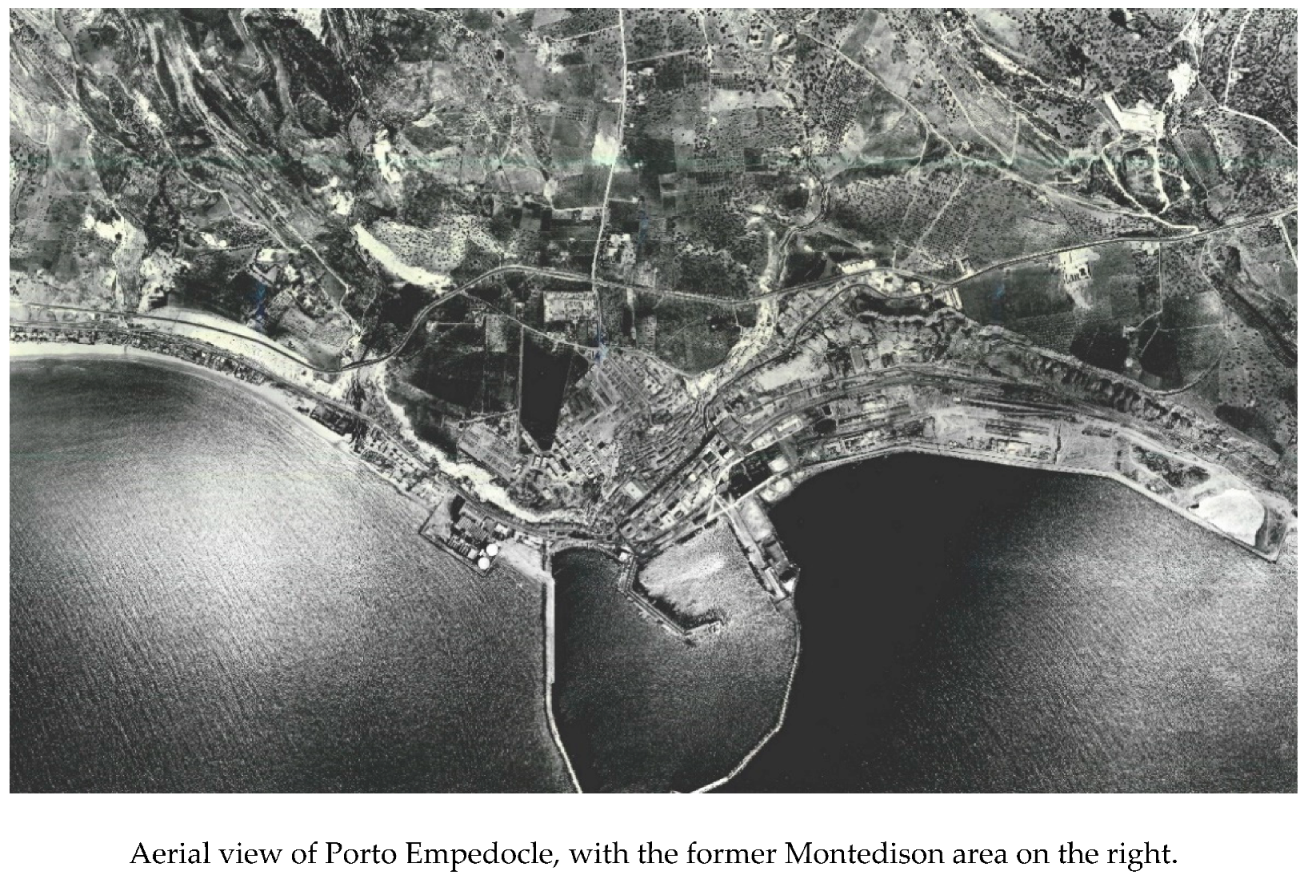

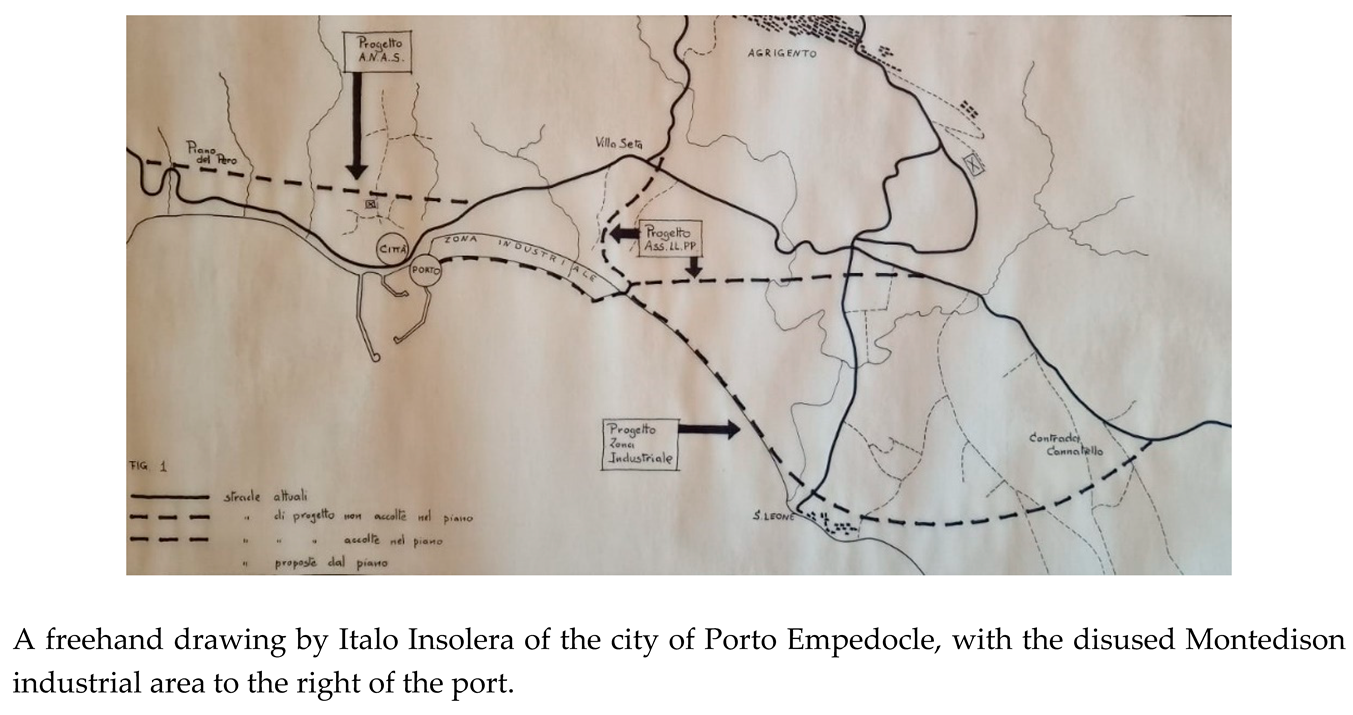

Additionally, Porto Empedocle had a port planned for continuous development and a SGES (Società Generale Elettrica Siciliana) power plant. The only issue was the water supply, which faced serious shortages until 1962, when Montedison, with significant economic efforts, installed its own aqueduct in the Margimuto area, in the municipality of Santa Stefano di Quisquina (Ag), 80 km from Porto Empedocle.

The plant was commissioned in 1955 and ceased production in 1984.

2.4. The Technical Description of the Buildings and General Works

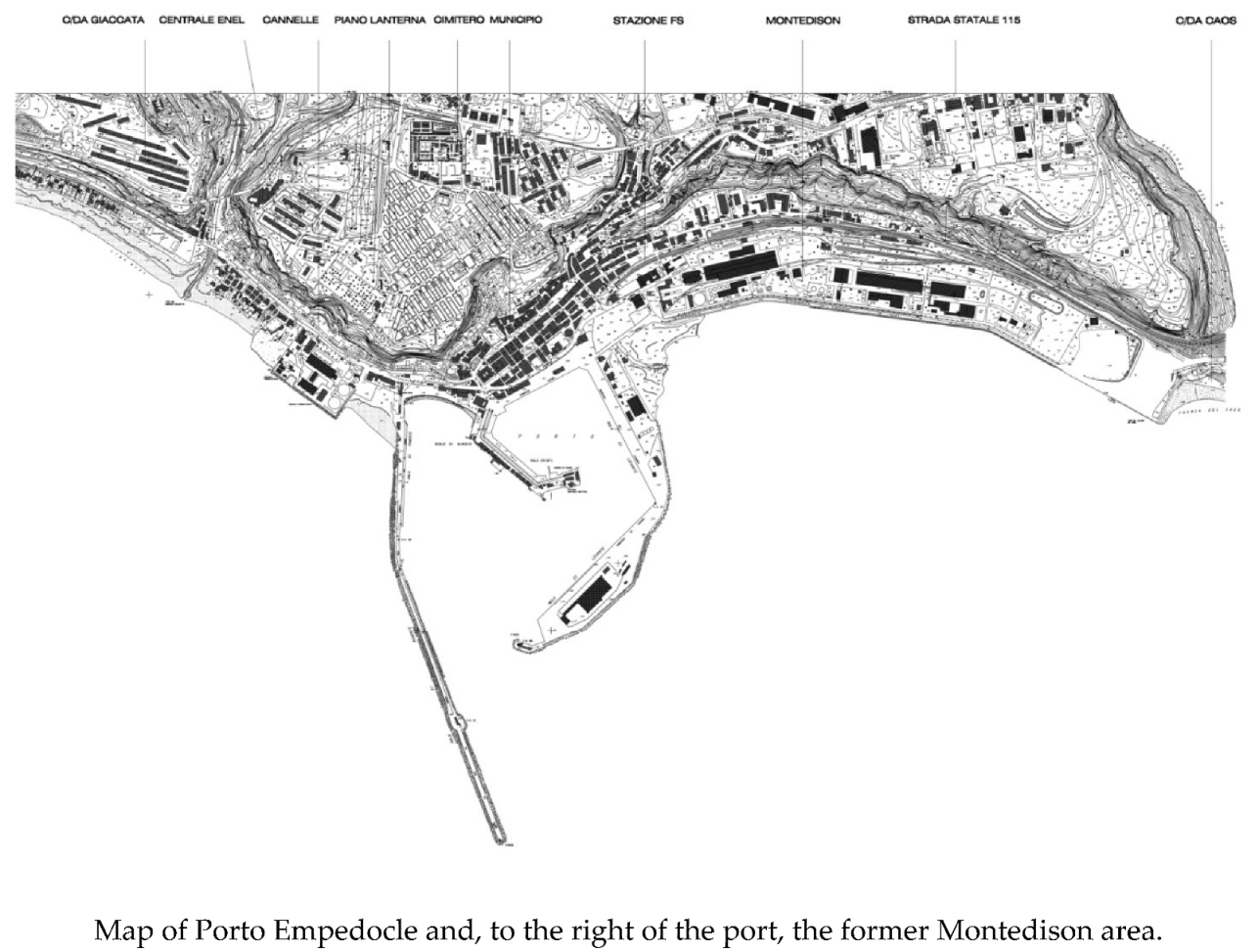

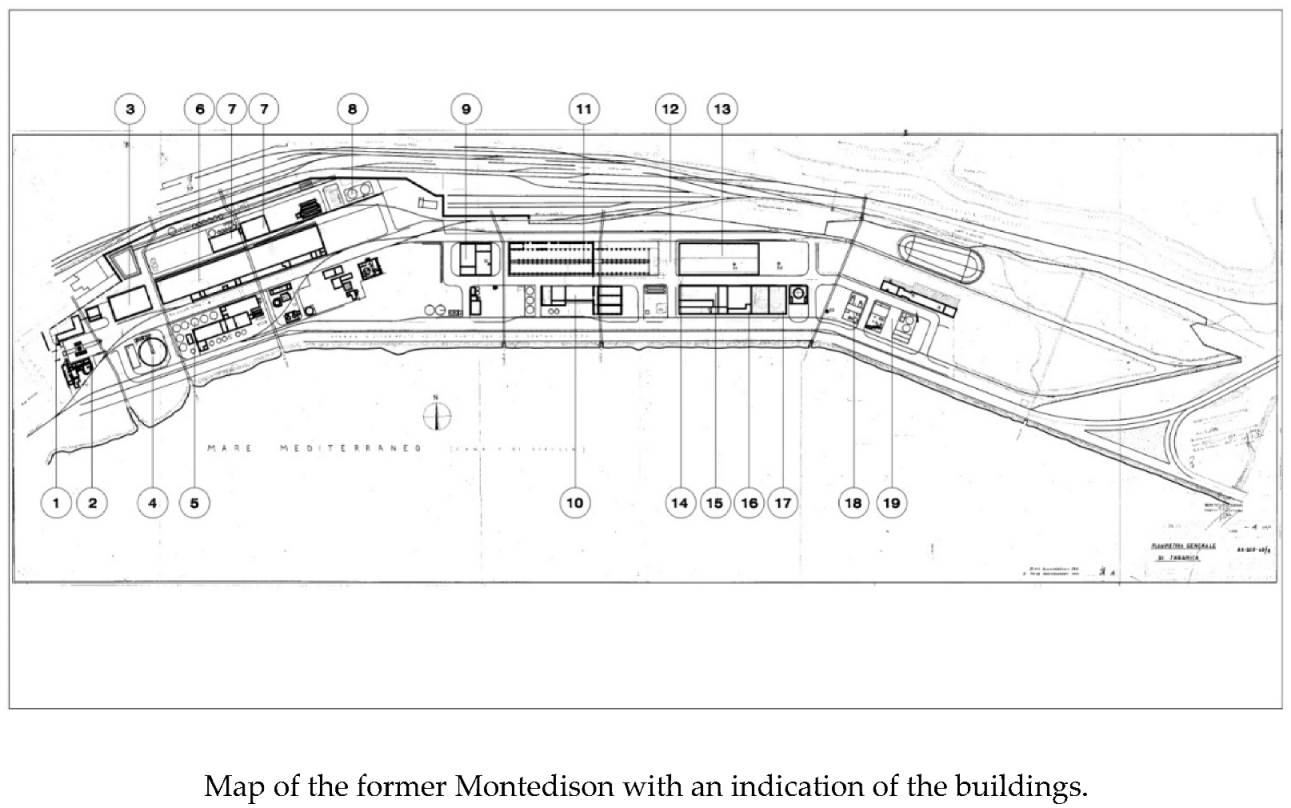

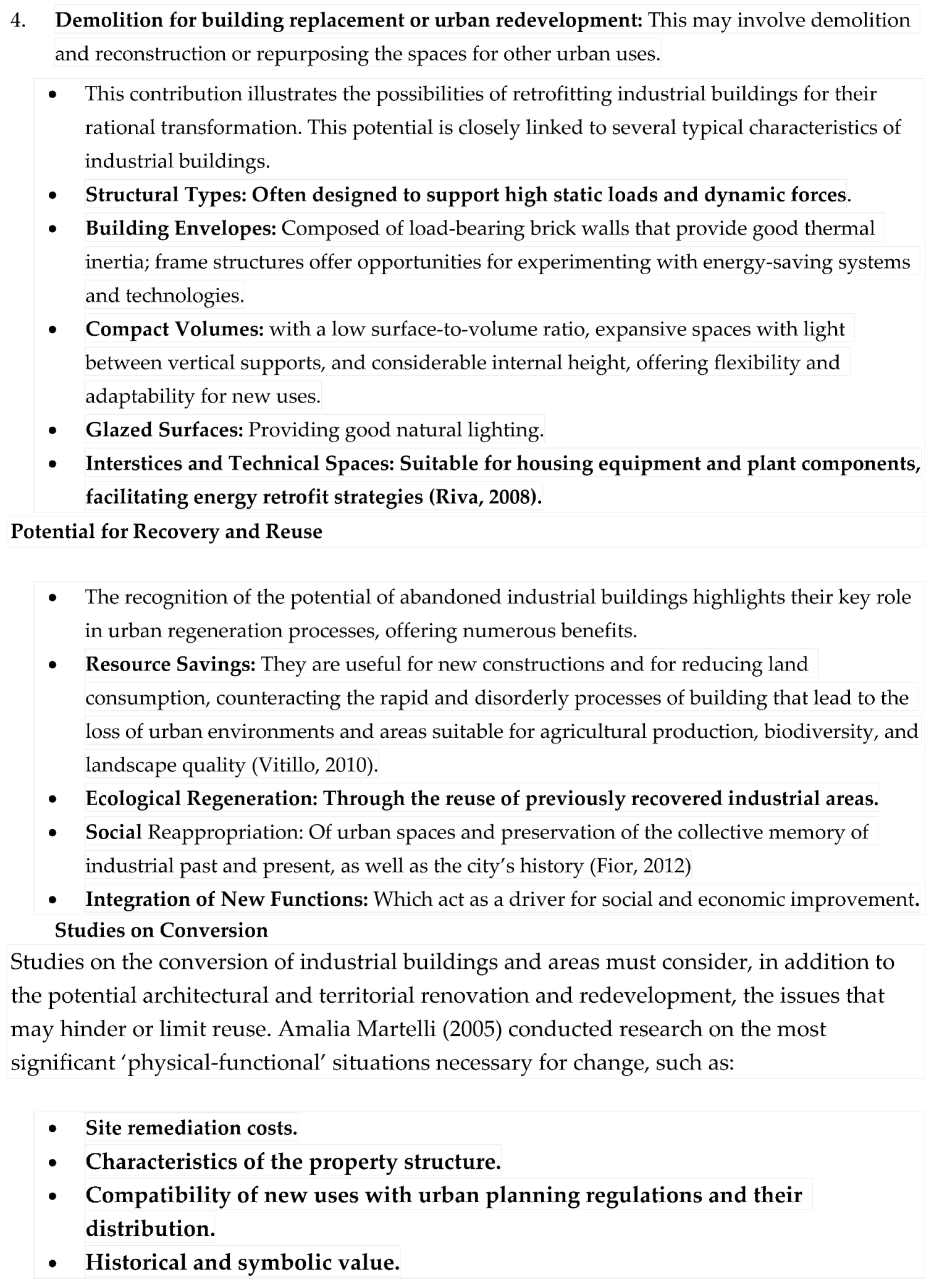

The description of the buildings and structures within the plant is based on the site plan of the plant and follows a narrative from west (where the entrance to the plant is located) to east, providing (where possible) the year of construction, whether the structure is still present (or has been demolished), and a brief technical description. The documentation was obtained from the Technical Office of the Municipality of Porto Empedocle. The former Montedison area has undergone demolitions by the company Syndial, commissioned by the Maritime Property Authority.

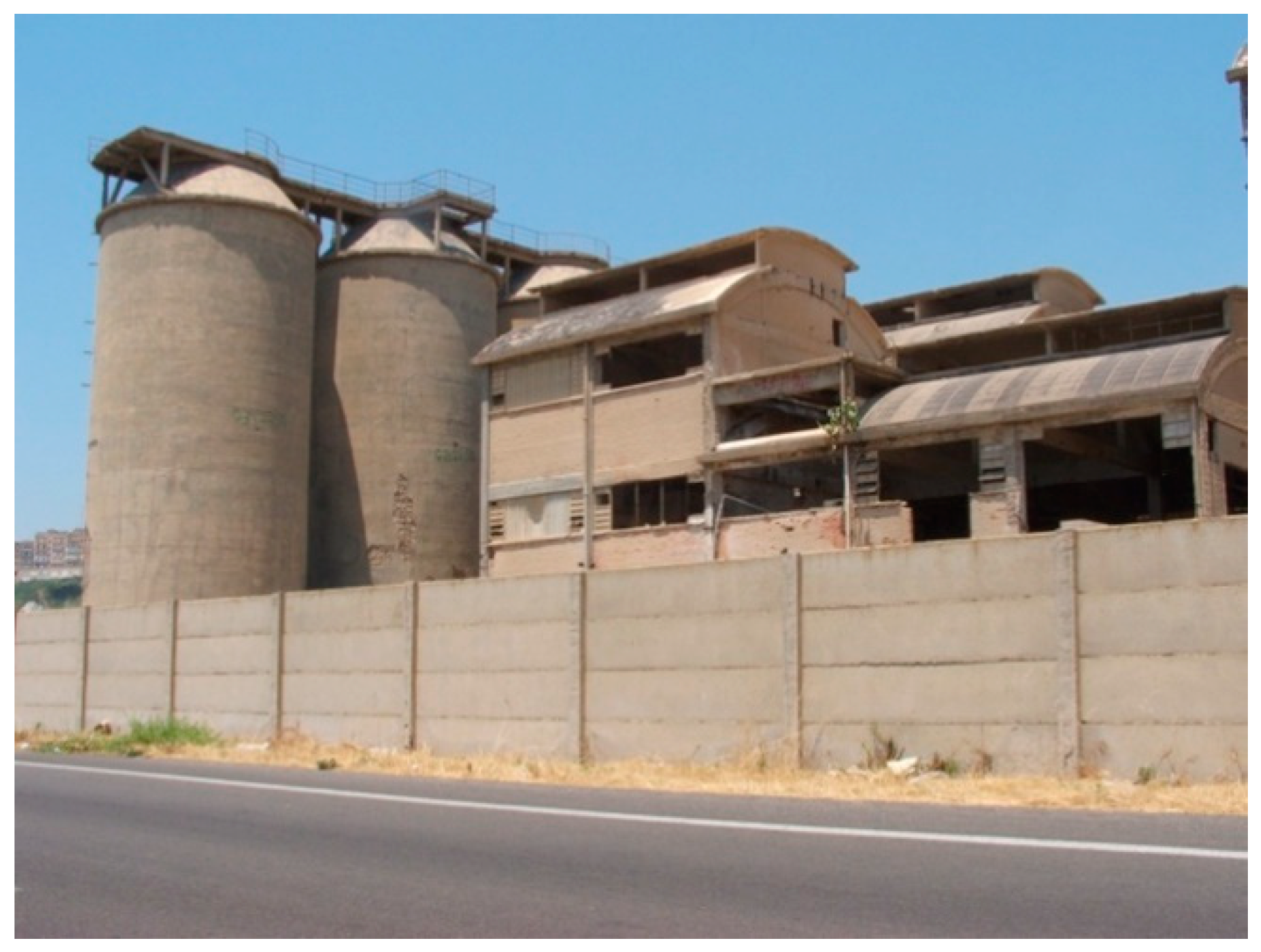

Map of the former Montedison area. Plates AK-SG 0, AK-SG 0-40/3, and PE 16184/6. The description of the buildings that follows was made possible thanks to the site plans of the former Montedison plant. It is also noted that some of the buildings described below were unfortunately demolished between 2007 and 2010. This has worsened the possibility of recovering the area, which today appears altered from an architectural and urban planning perspective compared to the original layout and the logic of the operations and production processes that were carried out.

In plate SG 0-40/3, north of the nitric plant and the water tower, beyond the internal tracks serving the plant, a water collection basin is shown, which was never built.

1. Management, Technical Offices, Administrative Offices, and Chemical Laboratory. Plate 3A-380/2. Existing building. On the west side, adjacent to the square facing the current Via Giuliano Guazzelli, there are two buildings connected by a portico with two entrances, allowing vehicles to enter and exit the plant.

The building located at the bottom (to the south) on the general plan, with a covered area of 240 square meters, housed the plant management, offices, and a small chemical laboratory. It has an almost rectangular shape (18 x 30 meters) and rises over two floors with a pavilion roof. The structure is made of reinforced concrete and dates back to the 1960s. The building is accessible, in good condition, and currently in use by the Carabinieri Station Command.

The building located at the bottom (to the south) on the general plan, with a covered area of 240 square meters, housed the plant management, offices, and a small chemical laboratory. It has an almost rectangular shape (18 x 30 meters) and rises over two floors with a pavilion roof. The structure is made of reinforced concrete and dates back to the 1960s. The building is accessible, in good condition, and currently in use by the Carabinieri Station Command.

1. Gatehouse, Welfare Services, Cafeteria, Changing Rooms, and Sanitary Facilities for Workers. Practices 1928 of 28.07.1974 and 35/74 of 29.07.1974. Existing building. Connected by a driveway portico, it continues upward (to the north) from the general plan of the previous building. This is a civil building with an area of 650 square meters, designed to house the gatehouse, welfare services, cafeteria, changing rooms, and sanitary facilities for the workers. It has an L shape, with the base facing north, measuring 23.50 meters in length, 35.70 meters in height, and 9.30 meters in depth. It rises over two floors with a pavilion roof. The structure is made of reinforced concrete and was built in the 1960s. The building is accessible and in good condition.

2. Building and Silos for Phosphorite. Project plans not found. Existing building. Continuing east along the central driveway, there is a rectangular building measuring 10 x 30 meters, with its longer side oriented north-south, rising over two floors with a pavilion roof. The ground floor has large openings for vehicle entry, and the first floor has large windows. This is a building used for material storage. The building is in good condition.

Adjacent to it on the east side is the phosphorite silo, a circular reinforced concrete structure with an internal diameter of 36 meters. The foundations consist of a circular perimeter ring resting on drilled piles with a diameter of 600 mm and a maximum length of 12 meters.

The perimeter wall was built with a constant thickness of 40 cm and a height of 13.90 meters above ground level. The upper closure was made with a truncated conical slab varying in thickness from 40 cm to 20 cm. Inside the silos, beneath the floor, there is a diametral tunnel with a net section of 2.10 x 2.10 meters, with foundations resting on drilled piles with a diameter of 600 mm and a length of 12 meters. The building is in good condition.

3. Building - Warehouse for Nitrogen Salts and Bags. Project plans not found. Existing building. In front of the silo, toward the top (north side) of the general plan, across the driveway, there is a rectangular building measuring 30.60 x 50.00 meters (with the longer side parallel to the road). The building, intended as a warehouse for storing nitrogen salts (30,000 quintals) and bags (10,000 units), is located east of the gatehouse and service building. It rises over two floors and has a flat, non-walkable roof, currently used for solar panels. The structure is made of reinforced concrete and was built in the 1970s. The building is accessible and in good condition.

4. Seven (Currently Four) Phosphate Silos and Phosphoric Acid Plant Building. Project plans not found. Part of the buildings were demolished in 2007. Next to the large silo mentioned in point 2, on the right (east side), there were seven silos intended to contain phosphate. Three of these silos were positioned perpendicular to the internal driveway, and the other four were parallel to the road, forming an L shape. The silos, with a diameter of 10 meters and a height of approximately 21 meters, have a reinforced concrete structure and can each hold 2,000 tons of phosphate. All the silos were connected at the top by a reinforced concrete walkway with a parapet. Subsequently, the three silos perpendicular to the road were demolished, and currently, four remain parallel to the road. The remaining silos are accessible and in mediocre condition.

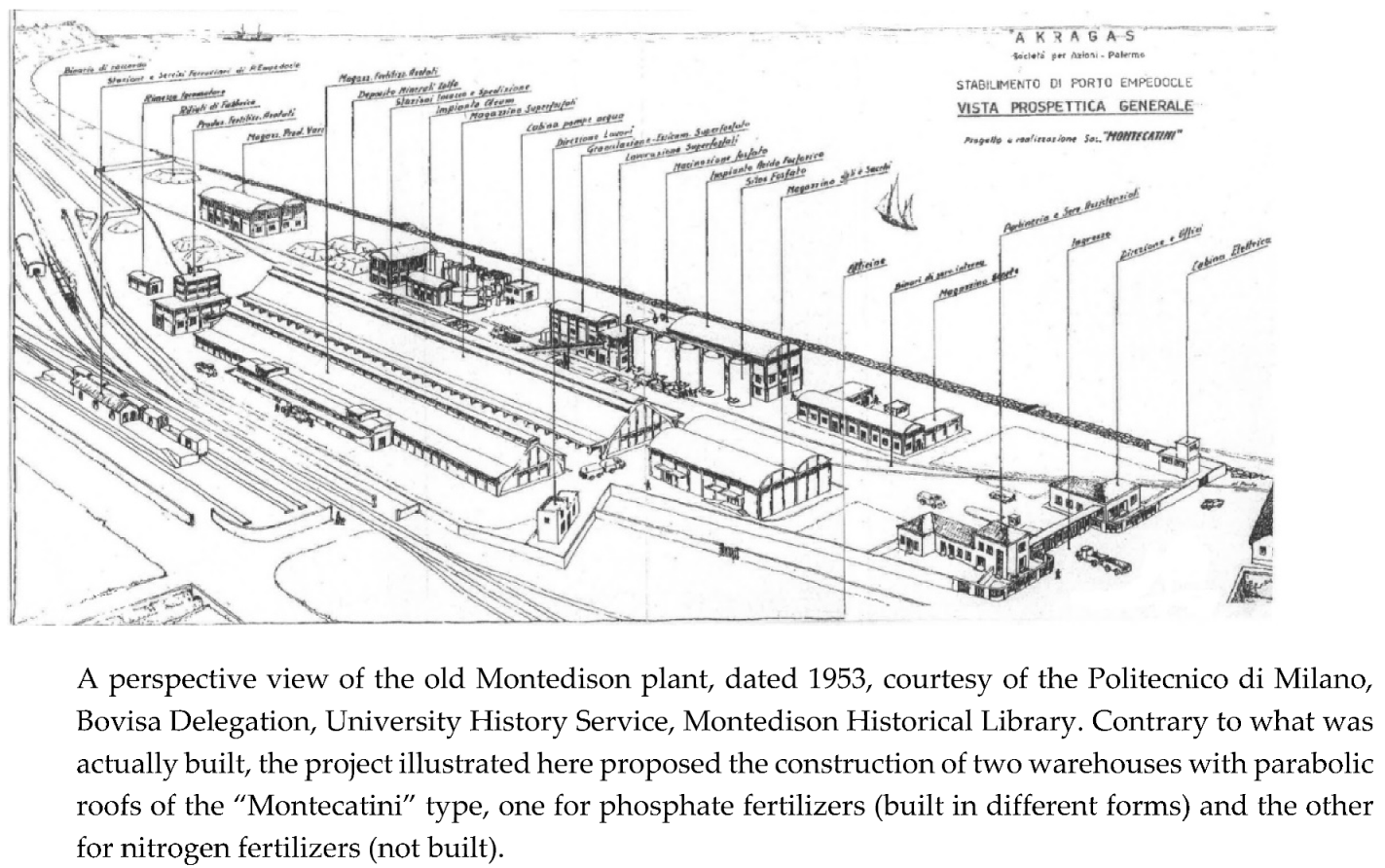

Within the L shape of the silos, there were two rectangular buildings, placed adjacent but offset from each other. One, with a rectangular shape of 75.00 x 16.50 meters, was intended for the phosphoric acid plant and extended over three floors with a barrel-vaulted roof. The second, placed adjacent and offset relative to the first, had a rectangular shape of 50.00 x 16.50 meters and was intended for subsequent processing. Both were demolished in 2007.

5. Nitrogen Fertilizer Warehouse (Superphosphate). Project plans not found. The building was demolished in 2007. Crossing the driveway to the north, with the silos behind, there is the large nitrogen fertilizer warehouse used for storage. Built in 1953, the building is a large common paraboloid with a reinforced key, measuring 145 meters in length and 32.50 meters in width, reached at the top by an aerial walkway connecting to the production plants. In the following three years, the company began producing phosphazote, a binary fertilizer with a high phosphoric acid content. Consequently, to increase the storage capacity of the plant, the parabolic silo was expanded with the addition of a second section, 70 meters long, identical to the first, also connected to the phosphazote plant. Fully completed in 1956, the paraboloid reached a record length of 215 meters and a maximum ridge height of 17 meters. Particularly interesting is the introduction of automated bagging and distribution stations, consisting of multi-story towers with a base of 7.50 x 6.50 meters, positioned along one of the longer sides of the warehouse.

The design of the superphosphate warehouse in Porto Empedocle, as well as the entire plant, was directly managed by the Technical Directorate of Montecatini and carried out by Borio Mangiarotti of Milan, with contributions from engineer Giuseppe Borio for the construction of reinforced concrete and features very similar to those of Montecatini in Vercelli. Following renovation work, the bagging stations and some of the side canopies were removed, partially altering the building. The building is accessible, currently used as a kennel, and is in a mediocre state of conservation. Solar panels have been placed on the roof.

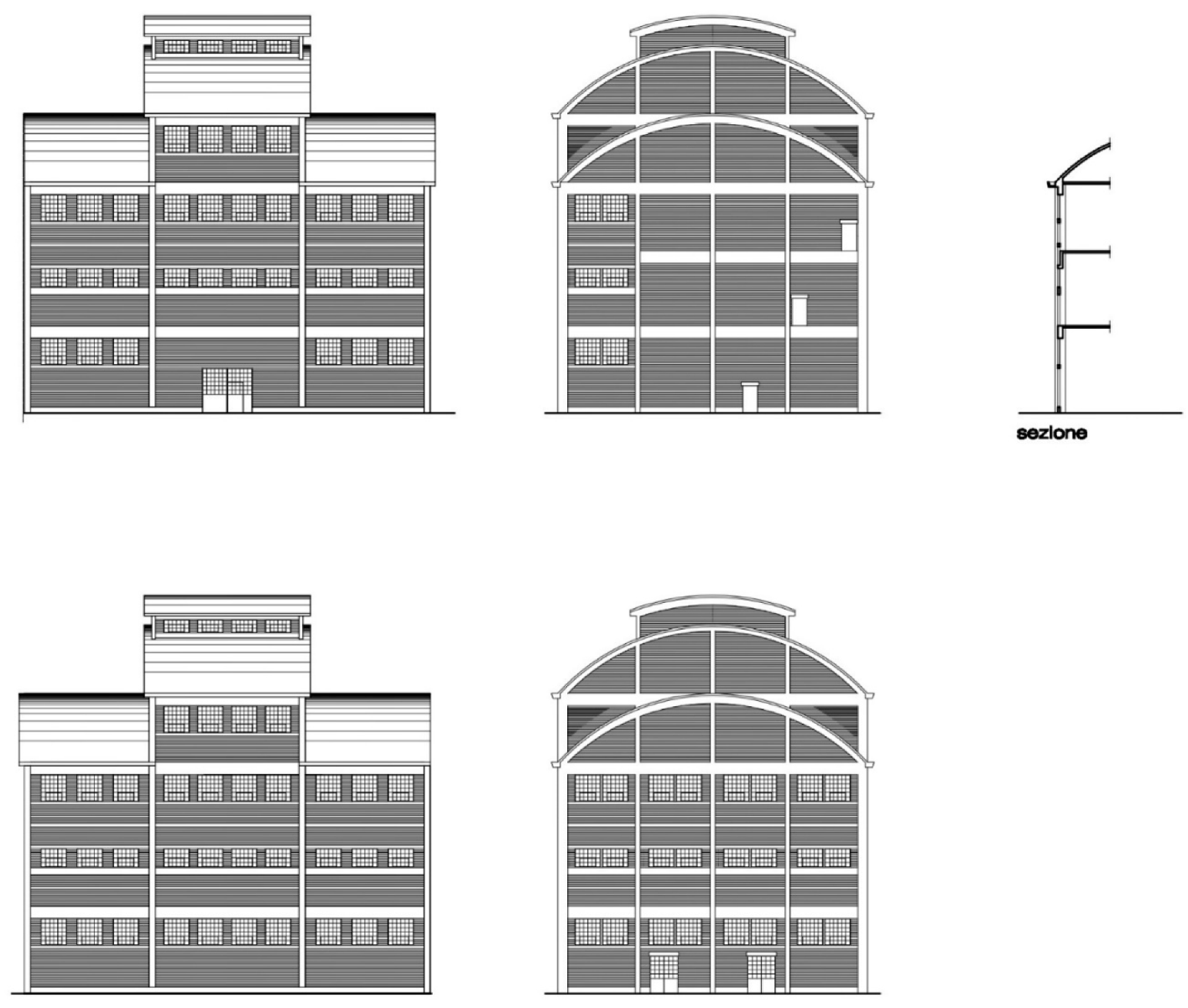

6. Potassium Nitrate Warehouses. Plates 2F-353, 2F-354/3, 2B-544, and 2B-542/4. The buildings were demolished in 2007. Above the nitrogen fertilizer warehouse, also known as the superphosphate warehouse (to the north), there was a structure intended for the storage of potassium nitrate, consisting of two buildings that were structurally independent and separated by 10 cm. The buildings, placed parallel to the superphosphate warehouse, were called Plant 390 (to the west) and Plant 335 (to the east). Plant 390 had a rectangular plan measuring 43 x 18 meters with a reinforced concrete frame structure spanning seven bays, rising over four floors above ground with a gutter height of 18.50 meters, and a barrel-vaulted roof with an overhead skylight. Almost adjoining (at a distance of 10 cm), to the east was Plant 335, a rectangular building measuring 32 x 24 meters, with a reinforced concrete frame structure spanning three bays, rising over three floors above ground with a gutter height of 24 meters, and a barrel-vaulted roof with an overhead skylight. The buildings were demolished in 2007.

7. Spherical Tanks (two) for NH3, Ammonia. Plate AK 182-15. The buildings were demolished in 2007. Continuing east, in line with the warehouses for potassium nitrate production and near the perimeter wall of the plant, we find the spherical tanks that contained ammonia. There were two tanks, each with a diameter of 16 meters and a height of about 20 meters. The structure was made of reinforced concrete and was built in the mid-1960s. The tanks were demolished in 2007.

8. Workshop and Stock Warehouse Building. Project plans not found. The building is existing.. Continuing east, there was the building designated as a workshop and stock warehouse. This building is located in the area secured in 2007 by the reclamation company Syndial S.p.A., near the border with the area assigned to the Moncada Energy Group and aligned with the slab of the former superphosphate warehouse. The construction was carried out in the second half of the 1960s, placing two sheds measuring 20 x 40 meters next to each other. The frame structure is made of reinforced concrete, set on a square plan measuring 40 x 40 meters between the axes of the end columns. It has a gutter height of 6.40 meters and a vault roof in lightweight SAP with iron chains.

The supporting structures consist of isolated footings resting on precast prestressed concrete piles, 7 meters long, driven in with an appropriate pile driver, reinforced concrete columns all with a center distance of 5 meters, connecting beams for footings, roof beams, and overhead crane beams in the carpentry and repair rooms. The perimeter infill walls are made with brick masonry, plastered to a smooth finish inside and with exposed brick on the outside. The building is currently inaccessible but appears to be in good condition from the outside.

9. Complex Plant - M and B Title, Milling, and Mixing. Plates 2B-548, 2B-555, 2B-546, 2B-550, 2B-551. The building is existing. Below (to the south) of the majestic complex plant - product warehouse, there is a complex of three buildings, which from west to east are named: Complex Plant - M and B Title Milling and Mixing, Complex Plant - M and B Title, and Complex Plant - M and B Title Intermediate Warehouse.

The first is a rectangular building measuring 24 x 12 meters (with the longer side parallel to the coastline), on two/three levels, with a reinforced concrete structure and a barrel-vaulted roof with an overhead skylight. The second is a rectangular building measuring 36 x 18 meters (with the longer side parallel to the coastline), on four levels, with a reinforced concrete structure and a barrel-vaulted roof with an overhead skylight. The third building has characteristics similar to the second.

The following buildings, 10, 11, 12, 13, and 14, are connected by walkways for material handling.

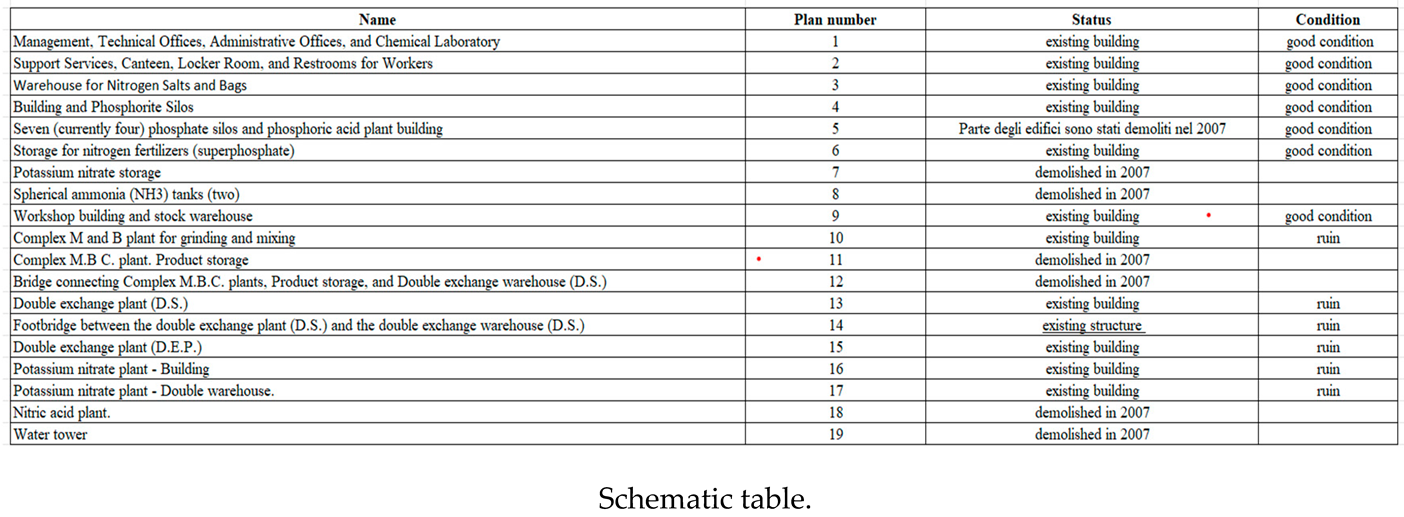

10. Complex Plant M. B. C., Product Warehouse. Plate 2B-547/7. The building was demolished in 2007. North of the double exchange plant was the majestic complex plant, product warehouse. It was a rectangular building that combined two buildings in continuity. The first building, 18 bays long, was intended for the production of complex fertilizers and was characterized by greater width due to the presence, in contact and throughout the length, of a structure intended for various warehouses and services. In continuity, for 12 bays, there was the building intended for superphosphate. As a whole, it was a single building, consisting of 30 aligned bays, each 3 meters wide, with overall dimensions of 32 x 180 meters, and featured a discontinuous arched roof. The building was demolished in 2007.

11. Walkway Connecting Complex Plants M. B. C., Product Warehouse, and Double Exchange Warehouse (D.S.) Plate 2B-547/7. The structure was demolished in 2007. The walkway was a reinforced concrete structure with pillars, beams, and a slab, extending approximately 28 meters, with intermediate support on isolated footing foundations resting directly on the ground. The perimeter closure was made of reinforced concrete, featuring 10 rectangular windows on both sides. The walkway was demolished in 2007.

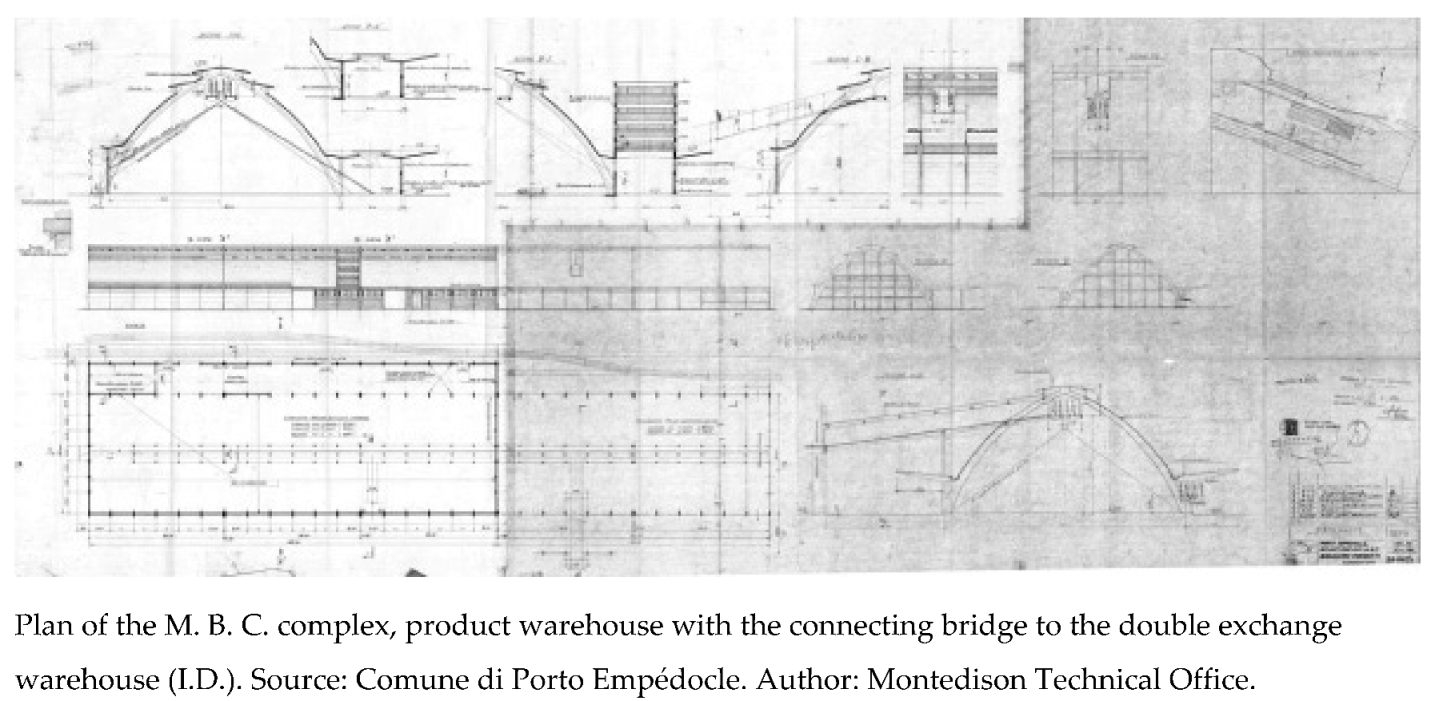

12. Double Exchange Warehouse (D.S.). Project plans not found. The building is existing. East of the complex plant, there is the double exchange warehouse, consisting of a shed measuring 102 x 40 meters in plan, with a maximum height of 20.50 meters. The foundations are made with isolated footings resting on precast reinforced concrete piles 7 meters long, driven in with an appropriate pile driver, and perimeter connecting beams.

The supporting structure consists of 18 arches, with a center distance of 6 meters, connected by longitudinal beams and two eaves beams at a height of +5.70 meters. The roof is made with prefabricated reinforced concrete purlins, on which rests a layer of fiber cement sheets (eternit) and ondulux. The supporting structure is made of pillars, beams, and a brick slab. The perimeter and upper closure was executed with fiber cement and ondulux sheets.

The warehouse, whose connecting roof between the arches has been removed, is currently in an advanced state of decay and is impractical and inaccessible.

13.Walkway between Double Exchange Plant (D.S.) and Double Exchange Warehouse (D.S.). Project plans not found. The structure is existing. The double exchange plant is associated with a double exchange warehouse, to which it is connected by a walkway, still existing, measuring 47.30 meters in reinforced concrete, supported by pillars founded on footings, similar to the neighboring buildings. Originally, the passage was protected by sheets of fiber cement (eternit) and ondulux. The structure is in a state of decay.

14. Double Exchange Plant (D.S.). Plates AK-384-5/4 and AK-384-15/1. The building is existing. Below (to the south) of the complex plant, there is the double exchange plant, positioned parallel to the seafront and near the transverse perimeter wall that divides the entire former industrial area into two further compartments. The building complex consists of the D.S. plant building, the filtration plant, and the electrical control and instrumentation cabin.

The first has an L-shaped plan and is a single building block with a reinforced concrete frame structure, with plan dimensions of 46.00 x 18.00 – 27.00 meters. The roofs are vaulted in lightweight SAP with iron chains. The perimeter closure (where provided) is made of brick masonry, plastered to a smooth finish on the inside and with exposed brick on the outside.

The filtration plant is a rectangular building measuring 15.00 x 8.00 meters (center distance between extreme pillars) with a gutter height of 22.30 meters. Here too, the structure is a reinforced concrete frame with two floors at levels +11.55 and +16.00 meters and a staircase accessing these floors. The roof vault is in lightweight SAP.

Finally, concluding the previously described group of buildings is the rectangular control and instrumentation cabin, measuring 10.05 x 6.40 meters in plan (center distance between extreme pillars), with a gutter height of approximately +11.50 meters. The structure, with pillars and beams, rises over two levels, supported (similar to the other buildings) on foundations with footings connected by wall beams and resting on precast reinforced concrete piles. The entire complex is in a severe state of decay, both in the supporting and non-supporting structures.

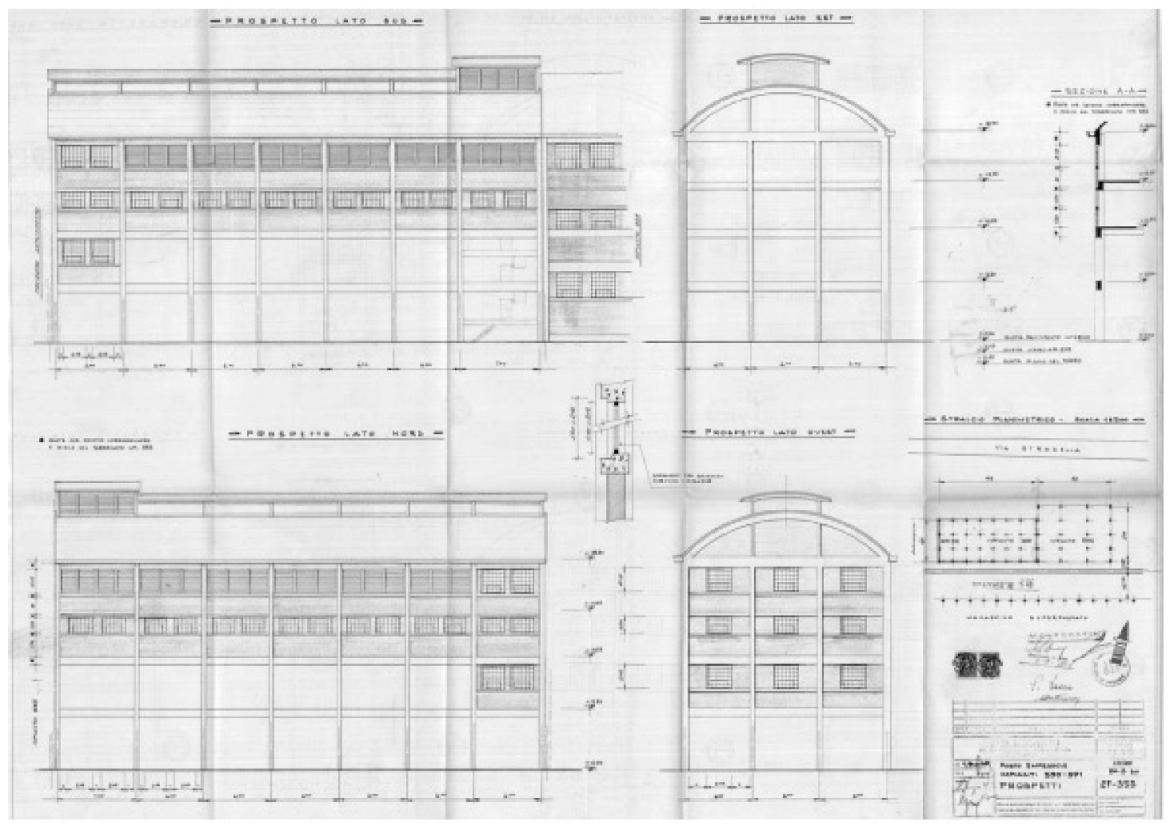

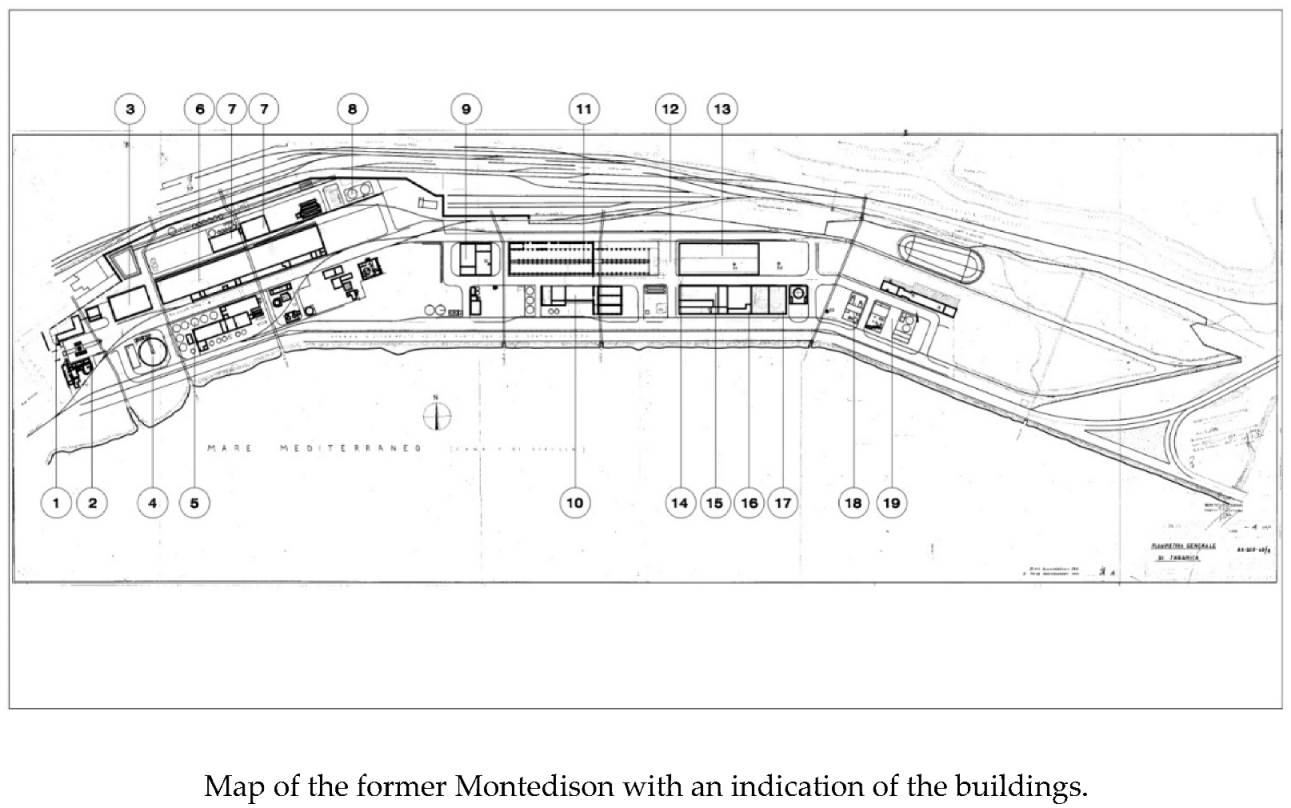

15. Potassium Nitrate Plant – Building. Plates AK-375-28, plates 5, 6, 7, 8, and file 1783. The building is existing The building was constructed in the early 1970s as an extension of the double exchange plant (D.S.). The production cycle was aimed at producing fertilizers with high nitrogen, phosphorus, and potassium content through a complex process of potassium nitrate transformation. This was extracted from the solutions produced in the DS plant and underwent a processing cycle to obtain a product for agricultural use and, alternatively, for industrial use. Constructed as independent from the other buildings, due to the delicacy of the processes that had to be carried out within it, the plant was located between the D.S. plant (to the west) and the double warehouse (to the east), intended for product storage. As reported in the project report, the building was specifically spaced 0.60 meters from the D.S. plant and 0.25 meters from the warehouse, with some connection points planned.

The four-story construction has an L-shaped plan, with the front facing the seafront measuring 30.50 meters and a gutter height of 20.10 meters. The western part at the front is designated for stairs, while the back houses rooms for command and control equipment. It develops over four floors and a terrace accessed with walkways and iron stairs from adjacent buildings. Currently, only the reinforced concrete structure of the building remains, entirely exposed and devoid of any perimeter infill closure. From an outside view, it can be observed that the floors at various levels are extensively degraded and collapsed in several areas.

16. Potassium Nitrate Plant – Double Warehouse. Plates AK-375-51, plates 1, 2, 3, 4, 9. The building is existing. Located east of the potassium nitrate production plant, the rectangular building with dimensions of 45.00 x 36.00 meters and a gutter height of 8.50 meters was designed to serve the previously described plant. The building is divided into two areas, considering the differentiated storage of products: the west area was intended for the product for agricultural use, labeled as raw, while the east area was designated for the product for industrial use.

The building was constructed with a reinforced concrete frame structure that supports a metal truss on which sheets of eternit were originally placed. Additionally, on the same roof, there were walkways connecting to the adjacent building (located to the west). The infill walls are made of exposed brick. The building is in a fair state of conservation, as it is still the only one that has been recovered and reused by a craft company (Meccanica Martines).

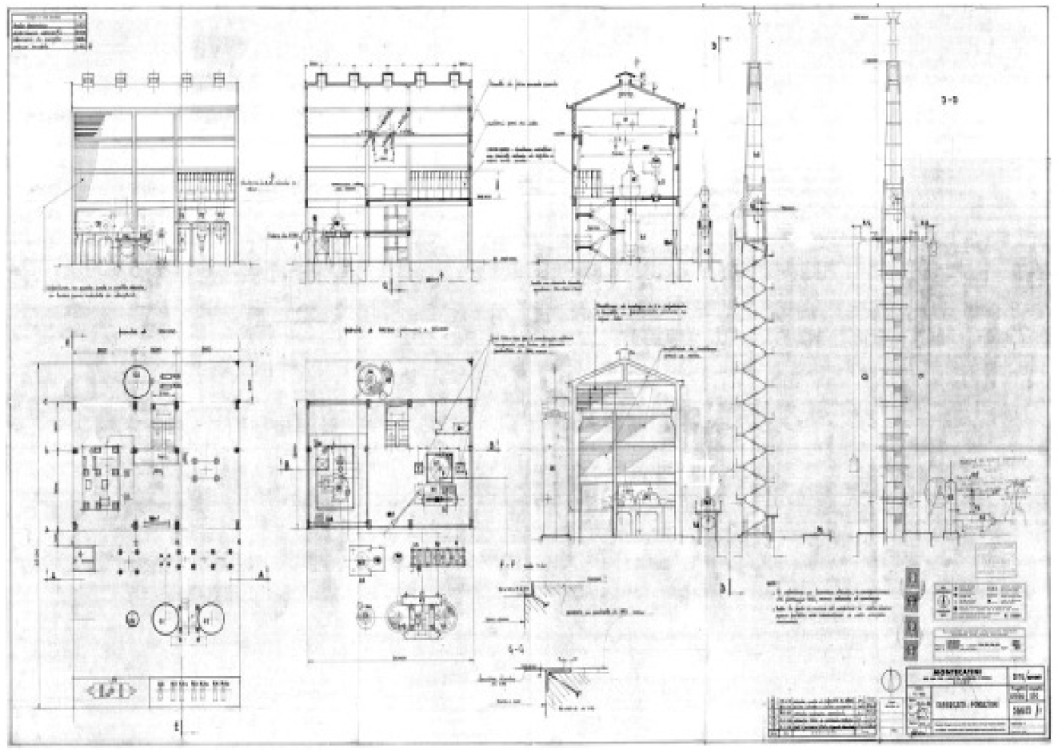

17. Nitric Plant. Plate 56655/5. The buildings were demolished in 2007. The buildings of the nitric plant and the associated water tower, built in the mid-1960s, were located in the southeast, at the extreme limit of the former Montedison area and near the Vetem factory. There were three structures in total: two buildings and the water tower. The two buildings are “Plant 200” (to the west) and a building that housed the boiler (to the east). The first is a reinforced concrete and masonry building called “Plant 200” with dimensions of 35 x 20 meters and a maximum height of about 13.70 meters. The second is a rectangular building with dimensions of 13.00 x 20.00 meters and a height to the eaves line of 15.25 meters. The supporting frame structure is made of reinforced concrete and was elevated on foundation footings resting on precast reinforced concrete piles 7 meters long, driven into the ground with an appropriate pile driver.The building, with two floors above ground, had a trussed roof with a system of five ventilation skylights. The perimeter closures on the first floor were partly in brick masonry, plastered to a smooth finish on the inside and with exposed brick on the outside, and in lightweight materials like ondulux. On the second floor, the perimeter closures were made of solid bricks spaced in horizontal courses to form a perforated wall, allowing ventilation of the floor. The buildings were demolished in 2007.

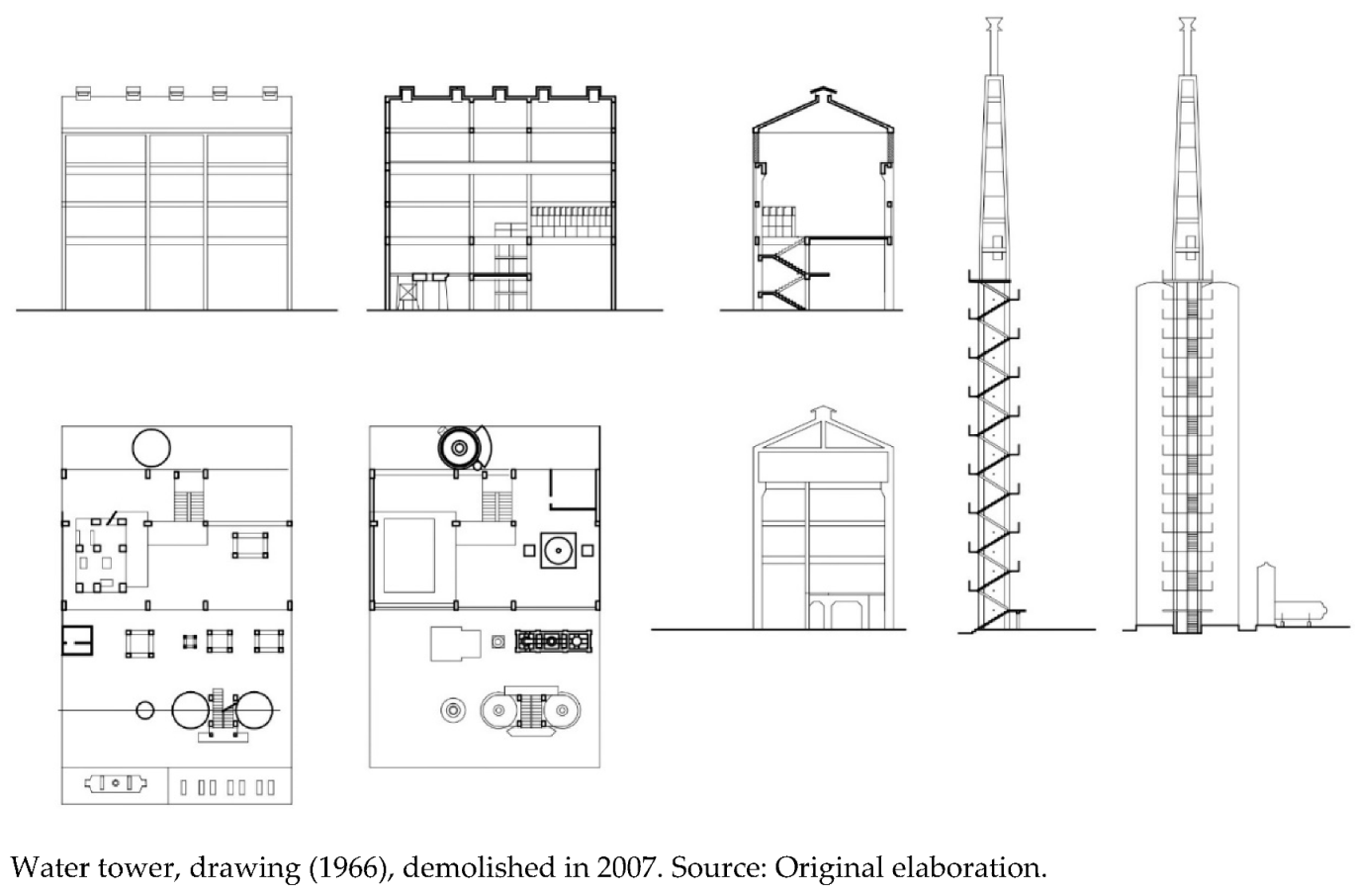

17. Water Tower. Plate 56655/5. The structure was demolished in 2007. Located southeast, at a distance of 16 meters from the nitric plant, was the water tower, a particularly beautiful structure standing 15.50 meters high. The structure was supported by four pillars around which an external staircase developed up to a height of 11.95 meters. The pillars continued their development, narrowing up to a height of 14.80 meters, and concluded at the final height of 15.50 meters. The building was demolished in 2007.

Figure 1.

Entrance to the Complex with Phosphate Silos and Warehouses. Source: Own Elaboration.

Figure 1.

Entrance to the Complex with Phosphate Silos and Warehouses. Source: Own Elaboration.

Figure 2.

The nitrogenous fertilizers warehouse (superphosphate), demolished in 2007. Source: Own elaboration.

Figure 2.

The nitrogenous fertilizers warehouse (superphosphate), demolished in 2007. Source: Own elaboration.

Figure 3.

Floor plan of the M. B. C. complex, product warehouse with the connecting walkway to the double exchange warehouse (I.D.), demolished in 2007. Source: Own elaboration.

Figure 3.

Floor plan of the M. B. C. complex, product warehouse with the connecting walkway to the double exchange warehouse (I.D.), demolished in 2007. Source: Own elaboration.

Figure 4.

The double exchange warehouse (D.I.). Source: Own elaboration.

Figure 4.

The double exchange warehouse (D.I.). Source: Own elaboration.

The double warehouse and the potassium nitrate plant. Source: Comune di Porto Empédocle. Author: Montedison Technical Office.

Drawing of the double warehouse and the potassium nitrate plant. Source: Own elaboration

Figure 5.

Impianto di nitrato di potassio - doppio stoccaggio. Fonte: Elaborazione propria .

Figure 5.

Impianto di nitrato di potassio - doppio stoccaggio. Fonte: Elaborazione propria .

Figure 6.

Impianto complesso M. B. C., magazzino prodotti. L’edificio è stato demolito nel 2007. Fonte: Elaborazione propria .

Figure 6.

Impianto complesso M. B. C., magazzino prodotti. L’edificio è stato demolito nel 2007. Fonte: Elaborazione propria .

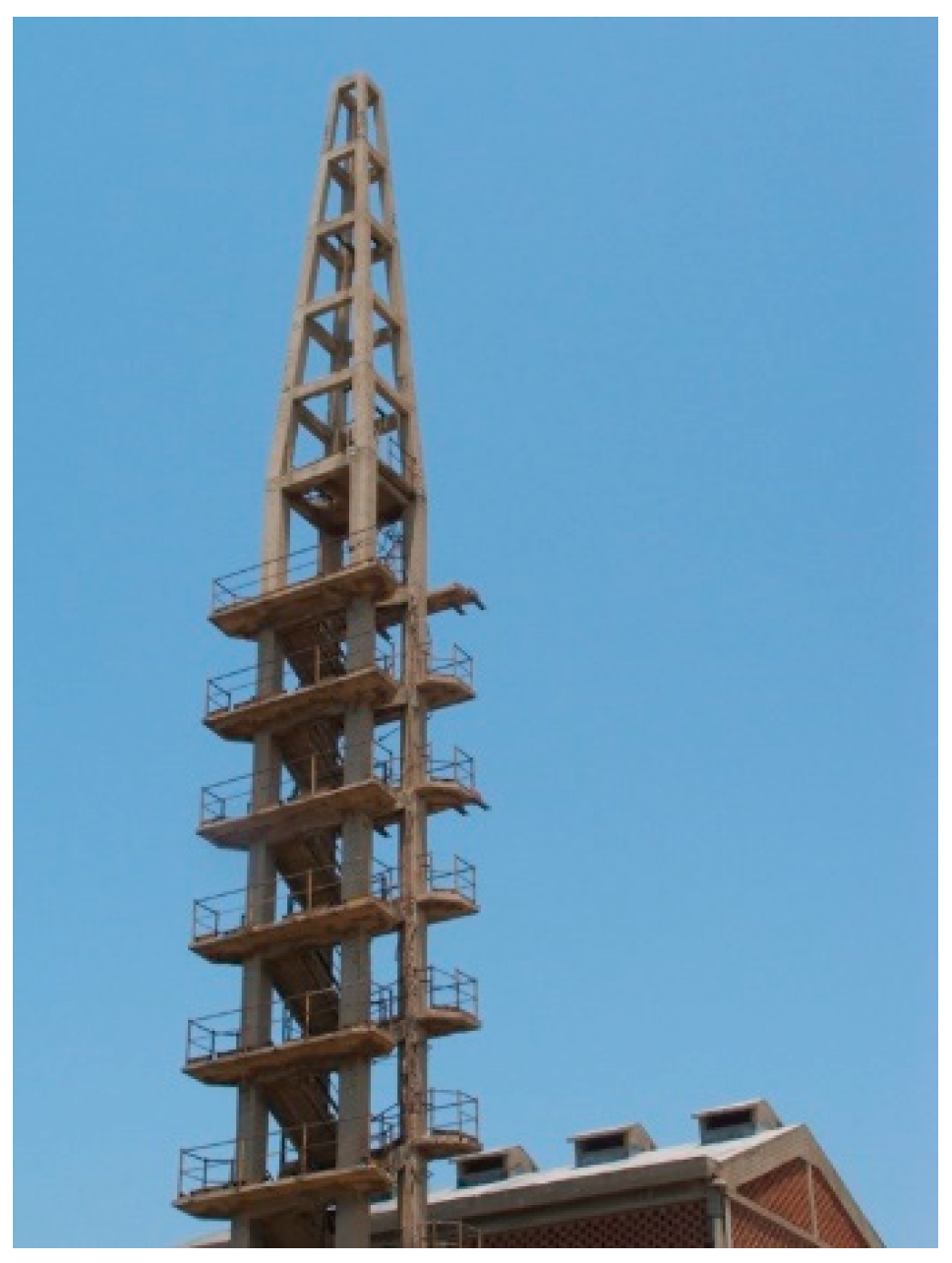

The potassium nitrate plant and the water tower (1966).

Nitrate plant and water tower. The buildings were demolished in 2007. Source: Municipality of Porto Empédocle. Author: Montedison Technical Office.

Figure 7.

The water tower (1966), demolished in 2007. Source: Original elaboration.

Figure 7.

The water tower (1966), demolished in 2007. Source: Original elaboration.