Submitted:

26 August 2024

Posted:

28 August 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

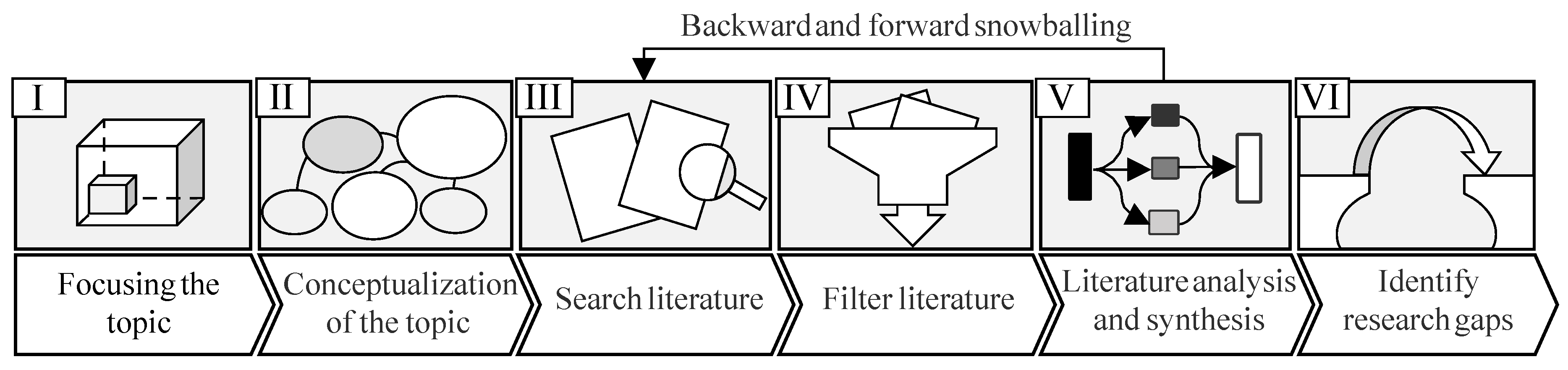

2. Review Methodology

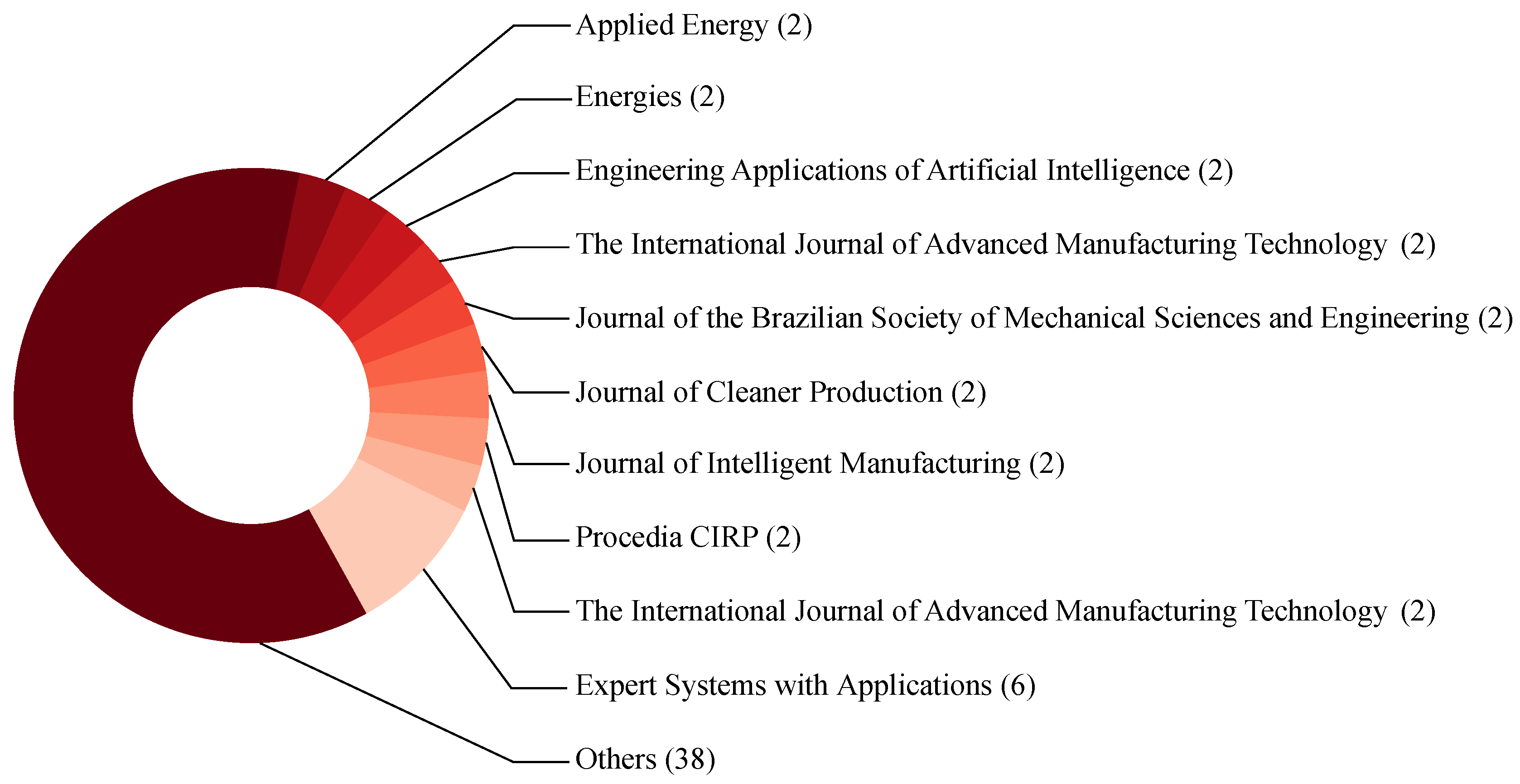

3. Literature Review

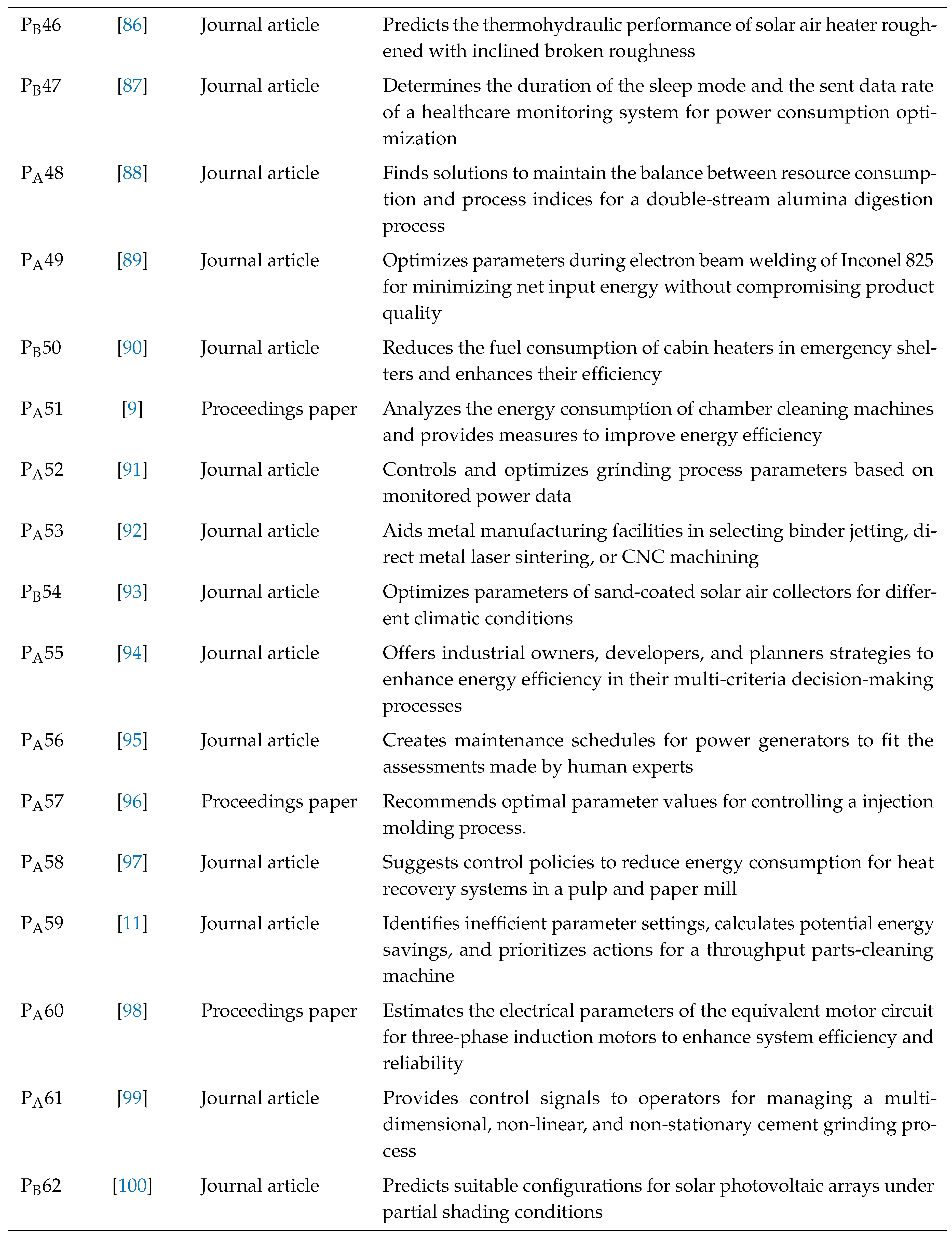

3.1. Narrowing the Topic

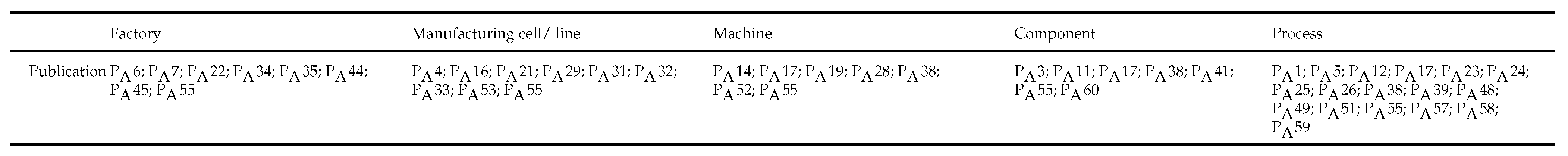

3.1.1. System Boundary

- Factory: Distinct physical entity containing multiple devices [25].

- Manufacturing cell/ line: Logical organization of multiple machines to achieve a better division of labor [26].

- Machine: Entity required to perform a specific production task [27].

- Component: Individual parts or consumers of a machine which represent the lowest hierarchical level for energy metering [28].

- Process: Value-adding and non-value-adding technical operations [26].

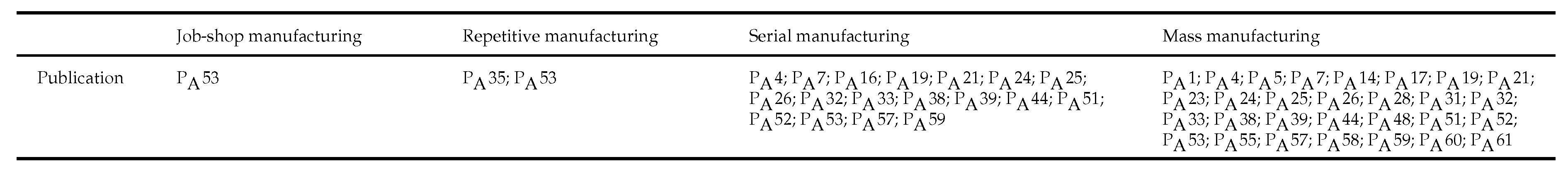

3.1.2. Manufacturing type

- Job-shop manufacturing: Custom manufacturing, i.e. according to customer requirements, in which products are only manufactured once.

- Repetitive manufacturing: Products are manufactured at irregular intervals. If orders are repeated, less preparation is required.

- Variant manufacturing: Similar products of the same basic type, which generally involve similar manufacturing effort.

- Serial manufacturing: Mostly contract manufacturing of standardized products in limited quantities.

- Mass manufacturing: Manufacturing large quantities for an anonymous market. High initial investment costs, but low in relation to the sum of manufactured products.

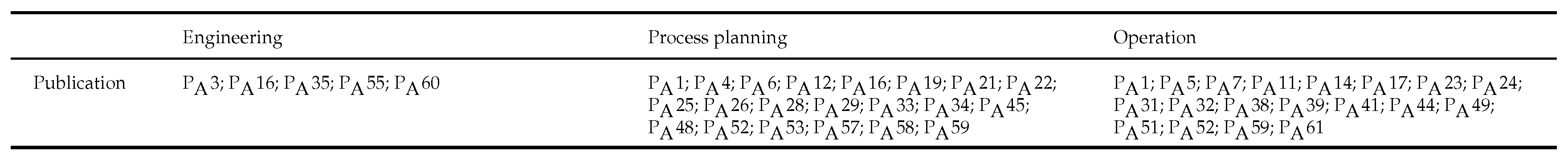

3.1.3. Application Perspective

- Engineering: ESs are used for energy-optimized design at a high level of abstraction, e.g. by supporting the selection of sustainable technologies.

- Process planning: The objective of applying ESs in this phase is to plan and optimize manufacturing processes with regard to energy efficiency prior to actual operation, e.g. by optimizing parameters

- Operation: In the phase in which the actual manufacturing process takes place, ESs are utilized to improve the energy efficiency of the operation, e.g. by detecting inefficient operating points.

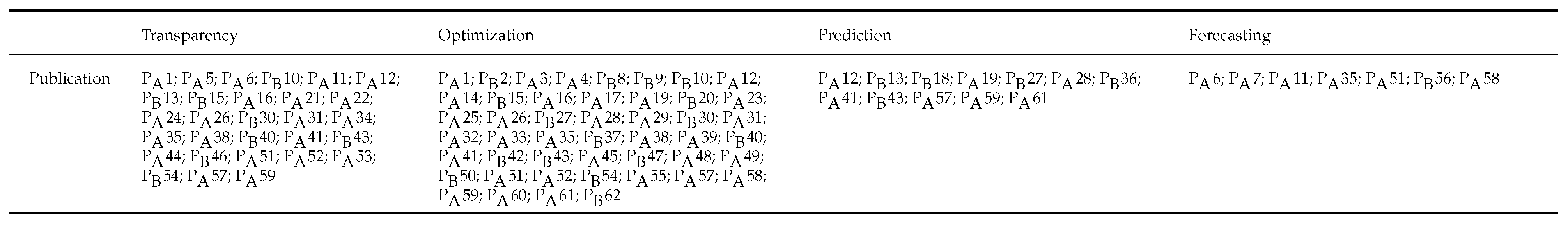

3.1.4. Application Focus

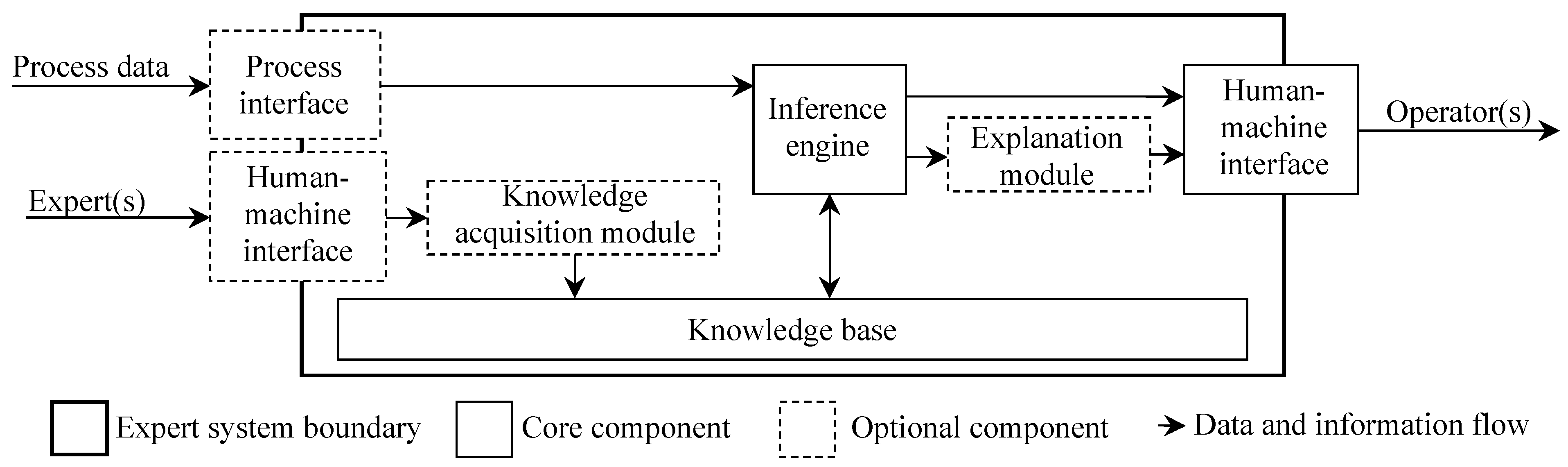

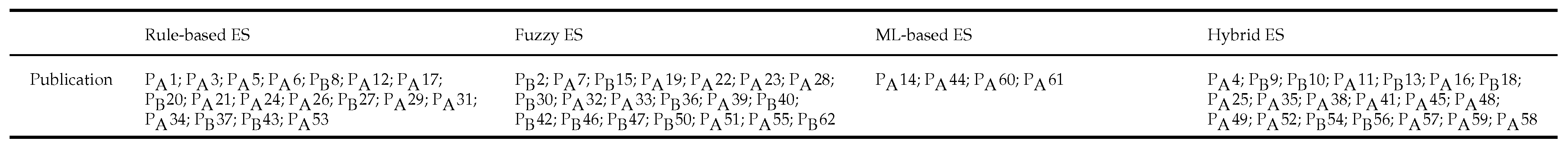

3.1.5. Expert System Type

- Rule-based expert system: A rule-based ES represents information in the form of IF-THEN-rules. These rules are applied to perform operations on data in order to reach a conclusion [13].

- Fuzzy expert system: Fuzzy ESs are characterized by dealing with uncertainties using fuzzy logic. While rule-based ESs only allow conditions or conclusions that are either true or false, fuzzy ESs allow also conditions or conclusions that are partly true or false. This approach is based on the premise that human experts often decide without precisely quantified information [13].

- Machine learning (ML) based expert system: This type of ES uses ML as its "intelligent" component to solve problems. Like ESs, ML belongs to the domain of AI and combines a collection of data-driven algorithms that can learn from data without being explicitly programmed. ML also includes deep learning and reinforcement learning. [31]

- Hybrid expert system: Hybrid ESs are a combination of several previously mentioned types or a previously mentioned type with a further approach. Further approaches can be mathematical optimization methods or physical simulation models.

3.1.6. Application Purpose

- Transparency: To reduce the energy consumption in industry, stakeholders need a sufficient level of energy transparency to create a meaningful basis for decision-making [32]

- Optimization: Optimization in the context of this work means improving energy efficiency as far as necessary and feasible.

- Prediction: Prediction means determining unknown values from known inputs. For energy analysis, this means that the available observations at time t are used to predict the energy or energy efficiency at the same time t. [22]

- Forecasting: Statements are made about the future. In energy analyses, future values t+x for energy or energy efficiency are estimated based on current and/or past information at time t. [33]

3.2. Conceptualization of the Topic

3.2.1. Research Questions

- RQ-1 Which industries deploy ESs to increase energy efficiency?

- RQ-2 How have ESs been applied in the manufacturing industry to enhance energy efficiency?

- RQ-3 How are ESs for improving energy efficiency in industry structured and implemented?

- RQ-4 How are ESs for improving energy efficiency in industrial applications developed?

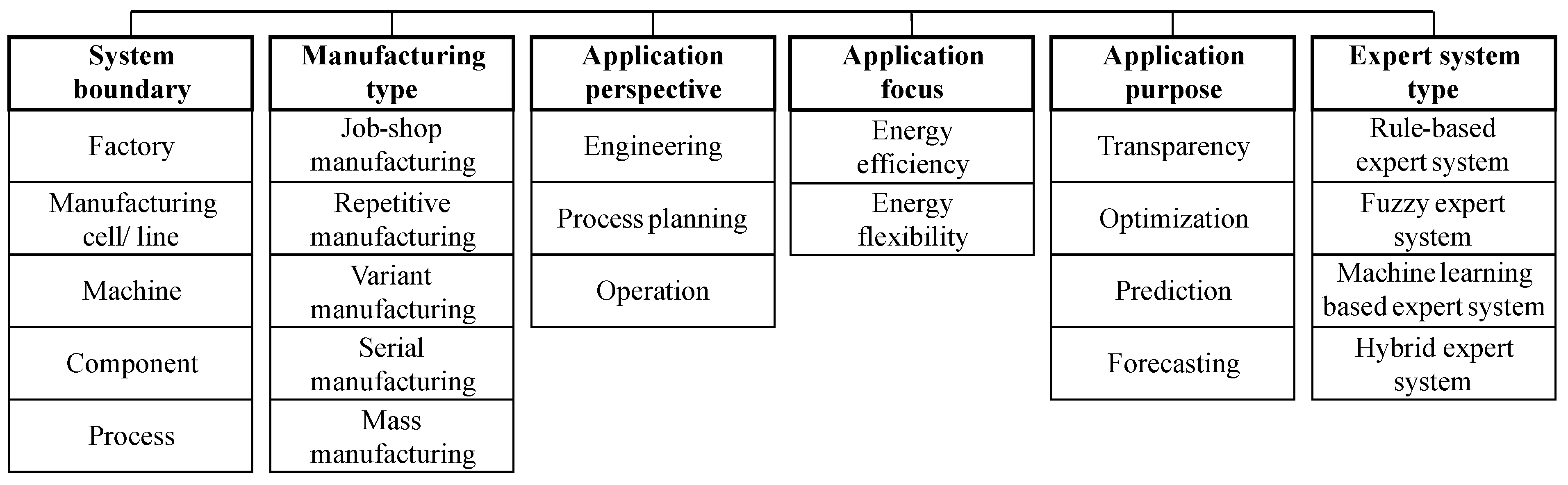

3.2.2. Inclusion and Exclusion Criteria

- IC-1 Studies written in English or German

- IC-2 Reviewed studies

- IC-3 Online full text availability

- IC-4 Empirical studies with a focus on ESs to improve energy efficiency in industry

- EC-1 Studies that do not meet the inclusion criteria

- EC-2 Duplicates

- EC-3 Excerpts from research results

- EC-4 Surveys or reviews (however, should they pertain to this review, they are integrated into Section 1 to address related work)

3.2.3. Keywords and Search Query String

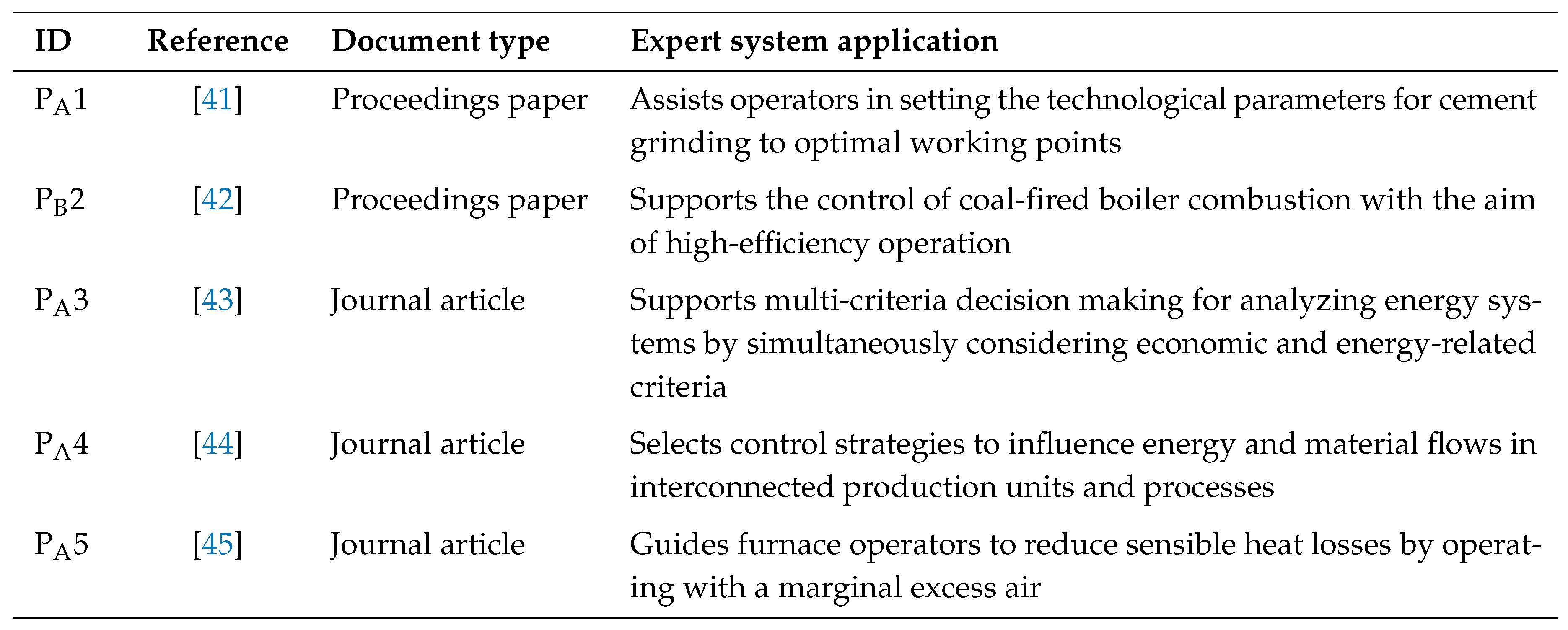

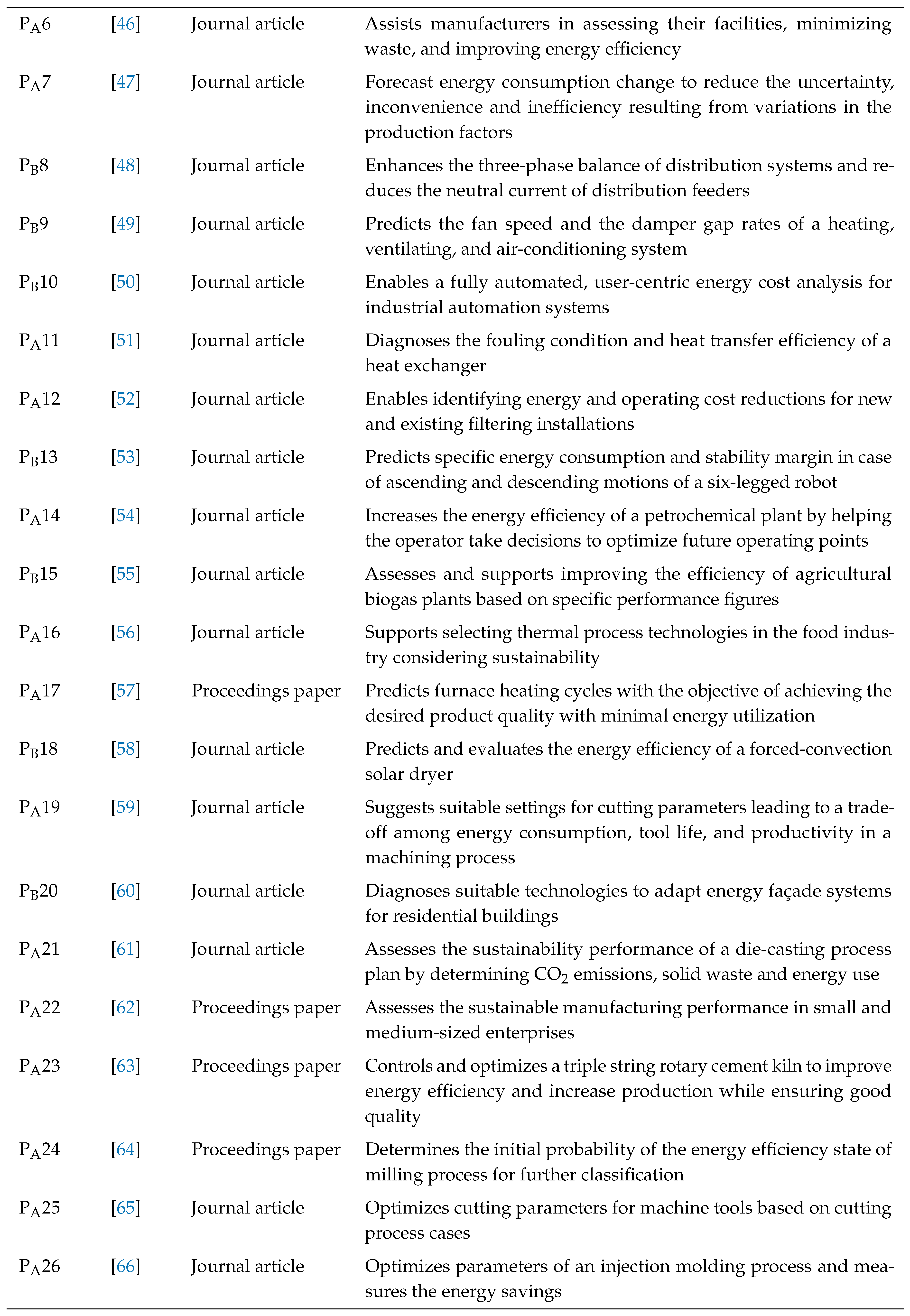

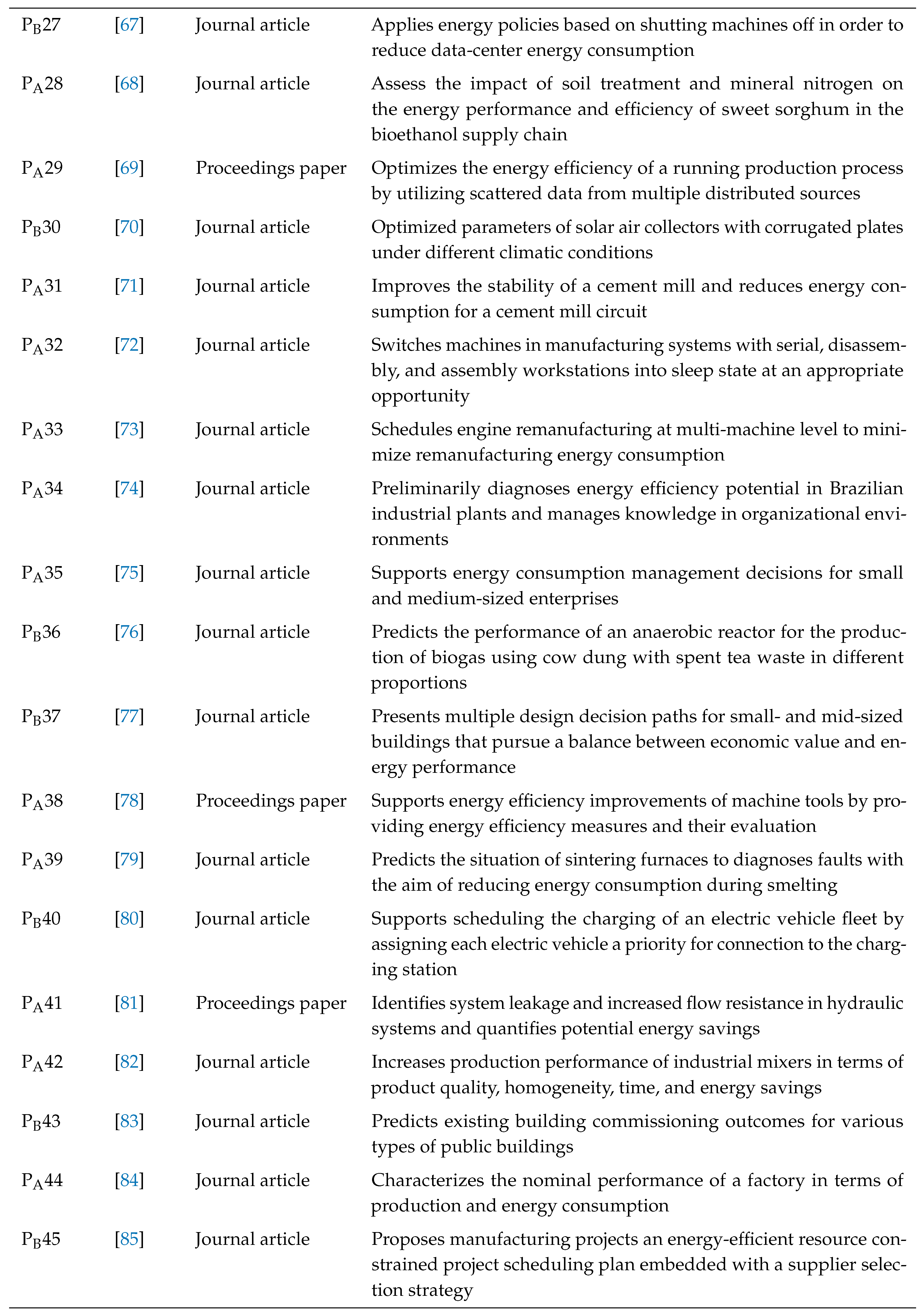

3.3. Search and Filter Literature

3.4. Literature Analysis and Synthesis

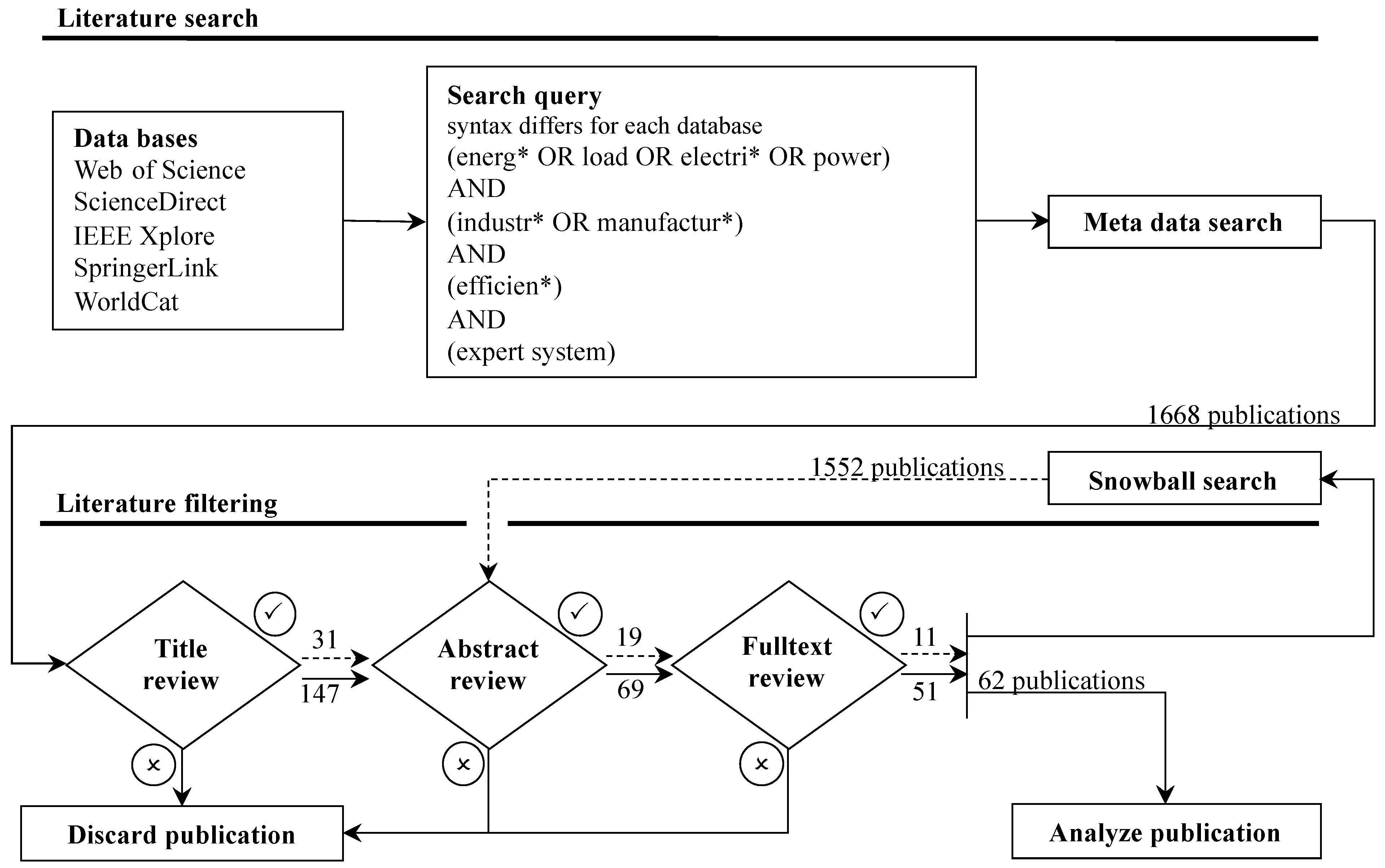

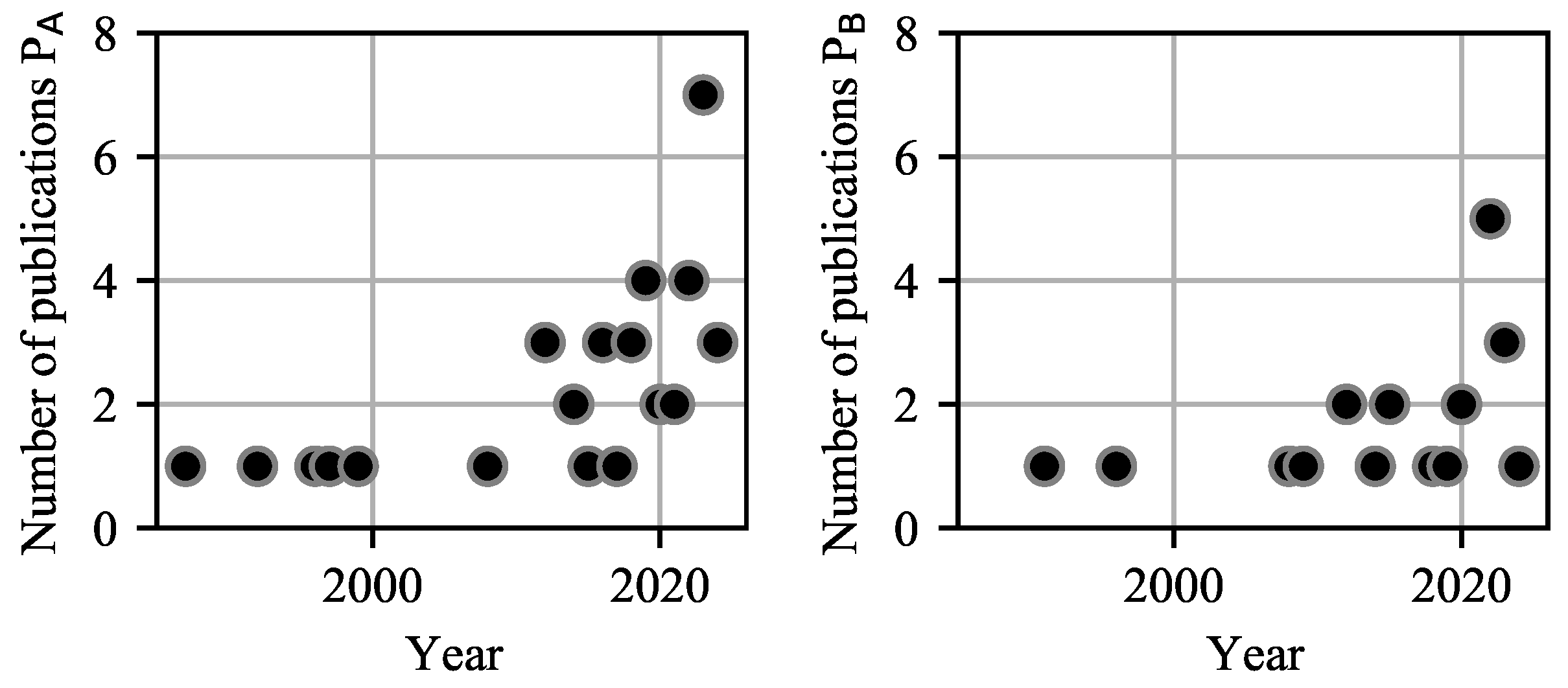

3.4.1. Data Sources and Publication Trend

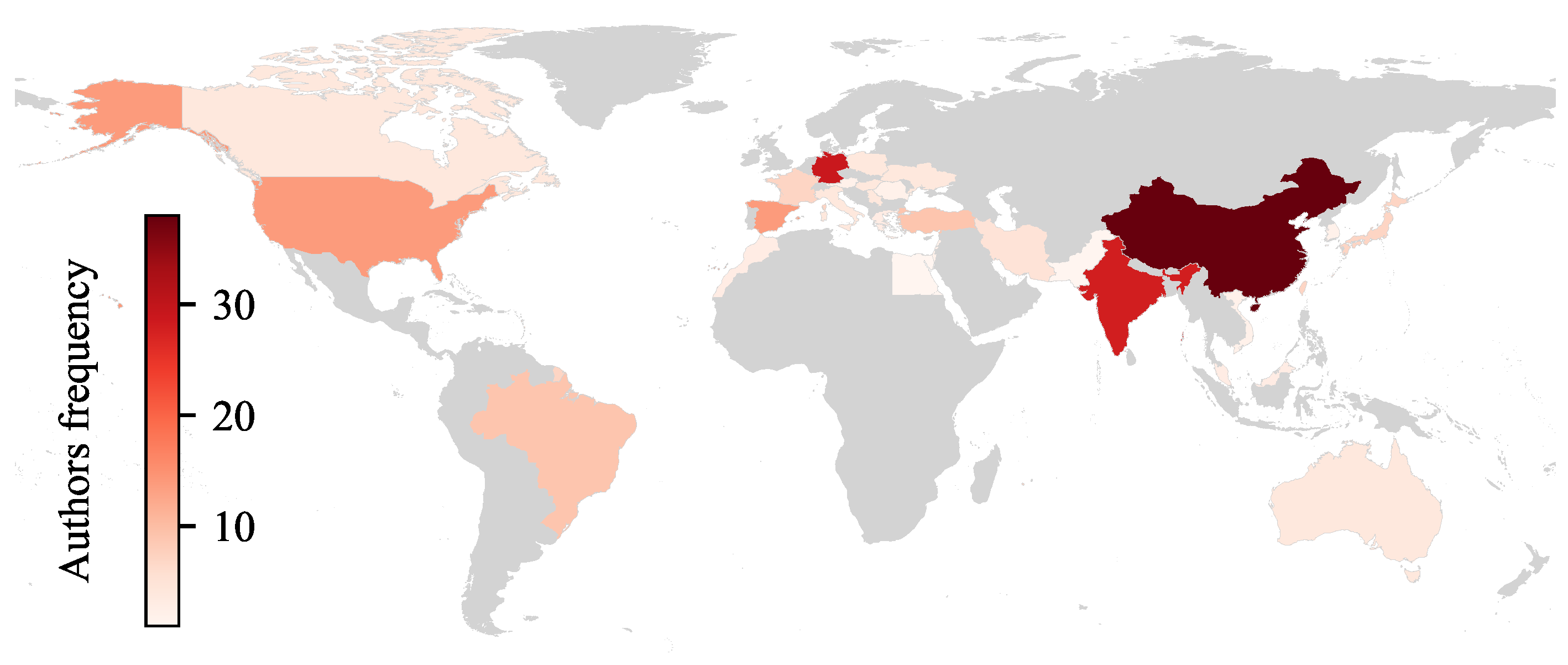

3.4.2. Authors Country Distribution

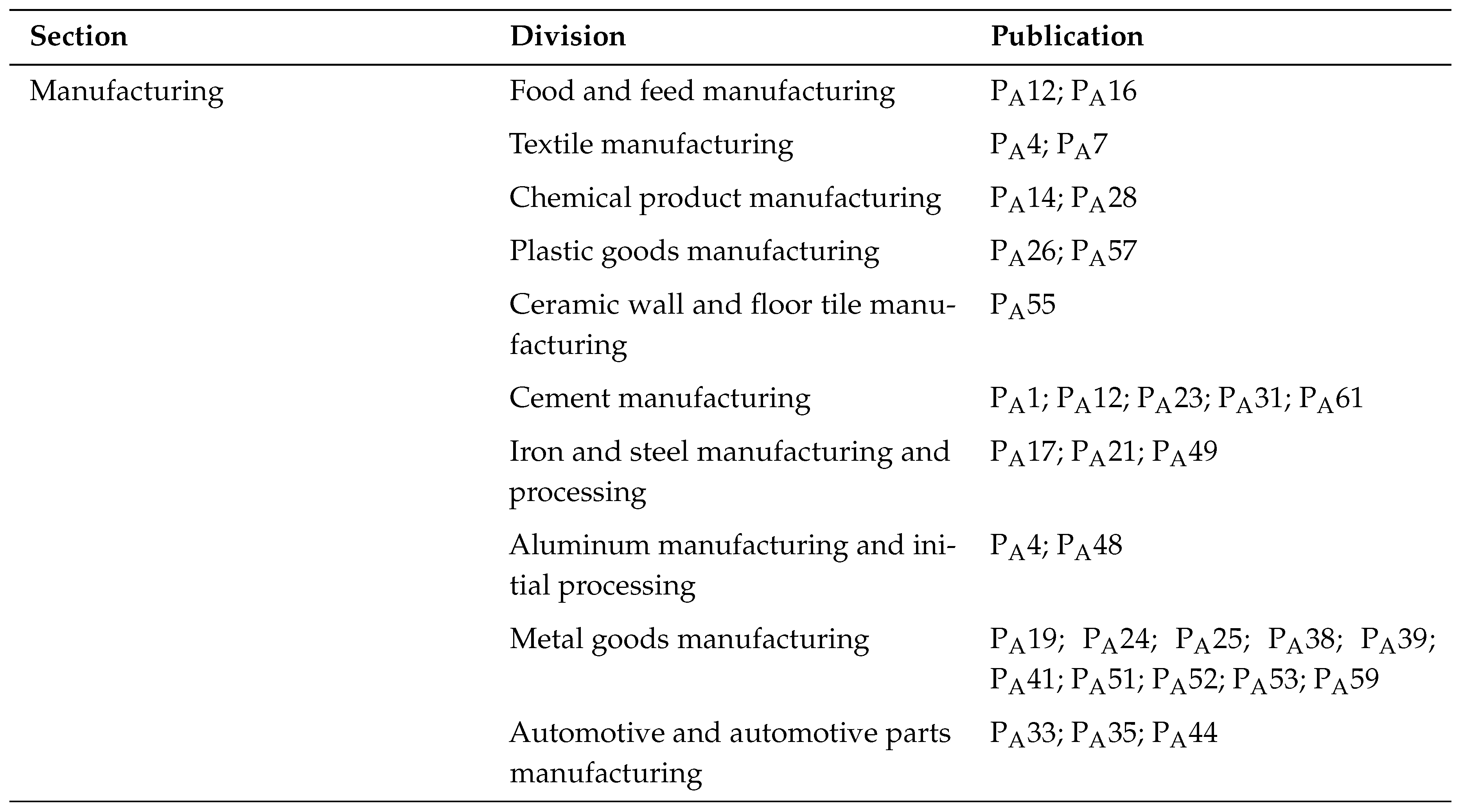

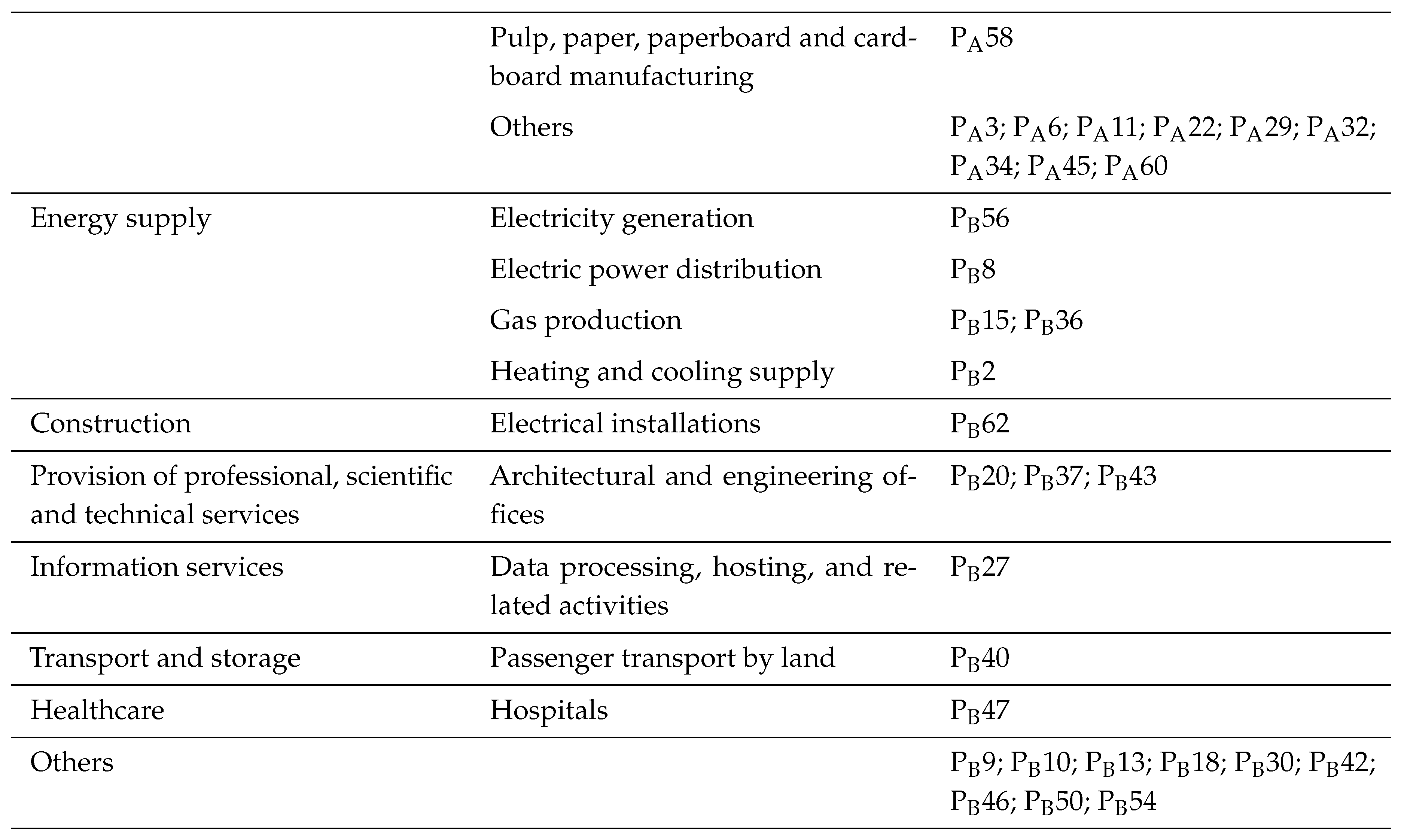

3.4.3. Literature Categorization

3.5. Identify Research Gaps

3.5.1. Classification of ESs by Industries

3.5.2. Utilizations of ESs in Industry

3.5.3. Structure and Implementations of ESs

3.5.4. Development of ESs for Industrial Applications

- Situation analysis: Create an overview of the situation and examine the problem to be solved [47].

- Creation of a knowledge base and knowledge representation: Knowledge is gathered and represented as described in subSection 3.5.3.

- Application and validation: The ES can be qualitatively validated via user interviews and quantitatively through case studies [83].

4. Conclusion

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AI | Artificial intelligence |

| ES | Expert system |

| EC | Exclusion criteria |

| IC | Inclusion criteria |

| ID | Identifier |

| ML | Machine learning |

| P | Publication |

| RQ | Research question |

| SLR | Systematic literature review |

References

- European Parliament, Council of the European Union. Regulation (EU) 2021/1119. https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32021R1119, accessed on 29.11.2024.

- Ritchie, H.; Roser, M.; Rosado, P. CO2 and Greenhouse Gas Emissions. https://ourworldindata.org/co2-and-greenhouse-gas-emissions, accessed on 27.07.2024.

- International Energy Agency. Key World Energy Statistics 2021. https://www.iea.org/reports/key-world-energy-statistics-2021/final-consumption, accessed on 27.07.2024.

- ABB Ltd. Accelerating Ambition: How global industry is speeding up investment in energy efficiency. https://www.energyefficiencymovement.com/wp-content/uploads/2022/04/ABB-Energy-Efficiency-Survey-Report-2022.pdf, accessed on 16.08.2024.

- Deutsches Institut für Normung, e.V. . Energy management systems – Requirements with guidance for use (ISO 50001:2018): German version EN ISO 50001:2018, 2018 ed.; Number 50001 in 03.100.70; 27.015, Beuth Verlag GmbH: Berlin, 2018. [Google Scholar]

- International Energy Agency. Energy Efficiency 2022. https://www.iea.org/reports/energy-efficiency-2022, accessed on 31.07.2024.

- International Energy Agency. Digitalization and Energy. https://www.iea.org/reports/digitalisation-and-energy, accessed on 06.11.2023.

- DeTore, A.W. An introduction to expert systems. Journal of insurance Medicine 1989, 21, 233–236. [Google Scholar]

- Ioshchikhes, B.; Elserafi, G.; Weigold, M. An Expert System-Based Approach For Improving Energy Efficiency Of Chamber Cleaning Machines. In Proceedings of the Conference on Production Systems and Logistics (CPSL 2023); publish-Ing.: Offenburg; 2023. [Google Scholar] [CrossRef]

- Jackson, P. Introduction to Expert Systems, 3rd ed.; Addison-Wesley Longman Publishing Co., Inc: USA, 1998. [Google Scholar]

- Ioshchikhes, B.; Frank, M.; Elserafi, G.; Magin, J.; Weigold, M. Developing Expert Systems for Improving Energy Efficiency in Manufacturing: A Case Study on Parts Cleaning. Energies 2024, 17, 3417. [Google Scholar] [CrossRef]

- Hassija, V.; Chamola, V.; Mahapatra, A.; Singal, A.; Goel, D.; Huang, K.; Scardapane, S.; Spinelli, I.; Mahmud, M.; Hussain, A. Interpreting Black-Box Models: A Review on Explainable Artificial Intelligence. Cognitive Computation 2024, 16, 45–74. [Google Scholar] [CrossRef]

- Liao, S.H. Expert system methodologies and applications—a decade review from 1995 to 2004. Expert Systems with Applications 2005, 28, 93–103. [Google Scholar] [CrossRef]

- Biel, K.; Glock, C.H. Systematic literature review of decision support models for energy-efficient production planning. Computers & Industrial Engineering 2016, 101, 243–259. [Google Scholar] [CrossRef]

- Wagner, W.P. Trends in expert system development: A longitudinal content analysis of over thirty years of expert system case studies. Expert Systems with Applications 2017, 76, 85–96. [Google Scholar] [CrossRef]

- Kumar, L.S.P. Knowledge-based expert system in manufacturing planning: state-of-the-art review. International Journal of Production Research 2019, 57, 4766–4790. [Google Scholar] [CrossRef]

- Piller, F.T. Einführung: Informationsrevolution und industrielle Produktion. In Mass Customization; Picot, A., Reichwald, R., Franck, E., Eds.; Springer Fachmedien Wiesbaden GmbH: Wiesbaden, 2006; pp. 1–9. [Google Scholar]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review. British Journal of Management 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Feak, C.B.; Swales, J.M. Telling a Research Story: Writing a Literature Review, 2 ed.; The University of Michigan Press: Ann Arbor, 2009. [Google Scholar] [CrossRef]

- Reynolds, N.; Simintiras, A.; Vlachou, E. International business negotiations. International Marketing Review 2003, 20, 236–261. [Google Scholar] [CrossRef]

- Glock, C.H.; Hochrein, S. Purchasing Organization and Design: A Literature Review. Business Research 2011, 4, 149–191. [Google Scholar] [CrossRef]

- Walther, J.; Weigold, M. A Systematic Review on Predicting and Forecasting the Electrical Energy Consumption in the Manufacturing Industry. Energies 2021, 14, 968. [Google Scholar] [CrossRef]

- Panten, N. Deep Reinforcement Learning zur Betriebsoptimierung hybrider industrieller Energienetze; Schriftenreihe des PTW: Innovation Fertigungstechnik, Shaker Verlag: Düren, 2019. [Google Scholar]

- vom Brocke, J.; Simons, A.; Niehaves, B.; Reimer, K.; Plattfaut, R.; Cleven, A. Reconstructing the giant: On the importance of rigour in documenting the literature search process. European Conference on Information Systems, 2009.

- Duflou, J.R.; Sutherland, J.W.; Dornfeld, D.; Herrmann, C.; Jeswiet, J.; Kara, S.; Hauschild, M.; Kellens, K. Towards energy and resource efficient manufacturing: A processes and systems approach. CIRP Annals 2012, 61, 587–609. [Google Scholar] [CrossRef]

- Westkämper, E. Einführung in die Organisation der Produktion; Springer-Lehrbuch, Springer: Berlin and Heidelberg, 2006. [Google Scholar]

- Weck, M. Werkzeugmaschinen 4; Springer Berlin Heidelberg: Berlin, Heidelberg, 2006. [Google Scholar] [CrossRef]

- Kara, S.; Bogdanski, G.; Li, W. Electricity Metering and Monitoring in Manufacturing Systems. In Glocalized Solutions for Sustainability in Manufacturing; Hesselbach, J., Herrmann, C., Eds.; Springer Berlin Heidelberg: Berlin, Heidelberg, 2011; pp. 1–10. [Google Scholar]

- International Organization for Standardization. Machine tools - Environmental evaluation of machine tools - Part 1: Design methodology for energy-efficient machine tools, 2017 ed.; International Organization for Standardization,: Geneva, 2017. [Google Scholar]

- Verein Deutscher Ingenieure, e.V. Energy-flexible factory: Fundamentals; Number 5207-1 in 91.120.10, VDI-Gesellschaft Produktion und Logistik (GPL): Düsseldorf, 2020. [Google Scholar]

- Ongsulee, P. Artificial intelligence, machine learning and deep learning. 2017 15th International Conference on ICT and Knowledge Engineering (ICT&KE), 2017, pp. 1–6. [CrossRef]

- Posselt, G. Towards Energy Transparent Factories; Springer International Publishing: Cham, 2016. [Google Scholar]

- Box, G.E.P.; Jenkins, G.M.; Reinsel, G.C.; Ljung, G.M. Time Series Analysis: Forecasting and Control, 5th Edition, 5 ed.; John Wiley and Sons Inc.: Hoboken, New Jersey, 2015. [Google Scholar]

- dos Santos, S.B.A.; Soares, J.M.; Barroso, G.C.; Prata, B.d.A. Demand response application in industrial scenarios: A systematic mapping of practical implementation. Expert Systems with Applications 2023, 215, 119393. [Google Scholar] [CrossRef]

- Solnørdal, M.; Foss, L. Closing the Energy Efficiency Gap—A Systematic Review of Empirical Articles on Drivers to Energy Efficiency in Manufacturing Firms. Energies 2018, 11, 518. [Google Scholar] [CrossRef]

- Clarivate. Web of Science. https://www.webofscience.com/wos/woscc/basic-search, accessed on 08.08.2024.

- Elsevier. ScienceDirect. https://www.sciencedirect.com/, accessed on 08.08.2024.

- IEEE. IEEE Xplore. https://ieeexplore.ieee.org, accessed on 08.08.2024.

- SpringerNature. SpringerLink. https://link.springer.com/, accessed on 08.08.2024.

- OCLC. WorldCat. https://www.worldcat.org, accessed on 08.08.2024.

- Keviczky, L.; Bányász, C.; Haber, R.; Hilger, M. Cemexpert: An Expert System for the Cement Grinding Process. IFAC Proceedings Volumes 1987, 20, 157–162. [Google Scholar] [CrossRef]

- Miyayama, T.; Tanaka, S.; Miyatake, T.; Umeki, T.; Miyamoto, Y.; Nishino, K.; Harada, E. A combustion control support expert system for a coal-fired boiler. Proceedings IECON ’91: 1991 International Conference on Industrial Electronics, Control and Instrumentation, 1991, pp. 1513–1516 vol.2. [CrossRef]

- Zhu, M.S.; Wang, B.X.; Xiao, Y.H. A multi-criteria decision making procedure for the analysis of an energy system. Journal of Thermal Science 1992, 1, 221–225. [Google Scholar] [CrossRef]

- Tuma, A.; Haasis, H.D.; Rentz, O. Development of emission orientated production control strategies using fuzzy expert systems, neural networks and neuro-fuzzy approaches. FUZZY SETS AND SYSTEMS 1996, 77, 255–264. [Google Scholar] [CrossRef]

- Kontopoulos, A.; Krallis, K.; Koukourakis, E.; Denaxas, N.; Kostis, N.; Broussaud, A.; Guyot, O. A hybrid, knowledge-based system as a process control `tool’ for improved energy efficiency in alumina calcining furnaces. APPLIED THERMAL ENGINEERING 1997, 17, 935–945. [Google Scholar] [CrossRef]

- Dunning, S.; Segee, B.; Allen, V. A Self-Assessment Software Application for Industrial Manufacturers. Energy Engineering 1999, 96, 70–77. [Google Scholar] [CrossRef]

- Lau, H.; Cheng, E.; Lee, C.; Ho, G. A fuzzy logic approach to forecast energy consumption change in a manufacturing system. Expert Systems with Applications 2008, 34, 1813–1824. [Google Scholar] [CrossRef]

- Lin, C.H.; Chen, C.S.; Chuang, H.J.; Huang, M.Y.; Huang, C.W. An Expert System for Three-Phase Balancing of Distribution Feeders. IEEE Transactions on Power Systems 2008, 23, 1488–1496. [Google Scholar]

- Soyguder, S.; Alli, H. Predicting of fan speed for energy saving in HVAC system based on adaptive network based fuzzy inference system. Expert Systems with Applications 2009, 36, 8631–8638. [Google Scholar] [CrossRef]

- Beck, A.; Göhner, P. An approach for model-based energy cost analysis of industrial automation systems. Energy Efficiency 2012, 5, 303–319. [Google Scholar] [CrossRef]

- Garcia, R.F. Improving heat exchanger supervision using neural networks and rule based techniques. Expert Systems with Applications 2012, 39, 3012–3021. [Google Scholar] [CrossRef]

- Klein, G.M.; Schrooten, T.; Neuhaus, T. Reduction of Energy Demand for Industrial Dedusting Plants. Chemie Ingenieur Technik 2012, 84, 1121–1129. [Google Scholar] [CrossRef]

- Roy, S.S.; Pratihar, D.K. Soft computing-based approaches to predict energy consumption and stability margin of six-legged robots moving on gradient terrains. Applied Intelligence 2012, 37, 31–46. [Google Scholar] [CrossRef]

- Monedero, I.; Biscarri, F.; León, C.; I. Guerrero, J.; González, R.; Pérez-Lombard, L. Decision system based on neural networks to optimize the energy efficiency of a petrochemical plant. Expert Systems with Applications 2012, 39, 9860–9867. [Google Scholar] [CrossRef]

- Djatkov, D.; Effenberger, M.; Martinov, M. Method for assessing and improving the efficiency of agricultural biogas plants based on fuzzy logic and expert systems. Applied Energy 2014, 134, 163–175. [Google Scholar] [CrossRef]

- Do, T.T.H.; Schnitzer, H.; Le, T.H. A decision support framework considering sustainability for the selection of thermal food processes. JOURNAL OF CLEANER PRODUCTION 2014, 78, 112–120. [Google Scholar] [CrossRef]

- Mitra, S.; Singh, R.K.; Mondal, A.K. An Expert System Based Process Control System for Silicon Steel Mill Furnace of Rourkela Steel Plant. 2014 Fourth International Conference of Emerging Applications of Information Technology, 2014, pp. 29–33. [CrossRef]

- Bagheri, N.; Tarabi, N.; Javadikia, H. Development and evaluation of an adaptive neuro-fuzzy interface models to predict performance of a solar dryer. Agricultural Engineering International : The CIGR e-journal 2015, 17, 112–121. [Google Scholar]

- Iqbal, A.; Zhang, H.C.; Kong, L.L.; Hussain, G. A rule-based system for trade-off among energy consumption, tool life, and productivity in machining process. JOURNAL OF INTELLIGENT MANUFACTURING 2015, 26, 1217–1232. [Google Scholar] [CrossRef]

- Ochoa, C.E.; Capeluto, I.G. Decision methodology for the development of an expert system applied in an adaptable energy retrofit façade system for residential buildings. Renewable Energy 2015, 78, 498–508. [Google Scholar] [CrossRef]

- Singh, P.P.; Madan, J. A computer-aided system for sustainability assessment for the die-casting process planning. The International Journal of Advanced Manufacturing Technology 2016, 87, 1283–1298. [Google Scholar] [CrossRef]

- Singh, S.; Olugu, E.U.; Musa, S.N. Development of Sustainable Manufacturing Performance Evaluation Expert System for Small and Medium Enterprises. Procedia CIRP 2016, 40, 608–613. [Google Scholar] [CrossRef]

- Teja, R.; Sridhar, P.; Guruprasat, M. Control and Optimization of a Triple String Rotary Cement Kiln using Model Predictive Control. IFAC-PapersOnLine 2016, 49, 748–753. [Google Scholar] [CrossRef]

- Cai, Y.; Shao, H. (Eds.) Energy Efficiency State Identification in Milling Processing Based on Improved HMM, Vol. Volume 2: Additive Manufacturing; Materials, International Manufacturing Science and Engineering Conference, 2017. [CrossRef]

- Deng, Z.; Zhang, H.; Yahui, F.; Wan, L.; Lv, L. Research on intelligent expert system of green cutting process and its application. JOURNAL OF CLEANER PRODUCTION 2018, 185, 904–911. [Google Scholar] [CrossRef]

- Cheng, C.C.; Liu, K.W. Optimizing energy savings of the injection molding process by using a cloud energy management system. Energy Efficiency 2018, 11, 415–426. [Google Scholar] [CrossRef]

- Fernández-Cerero, D.; Fernández-Montes, A.; Ortega, J.A. Energy policies for data-center monolithic schedulers. Expert Systems with Applications 2018, 110, 170–181. [Google Scholar] [CrossRef]

- Garofalo, P.; Campi, P.; Vonella, A.V.; Mastrorilli, M. Application of multi-metric analysis for the evaluation of energy performance and energy use efficiency of sweet sorghum in the bioethanol supply-chain: A fuzzy-based expert system approach. Applied Energy 2018, 220, 313–324. [Google Scholar] [CrossRef]

- Burow, K.; Franke, M.; Deng, Q.; Hribernik, K.; Thoben, K.D. Sustainable Data Management for Manufacturing. 2019 IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC), 2019, pp. 1–5. [CrossRef]

- Debnath, S.; Reddy, J.; Jagadish. ; Das, B. An expert system-based modeling and optimization of corrugated plate solar air collector for North Eastern India. Journal of the Brazilian Society of Mechanical Sciences and Engineering 2019, 41. [Google Scholar] [CrossRef]

- Simmons, A.; Sarao, G.; Campain, D. A Cement Mill Upgrade Story Reboot. 2019 IEEE-IAS/PCA Cement Industry Conference (IAS/PCA), 2019, pp. 1–8. [CrossRef]

- Wang, J.; Fei, Z.; Chang, Q.; Li, S.; Fu, Y. Multi-state decision of unreliable machines for energy-efficient production considering work-in-process inventory. INTERNATIONAL JOURNAL OF ADVANCED MANUFACTURING TECHNOLOGY 2019, 102, 1009–1021. [Google Scholar] [CrossRef]

- Zhao, J.; Peng, S.; Li, T.; Lv, S.; Li, M.; Zhang, H. Energy-aware fuzzy job-shop scheduling for engine remanufacturing at the multi-machine level. Frontiers of Mechanical Engineering 2019, 14, 474–488. [Google Scholar] [CrossRef]

- Buccieri, G.P.; Balestieri, J.A.P.; Matelli, J.A. Energy efficiency in Brazilian industrial plants: knowledge management and applications through an expert system. JOURNAL OF THE BRAZILIAN SOCIETY OF MECHANICAL SCIENCES AND ENGINEERING 2020, 42. [Google Scholar] [CrossRef]

- Grigoras, G.; Neagu, B.C. An Advanced Decision Support Platform in Energy Management to Increase Energy Efficiency for Small and Medium Enterprises. APPLIED SCIENCES-BASEL 2020, 10. [Google Scholar] [CrossRef]

- Khayum, N.; Rout, A.; Deepak, B.B.V.L.; Anbarasu, S.; Murugan, S. Application of Fuzzy Regression Analysis in Predicting the Performance of the Anaerobic Reactor Co-digesting Spent Tea Waste with Cow Manure. Waste and Biomass Valorization 2020, 11, 5665–5678. [Google Scholar] [CrossRef]

- Kim, S.H.; Nam, J. Can Both the Economic Value and Energy Performance of Small- and Mid-Sized Buildings Be Satisfied? Development of a Design Expert System in the Context of Korea. Sustainability 2020, 12, 4946. [Google Scholar] [CrossRef]

- Petruschke, L.; Elserafi, G.; Ioshchikhes, B.; Weigold, M. Machine learning based identification of energy efficiency measures for machine tools using load profiles and machine specific meta data. MM Science Journal 2021, 2021, 5061–5068. [Google Scholar] [CrossRef]

- Qu, N.; You, W. Design and fault diagnosis of DCS sintering furnace’s temperature control system for edge computing. PloS one 2021, 16, e0253246. [Google Scholar] [CrossRef]

- Davydenko, L.; Davydenko, N.; Bosak, A.; Bosak, A.; Deja, A.; Dzhuguryan, T. Smart Sustainable Freight Transport for a City Multi-Floor Manufacturing Cluster: A Framework of the Energy Efficiency Monitoring of Electric Vehicle Fleet Charging. Energies 2022, 15, 3780. [Google Scholar] [CrossRef]

- Ioshchikhes, B.; Borst, F.; Weigold, M. Assessing Energy Efficiency Measures for Hydraulic Systems using a Digital Twin. Procedia CIRP 2022, 107, 1232–1237. [Google Scholar] [CrossRef]

- Kalayci, O.; Pehlivan, I.; Coskun, S. Improving the performance of industrial mixers that are used in agricultural technologies via chaotic systems and artificial intelligence techniques. TURKISH JOURNAL OF ELECTRICAL ENGINEERING AND COMPUTER SCIENCES 2022, 30, 2418–2432. [Google Scholar] [CrossRef]

- Li, P.; Lu, Y.; Qian, Y.; Wang, Y.; Liang, W. An explanatory parametric model to predict comprehensive post-commissioning building performances. Building and Environment 2022, 213, 108897. [Google Scholar] [CrossRef]

- Mendia, I.; Gil-Lopez, S.; Grau, I.; Del Ser, J. A novel approach for the detection of anomalous energy consumption patterns in industrial cyber–physical systems. Expert Systems 2022. [Google Scholar] [CrossRef]

- Rahman, H.F.; Chakrabortty, R.K.; Elsawah, S.; Ryan, M.J. Energy-efficient project scheduling with supplier selection in manufacturing projects. Expert Systems with Applications 2022, 193, 116446. [Google Scholar] [CrossRef]

- Rahmati, A.H.; Nikbakht, A.M. Fuzzy-based modeling of thermohydraulic aspect of solar air heater roughened with inclined broken roughness. Neural Computing and Applications 2022, 34, 2393–2412. [Google Scholar] [CrossRef]

- Taleb, H.; Nasser, A.; Andrieux, G.; Charara, N.; Cruz, E.M. Energy Consumption Improvement of a Healthcare Monitoring System: Application to LoRaWAN. IEEE Sensors Journal 2022, 22, 7288–7299. [Google Scholar] [CrossRef]

- Wang, X.l.; Lu, M.y.; Wei, S.m.; Xie, Y.f. Multi-objective optimization based optimal setting control for industrial double-stream alumina digestion process. Journal of Central South University 2022, 29, 173–185. [Google Scholar] [CrossRef]

- Choudhury, B.; Chandrasekaran, M. Electron Beam Welding Investigation of Inconel 825 and Optimize Energy Consumption Using Integrated Fuzzy Logic-Particle Swarm Optimization Approach. International Journal of Fuzzy Systems 2023, 25, 1377–1399. [Google Scholar] [CrossRef]

- Duman, E.; Seckin, D. Enhancing the efficiency of cabin heaters in emergency shelters after earthquakes through an optimized fuzzy controller. Building Simulation 2023, 16, 1759–1776. [Google Scholar] [CrossRef]

- Wang, J.; Tian, Y.; Hu, X.; Fan, Z.; Han, J.; Liu, Y. Development of grinding intelligent monitoring and big data-driven decision making expert system towards high efficiency and low energy consumption: experimental approach. JOURNAL OF INTELLIGENT MANUFACTURING 2023. [Google Scholar] [CrossRef]

- Perera, J.C.; Gopalakrishnan, B.; Bisht, P.S.; Chaudhari, S.; Sundaramoorthy, S. A Sustainability-Based Expert System for Additive Manufacturing and CNC Machining. Sensors (Basel, Switzerland) 2023, 23. [Google Scholar] [CrossRef] [PubMed]

- Reddy, J.; Jagadish. ; Das, B.; Debnath, S. Experimental investigation and optimization of sand-coated solar air collector parameters by fuzzy-MCDM integrated decision approach. Journal of Thermal Analysis and Calorimetry 2023, 148, 5543–5556. [Google Scholar] [CrossRef]

- Banadkouki, M.R.Z. Selection of strategies to improve energy efficiency in industry: A hybrid approach using entropy weight method and fuzzy TOPSIS. Energy 2023, 279, 128070. [Google Scholar] [CrossRef]

- Ilić, D.; Žarković, M. Machine learning for power generator condition assessment. Electrical Engineering 2023, 106, 2691–2703. [Google Scholar] [CrossRef]

- Mohamed, E.G.; Ahmed, M.; Redouane, M. Smart Energy Consumption Control System While Respecting the Quality of the Injection Molded Product. 2023 3rd International Conference on Innovative Research in Applied Science, Engineering and Technology (IRASET). IEEE, 2023, pp. 1–6.

- Nadim, K.; Ouali, M.S.; Ghezzaz, H.; Ragab, A. Learn-to-supervise: Causal reinforcement learning for high-level control in industrial processes. Engineering Applications of Artificial Intelligence 2023, 126, 106853. [Google Scholar] [CrossRef]

- Lourenço, G.; de Arruda, G.T.; La Correia de Rosa, V.E.; Castoldi, M.F.; Goedtel, A.; de Souza, W.A. Three-Phase Induction Motor Electrical Parameter Estimation Using Artificial Neural Networks. 2024 International Symposium on Power Electronics, Electrical Drives, Automation and Motion (SPEEDAM). IEEE, 2024, pp. 883–888. [CrossRef]

- Pawuś, D.; Paszkiel, S. Identification and Expert Approach to Controlling the Cement Grinding Process Using Artificial Neural Networks and Other Non-Linear Models. IEEE Access 2024, 12, 26364–26383. [Google Scholar] [CrossRef]

- Sharma, M.; Pareek, S.; Singh, K. An efficient power extraction using artificial intelligence based machine learning model for SPV array reconfiguration in solar industries. Engineering Applications of Artificial Intelligence 2024, 129, 107516. [Google Scholar] [CrossRef]

- Statistisches Bundesamt. Klassifikation der Wirtschaftszweige 2008 (WZ 2008). https://www.destatis.de/DE/Methoden/Klassifikationen/Gueter-Wirtschaftsklassifikationen/Downloads/klassifikation-wz-2008-3100100089004-aktuell.pdf?__blob=publicationFile, accessed on 18.06.2024.

- Wehking, K.H.; Albrecht, W.; Becker, J.; Hager, H.J.; Kille, C.; Popp, J.; Scherner, T.; Yousefifar, R. Technisches Handbuch Logistik; Springer Vieweg: Berlin and Heidelberg, 2020. [Google Scholar]

- Quinn, K. Expert system shells: What to look for. Reference Services Review 1990, 18, 83–86. [Google Scholar] [CrossRef]

| Database | Search query | Number of results |

|---|---|---|

| Web of Science | ((TS=(energ*) OR TS=(load) OR TS=(electri*) OR TS=(power)) AND (TS=(industr*) OR TS=(manufactur*)) AND (TS=(efficien*)) AND (TS=(expert system))) | 817 |

| ScienceDirect | (energy OR load OR electricity OR power) AND (industry OR manufacturing) AND (efficiency) AND (expert system) | 128 |

| IEEE Xplore | ("All Metadata": energ* OR load OR electri* OR power) AND ("All Metadata": industr* OR manufactur*) AND ("All Metadata": efficien*) AND ("All Metadata": expert system) | 139 |

| SpringerLink | ("energy efficiency") AND (industr* OR manufactur*) AND ("expert system") | 270 |

| WorldCat | (energy efficiency) AND (industr* OR manufactur*) AND ("expert system") | 314 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).