Submitted:

03 September 2024

Posted:

03 September 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Thermopressing of Fiberboards through Experimental Design

2.2. Board’s Characterization

2.2.1. Density

2.2.2. Flexural Properties

2.2.3. Shore D Surface Hardness

2.2.4. Internal Bond Strength

2.2.5. Color Characteristics

2.2.6. Water Sensitivity

2.3. Cost-Related Factors

2.3.1. Energy Consumption

- A closing force of 400 tons (corresponding to a 275 bars maximal hydraulic oil pressure in the piston).

- 33 kW for the available heating power (total for both hot-plates), and 250°C for maximum attainable temperature.

- 22 kW for the pump unit power required to close the press at 275 bars (maximum attainable pressure).

2.3.2. Total Manufacturing Cost

2.4. Climate Change as Environmental Indicator

3. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- ALIGNED PROJECT. The EU construction sector: Environmental impacts. Available online: https://alignedproject.eu/sectors/construction/ (accessed on 10 October 2023).

- Ukpanah, I. The Environmental Impact of Wood Construction: Is It a Sustainable Choice?. Available online: https://www.greenmatch.co.uk/blog/is-building-with-wood-bad (accessed on 17 May 2024).

- Nguyen, T. Wood production, its environmental impacts and what the finnish think about the matter. Available online: http://globetamk.weebly.com/1/post/2017/12/wood-production-its-environmental-impacts-and-what-the-finnish-think-about-the-matter.html (accessed on 13 Feb. 2024).

- Uitterhaegen, E.; Labonne, L.; Merah, O.; Talou, T.; Ballas, S.; Véronèse, T.; Evon, P. Impact of Thermomechanical Fiber Pre-Treatment Using Twin-Screw Extrusion on the Production and Properties of Renewable Binderless Coriander Fiberboards. Int. J. Mol. Sci. 2017, 18(7), 1539. [CrossRef]

- European Environment Agency. The circular economy and the bioeconomy: partners in sustainability. Available online: https://data.europa.eu/doi/10.2800/02937 2018 (accessed on 24 Jun. 2024).

- Theng, D.; Arbat, G.; Delgado-Aguilar, M.; Ngo, B.; Labonne, L.; Mutjé, P.; Evon, P. Production of fiberboard from rice straw thermomechanical extrudates by thermopressing: influence of fiber morphology, water and lignin content. Eur. J. Wood Wood Prod 2019, 77, 15–32. [CrossRef]

- Theng, D.; Arbat, G.; Delgado-Aguilar, M.; Ngo, B.; Labonne, L.; Evon, P.; Mutjé, P. Comparison between two different pretreatment technologies of rice straw fibers prior to fiberboard manufacturing: Twin-screw extrusion and digestion plus defibration. Ind. Crops Prod 2017, 107, 184–197. [CrossRef]

- Evon, P.; Barthod-Malat, B.; Grégoire, M.; Vaca-Medina, G.; Labonne, L.; Ballas, S.; Véronèse, T.; Ouagne, P. Production of fiberboards from shives collected after continuous fiber mechanical extraction from oleaginous flax. J. Nat. Fibers 2019,16, 453–469. [CrossRef]

- Evon, P.; Vandenbossche, V.; Pontalier, P.-Y.; Rigal, L. New process for the biorefinery of sunflower whole plant by thermomechanical fractionation and aqueous extraction in a twin-screw extruder. 5th International Conference on Renewable Resources and Biorefineries, Ghent, Belgium, 10 June 2009.

- Uitterhaegen, E.; Labonne, L.; Merah, O.; Talou, T. ; Ballas, S.; Véronèse, T.; Evon, Ph. Optimization of thermopressing conditions for the production of binderless boards from a coriander twin-screw extrusion cake. J. Appl. Polym. Sci. 2017, 134. [CrossRef]

- Uitterhaegen, E.; Labonne, L.; Merah, O.; Talou, T.; Ballas, S.; Véronèse, T.; Evon, P. Innovative insulating materials from coriander (Coriandrum sativum L.) straw for building applications. J. Agric. Stud. 2020, 8, 1–18. [CrossRef]

- Evon, P.; De Langalerie, G.; Labonne, L.; Merah, O.; Talou, T.; Ballas, S.; Véronèse, T. Low-Density Insulation Blocks and Hardboards from Amaranth (Amaranthus cruentus) Stems, a New Perspective for Building Applications. Coatings 2021, 11, 349. [CrossRef]

- Halvarsson, S.; Edlund, H.; Norgren, M. Wheat straw as raw material for manufacture of medium density fiberboard (MDF). BioResources 2010, 5, 1215–1231. [CrossRef]

- Widyorini, R.; Xu, J.; Umemura, K.; Kawai, S. Manufacture and properties of binderless particleboard from bagasse I: effects of raw material type, storage methods, and manufacturing process. J. Wood Sci. 2005, 51, 648–654. [CrossRef]

- Simon, V.; Uitterhaegen, E.; Robillard, A.; Ballas, S.; Véronèse, T.; Vilarem, G.; Merah, O.; Talou, T.; Evon, P. VOC and carbonyl compound emissions of a fiberboard resulting from a coriander biorefinery: comparison with two commercial wood-based building materials. Environ. Sci. Pollut. Res. 2020, 27, 16121–16133. [CrossRef]

- Uitterhaegen, E., Burianová, K., Ballas, S., Véronèse, T., Merah, O., Talou, T., Stevens, C.V., Evon, Ph., Simon, V. Characterization of volatile organic compound emissions from self-bonded boards resulting from a coriander biorefinery. Ind. Crops Prod. 2018, 122, 57–65. [CrossRef]

- Evon, P.; Labonne, L.; Simon, V.; Talou, T.; Ballas, S.; Véronèse, T.; Merah, O. “Coriander Straw and Press Cake from Seeds: Compositions and Possible Uses in the Field of Bio-Sourced Materials.” In Handbook of Coriander (Coriandrum Sativum). 1st ed., Boca Raton: CRC Press, 2022, pp. 261–286.

- EFSA. Scientific Opinion on the safety of “coriander seed oil” as a Novel Food ingredient. EFSA J. 2013, 11, 3422. [CrossRef]

- Uitterhaegen, E.; Sampaio, K.A.; Delbeke, E.I.P.; De Greyt, W.; Cerny, M.; Evon, P.; Merah, O.; Talou, T.; Stevens, C.V. Characterization of French Coriander Oil as Source of Petroselinic Acid. Molecules 2016, 21, 1202. [CrossRef]

- Uitterhaegen, E., Nguyen, Q.H., Sampaio, K.A., Stevens, C.V., Merah, O., Talou, T., Rigal, L., Evon, P. Extraction of Coriander Oil Using Twin-Screw Extrusion: Feasibility Study and Potential Press Cake Applications. J. Am. Oil Chem. Soc. 2015, 92, 1219–1233. [CrossRef]

- Tajuddin, M.; Ahmad, Z.; Ismail, H. A review of natural fibers and processing operations for the production of binderless boards. BioResources 2016, 11(2), 5600–5617.

- Schaal, L. RocTool launches an innovative composites process: Light Induction Tooling. Reinf. Plast. 2017, 61, 173–175. [CrossRef]

- Evon, P. Procédés compacts pour le bioraffinage intégré de plantes entières : valorisation multi-produit à valeur ajoutée. HDR, Institut National Polytechnique de Toulouse, 2019.

- Cavailles, J., Vaca-Medina, G., Wu-Tiu-Yen, J., Peydecastaing, J., Pontalier, P.-Y. Influence of Thermocompression Conditions on the Properties and Chemical Composition of Bio-Based Materials Derived from Lignocellulosic Biomass. Materials 2024, 17, 1713. [CrossRef]

- Bauta, J., Vaca-Medina, G., Delgado Raynaud, C., Simon, V., Vandenbossche, V., Rouilly, A. Development of a Binderless Particleboard from Brown Seaweed Sargassum spp. Materials 2024, 17, 539. [CrossRef]

- Lundstedt, T.; Seifert, E.; Abramo, L.; Thelin, B.; Nyström, Å.; Pettersen, J.; Bergman, R. Experimental design and optimization. Chemom. Intell. Lab. Syst. 1998, 42, 3–40. [CrossRef]

- Phan-Tan-Luu, R. NemrodW. Available online: https://www.nemrodw.com/software (accessed on 19 June 2024).

- ISO 16978:2003; Wood-based panel - Determination of modulus of elasticity in bending and of bending strength. European Committee for Standardization. Switzerland, 2003.

- ISO 868:2003; Plastics and ebonite – Determination of indentation hardness by means of a durometer (Shore hardness). European Committee for Standardization. Brussel, Belgium, 2003.

- ISO 16260:2016; Paper and board - Determination of internal bond strength. European Committee for Standardization. Geneva, Switzerland., 2016.

- ISO/CIE 11664-4: 2019; Colorimetry - Part 4: CIE 1976 L*a*b* colour space. European Committee for Standardization. Brussel, Belgium, 2019.

- ISO 16983:2003; Wook-based panels – Determination of swelling in thickness after immersion in water. International Organization for Standardization. Geneve, Switzerland, 2003.

- ISO 14044:2006; Environmental Management - Life Cycle Assessment –Principles and framework. International Organization for Standardization. Geneva, Switzerland, 2006.

- PRé Sustainability. SimaPro. Available online: https://simapro.com/SimaPro (accessed on 21 March 2024).

- ISO 16895:2016; Wood-based panels - Dry-process fibreboard. European Committee for Standardization. Switzerland, 2016.

- Kariuki, S.W.; Wachira, J.; Kawira, M.; Murithi, G. Crop residues used as lignocellulose materials for particleboards formulation. Heliyon 2020, 6, e05025. [CrossRef]

- Evon, P., Jégat, L., Labonne, L., Véronèse, T., Ballas, S., Tricoulet, L., Li, J., Geelen, D. Bio-based materials from sunflower co-products, a way to generate economical value with low environmental footprint. OCL 2023, 30, 25. [CrossRef]

- Pintiaux, T.; Viet, D.; Vandenbossche, V.; Rigal, L.; Rouilly, A. High Pressure Compression-Molding of α-Cellulose and Effects of Operating Conditions. Materials 2013, 6, 2240–2261. [CrossRef]

| Board number | x1 | Applied pressure (MPa) | x2 | Molding time (s) | x3 | Mold temperature (°C) |

|---|---|---|---|---|---|---|

| 1 | 1.0 | 50 | 0.000 | 180 | 0.000 | 180 |

| 2 | -1.0 | 10 | 0.000 | 180 | 0.000 | 180 |

| 3 | 0.5 | 40 | 0.866 | 284 | 0.000 | 180 |

| 4 | -0.5 | 20 | -0.866 | 76 | 0.000 | 180 |

| 5 | 0.5 | 40 | -0.866 | 76 | 0.000 | 180 |

| 6 | -0.5 | 20 | 0.866 | 284 | 0.000 | 180 |

| 7 | 0.5 | 40 | 0.289 | 215 | 0.816 | 200 |

| 8 | -0.5 | 20 | -0.289 | 145 | -0.816 | 160 |

| 9 | 0.5 | 40 | -0.289 | 145 | -0.816 | 160 |

| 10 | 0.0 | 30 | 0.577 | 249 | -0.816 | 160 |

| 11 | -0.5 | 20 | 0.289 | 215 | 0.816 | 200 |

| 12 | 0.0 | 30 | -0.577 | 111 | 0.816 | 200 |

| 13 | 0.0 | 30 | 0.000 | 180 | 0.000 | 180 |

| 14 | 0.0 | 30 | 0.000 | 180 | 0.000 | 180 |

| 15 | 0.0 | 30 | 0.000 | 180 | 0.000 | 180 |

| 16 | 0.0 | 30 | 0.000 | 180 | 0.000 | 180 |

| Board 1 | Board 2 | Board 3 | Board 4 | Board 5 | Board 6 | Board 7 | Board 8 | Board 9 | Board 10 | Board 11 | Board 12 | Board 13 | Board 14 | Board 15 | Board 16 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Density (kg/m3) | 1,396±18 | 1,122±64 | 1,378±18 | 1,271±27 | 1,365±26 | 1,424±30 | 1,434±31 | 1,302±35 | 1,335±22 | 1,350±52 | 1,364±29 | 1,378±32 | 1,383±28 | 1,373±47 | 1,340±46 | 1,354±49 |

| Flexural properties | ||||||||||||||||

| Fmax (N) | 36.9±2.7 | 13.2±0.4 | 42.1±1.5 | 22.1±1.6 | 29.4±1.7 | 44.6±3.7 | 46.2±2.8 | 20.8±2.9 | 25.8±3.1 | 34.3±2.9 | 44.6±1.8 | 40.7±0.5 | 39.0±2.9 | 40.7±2.0 | 40.7±2.6 | 38.8±1.7 |

| σf (MPa) | 28.3±1.1 | 6.6±0.2 | 30.2±1.0 | 14.8±0.8 | 21.5±1.2 | 34.8±0.7 | 36.0±1.6 | 14.3±1.0 | 18.1±0.4 | 24.1±1.3 | 31.2±1.1 | 31.3±1.0 | 28.4±1.2 | 30.5±1.3 | 29.0±1.1 | 28.1±1.2 |

| Ef (GPa) | 5.3±0.3 | 1.0±0.1 | 5.5±0.2 | 2.2±0.3 | 3.5±0.3 | 6.2±0.5 | 6.0±0.2 | 2.3±0.1 | 3.0±0.2 | 4.5±0.4 | 4.9±0.2 | 5.4±0.2 | 4.9±0.4 | 5.3±0.5 | 4.7±0.3 | 4.8±0.5 |

| Surface hardness | ||||||||||||||||

| Shore D (°) | 77.3±1.9 | 65.4±3.7 | 77.4±2.0 | 71.2±4.6 | 75.9±3.2 | 78.4±1.3 | 78.0±1.4 | 72.9±3.2 | 75.0±2.7 | 77.0±1.9 | 76.7±2.4 | 75.5±2.5 | 75.9±2.3 | 76.5±2.2 | 75.6±1.9 | 75.1±2.4 |

| Color characteristics | ||||||||||||||||

| L* | 70.8±2.5 | 79.9±4.6 | 70.0±0.5 | 79.5±1.1 | 74.6±6.1 | 72.1±0.2 | 71.0±1.2 | 79.0±0.4 | 75.7±5.3 | 74.9±1.2 | 73.2±0.1 | 73.5±4.2 | 73.0±2.3 | 73.9±2.1 | 73.9±1.7 | 73.7±2.2 |

| a* | 2.4±0.7 | 4.3±0.4 | 2.3±0.1 | 4.1±0.2 | 3.0±1.3 | 2.8±0.0 | 2.4±0.4 | 3.9±0.2 | 3.1±1.2 | 3.1±0.4 | 2.7±0.0 | 2.4±1.0 | 2.6±0.8 | 2.7±0.6 | 2.8±0.6 | 2.8±0.7 |

| b* | 3.9±1.8 | 10.9±3.0 | 3.5±0.2 | 9.7±0.8 | 6.1±4.4 | 4.7±0.2 | 3.7±0.9 | 9.2±0.3 | 6.5±3.9 | 6.2±0.9 | 5.1±0.1 | 4.8±3.1 | 5.0±2.1 | 5.4±1.6 | 5.6±1.4 | 5.5±1.8 |

| ΔE | 14.2±3.1 | 4.1±3.5 | 15.2±0.5 | 4.0±1.2 | 10.0±7.5 | 12.7±0.3 | 14.3±1.6 | 4.7±0.5 | 9.1±6.5 | 9.7±1.5 | 11.7±0.2 | 11.8±5.3 | 12.0±3.2 | 11.0±2.7 | 10.8±2.2 | 11.0±2.9 |

| Water sensitivity | ||||||||||||||||

| TS (%) | 981 | n.m. | 236±19 | n.m. | n.m. | 232±9 | 165±37 | n.m. | n.m. | n.m. | 130±14 | 551 | n.m. | 1111 | 871 | 98±12 |

| WA (%) | 180±17 | 247±17 | 170±15 | 200±8 | 193±4 | 144±10 | 78±8 | 149±14 | 163±11 | 136±7 | 146±19 | 141±10 | 131±5 | 157±13 | 166±13 | 139±13 |

| Cost-related factors | ||||||||||||||||

| Energy consumption (kW h/m2) |

28.6 | 17.4 | 40.8 | 8.6 | 10.9 | 31.9 | 33.0 | 14.9 | 19.4 | 29.4 | 26.3 | 15.3 | 23.0 | 23.0 | 23.0 | 23.0 |

| Total manufacturing cost (€/m2) |

8.55 | 5.74 | 11.58 | 3.53 | 4.12 | 9.37 | 9.64 | 5.10 | 6.23 | 8.73 | 7.96 | 5.21 | 7.15 | 7.15 | 7.15 | 7.15 |

| Environmental indicator | ||||||||||||||||

| Climate change (kg CO2 eq/m2) |

2.00 | 1.22 | 2.85 | 0.60 | 0.76 | 2.23 | 2.31 | 1.04 | 1.36 | 2.06 | 1.84 | 1.07 | 1.61 | 1.61 | 1.61 | 1.61 |

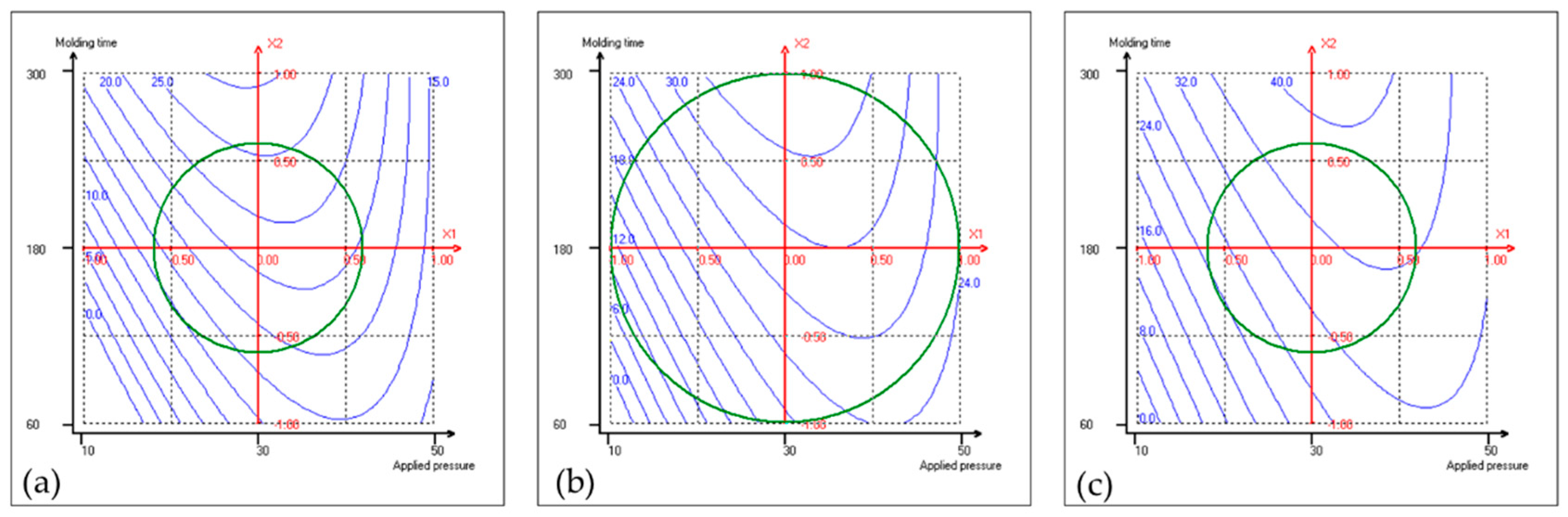

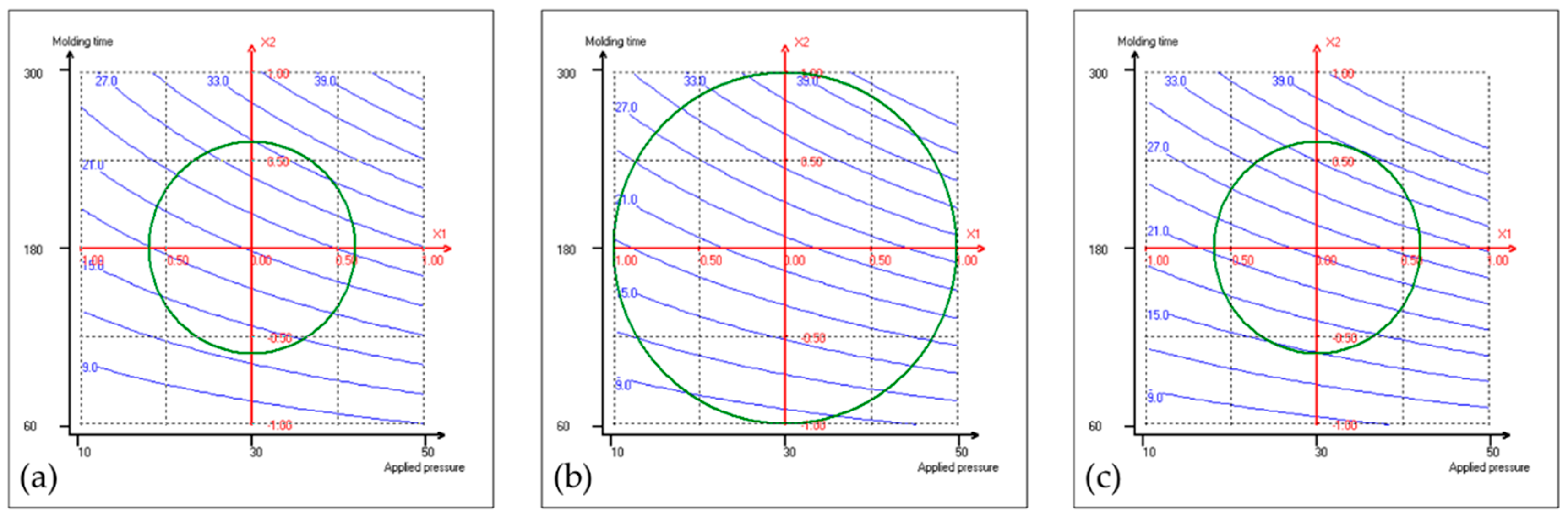

| Coefficient | b0 | b1 | b2 | b3 | b11 | b22 | b33 | b12 | b13 | b23 | R2 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Density (kg/m3) | 1363 | 88 | 43 | 38 | -103 | 31 | 15 | -81 | 51 | 40 | 0.854 |

| Flexural properties | |||||||||||

| Fmax (N) | 39.81 | 7.37 | 9.89 | 10.32 | -14.79 | -2.09 | -2.41 | -5.70 | -0.08 | -0.03 | 0.942 |

| σf (MPa) | 29.0 | 6.8 | 7.7 | 8.6 | -11.5 | -1.0 | -1.6 | -6.5 | 2.9 | -0.2 | 0.921 |

| Ef (GPa) | 4.9 | 1.4 | 1.6 | 1.3 | -1.8 | -0.2 | -0.4 | -1.2 | 0.6 | -0.7 | 0.911 |

| Surface hardness | |||||||||||

| Shore D (°) | 75.8 | 3.9 | 2.6 | 1.1 | -4.4 | 1.4 | 0.9 | -3.3 | 0.7 | 1.2 | 0.879 |

| Color characteristics | |||||||||||

| L* | 73.63 | -3.83 | -3.17 | -2.42 | 1.72 | 0.02 | 0.93 | 1.56 | 0.19 | 0.17 | 0.971 |

| a* | 2.74 | -0.79 | -0.46 | -0.53 | 0.69 | 0.23 | 0.09 | 0.32 | 0.22 | 0.21 | 0.948 |

| b* | 5.38 | -2.85 | -1.95 | -1.70 | 2.03 | 0.12 | 0.25 | 1.35 | 0.36 | 0.19 | 0.963 |

| ΔE | 11.2 | 4.5 | 3.6 | 2.9 | -2.0 | -0.3 | -0.9 | -2.0 | -0.4 | -0.5 | 0.974 |

| Cost-related factors | |||||||||||

| Energy consumption (kW h/m2) | 23.00 | 5.60 | 15.36 | 2.22 | 0.00 | 0.07 | 0.06 | 3.81 | 0.00 | 1.51 | 1.000 |

| Total manufacturing cost (€/m2) | 7.150 | 1.404 | 3.840 | 0.561 | -0.005 | 0.002 | -0.007 | 0.935 | 0.006 | 0.374 | 1.000 |

| Environmental Indicator | |||||||||||

| Climate change (kg CO2 eq/m2) | 1.610 | 0.391 | 1.075 | 0.155 | 0.000 | 0.000 | 0.005 | 0.266 | -0.002 | 0.103 | 1.000 |

| Thermopressing conditions for maximal flexural strength | MDF-like thermopressing conditions associated with minimal energy consumption | |||

|---|---|---|---|---|

| Flexural properties | Calculated from mathematical model | Obtained from the experiment | Calculated from mathematical model | Obtained from the experiment |

| Density (kg/m3) | 1,537 | 1,458 ± 11 | 1,346 | 1,313 ± 11 |

| Fmax (N) | 55 | 53.4 ± 3.3 | 29.7 | 28.0 ± 0.4 |

| σf (MPa) | 42.5 | 40.6 ± 1.7 | 20.7 | 17.9 ± 0.6 |

| Ef (GPa) | 7.4 | 6.7 ± 0.5 | 3.5 | 2.9 ± 0.2 |

| Water sensitivity | ||||

| TS (%) | n.c. | 161 ± 2 | n.c. | n.m. |

| WA (%) | n.c. | 123 ± 18 | n.c. | 198 ± 5 |

| Internal bond strength (MPa) | - | 1.45 ± 0.14 | - | 0.35 ± 0.07 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).