Submitted:

21 August 2024

Posted:

24 August 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

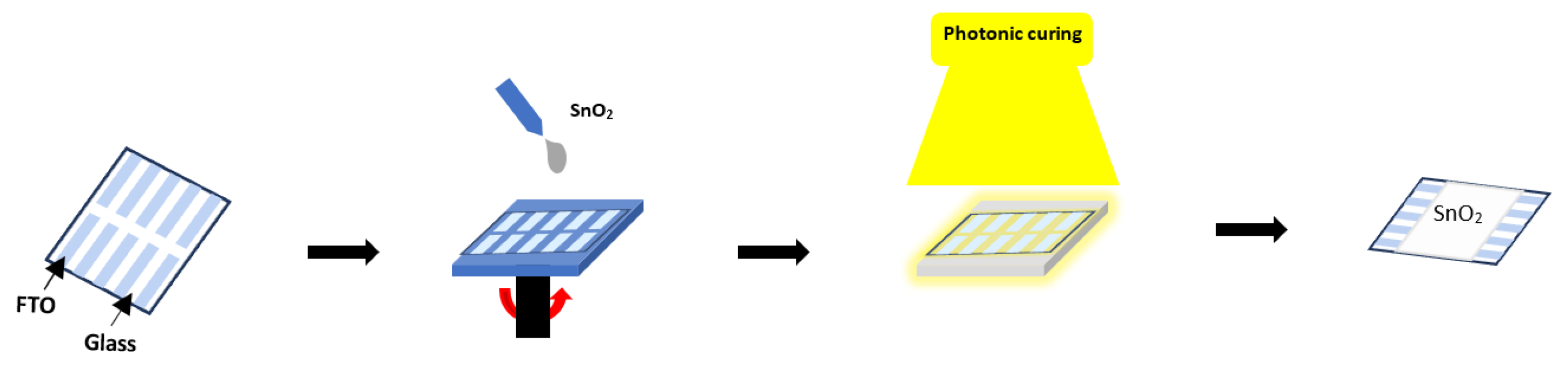

2. Experimental Section

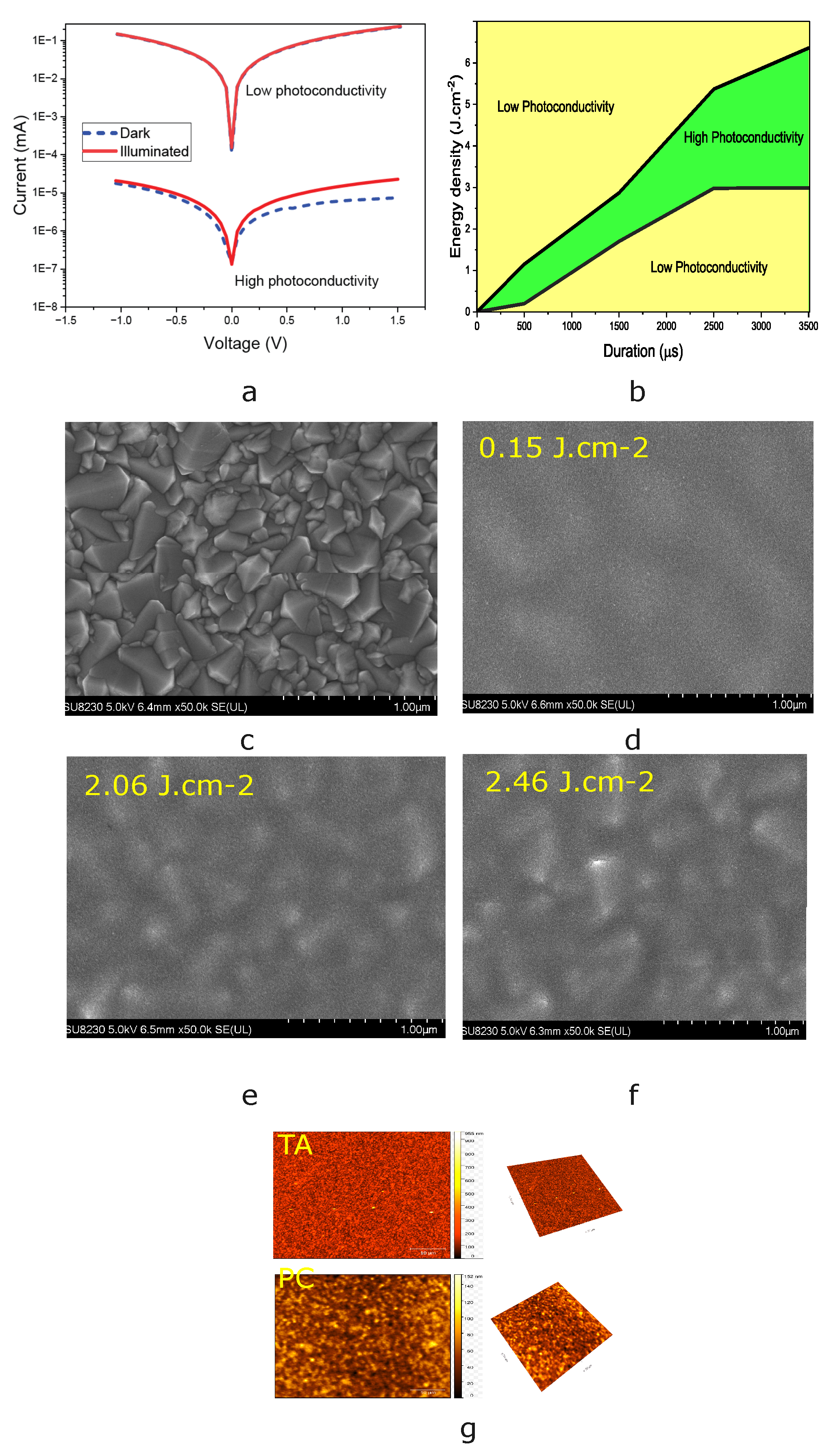

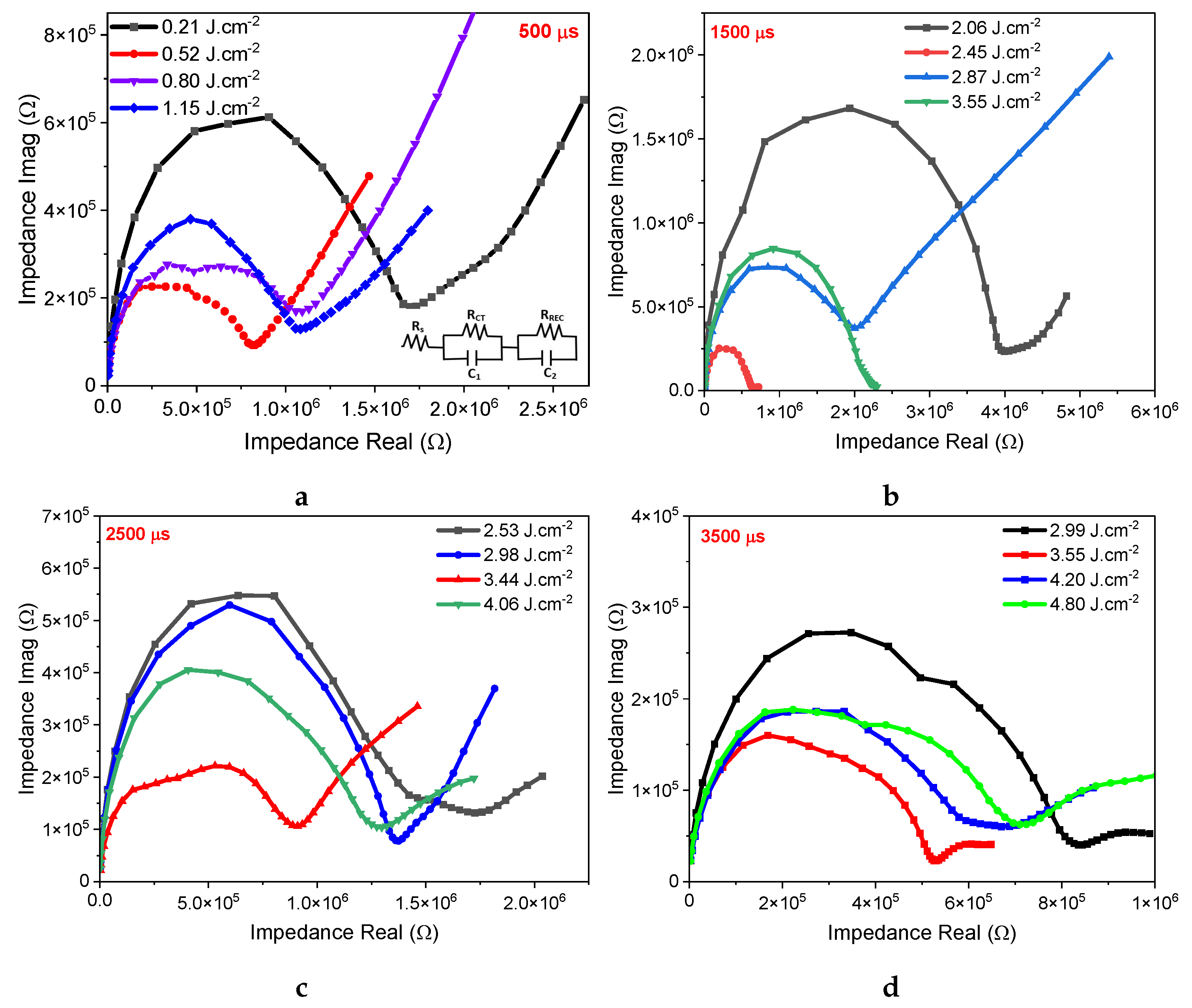

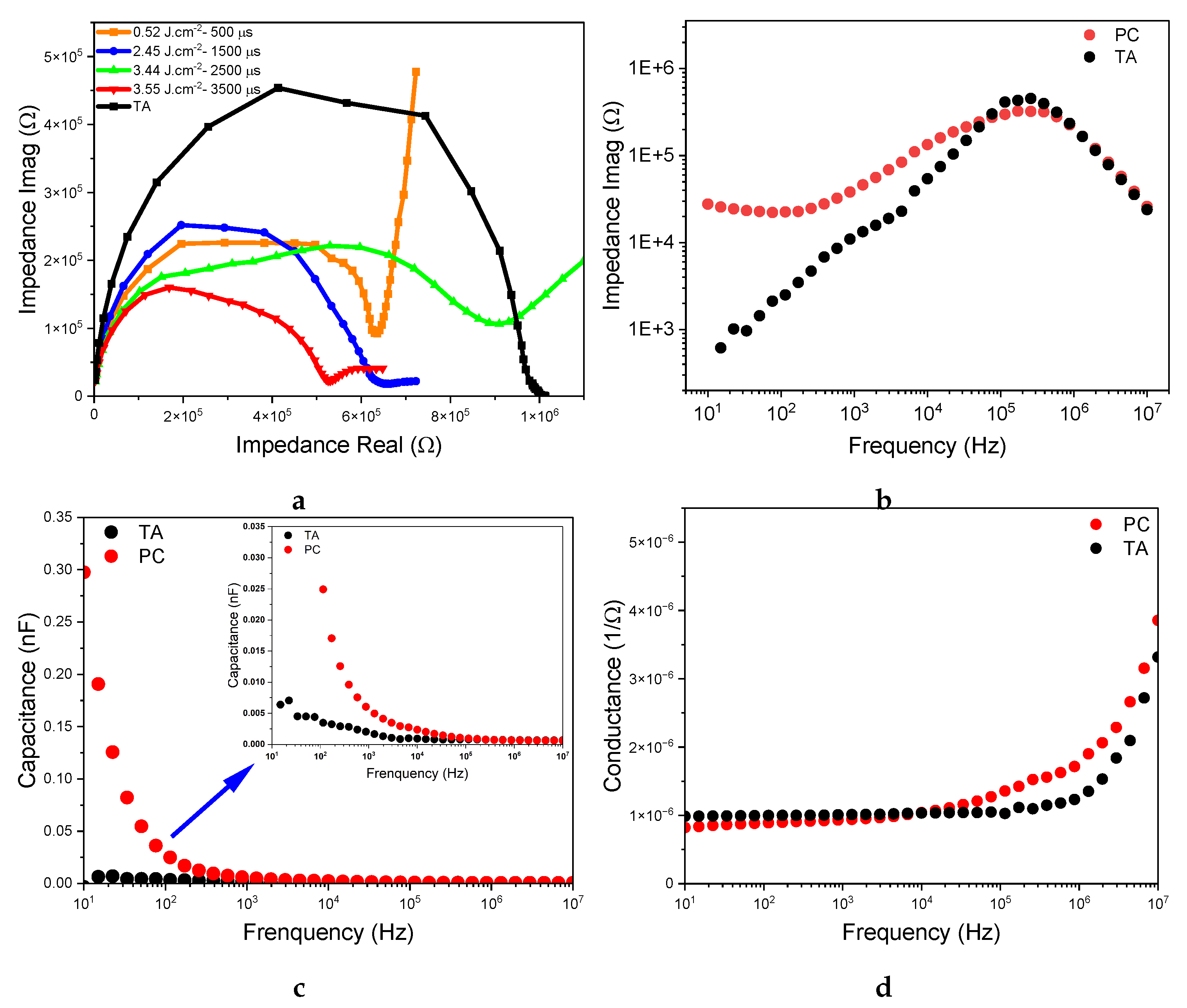

3. Results and Discussion

4. Conclusion

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| ETL | Electron-transporting layer |

| PSC | perovskite solar cell |

| TA | Thermal annealing |

| PC | Potonic curing |

References

- Yang, Y.; Maeng, B.; Jung, D.G.; Lee, J.; Kim, Y.; Kwon, J.; An, H.K.; Jung, D. Annealing effects on SnO2 thin film for H2 gas sensing. Nanomaterials 2022, 12, 3227. [Google Scholar] [CrossRef] [PubMed]

- Wei, Z.; Zhao, Y.; Jiang, J.; Yan, W.; Feng, Y.; Ma, J. Research progress on hybrid organic–inorganic perovskites for photo-applications. Chinese Chemical Letters 2020, 31, 3055–3064. [Google Scholar] [CrossRef]

- Jing, H.; Zhu, Y.; Peng, R.W.; Li, C.Y.; Xiong, B.; Wang, Z.; Liu, Y.; Wang, M. Hybrid organic-inorganic perovskite metamaterial for light trapping and photon-to-electron conversion. Nanophotonics 2020, 9, 3323–3333. [Google Scholar] [CrossRef]

- Yang, Z.; Lai, J.; Zhu, R.; Tan, J.; Luo, Y.; Ye, S. Electronic Disorder Dominates the Charge-Carrier Dynamics in Two-Dimensional/Three-Dimensional Organic–Inorganic Perovskite Heterostructure. The Journal of Physical Chemistry C 2022, 126, 12689–12695. [Google Scholar] [CrossRef]

- Jiang, Q.; Chu, Z.; Wang, P.; Yang, X.; Liu, H.; Wang, Y.; Yin, Z.; Wu, J.; Zhang, X.; You, J. Planar-structure perovskite solar cells with efficiency beyond 21%. Advanced materials 2017, 29, 1703852. [Google Scholar] [CrossRef]

- Liu, C.; Hu, M.; Zhou, X.; Wu, J.; Zhang, L.; Kong, W.; Li, X.; Zhao, X.; Dai, S.; Xu, B. Efficiency and stability enhancement of perovskite solar cells by introducing CsPbI3 quantum dots as an interface engineering layer. NPG Asia materials 2018, 10, 552–561. [Google Scholar] [CrossRef]

- Schroder, K.A. Mechanisms of photonic curing™: Processing high temperature films on low temperature substrates. Nanotechnology 2011, 2, 220–223. [Google Scholar]

- Akhavan, V.; Schroder, K.; Farnsworth, S. Photonic Curing. Inkjet Printing in Industry: Materials, Technologies, Systems, and Applications 2022, 2, 1051–1064. [Google Scholar]

- Secor, E.B.; Ahn, B.Y.; Gao, T.Z.; Lewis, J.A.; Hersam, M.C. Rapid and versatile photonic annealing of graphene inks for flexible printed electronics. Advanced Materials 2015, 27, 6683–6688. [Google Scholar] [CrossRef]

- Zhu, M.; Liu, W.; Ke, W.; Clark, S.; Secor, E.B.; Song, T.B.; Kanatzidis, M.G.; Li, X.; Hersam, M.C. Millisecond-pulsed photonically-annealed tin oxide electron transport layers for efficient perovskite solar cells. Journal of Materials Chemistry A 2017, 5, 24110–24115. [Google Scholar] [CrossRef]

- Altay, B.N.; Turkani, V.S.; Pekarovicova, A.; Fleming, P.D.; Atashbar, M.Z.; Bolduc, M.; Cloutier, S.G. One-step photonic curing of screen-printed conductive Ni flake electrodes for use in flexible electronics. Scientific Reports 2021, 11, 3393. [Google Scholar] [CrossRef] [PubMed]

- Piper, R.T.; Daunis, T.B.; Xu, W.; Schroder, K.A.; Hsu, J.W. Photonic curing of nickel oxide transport layer and perovskite active layer for flexible perovskite solar cells: a path towards high-throughput manufacturing. Frontiers in Energy Research 2021, 9, 640960. [Google Scholar] [CrossRef]

- Maskey, B.B.; Koirala, G.R.; Kim, Y.; Park, H.; Yadav, P.; Park, J.; Sun, J.; Cho, G. Photonic curing for enhancing the performance of roll-to-roll printed electronic devices 2019. Type: Journal Article.

- Dong, Q.; Shi, Y.; Wang, K.; Li, Y.; Wang, S.; Zhang, H.; Xing, Y.; Du, Y.; Bai, X.; Ma, T. Insight into perovskite solar cells based on SnO2 compact electron-selective layer. The Journal of Physical Chemistry C 2015, 119, 10212–10217. [Google Scholar] [CrossRef]

- Matacena, I.; Guerriero, P.; Lancellotti, L.; Alfano, B.; De Maria, A.; La Ferrara, V.; Mercaldo, L.V.; Miglietta, M.L.; Polichetti, T.; Rametta, G. Impedance spectroscopy analysis of perovskite solar cell stability. Energies 2023, 16, 4951. [Google Scholar] [CrossRef]

- Hu, M.; Zhang, L.; She, S.; Wu, J.; Zhou, X.; Li, X.; Wang, D.; Miao, J.; Mi, G.; Chen, H. Electron transporting bilayer of SnO2 and TiO2 nanocolloid enables highly efficient planar perovskite solar cells. Solar RRL 2020, 4, 1900331. [Google Scholar] [CrossRef]

- Irfan, M.; Ünlü, F.; Lê, K.; Fischer, T.; Ullah, H.; Mathur, S. Electrospun Networks of ZnO-SnO2 Composite Nanowires as Electron Transport Materials for Perovskite Solar Cells. Journal of Nanomaterials 2022, 2022, 1–13. [Google Scholar] [CrossRef]

- Martínez-Denegri, G.; Colodrero, S.; Kramarenko, M.; Martorell, J. All-nanoparticle SnO2/TiO2 electron-transporting layers processed at low temperature for efficient thin-film perovskite solar cells. ACS Applied Energy Materials 2018, 1, 5548–5556. [Google Scholar] [CrossRef]

- Magar, H.S.; Hassan, R.Y.; Mulchandani, A. Electrochemical impedance spectroscopy (EIS): Principles, construction, and biosensing applications. Sensors 2021, 21, 6578. [Google Scholar] [CrossRef]

- Pascoe, A.R.; Duffy, N.W.; Scully, A.D.; Huang, F.; Cheng, Y.B. Insights into planar CH3NH3PbI3 perovskite solar cells using impedance spectroscopy. The Journal of Physical Chemistry C 2015, 119, 4444–4453. [Google Scholar] [CrossRef]

- Sinclair, D.C. Characterisation of electro-materials using ac impedance spectroscopy. Boletín de la Sociedad Española de Cerámica y Vidrio 1995, 34, 55–65. [Google Scholar]

- Middlemiss, L.A.; Rennie, A.J.; Sayers, R.; West, A.R. Characterisation of batteries by electrochemical impedance spectroscopy. Energy Reports 2020, 6, 232–241. [Google Scholar] [CrossRef]

- Shohan, S.; Harm, J.; Hasan, M.; Starly, B.; Shirwaiker, R. Non-destructive quality monitoring of 3D printed tissue scaffolds via dielectric impedance spectroscopy and supervised machine learning. Procedia Manufacturing 2021, 53, 636–643. [Google Scholar] [CrossRef]

- Cherian, C.T.; Zheng, M.; Reddy, M.; Chowdari, B.; Sow, C.H. Zn2SnO4 nanowires versus nanoplates: electrochemical performance and morphological evolution during Li-cycling. ACS applied materials & interfaces 2013, 5, 6054–6060. [Google Scholar]

- Piper, R.T.; Xu, W.; Hsu, J.W. How Optical and Electrical Properties of ITO Coated Willow Glass Affect Photonic Curing Outcome for Upscaling Perovskite Solar Cell Manufacturing. IEEE Journal of Photovoltaics 2022, 12, 722–727. [Google Scholar] [CrossRef]

- Albrecht, A.; Rivadeneyra, A.; Abdellah, A.; Lugli, P.; Salmerón, J.F. Inkjet printing and photonic sintering of silver and copper oxide nanoparticles for ultra-low-cost conductive patterns. Journal of Materials Chemistry C 2016, 4, 3546–3554. [Google Scholar] [CrossRef]

- Pan, D.; Fan, H.; Li, Z.; Wang, S.; Huang, Y.; Jiao, Y.; Yao, H. Influence of substrate on structural properties and photocatalytic activity of TiO2 films. Micro & Nano Letters 2017, 12, 82–86. [Google Scholar] [CrossRef]

- Hamdi, M.; Saleh, M.N.; Poulis, J.A. Improving the adhesion strength of polymers: effect of surface treatments. Journal of Adhesion Science and Technology.

- Bandara, T.; Aththanayake, A.; Kumara, G.; Samarasekara, P.; DeSilva, L.A.; Tennakone, K. Transparent and conductive F-Doped SnO 2 nanostructured thin films by sequential nebulizer spray pyrolysis. MRS Advances 2021, 6, 417–421. [Google Scholar] [CrossRef]

- Ghahremani, A.H.; Martin, B.; Gupta, A.; Bahadur, J.; Ankireddy, K.; Druffel, T. Rapid fabrication of perovskite solar cells through intense pulse light annealing of SnO2 and triple cation perovskite thin films. Materials & Design 2020, 185, 108237. [Google Scholar]

- Mukhamedshina, D.M.; Beisenkhanov, N.B. Influence of crystallization on the properties of SnO2 thin films. In Advances in Crystallization Processes; IntechOpen, 2012. Type: Book Section.

- Zhu, Z.; Bai, Y.; Liu, X.; Chueh, C.; Yang, S.; Jen, A.K. Enhanced efficiency and stability of inverted perovskite solar cells using highly crystalline SnO2 nanocrystals as the robust electron-transporting layer. Advanced Materials 2016, 28, 6478–6484. [Google Scholar] [CrossRef]

- Salado, M.; Contreras-Bernal, L.; Caliò, L.; Todinova, A.; López-Santos, C.; Ahmad, S.; Borras, A.; Idígoras, J.; Anta, J.A. Impact of moisture on efficiency-determining electronic processes in perovskite solar cells. Journal of Materials Chemistry A 2017, 5, 10917–10927. [Google Scholar] [CrossRef]

- Li, N.; Yan, J.; Ai, Y.; Jiang, E.; Lin, L.; Shou, C.; Yan, B.; Sheng, J.; Ye, J. A low-temperature TiO2/SnO2 electron transport layer for high-performance planar perovskite solar cells. Sci. China Mater 2020, 63, 207–215. [Google Scholar] [CrossRef]

- Shibuya, H.; Inoue, S.; Ihara, M. Evaluation of dye-sensitized solar cells using forward bias applied impedance spectroscopy under dark. ECS Transactions 2009, 16, 93. [Google Scholar] [CrossRef]

- Abdulrahim, S.M.; Ahmad, Z.; Bahadra, J.; Al-Thani, N.J. Electrochemical impedance spectroscopy analysis of hole transporting material free mesoporous and planar perovskite solar cells. Nanomaterials 2020, 10, 1635. [Google Scholar] [CrossRef] [PubMed]

- Bredar, A.R.; Chown, A.L.; Burton, A.R.; Farnum, B.H. Electrochemical impedance spectroscopy of metal oxide electrodes for energy applications. ACS Applied Energy Materials 2020, 3, 66–98. [Google Scholar] [CrossRef]

- Chang, B.Y.; Park, S.M. Integrated description of electrode/electrolyte interfaces based on equivalent circuits and its verification using impedance measurements. Analytical chemistry 2006, 78, 1052–1060. [Google Scholar] [CrossRef]

- Matacena, I. Equivalent circuit extraction procedure from Nyquist plots for graphene-silicon solar cells. 2019 15th Conference on Ph.D Research in Microelectronics and Electronics (PRIME), 2019, pp. 273–276. [CrossRef]

- Prochowicz, D.; Trivedi, S.; Parikh, N.; Saliba, M.; Kalam, A.; Mahdi Tavakoli, M.; Yadav, P. In the Quest of Low-Frequency Impedance Spectra of Efficient Perovskite Solar Cells. Energy Technology 2021, 9, 2100229. [Google Scholar] [CrossRef]

- Alvarez, A.O.; Arcas, R.; Aranda, C.A.; Bethencourt, L.; Mas-Marzá, E.; Saliba, M.; Fabregat-Santiago, F. Negative capacitance and inverted hysteresis: matching features in perovskite solar cells. The journal of physical chemistry letters 2020, 11, 8417–8423. [Google Scholar] [CrossRef]

- Laschuk, N.O.; Easton, E.B.; Zenkina, O.V. Reducing the resistance for the use of electrochemical impedance spectroscopy analysis in materials chemistry. RSC advances 2021, 11, 27925–27936. [Google Scholar] [CrossRef]

- Hernández, H.H.; Reynoso, A.R.; González, J.T.; Morán, C.G.; Hernández, J.M.; Ruiz, A.M.; Hernández, J.M.; Cruz, R.O. Electrochemical impedance spectroscopy (EIS): A review study of basic aspects of the corrosion mechanism applied to steels. Electrochemical Impedance Spectroscopy 2020, pp. 137–144. Type: Journal Article.

- Guerrero, A.; Garcia-Belmonte, G.; Mora-Sero, I.; Bisquert, J.; Kang, Y.S.; Jacobsson, T.J.; Correa-Baena, J.P.; Hagfeldt, A. Properties of contact and bulk impedances in hybrid lead halide perovskite solar cells including inductive loop elements. The Journal of Physical Chemistry C 2016, 120, 8023–8032. [Google Scholar] [CrossRef]

- Almora, O.; Zarazua, I.; Mas-Marza, E.; Mora-Sero, I.; Bisquert, J.; Garcia-Belmonte, G. Capacitive dark currents, hysteresis, and electrode polarization in lead halide perovskite solar cells. The journal of physical chemistry letters 2015, 6, 1645–1652. [Google Scholar] [CrossRef]

- Mahapatra, A.; Parikh, N.; Kumar, P.; Kumar, M.; Prochowicz, D.; Kalam, A.; Tavakoli, M.M.; Yadav, P. Changes in the electrical characteristics of perovskite solar cells with aging time. Molecules 2020, 25, 2299. [Google Scholar] [CrossRef] [PubMed]

- Todinova, A.; Contreras-Bernal, L.; Salado, M.; Ahmad, S.; Morillo, N.; Idígoras, J.; Anta, J.A. Towards a universal approach for the analysis of impedance spectra of perovskite solar cells: equivalent circuits and empirical analysis. ChemElectroChem 2017, 4, 2891–2901. [Google Scholar] [CrossRef]

- Zarazua, I.; Han, G.; Boix, P.P.; Mhaisalkar, S.; Fabregat-Santiago, F.; Mora-Seró, I.; Bisquert, J.; Garcia-Belmonte, G. Surface recombination and collection efficiency in perovskite solar cells from impedance analysis. The journal of physical chemistry letters 2016, 7, 5105–5113. [Google Scholar] [CrossRef] [PubMed]

- Zarazua, I.; Bisquert, J.; Garcia-Belmonte, G. Light-induced space-charge accumulation zone as photovoltaic mechanism in perovskite solar cells. The journal of physical chemistry letters 2016, 7, 525–528. [Google Scholar] [CrossRef] [PubMed]

- Li, J.V.; Ferrari, G. Capacitance spectroscopy of semiconductors; CRC Press, 2018. Type: Book.

- Heeger, A.J.; MacDiarmid, A.G.; Shirakawa, H. The Nobel Prize in chemistry, 2000: conductive polymers. Stockholm, Sweden: Royal Swedish Academy of Sciences 2000, pp. 1–16. Type: Journal Article.

- Namsheer, K.; Rout, C.S. Conducting polymers: a comprehensive review on recent advances in synthesis, properties and applications. RSC advances 2021, 11, 5659–5697. [Google Scholar]

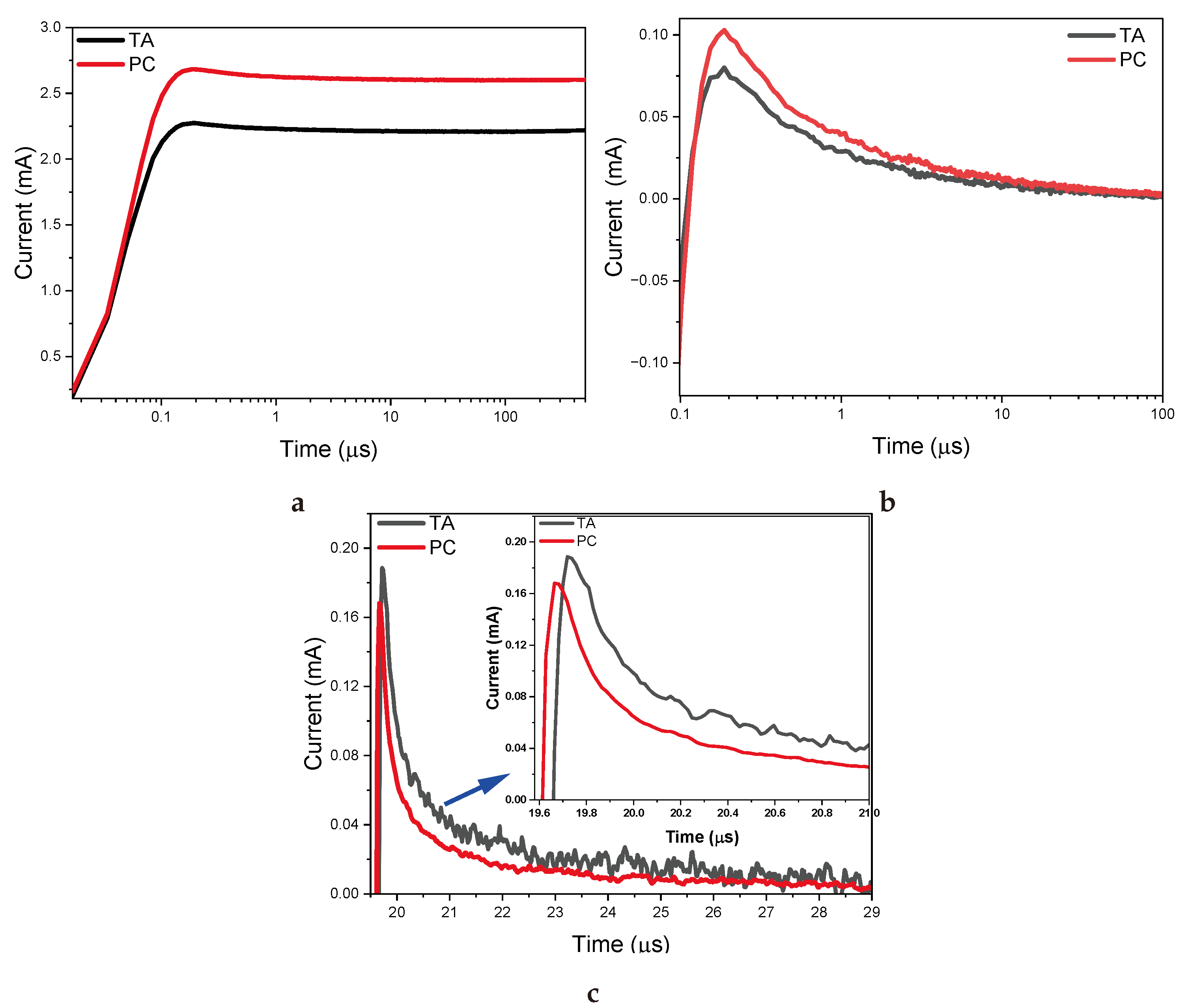

- Esward, T.; Knox, S.; Jones, H.; Brewer, P.; Murphy, C.; Wright, L.; Williams, J. A metrology perspective on the dark injection transient current method for charge mobility determination in organic semiconductors. Journal of Applied Physics 2011, 109. [Google Scholar] [CrossRef]

- Sarda, N.; Vidhan, A.; Basak, S.; Hazra, P.; Behera, T.; Ghosh, S.; Choudhary, R.J.; Chowdhury, A.; Sarkar, S.K. Photonically Cured Solution-Processed SnO2 Thin Films for High-Efficiency and Stable Perovskite Solar Cells and Minimodules. ACS Applied Energy Materials 2023, 6, 3996–4006. [Google Scholar] [CrossRef]

- Knapp, E.; Ruhstaller, B. The role of shallow traps in dynamic characterization of organic semiconductor devices. Journal of Applied Physics 2012, 112. [Google Scholar] [CrossRef]

| Device | Rs () | () | Ceq () | () |

|---|---|---|---|---|

| Thermally-annealed | 1.96 | 0.99 | 0.88 | 0.87 |

| Photonically-treated | 3.06 | 0.49 | 0.78 | 0.38 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).