1. Introduction

Coal and gas outburst constitutes the most severe coal mining disasters in China. According to data from the National Mine Safety Supervision Bureau as of the beginning of 2022, a total of eight accidents of coal and gas outburst have occurred in the past two years in provinces such as Guizhou, Yunnan, Shanxi, Shaanxi, Heilongjiang, and Henan. These accidents resulted in 44 fatalities and significant economic losses [

1]. Most of the accidents occurred in the roadway excavation after a regional prevention completed. Notable incidents include a gas outburst on March 25, 2021, in the excavation roadway of the Shanxi Shigang coal mine, which claimed four lives. On June 4, 2021, eight fatalities were recorded in a gas outburst accident in the excavation roadway at Hebi No. 6 Mine in Henan. Additionally, on March 2, 2022, eight individuals lost their lives in an outburst accident in excavation roadway at the Limin coal mine in Guizhou. Thus, developing efficient technologies for secondary outburst prevention remains an ongoing and long-term scientific and technology challenge for the Chinese coal industry [

2,

3,

4], particularly as mining operations is going deeper and deeper. Recognizing this urgency, the National Mine Safety Supervision Bureau has issued a notice emphasizing the need to strengthen the identification of outburst hazards, enhance gas geological exploration, improve gas pre-drainage techniques, and implement comprehensive gas control measures [

1]. These directives are of paramount importance in ensuring the safety of coal mining production in China.

Extensive theoretical exploration and technological research have been conducted in China regarding gas outburst prevention and control, resulting in the development of various effective prevention technologies [

5,

6,

7,

8,

9].Currently, there are several widely applied technologies that include mining liberation layer, gas pre-drainage underlying roadway GPDUR [

10,

11], dense borehole gas drainage technology [

12,

13], hydraulic fracturing [

14,

15,

16], hydraulic punching [

17,

18], water jet [

19,

20] and hydraulic slotting technologies [

21,

22]. Among these, GPDUR has gained common adoption and achieved favorable outcomes in the mining areas such as Huainan, Huaibei, Pingdingshan, Zhengzhou, and Jiaozuo [

23,

24,

25,

26]. However, in coal seams characterized by complex geological conditions, tectonically deformed coal (TDC) development, and severe gas outbursts, combined with limited mining intervals and short drainage durations, the GPDUR may result in inadequate drainage or uneven effectiveness in preventing outbursts. Even when gas content meets the standards, there can still be significant outburst hazards in specific local sections. For instance, the 3 gas outburst accidents mentioned in reference occurred during tunneling excavation after GPDUR, resulting in many fatalities [

27]. Under such circumstances, the research and development of universally applicable secondary outburst prevention technologies hold practical importance and prospects for broader implementation.

The Yuxi Coal Mine of Shanxi Lanhua Group, has implemented GPDUR techniques as precautionary measures against gas-related hazards in the initial working face 1301 of the coal mine. Following a drainage period of one year, tests conducted at 33 locations revealed an average residual gas content of 4.3 m

3/t and a maximum content of 7.40 m

3/t, indicating the absence of gas outburst risks in the region based on the national standard. However, during subsequent coal roadway tunneling, abnormal gas emission or small-scale outbursts occurred on multiple occasions. The gas outburst parameter

K1 consistently surpassed the standard limit, resulting in sluggish tunneling progress and severe hindrance to safe and efficient mining operations. To prevent coal and gas outburst accidents, a joint research team conducted studies and industrial trials on CO

2-Frac technology during tunneling. Leveraging previous theoretical research outcomes on CO

2-Frac for outburst prevention [

28,

29,

30,

31] and numerous successful practical cases [

32,

33,

34], this study amalgamated field experiments and technological optimization, resulting in the innovative development of a dual borehole and high-pressure CO

2-Frac and established the efficient secondary outburst prevention and safe tunneling technology model. This model effectively diminishes the

K1 value, eradicates abnormal gas emission and outbursts, and ensures the secure and rapid tunneling of the coal mine. The application of this technology model holds significant universal significance for secondary outburst prevention and safe mining in coal seams prone to intense outbursts, thus making it suitable for widespread promotion and implementation.

2. Research Background

2.1. Engineering Background

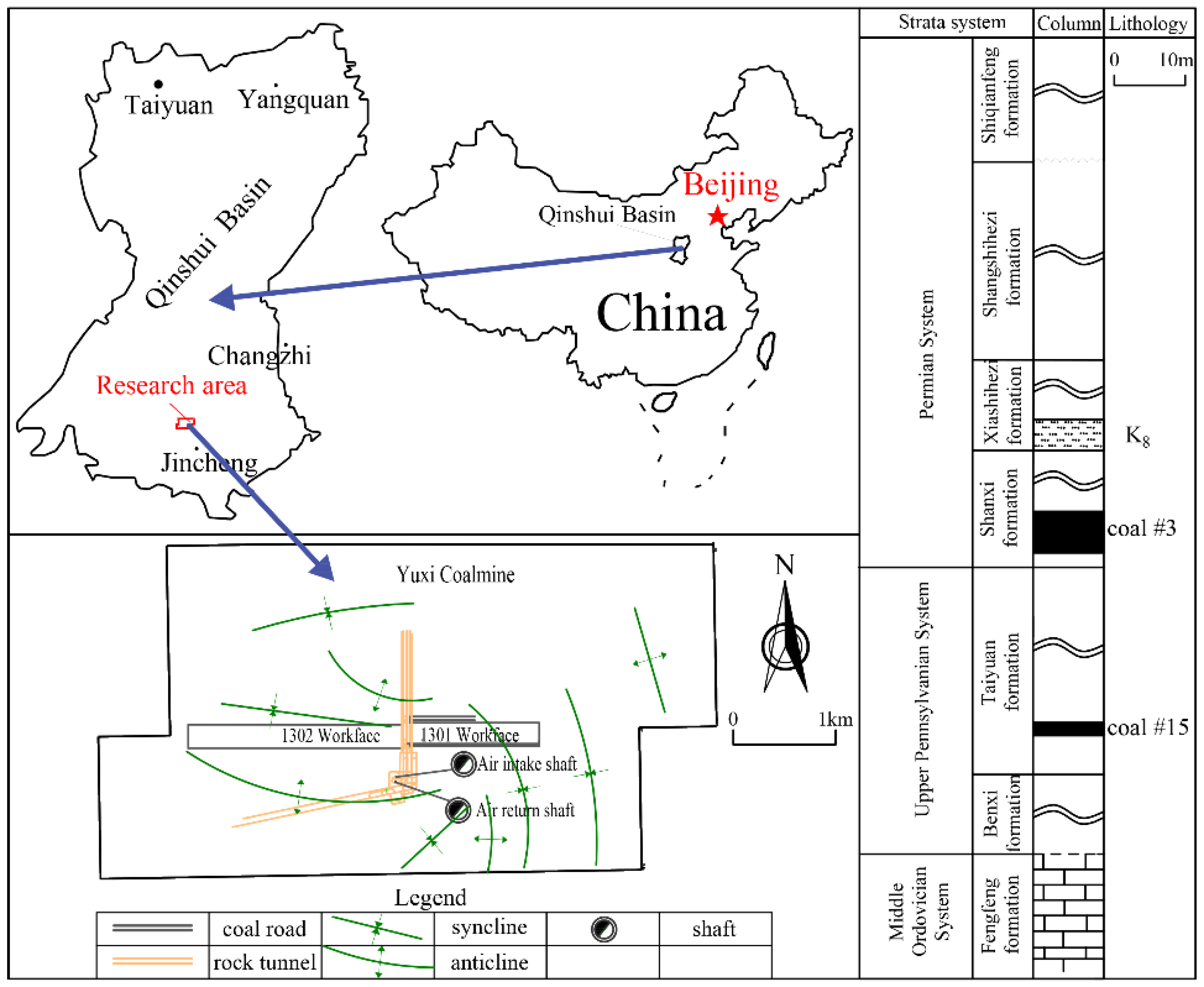

Yuxi Coal Mine is situated in Qinshui County in the southern region of the Qinshui Basin. The mining area is 26.147 km

2 and has a designed production capacity of 2.40 million tons per annum (Mt/a), with an expected operational lifespan of 41.7 a. The primary coal seam currently being extracted is the No. 3 coal seam in the Shanxi Formation (

Figure 1). The coal is classified as No. 3 anthracite, and quality parameters is detailed in

Table 1.

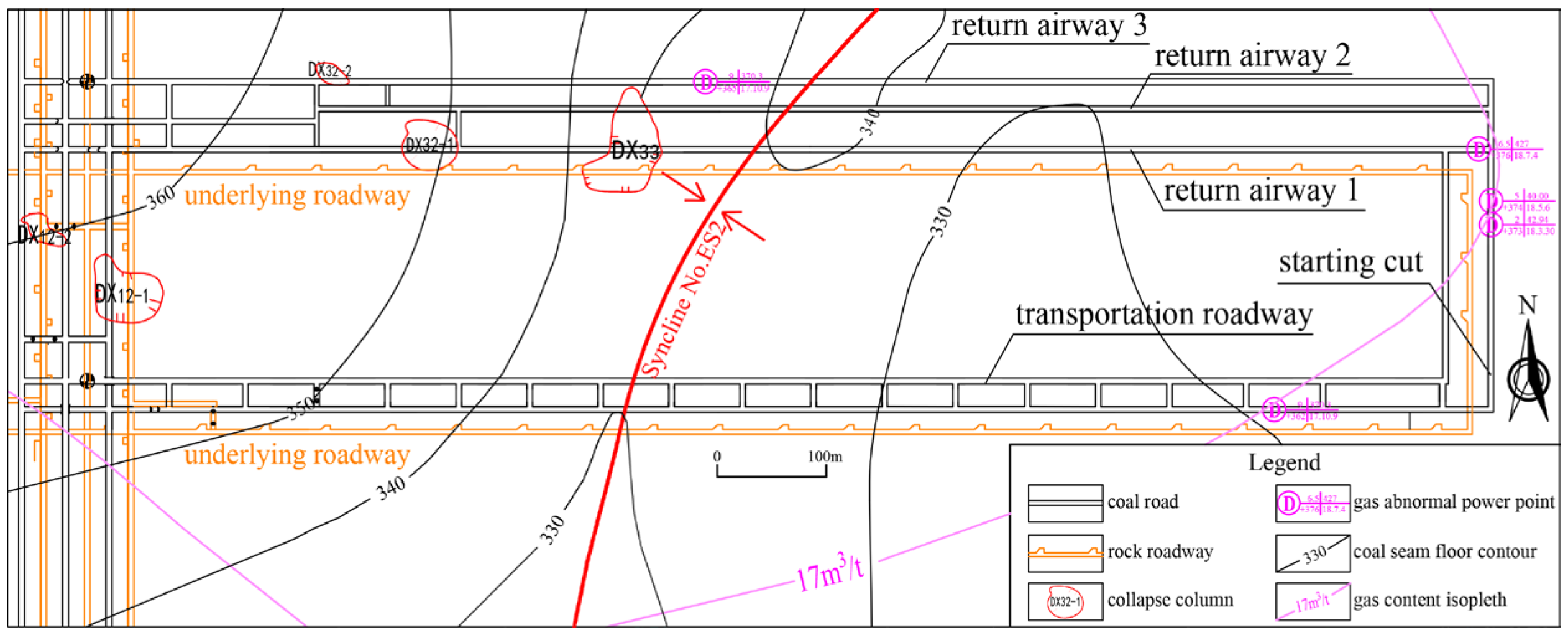

The 1301 working face serves as the initial mining area within Yuxi Mine, spanning 1250 m in strike length and 200 m in dip length. The geology of this working face exhibits relative simplicity, positioned on a large reginal monocline that dips towards the west at an angle of 3-6°. There are few of faults, although collapse column has been well developed (

Figure 1). Considering the high gas content, the ventilation system comprises two intakes and three returns airways, as depicted in

Figure 2. The roadway heading dimension is of 3.8 m in height and 5.8 m in width. As part of the initial preparations, two GPDUR have been completed, utilizing drilling and pre-drainage techniques to mitigate gas outbursts and prioritize safety (

Figure 2).

2.2. Coal Mine Gas Geological Properties

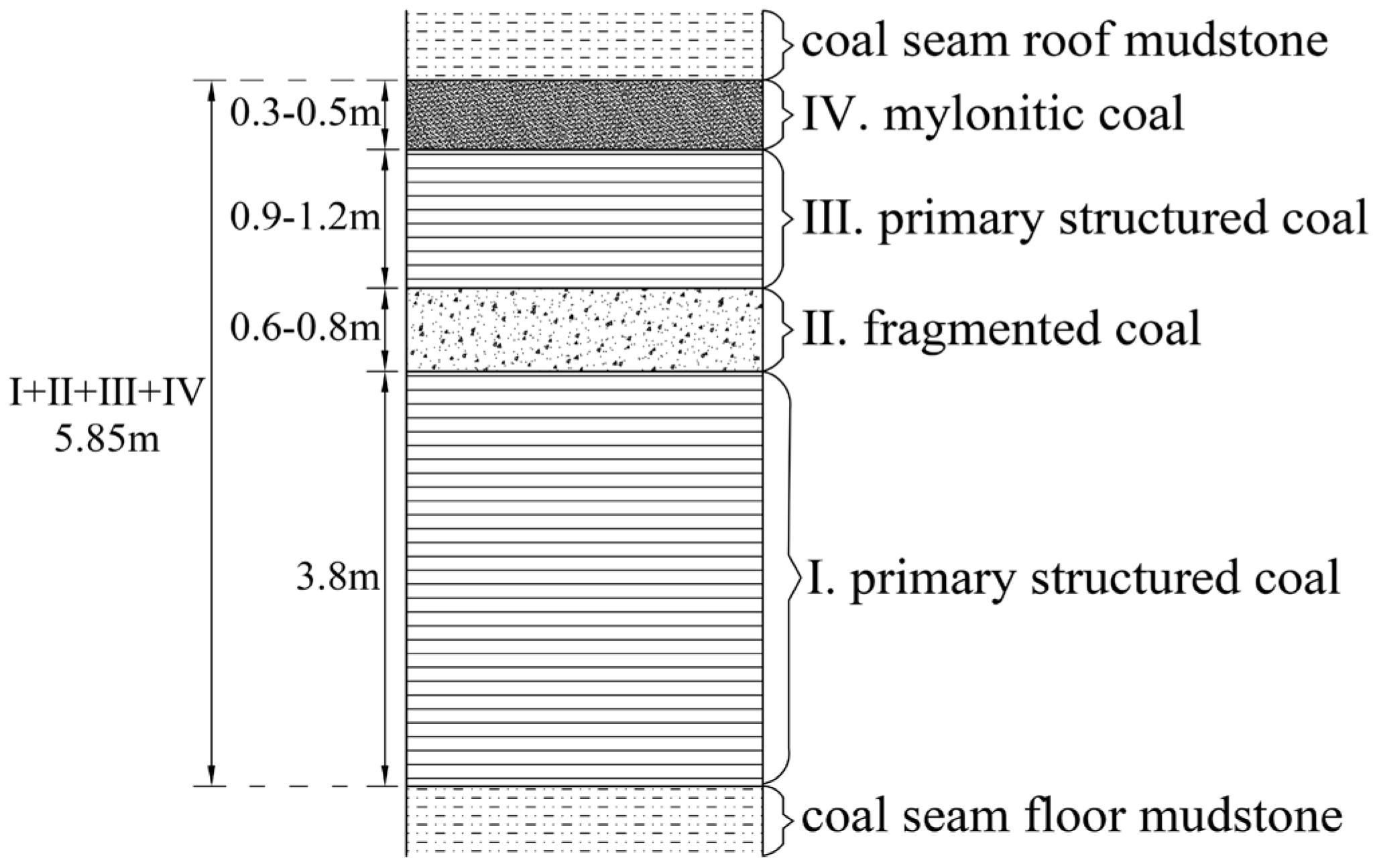

The coal No. 3 exhibits a thickness that ranges from 5.12 to 7.20 m, with an average thickness of 5.85 m. This coal seam is characterized by a simple structure, consistent thickness, and is deemed fully recoverable across the entire area. The roof of the coal seam comprises mudstone, sandy mudstone, and siltstone, while in certain regions, fine-grained sandstone is prevalent. The floor consists of black carbonaceous mudstone, creating favorable conditions for gas preservation. In terms of composition, the coal seam primarily consists of bright coal with original undeformed structures, characterized by its hardness and protodyakonov coefficient (

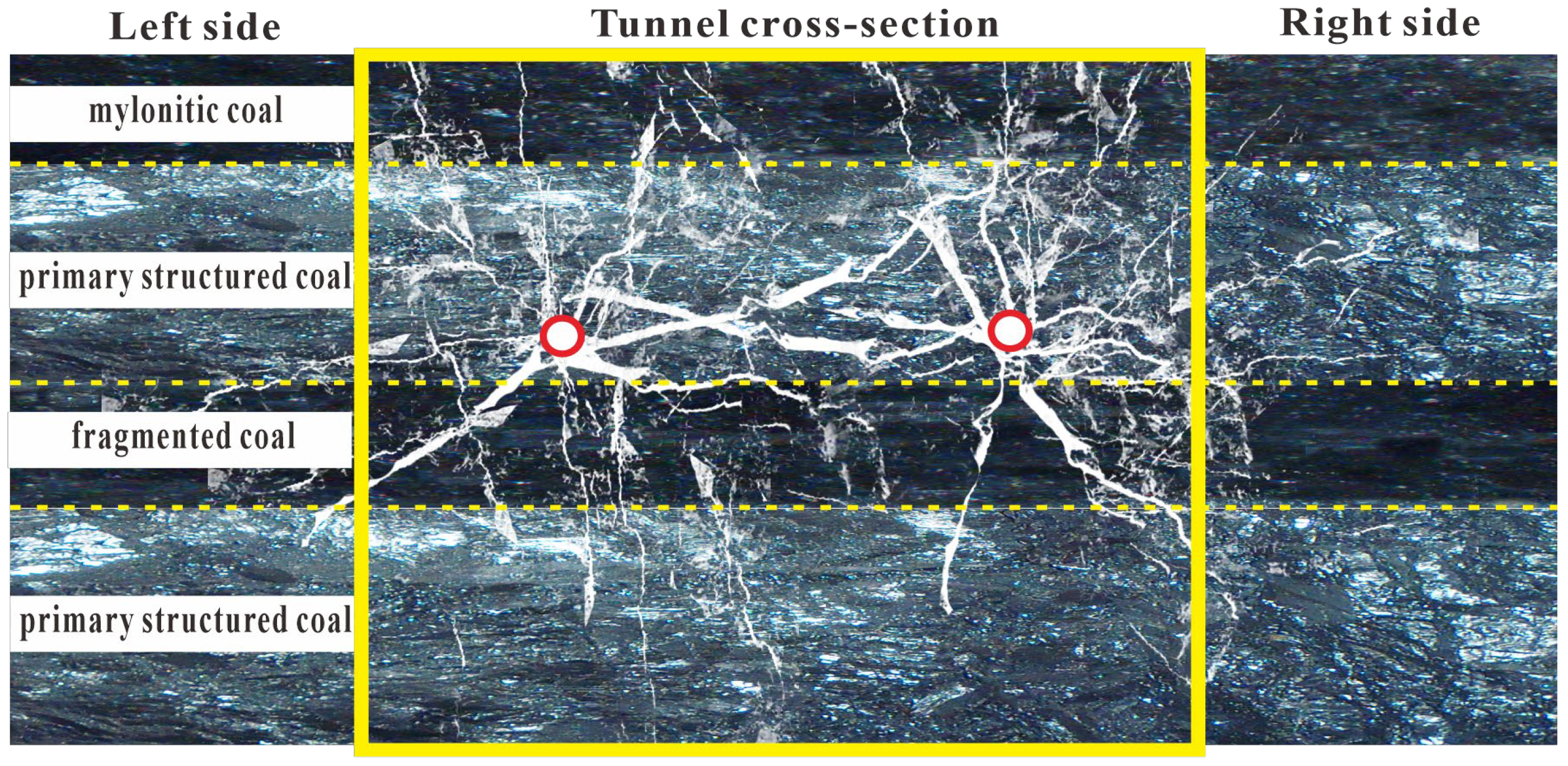

f-value), which ranges from 0.8 to 1.0. Within the middle to upper section, there exist two layers of TDC layers with soft property (

Figure 3). The upper TDC layer is mylonitic coal in thickness of 0.3 to 0.5 m. It lacks discernible bedding planes, possesses a soil-like luster, and exhibits a fragile structure. The

f-value of this layer generally ranges from 0.1 to 0.5. These characteristics align with typical outburst prone coal, and all instances of gas abnormal emission have been observed within this upper layer. One meter to 1.8 m below the roof, there lies an unstable fragmented coal layer with thickness varying from 0.5 to 0.8 m. Although the deformation degree is less pronounced compared to the upper one, this layer primarily consists of cataclastic and fragmented coal, characterized by disturbed bedding planes. It exhibits low hand-test strength and exemplifies angular and fragmented features. The

f-value for this layer ranges from 0.3 to 0.5. No gas outbursts have been observed within this layer.

The gas parameters in the Yuxi coal mine have been obtained during the exploration period from borehole drilling and initial mining activities. The maximum measured original gas content was found to be 25.59 m

3/t, 19.92 m

3/t, and 18.53 m

3/t at the main inclined shaft, auxiliary inclined shaft, and return air upcast shaft, respectively. Correspondingly, the maximum original gas pressures were recorded as 2.90 MPa, 2.79 MPa, and 1.76 MPa for each location. The initial gas emission velocity

ΔP was relatively high, ranging from 25.2 to 27.8 mmHg, while the coal’s f values varied from 0.45 to 1.09 (

Table 2). According to the “Code for Prevention of Coal and Gas Outbursts” [

35], the gas content and gas pressure are both greater than the critical value, indicating that the No. 3 coal seam is considered to possess the risk of coal and gas outbursts.

3. Methods

3.1. Evaluation of Gas Outburst Prevention Measures

The 1301 working face comprises six primary excavation roadways: the transportation roadway, starting cut, return airway 1, return airway 2, return airway 3, and counter-excavation of return airway 1 (Fig.2). Prior to the experimental phase of this project, 2 GPDUR were constructed. Gas pre-drainage was implemented through drilling grid boreholes into the coal seam in order to reduce the risk of outbursts in the coal roadway coverage area (

Figure 2). After 1 year of gas extraction, the effectiveness of gas extraction and outburst prevention was conducted. The evaluation method involved performing borehole drilling every 50 m along the underlying roadways to collect coal samples for residual gas content analysis, and total of 33 sampling tests were carried out. The results indicated that the residual gas content varied from 1.35 to 7.40 m

3/t, with an average value of 4.34 m

3/t, which was below the critical value of 8 m

3/t. Thus, it is concluded that the gas extraction and outburst prevention were adequate, indicating that there was no risk of outbursts in the entire area. As a result, the excavation and construction of the coal roadway were able to proceed.

After confirming the absence of outburst risks, the excavation of the coal roadway commenced in May 2017. Throughout the excavation process, significant variations in gas emission were observed in most sections. While some sections displayed low gas emissions, facilitating smooth excavation, the majority of sections experienced high gas emissions, including multiple instances of short-duration anomalies and minor outbursts, which were observed in the upper mylonitic coal layer. The gas desorption index,

K1, frequently exceeded the standard [

36,

37], with values surpassing 0.5 or even 1.0. By October 2017, five occurrences of gas anomalies and outbursts, shown in

Figure 2, were documented within 150d of the excavation process, resulting in gas exceedances in ventilation system and tunneling stoppages.

The localized gas abnormal outbursts are mainly caused by the high original gas content and pressure of the coal seam. This is further exacerbated by inadequate and uneven gas extraction from the underlying roadway, leading to a persistently high local gas content or pressure, thereby increasing the risk of outbursts. Moreover, the locally increased thickness of the upper TDC layer induced by the coal bedding faults is the geological factor that contribute to these abnormal outbursts [

38,

39,

40]. To ensure safe mining operations, it is crucial to develop techniques for specifically secondary outburst elimination as the current measures of GPDUR and outburst prevention are insufficient. Thus, the project team has undertaken research and is promoting the use of CO

2-Frac for outburst prevention in the excavation of the coal roadway since March 2018.

3.2. Experiment of the CO2-Frac for Outburst Prevention and Safe Excavation

3.2.1. CO2-Frac: Its Principles, Key Technical Parameters and Experiment Scheme

Extensive industrial practices have demonstrated that CO

2-Frac technology has comprehensive effects on enhancing fissure formation, pressure relief, permeability improvement, and gas extraction for coal mine gas control [

28,

33,

41,

42]. The fundamental principle of this technology involves heating chemicals combustion providing thermal energy and leading the liquid CO

2 in the storage tube to undergo a phase transition of gas or supercritical that creates a high-pressure jet acts on the coal of the borehole walls. This process leads to a complex fractures network dispersed in the coal seam and matrix, relieving stress in the crack zone. Additionally, it significantly increases permeability and improves gas extraction efficiency.

The parameters of the CO2-Frac are designed as follows: equipment model is C-74L, and the tube diameter is 73 mm with length of 1200 mm, which can fill liquid CO2 mass 2.2-2.5 kg per tube. The test pressures are designed as 120 MPa to 185 MPa, but 185 MPa was accepted as the most effective pressure.

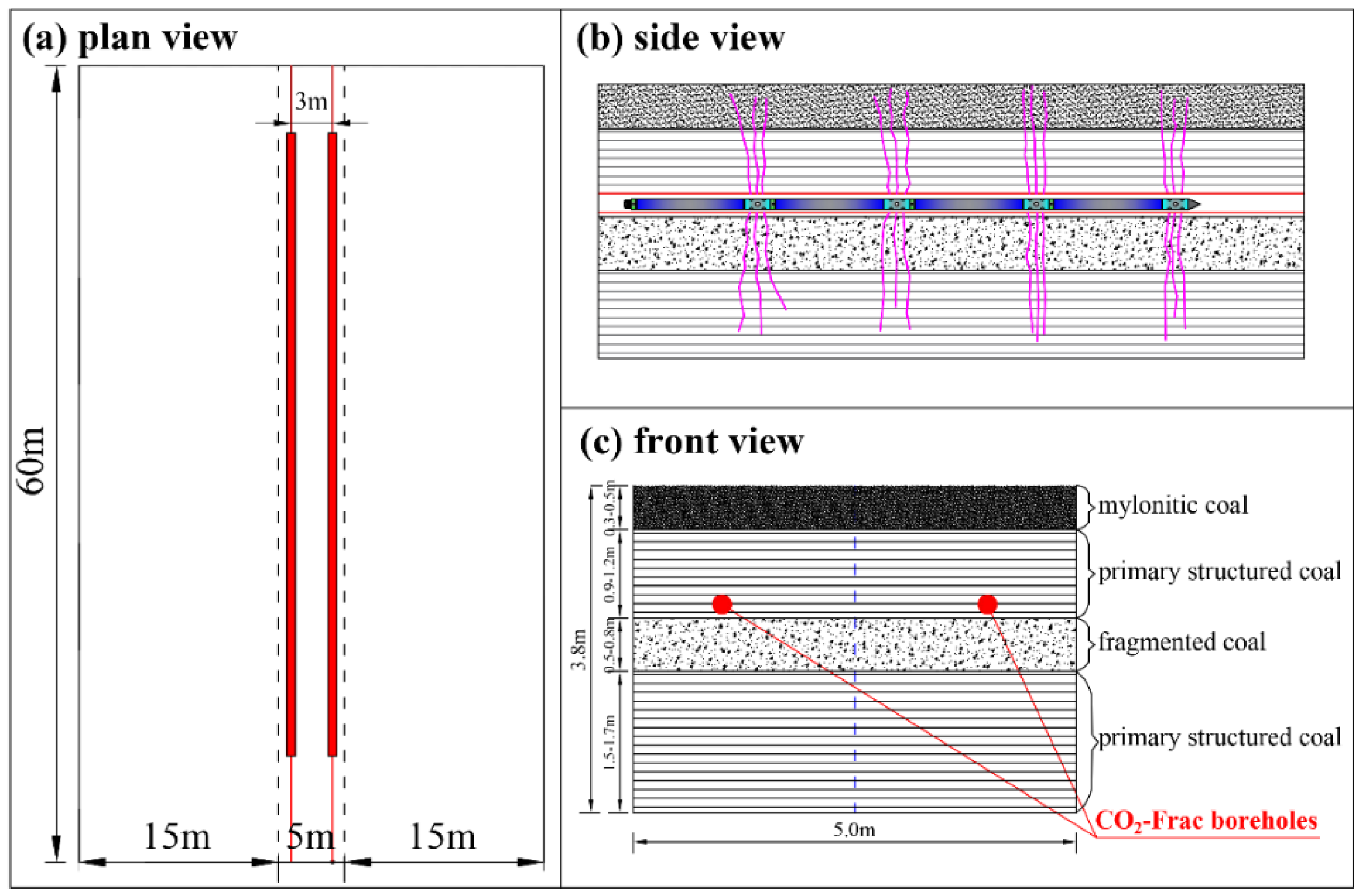

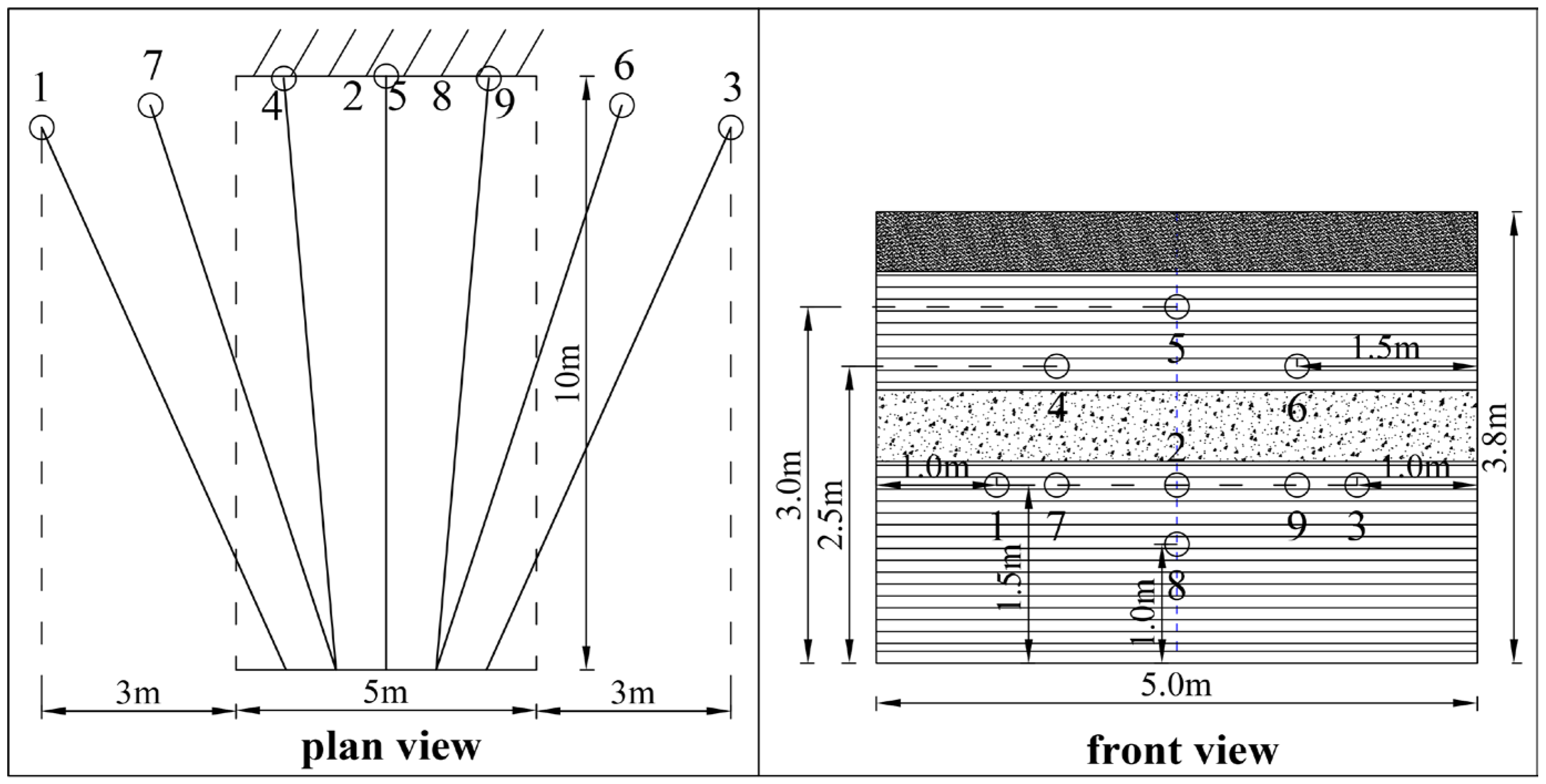

Double fracturing boreholes, 1 m from the roadway walls (

Figure 4), are drilled parallel to the direction of roadway excavation using a 113 mm bit. The depth of the boreholes ranges from 60-80 m, and each borehole is equipped with 15-30 sets of fracturing tubes, and the length of the fracturing section is 30-60 m. It is the key rule that a strict control is exercised within the fracturing section that was evaluated as none outburst risk during the subsequent excavation after the fracturing, with over excavation being prohibited.

3.2.2. Evaluation of the Effectiveness of Eliminating Outbursts with K1 Value

Following the safety regulations of Chinese coal mining industry, the effectiveness of the outburst prevention has to be evaluated with specific index mining regulations determined [

35,

36]. Subsequently, gas desorption index

K1 is used to evaluate the effectiveness of outburst prevention in this study. It is regulated that excavation can resume when all

K1 values tested are below 0.5. In cases where

K1 values exceed 0.5, additional measures for gas release through shallow boreholes are undertaken until the

K1 value falls below 0.5, after which excavation may proceed [

35,

43].

The

K1, an index of gas desorption of drilling cuttings is determined as Eq. (1)

where,

Qt is the gas content disported from the coal cuttings at the moment of exposure to time t, cm

3/g.

Qmax is the maximum gas content desorbed from the coal sample, cm

3/g.

S is the surface area of the tested coal cuttings, cm

2/g.

V is the total volume of coal sample, cm

3/g.

D is the diffusion coefficient of coal sample, cm

2/min,

t is the diffusion time of coal sample, min.. Here define:

K1 value is a parameter indicating the gas desorption velocity, and promotional with gas content of the coal cutting. K1 is determined as following steps in the working face:

(1) After the CO

2-Frac completed in the 2 boreholes, 18 shallow boreholes, with 75mm bits and depth of 16m, shall be drilled on the working face to release gas for a period of 8-24 hours (

Figure 5).

(2) Then drill 9 holes with depth of 10m and 42 mm bits in the working face showing as

Figure 5. The regulations require

K1 test from only 3 holes in which 1 drilled in front and 2 in the two walls. The 9 holes designed here by the safety management for evaluating the serious outburst prone covering a large area.

(3) Take 5 coal cutting samples as drilling ahead each 2 m deep of the hole regularly.

(4) Take 10 g of 1-3mm coal cuttings screened for gas desorption index

K1 test in a test equipment GDT following the Standard of AQ/1065-2008 [

43].

(5) Totally 45 K1 value were obtained from the 45 cutting samples of 9 holes.

(6) When K1<0.5 from all the 45 tests, indicating there is no outburst risk in the sampling and testing area and excavation ahead of 7m is allowed.

(7) If there is 1 sample with K1≥0.5 from the 45 tests, indicating outburst risk existing in the area. Thus, continue to drill 18 shallow boreholes for gas releasing on the working face for the next round K1 test and evaluation, until K1<0.5 then allowing 7 m excavation ahead.

4. Results Analysis and Discussions

The high-pressure double-hole CO

2-Frac and outburst prevention technology scheme was implemented in four tunnels, including return airway 1, return airway 2, return airway 3, and cutting airway in the 1301 face. The fracturing borehole dimension and fracturing pressure was designed as

Figure 4. The gas desorption index of

K1 value were regularly tested after the fracturing following the measures of 4.2 described, and tunnel excavation speed before and after the CO

2-Frac were compared and analyzed.

4.1. Outburst Risk Evaluation with K1 Value after CO2-Frac

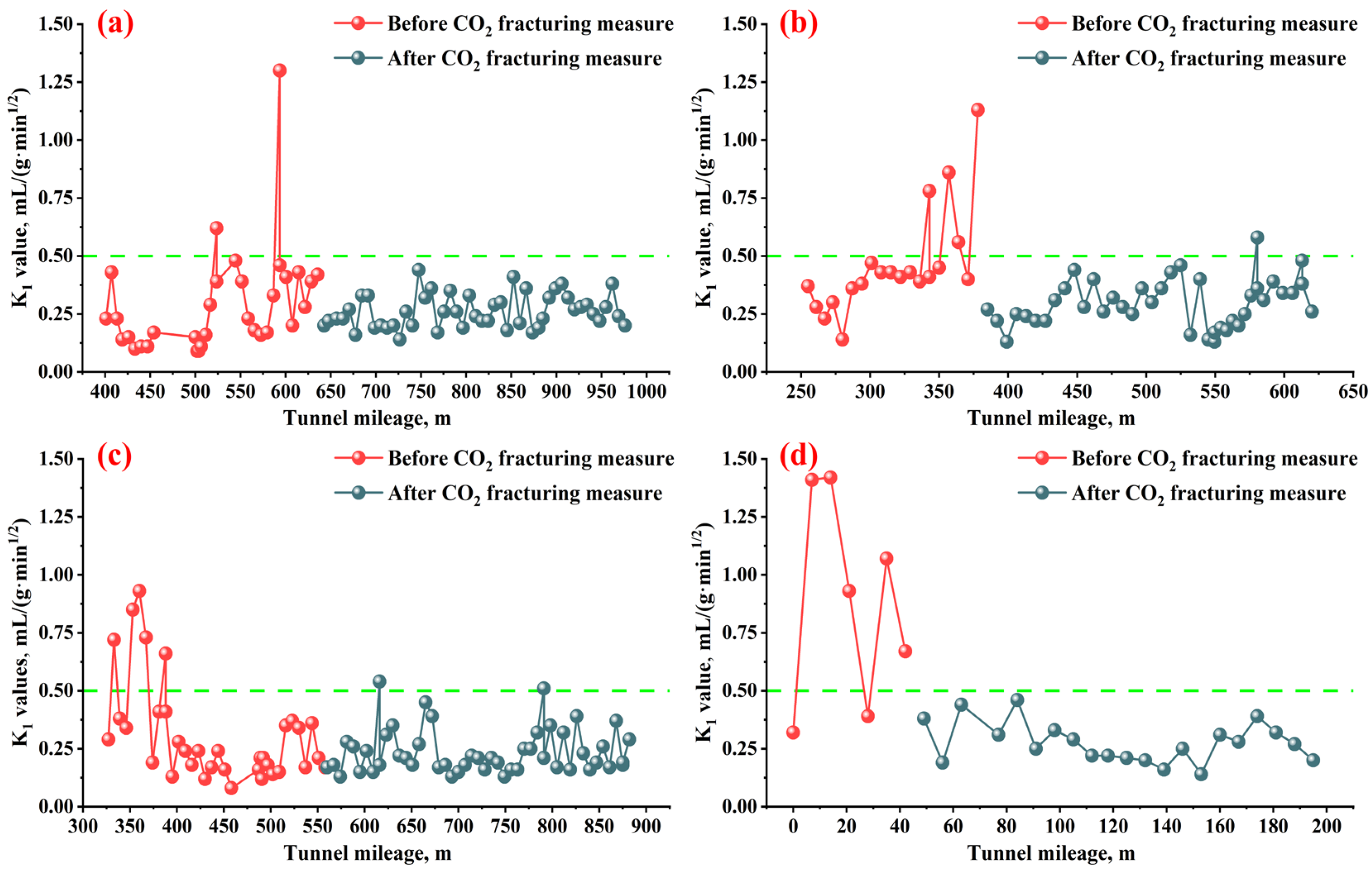

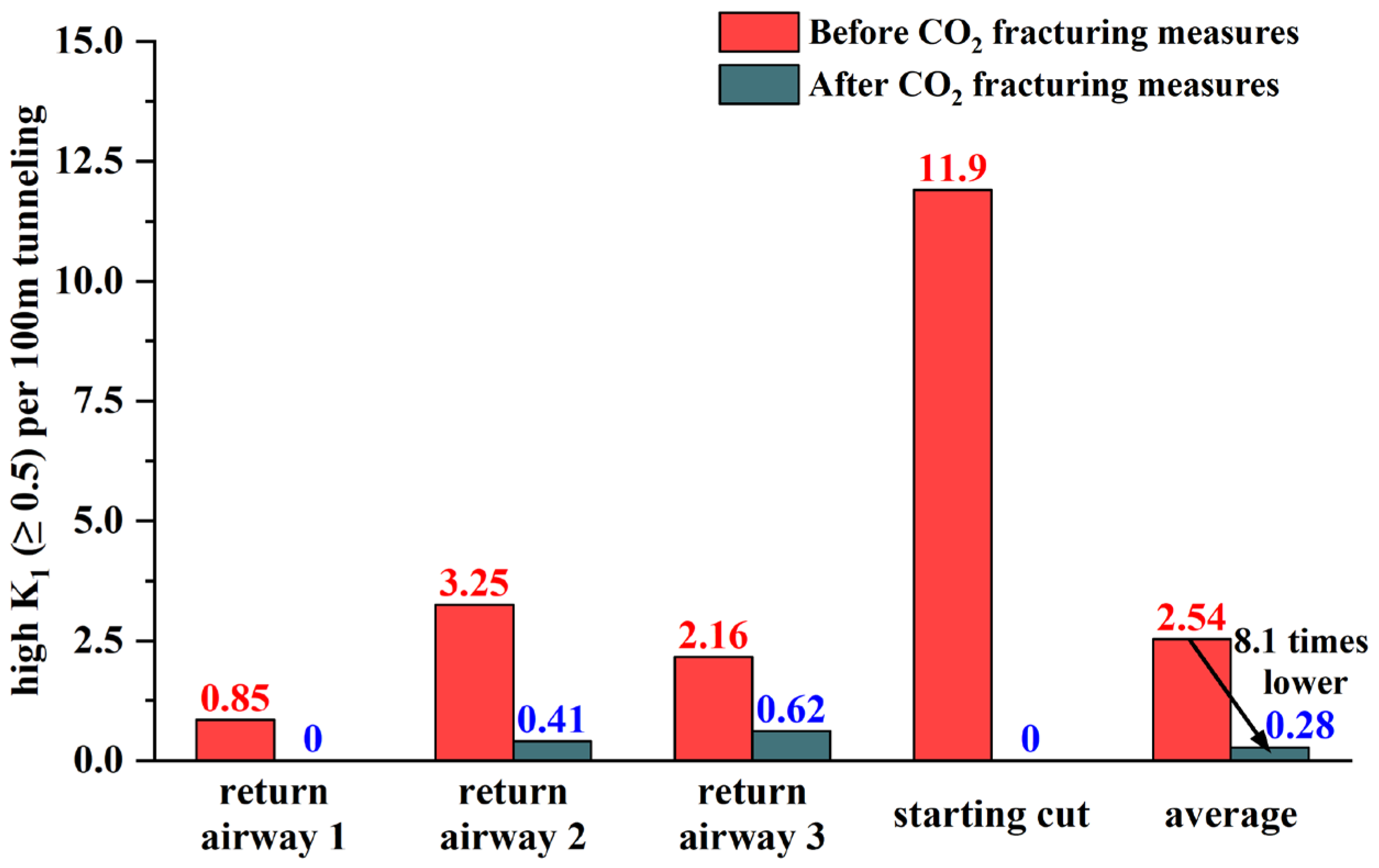

It was estimated that all the tests of gas desorption index K1 value significantly decreased after the CO2-Frac in the four trial tunnels of totally 1059.5 m roadway. It is confirmed that outburst prone was significantly mitigated indicated by CO2-Frac.

The test results shown that in the tunnel excavation of 630.5m without CO

2-Frac, high

K1 value (exceeded the standard or

K1≥0.5) was tested for 16, which means that there are 2.54 samples tested for high

K1 value per 100 m excavation, indicating the roadway exists outburst risk. After CO

2-Frac, there are only 3 samples tested for high

K1 value in the excavation tunnel of 1059.5 m, or only 0.28 samples tested for high

K1 per 100 m roadway excavation. It is to say that high

K1 reduced from 2.54 tests in 100 m excavation without CO

2-Frac to 0.28 test with CO

2-Frac, a decrease of 8.1 folds (

Table 3,

Figure 6 and

Figure 7), confirmed that CO

2-Frac significantly reduces the risk of outburst and effectively ensures continuous safe excavation (

Figure 6).

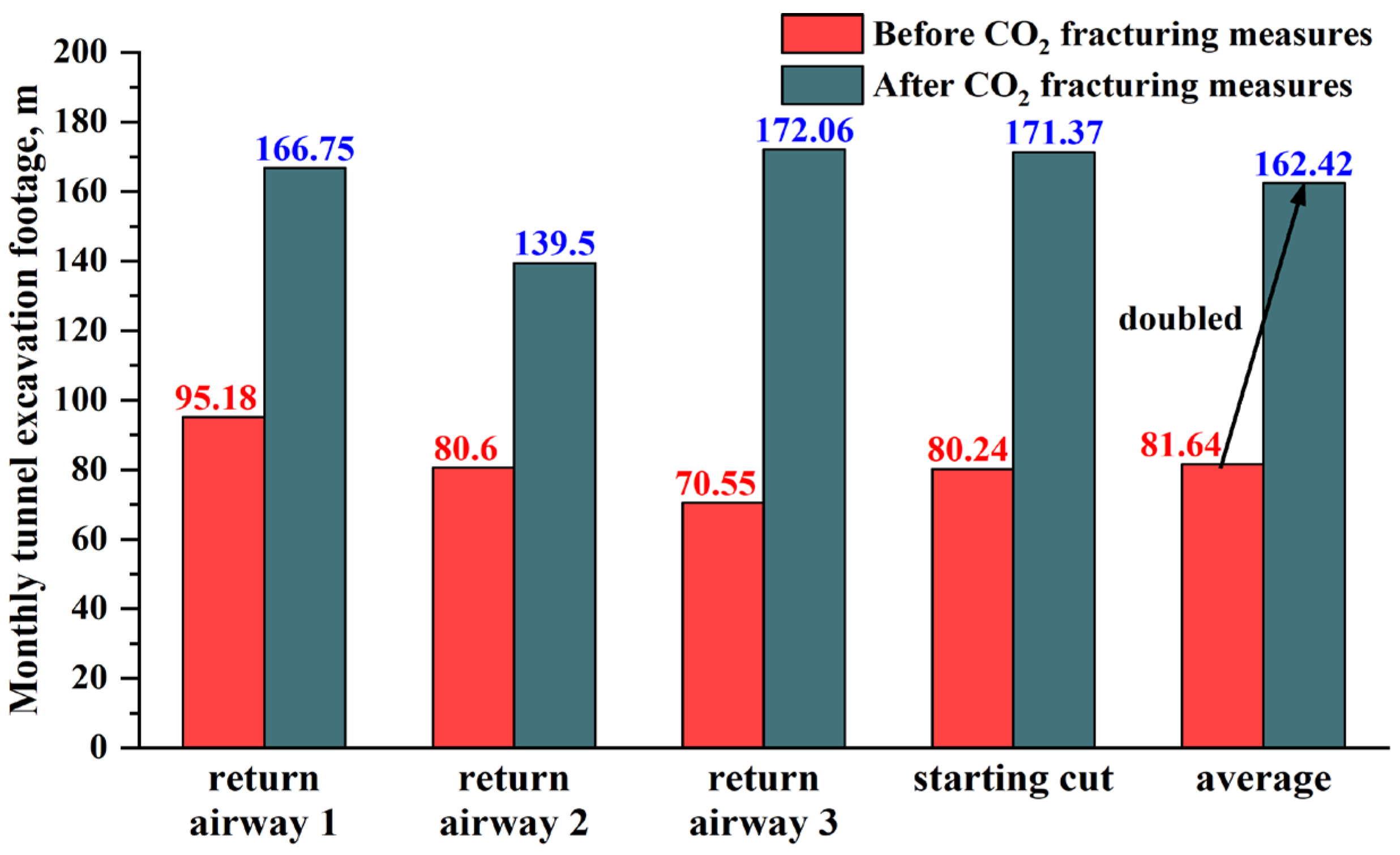

4.2. Analyzing the Monthly Roadway Excavation

After CO

2-Frac, the monthly excavation of the roadway is significantly increased. Sown in

Figure 8, the average monthly footage of return airway 1, return airway 2, return airway 3, and starting cut were 95.18 m, 80.6 m, 70.55 m, and 80.24 m, respectively, with an average monthly footage of 81.64m. After using dual hole CO

2-Frac, the monthly excavation footage of the 4 tunnels reached 166.75 m, 139.50 m, 172.06 m, 171.37 m, and an average of 162.42 m, respectively. The monthly excavation significantly increased by 0.75 times, 0.73 times, 1.44 times and 1.14times, with an average increase of 1 time (

Figure 8). This indicates that CO

2-Frac is an effective technical measure for secondary outburst prevention and rapid excavation in the outburst coal seam in Yuxi Coal Mine.

4.3. Mechanism of Outburst Elimination and K1 Value Reduction by CO2-Frac

The No. 3 coal seam in Yuxi Coal Mine has a maximum gas content of 25.59 m

3/t and a maximum gas pressure of 2.90 MPa, which causes the highly prone to outburst across a large area in the first working face 1301. The 1 year gas pre-drainage of the underlying roadway has been conducted and reduced the gas content below 8 m

3/t, thereby significantly reducing the risk of outbursts. However, due to the high prone to outbursts risk of original gas condition, the gas pre-drainage is inadequate and uneven effectiveness in controlling outbursts. Specifically, areas with a thick mylonitic coal layer at the top of the seam are still facing gas abnormalities and frequent occurrences of small-scale outbursts during the roadway excavation. This phenomenon, which involves numerous small-scale outbursts occurring after extraction and a first round of outburst control measures, is common in severely outburst-prone coal seams. The outburst encountered during the excavation of the coal roadway in the 1301 working face is a typical example after the regional outburst control measures. The occurrence mechanism of this kind of outburst is primarily influenced by the regional distribution of layered mylonitic coal at the top as a result of coal bedding faults [

38,

39,

40], and implementing targeted secondary prevention measures is of highly necessary and urgent in China and globally.

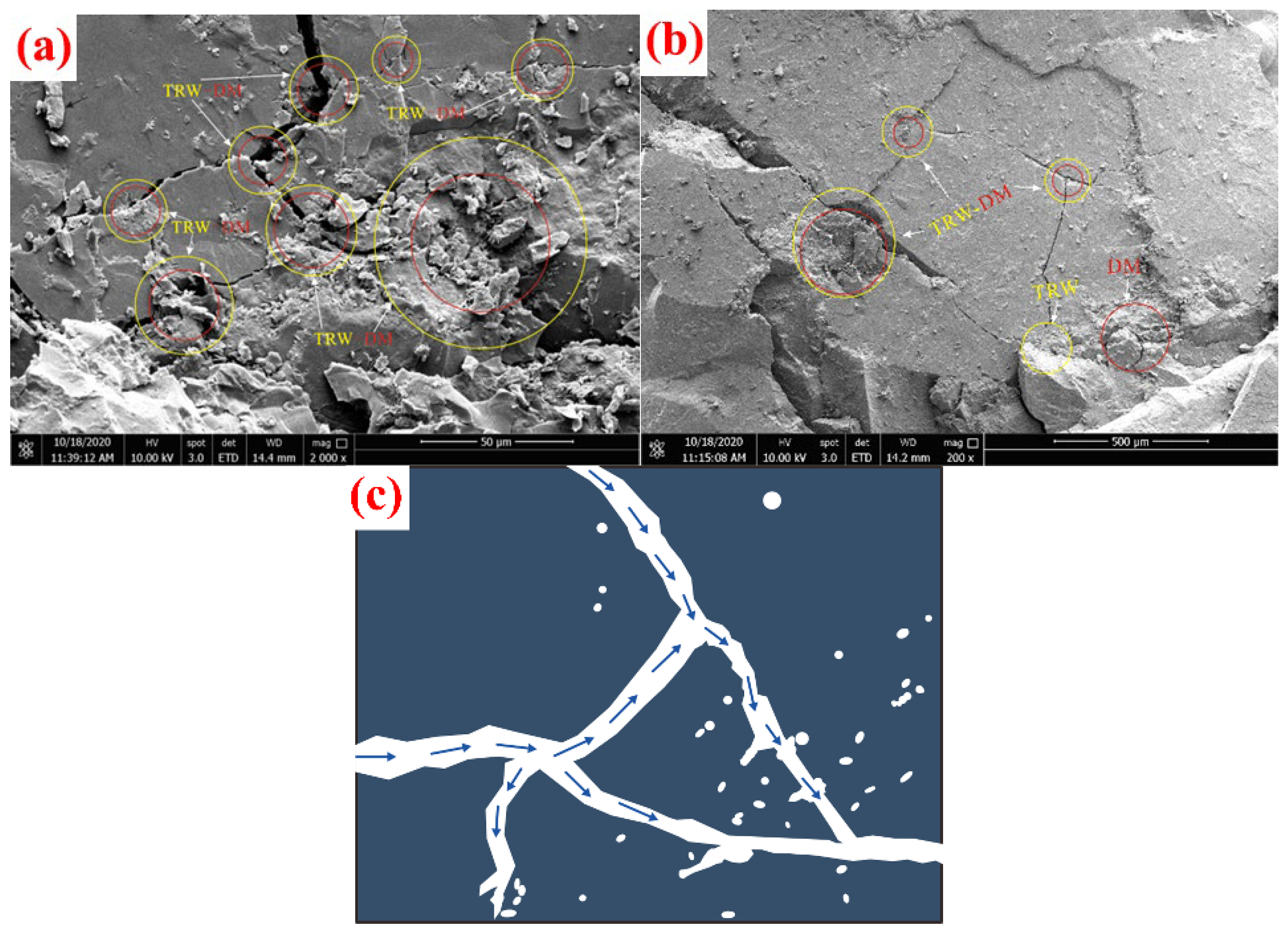

Con

sidering the mechanism of the small-scale outbursts occurred in the top mylonitic coal layer during the excavation, secondary outburst prevention should effectively mitigate the outburst prone of the top-layer. The high-pressure CO

2-Frac generates two sets of fracture system: the first is the radial long fractures system dispersing in the whole coal seam [

33,

34] including the top mylonitic layer (

Figure 9). Additionally, nm to µm scale micro-fractures network formed by multiple tri-wing fractures that disperses in coal matrix (

Figure 10) [

28]. The two sets of fracture system built complex gas migration highway in coal that significantly enhances gas desorption and releasing out of the coal seam, and finally result in gas content dropped low. Thereby, the outburst mitigation mechanisms of CO

2-Frac in this study is described as: the complex artificial fracture system induced by CO

2-Frac in coal effectively enhanced pressure relieving, permeability increasing, gas emission quickly, further in gas content reducing, and finally the outburst prone eliminating.

Quickly reducing gas content then the outburst risk is the key function of CO

2-Frac, which can be clearly illustrated by the large amount of the reduced

K1 tests after CO

2-Frac as shown in

Figure 5 and

Figure 6. Review the Eq. (3) where,

K1 is directly proportional to gas content

Q1 of the coal cutting samples. The lower

K1 tests after CO

2-Frac means that the gas content has dropped low and outburst risk has been mitigated. Thus, we are confident that CO

2-Frac can quickly reduce gas content through the highly developed artificial fracture system then mitigate the outburst risk, since gas content always plays the most important role induing the coal and gas outburst. Chinese coal mining regulations defined that when gas content is higher than 8 m

3/t the coal bearing outburst risk, and without outburst when gas content is lower than 8 m

3/t.

5. Conclusions

To tackle the challenges associated with gas anomalies and small-scale outbursts persist during the excavation stages after regional outburst prevention measures of gas pre-drainage underlying roadway (GPDUR) in coal seams. A research and industrial trial of CO2-Frac for secondary outburst prevention and rapid excavation was completed on the 1301 working face. The following conclusions were drawn:

(1) Dual-bole and high pressure CO2-Frac can promote the rapid release of gas, homogenize and rapidly reduce the gas pressure and gas content through intensive and uniform fracturing and wide range of pressure relieving, so as to fully eliminate the outburst risks of tectonic coal zones that prone to outburst, and it can effectively solve the problem of the mining-excavation connection.

(2) After implementing high pressure CO2-Frac, K1 exceedances per hundred meters of tunnel excavations decreased from average 2.54 without CO2-Frac to average 0.28 with CO2-Frac, a 8-fold decrease. The monthly excavation speed also increased from 81.64m without CO2-Frac to 162.42m with CO2-Frac, a 2-fold increase.

(3) On site industrial tests have proven that high pressure CO2-Frac, as an economical and efficient secondary outburst prevention technology, can effectively solve the problem of uneven and insufficient initial outburst prevention under complex gas geological conditions. As an effective safety measure for secondary outburst prevention in coal tunnels, it is worth learning from and promoting in coal tunnel excavation of severely protruding coal seams with similar gas geological conditions.

Author Contributions

Formal analysis, funding acquisition, methodology, supervision, writing—review and editing, J. Zhang; data analysis, writing—original draft, Y. Cao; writing—review and editing, Z. Li; review and editing, S. Wang and L, Marcin; data analysis, B. Yang; Y Cao and X Zhang. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Natural Science Foundation of China (42230814), and Post-doctoral foundation of Henan Province (HN2022009), and Key scientific and technological projects of Henan province (232102320331).

Data Availability Statement

Data were curated by the authors and are available upon request.

Acknowledgments

Thank you to Shanxi Lu'an Mining (Group) Co., Ltd. for providing a scientific research platform and industrial testing site for Yuxi Coal Mine.

Conflicts of Interest

The authors declare that they have no conflict of interest.

References

- Li, J. The State Bureau of Mine Safety Supervision on Notice on strengthening the prevention and control of coal and gas outburst [EB/OL]. Available online: https://www.chinamine-safety.gov.cn/zfxxgk/fdzdgknr/tzgg/202204/t20220415_411767.shtml (accessed on 2023/6/19).

- Lin, B. China’s High-Quality Economic Growth in the Process of Carbon Neutrality. China Finance and Economic Review. 2022, 11, 3–22. [Google Scholar] [CrossRef]

- Yuan, L. Challenges of countermeasures for high quality development of China's coal industry. China Coal. 2020, 46, 6–12. [Google Scholar] [CrossRef]

- Xie, H.; Ren, S.; Xie, Y. Development opportunities of the coal industry towards the goal of carbon neutrality. Journal of China Coal Society. 2021, 46, 2197–2211. [Google Scholar] [CrossRef]

- Cheng, Y.; Lei, Y. Causality between tectonic coal and coal and gas outbursts. Journal of China Coal Society. 2021, 46, 180–198. [Google Scholar] [CrossRef]

- Xu, J.; Zhou, B.; Peng, S.; Yan, F. Evolution of outburst energy based on development of heat-flow-solids parameter. Journal of China Coal Society. 2020, 45, 213–222. [Google Scholar] [CrossRef]

- Zhou, S.; He, X. Rheological hypothesis of coal and methane outburst mechanism. Journal of China University of Mining & Technology. 1990, 19, 4–11. [Google Scholar]

- Nie, B.; Ma, Y.; He, X. Micro-scale mechanism of coal and gas outburst: A preliminary study. Journal of China University of Mining & Technology. 2022, 51, 207–220. [Google Scholar] [CrossRef]

- Jiang, J.; Shi, X.; Cheng, Y. Study on stress release law of tectonic coal under rapid unloading confining pressure. Journal of Mining & Safety Engineering. 2024, 41, 634–644. [Google Scholar] [CrossRef]

- Chen, H.; An, F.; Wang, Z.; Chen, X. Study on the ideal location of a bottom drainage roadway. Journal of the Southern African Institute of Mining and Metallurgy. 2022, 122, 259–266. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.L.; Han, P.H.; Zhao, Z.N.; Chen, W. The Method of Determining Layer in Bottom Drainage Roadway Taking Account of the Influence of Drilling Angle on Gas Extraction Effect. Sustainability-Basel. 2022, 14, 5449. [Google Scholar] [CrossRef]

- Wang, H.F.; Cheng, Y.P.; Wang, L. Regional gas drainage techniques in Chinese coal mines. International Journal of Mining Science and Technology. 2012, 22, 873–878. [Google Scholar] [CrossRef]

- Xie, S.; Yang, B.; Zhang, Q.; Song, H. Research on lift pressure system with combined pipeline and intensive drill-hole gas drainage along the layer in low permeability coal seam. Journal of Mining Science and Technology. 2019, 4, 34–40. [Google Scholar] [CrossRef]

- Mou, P.W.; Pan, J.N.; Wang, K.; Wei, J.; et al. Influences of hydraulic fracturing on microfractures of high-rank coal under different in-situ stress conditions. Fuel 2021, 287, 119566. [Google Scholar] [CrossRef]

- Dontsov, E.V. Morphology of multiple constant height hydraulic fractures versus propagation regime. International Journal for Numerical and Analytical Methods in Geomechanics. 2022, 46, 1177–1183. [Google Scholar] [CrossRef]

- Cheng, Y.; Lu, Y.; Ge, Z.; Cheng, L.; et al. Experimental study on crack propagation control and mechanism analysis of directional hydraulic fracturing. Fuel 2018, 218, 316–324. [Google Scholar] [CrossRef]

- Min, R.; Chen, X.J.; Wang, L.; Huang, Z.; Li, H.T. Study and application of reasonable parameters for hydraulic punching of layer penetration boreholes in Changping Coal Mine. Energy Science & Engineering. 2023, 11, 3020–3032. [Google Scholar] [CrossRef]

- Kalore, S.A.; Sivakumar Babu, G.L. Hydraulic conductivity requirement of granular and geotextile filter for internally stable soils. Geotextiles & Geomembranes. 2022, 50, 510–520. [Google Scholar] [CrossRef]

- Wen, H.; Mi, W.S.; Fan, S.X.; Liu, M.Y.; Cheng, X.J.; Wang, H. Determining the reasonable volume required to inject liquid CO2 into a single hole and displace CH4 within the coal seam in bedding boreholes: case study of SangShuPing coal mine. Energy 2023, 266, 126522. [Google Scholar] [CrossRef]

- Mi, W.; Wen, H.; Fan, S.X.; et al. Pilot test of high-pressure water jet slotting with liquid CO2 injection to displace CH4 and improve coal seam permeability. Fuel 2023, 351, 128822. [Google Scholar] [CrossRef]

- Zou, Q.; Liu, H.; Cheng, Z.; Zhang, T.; Lin, B. Effect of Slot Inclination Angle and Borehole-Slot Ratio on Mechanical Property of Pre-cracked Coal: Implications for ECBM Recovery Using Hydraulic Slotting. Natural Resources Research. 2020, 29, 1705–1729. [Google Scholar] [CrossRef]

- Zou, Q.; Liu, H.; Jiang, Z.; Wu, X. Gas flow laws in coal subjected to hydraulic slotting and a prediction model for its permeability-enhancing effect. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects. 2021, 1–15. [Google Scholar] [CrossRef]

- Xiao, W.; Li, K.; Zhu, C.; Li, Z.; et al. Numerical Investigation on Potential Influencing Factors Affecting Drainage Effective Radius of Crossing Borehole. Sustainability-Basel. 2023, 15, 2485. [Google Scholar] [CrossRef]

- Li, Y.; Zhai, C.; Ding, X. Technology and application of dynamic pressure gas secondary drainage through borehole in bottom drainage roadway of high gas outburst coal seam. Safety in Coal Mines. 2022, 53, 191–196. [Google Scholar] [CrossRef]

- Wang, Z.; Xi, J.; Chen, J.; Ma, X. Study on time effectiveness of gas drainage by crossing layer drilling in floor rock roadway with one hole and multi-purpose. Coal Science and Technology. 2021, 49, 248–256. [Google Scholar] [CrossRef]

- Cheng, Z. Study on optimization of strata passing borehole sealing depth and borehole layout space in floor gas drainage gateway. Coal Science and Technology. 2017, 45, 76–82. [Google Scholar] [CrossRef]

- Hebi Coal and Electricity Company Sixth Coal Mine '6.4' large coal and gas outburst accident case. In: China Coal News. 2022.

- Cao, Y.; Zhang, J.; Zhang, X.; Liu, S.; Elsworth, D. Micro-fractures in coal induced by high pressure CO2 gas fracturing. Fuel 2022, 311, 122148. [Google Scholar] [CrossRef]

- Zhang, J.; Guo, S.; Zhang, X.; Cao, Y.; Liu, G. Dynamic damage constitutive model of plastic hardening-softening process of coal under impacting load. Journal of China Coal Society. 2021, 46, 759–769. [Google Scholar] [CrossRef]

- Cao, Y.; Tian, L.; Fan, Y. Study on cracking ring form of carbon dioxide gas phase fracturing in low permeability coal seam. Coal Science and Technology. 2018, 46, 46–51. [Google Scholar] [CrossRef]

- Wang, Z.Z.; Fu, X.H.; Pan, J.N.; et al. Effect of N2/CO2 injection and alternate injection on volume swelling/shrinkage strain of coal. Energy 2023, 275, 127377. [Google Scholar] [CrossRef]

- Shi, B.; Cao, Y.; Tian, L.; Zhang, J.; Liu, S. CO2 Gas Fracturing in High Dip Angled Coal Seams for Improved Gas Drainage Efficiency at Hashatu Coal Mine. Energy & Fuel. 2022, 36, 2763–2774. [Google Scholar] [CrossRef]

- Cao, Y.; Zhang, J.; Zhai, H.; Fu, G.; Tian, L.; Liu, S. CO2 gas fracturing: A novel reservoir stimulation technology in low permeability gassy coal seams. Fuel. 2017, 203, 197–207. [Google Scholar] [CrossRef]

- Cao, Y.; Zhang, J.; Tian, L.; Zhai, H.; Fu, G. Research and application of CO2 gas fracturing for gas control in low permeability coal seams. Journal of China Coal Society. 2017, 42, 2631–2641. [Google Scholar] [CrossRef]

- National Mine Safety Administration. Provisions on Prevention and Control of Coal and Gas Outbursts; China Coal Industry Publishing House: China, 2019. [Google Scholar]

- Coal Information Research Institute. Prevention of coal and gas outburst rules and prevention of coal and gas outburst provisions; China Coal Industry Publishing House: China, 2019. [Google Scholar]

- Cheng, Y.; Zhou, H. Research progress of sensitive index and critical values for coal and gas outburst prediction. Coal Science and Technology. 2021, 49, 146–154. [Google Scholar] [CrossRef]

- Cao, Y.; Peng, L.; Hou, Q. Basic characteristics of coal seam faults and their geological significance. Geological Review. 1993, 39, 522–528. [Google Scholar]

- Cao, Y.; Peng, L. Basic type of coal seam faults and their effect on controlling gas outburst zone. Journal of China Coal Society 1995, 20, 413–417. [Google Scholar]

- Cao, Y.; Zhang, H.; Zhang, Z.; Liu, G. Characteristics of coal and gas outburst and controlling mechanism of stress field in the hanging wall of normal faults. Coal Geology & Exploration. 2022, 50, 61–69. [Google Scholar] [CrossRef]

- Zhang, F. Research into the Mechanism and Application of Liquid CO2 Phase-Transition Fracturing in a Coal Seam to Enhance Permeability. Sustainability-Basel. 2023, 15, 3308. [Google Scholar] [CrossRef]

- Shang, Z.; Wang, H.; Li, B.; Cheng, Y.; et al. The effect of leakage characteristics of liquid CO2 phase transition on fracturing coal seam: Applications for enhancing coalbed methane recovery. Fuel. 2022, 308, 122044. [Google Scholar] [CrossRef]

- Chongqing Research Institute of Coal Science Research Institute. Determination method of gas desorption index by drill cuttings. In: AQ/T 1065-2008.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).