Submitted:

28 August 2024

Posted:

29 August 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

- To develop a mathematical model using the Harris Hawks algorithm on a solar-assisted CCHP system.

- Optimize the net power output and exergy efficiency, while simultaneously limiting CO2 emissions, in a solar energy-integrated CCHP system utilizing the Harris Hawks optimizer.

2. Literature Review

| S/N | Source | Methods for Optimization |

Renewable energy employed | Metrics for Performance Improvement | System Analyzed |

|---|---|---|---|---|---|

| 1 | Cao et al. [19] | Genetic algorithm | Solar | Exergy efficiency, net output electricity and cost per unit exergy | Tri-generation |

| 2 | Wang et al. [20] | Genetic algorithm | Solar, natural gas | Energy efficiency, exergy efficiency | Tri-generation |

| 3 | Wang et al. [21] | Genetic algorithm | Solar | Primary energy saving ratio, CO2 emission reduction ratio, annual cost saving rate | Tri-generation |

| 4 | Song Liu & Lin [22] | NSGA-II | Solar | Annual cost saving ratio, primary energy saving ratio | Tri-generation |

| 5 | Abba et al. [23] |

HHO, PSO & SVR | Solar | Annual capital and maintenance cost | Power generation |

| 6 | Yousri, Babu & Fathy [24] | HHO | Solar, wind | Integral time absolute error, tie-line power | Power generation |

| 7 | Zhao et al. [25] | HHO | N/A | GHG emission reduction, exergy efficiency, annual cost rate | Tri-generation |

| 8 | Song, Tan & Mizzi [26] | HHO | N/A | Squared deviation between actual and true output voltage | Power generation |

| 9 | Pandey & Jadoun [27] | HHO | N/A | Net profit, GHG emission reduction | Co-generation |

| 10 | Mahalekshmi & Maruthupandi [28] | HHO | Wind | Total cost, emission dispatch | Power generation |

3. Materials and Methods

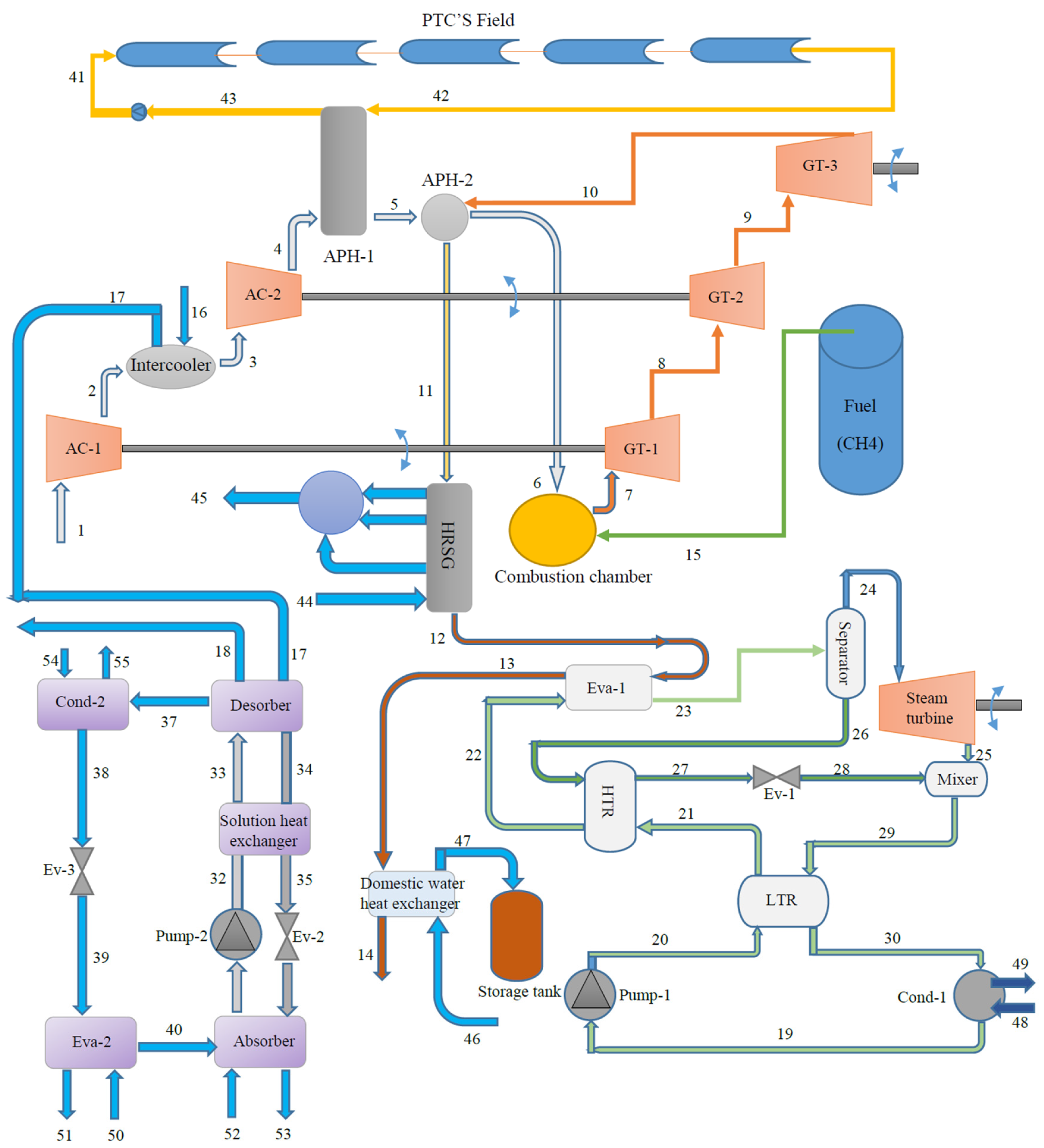

3.1. Description of the System

3.2. Response Surface Method

- Experimental design: This stage entails establishing the circumstances for the experiment. It involves choosing pertinent input factors that may influence the response variable. Constraints are subsequently identified to evaluate the design variables during the experiment.

- Experimental testing: This involves the execution of tests according to a predetermined experimental strategy. Data pertaining to the outcome variable is gathered across different combinations of design factor levels. These tests are carefully performed to minimize the influence of less significant design variables.

- Regression model fitting: This involves the development of models utilizing data collected from experiments. This is accomplished using techniques such as the least squares or maximum likelihood estimation. The resulting regression models are evaluated to determine their level of conformity to the initial model assumptions.

- Validation of the regression model: This occurs after successful fitting of the model by predicting outcomes using new, unused data from further experimental tests. This stage guarantees the dependability and precision of the established model.

- Net power output: This refers to the combined power created by the gas turbine and the Kalina cycle, taking into account the work generated from both systems. The mathematical expression can be represented using the formula proposed by Mahdavi, Mojaver, and Khalilarya [29].

- 2.

- Exergy efficiency: This is a useful and effective measure used to evaluate the extent, size, and positions of irreversibilities in a thermodynamic system [31]. The efficiency is mathematically defined as the quotient of the output exergy divided by the input exergy.

- 3.

- CO2 Emission: The discharge of CO2 into the atmosphere poses adverse environmental impacts, emphasizing the ongoing need for its mitigation within thermal energy systems. Emission, a metric assessing the level of CO2 production, is defined as the ratio of the mass flow rate of CO2 to the overall output energy, as defined by Mahdavi and Khalilarya [29].

3.3. Harris Hawk Optimization

3.3.1. Exploration Stage

3.3.2. Exploitation Stage

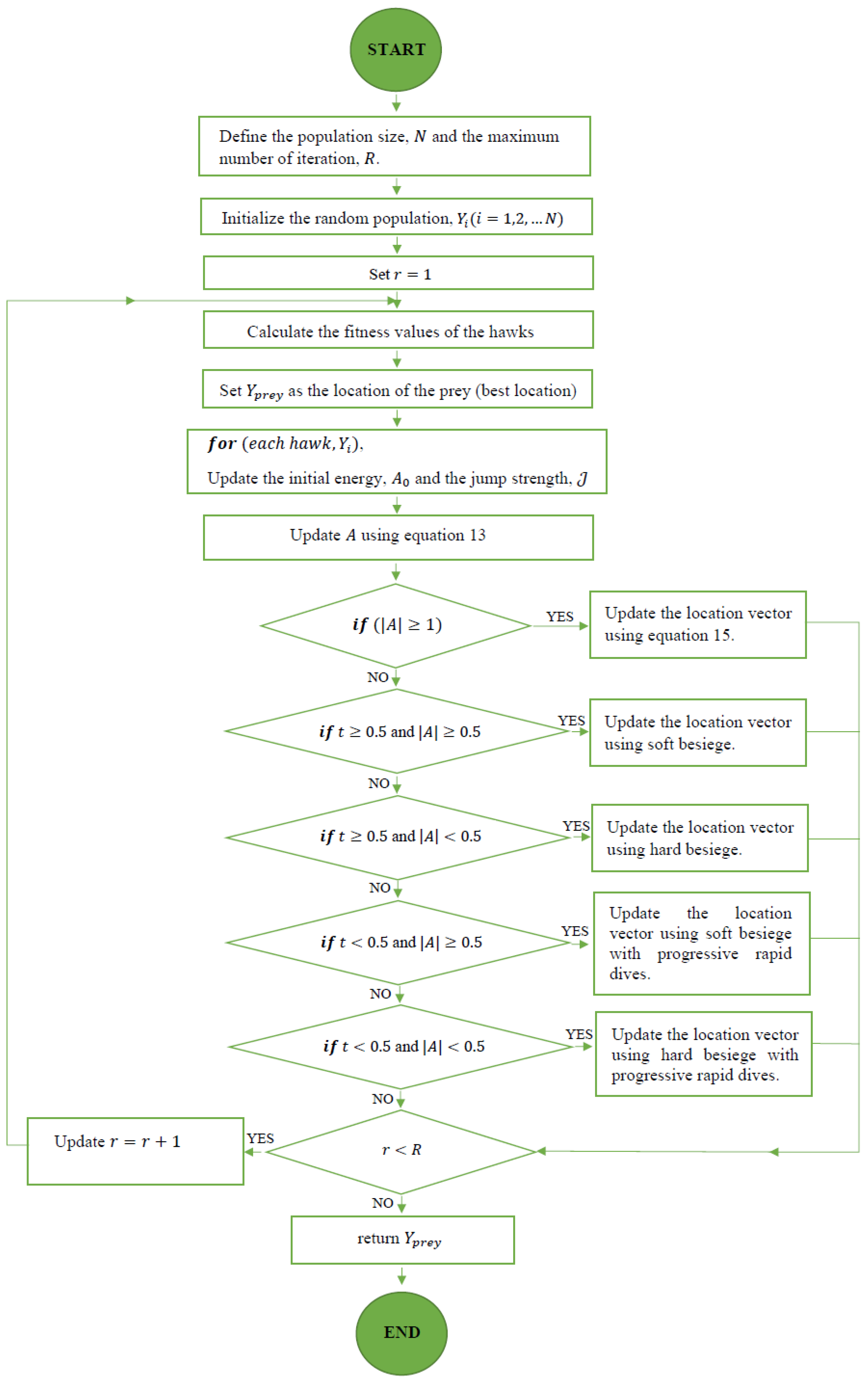

3.3.3. Single-Objective Harris Hawk Optimization

- Problem definition: The objective functions and the HHO parameters such as upper and lower boundaries of the decision variables, maximum number of iterations, etc. were defined.

- Initialization: The initial population size of solutions was initialized. The initialization function was created to ensure that the initialized values do not exceed the defined boundaries of the decision variables.

- Evaluation: The prey’s energy, calculated using equations 13 and 14, determined if the HHO algorithm employed exploration or exploitation. For any of the two methods employed, the prey’s energy was employed to calculate the fitness value of the hawks (objective value) while the prey’s location was regarded as the solution for the decision variable. The prey’s location and hawks’ fitness value were updated at each iteration until the maximum number of iterations was attained. The prey’s location at the final iteration became the optimal decision variable solution returned by the algorithm and the corresponding objective value was obtained.

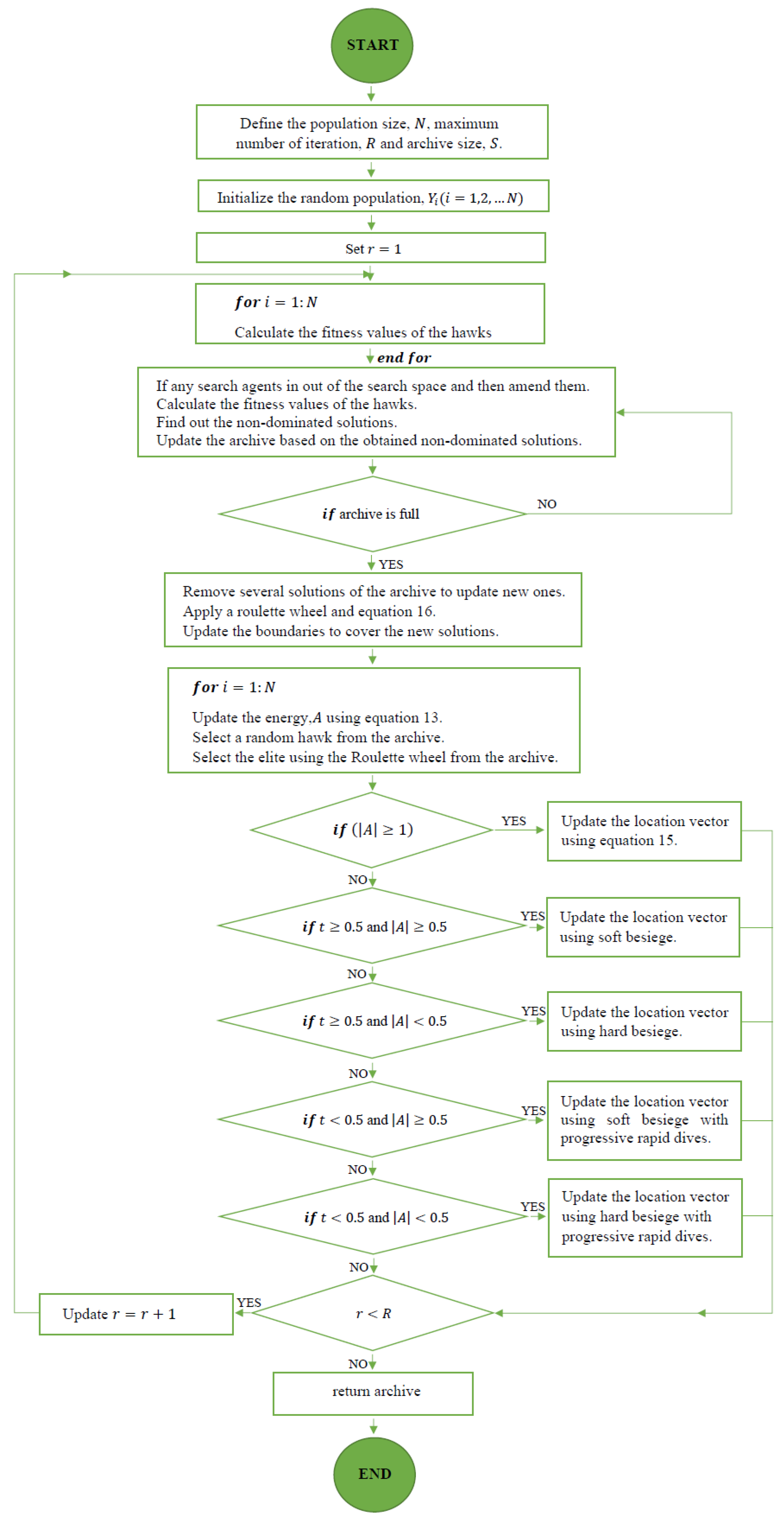

3.3.4. Multi-Objective Harris Hawk Optimization

- Problem definition: All three objective functions as well as the upper and lower boundaries of the decision variables were defined. Additionally, parameters such as the inertia weight, global learning coefficient, inflation rate, leader selection pressure, mutation rate, etc., were defined.

- Initialization: The initial population size, number of iterations, and archive/repository size were initialized to store the non-dominated solutions.

- Iteration improvement: The leader selection approach was employed in this algorithm to maintain the diversity of the repository. The leader selection pressure parameter (beta) and the non-dominated solution were passed as arguments to the ‘leader’ function and yielded the fittest non-dominated solution as output. This output was subsequently employed to guide the algorithm in performing exploration and exploitation. The roulette wheel was employed to select the leader of the MOHHO where each solution’s probability of being selected as a leader depended on their fitness value.

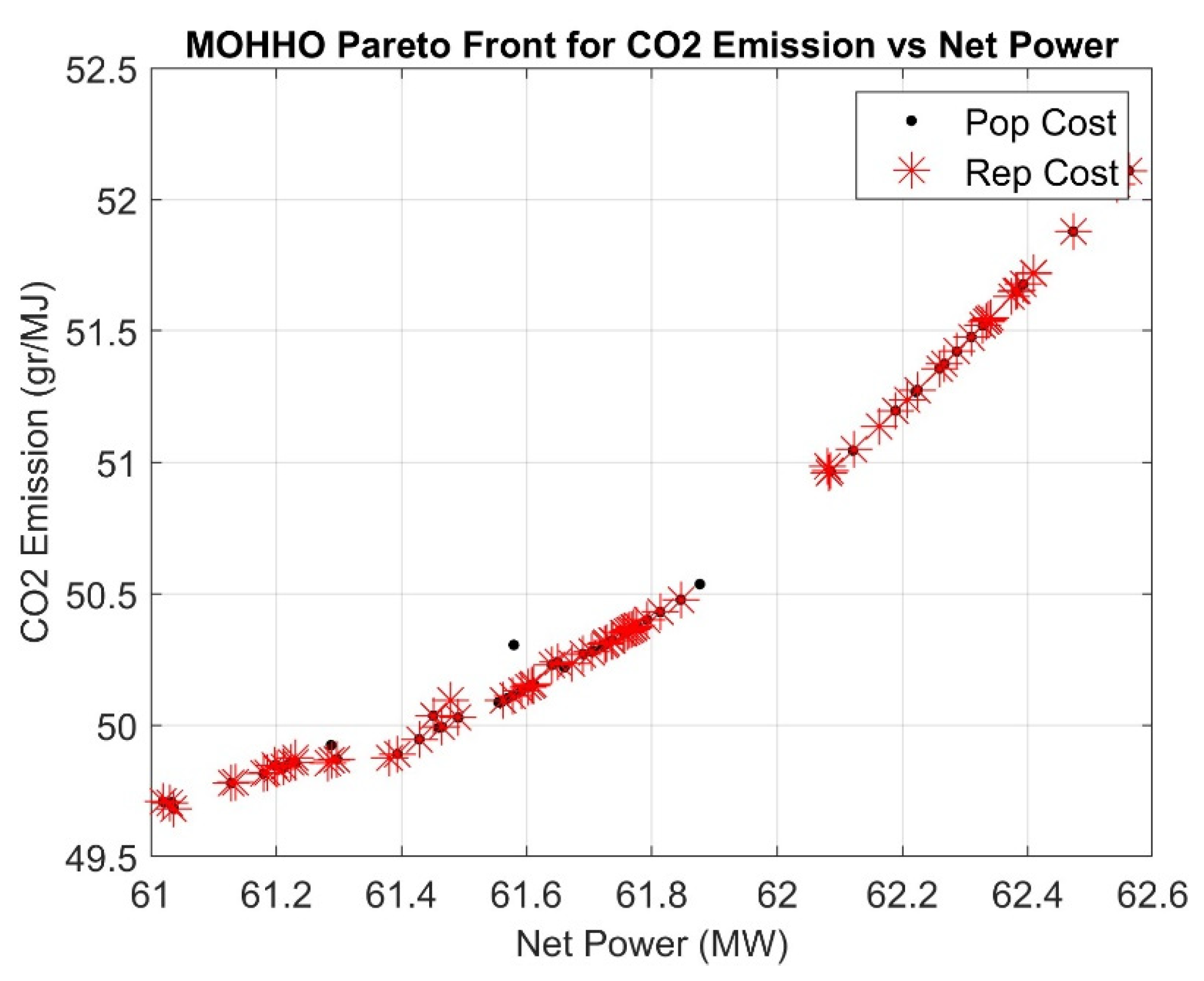

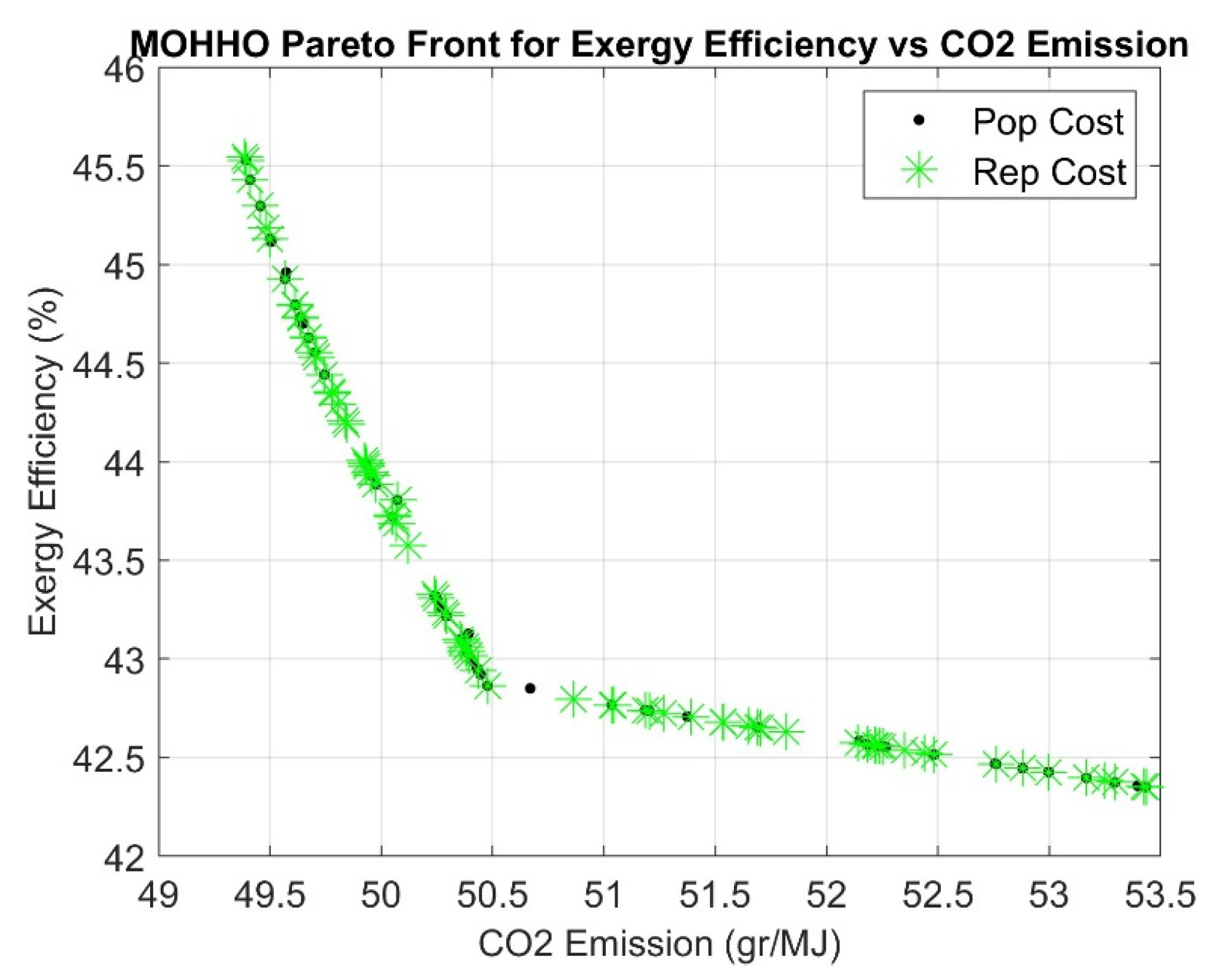

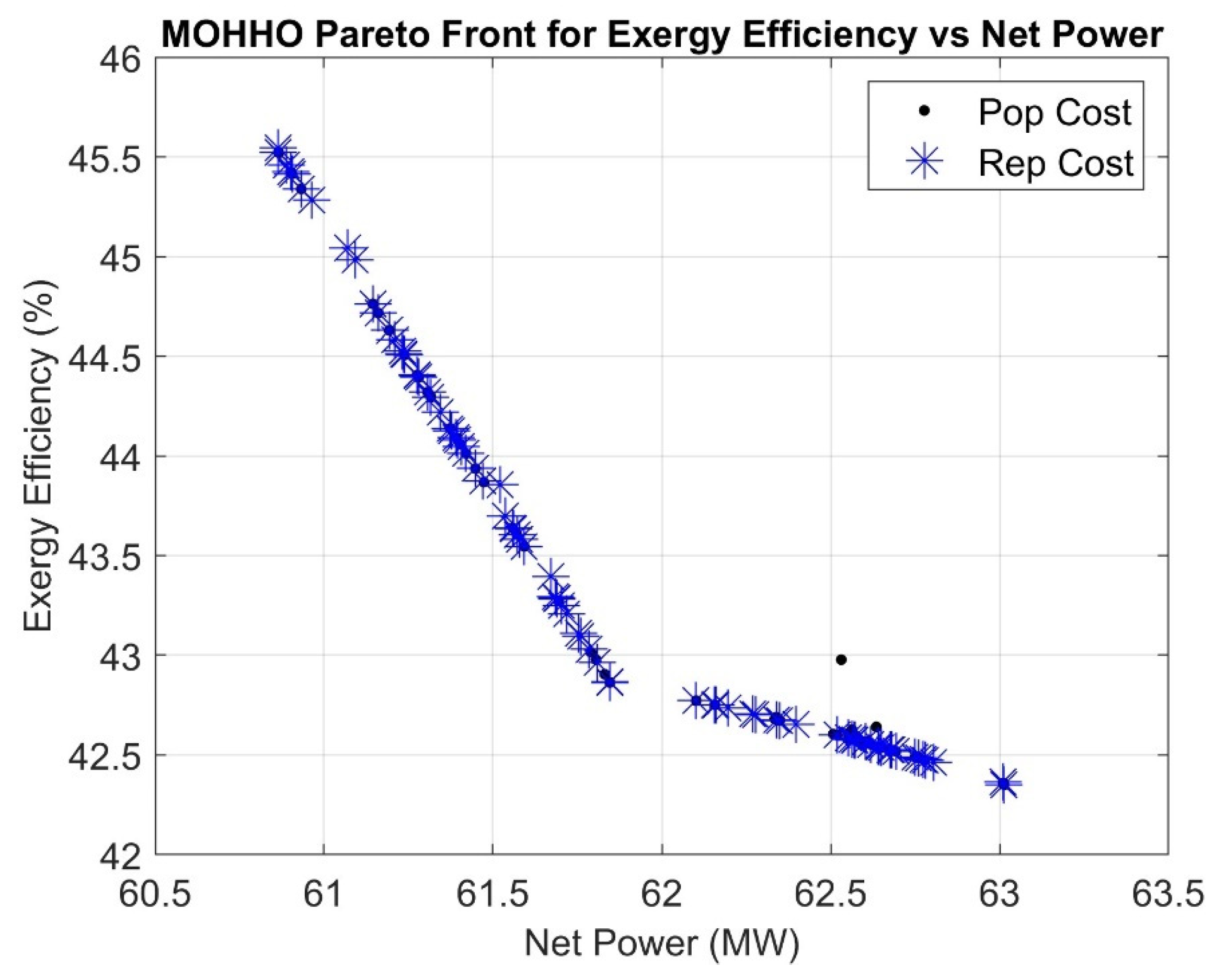

- Evaluation: During the evaluation process, the Pareto dominance was used to determine the domination of the solutions. During each iteration, a solution was included in the archive if it outperformed one or more of the existing solutions in the archive, and if neither the new solution nor the existing solutions in the archive outperformed each other. However, a recently acquired solution was excluded from the archive if it was surpassed by at least one of the existing solutions. When a solution was added to the archive, a resident solution was deleted to maintain the pre-defined archive size. Within each iteration, non-dominated solutions and objective values were obtained and updated until the maximum m number of iterations was attained. The Pareto fronts were used to represent the optimal solutions and their accompanying objective values.

3.4. Mathematical Formulation

4. Results and Discussion

4.1. Single-Objective Optimization

4.1.1. Net Power, CO2 Emission, Exergy Efficiency and Optimization

- Lower the compression ratio, pinch point temperature difference, and the combustion chamber inlet temperature.

- Increase the turbine inlet temperature.

- Decrease the compression ratio, pinch point temperature difference, and turbine inlet temperature.

- Increase the combustion chamber inlet temperature to its highest possible level.

4.1.2. Analysis of the Single-Objective Optimization Outcomes

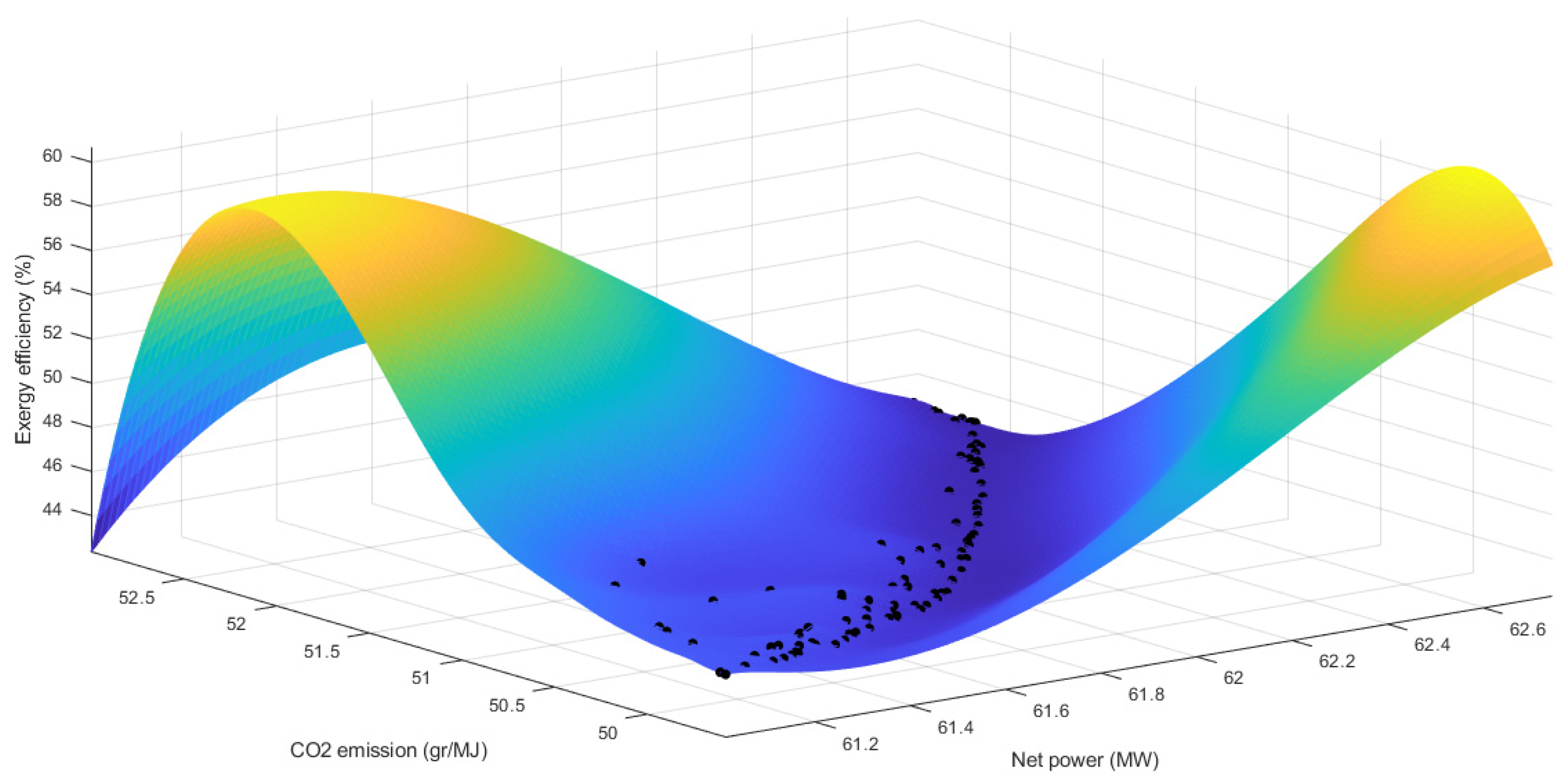

4.2. Multi-Objective Optimization

5. Conclusions

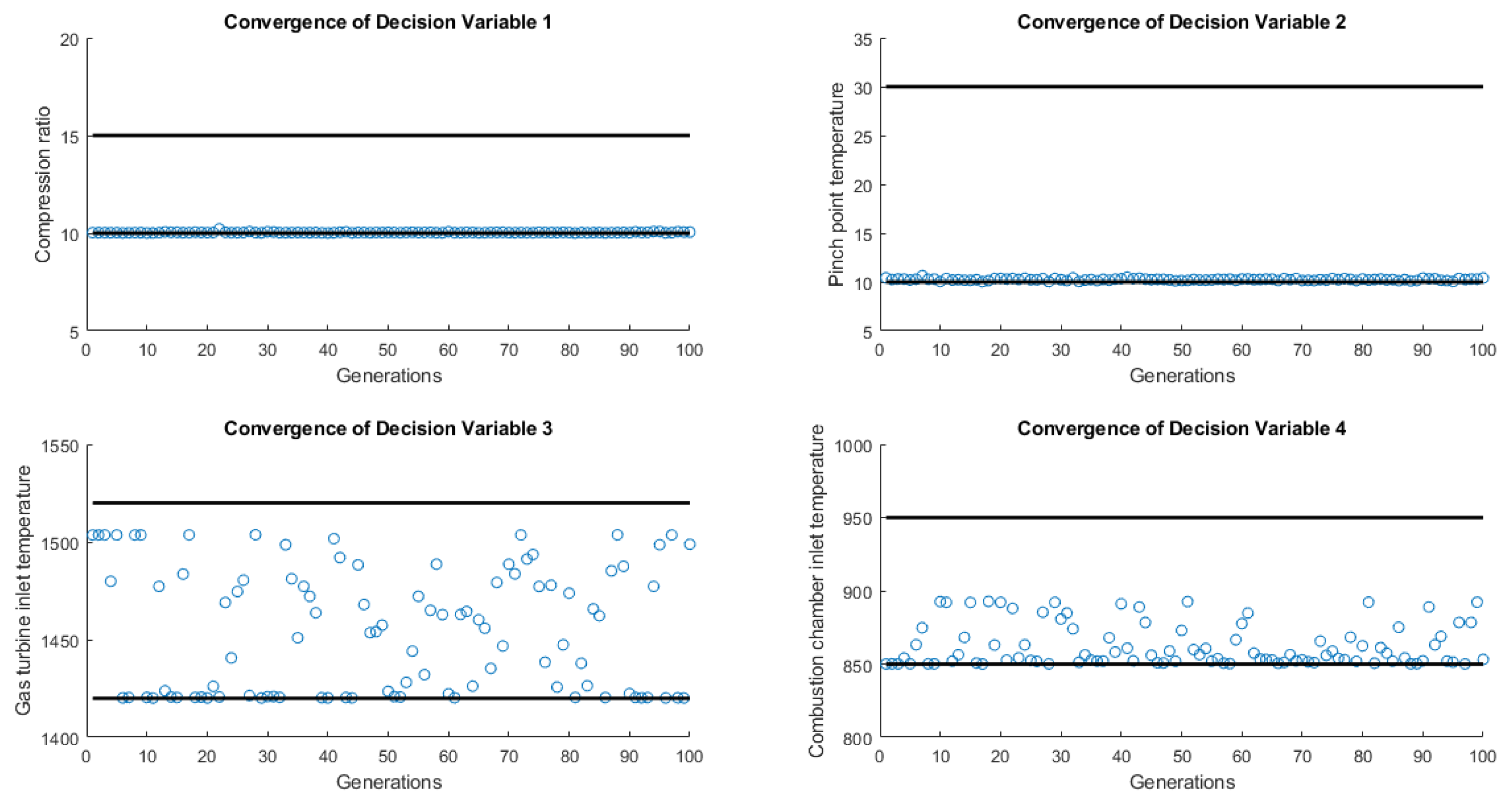

- The most effective parameter configuration for the thermodynamic design of the solar-powered CCHP system is identified using a multi-objective optimization technique with decision variables including compression ratio, pinch point temperature difference, turbine inlet temperature, and combustion chamber inlet temperature.

- The net power, CO2 emissions, and exergy efficiency serve as objective functions for evaluating the efficacy of the CCHP system by assessing how effectively the decision variables meet the restrictions.

- The Harris-Hawk technique is utilized to accomplish multi-objective optimization by generating non-dominated Pareto optimum solutions. This study calculates a collection of Pareto optimal solutions, which are then presented as alternative choices to the decision maker. The objective is to empower the decision-makers to exercise their judgment and improve the efficiency of the CCHP system. The convergence of the individual decisions streamlines the decision-making process.

- Interestingly, the mutual reliance among the four decision variables, within the CCHP system under study, signifies that alterations to a single variable will invariably influence the remaining three. Consequently, employing a multi-objective optimization methodology is recommended for the comprehensive assessment of the system’s operational efficacy.

- The research identified a conflict within decision-making processes concerning the optimization of net power and CO2 emissions. Maximizing net power tends to correlate with increased CO2 emissions, presenting a trade-off as higher net power often leads to elevated CO2 emissions, which is undesirable.

- Another significant observation pertains to the correlation between exergy efficiency and CO2 emissions. It suggests that a system characterized by minimal CO2 emissions tends to exhibit high exergy efficiency. This indicates compatibility wherein a system with minimal CO2 emissions tends to be highly efficient. The study’s findings challenge the assumption that a system with high net power production invariably guarantees high efficiency. This assertion is supported by the inverse relationship observed between net power and exergy efficiency. Hence, it is important to note that attaining a high level of net power does not always result in higher efficiency, as there exists a negative correlation between net power and exergy efficiency.

- The analysis of the convergence of decision variables reveals that optimizing the objective values can be achieved by minimizing the compression ratio, pinch point temperature difference, and inlet combustion chamber temperature. However, it’s noteworthy that the ranges for the gas turbine temperature are spread across the upper and lower bounds of the constraints. This dispersion suggests challenges in achieving convergence for this variable, hinting at potential difficulties in its optimization. Consequently, additional techniques may be necessary to address these challenges and achieve convergence for the gas turbine temperature within the defined constraints.

Author Contributions

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ortiga, J.; Bruno, J.C.; Coronas, A. Operational optimization of a complex trigeneration system connected to a district heating and cooling network. Applied Thermal Engineering 2013, 50, 1536–1542. [Google Scholar] [CrossRef]

- Lozano, M.A.; Carvalho, M.; Serra, L.M. Allocation of economic costs in trigeneration systems at variable load conditions. Energy and Buildings 2011, 43, 2869–2881. [Google Scholar] [CrossRef]

- Wang, L.; Lu, J.; Wang, W.; Ding, J. Energy, environmental and economic evaluation of the CCHP systems for a remote island in south of China. Applied Energy 2016, 183, 874–883. [Google Scholar] [CrossRef]

- Sharma, M.K.; Bhattacharya, J. Finding optimal operating point for advection-cooled concentrated photovoltaic system. Sustainable Energy Technologies and Assessments 2022, 49, 101769. [Google Scholar] [CrossRef]

- Dincer, I.; Zamfirescu, C. Renewable-energy-based multigeneration systems. Int. J. Energy Res. 2012, 36, 1403–1415. [Google Scholar] [CrossRef]

- Nadimi-Shahraki, M.H.; Taghian, S.; Mirjalili, S.; Zamani, H.; Bahreininejad, A. GGWO: Gaze cues learning-based grey wolf optimizer and its applications for solving engineering problems. J. Comput. Sci. 2022, 61, 101636. [Google Scholar] [CrossRef]

- N. Hansen, S.D. Muller, P. Koumoutsakos, Reducing the time complexity of the derandomized evolution strategy with covariance matrix adaptation (CMA-ES). Evol. Comput. 2003, 11, 1–18. [CrossRef]

- Abualigah, L. Multi-verse optimizer algorithm: A comprehensive survey of its results, variants, and applications. Neural Comput. Appl. 2020, 32, 12381–12401. [Google Scholar] [CrossRef]

- Mirjalili, S.; Saremi, S.; Mirjalili, S.M.; Coelho, L.D.S. Multi-objective grey wolf optimizer: A novel algorithm for multi-criterion optimization. Expert Syst. Appl. 2016, 47, 106–119. [Google Scholar] [CrossRef]

- Hasanzadeh, R.; Mojaver, M.; Azdast, T.; Park, C.B. A novel systematic multi-objective optimization to achieve high-efficiency and low-emission waste polymeric foam gasification using response surface methodology and TOPSIS method. Chem. Eng. J. 2022, 430, 132958. [Google Scholar] [CrossRef]

- Ren, F.; Wang, J.; Zhu, S.; Chen, Y. Multi-objective optimization of combined cooling, heating and power system integrated with solar and geothermal energies. Energy Convers. Manag. 2019, 197, 111866. [Google Scholar] [CrossRef]

- Azaza, M.; Wallin, F. Multi objective particle swarm optimization of hybrid micro-grid system: A case study in Sweden. Energy 2017, 123, 108–118. [Google Scholar] [CrossRef]

- Shehab, M.; Mashal, I.; Momani, Z.; Shambour, M.K.Y.; Al-Badareen, A.; Al-Dabet, S.; Bataina, N.; Alsoud, A.R.; Abualigah, L. Harris Hawks Optimization Algorithm: Variants and Applications. Arch. Comput. Methods Eng. 2022, 29, 5579–5603. [Google Scholar] [CrossRef]

- Sharifian, Y.; Abdi, H. Solving multi-zone combined heat and power economic emission dispatch problem considering wind uncertainty by applying grasshopper optimization algorithm. Sustain. Energy Technol. Assess. 2022, 53, 102512. [Google Scholar] [CrossRef]

- Ji, J.; Wang, F.; Zhou, M.; Guo, R.; Ji, R.; Huang, H.; Zhang, J.; Nazir, M.S.; Peng, T.; Zhang, C.; et al. Evaluation Study on a Novel Structure CCHP System with a New Comprehensive Index Using Improved ALO Algorithm. Sustainability 2022, 14, 15419. [Google Scholar] [CrossRef]

- Xu, L.; Luo, X.; Wen, Y.; Wu, T.; Wang, X.; Guan, X. Energy Management of Hybrid Power Ship System Using Adaptive Moth Flame Optimization Based on Multi-Populations. IEEE Trans. Power Syst. 2023, 1–15. [Google Scholar] [CrossRef]

- Ukaegbu, U.; Tartibu, L.; Lim, C.W. Multi-Objective Optimization of a Solar-Assisted Combined Cooling, Heating and Power Generation System Using the Greywolf Optimizer. Algorithms 2023, 16, 463. [Google Scholar] [CrossRef]

- Wang, J.; Han, Z.; Guan, Z. Hybrid solar-assisted combined cooling, heating, and power systems: A review. Renew. Sustain. Energy Rev. 2020, 133, 110256. [Google Scholar] [CrossRef]

- Cao, Y.; Dhahad, H.A.; Togun, H.; Haghghi, M.A.; Athari, H.; Mohamed, A.M. Exergetic and economic assessments and multi-objective optimization of a modified solar-powered CCHP system with thermal energy storage. J. Build. Eng. 2021, 43, 102702. [Google Scholar] [CrossRef]

- Wang, J.; Lu, Y.; Yang, Y.; Mao, T. Thermodynamic performance analysis and optimization of a solar-assisted combined cooling, heating and power system. Energy 2016, 115, 49–59. [Google Scholar] [CrossRef]

- Wang, J.; Liu, Y.; Ren, F.; Lu, S. Multi-objective optimization and selection of hybrid combined cooling, heating and power systems considering operational flexibility. Energy 2020, 197, 117313. [Google Scholar] [CrossRef]

- Song, Z.; Liu, T.; Lin, Q. Multi-objective optimization of a solar hybrid CCHP system based on different operation modes. Energy 2020, 206, 118125. [Google Scholar] [CrossRef]

- Abba, S.I.; Rotimi, A.; Musa, B.; Yimen, N.; Kawu, S.J.; Lawan, S.M.; Dagbasi, M. Emerging Harris Hawks Optimization based load demand forecasting and optimal sizing of stand-alone hybrid renewable energy systems–A case study of Kano and Abuja, Nigeria. Results in Engineering 2021, 12, 100260. [Google Scholar] [CrossRef]

- Yousri, D.; Babu, T.S.; Fathy, A. Recent methodology based Harris Hawks optimizer for designing load frequency control incorporated in multi-interconnected renewable energy plants. Sustainable Energy, Grids and Networks 2020, 22, 100352. [Google Scholar] [CrossRef]

- Zhao, L.; Li, Z.; Chen, H.; Li, J.; Xiao, J.; Yousefi, N. A multi-criteria optimization for a CCHP with the fuel cell as primary mover using modified Harris Hawks optimization. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 2020, pp.1-16.

- Song, Y.; Tan, X.; Mizzi, S. Optimal parameter extraction of the proton exchange membrane fuel cells based on a new Harris Hawks Optimization algorithm. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 2020, pp.1-18.

- Pandey, A.K.; Jadoun, V.K. Real-time and day-ahead risk averse multi-objective operational scheduling of virtual power plant using modified Harris Hawk’s optimization. Electric Power Systems Research 2023, 220, 109285. [Google Scholar] [CrossRef]

- Mahalekshmi, T.; Maruthupandi, P. Multiobjective Economic/Environmental Dispatch Using Harris Hawks Optimization Algorithm. Intelligent Automation And Soft Computing 2023, 36, 445–460. [Google Scholar] [CrossRef]

- Mahdavi, N.; Mojaver, P.; Khalilarya, S. Multi-objective optimization of power, CO2 emission and exergy efficiency of a novel solar-assisted CCHP system using RSM and TOPSIS coupled method. Renew. Energy 2022, 185, 506–524. [Google Scholar] [CrossRef]

- Costa, E.; Almeida, M.F.; Alvim-Ferraz, C.; Dias, J.M. Otimization of Crambe abyssinica enzymatic transesterification using response surface methodology. Renewable Energy 2021, 174, 444–452. [Google Scholar] [CrossRef]

- Kumar, R. A critical review on energy, exergy, exergoeconomic and economic (4-E) analysis of thermal power plants. Engineering Science and Technology, an International Journal 2017, 20, 283–292. [Google Scholar] [CrossRef]

- Bednarz, J.C. Cooperative hunting Harris’ hawks (Parabuteo unicinctus). Science 1988, 239, 1525–1527. [Google Scholar] [CrossRef]

- Heidari, A.A.; Mirjalili, S.; Faris, H.; Aljarah, I.; Mafarja, M.; Chen, H. Harris hawks optimization: Algorithm and applications. Future generation computer systems 2019, 97, 849–872. [Google Scholar] [CrossRef]

| Decision variable | Constraints |

|---|---|

| Compression ratio | 10≤ X1≤15 |

| Pinch point temperature differential | 10≤ X2 ≤30 |

| Turbine inlet temperature | 1420≤ X3≤1520 |

| Combustion chamber inlet temperature | 850≤ X4≤950 |

| S/N | Parameter | Value |

|---|---|---|

| 1 | Maximum Iterations (MaxIt) | 100 |

| 2 | Population Count (nPop) | 100 |

| 3 | Repository Capacity (nRep) | 100 |

| 4 | Inertia Weight | 0.5 |

| 5 | Inertia Weight Damping Factor | 0.99 |

| 6 | Personal Learning Factor | 1 |

| 7 | Global Learning Factor | 2 |

| 8 | Grids per Dimension (nGrid) | 4 |

| 9 | Inflation Factor (alpha) | 0.1 |

| 10 | Leader Selection Pressure (beta) | 2 |

| 11 | Deletion Selection Pressure (gamma) | 2 |

| 12 | Mutation Rate (mu) | 0.1 |

| Objective | X1 | X2 | X3 | X4 | Optimal Objective Value |

|---|---|---|---|---|---|

| Maximum Power | 10 | 10 | 1520 | 850 | 60.8552 |

| Minimum CO2 | 10 | 10 | 1520 | 850 | 49.3771 |

| Maximum Exergy Efficiency | 10 | 10 | 1420 | 950 | 42.3507 |

| Decision variable | Net power | CO2 emission | Exergy efficiency |

|---|---|---|---|

| X1 | ↓ | ↓ | ↓ |

| X2 | ↓ | ↓ | ↓ |

| X3 | ↑ | ↑ | ↓ |

| X4 | ↓ | ↓ | ↑ |

| Optimization technique | Best-Performing Decision Variables | Optimal Performance Metrics | |||||

|---|---|---|---|---|---|---|---|

| X1 | X2 | X3 | X4 | Net Power | CO2 Emission |

Exergy Efficiency |

|

| MOHHO | 10 | 10 | 1420 | 855.34 | 61.91 | 50.61 | 42.84 |

| 10 | 10 | 1422.67 | 850 | 61.82 | 50.44 | 42.94 | |

| 10.28 | 11.14 | 1514.57 | 896.17 | 61.52 | 50.66 | 45.28 | |

| 10 | 10 | 1426.26 | 850 | 61.78 | 50.38 | 43.04 | |

| 10.01 | 10.77 | 1469.76 | 870.77 | 61.60 | 50.33 | 44.15 | |

| 10.28 | 11.14 | 1514.31 | 896.01 | 61.52 | 50.66 | 45.28 | |

| RSM (Mahdavi, Mojaver & Khalilarya [29]) |

11.66 | 11.96 | 1470 | 900 | 61.73 | 52.87 | 44.22 |

| 11.11 | 20.00 | 1470 | 900 | 61.73 | 52.99 | 44.09 | |

| 11.98 | 20.00 | 1470 | 890 | 61.75 | 53.84 | 44.12 | |

| 12.50 | 16.10 | 1484 | 900 | 61.75 | 54.07 | 44.58 | |

| 12.50 | 15.72 | 1470 | 891 | 61.79 | 54.07 | 44.10 | |

| 12.50 | 20.00 | 1468 | 882 | 61.75 | 54.28 | 44.30 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).