Submitted:

20 August 2024

Posted:

22 August 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Methodology

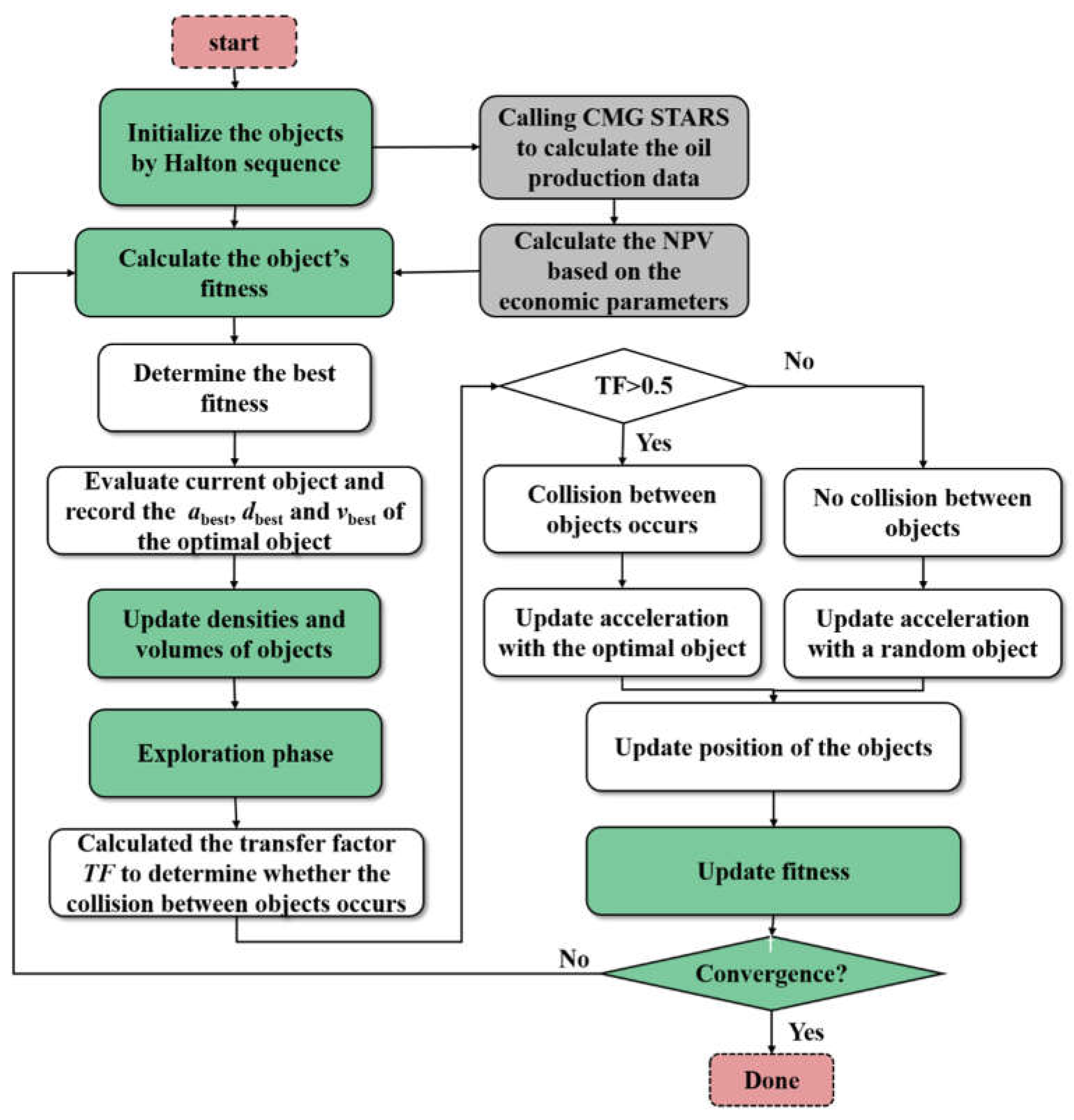

2.1. Improved AOA with Halton Sequence

2.2. Objective Function

| Parameters | Values |

|---|---|

| i | 1.05 |

| T (years) | 15 |

| Poil ($/m3) | 428 |

| costp ($/year) | 443 |

| costd (108$) | 0.04 |

2.3. Handling Infeasible Solutions

3. Applications and Results

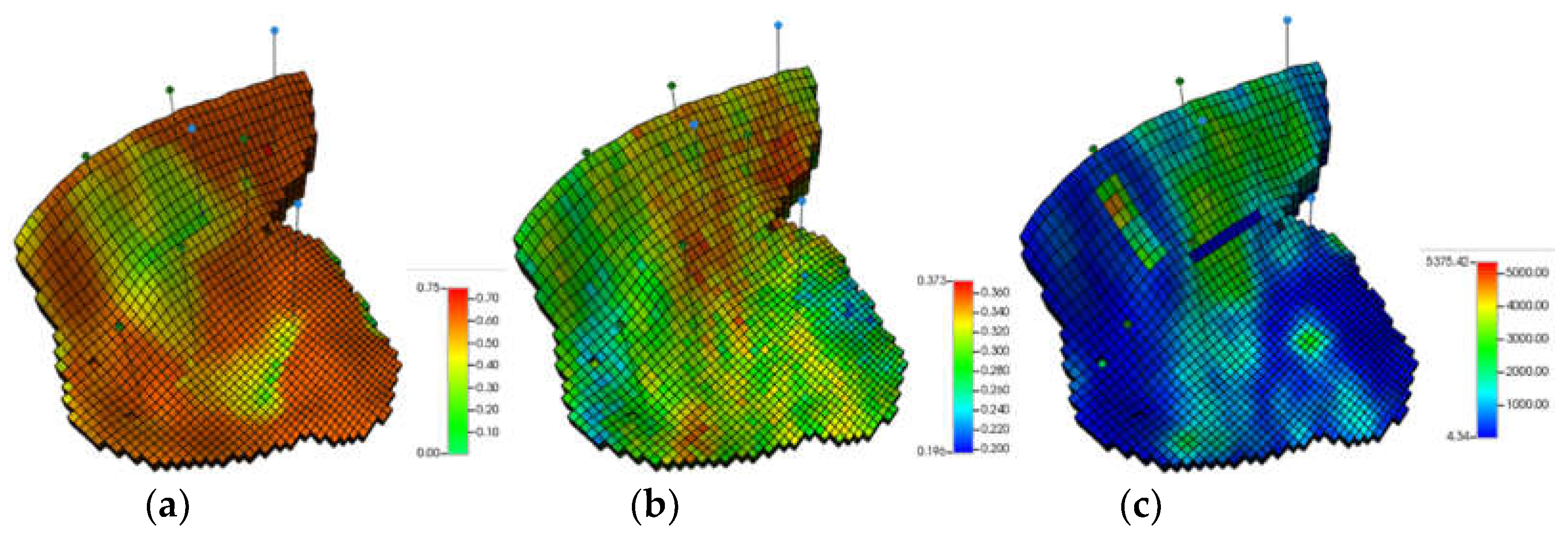

3.1. Reservoir Simulation Model

- (1)

- Polymer viscosification

- (2)

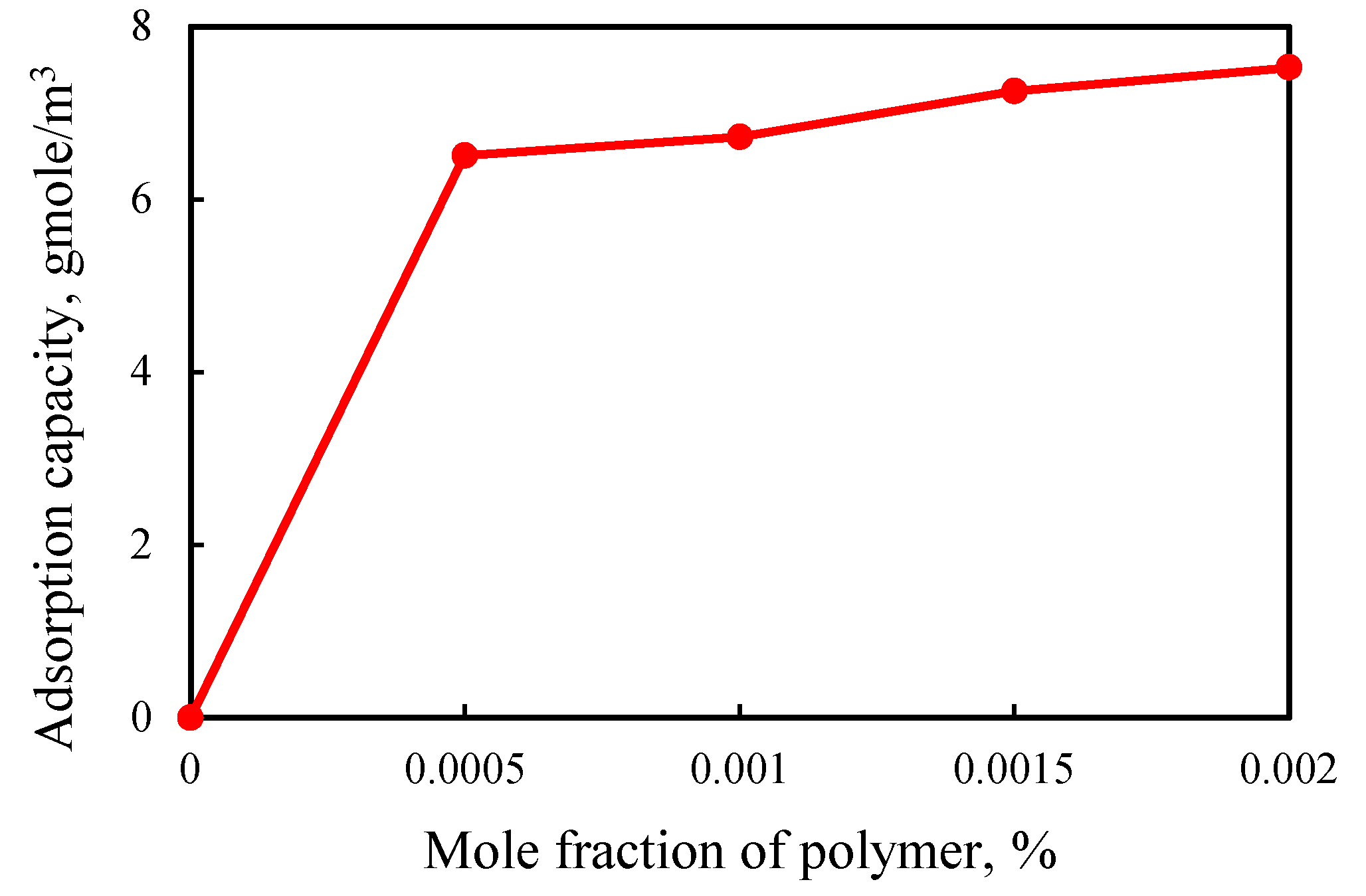

- Polymer adsorption

- (3)

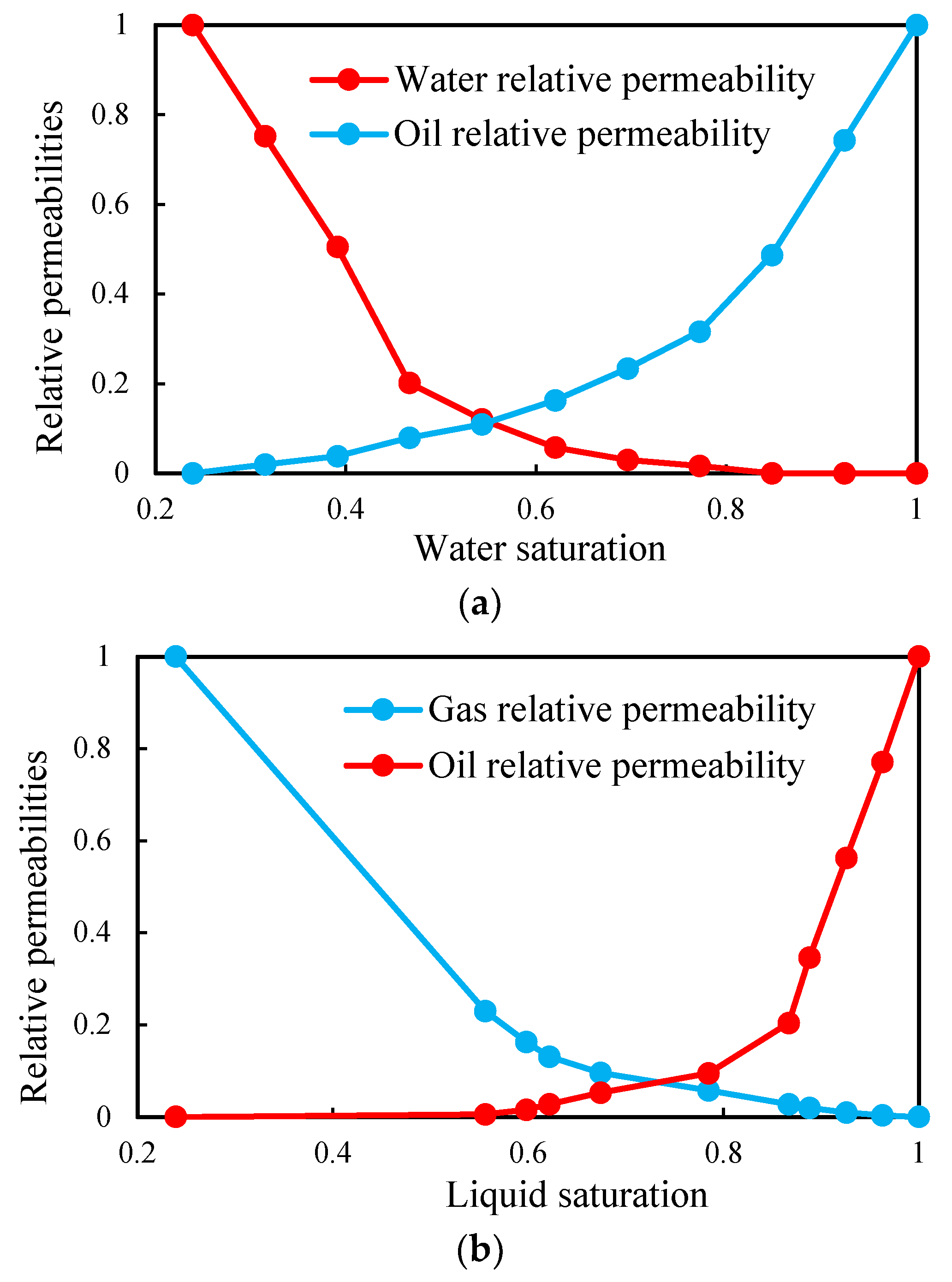

- Permeability reduction

- (4)

- Inaccessible pore volume (IPV)

- (5)

- Polymer degradation

| Reservoirparameters | Values |

| Reservoir middle depth (m) | 1195 |

| Average porosity (%) | 31 |

| Average permeability (mD) | 1083 |

| Average oil saturation (%) | 63 |

| Initial pressure (MPa) | 10.99 |

| Temperature (°C) | 58 |

| Fluid parameters | Values |

| Oil density (kg/m3) | 850 |

| Oil viscosity (mPa·s) | 2.1478 |

| Water density (kg/m3) | 900 |

| Water viscosity (mPa·s) | 1 |

| Polymer density (kg/m3) | 1000 |

| Polymer molecular weight (kg/mole) | 9.5 |

| T1/2 (day) | 750 |

| Rock and fluid interaction parameters | Values |

| Rock compressibility (1/kPa) | 10 e−4 |

| RRF | 1.25 |

| IPV | 0.25 |

| ADMAX (gmole/m3) | 7.53 |

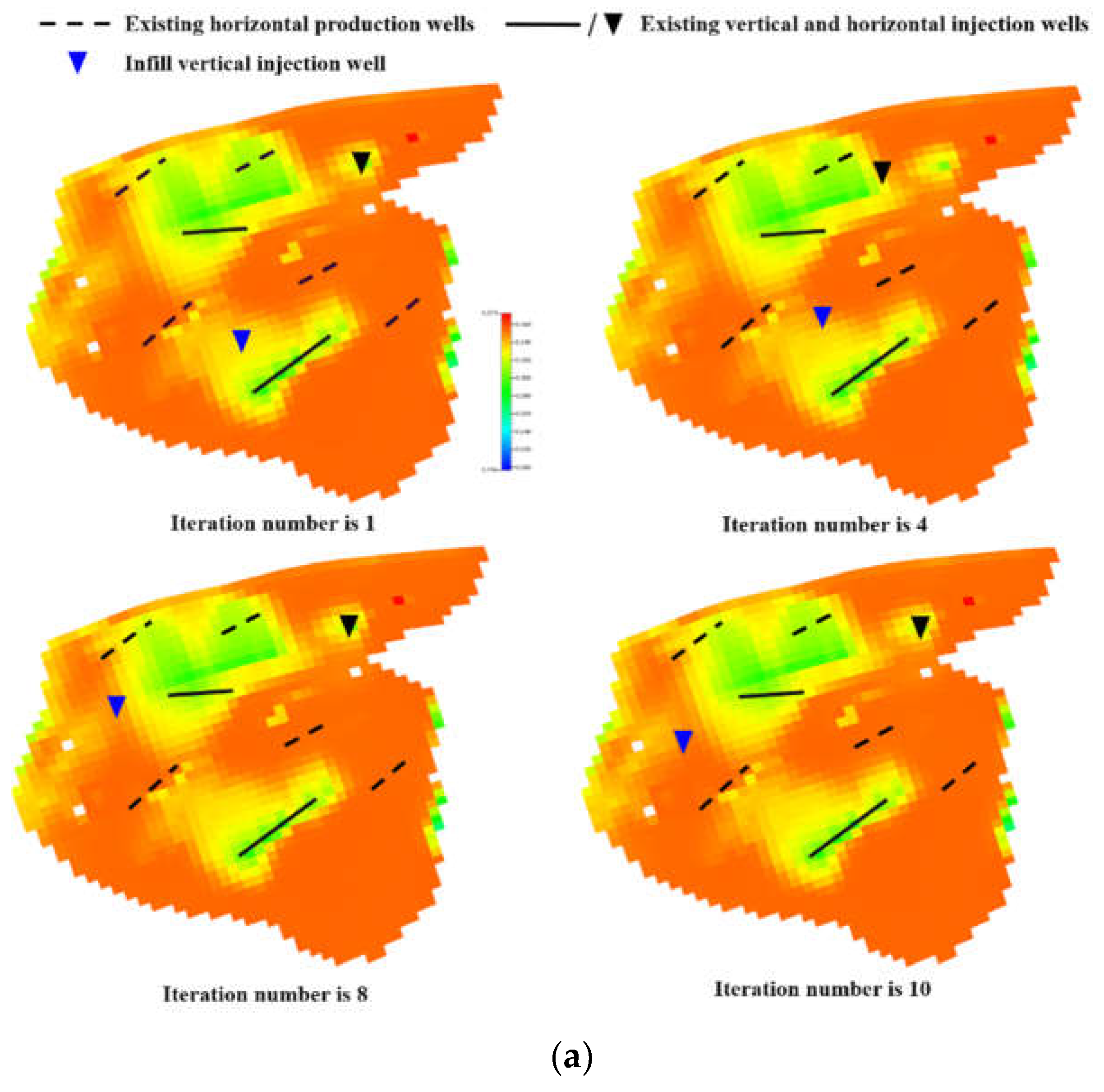

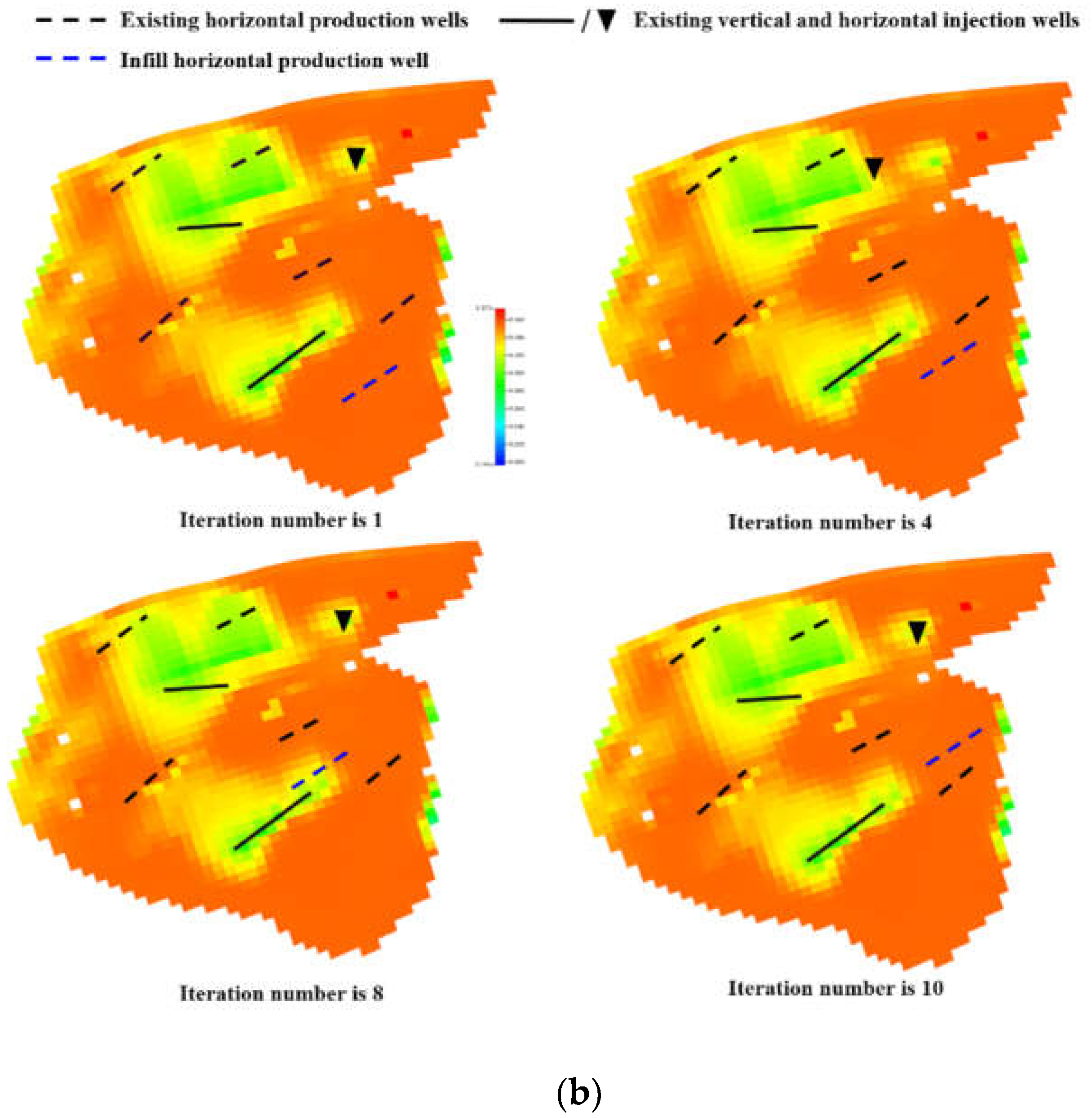

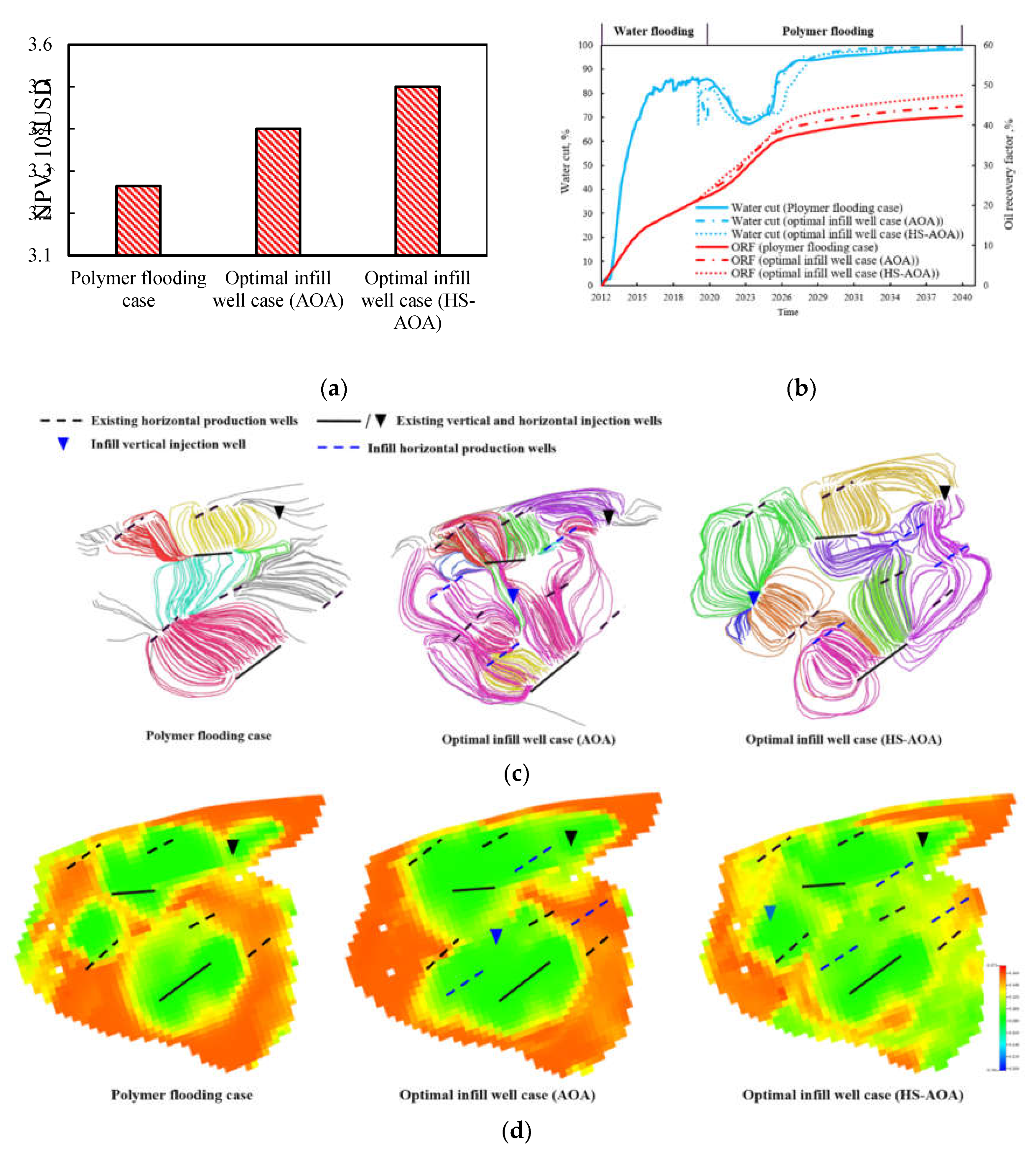

3.2. Results and Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pope, G.A. Recent developments and remaining challenges of enhanced oil recovery. J. Pet. Technol. 2011, 63, 65–68. [Google Scholar] [CrossRef]

- Sheng, J.J.; Leonhardt, B.; Azri, N. Status of polymer-flooding technology. J. Can. Pet. Technol. 2015, 54, 116–126. [Google Scholar] [CrossRef]

- Wang, D.; Cheng, J.; Xia, H.; Li, Q.; Shi, J.P. Viscous-elastic fluids can mobilize oil remaining after water-flood by force parallel to the Oil-Water interface. In Proceedings of the SPE Asia Pacific Improved Oil Recovery Conference, Kuala Lumpur, Malaysia, 8–9 October 2001. [Google Scholar]

- Wei, B.; Romero-Zerón, L.; Rodrigue, D. Oil displacement mechanisms of viscoelastic polymers in enhanced oil recovery (EOR): A review. J. Pet. Explor. Prod. Te. 2014, 4, 113–121. [Google Scholar] [CrossRef]

- Morel, D.C.; Vert, M.; Jouenne, S.; Gauchet, R.; Bouger, Y. First polymer injection in deep offshore field Angola: recent advances in the Dalia/Camelia field case. Oil Gas Facil. 2012, 1, 43–52. [Google Scholar] [CrossRef]

- Morel, D.; Jouenne, S.; Zaugg, E.; Bouger, Y. EOR polymer in deep offshore field Angola: development strategy and polymer performance surveillance. In Proceedings of the20th World Petroleum Congress, Doha, Qatar, 4 December 2011. [Google Scholar]

- Seright, R.S. How much polymer should be injected during a polymer flood? Review of previous and current practices. SPE J. 2017, 22, 1–18. [Google Scholar]

- Rathinasamy, M.; Chandramouli, S.; Phanindra, K.B.V.N. Estimation of reservoir storage using artificial neural network. In Proceedings of theWater Resources and Environmental Engineering, Springer, SG, 2 September 2018. [Google Scholar]

- Dovan, H.T.; Hutchins, R.D.; Terzian, G.A. Dos cuadras offshore polymer flood. In Proceedings of the SPE California Regional Meeting, Ventura, CA, USA, 4–6 April 1990. [Google Scholar]

- Pan, G.M.; Zhang, L.; Huang, J.; Li, H.; Qu, J.F. Twelve years field applications of offshore heavy oil polymer flooding from continuous injection to alternate injection of polymer-water. In Proceedings of the Offshore Technology Conference Asia, Kuala Lumpur, Malaysia, 2–6 November 2020. [Google Scholar]

- Wang, J.; Song, L.; Song, K.; Dong, C.; Tian, L.; Chen, G. A Study on the Water/Polymer Co-Flooding Seepage Law and Reasonable Polymer Injection Volume in Offshore Oilfields. Processes. 2020, 8, 515. [Google Scholar] [CrossRef]

- Wang, X.; Haynes, R.; Feng, Q. A multilevel coordinate search algorithm for well placement, control and joint optimization. Comput. Chem. Eng. 2016, 95, 75–96. [Google Scholar] [CrossRef]

- Yeten, B.; Durlofsky, L.J.; Aziz, K. Optimization of nonconventional well type. SPE J. 2008, 03, 200–210. [Google Scholar]

- Güyagüler, B.; Horne, R.N.; Rogers, L.; Rosenzweig, J.J. Optimization of well placement in a gulf of mexico waterflooding project. SPE Reserv. Eval. Eng. 2002, 05, 229–236. [Google Scholar] [CrossRef]

- Bouzarefrkounas, Z.; Didier, Y.D.; Auger, A. Well placement optimization with the covariance matrix adaptation evolution strategy and meta-models. Comput. Geosci. 2012, 16, 75–92. [Google Scholar] [CrossRef]

- Carosio, G.L.C.; Humphries, T.D.; Haynes, R.D.; Farquharson, C.G. A closer look at differential evolution for the optimal well placement problem. In Proceedings of the 2015 Annual Conference on Genetic and Evolutionary Computation, New York, USA, 11-15 July 2015. [Google Scholar]

- Yu, W.; Sepehrnoori, K. An efficient reservoir-simulation approach to design and optimize unconventional gas production. J. Can. Pet. Technol. 2014, 53, 109–121. [Google Scholar] [CrossRef]

- Singh, H.; Srinivasan, S. Uncertainty analysis by model selection technique and its application in economic valuation of a large field. In Proceedings of theNorth Africa Technical Conference and Exhibition, Cairo, EGY, 15 April 2013. [Google Scholar]

- Singh, H.; Srinivasan, S. Scale up of reactive processes in heterogeneous media-numerical experiments and semi-analytical modeling. In Proceedings of the Improved Oil Recovery Conference, Oklahoma, USA, 12 April 2014. [Google Scholar]

- Atashnezhad, A.; Wood, D.A.; Fereidounpour, A.; Khosravanian, R. Designing and optimizing deviated wellbore trajectories using novel particle swarm algorithms. J. Nat. Gas. Sci. Eng. 2014, 21, 1184–1204. [Google Scholar] [CrossRef]

- Humphries, T.D.; Haynes, R.D. Joint optimization of well placement and control for nonconventional well types. J. Pet. Sci. Eng. 2015, 12, 242–253. [Google Scholar] [CrossRef]

- Emerick, A.; Almeida, L.; Szwarcman, D.; Pacheco, M.A.; Vellasco, M. Well placement optimization using a genetic algorithm with nonlinear constraints. In Proceedings of the Reservoir Simulation Conference, Texas, USA, 2 February 2009. [Google Scholar]

- Montes, G.; Bartolome, P.; Udias, A.L. The use of genetic algorithms in well placement optimization. In Proceedings of the SPE Latin American and Caribbean Petroleum Engineering Conference, Buenos Aires, ARG, 25 March 2001. [Google Scholar]

- Awotunde, A.A. On the joint optimization of well placement and control. In Proceedings of theSPE Saudi Arabia section technical symposium and exhibition, Al-Khobar, SAU, 21 April 2014. [Google Scholar]

- Onwunalu, J.; Durlofsky, L. Application of a particle swarm optimization algorithm for determining optimum well location and type. Comput. Geosci. 2010, 14, 183–198. [Google Scholar] [CrossRef]

- Dossary, M.A.A.; Nasrabadi, H. Well placement optimization using imperialist competitive algorithm. J. Pet. Sci. Eng. 2016, 147, 237–248. [Google Scholar] [CrossRef]

- Hamida, Z.; Azizi, F.; Saad, G. An efficient geometry-based optimization approach for well placement in oil fields. J. Petrol. Sci. Eng. 2017, 149, 383–392. [Google Scholar] [CrossRef]

- Khoshneshin, R.; Sadeghnejad, S. Integrated well placement and completion optimization using heuristic algorithms: A case study of an Iranian carbonate formation. J. Chem. Pet. Eng. 2018, 52, 35–47. [Google Scholar]

- Janiga, D.; Czarnota, R.; Stopa, J.; Wojnarowski, P. Self-adapt reservoir clusterization method to enhance robustness of well placement optimization. J. Pet. Sci. Eng. 2019, 173, 37–52. [Google Scholar] [CrossRef]

- Hashim, F.A.; Hussain, K.; Houssein, E.H.; Mabrouk, M.S.; Al-Atabany, W. Archimedes optimization algorithm: a new metaheuristic algorithm for solving optimization problems. Appl. Intell. 2021, 51, 1531–1551. [Google Scholar] [CrossRef]

- Abualigah, L.; Diabat, A.; Mirjalili, S.; Abd Elaziz, M.; Gandomi, A.H. The arithmetic optimization algorithm. comput. methods, Appl Mech Eng, 2021, 376, 113609. [Google Scholar] [CrossRef]

- Khan, R.A.; Farooqui, S.A.; Sarwar, M.I.; Ahmad, S.; Tariq, M.; Sarwar, A.; Zaid, M.; Ahmad, S.; Shah Noor Mohamed, A. Archimedes optimization algorithm based selective harmonic elimination in a cascaded h-bridge multilevel inverter. Sustainability. 2021, 14, 310. [Google Scholar] [CrossRef]

- Bouzarkouna, Z.; Ding, D.; Auger, A. Well placement optimization with the covariance matrix adaptation evolution strategy and meta-models. Comput. Geosci. 2012, 16, 75–92. [Google Scholar] [CrossRef]

- Jesmani, M.; Bellout, M.C.; Hanea, R. Foss, B. Well placement optimization subject to realistic field development constraints. Comput. Geosci. 2016, 20, 1185–1209. [Google Scholar] [CrossRef]

- Michalewicz, Z. A survey of constraint handling techniques in evolutionary computation methods. Evol. Program. 1995, 4, 135–155. [Google Scholar]

- Zhang, P.; Tan, X.; Yang, R.; Yang, R.F.; Zheng, W.; Zhang, X.L.; Xie, H.J.; Sun, X.F. Numerical simulations of nitrogen foam and gel-assisted steam flooding for offshore heavy oil reservoirs. J. Porous Media. 2023, 26, 17–32. [Google Scholar] [CrossRef]

- Gao, S.L.; Chen, Y.; Wang, X.; Li, S.Q.; Yan, S.G.; Hou, B.F. Research on dynamic performance of anti-polymer adsorbent in Henan oilfield. Dangdai Huagong 2021, 50, 2170–2175. (In Chinese) [Google Scholar]

- Al-Shalabi, E.W.; Alameri, W.; Hassan, A.M. Mechanistic modeling of hybrid low salinity polymer flooding: Role of geochemistry. J. Pet. Sci. Eng. 2022, 210, 110013. [Google Scholar] [CrossRef]

- Tellez Arellano, A.G.; Hassan, A.M.; Al-Shalabi, E.W.; AlAmeri, W.; Kamal, M.S.; Patil, S. An extensive evaluation of different reservoir simulators used for polymer flooding modeling. In Proceedings of the Gas & Oil Technology Showcase and Conference, Dubai, UAE, 13 March 2023. [Google Scholar]

| Parameters | Values |

|---|---|

| N | 10 |

| tmax | 10 |

| C1 | 2 |

| C2 and C3 | 3 |

| C4 | 5 |

| Well name | Well type | Perforation | i | j | z | |

|---|---|---|---|---|---|---|

| Form (m) |

To (m) |

|||||

| Infill injection well 1 | Vertical | 1181 | 1191 | 20 | 33 | 1 |

| 20 | 33 | 2 | ||||

| 20 | 33 | 3 | ||||

| Horizontal | 1189 | 1196 | 37 | 33 | 1 | |

| 38 | 34 | 1 | ||||

| Infill production well 1 | 39 | 35 | 1 | |||

| 40 | 36 | 2 | ||||

| 41 | 37 | 2 | ||||

| Horizontal | 1209 | 1212 | 43 | 28 | 2 | |

| 44 | 29 | 1 | ||||

| Infill production well 2 | 45 | 30 | 2 | |||

| 46 | 31 | 2 | ||||

| 47 | 32 | 2 | ||||

| Horizontal | 1193 | 1195 | 27 | 28 | 1 | |

| 28 | 29 | 1 | ||||

| Infill production well 3 | 29 | 30 | 1 | |||

| 30 | 31 | 2 | ||||

| 31 | 32 | 2 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).