1. Introduction

The drilling, as a pre-assembly operation in processes such as riveting, requires that the machined holes achieve good surface quality, to avoid subsequent finishing operations. The importance of this operation is demonstrated in the tolerances set in the industry for holes, and numerous studies have been carried out on all types of materials, such as reinforced polymers [

1,

2] to find adequate cutting conditions. More recently, sandwich materials are being highly studied because they can expand their industrial use, due to the combination of material properties. This type of materials can be found in such as aerospace, marine, construction and automotive applications. An essential reason is that these composites can allow lighter structures, especially when combined with skin materials such as carbon fiber [

3]. Recent efforts have been undertaken to determine mainly mechanical properties, for example in panels of cork and a basalt fiber reinforced, used as core and skin materials, respectively; in them the relationship between stress-strain is determined [

4]. For this reason, the drilling operation is particularly complex. Doluk et al., [

5] analyze the outcomes of values quality surface considering different configurations and tools, in the milling of composites reinforced with carbon fiber and aluminum; they find that the CFRP/Al configuration increased the values of Ra, Rz and Rmax surface roughness parameters on the surfaces of both materials, respect to the configuration Al/CFRP.

In drilling operations several studies can be analyzed. In a composite of two external aluminum plates bound to a polyethylene core, can be observed as the tool and the cutting speed are identified as the parameters with more weight on the thrust force and for burr height they were the tool and the interaction between tool and feed [

6].

The drilling of a carbon/glass fiber sandwich structure shows the influence of coatings in the surface quality, finding that the delamination damage is greater in inlet holes that in outlet hole, and a slightly reduced diameter at the hole exit [

7]

In this type of materials, as balsa wood composite sandwich panel and corrugated foam and PVC foam sandwich panels, the feed rate has been shown as the more significant factor in the delamination and uncut fiber factors during the drilling [

8]. In other composites as polyurethane foam sandwiched between glass fiber reinforced plastic laminates, the thrust force is affected by the thickness of the material, the thrust force is increased when the thickness is increased if the feed rate is increased, but the thrust force is decreased when the thickness is increased in the rotational speed is increased [

9]. In the drilling of aluminum honeycomb, as core material, with carbon fiber-reinforced polymer (CFRP) as the top and bottom surfaces, the thrust force has been increased with increased feed rate and aluminum thickness, and the delamination at the entrance has been low and without significant factors, while the delamination at the exit has resulted much higher [

10]. Ekici et al., [

11] have found that in drilling CARALL (material composed by aluminum stack plus CFRP layers) lower diameter values were obtained at the hole exit compared to the hole entry in drilling. Other material is CFRP with core of foamed polyvinyl chloride, with important marine applications [

12], including protection structure of Polar engineering equipment [

13] and still without analyzing its behavior in manufacturing operations.

Although recently, in a literature review regarding drilling temperature, same findings can be highlighted, as that the different cooling methods and workpiece and tools materials used in the experiments may result in different outcomes, as can be seen in different machining processes [

14,

15]. Moreover, the influence of these factors on drilling temperature is not a purely linear relationship [

16] and the temperature has little influence on the thermal expansion coefficient and more in the fibers, at least in the polyether-ether-ketone and the glass fibers [

17]. As is seen, cooling achieved through a Ranque–Hilsch vortex tube, with compressed air impinging on the tool during machining; this method has allowed decreasing the cutting force, increasing the tool life, improving the surface finish, among other advantages [

18]. Regarding fiber reinforced composites, this technique has allowed improving some outcomes, as can be appreciated in the drilling of reinforced polyether-ether-ketone that avoid oversized holes [

19] or in the tapping of reinforced polyamide where an energy reduction can be achieved at temperatures closed to 0ºC [

20].

At even lower temperatures, such as those achieved in cryogenic machining, improvements in results are also attained. Cryogenic refrigerants are increasingly used, mainly in energy development and in the aerospace industry, and their influence on polymeric materials should be studied in depth [

21]. Regarding cryogenic drilling in CFRP material, the liquid N

2 reduces the surface roughness of the drilled parts and tool wear [

22]. Other findings are related to the hole diameter error, which cryogenic drilling reduces compared to dry drilling, also in CFRP [

23,

24]. This can be also appreciated in reinforced composites, for example in glass fiber reinforced composites, where improvements are achieved, and second-order relationship are found between the variables thrust forces and average roughness and the parameters defined in the cutting factor; although the diameter of holes has not a relationship between the cutting conditions [

25].

As seen previously, the dimensional precision of the holes is a relevant factor because it determines the tolerances, also the roughness because it can avoid subsequent finishing operations, as well as delamination and thrust forces; the latter also because they contribute to energy consumption during drilling, although in a smaller proportion than the torque. Accordingly with the above, the main objectives of this work focus on determining the influence of cutting conditions and the thickness of the core of the composites on the thrust forces, the variation of the diameters at the entrance and exit of the hole at very low temperatures.

2. Materials and Methods

This Section is dedicated to explaining the experimental procedures deployed for measuring the variables to be studied and the procedures used for data processing.

2.1. Experimental Method

The materials used are carbon fiber sandwich sheets with inner foam core, and they were manufactured by prepreg, pressed and oven cured. The orientation of the carbon fibers was bidirectional 90º/0º, with 3000 filaments per yarn strand and 200 gr/m2, and 2×2 twill fabric type; its moisture content was of 0.5%. The core was foamed polyvinyl chloride (PVC), closed cell and density of 60 kg/m3. Epoxy resin was used as binder between layers. Two dimensions were used of 12 mm and 6 mm of thickness, and surface of 175×110 mm2 in both specimens. The thickness of each carbon fiber sheet was 1 mm.

These plates were drilled in a Manga Tongtai TMV-510 (Tong-tai Machine and Tool Co., Ltd., Kaohsiung Hsien, Tai-wan) machining center, using a 6 mm diameter PCD (polycrystalline diamond) drill bit, with a 120º point angle and a 30º helix angle. This type of tool, twist drills, has given better results in sandwich materials with carbon fiber than other drill bits [

10]. The cutting conditions were drill rotation speeds between 2000 rpm and 6000 rpm and feed rates between 200 mm/min and 600 mm/min. During the machining, the temperature reached slightly lower than -120ºC due to liquid nitrogen (LN

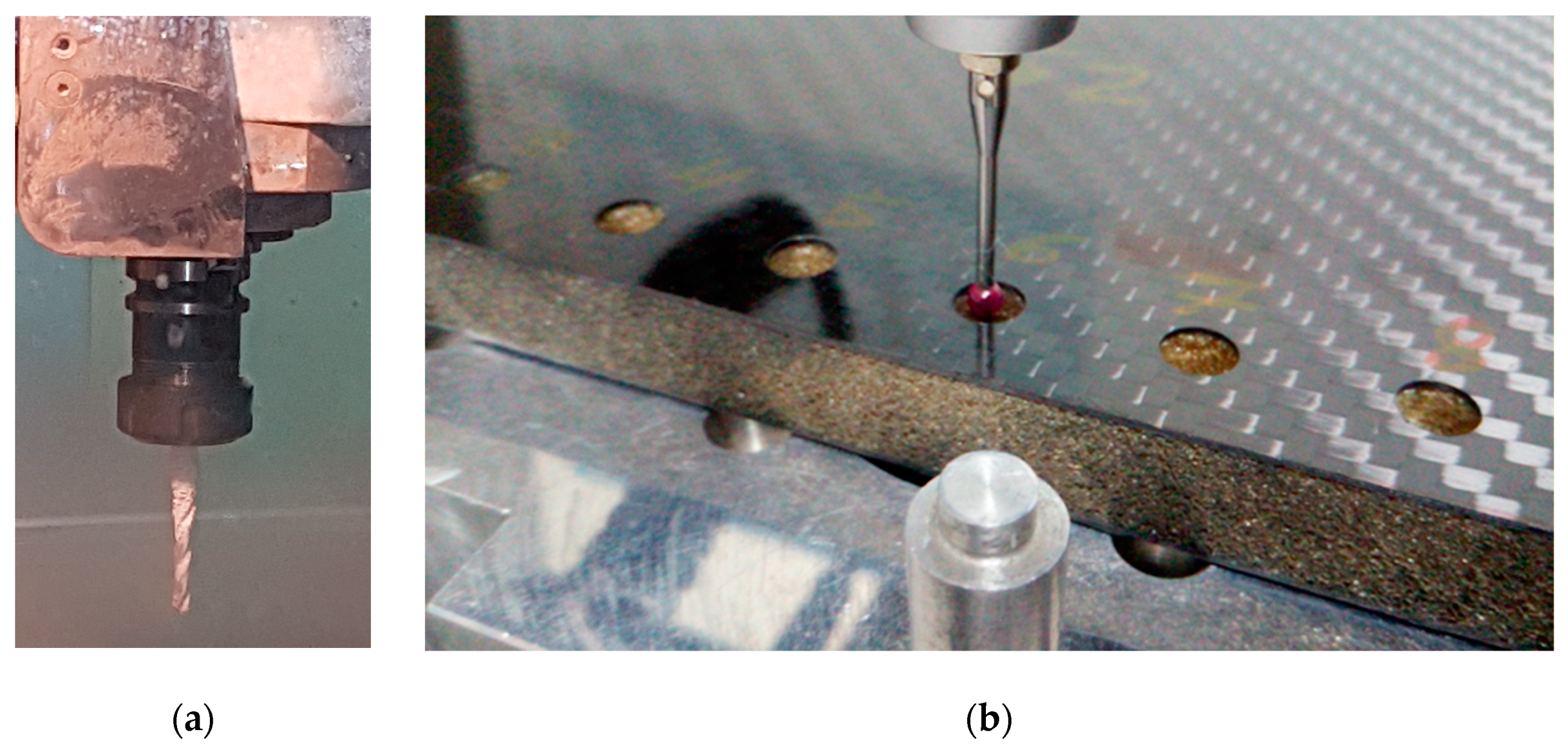

2) used as refrigerant and supplied by Air Liquide; this temperature was measured by an infrared pyrometer (Optris Infrared Sensing, Portsmouth, NH, USA). The drill bit after cryogenic machining can be seen in

Figure 1.a. During drilling, the thrust forces have been monitored by a piezoelectric dynamometer type Kistler 9257B; this equipment was connected to a multichannel signal amplifier, Kistler 5070A and the data collected were processed by DasyLab software.

The diameters were measured by a coordinate measuring machine, Mitutoyo BX 303 (Mitutoyo Corp., Kawasaki-shi, Japan) (see

Figure 1.b), using the least squares method to determine the diameter value through the measured points in the hole. The points were measured at 0.5 mm from the outer surface. Moreover, a three-dimensional measurement device with a TESA VISIO optical sensor (TESA SA, Renens, Switzerland) was used.

The experiments were repeated four times, as a result, 72 tests were performed.

2.2. Data Processing

A design of experiments was carried out, in particular, an orthogonal design, L18(2

1×3

7), defined by Taguchi, that allows combining a factor of two levels and seven factors of three levels, at most [

26]. In this case, two factors od three levels for Fz, ∆Di and ∆Do; their values can be seen in

Table 1. The foam thickness is also considered for ∆Di because the chip exit can influence the final diameter. Mean analysis has been selected because all are control factors and there are no noise factors, and its interpretation is more intuitive than the signal-to-noise ratio. Thus, the design was applied to averages of experimental values obtained, and considering the assumption, smaller is better and nominal is better for diameters variation in the optimization process. An Analysis of Variance (ANOVA) was performed to determine the significant factors at the 95% confidence level, through a P-value less than 0.05. Later, a third-degree regression model was defined [

27]; this model was used because it allowed to obtain a higher determination coefficient, R

2, that is, a higher goodness of fit.

3. Results and Discussion

This section is divided by three subheadings devoted to experimental and statistical outcomes, and process optimization and predictions.

3.1. Experimental Results

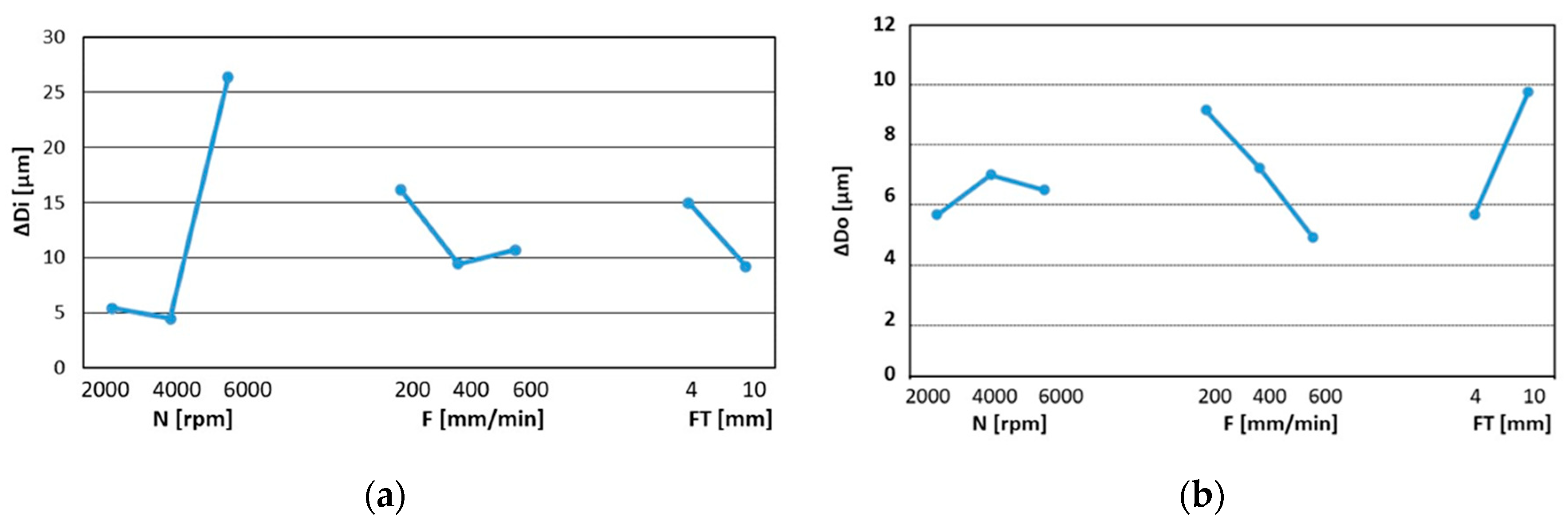

Thrust forces required to drill laminates are low, according to

Table 2, perhaps due to the small thickness of the carbon fiber laminates and the low density of the foamed polyvinyl chloride; this parameter was already found conclusive in the required thrust forces [

28]. The average values for cutting conditions and foam thickness can be seen in Figure 2. Moreover, these forces are in line with values obtained in studies focused on cryogenic drilling of CFRP although lower due to different cutting conditions and drill bit [

29].

As expected, the difference in Di (ΔDi) is similar in the two types of laminates (see

Table 1); in general, ΔDi increases as N increases and reduces as F decreases. Note that the differences between 2000 and 4000 rpm and between 400 and 600 mm/min are minimal. More clearly,

Figure 3.a shows the mean values of ΔDi, their values allow these composites to be kept within H7 tolerances, according to ISO 286-2 standard [

30] and they have been found in other plates of different thickness. Avoidable cutting conditions would be identified with high cutting speeds and low feed rates.

The difference in Do (ΔDo) is less than ΔDi as expected. The best results in outlet diameter are achieved in low feed rates, but when the FT is increased, the feed rate also can be increase until 400 mm/min. Considering ISO 286-2 standard [

30], these external diameters are within H8 tolerances. In very strict industries, fiber-reinforced polymers usually require tolerances between 0 and 30 µm [

1], therefore, the results obtained are very acceptable, and all cutting conditions may be recommended for FT=4 mm, and excluding the conditions N=6000 rpm, F=200 mm/min and N=6000 rpm, F=400 mm/min for FT=10 mm (see test 7 and 8 in

Table 2).

Table 2 shows values very close to zero for both diameter differences. But these results are an average of four values (see Subsection 2.1), so some of these measurements are negative, the diameter found is less than the nominal diameter.

3.2. Statitical Results

The section is structured in the results of the ANOVA study, the regression analysis and its coefficient of determination, R2.

3.2.1. Thrust Forces

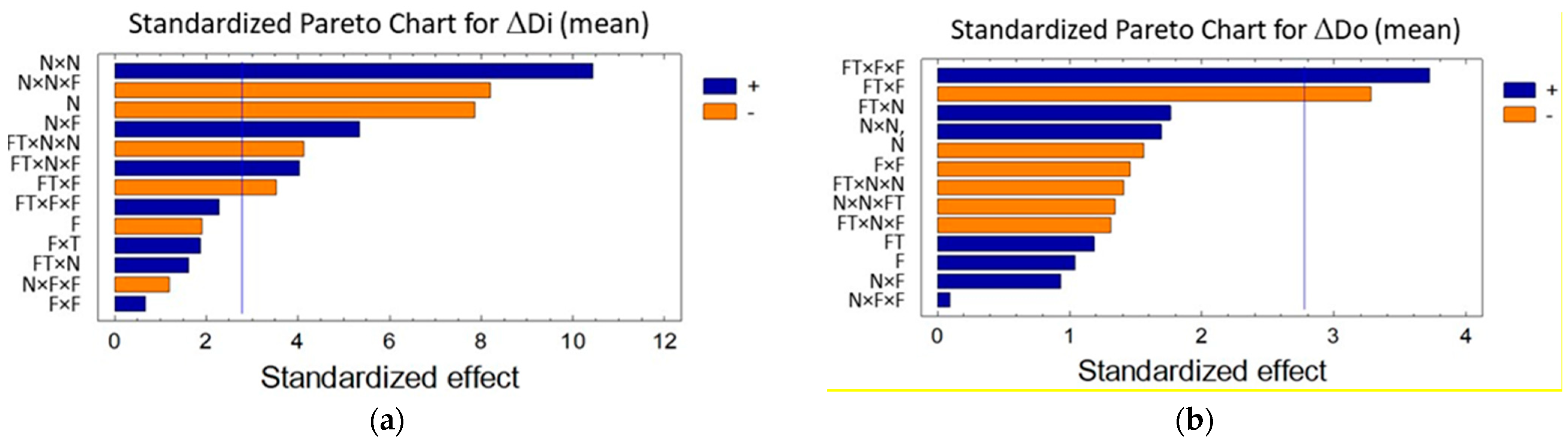

Table 4 shows the ANOVA where the significant factors can be identified, N

2 and N

2×F at a confidence level of 92% as observed in P-value (0.0755 and 0.0722 respectively). Although is a confidence level higher than 95%, in environmental manufacturing, this confidence level can be considered acceptable [

27]. As can be seen, no main factor is significant, but the la influence of N is clear; the contribution of N

2 and N

2×F reaches almost 45%. These considerations are clearly shown in

Figure 3. Note that no factor related to FT has emerged as significant. In these dimensions, foamed polyvinyl chloride has easily been machinable and the thickness of the carbon fiber sheet has allowed the holes to be executed with very low forces.

The regression analysis for a third-degree model defined in Eq. (1) provides how to determine the force forecast. The coefficient of determination, R

2, is 84.2% that can be considered acceptable.

3.2.2. Dimensional Accuracy of Holes

The inlet diameters variation, ∆Di, and their influencing factors can be observed in

Table 5. As significant factors can be identified a main factor N, a second-order factors N

2, and five interactions, FT×F, N×F, FT×N

2, FT×N×F and N

2×F, at 95% confidence level (see P-value in Table 3). The greatest contribution was identified in N

2 (32.78%), followed by N

2×F (20.16%) and N (18.48%) as main influencing factors. Note that the residual contribution is close to 1%.

ANOVA study identifies the significant factors for the outlet diameters variation, ∆Do, at the 95% confidence level (see

Table 6). Factors with a P-value less than 0.05 are interactions between and foam thickness and feed rate, FT×F and FT×F

2. It is noteworthy that no main factor is significant, and unlike ∆Di, rotation speed is not an influencing factor, probably due to the strong effect of the fiber layer thickness. The main contribution to the variability come from FT×F

2 (33.08%) and FT×F (25.67%).

The regression analysis provides the relationships described in Eq. (2) for ∆Di and in Eq. (3) for ∆Do. Their coefficients of determination, R

2 are 98.9% and 90.5% respectively.

These results confirm the differences found in the experimental data between inlet and outlet diameters. Very different significant factors and interactions are identified as shown in

Figure 4.

3.3. Optimizatized Cutting Conditions and Predictions

The optimization process provides ideal values of cutting conditions shown in

Table 7. For FT of 4 mm, Fz is 16.6 N, ∆Di and ∆Do is 0 µm. For FT of 10 mm, Fz take a value of 19.3 N, ∆Di and ∆Do is 0 µm. Experimental tests could corroborate these outcomes.

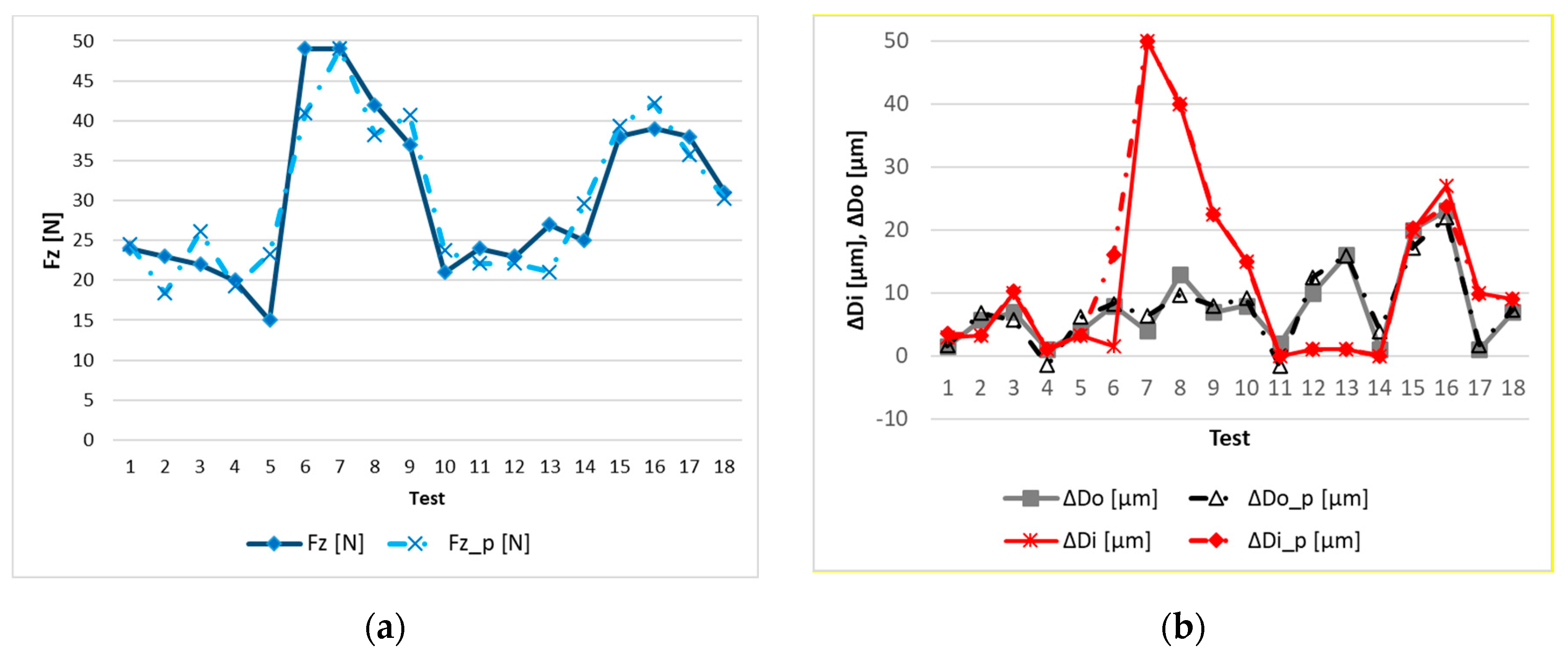

Moreover, to validate the models, predictions provide the results shown in

Figure 5. As can be seen, the outcomes are acceptable for FT=4 mm and FT=10 mm. In particular, in

Figure 5.b, the phenomenon of outlet diameter contraction is observed in the predictions obtained (see test 4 and test 11).

4. Discussion

The different significant factors found in the inlet and outlet diameters are common in other materials, such as fiberglass reinforced composites [

1]. Also in these cases, N was not significant in the exit diameters. Once known the coefficient of determination, the predictive models for all variables thrust forces and diameters can be considered acceptable. In addition, the models can show the contraction achieved at some outlet diameters. Core thickness was significant for diameters (as interactions), but not for forces probably because foamed polyvinyl chloride is an easy-to-machined material.

Regarding the difference in diameters, the result within tolerances is the most relevant. A possible explanation is a slight contraction that can be produced in the hole, particularly at exit hole because the frictional force is increased; this phenomenon has been identify in reinforced polymers such as GFRP [

31] or in CFRP [

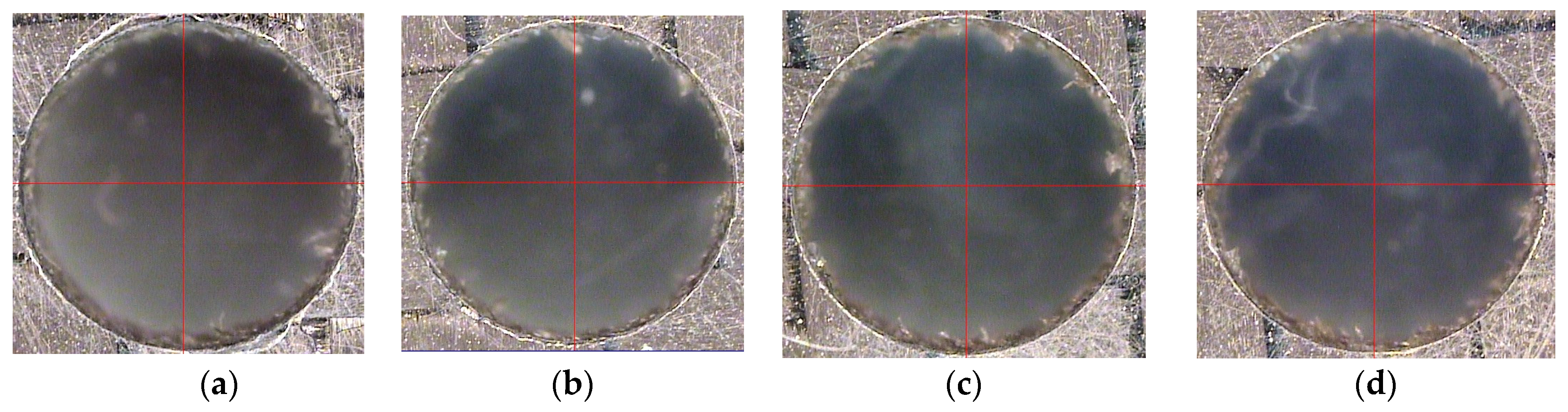

29]. Inlet diameters can be observed in

Figure 6, where diameters with greater (

Figure 6.a and 6.b) and lesser (

Figure 6.c and 6.d) deviations are shown. The differences are very small and the fibers inside are due to the foamed polyvinyl chloride so they do not hinder possible riveting.

5. Conclusions

This work has developed a study regarding the cryogenic machining in a sandwich material with carbon fiber and core of foamed polyvinyl chloride. The outcomes are of interest because these materials can be used in ships sailing in very cold waters. In the cutting conditions selected, inlets and outlets diameters have researched very low deviations, meeting strict tolerances. This allows avoiding pre-assembly additional operations, and it can be important in maintenance operations.

A contraction has occurred in the outlet diameters regarding the inlet diameters, in laminates of both core thicknesses. This phenomenon is identified by the predictive model developed fir outlet diameters. This model and those developed for inlet diameters and thrust forces have a high coefficient of determination and provide adequate predictions.

Author Contributions

Conceptualization, R.D. and M.M.M.; methodology, R.D., M.M.M. and N.R.-P.; validation, R.D. and M.M.M.; formal analysis, R.D. and M.M.M,; investigation, R.D., M.M.M., N.R.-P. and R.A.-F.; resources, R.D.; writing—original draft preparation, R.D.N., N.R.-P. and R.A.-F.; writing—review and editing, R.D, M.M.M., N.R.-P. and R.A—F.; supervision, R.D.; project administration, R.D.; funding acquisition, R.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Spanish Ministry of Science and Innovation, RTI2018-102215-B-I00 and PID2022-143329OA-I00 projects and the College of Industrial Engineers of UNED, 2023-ETSII-UNED-05 project.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors would like to thank the College of Industrial Engineers of UNED for supporting them.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Koklu, U.; Morkavuk, S.; Featherston, C.; Haddad, M.; Sanders, D.; Aamir, M.; Pimenov, D.Y.; Giasin, K. The effect of cryogenic machining of S2 glass fibre composite on the hole form and dimensional tolerances. Int. J. Adv. Manuf. Technol. 2021, 115, 125–140. [CrossRef]

- Domingo, R.; García, M.; Sánchez, A.; Gómez, R. A Sustainable Evaluation of Drilling Parameters for PEEK-GF30. Materials 2013, 6, 5907-5922. [CrossRef]

- Vijaya Ramnath, B.; Alagarraja, K.; Elanchezhian, C. Review on Sandwich Composites and their Applications. Mater. Today: Proc. 2019, 16, 859-864. [CrossRef]

- Torres, J.P.; Hoto, R.; Andrés, J.; García-Manrique, J.A. Manufacture of Green-Composite Sandwich Structures with Basalt Fiber and Bioepoxy Resin. Adv. Mater. Sci. Eng. 2013, 2013, Article ID 214506, 9 pages; https://doi.org/10.1155/2013/214506.

- Doluk, E.; Rudawska, A.; Miturska-Barańska, I. Investigation of the Surface Roughness and Surface Uniformity of a Hybrid Sandwich Structure after Machining. Materials 2022, 15, 7299. [CrossRef]

- Rezende, B.A.; Silveira, M.L.; Vieira, L.M.G.; Abrão, A.M.; Faria, P.E.d.; Rubio, J.C.C. Investigation on the Effect of Drill Geometry and Pilot Holes on Thrust Force and Burr Height When Drilling an Aluminium/PE Sandwich Material. Materials 2016, 9, 774. [CrossRef]

- Gutiérrez, S.C.; Meseguer, M.D.; Muñoz-Sánchez, A.; Feito, N. Study of the Influence of Tool Wear of Two Drill Bits Manufactured with Different Coating Processes in Drilling Carbon/Glass Fiber Hybrid Composite Bounded with Epoxy Polymer. Coatings 2023, 13, 1440. [CrossRef]

- Khoran, M.; Ghabezi, P.; M. Frahani, M.; Besharati, M.K. Investigation of drilling composite sandwich structures. Int. J. Adv. Manuf. Technol. 2015, 76, 1927–1936. [CrossRef]

- Kaushal, K.N.; Sunith Babu L.; Mathivanan, R. Study on drilling parameters of GFRP-PUF sandwich composites. Mater. Today Proc. 2018, 5, 24439–24447. [CrossRef]

- Ekici, E.; Uzun, G.; Altas, S. Evaluation of the effects of drilling parameters, tool geometry and core material thickness on thrust force and delamination in the drilling of sandwich composites. Surf. Rev. Lett. 2021, 28(12), 2150112. [CrossRef]

- Ekici, E.; Motorcu, A.R.; Yildirim, E. An Experimental Study on Hole Quality and Different Delamination Approaches in the Drilling of CARALL, a New FML Composite. FME Trans. 2021, 49, 950-961. [CrossRef]

- Bull, P.H.; Edgren, F. Compressive strength after impact of CFRP-foam core sandwich panels in marine applications. Compos. B Eng. 2004, 35, 535-541. [CrossRef]

- Xiao, W.; Hu, Y.; Li, Y. Ice impact response and energy dissipation characteristics of PVC foam core sandwich plates: Experimental and numerical study. Mar. Struct. 2023, 89, 103407. [CrossRef]

- Morkavuk, S.; Köklüa, U.; Bağcı, M., Gemi, L. Cryogenic machining of carbon fiber reinforced plastic (CFRP) composites and the effects of cryogenic treatment on tensile properties: A comparative study. Compos. B Eng. 2018, 147, 1–11. [CrossRef]

- Domingo, R.; Marín, M.M.; De Agustina, B. Study of the roughness of carbon fiber-reinforced composite plates in peripheral cryogenic milling. AIP Conf. Proc. 2019, 2113, 080013. [CrossRef]

- Zhu, Z.; Sun, X.; Guo, K.; Sun, J.; Li, J. Recent Advances in Drilling Tool Temperature: A State-of-the-Art Review. Chin. J. Mech. Eng. 2022, 35, 148. [CrossRef]

- Chu, X.X.; Wu, Z.X.; Huang, R.J.; Zhou, Y.; Li, L.F. Mechanical and thermal expansion properties of glass fibers reinforced PEEK composites at cryogenic temperatures. Cryogenics 2010, 50, 84–88. [CrossRef]

- Swain, S.; Patra, S.K.; Roul, M.K.; Sahoo, L.K. A short review on cooling process using compressed cold air by vortex tube in machining. Mater. Today Proc. 2022, 64 Part 1, 382-389. [CrossRef]

- Domingo, R.; de Agustina, B.; Marín, M.M. Study of Drilling Process by Cooling Compressed Air in Reinforced Polyether-Ether-Ketone. Materials 2020, 13, 1965. [CrossRef]

- Domingo, R.; De Agustina, B.; Marín, M.M. A Multi-Response Optimization of Thrust Forces, Torques, and the Power of Tapping Operations by Cooling Air in Reinforced and Unreinforced Polyamide PA66. Sustainability 2018, 10, 889. [CrossRef]

- Chen, D.; Li, J.; Yuan, Y.; Gao, C.; Cui, Y.; Li, S.; Liu, X.; Wang, H.; Peng, C.; Wu, Z. A Review of the Polymer for Cryogenic Application: Methods, Mechanisms and Perspectives. Polymers 2021, 13, 320. [CrossRef]

- Basmaci, G.; Yoruk, A.S.; Koklu, U.; Morkavuk, S. Impact of Cryogenic Condition and Drill Diameter on Drilling Performance of CFRP. Appl. Sci. 2017, 7, 667. [CrossRef]

- Xia, T.; Kaynak Y.; Arvin C.; Jawahir, I. Cryogenic cooling induced process performance and surface integrity in drilling CFRP composite material. Int. J. Adv. Manuf. Technol. 2016, 82(1-4), 605–616. [CrossRef]

- Angelone, R.; Caggiano, A.; Improta, I.; Nele, L.; Teti, R. Characterization of hole quality and temperature in drilling of Al/CFRP stacks under different process condition. Procedia CIRP 2019, 79, 319-324. [CrossRef]

- Domingo, R.; de Agustina, B.; Ayllón, J. Study of Drilled Holes after a Cryogenic Machining in Glass Fiber-Reinforced Composites. Appl. Sci. 2022, 12, 10275. [CrossRef]

- Taguchi, G.; Chowdhury, S.; Wu, Y. Taguchi’s Quality Engineering Handbook. John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2005.

- Montgomery, D.C.; Runger, G.C. Applied Statistics and Probability for Engineers. 7th edition. John Wiley & Sons, Inc.: Hoboken, NJ, USA: 2018.

- Vijayalakshmi Rao, R.; Manujesh, B.J.; Umashankar, K.S.; Sham Aan, M.P. Drillability Studies of E-Glass: Polyurethane Foam: Vinyl Ester Sandwich Composites. Trans. Indian Inst. Met. 2012, 65(1), 71–75. [CrossRef]

- Ferreira Batista, M.; Basso, I.; Toti, F.A.; Rodrigues, A.R.; Tarpani, J.R. Cryogenic drilling of carbon fibre reinforced thermoplastic and thermoset polymers. Compos. Struct. 2020, 251, 112625. [CrossRef]

- ISO 286-2. Geometrical product specifications (GPS) — ISO code system for tolerances on linear sizes — Part 2: Tables of standard tolerance classes and limit deviations for holes and shafts; International Organization for Standardization (ISO): Geneve, Switzerland, 2010.

- Giasin, K.; Ayvar-Soberanis, S.; Hodzic, A. The effects of minimum quantity lubrication and cryogenic liquid nitrogen cooling on drilled hole quality in GLARE fibre metal laminates. Mater. Design 2016, 89, 996–1006. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).