Submitted:

29 August 2024

Posted:

02 September 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Results

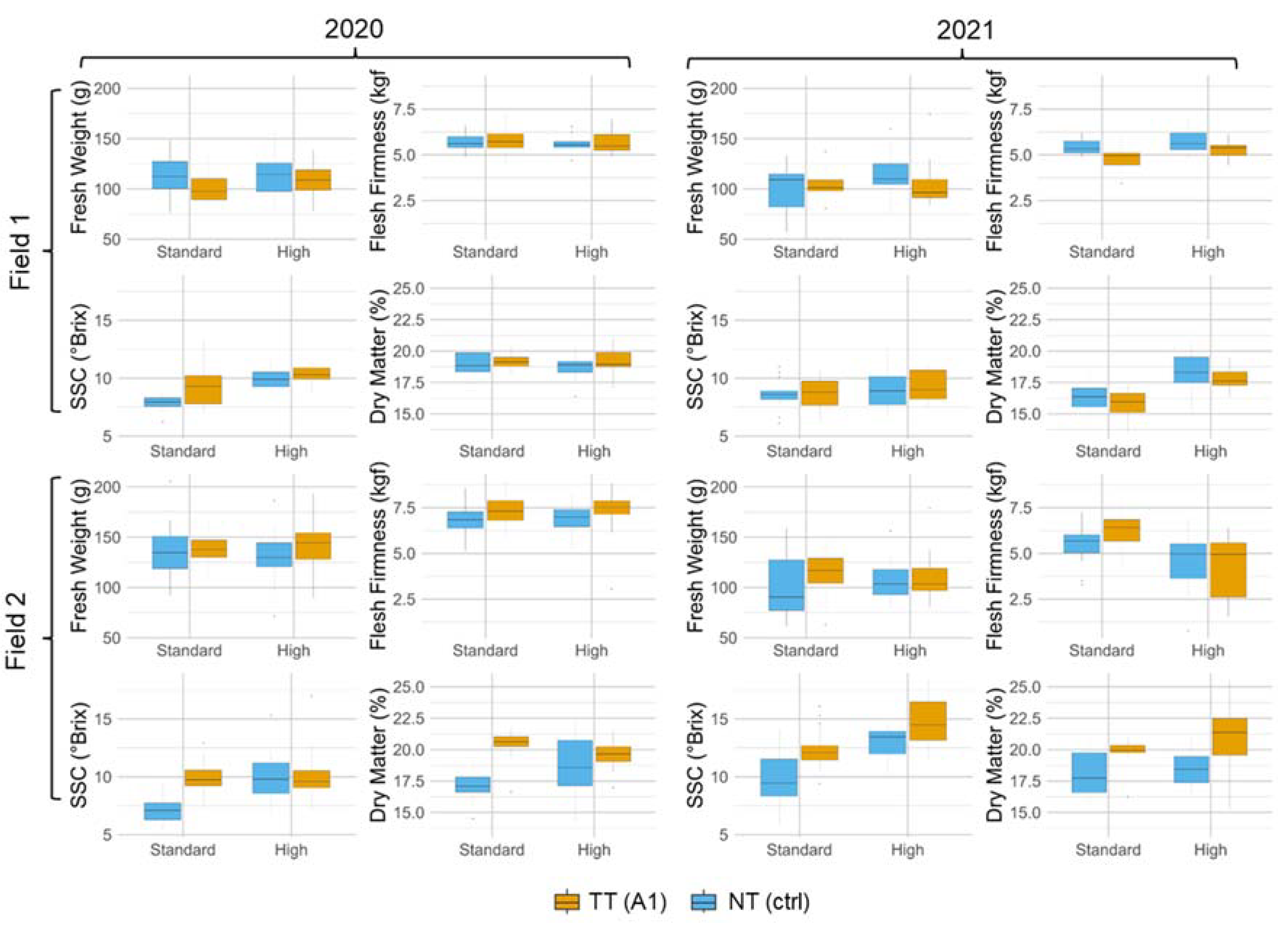

2.1. Application Strategy A1

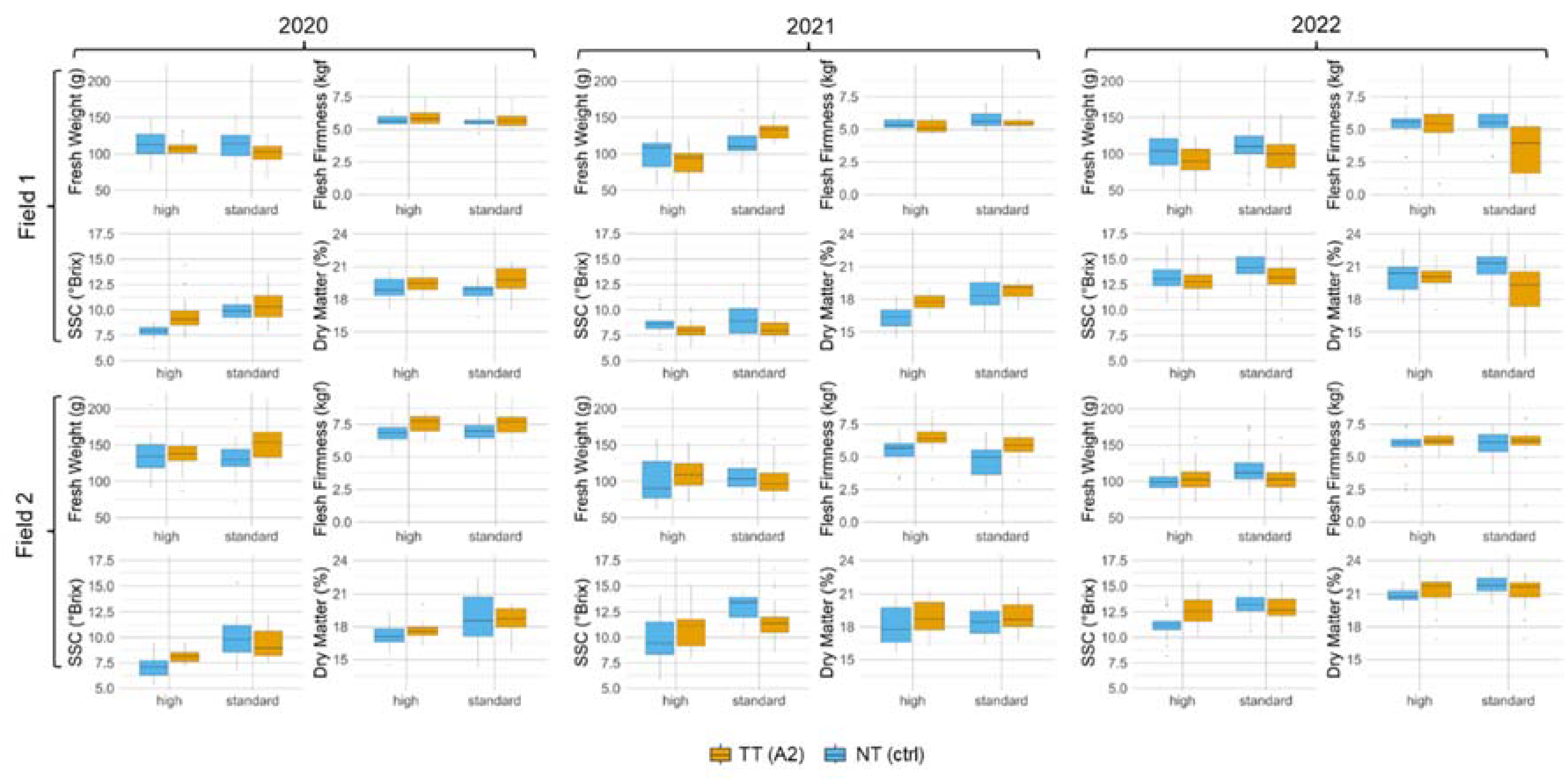

2.2. Application Strategy A2

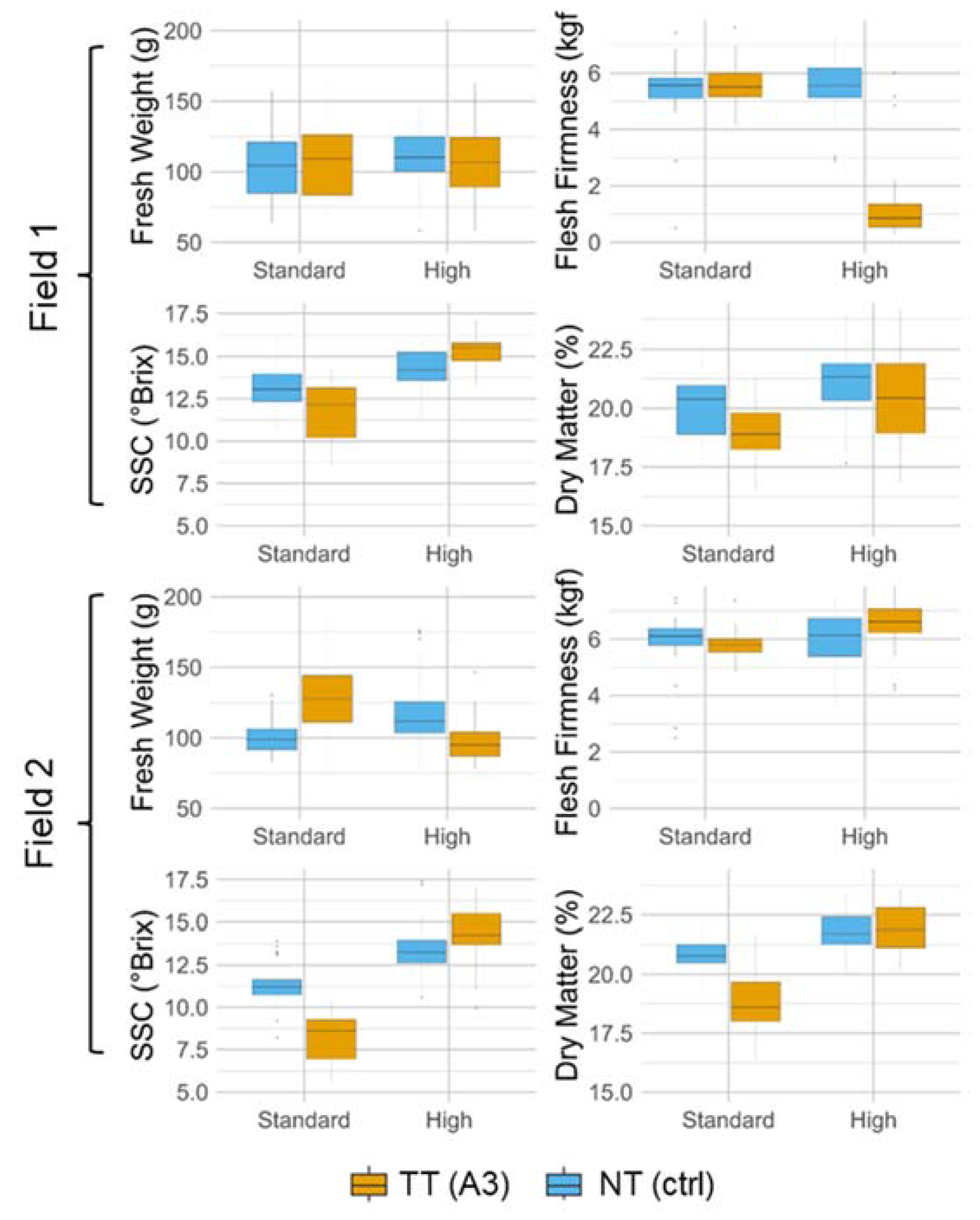

2.3. Application Strategy A3

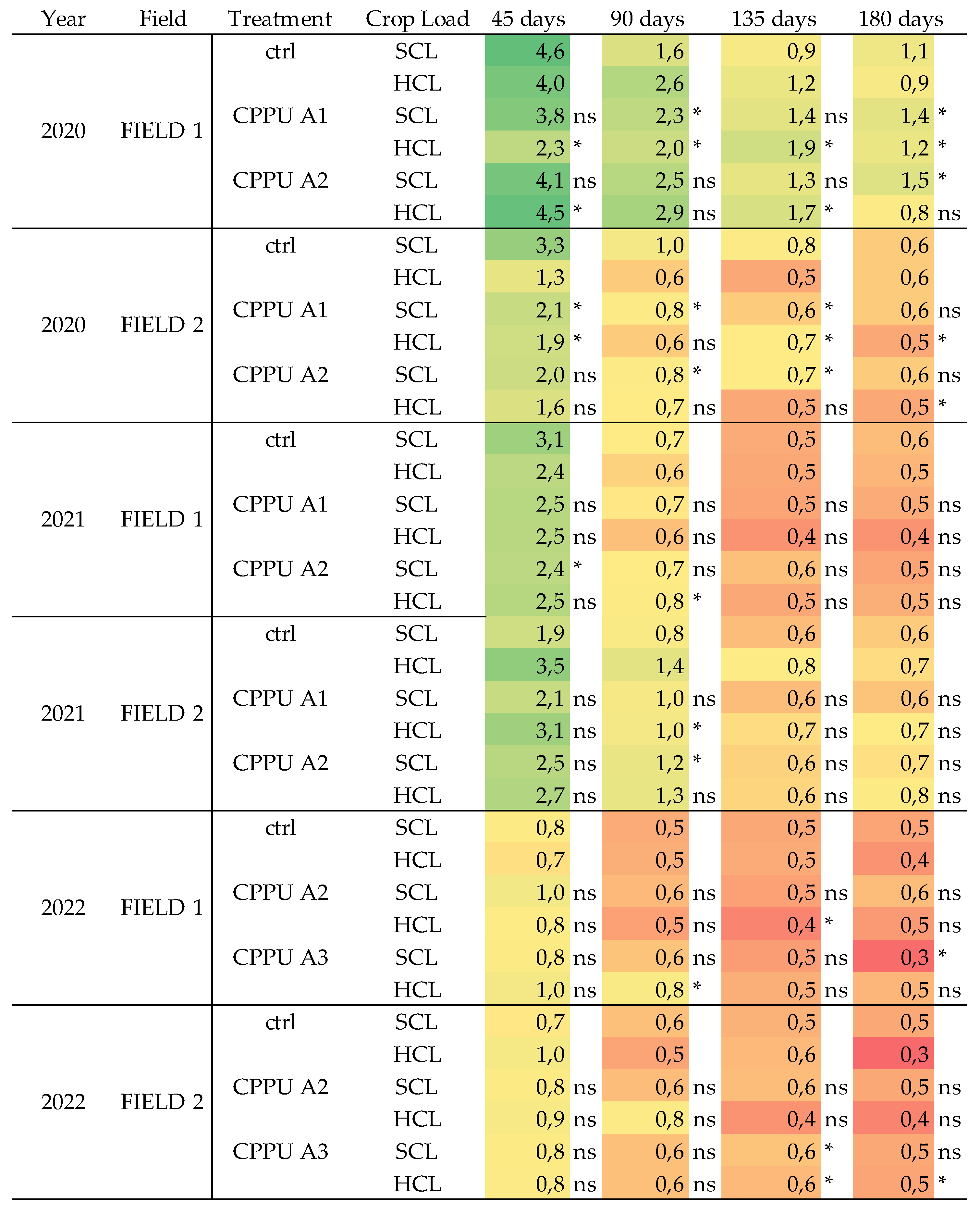

2.5. Post-Harvest Performances

3. Discussion

4. Conclusions

5. Materials and Methods

5.1. Experimental Design

5.2. Fruit Analysis and Storage Conditions

5.3. Statistical Analysis

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bons, H.K.; Kaur, M. Role of Plant Growth Regulators in Improving Fruit Set, Quality and Yield of Fruit Crops: A Review. J. Hortic. Sci. Biotechnol. 2020, 95, 137–146. [Google Scholar] [CrossRef]

- Kumar, A.; Rajan, R.; Pandey, K.; Ramprasad, R.R.; Kaur, G.; Vamshi, T.; Singh, T. Impact of New Generation Plant Growth Regulators on Fruit Crops - A Review. Hortic. Sci. 2024. [Google Scholar] [CrossRef]

- Rademacher, W. Plant Growth Regulators: Backgrounds and Uses in Plant Production. J. Plant Growth Regul. 2015, 34, 845–872. [Google Scholar] [CrossRef]

- Costa, G.; Spinelli, F.; Soto, A.; Nardozza, S.; Asteggiano, L.; Vittone, G. USE OF PLANT BIOREGULATORS IN KIWIFRUIT PRODUCTION. Acta Hortic. 2011. [Google Scholar] [CrossRef]

- Fischer, T.C.; Halbwirth, H.; Roemmelt, S.; Sabatini, E.; Schlangen, K.; Andreotti, C.; Spinelli, F.; Costa, G.; Forkmann, G.; Treutter, D.; et al. Induction of Polyphenol Gene Expression in Apple (Malus x Domestica) after the Application of a Dioxygenase Inhibitor. Physiol. Plant. 2006, 128, 604–617. [Google Scholar] [CrossRef]

- Costa, G.; Sabatini, E.; Spinelli, F.; Andreotti, C.; Bomben, C.; Vizzotto, G. TWO YEARS OF APPLICATION OF PROHEXADIONE-CA ON APPLE: EFFECT ON VEGETATIVE AND CROPPING PERFORMANCE, FRUIT QUALITY, RETURN BLOOM AND RESIDUAL EFFECT. Acta Hortic. 2004, 35–40. [Google Scholar] [CrossRef]

- Costa, G.; Rocchi, L.; Farneti, B.; Busatto, N.; Spinelli, F.; Vidoni, S. Use of Nondestructive Devices to Support Pre- and Postharvest Fruit Management. Horticulturae 2016, 3, 12. [Google Scholar] [CrossRef]

- Greene, D.W. CPPU Influences Fruit Quality and Fruit Abscission of’McIntosh’apples. HortScience 2001, 36, 1292–1295. [Google Scholar] [CrossRef]

- Tartarini, S.; Sansavini, S.; Ventura, M. CPPU Control of Fruit Morphogenesis in Apple. Sci. Hortic. 1993, 53, 273–279. [Google Scholar] [CrossRef]

- Zhang, C.; Whiting, M.D. Improving ‘Bing’ Sweet Cherry Fruit Quality with Plant Growth Regulators. Sci. Hortic. 2011, 127, 341–346. [Google Scholar] [CrossRef]

- Azuara, M.; González, M.-R.; Mangas, R.; Martín, P. Effects of the Application of Forchlorfenuron (CPPU) on the Composition of Verdejo Grapes. BIO Web Conf. 2023, 56, 01022. [Google Scholar] [CrossRef]

- Costa, G.; Biasi, R.; Brigati, S.; Morigi, M.; Antognozzi, E. Effect of a Cytokinin-like Compound (CPPU) on Kiwifruit (Actinidia Deliciosa) Ripening and Storage Life. In Proceedings of the International Symposium on Quality of Fruit and Vegetables: Influence of Pre-and Post-Harvest Factors and Technology 379; 1993; pp. 421–428. [Google Scholar]

- Antognozzi, E.; Famiani, F.; Palliotti, A.; Tombesi, A. Effects of CPPU (Cytokinin) on Kiwifruit Productivity. In Proceedings of the VII International Symposium on Plant Growth Regulators in Fruit Production 329; 1992; pp. 150–152. [Google Scholar]

- Transcriptome Analysis Reveals the Effect of Pre-Harvest CPPU Treatment on the Volatile Compounds Emitted by Kiwifruit Stored at Room Temperature - PubMed Available online:. Available online: https://pubmed.ncbi.nlm.nih.gov/29195998/ (accessed on 14 June 2024).

- Luo, J.; Guo, L.; Huang, Y.; Wang, C.; Qiao, C.; Pang, R.; Li, J.; Pang, T.; Wang, R.; Xie, H.; et al. Transcriptome Analysis Reveals the Effect of Pre-Harvest CPPU Treatment on the Volatile Compounds Emitted by Kiwifruit Stored at Room Temperature. Food Res. Int. 2017, 102, 666–673. [Google Scholar] [CrossRef]

- Rana, V.S.; Bhardwaj, V.; Rana, N. INFLUENCE OF CPPU ALONE AND IN COMBINATION WITH OTHER PLANT BIO-REGULATORS ON FRUIT YIELD, QUALITY AND HARVEST MATURITY OF “ALLISON” KIWIFRUIT. Acta Hortic. 2011, 401–410. [Google Scholar] [CrossRef]

- Famiani, F.; Antognozzi, E.; Tombesi, A.; Moscatello, S.; Battistelli, A. CPPU Induced Alterations in Source-Sink Relationships in Actinidia Deliciosa. In Proceedings of the VIII International Symposium on Plant Bioregulation in Fruit Production 463; 1997; pp. 306–310. [Google Scholar]

- CPPU Application on Size and Quality of Hardy Kiwifruit - ScienceDirect Available online:. Available online: https://www.sciencedirect.com/science/article/pii/S030442380600238X (accessed on 14 June 2024).

- Ainalidou, A.; Karamanoli, K.; Menkissoglu-Spiroudi, U.; Diamantidis, G.; Matsi, T. CPPU Treatment and Pollination: Their Combined Effect on Kiwifruit Growth and Quality. Sci. Hortic. 2015, 193, 147–154. [Google Scholar] [CrossRef]

- Pramanick, K.K.; Kashyap, P.; Kishore, D.K.; Sharma, Y.P. Effect of Summer Pruning and CPPU on Yield and Quality of Kiwi Fruit. J. Environ. Biol. 2015. [Google Scholar]

- Cruz-Castillo, J.G.; Woolley, D.J.; Famiani, F. Effects of Defoliation on Fruit Growth, Carbohydrate Reserves and Subsequent Flowering of ‘Hayward’ Kiwifruit Vines. Sci. Hortic. 2010, 125, 579–583. [Google Scholar] [CrossRef]

- MSci, S.D.W. A Review of Research and Development Undertaken on Psa.

- Zhang, Z.; Guo, K.; Bai, Y.; Dong, J.; Gao, Z.; Yuan, Y.; Wang, Y.; Liu, L.; Yue, T. Identification, Synthesis, and Safety Assessment of Forchlorfenuron (1-(2-Chloro-4-Pyridyl)-3-Phenylurea) and Its Metabolites in Kiwifruits. J. Agric. Food Chem. 2015, 63, 3059–3066. [Google Scholar] [CrossRef] [PubMed]

- Identification and Expression Analysis of Invertase Family Genes during Grape (Vitis Vinifera L.) Berry Development under CPPU and GA Treatment | Molecular Genetics and Genomics Available online:. Available online: https://link.springer.com/article/10.1007/s00438-023-02015-3 (accessed on 8 May 2024).

- Frontiers | Abnormal Endogenous Repression of GA Signaling in a Seedless Table Grape Cultivar with High Berry Growth Response to GA Application Available online:. Available online: https://www.frontiersin.org/journals/plant-science/articles/10.3389/fpls.2017.00850/full (accessed on 8 May 2024).

- Pre-Anthesis CPPU Low Dosage Application Increases ‘Hayward’ Kiwifruit Weight without Affecting the Other Qualitative and Nutritional Characteristics - ScienceDirect Available online:. Available online: https://www.sciencedirect.com/science/article/abs/pii/S0308814614001861 (accessed on 8 May 2024).

- Wang, W.; Khalil-Ur-Rehman, M.; Feng, J.; Tao, J. RNA-Seq Based Transcriptomic Analysis of CPPU Treated Grape Berries and Emission of Volatile Compounds. J. Plant Physiol. 2017, 218, 155–166. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.; Jiang, Y. Effect of Plant Growth Regulators on Banana Fruit and Broccoli during Storage. Sci. Hortic. 2012, 145, 62–67. [Google Scholar] [CrossRef]

- Xu, Y.; Hou, X.; Feng, J.; Khalil-Ur-Rehman, M.; Tao, J. Transcriptome Sequencing Analyses Reveals Mechanisms of Eliminated Russet by Applying GA3 and CPPU on ‘Shine Muscat’ Grape. Sci. Hortic. 2019, 250, 94–103. [Google Scholar] [CrossRef]

- Huang, H.; Jing, G.; Wang, H.; Duan, X.; Qu, H.; Jiang, Y. The Combined Effects of Phenylurea and Gibberellins on Quality Maintenance and Shelf Life Extension of Banana Fruit during Storage. Sci. Hortic. 2014, 167, 36–42. [Google Scholar] [CrossRef]

- Crop Load Influences Fruit Quality, Nutritional Balance, and Return Bloom in ‘Honeycrisp’ Apple in: HortScience Volume 51 Issue 3 (2016) Available online:. Available online: https://journals.ashs.org/hortsci/view/journals/hortsci/51/3/article-p236.xml (accessed on 8 May 2024).

- CROP LOAD AND IRRIGATION INTERACTIONS - A NEW DIMENSION OF RDI Available online:. Available online: https://www.actahort.org/books/1038/1038_12.htm (accessed on 8 May 2024).

- Snowball, A.M. The Seasonal Cycle of Leaf, Shoot and Bud Development in Kiwifruit. J. Hortic. Sci. 1995, 70, 787–797. [Google Scholar]

- Interactive Responses to Water Deficits and Crop Load in Olive (Olea Europaea L., Cv. Morisca) I. – Growth and Water Relations - ScienceDirect Available online:. Available online: https://www.sciencedirect.com/science/article/pii/S0378377411000059?via%3Dihub (accessed on 8 May 2024).

- Burge, G.K.; Spence, C.B.; Marshall, R.R. Kiwifruit: Effects of Thinning on Fruit Size, Vegetative Growth, and Return Bloom. N. Z. J. Exp. Agric. 1987, 15, 317–324. [Google Scholar] [CrossRef]

- Ainalidou, A.; Tanou, G.; Belghazi, M.; Samiotaki, M.; Diamantidis, G.; Molassiotis, A.; Karamanoli, K. Integrated Analysis of Metabolites and Proteins Reveal Aspects of the Tissue-Specific Function of Synthetic Cytokinin in Kiwifruit Development and Ripening. J. Proteomics 2016, 143, 318–333. [Google Scholar] [CrossRef] [PubMed]

- Antognozzi, E.; Famiani, F.; Proietti, P.; Tombesi, A.; Ferranti, F.; Frenguelli, G. EFFECT OF CPPU (CYTOKININ) TREATMENTS ON FRUIT ANATOMICAL STRUCTURE AND QUALITY IN ACTINIDIA DELICIOSA. Acta Hortic. 1997, 459–466. [Google Scholar] [CrossRef]

- Cruz-Castillo, J.G.; Woolley, D.J.; Lawes, G.S. EFFECTS OF CPPU AND OTHER PLANT GROWTH REGULATORS ON FRUIT DEVELOPMENT IN KIWIFRUIT. Acta Hortic. 1999, 173–178. [Google Scholar] [CrossRef]

- Patterson, K.J.; Mason, K.A.; Gould, K.S. Effects of CPPU (N-(2-chloro-4-pyridyl)-N’-phenylurea) on Fruit Growth, Maturity, and Storage Quality of Kiwifruit. N. Z. J. Crop Hortic. Sci. 1993, 21, 253–261. [Google Scholar] [CrossRef]

- Rojas, B.; Suárez-Vega, F.; Saez-Aguayo, S.; Olmedo, P.; Zepeda, B.; Delgado-Rioseco, J.; Defilippi, B.G.; Pedreschi, R.; Meneses, C.; Pérez-Donoso, A.G.; et al. Pre-Anthesis Cytokinin Applications Increase Table Grape Berry Firmness by Modulating Cell Wall Polysaccharides. Plants 2021, 10, 2642. [Google Scholar] [CrossRef]

- Percy, A.E.; Melton, L.D.; Jameson, P.E. Expansion during Early Apple Fruit Development Induced by Auxin and N-(2-Chloro-4-Pyridyl)-N′-Phenylurea: Effect on Cell Wall Hemicellulose. Plant Growth Regul. 1998, 26, 1–6. [Google Scholar] [CrossRef]

- Hopkirk, G.; Harker, F.R.; Harman, J.E. Calcium and the Firmness of Kiwifruit. N. Z. J. Crop Hortic. Sci. 1990, 18, 215–219. [Google Scholar] [CrossRef]

- Antunes, M.D.C.; Neves, N.; Curado, F.; Rodrigues, S.; Franco, J.; Panagopoulos, T. THE EFFECT OF CALCIUM APPLICATIONS ON KIWIFRUIT QUALITY PRESERVATION DURING STORAGE. Acta Hortic. 2007, 727–732. [Google Scholar] [CrossRef]

- Hocking, B.; Tyerman, S.D.; Burton, R.A.; Gilliham, M. Fruit Calcium: Transport and Physiology. Front. Plant Sci. 2016, 7. [Google Scholar] [CrossRef] [PubMed]

- FRUIT DEVELOPMENT IN DECIDUOUS TREE CROPS AS AFFECTED BY PHYSIOLOGICAL FACTORS AND ENVIRONMENTAL CONDITIONS (KEYNOTE) Available online:. Available online: https://www.actahort.org/books/636/636_52.htm (accessed on 18 June 2024).

- Prudent, M.; Dai, Z.W.; Génard, M.; Bertin, N.; Causse, M.; Vivin, P. Resource Competition Modulates the Seed Number–Fruit Size Relationship in a Genotype-Dependent Manner: A Modeling Approach in Grape and Tomato. Ecol. Model. 2014, 290, 54–64. [Google Scholar] [CrossRef]

- Famiani, F.; Baldicchi, A.; Farinelli, D.; Cruz-Castillo, J.G.; Marocchi, F.; Mastroleo, M.; Moscatello, S.; Proietti, S.; Battistelli, A. Yield Affects Qualitative Kiwifruit Characteristics and Dry Matter Content May Be an Indicator of Both Quality and Storability. Sci. Hortic. 2012, 146, 124–130. [Google Scholar] [CrossRef]

| Weight | Firmness | Brix | Dry Weight | |

| Year | *** | *** | *** | *** |

| Field | *** | *** | *** | *** |

| Crop load | ** | *** | *** | *** |

| Treatment | *** | *** | ||

| Year × Field | *** | *** | *** | *** |

| Year × Crop load | *** | *** | ||

| Field × Crop load | * | *** | ** | * |

| Year × Treatment | * | |||

| Field × Treatment | *** | . | *** | *** |

| Crop load × Treatment | *** | *** | ||

| Year × Field × Crop load | *** | . | ||

| Year × Field × Treatment | * | *** | ||

| Year × Crop load × Treatment | * | * | * | |

| Field × Crop load × Treatment | . | . | * | |

| Year × Field × Crop load × Treatment | ||||

| Significant codes: *** = p<0.001, ** = p<0.01, * = p<0.05, . = p<0.1 | ||||

| Weight | Firmness | Brix | Dry Weight | |

| Year | *** | *** | *** | |

| Field | * | *** | *** | *** |

| Crop load | ** | *** | *** | ** |

| Treatment | * | * | ||

| Year × Field | *** | *** | ||

| Year × Crop load | *** | * | * | |

| Field × Crop load | ** | |||

| Year × Treatment | ** | ** | ||

| Field × Treatment | ** | *** | ||

| Crop load × Treatment | *** | *** | * | |

| Year × Field × Crop load | ||||

| Year × Field × Treatment | ** | |||

| Year × Crop load × Treatment | * | |||

| Field × Crop load × Treatment | * | |||

| Year × Field × Crop load × Treatment | ** | . | ||

| Significant codes: *** = p<0.001, ** = p<0.01, * = p<0.05, . = p<0.1 | ||||

| Weight | Firmness | Brix | Dry Weight | |

| Field | *** | *** | *** | |

| Crop load | *** | *** | *** | |

| Treatment | *** | ** | *** | |

| Field × Crop load | *** | *** | * | |

| Field × Treatment | *** | * | ||

| Crop load × Treatment | *** | *** | *** | *** |

| Field × Crop load × Treatment | *** | *** | ** | |

| Significant codes: *** = p<0.001, ** = p<0.01, * = p<0.05, . = p<0.1 | ||||

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).