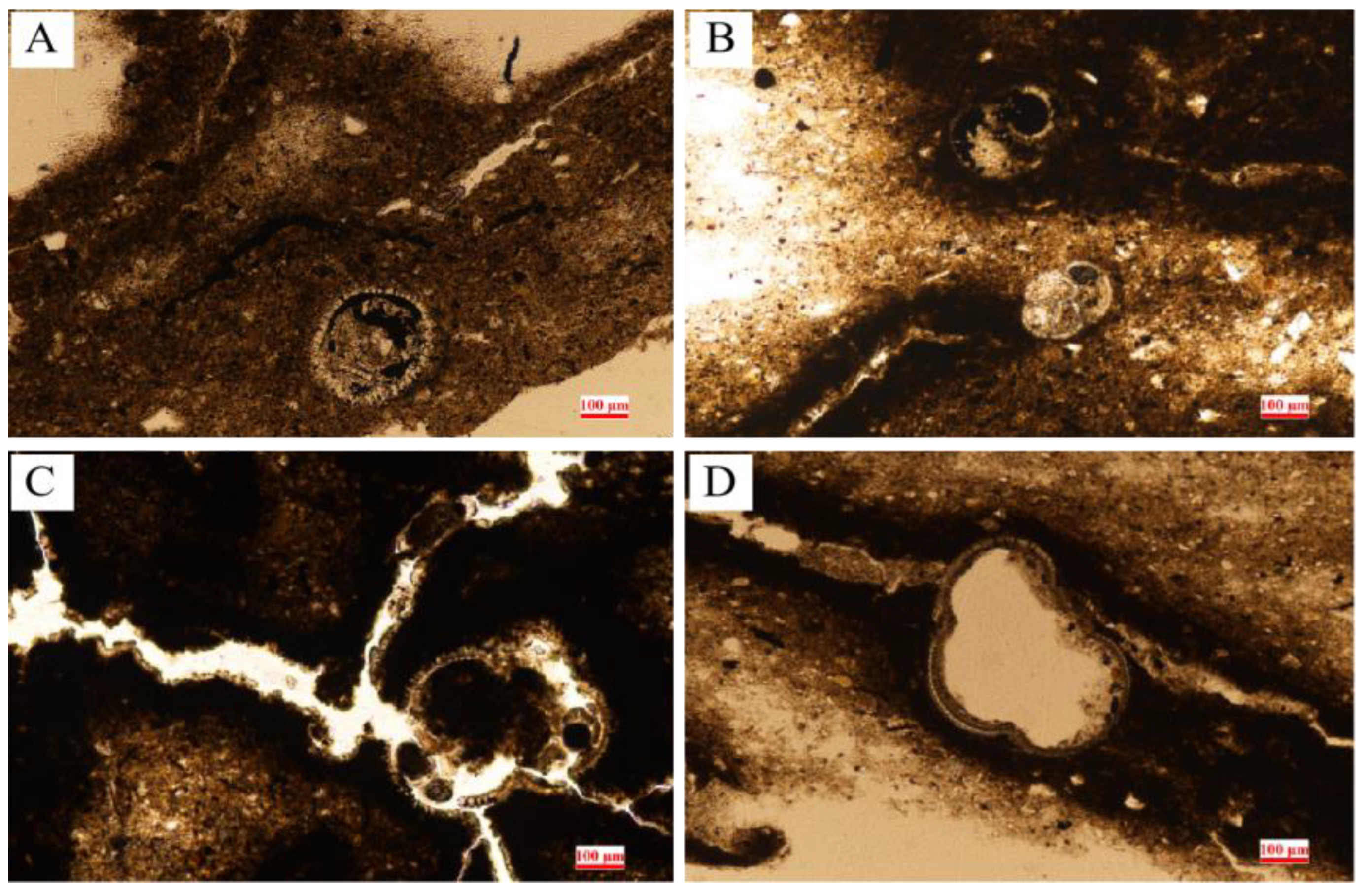

4.2.1. Intragranular pore

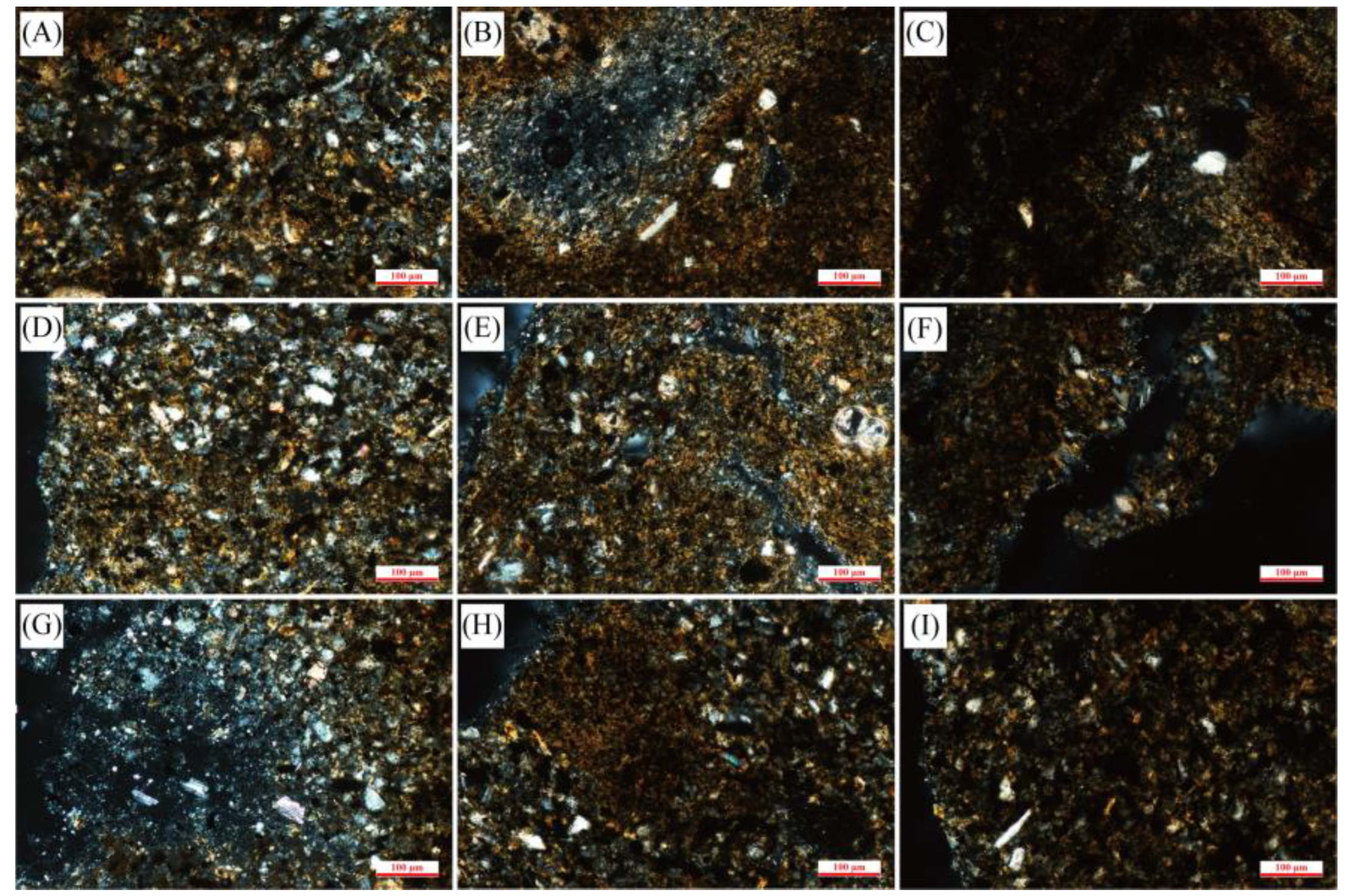

4.2.2. Intergranular Pore

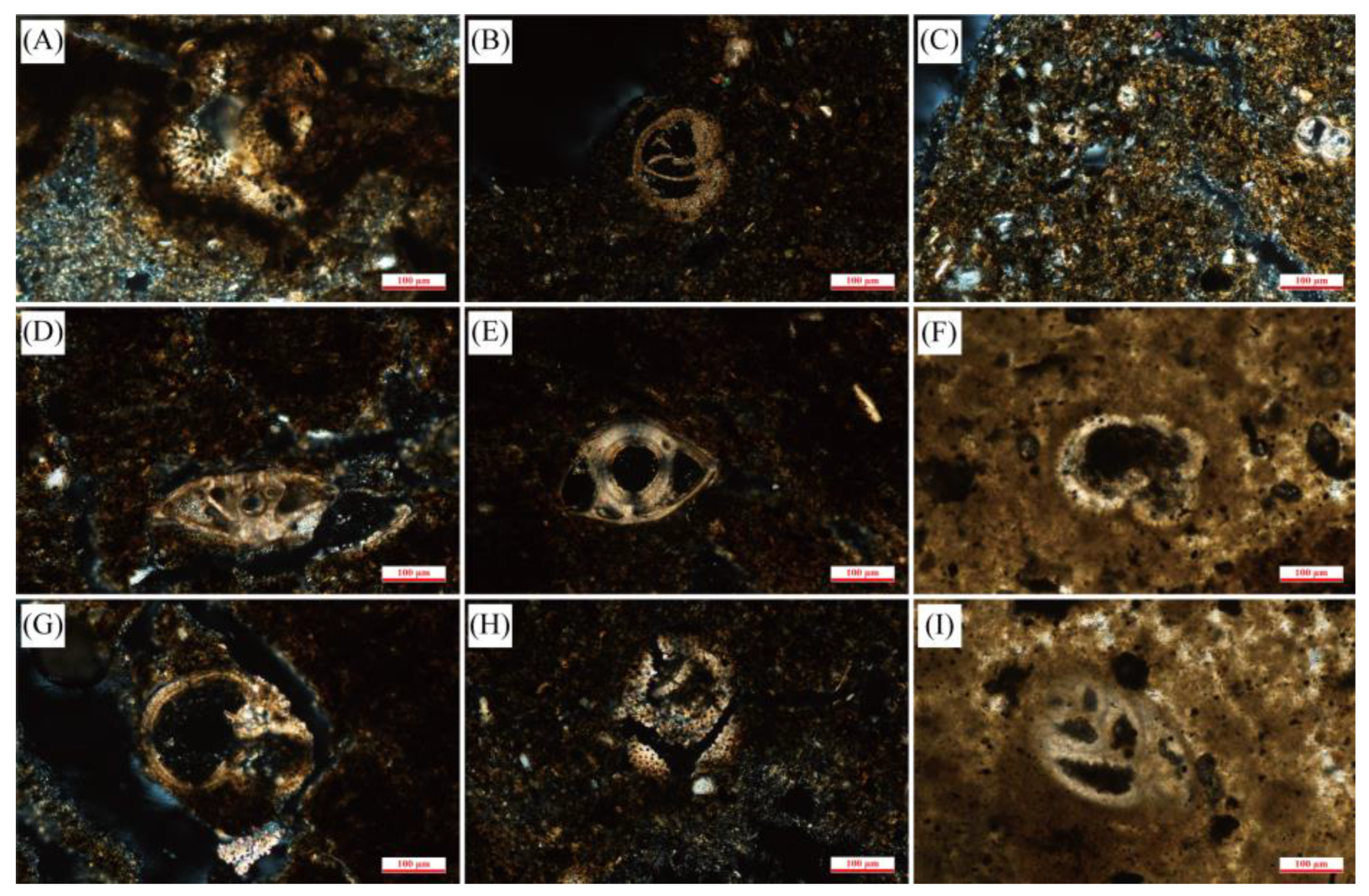

4.2.3. Crack

4.3. Pore Size Distribution (PSD) and Connectivity

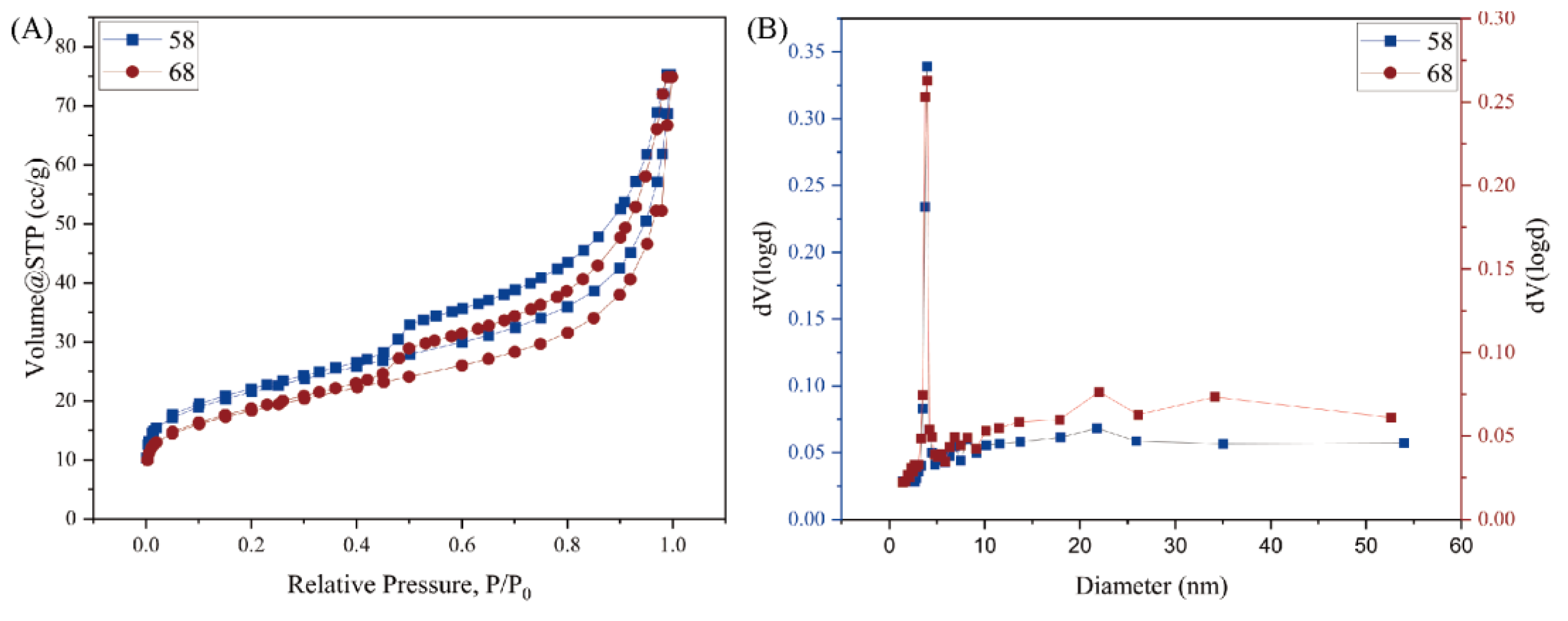

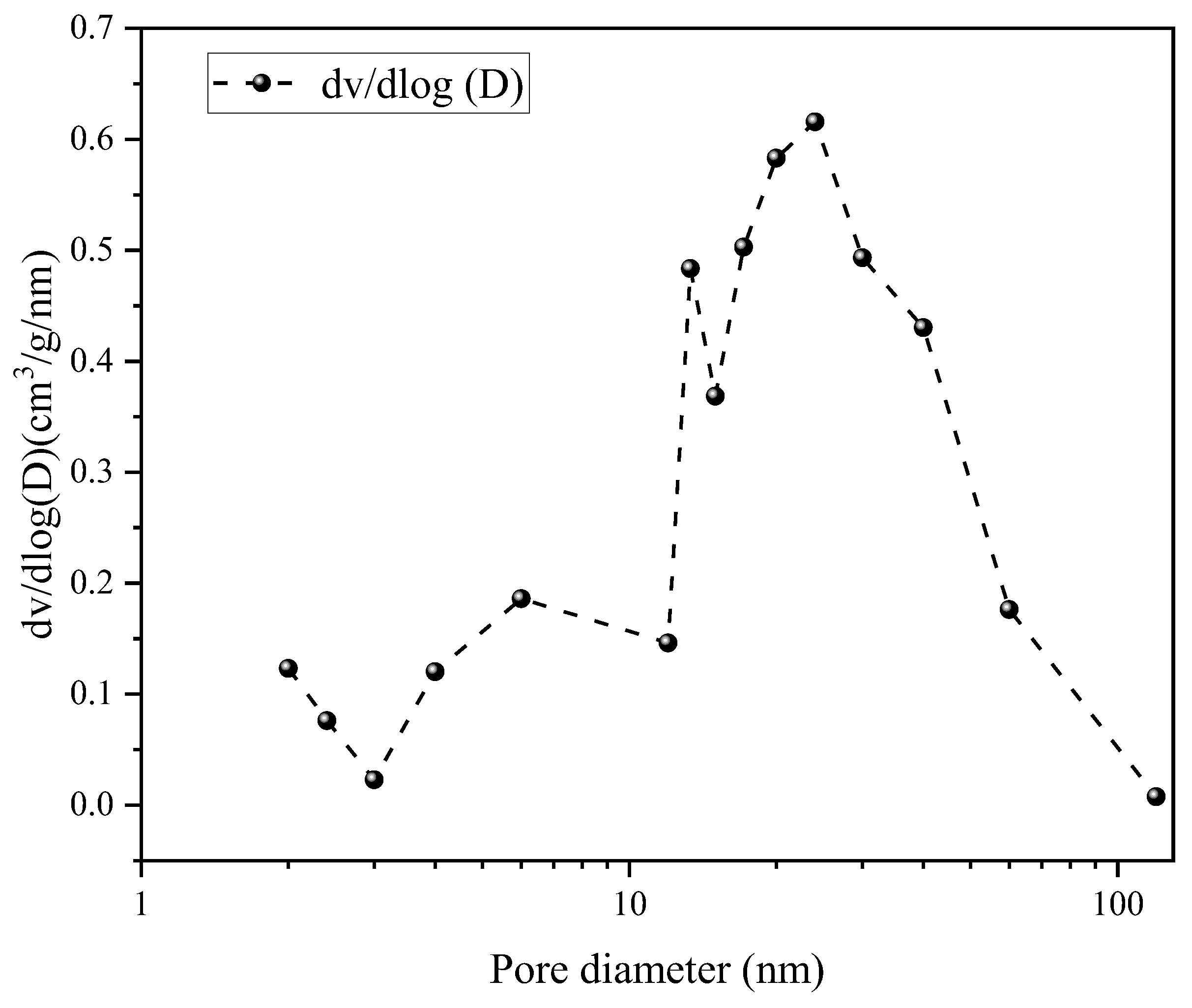

4.3.1. Nanometer-Scale Characterization—N2GA

4.3.2. Nanometer-scale characterization—NMRC

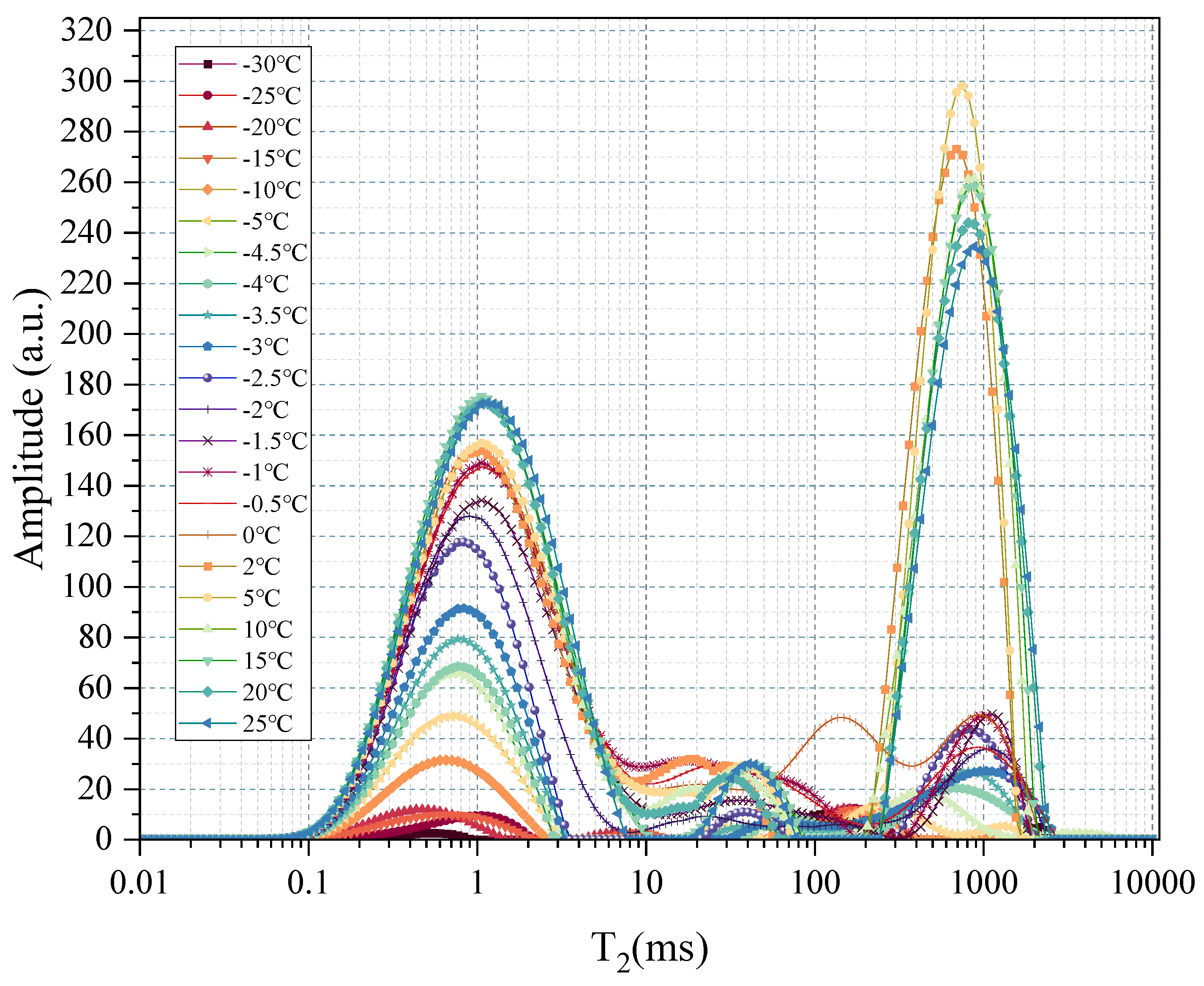

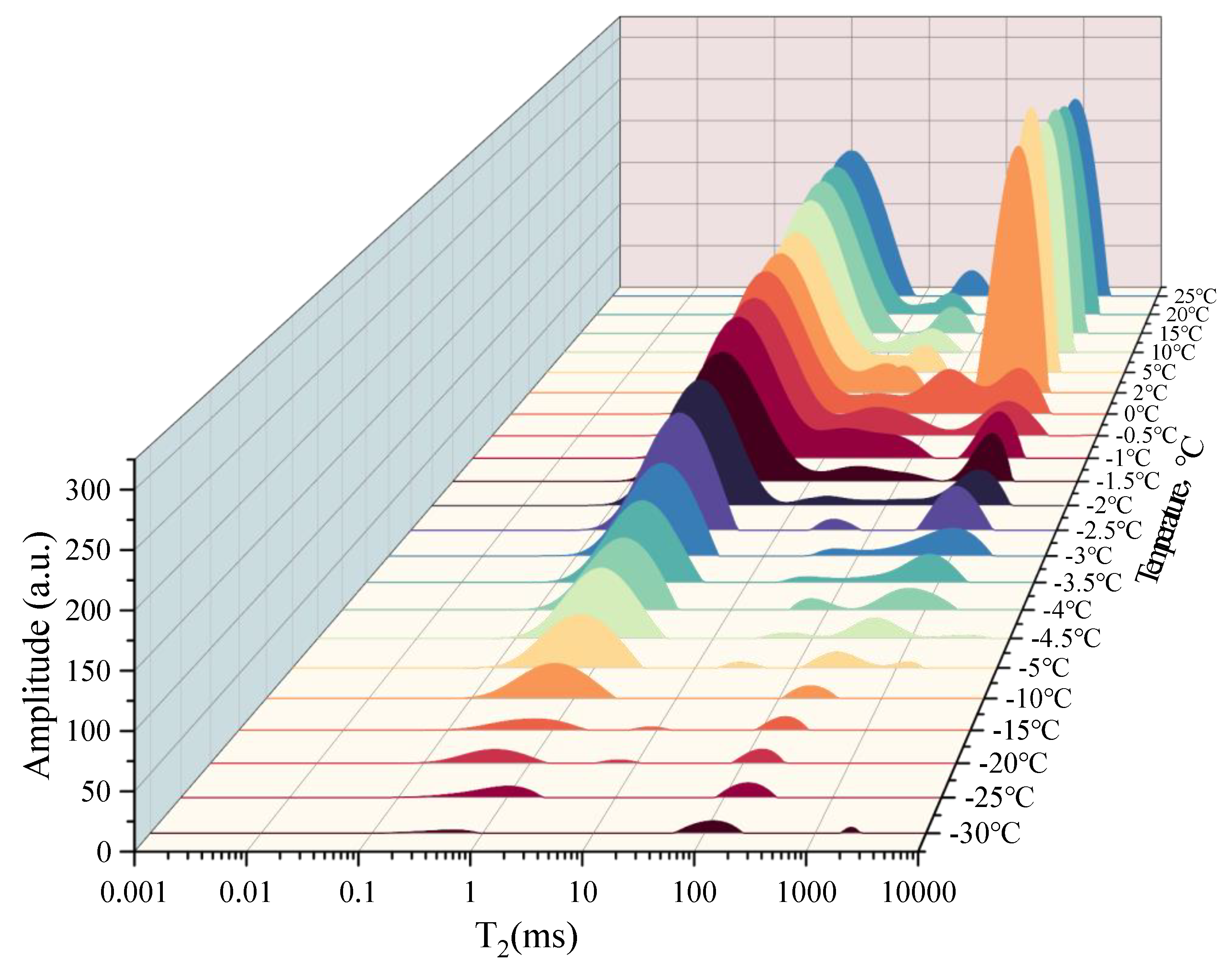

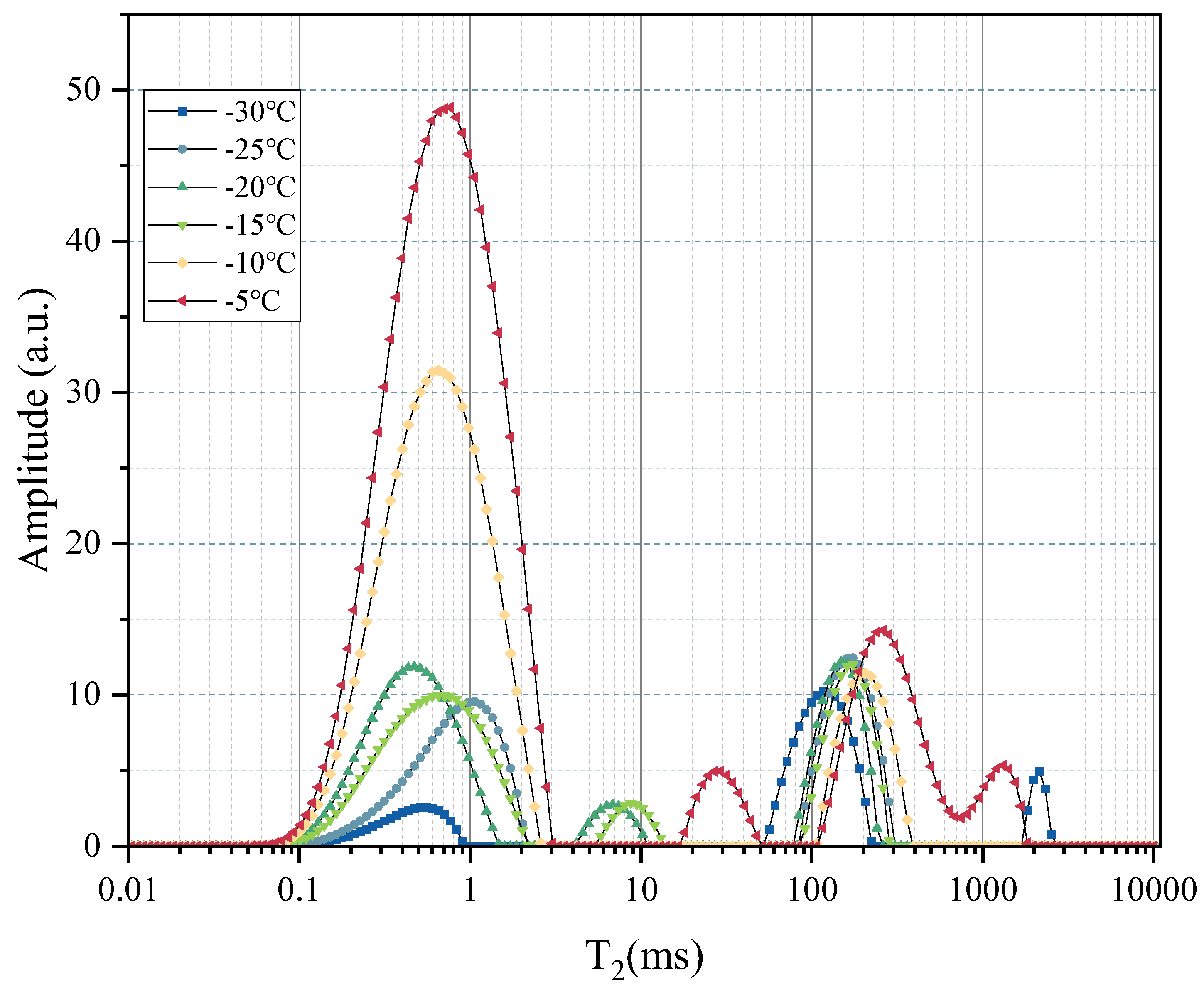

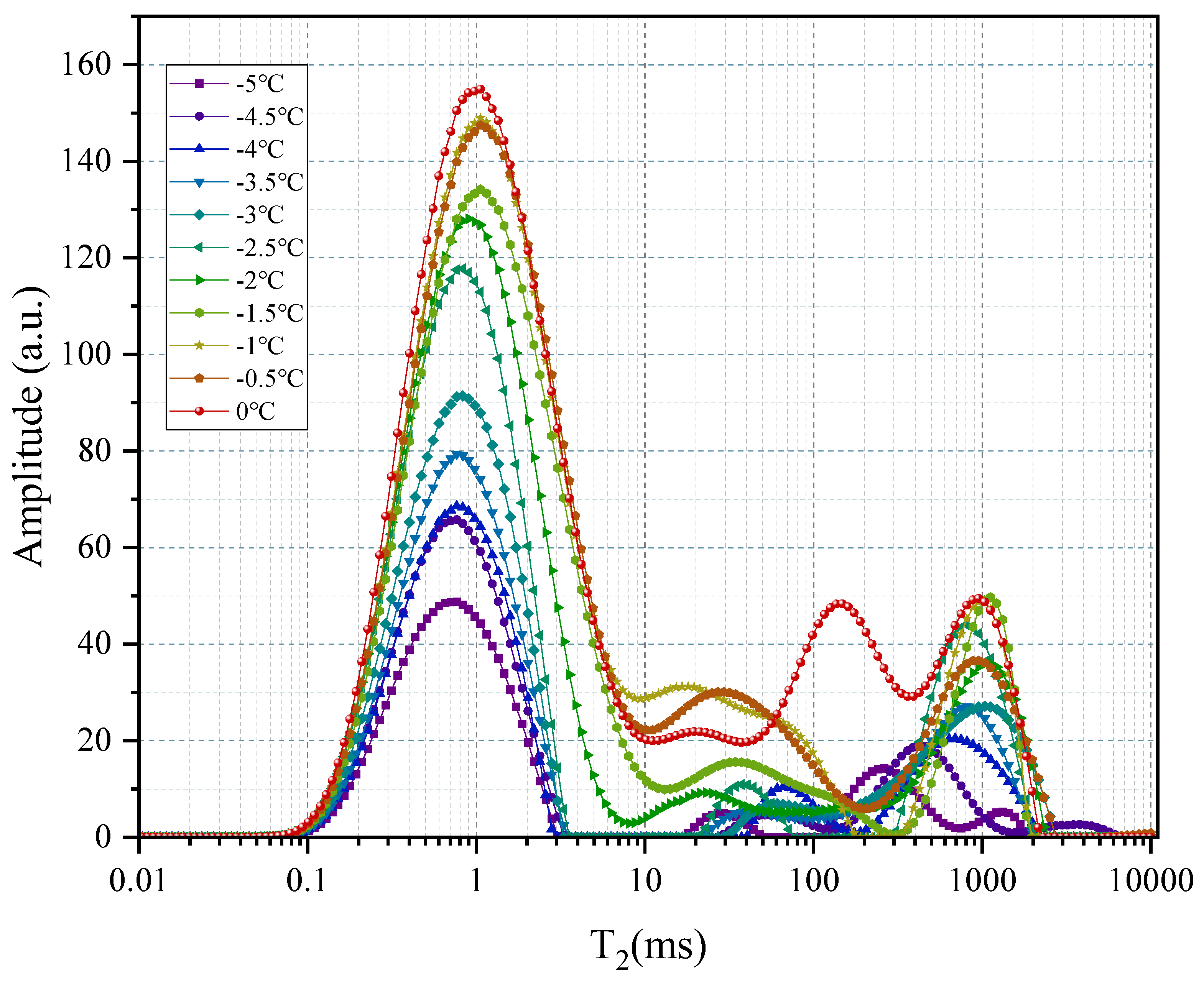

NMR T2 spectrum

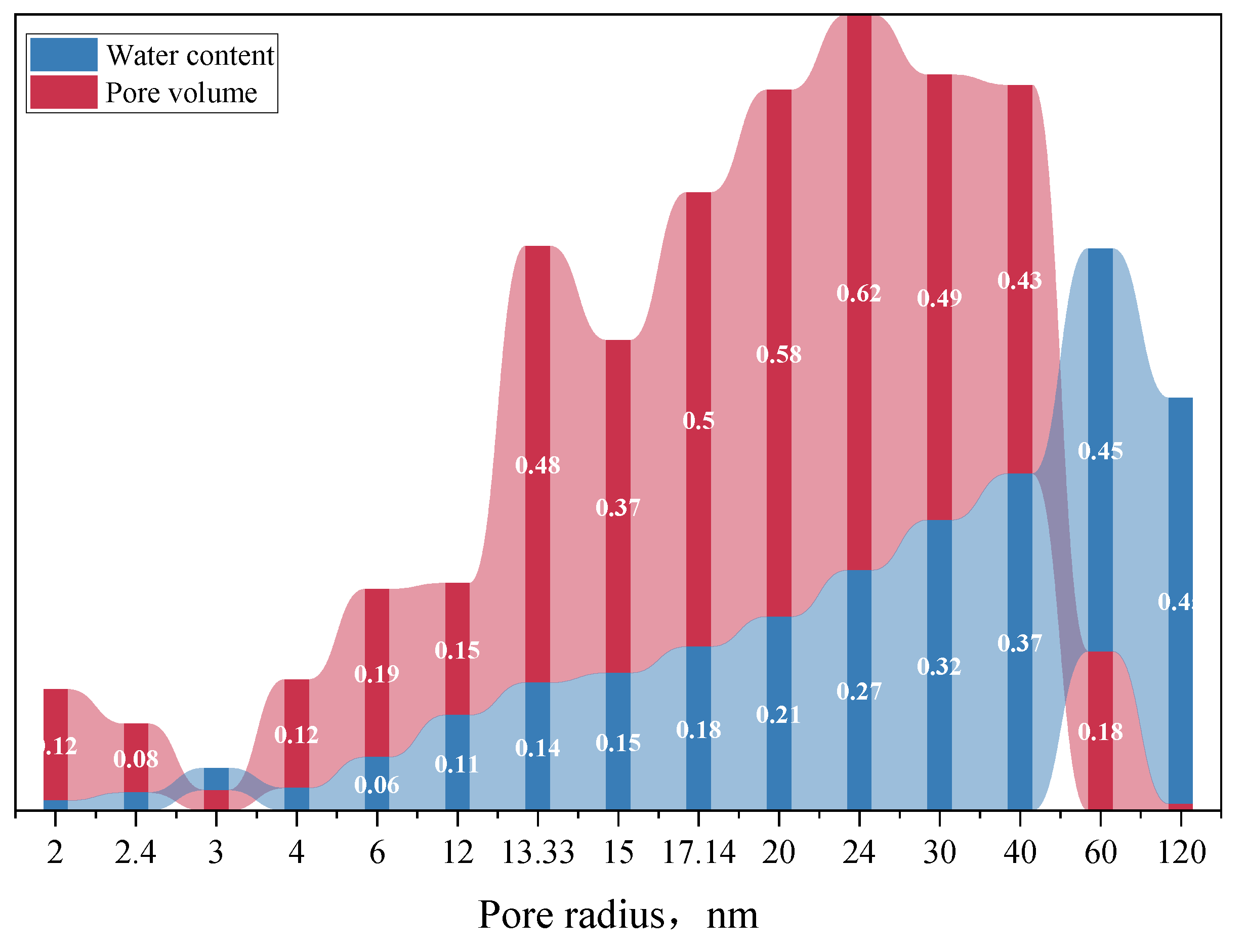

Pore Size Distribution

4.3.3 Pore Volume (PV) and Surface Area (SSA)

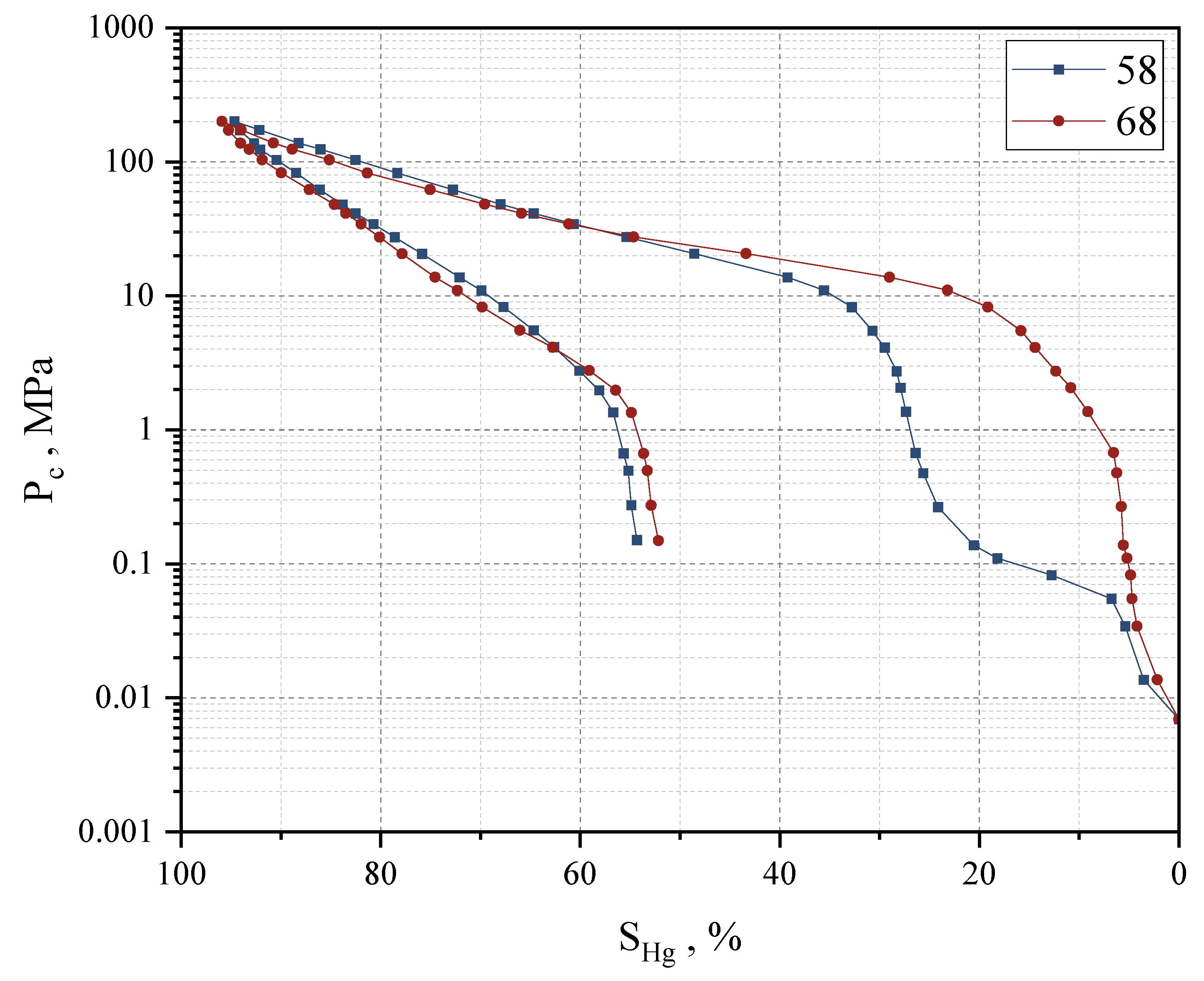

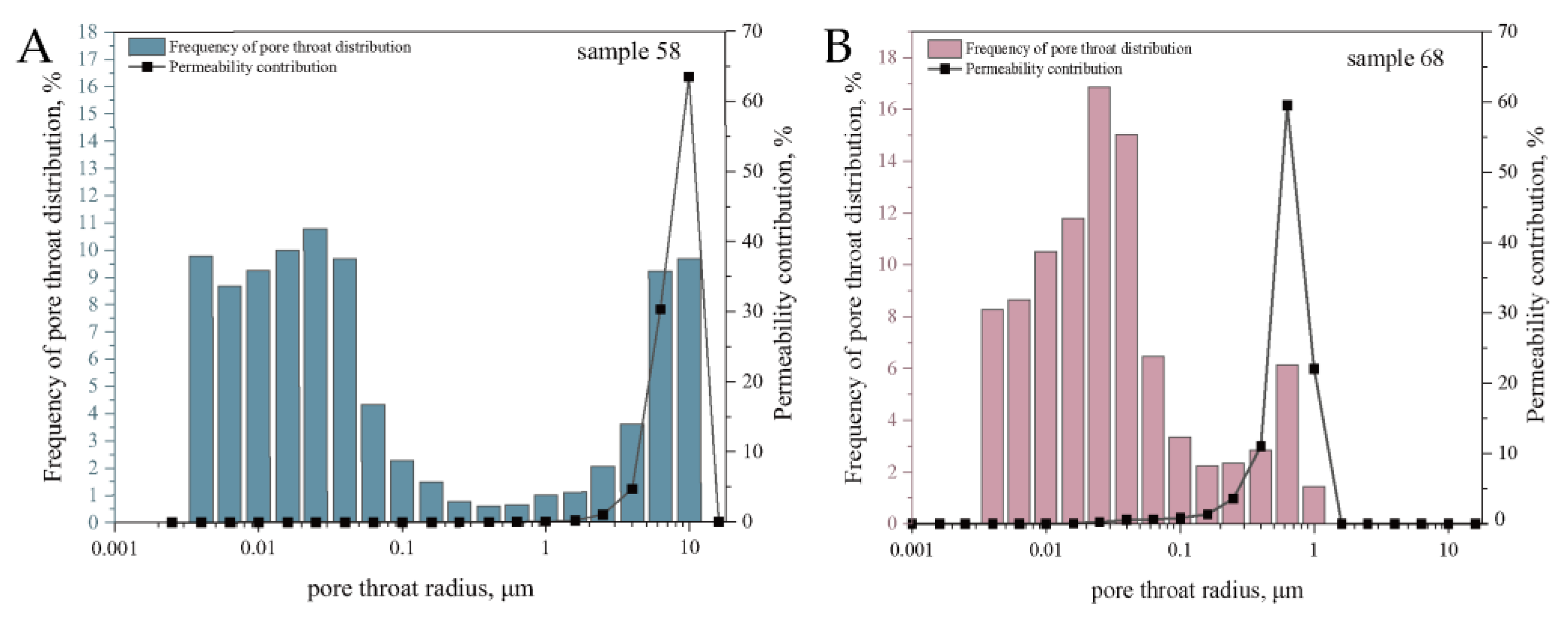

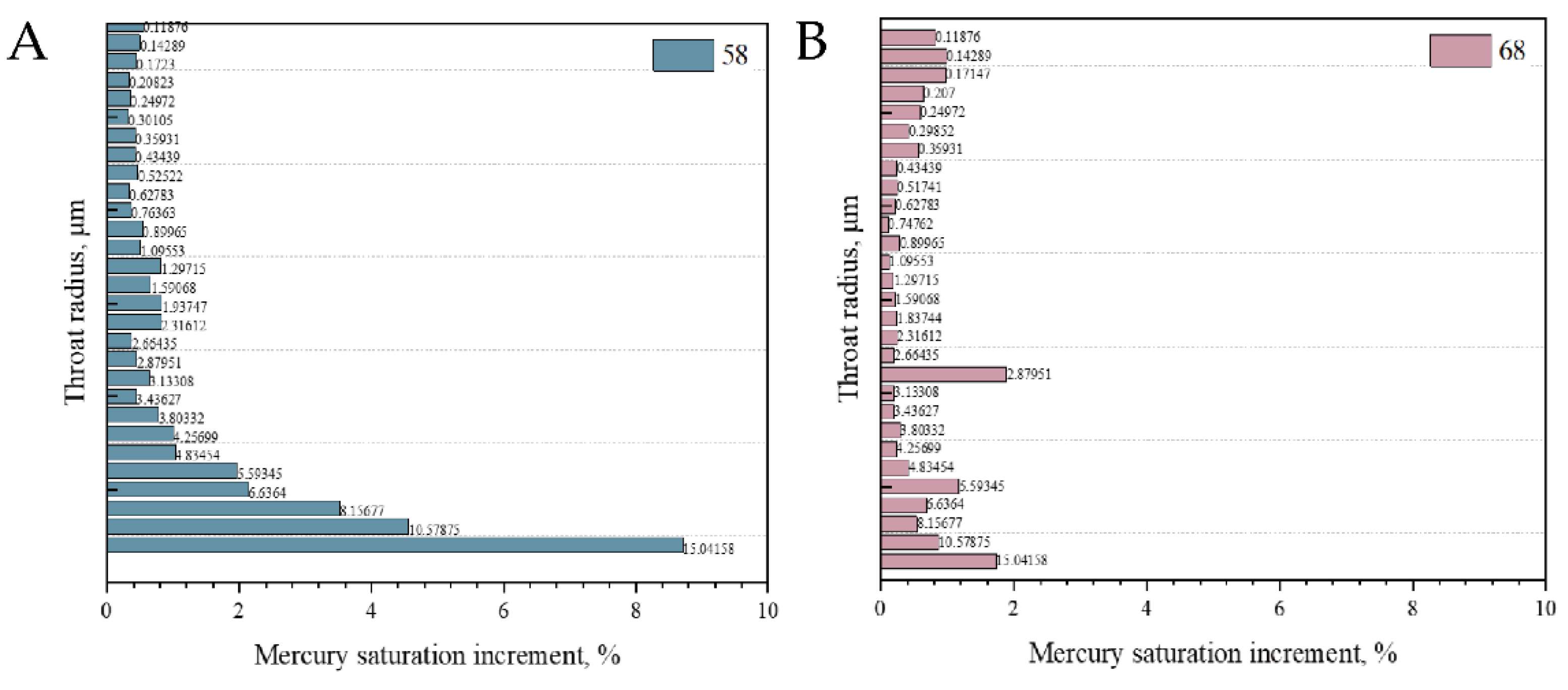

4.3.4 Micrometer Scale Characterization—HPMI

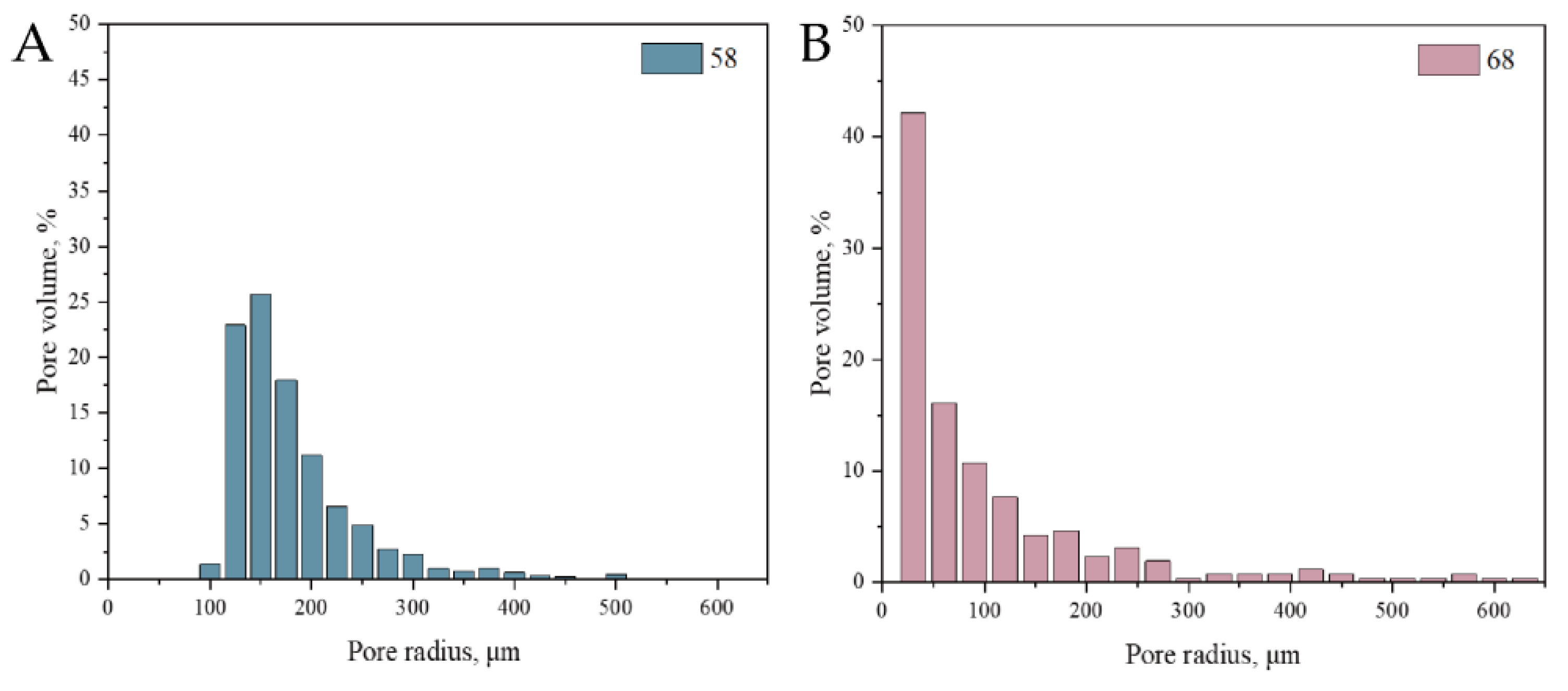

4.3.5 Micrometer Scale Characterization—CRMI

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Lijith, K.P., R. Srinivasa Rao, and D. Narain Singh, Investigations on the influence of wellbore configuration and permeability anisotropy on the gas production from a turbidite hydrate reservoir of KG Basin. Fuel, 2022. 317. [CrossRef]

- Chaturvedi, E., M. Maiti, S. Laik, et al., Mineralogical and structural characterization of the sediments of Krishna Godavari and Mahanadi Basin and their influences on hydrate formation kinetics. Advanced Powder Technology, 2021. 32(4): p. 1247-1263. [CrossRef]

- Bhawangirkar, D.R., V.C. Nair, S.K. Prasad, et al., Natural Gas Hydrates in the Krishna-Godavari Basin Sediments under Marine Reservoir Conditions: Thermodynamics and Dissociation Kinetics using Thermal Stimulation. Energy & Fuels, 2021. 35(10): p. 8685-8698. [CrossRef]

- Liu, Z., L. Chen, Z. Wang, et al., Hydrate phase equilibria in natural sediments: Inhibition mechanism and NMR-based prediction method. Chemical Engineering Journal, 2023. 452. [CrossRef]

- Bian, H., L. Ai, K. Hellgardt, et al., Phase Behaviour of Methane Hydrates in Confined Media. Crystals, 2021. 11(2). [CrossRef]

- Zhang, Y., T. Wang, X. Li, et al., Decomposition behaviors of methane hydrate in porous media below the ice melting point by depressurization. Chinese Journal of Chemical Engineering, 2019. 27: p. 2207-2212.

- Lee, S. and Y. Seo, Experimental measurement and thermodynamic modeling of the mixed CH4 + C3H8 clathrate hydrate equilibria in silica gel pores: effects of pore size and salinity. Langmuir, 2010. 26(12): p. 9742-8. [CrossRef]

- Liu, H., S. Zhan, P. Guo, et al., Understanding the characteristic of methane hydrate equilibrium in materials and its potential application. Chemical Engineering Journal, 2018. 349: p. 775-781. [CrossRef]

- Fang, B., T. Lü, W. Li, et al., Microscopic insights into poly- and mono-crystalline methane hydrate dissociation in Na-montmorillonite pores at static and dynamic fluid conditions. Energy, 2024. 288. [CrossRef]

- Yoneda, J., M. Oshima, M. Kida, et al., Permeability variation and anisotropy of gas hydrate-bearing pressure-core sediments recovered from the Krishna–Godavari Basin, offshore India. Marine and Petroleum Geology, 2019. 108: p. 524-536. [CrossRef]

- Oshima, M., K. Suzuki, J. Yoneda, et al., Lithological properties of natural gas hydrate–bearing sediments in pressure-cores recovered from the Krishna–Godavari Basin. Marine and Petroleum Geology, 2019. 108: p. 439-470. [CrossRef]

- Yamamoto, K., Overview and introduction: Pressure core-sampling and analyses in the 2012–2013 MH21 offshore test of gas production from methane hydrates in the eastern Nankai Trough. Marine and Petroleum Geology, 2015. 66: p. 296-309. [CrossRef]

- Daigle, H. and A. Johnson, Combining Mercury Intrusion and Nuclear Magnetic Resonance Measurements Using Percolation Theory. Transport in Porous Media, 2015. 111(3): p. 669-679. [CrossRef]

- Daigle, H. and B. Dugan, Pore size controls on the base of the methane hydrate stability zone in the Kumano Basin, offshore Japan. Geophysical Research Letters, 2014. 41(22): p. 8021-8028. [CrossRef]

- Kocherla, M., D. Ray, M. Satyanarayanan, et al., Trace and rare earth element systematics of cold-seep carbonates from the Krishna-Godavari basin: A comparison between isotopically distinct carbonate deposits. Marine Chemistry, 2024. 259. [CrossRef]

- Singh, A. and M. Ojha, Machine learning in the classification of lithology using downhole NMR data of the NGHP-02 expedition in the Krishna-Godavari offshore Basin, India. Marine and Petroleum Geology, 2022. 135. [CrossRef]

- Peketi, A., A. Mazumdar, B. Sawant, et al., Biogeochemistry and trophic structure of a cold seep ecosystem, offshore Krishna-Godavari basin (east coast of India). Marine and Petroleum Geology, 2022. 138. [CrossRef]

- Nukapothula, S., C. Chen, and A.P. Yunus, Seasonal sediment plumes in the Krishna-Godavari basin using satellite observations. Deep Sea Research Part I: Oceanographic Research Papers, 2022. 188. [CrossRef]

- Rehitha, T.V., N.V. Madhu, P.V. Vipindas, et al., Influence of oil and gas exploration activities on the macrobenthic community structure of the Krishna-Godavari basin (Ravva coast), Western Bay of Bengal. Continental Shelf Research, 2021. 224. [CrossRef]

- Chatterjee, R., D.K. Singha, M. Ojha, et al., Porosity estimation from pre-stack seismic data in gas-hydrate bearing sediments, Krishna-Godavari basin, India. Journal of Natural Gas Science and Engineering, 2016. 33: p. 562-572. [CrossRef]

- Qiao, J., J. Zeng, S. Jiang, et al., Heterogeneity of reservoir quality and gas accumulation in tight sandstone reservoirs revealed by pore structure characterization and physical simulation. Fuel, 2019. 253: p. 1300-1316. [CrossRef]

- Mazumdar, A., M. Kocherla, M.A. Carvalho, et al., Geochemical characterization of the Krishna–Godavari and Mahanadi offshore basin (Bay of Bengal) sediments: A comparative study of provenance. Marine and Petroleum Geology, 2015. 60: p. 18-33. [CrossRef]

- Xie, S., Q. Cheng, Q. Ling, et al., Fractal and multifractal analysis of carbonate pore-scale digital images of petroleum reservoirs. Marine and Petroleum Geology, 2010. 27(2): p. 476-485. [CrossRef]

- Liu, X. and B. Nie, Fractal characteristics of coal samples utilizing image analysis and gas adsorption. Fuel, 2016. 182: p. 314-322. [CrossRef]

- Liu, J., C. Zhang, Y. Jiang, et al., Investigation on pore structure characteristics of ultra-tight sandstone reservoirs in the upper Triassic Xujiahe Formation of the northern Sichuan Basin, China. Marine and Petroleum Geology, 2022. 138. [CrossRef]

- Qin, Y., S. Yao, H. Xiao, et al., Pore structure and connectivity of tight sandstone reservoirs in petroleum basins: A review and application of new methodologies to the Late Triassic Ordos Basin, China. Marine and Petroleum Geology, 2021. 129. [CrossRef]

- Fleury, M., T. Chevalier, R. Jorand, et al., Oil-water pore occupancy in the Vaca Muerta source-rocks by NMR cryoporometry. Microporous and Mesoporous Materials, 2021. 311. [CrossRef]

- Zhao, Y., L. Peng, S. Liu, et al., Pore structure characterization of shales using synchrotron SAXS and NMR cryoporometry. Marine and Petroleum Geology, 2019. 102: p. 116-125. [CrossRef]

- Yin, T., D. Liu, Y. Cai, et al., Methane adsorption constrained by pore structure in high-rank coals using FESEM, CO2 adsorption, and NMRC techniques. Energy Science & Engineering, 2019. 7(1): p. 255-271. [CrossRef]

- Zhou, T., C. Wu, Z. Shi, et al., Multi-Scale Quantitative Characterization of Pore Distribution Networks in Tight Sandstone by integrating FE-SEM, HPMI, and NMR with the Constrained Least Squares Algorithm. Energies, 2019. 12(18). [CrossRef]

- Zhang, M. and X. Fu, Characterization of pore structure and its impact on methane adsorption capacity for semi-anthracite in Shizhuangnan Block, Qinshui Basin. Journal of Natural Gas Science and Engineering, 2018. 60: p. 49-62. [CrossRef]

- Zhang, H., J. Shen, G. Wang, et al., Experimental study on the effect of high-temperature nitrogen immersion on the nanoscale pore structure of different lithotypes of coal. Energy, 2023. 284. [CrossRef]

- Xiong, J., X. Liu, and L. Liang, Experimental study on the pore structure characteristics of the Upper Ordovician Wufeng Formation shale in the southwest portion of the Sichuan Basin, China. Journal of Natural Gas Science and Engineering, 2015. 22: p. 530-539. [CrossRef]

- Wang, Z., C. Hao, X. Wang, et al., Effects of micro-mesopore structure characteristics on methane adsorption capacity of medium rank coal. Fuel, 2023. 351. [CrossRef]

- Wang, X., M. Wang, J. Li, et al., Thermal maturity: The controlling factor of wettability, pore structure, and oil content in the lacustrine Qingshankou shale, Songliao Basin. Journal of Petroleum Science and Engineering, 2022. 215. [CrossRef]

- Wang, X., J. Geng, D. Zhang, et al., Influence of sub-supercritical CO2 on pore structure and fractal characteristics of anthracite: An experimental study. Energy, 2022. 261. [CrossRef]

- Yu, S., J. Bo, L. Ming, et al., A review on pore-fractures in tectonically deformed coals. Fuel, 2020. 278. [CrossRef]

- Zang, Q., C. Liu, R.S. Awan, et al., Occurrence characteristics of the movable fluid in heterogeneous sandstone reservoir based on fractal analysis of NMR data: A case study of the Chang 7 Member of Ansai Block, Ordos Basin, China. Journal of Petroleum Science and Engineering, 2022. 214. [CrossRef]

- Brunelli, D.N. and R.T. Skodje, Kinetics of multicomponent nanosize clusters on solid surfaces. Langmuir, 2003. 19: p. 7130-7140.

- Sliwinska-Bartkowiak, M., G. Dudziak, R. Sikorski, et al., Melting/freezing behavior of a fluid confined in porous glasses and MCM-41: Dielectric spectroscopy and molecular simulation. The Journal of Chemical Physics, 2001. 114(2): p. 950-962. [CrossRef]

- Sliwinska-Bartkowiak, M. and M. Jazdzewska, Melting behavior of bromobenzene within carbon nanotubes. J. Chem. Eng. Data, 2010. 55: p. 4183–4189.

- Coasne, B., J. Czwartos, M. Sliwinska-Bartkowiak, et al., Effect of pressure on the freezing of pure fluids and mixtures confined in nanopores. J. Phys. Chem. B 2009.

- Jaeger, F., S. Bowe, H. Van As, et al., Evaluation of 1H NMR relaxometry for the assessment of pore-size distribution in soil samples. European Journal of Soil Science, 2009. 60(6): p. 1052-1064. [CrossRef]

| Sample | BET surface area (m2/g) | BJH pore volume (cc/g) |

|---|---|---|

| 58 | 76.232 | 0.108 |

| 68 | 64.751 | 0.110 |

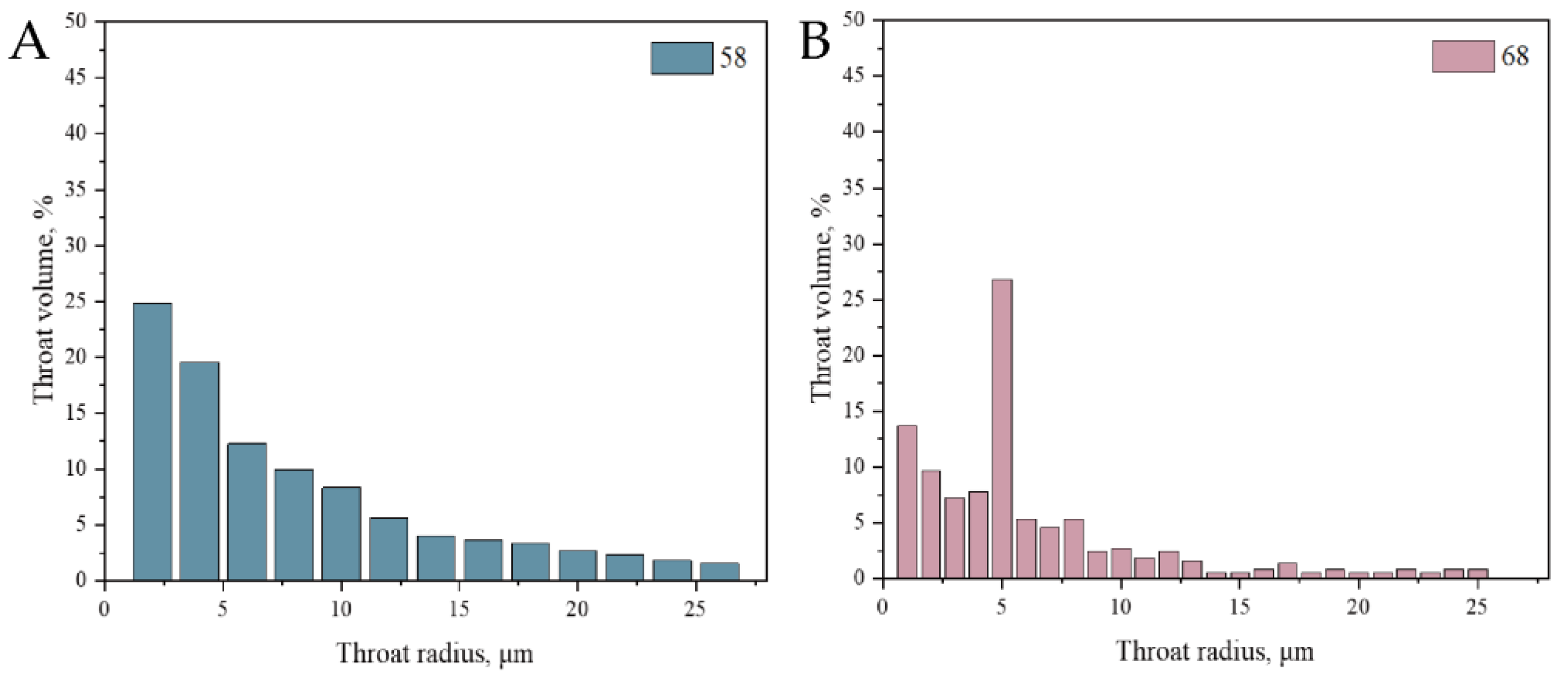

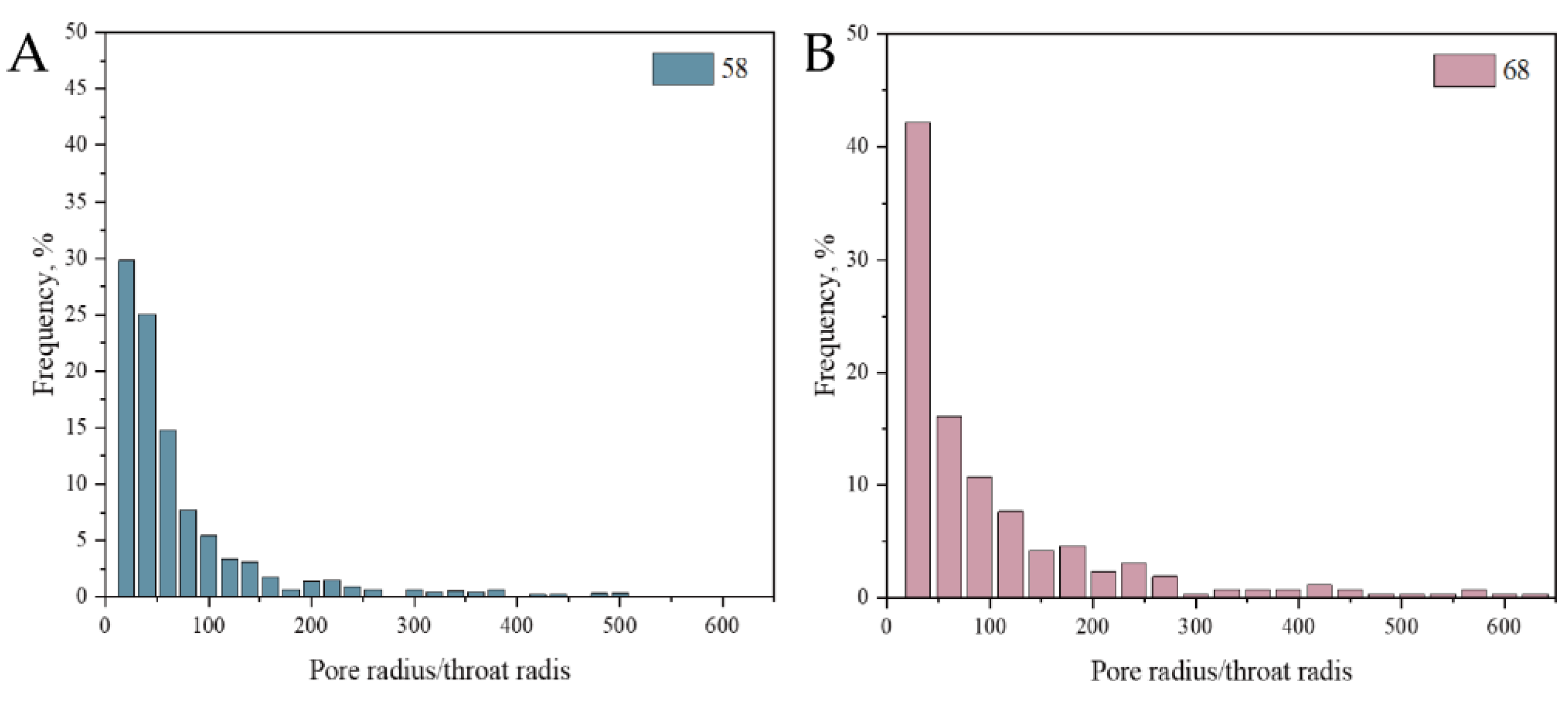

| Permeability | Porosity | Pore throat radius | Pore throat size distribution | Permeability distribution | ||||

|---|---|---|---|---|---|---|---|---|

| 10-3μm2 | (%) | Maximum | Average | Median | Peak position | Peak value | Peak position | Peak value |

| (μm) | (%) | (μm) | (%) | |||||

| K | φ | Ra | Rp | R50 | Rv | Rm | Rf | Fm |

| 160.8 | 36.04 | 13.368 | 2.937 | 0.035 | 0.025 | 10.769 | 10.000 | 63.510 |

| 0.142 | 31.44 | 1.088 | 0.114 | 0.031 | 0.025 | 16.868 | 0.630 | 59.533 |

| Sorting factor | Skewness | Kurtosis | Mean radius (μm) | Structural coefficient | Relative sorting coefficient | Characteristic structural parameters | Homogeneity coefficient |

|---|---|---|---|---|---|---|---|

| Sp | Skp | Kp | Dm | Φ | D | 1/DΦ | α |

| 4.273 | -0.494 | 0.622 | 2.495 | 2.417 | 1.713 | 0.242 | 0.220 |

| 2.184 | -0.146 | 1.312 | 0.060 | 3.622 | 36.264 | 0.008 | 0.105 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).