Submitted:

30 August 2024

Posted:

30 August 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

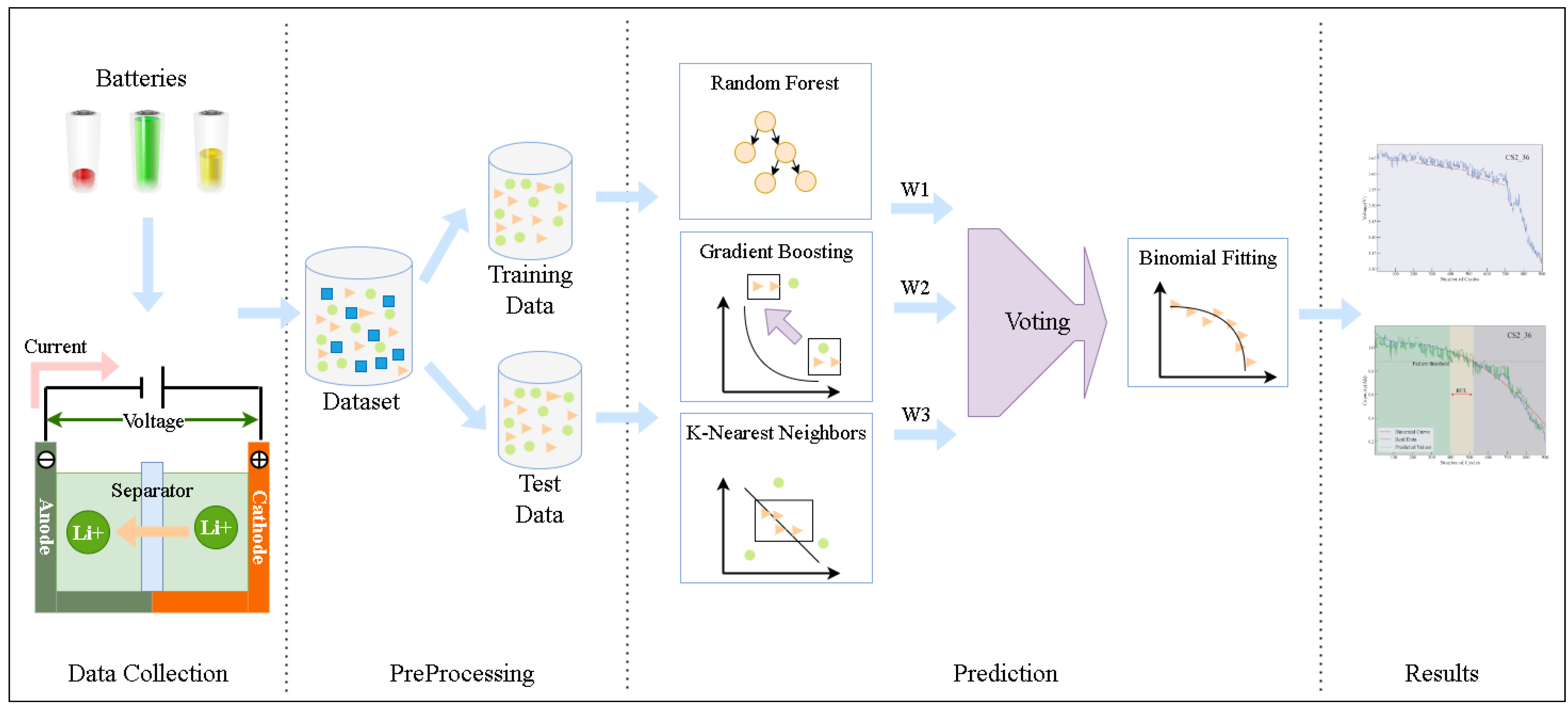

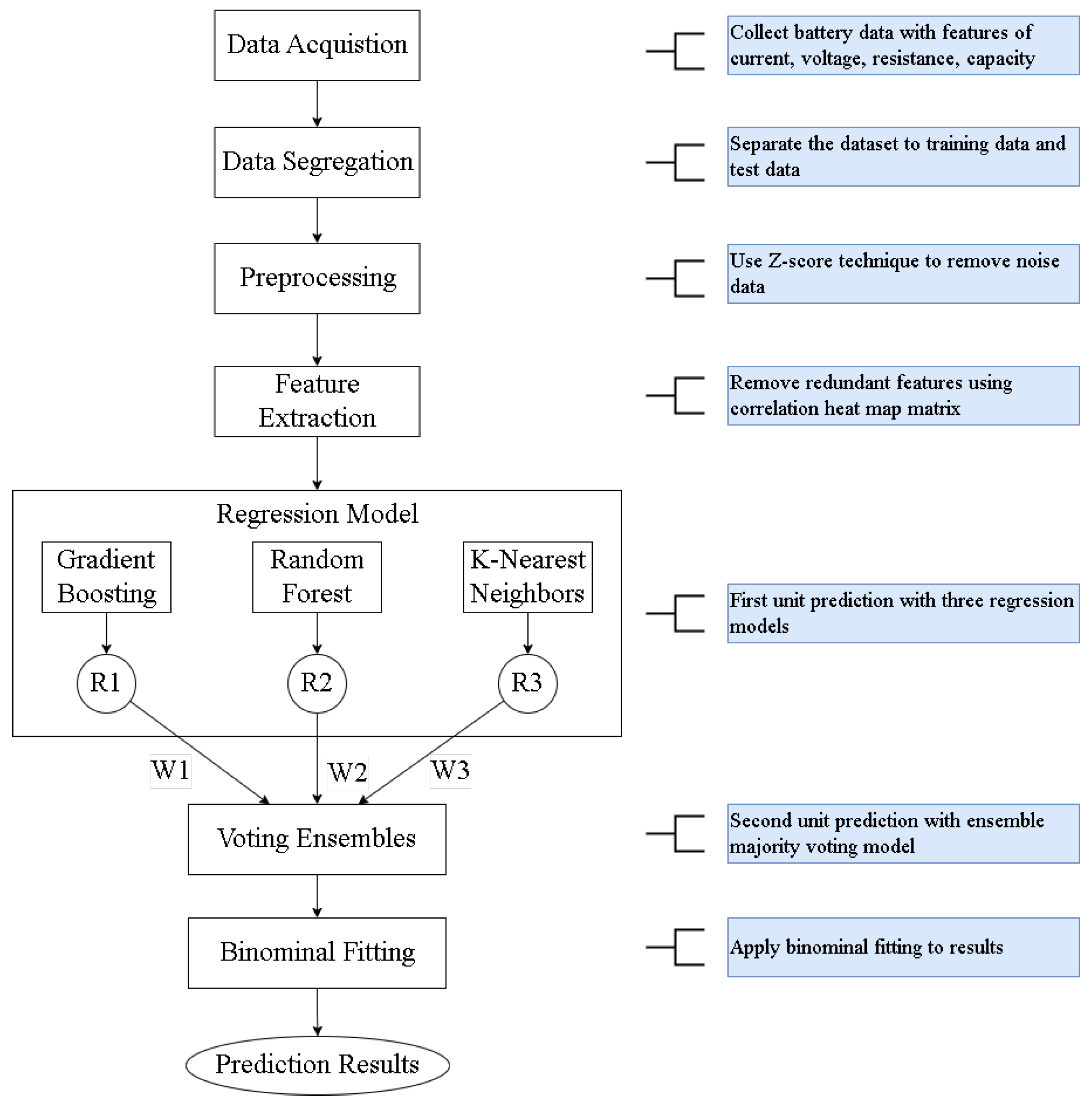

2. Methods

2.1. Gradient Boosting

2.2. Random Forest

2.3. K-Nearest Neighbor

2.4. Voting Ensembles

3. Experiments

3.1. Experiment and Dataset

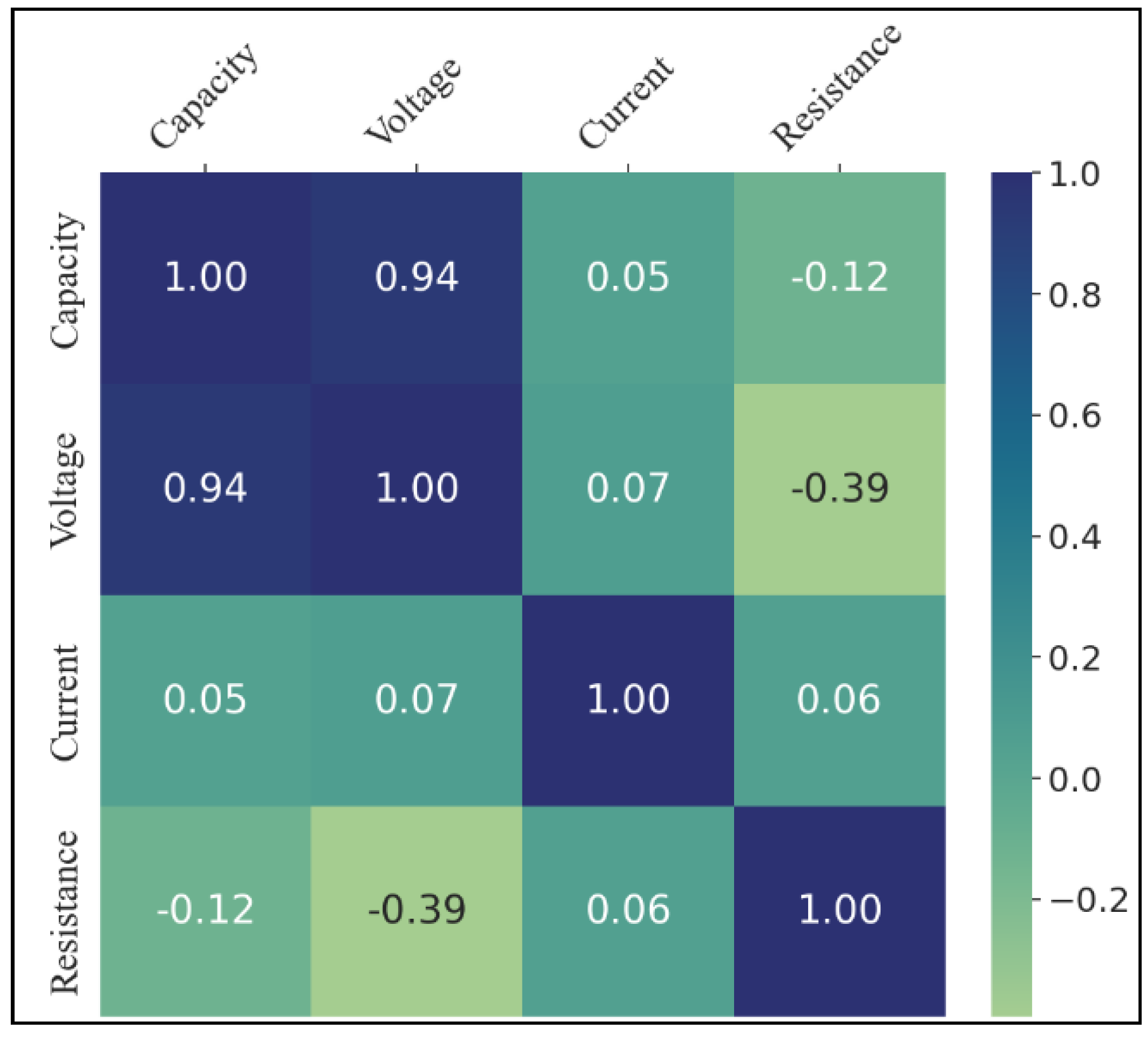

3.2. Data Standardization

3.3. Estimation Indicator and Process

3.4. Evaluation Metrics

4. Result and Discussion

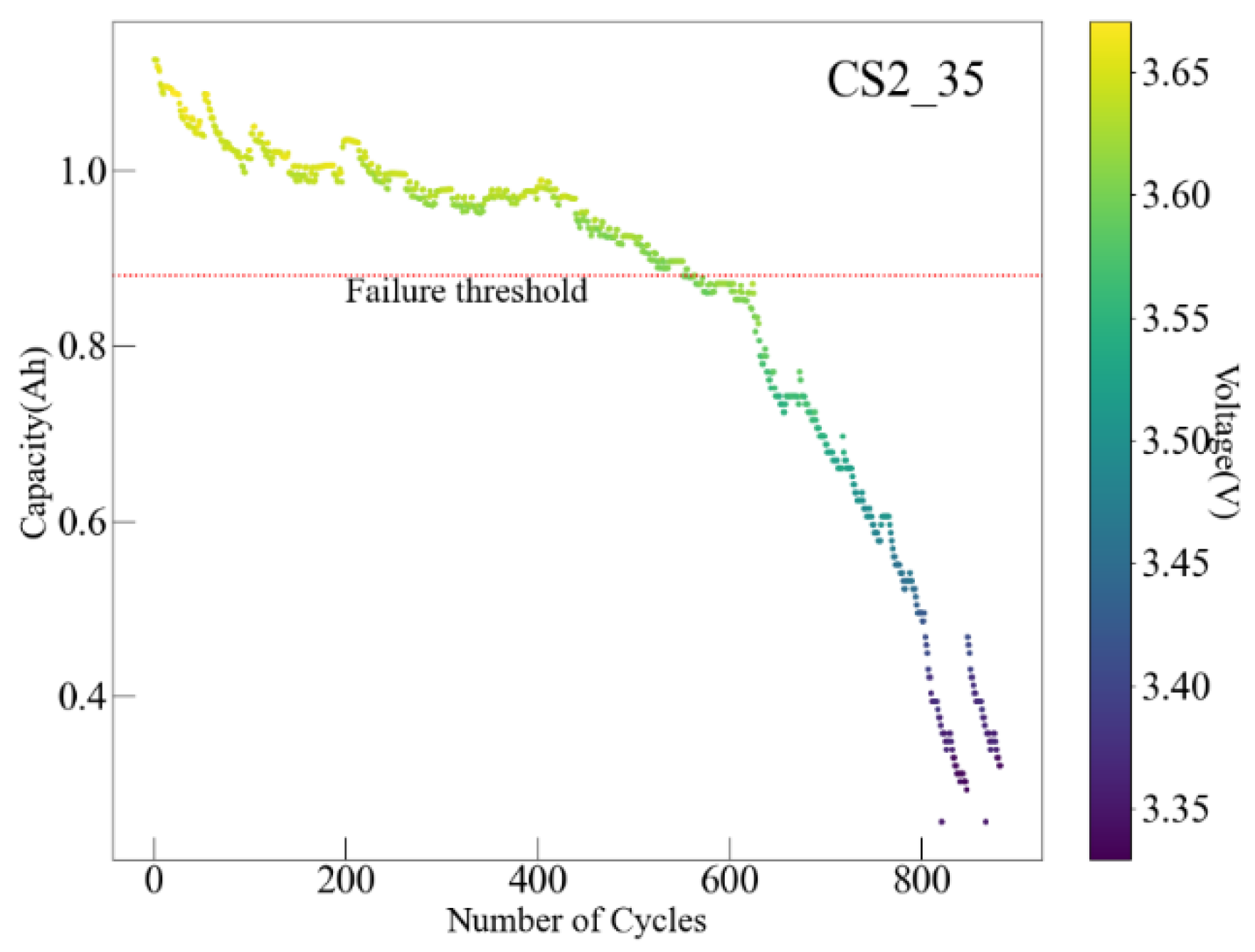

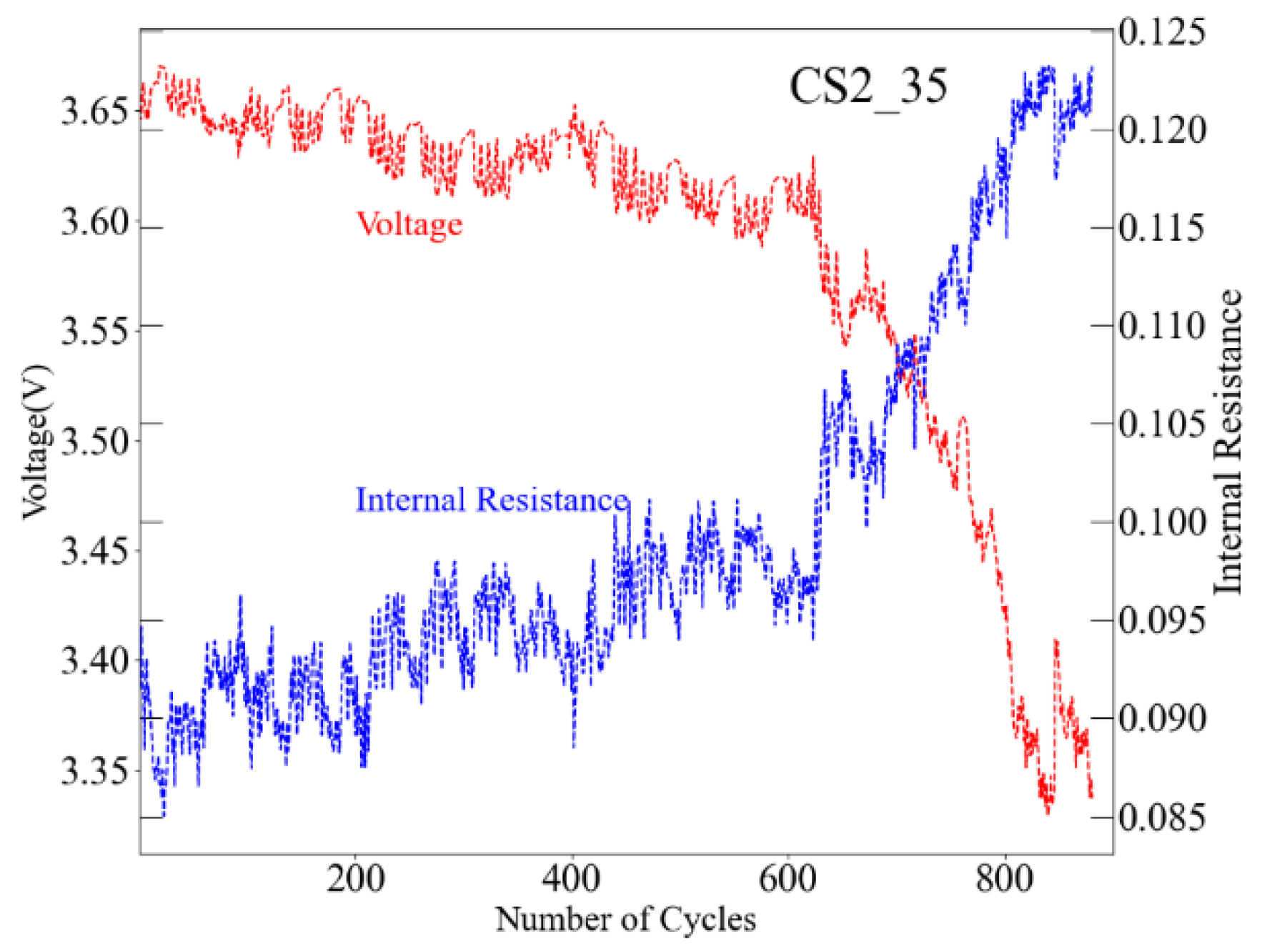

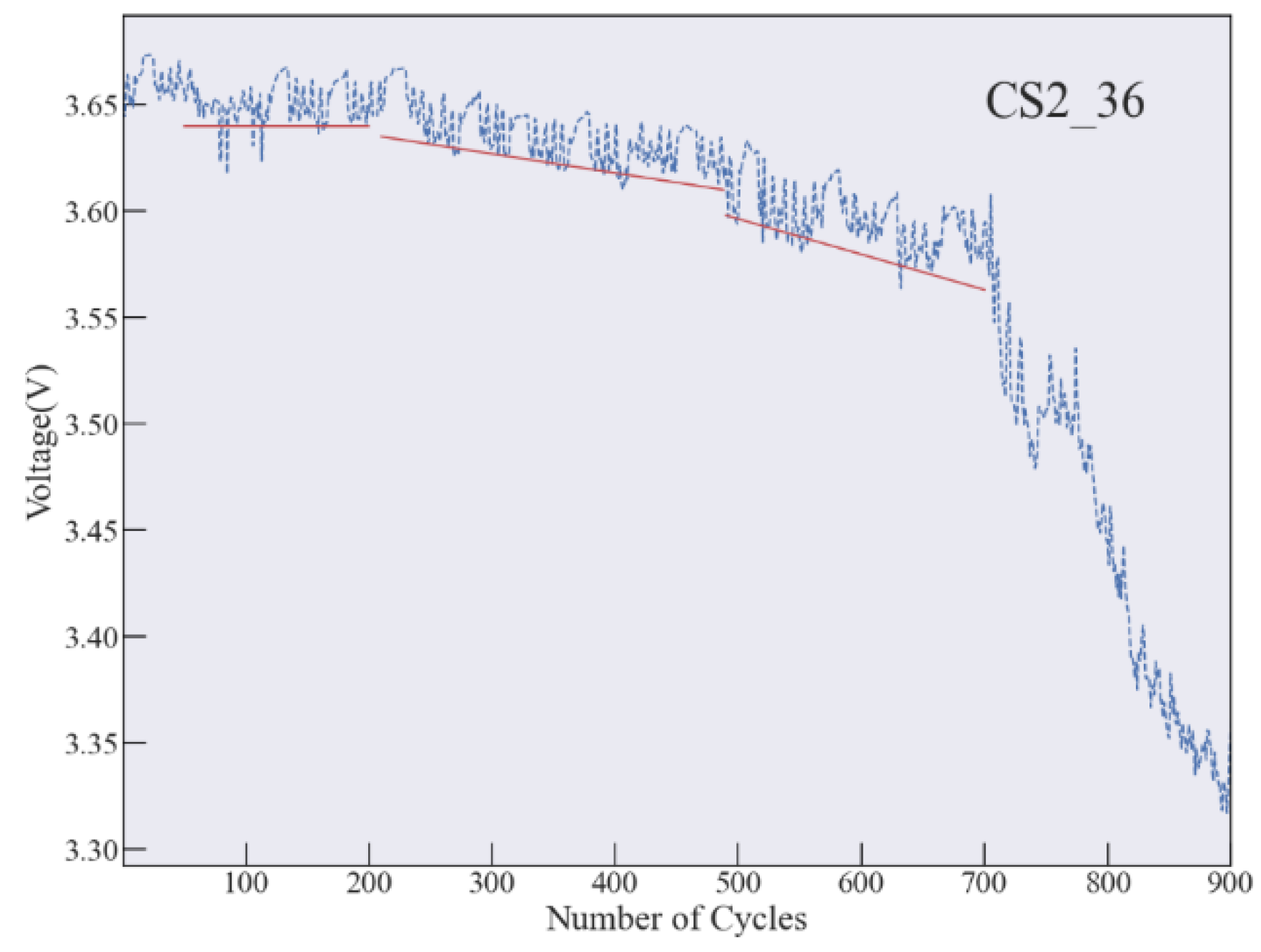

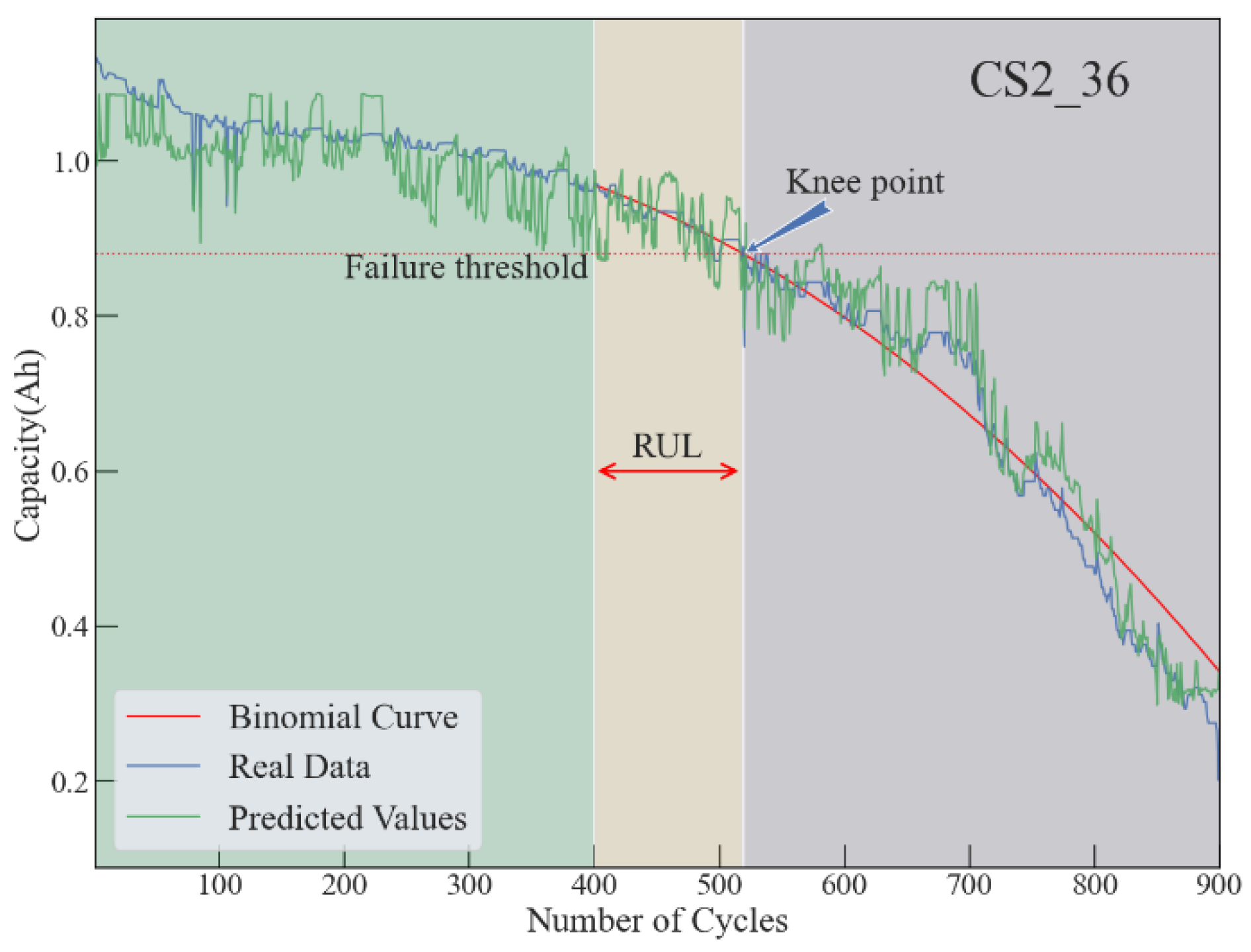

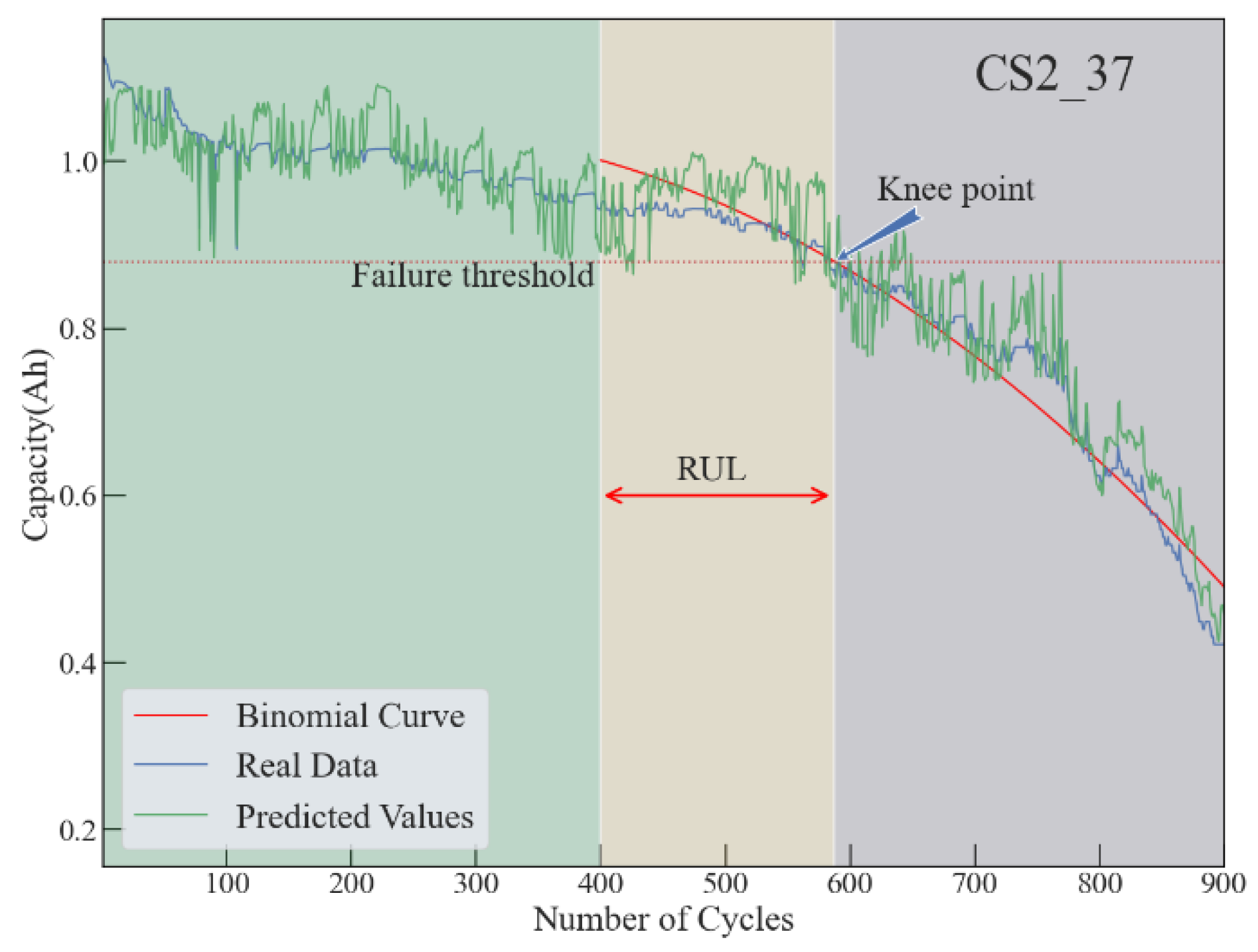

4.1. Prediction for Battery with Short Voltage Decline Period

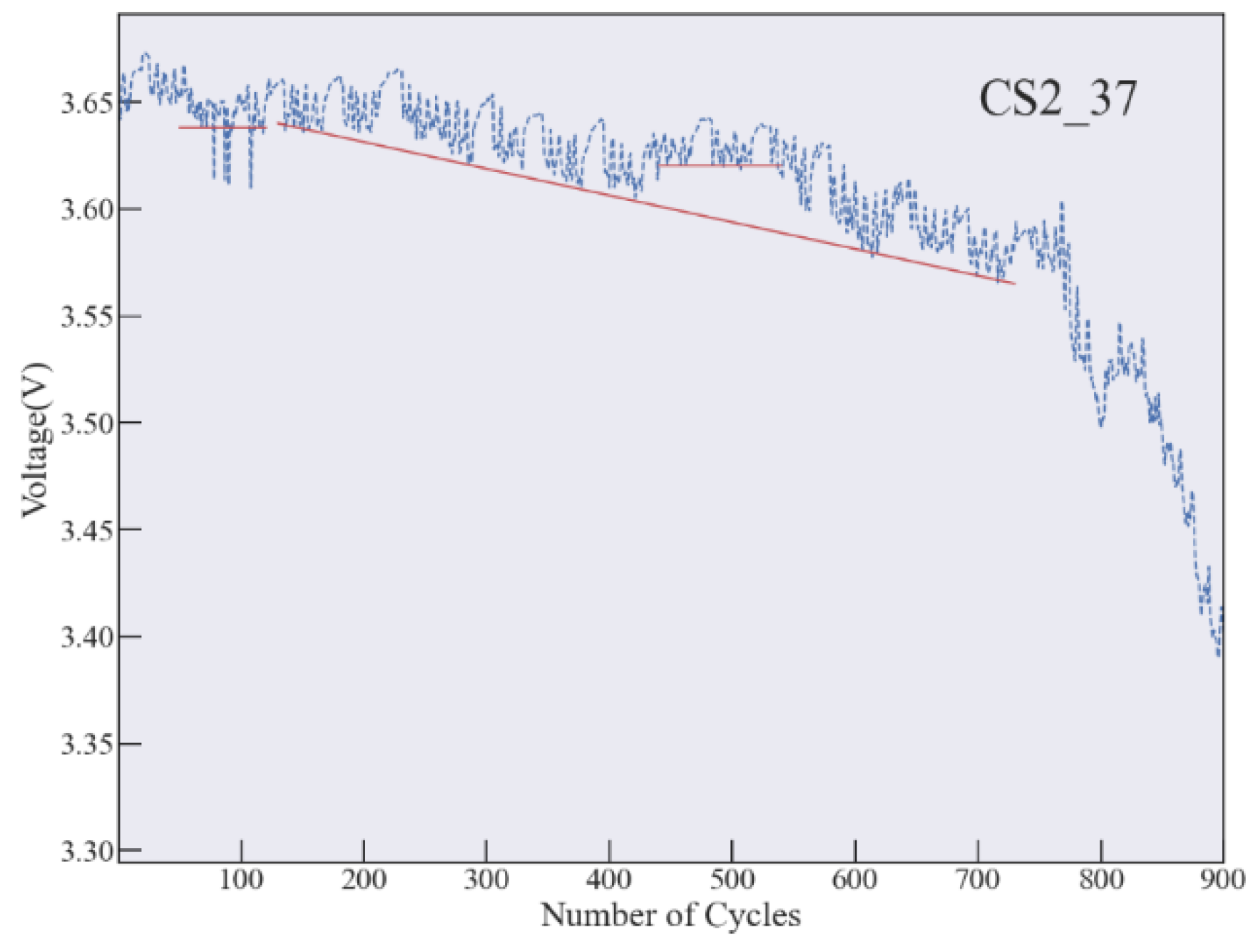

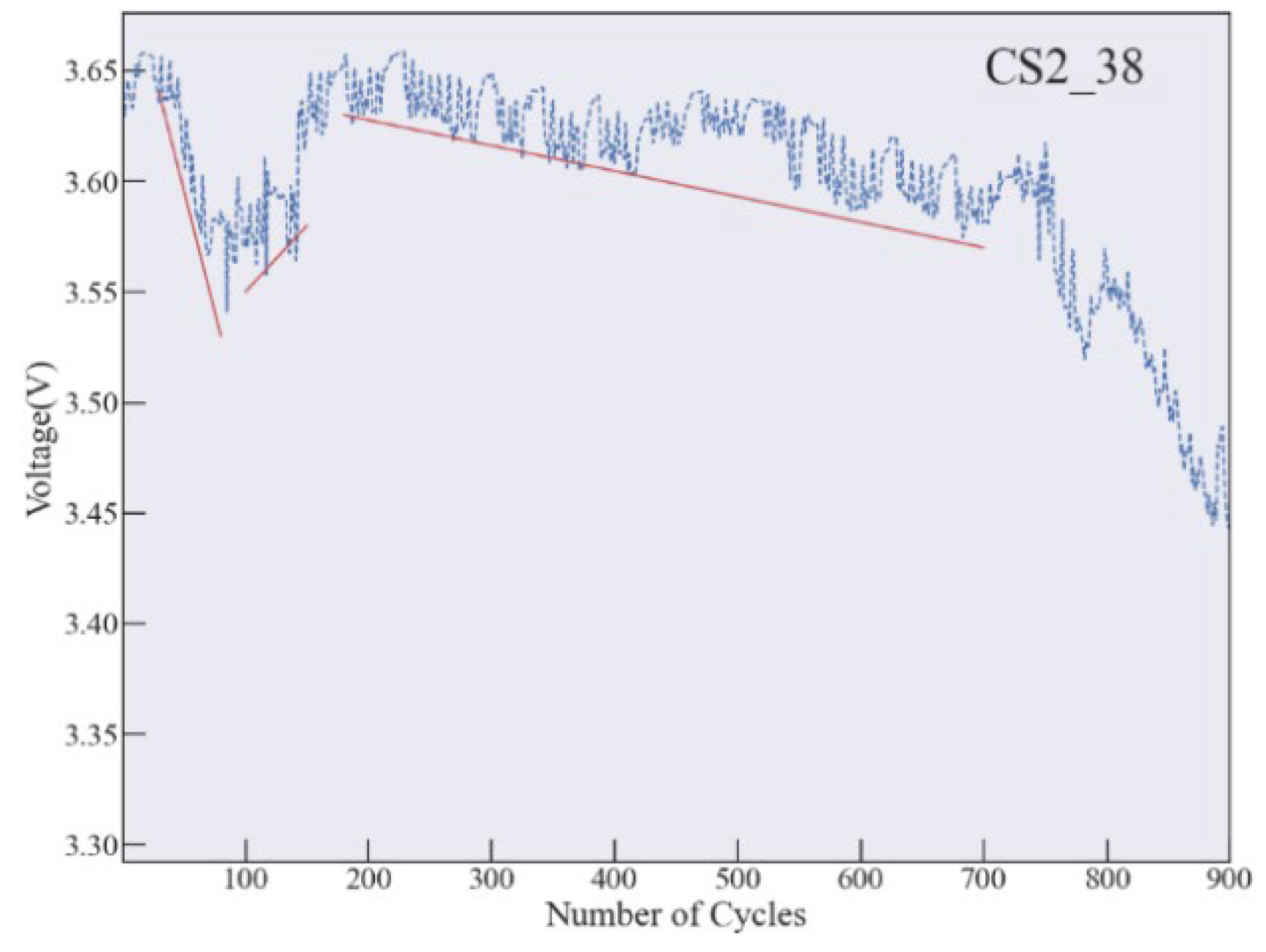

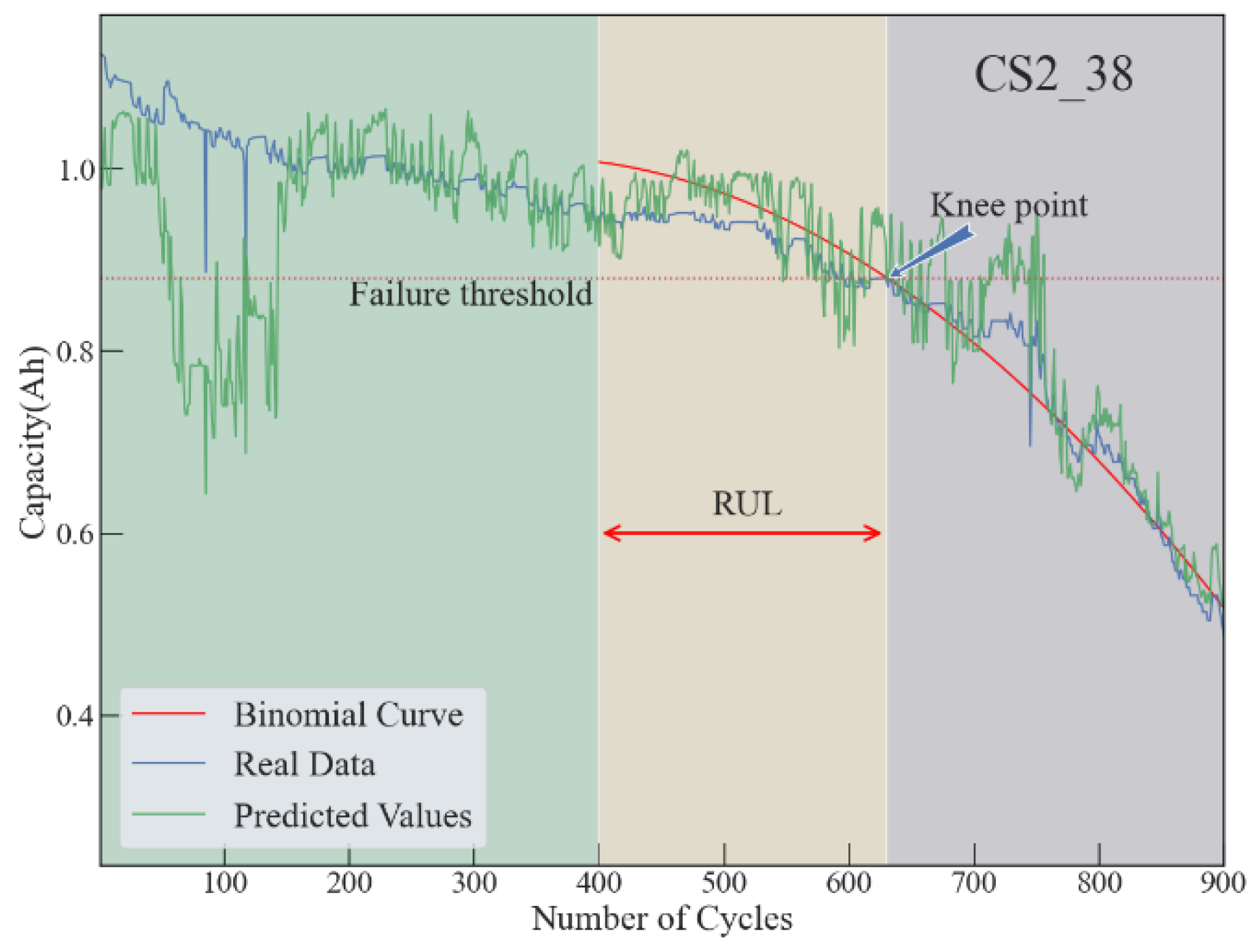

4.2. Prediction for Battery with Stable Voltage Decline Period

4.3. Prediction for Battery with Unstable Voltage Decline Period

4.4. Overall Performance

5. Conclusion

Acknowledgments

References

- Perera F. Pollution from Fossil-Fuel Combustion is the Leading Environmental Threat to Global Pediatric Health and Equity: Solutions Exist. International Journal of Environmental Research and Public Health, 2018. [CrossRef]

- Xuebing Han, Languang Lu, Yuejiu Zheng, Xuning Feng, Zhe Li, Jianqiu Li, Minggao Ouyang. A review on the key issues of the lithium ion battery degradation among the whole life cycle, eTransportation, 2019, 1: 100005. [CrossRef]

- Liang Ma, Jinp eng Tian, Tieling Zhang, Qinghua Guo, Chunsheng Hu. Accurate and efficient remaining useful life prediction of batteries enabled by physics-informed machine learning, Journal of Energy Chemistry, 2024, 91: 512-521. [CrossRef]

- Xiao-Sheng Si, Wenbin Wang, Chang-Hua Hu, Dong-Hua Zhou. Remaining useful life estimation – A review on the statistical data driven approaches. European Journal of Operational Research, 2011, 213: 1-14. [CrossRef]

- M.S. Reza, M. Mannan, M. Mansor, Pin Jern Ker, T. M. Indra Mahlia, M.A. Hannan. Recent advancement of remaining useful life prediction of lithium-ion battery in electric vehicle applications: A review of modelling mechanisms, network configurations, factors, and outstanding issues. Energy Reports, 2024, 11: 4824-4848. [CrossRef]

- Lin Chen, Jingjing An, Huimin Wang, Mo Zhang, Haihong Pan. Remaining useful life prediction for lithium-ion battery by combining an improved particle filter with sliding-window gray model. Energy Reports, 2020, 6: 2086-2093. [CrossRef]

- K. Liu, Y. Shang, Q. Ouyang and W. D. Widanage. A Data-Driven Approach With Uncertainty Quantification for Predicting Future Capacities and Remaining Useful Life of Lithium-ion Battery. IEEE Transactions on Industrial Electronics, 2021, 68: 3170-3180. [CrossRef]

- Azevedo, B.F., Rocha, A.M.A.C., Pereira, A.I. Hybrid approaches to optimization and machine learning methods: a systematic literature review. Mach Learn, 2024, 113: 4055–4097. [CrossRef]

- Jun Yuan, Zhili Qin, Haikun Huang, Xingdong Gan, Ziwei Wang, Yichen Yang, Shujiang Liu, An Wen, Chuang Bi, Baihai Li, Chenghua Sun. Progress in the prognosis of battery degradation and estimation of battery states. Sci. China Mater, 2024, 67: 1014–1041. [CrossRef]

- Yapeng Zhou, Miaohua Huang, Michael Pecht. Remaining useful life estimation of lithium-ion cells based on k-nearest neighbor regression with differential evolution optimization. Journal of Cleaner Production, 2020, 249: 119409. [CrossRef]

- Jafari S, Shahbazi Z, Byun Y-C, Lee S-J. Lithium-Ion Battery Estimation in Online Framework Using Extreme Gradient Boosting Machine Learning Approach. Mathematics, 2022, 10(6): 888. [CrossRef]

- Jafari, S., Byun, YC. Enhancing Predictive Battery Maintenance Through the Use of Explainable Boosting Machine. Kabassi, K., Mylonas, P., Caro, J. (eds) Novel & Intelligent Digital Systems: Proceedings of the 3rd International Conference (NiDS 2023). Lecture Notes in Networks and Systems, 2023, 784.

- Wang G, Lyu Z, Li X. An Optimized Random Forest Regression Model for Li-Ion Battery Prognostics and Health Management. Batteries, 2023, 9(6), 332. [CrossRef]

- Jiaju Wu, Linggang Kong, Zheng Cheng, Yonghui Yang, Hongfu Zuo. RUL Prediction for Lithium Batteries Using a Novel Ensemble Learning Method. Energy Reports, 2022, 8(12): 313-326. [CrossRef]

- Lv K, Ma Z, Bao C, Liu G. Indirect Prediction of Lithium-Ion Battery RUL Based on CEEMDAN and CNN-BiGRU. Energies, 2024, 17(7): 1704. [CrossRef]

- Xu, Qing & Wu, Min & Khoo, Edwin & Chen, Zhenghua & Li, Xiaoli. A Hybrid Ensemble Deep Learning Approach for Early Prediction of Battery Remaining Useful Life. IEEE/CAA Journal of Automatica Sinica, 2023, 10: 177-187. [CrossRef]

- Paula Fermín-Cueto, Euan McTurk, Michael Allerhand, Encarni Medina-Lopez, Miguel F. Anjos, Joel Sylvester, Gonçalo dos Reis. Identification and machine learning prediction of knee-point and knee-onset in capacity degradation curves of lithium-ion cells. Energy and AI, 2020, 1: 100006. [CrossRef]

- Jerome H. Friedman. Greedy function approximation: A gradient boosting machine. Annals of Statistics, 2001, 29. [CrossRef]

- Leo Breiman. Random Forests. Machine Learning, 2001, 45.

- Adele Cutler, David Cutler, and John Stevens. Random Forests. Machine Learning – ML. 2011, 45.

- Syriopoulos, P.K., Kalampalikis, N.G., Kotsiantis, S.B. et al. kNN Classification: a review. Ann Math Artif Intell , 2023. [CrossRef]

- Ammar Mohammed, Rania Kora. A comprehensive review on ensemble deep learning: Opportunities and challenges. Journal of King Saud University - Computer and Information Sciences, 2023, 35(2): 757-774. [CrossRef]

- Eric Bax. Selecting a number of voters for a voting ensemble. CoRR abs/2104.11833, 2021.

- Gonçalo dos Reis, Calum Strange, Mohit Yadav, Shawn Li. Lithium-ion battery data and where to find it. Energy and AI, 2021, 5(100081). [CrossRef]

- Wei He, Nicholas Williard, Michael Osterman, Michael Pecht. Prognostics of lithium-ion batteries based on Dempster–Shafer theory and the Bayesian Monte Carlo method. Journal of Power Sources, 2011, 196(23): 10314-10321. [CrossRef]

- Yinjiao Xing, Eden W.M. Ma, Kwok-Leung Tsui, Michael Pecht. An ensemble model for predicting the remaining useful performance of lithium-ion batteries. Microelectronics Reliability, 2013, 53(6): 811-820. [CrossRef]

- Williard, Nick & He, Wei & Osterman, Michael & Pecht, Michael. Comparative Analysis of Features for Determining State of Health in Lithium-Ion Batteries. International Journal of Prognostics and Health Management, 2013, 4. [CrossRef]

- Omenya Fredrick, Paiss Matthew, Li Xiaolin, Reed David. Energy and Power Evolution Over the Lifetime of a Battery. ACS Energy Letters, 2023, 8(6). [CrossRef]

- Edge Jacqueline S, O’Kane Simon, Prosser Ryan, et al. Lithium-ion battery degradation: what you need to know. Phys. Chem. Chem. Phys, 2021, 23. [CrossRef]

- Cheng Lin, Aihua Tang, Hao Mu, Wenwei Wang, Chun Wang. Aging Mechanisms of Electrode Materials in Lithium-Ion Batteries for Electric Vehicles. Journal of Chemistry 2015, 2015, 1. [CrossRef]

- Jorn M. Reniers, Grietus Mulder, David A. Howey. Review and Performance Comparison of Mechanical-Chemical Degradation Models for Lithium-Ion Batteries. Journal of The Electrochemical Society, 2019, 166(14). [CrossRef]

- Tang X, Wan H, Wang W, Gu M, Wang L, Gan L. Lithium-Ion Battery Remaining Useful Life Prediction Based on Hybrid Model. Sustainability, 2023, 15(7): 6261. [CrossRef]

- Zuxin Li, Shengyu Shen, Yifu Ye, Zhiduan Cai, Aigang Zhen. An interpretable online prediction method for remaining useful life of lithium-ion batteries. Sci Rep 14, 2024, 12541. [CrossRef]

- Xing Shu, Shiquan Shen, Jiangwei Shen, Yuanjian Zhang, Guang Li, Zheng Chen, Yonggang Liu. State of health prediction of lithium-ion batteries based on machine learning: Advances and perspectives, iScience. 24, 2021, 11: 103265. [CrossRef]

- Daoquan Chen, Weicong Hong, Xiuze Zhou. Transformer Network for Remaining Useful Life Prediction of Lithium-Ion Batteries. IEEE Access, 2022, 10: 19621-19628. [CrossRef]

- Wei Liu , Yan Xu. Data-Driven Online Health Estimation of Li-Ion Batteries Using A Novel Energy-Based Health Indicator. IEEE Transactions on Energy Conversion, 2020, 35(3). [CrossRef]

- Yi Li, Kailong Liu, Aoife M. Foley, Alana Zülke, Maitane Berecibar, Elise Nanini-Maury, Joeri Van Mierlo, Harry E. Hoster. Data-driven health estimation and lifetime prediction of lithium-ion batteries: A review. Renewable and Sustainable Energy Reviews, 2019, 113: 109254. [CrossRef]

- Thieu Nguyen, Nhuan Tran, Binh Minh Nguyen, Giang Nguyen. A Resource Usage Prediction System Using Functional-Link and Genetic Algorithm Neural Network for Multivariate Cloud Metrics. 2018 IEEE 11th Conference on Service-Oriented Computing and Applications (SOCA), 2018.

- Thieu Nguyen, Binh Minh Nguyen, and Giang Nguyen. Building Resource Autoscaler with Functional-Link Neural Network and Adaptive Bacterial Foraging Optimization. Theory and Applications of Models of Computation, 2019. [CrossRef]

- Binh Minh Nguyen, Bao Hoang, Thieu Nguyen, Giang Nguyen. Nqsv-net: a novel queuing search variant for global space search and workload modeling. Journal of Ambient Intelligence and Humanized Computing, 2021. [CrossRef]

| Algorithm | MAE | RMSE | RE | |

|---|---|---|---|---|

| K-Nearest Neighbor | 0.044788 | 0.057151 | 0.085195 | 0.951340 |

| Random Forest | 0.044589 | 0.055903 | 0.083007 | 0.953442 |

| Gradient Boosting | 0.043230 | 0.054165 | 0.075759 | 0.956291 |

| Hybrid Ensembles for CS2_36 | 0.037993 | 0.048951 | 0.072705 | 0.964301 |

| Hybrid Ensembles for CS2_37 | 0.032584 | 0.040113 | 0.045291 | 0.962737 |

| Hybrid Ensembles for CS2_38 | 0.051992 | 0.084168 | 0.059868 | 0.829940 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).