1. Introduction

Our civilization is based on farming, despite the fact that farming harms wild nature more than any other aspect of human activity [

1]. India's economy revolves around agriculture, and the past 60 years have shown us that there is a direct correlation between agricultural growth and economic prosperity. India's current agricultural system is a result of both remarkable accomplishments and lost possibilities. India's agricultural output needs to catch up with the nations now ranked as the world's economic superpowers if it wants to become a global economic force[

2,

3]. Since smart farming makes farms more capable of detecting and regulating their own settings, it is thought to be the way of the future of agriculture. With the use of the Internet of Things, enormous amounts of data may be analysed by connecting and accessing different devices (IoT). For the data to be usable, though, self-sustaining agricultural output using analytics is just as important as having Internet support and sensor readings that update on their own [

4]. Today, soil-based agriculture faces challenges from a variety of man-made factors, including urbanization and industrialization. Additionally, abrupt natural disasters, climate change, and the uncontrolled use of chemicals in agriculture contribute to the depletion of fertile and high-quality soil [

5].

Since smart farming makes farms more capable of detecting and regulating their own settings, it is thought to be the way of the future of agriculture. With the use of the Internet of Things, enormous amounts of data may be analyzed by connecting and accessing different devices (IoT) [

6]. One popular and extensively used method for growing plants without soil is hydroponics, which allows for a great deal of control over the root's surrounding environment. Although

The practice of cultivating plants in nutrient-rich water may have originated in prehistoric times, the technology has an intriguing history of development and application that dates back to the middle of the 18th century [

7]. Nowadays, hydroponics, a soilless development strategy, guarantees to provide tall quality, sound, new, residue-free vegetables and natural products locally in arrange to combat the multi-manifestations of climate alter, new water shortage, and the squeezing necessity of the growing nourishment request [

8]. Because hydroponic gardening produces high-quality food and manages resources efficiently, it is currently becoming more and more popular worldwide. These days, soil-based agriculture faces a number of difficulties, including indiscriminate use of chemicals and pesticides that are reducing the fertility of the ground, urbanization, natural disasters, and climate change [

9,

10].

Today, soil-based agriculture faces challenges from a variety of man-made factors, including urbanization and industrialization. Additionally, abrupt natural disasters, climate change, and the uncontrolled use of chemicals in agriculture contribute to the depletion of fertile and high-quality soil [

11]. There is different technique like by extending crop production into the vertical dimension, vertical farming systems (VFS) have been presented as an engineering approach to boost productivity per unit area of cultivated land. Using lettuce as a model crop, a vertical flower garden (VFS) with plants grown in upright cylindrical columns was contrasted with a traditional horizontal hydroponic system (HHS) to see if this method offers a practical substitute for horizontal crop production methods [

12]. Hydroponic farming is a type of soil-less agriculture that uses less water and other resources than conventional soil-based agricultural methods [

13]. Nevertheless, because hydroponics farming requires simultaneous supervision of several factors, dietary recommendations, and a plant diagnostic system, monitoring the practice might be difficult. However, by implementing artificial intelligence-based controlling algorithms in the agriculture industry, recent technology advancements are highly helpful in solving these issues [14-16].

India's agricultural sector is its backbone, and in order to achieve high yields, farmers must make sophisticated judgements about things like seeding, fertilizer dispensing, and excavating. The soil's nitrogen (N), phosphorous (P), and potassium (K) contents are measured for this project, which also shows the NPK contents on an LCD. Robots apply fertilizer to soil based on need. The amount of labor and human effort needed to do this is decreased by this endeavor. Soil NPK levels can be determined by mixing a solution with the soil and comparing the results to a color chart. NPK are mostly needed in soil, and the right number of them must be there. The growth of the crop will be immediately impacted by their increase or decrease[17-21]. To solve linked issues including the use of fertilizers high in phosphate, potassium, and nitrogen, water consumption, land occupation or transformation, and greenhouse gas emissions, a thorough examination of many facets of food production is required [

21].

The essential nutrients for growing any crop are NPK. The quality and yield of a crop are determined by the proper NPK proportions. These elements are supplied by fertilizers in the proper amounts to speed up crop growth and boost output. However, because the plants are constantly consuming nutrients, the quantities of nutrients may fluctuate. As a result, it's important to control and continuously monitor the NPK levels in the water tank in real time [

22,

23,

24]. Compared to soil-based production, hydroponic agriculture uses a lot less water and other resources. The multiple factors, plant nutrients, and diagnostic techniques involved in hydroponics production make it difficult to monitor. Because of recent technological advancements, agriculture may now employ AI-based control algorithms, which has aided in the search for solutions [

25,

26,

27].

The application of four distinct dosages of nutrient solution (NPK) in combination with a culture of FLD Isolate L1 (B. cereus) had an impact on the plant N content and growth of a lettuce crop. When compared to an unfertilized control, inoculation with Isolate L1 (B. cereus) alone significantly enhanced wet weight, dry weight, and plant N. Applying Isolate L1 (B. cereus) along with a 25% or 50% NPK nutrition solution resulted in a highly significant increase in wet weight (P<0.001). It was determined that using the proper microbial inoculants in hydroponics along with lower concentrations of mineral fertilizers improved lettuce growth and supplied sufficient amounts of plant N [28-30].

2. Related Work

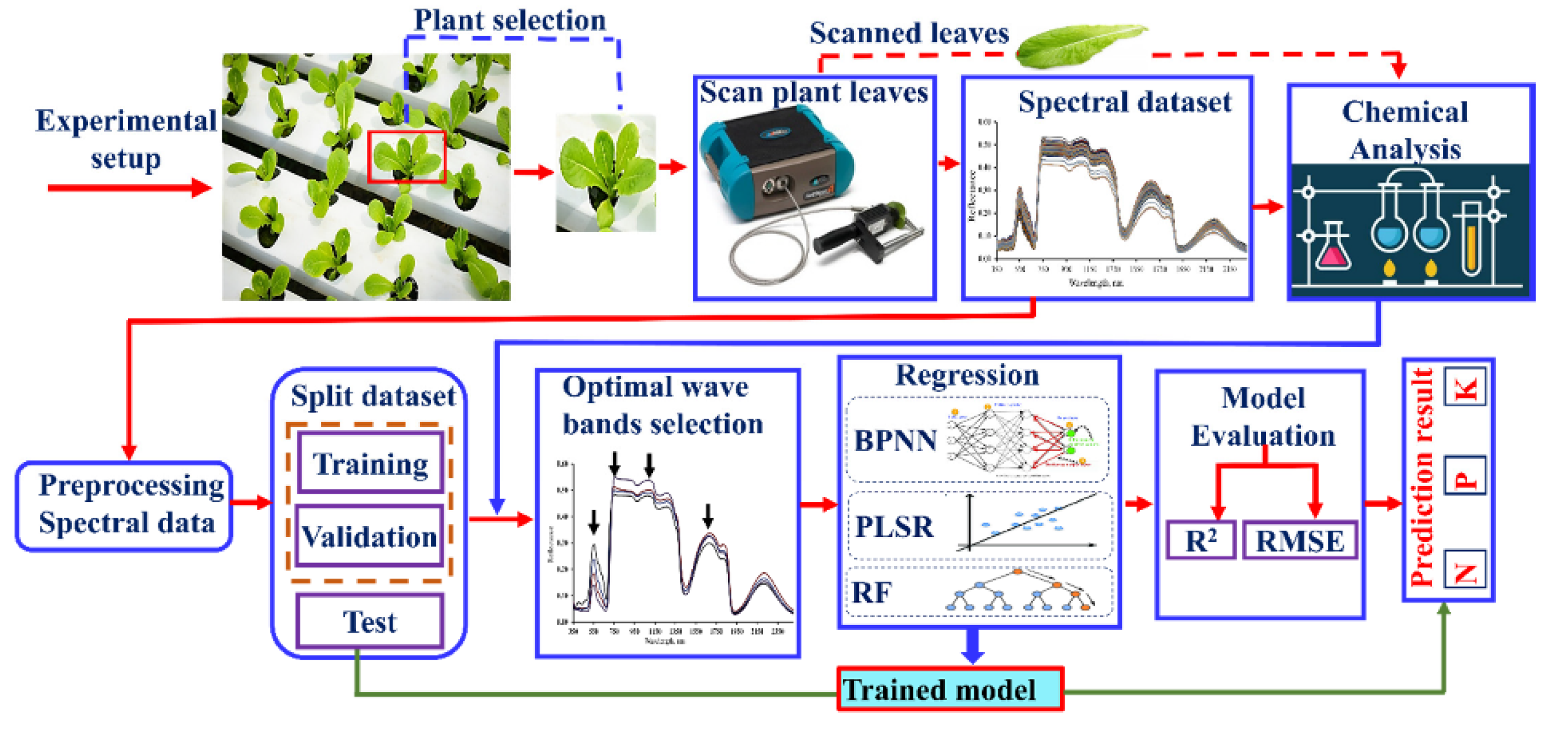

Taha, M.F ., et al examine the plant's nutrient content, one can determine the required amount of supplementation. The objective of this research is to create reliable machine learning models for estimating the levels of potassium (K), phosphorus (P), and nitrogen (N) in lettuce that is grown aquaponically. Leaf reflectance spectra were measured using a FieldSpec4, Pro FR portable spectroradiometer (ASD Inc., Analytical Spectral Devices Boulder, Boulder, CO, USA), and spectra and total NPK estimation were performed on 128 lettuce seedlings that were administered four NPK treatments [

31].

Figure 1.

Flowchart followed by Taha, M.F., et al for their proposed system with permission, this image has been reproduced[

31].

Figure 1.

Flowchart followed by Taha, M.F., et al for their proposed system with permission, this image has been reproduced[

31].

The low-cost hydroponics experiment aims to increase coriander production per unit area economically under laboratory conditions. The new scientific method of growing plants passively without artificial aeration and mechanical circulation around the root zone is the low-cost hydroponics system. Modified Kartky system passive approach is the kind used here. The experiment was set up using a completely randomized design and five distinct kinds of hydroponic fertilizer solutions [

32].

Technological improvements have led to the adoption of the hydroponics smart greenhouse method. Plants grown hydroponically grow faster and yield more than those grown in soil. this method of producing plants eliminates the need for dirt. In a typical hydroponics system, part of the greenhouse is utilized for harvesting, and variables like humidity and temperature can affect how quickly plants grow and how well they are nourished. Because rock wool is made of volcanic materials and is not biodegradable, organic coconut coir medium is used in this proposed system's hydroponics for germination [

33].

Figure 2.

A healthy and fully nourished plant that covers the entire region of Green House With permission, this image has been reproduced [

33]

.

Figure 2.

A healthy and fully nourished plant that covers the entire region of Green House With permission, this image has been reproduced [

33]

.

With the use of this technique, crops can be produced on less land and with fewer labourers. Small-scale unit farmers may have considered the total cost of the system; vertical hydro farming yields superior results over earlier traditional techniques. Big data analytics will be used for the analytics of the automated vertical hydro farming techniques that have been designed and implemented with IoT platforms [

34].

Some work has been done utilizing machine learning techniques, such as neural network models and Bayesian networks, to manage the growth of hydroponic plants. Artificially intelligent control of the hydroponic system and machine-to-machine interaction are made possible by the Internet of things. In order to forecast plant damage, weekly fertilizer supply, and agricultural output management in a diverse situation, the suggested study makes use of machine learning approaches. The performance of the various machine learning techniques—such as logistic regression, decision trees, support vector machines, and random forests is compared using the mean square error criteria and the model's accuracy percentage. A machine learning model is subjected to various hyper-parameter adjustments in order to achieve optimal accuracy and performance on a hydroponic farming dataset [

35]. To achieve optimal plant growth and encourage a wider commercial adoption of aquaponic culture, the primary goal of this research was to create statistical methodologies and machine learning algorithms to manage nutrient concentrations in aquaponic irrigation water depending on plant needs. Bolstered error estimation methodologies must be employed due to the sparsity of the data, which poses a significant barrier in the development of these algorithms. This consider surveyed a number of direct and non-linear calculations that were prepared on exceptionally constrained datasets utilizing Supported blunder estimation strategies in arrange to decide the ideal approach for controlling supplement levels in hydroponic settings [

36].

Four hydroponic datasets are analyzed, and machine learning calculations are compared in this investigate. Each day, data from hydroponic frameworks is collected in arrange to estimate their abdicate. In this consider, four particular hydroponic frameworks are utilized to look at the viability of the combined part learning, profound neural arrange, extraordinary gradient boosting (XGBoost), and direct relapse methods. The datasets of the hydroponic frameworks known as Nutrient Film Technic (NFT), Floating (FL), Aggregate (AG), and Aeroponic (AER) have been analyzed utilizing these strategies. The results appeared how well each show performed in each hydroponic framework as well as how each calculation utilized a assortment of numerous input highlights to appraise the onion bulb distance across and the blunders that each demonstrate encountered [

37].

Table 1.

Machine Learning Approaches for Agriculture Industry.

Table 1.

Machine Learning Approaches for Agriculture Industry.

| Author |

Year |

Work |

Outcome |

| Verma, M.S. and Gawade, S.D., [38] |

2021 |

Exhibits both positive and negative connections with the plant's absolute crop growth rate, dry fruit weights, and growth characteristics. |

Predicting and attaining a decent absolute CGR, and determining the ideal value for each crucial parameter will aid in the production of high-quality crops. |

| Popkova, E.G [39] |

2022 |

The purpose of the paper is to provide scientific evidence for the unique ideas and advantages of smart innovation in agriculture. |

A vertical farm model based on hydroponics, AI, and deep learning. |

| Komninos, A, etal ., [40] |

2019 |

Development of a scalable hydroponics monitoring system. |

Farmers may increase productivity while reducing the amount of manual labour required by keeping an eye on the environmental conditions within the greenhouse as well as the parameters of the solution. |

| Rukhiran, M. and Netinant, P [41] |

2020 |

Smart farm hydroponic system built on the Technology Acceptance Model (TAM). |

Allows for the development of improved Internet of Things applications and systems in a feasible smart architecture design for mobile consumption. [42]. |

| Md. Mamun Hossain., etal [43] |

2023 |

Main goal is to address agricultural difficulties by providing a through, Integrated solution. |

Give an assortment of administrations to agriculturists, counting pesticide proposals and water engine control through portable applications and a cloud database. |

| Perwiratama, R. and Setiadi, Y.K [44]. |

2020 |

Automated farming irrigation system that uses data from all the sensors attached to the Raspberry Pi and sends it over the network to an Internet of Things server. |

By gathering sensor reading data and applying machine learning techniques, it is possible to forecast the growth of the plants. |

| Andrianto, H. and Faizal, A [45]. |

2020 |

create Internet of Things-based smart greenhouses for hydroponic farming (IoT) [46] |

A smartphone application allows for the control of all actuators and the monitoring of the greenhouse's environmental parameters. |

| Ban, B.,etal [47] |

2020 |

The system handles the ion interference effect problem by measuring the separate concentrations of several ions and adding just the nutrients that are lacking. |

Use less water and create a more favourable climate for the crops. |

| Mehare, J.P. and Gaikwad, A [48]. |

2022 |

This paper offered a framework for Internet of Things-based automated smart farming in hydroponics[49,50]. |

The framework enhanced its display and allowed it to successfully carry out the purpose of the entire framework executed. |

| Gowtham, R. and Jebakumar, R., [51] |

2023 |

Support vector regression to handle the data from the Internet of Things system, which is primarily in charge of automating the lettuce environment without requiring human involvement. |

The suggested model generates a higher prediction accuracy score of 82.07%, which improves yield prediction. |

2.1. Approaches for Farming

2.1.1. Urban Horticulture

In rapidly urbanising areas, urban horticultural cropping systems present a promising alternative for sustainable agriculture and food security. This essay examines their changing surroundings, highlighting the patterns and difficulties that have shaped their growth and influence on metropolitan settings. Urban horticulture's major themes include vertical farming, rooftop gardens, hydroponics and aeroponics, Internet of Things (IoT), integration of optimised space and resources, and year-round growing [

52,

53,

54].

2.1.2. Vertical Farming Technique

The most advanced agricultural technique available today increases crop yield per unit area through vertical farming. The goal of this effort is to provide a regulated environment for plant growth in a smart vertical farming system that is facilitated by the Internet of Things. This system balances pH and total dissolved solids (TDS) automatically, and it makes use of many sensors as well as the hydroponic Deep Flow Technique (DFT). In terms of plant development characteristics including plant height, maximum leaf length, maximum leaf breadth, and fresh and dry weight of the plant [

55,

56,

57].

2.1.3. Green IoT-Based Automated Door Hydroponics Farming System

Integrating green IoT with a fully automated hydroponics system to ensure a sustainable, energy-efficient, and environmentally friendly agricultural technique [

46,

58]. Using the Internet of Things, this system automatically checks and modifies parameters, provides required resources, and uploads data to a cloud server. Users will be able to quickly monitor and maintain their mobile devices by using an application that provides them with the current state [

59].

2.1.4. Machine Learning Based Hydroponic Farming

It is now necessary to save water since, due to daily climate change and unpredictable rainfall, we will eventually have to deal with water scarcity issues. Utilizing machine learning and artificial intelligence, crop growth in hydroponic environments is tracked. Our system took the appropriate actions by receiving sensor information and regulating itself autonomously. Reusing water in a hydroponics system allows us to conserve 70% more water than we would in traditional farming. In our work, we use machine learning algorithms to determine crop growth accuracy [

60,

61,

62].

Table 2.

Advantages and Limitations of Different Farming Techniques.

Table 2.

Advantages and Limitations of Different Farming Techniques.

| Farming Technique |

Advantages |

Sensor Used |

Limitation |

| Precision Agriculture [63,64,65] |

1)improve Crop yield [66]

2) Efficient resource utilization

3) Reduced environmental impact [67] |

GPS, Soil Moisture Sensors, Weather Stations |

1) Initial setup costs [68]

2) Technical expertise required

3) Data security concerns |

| Hydroponics [5] |

1) Water and nutrient efficiency

2) Year-round crop production

3) Reduced pesticide use |

pH Sensors, EC Sensors, Temperature Sensors |

1) Energy consumption

2) Initial infrastructure investment [69]

3) Susceptible to system failures |

| Aquaponics [70,71] |

1) Integrated fish and plant cultivation [72]

2) Sustainable and resource-efficient

3) Reduced environmental impact |

Water Quality Sensors, pH Sensors, Dissolved Oxygen |

1) Complex system management

2) Initial cost barriers

3) Fish health management [73] |

| Vertical Farming [56] |

1) Maximized use of limited space [74]

2) Year-round crop production [75,76]

3) Reduced transportation costs [75] |

LED Lights, Temperature Sensors, Humidity Sensors |

1) High initial investment [77]

2) Energy consumption[56] |

| Agroforestry [78] |

1) Biodiversity promotion [79]

2) Carbon sequestration [80]

3) Soil erosion prevention [81] |

Soil Moisture Sensors, Climate Sensors, Light Sensors |

1) Longer time to realize economic benefits

2) Limited immediate income

3) Spatial competition with crops |

| Organic Farming [82,83,84] |

1) Reduced chemical inputs [85]

2) Enhanced soil fertility [86]

3) Improved ecosystem health [87] |

Soil Health Sensors, Weed Sensors, Insect Sensors |

1) Lower yields compared to conventional farming [88]

2) Labor-intensive |

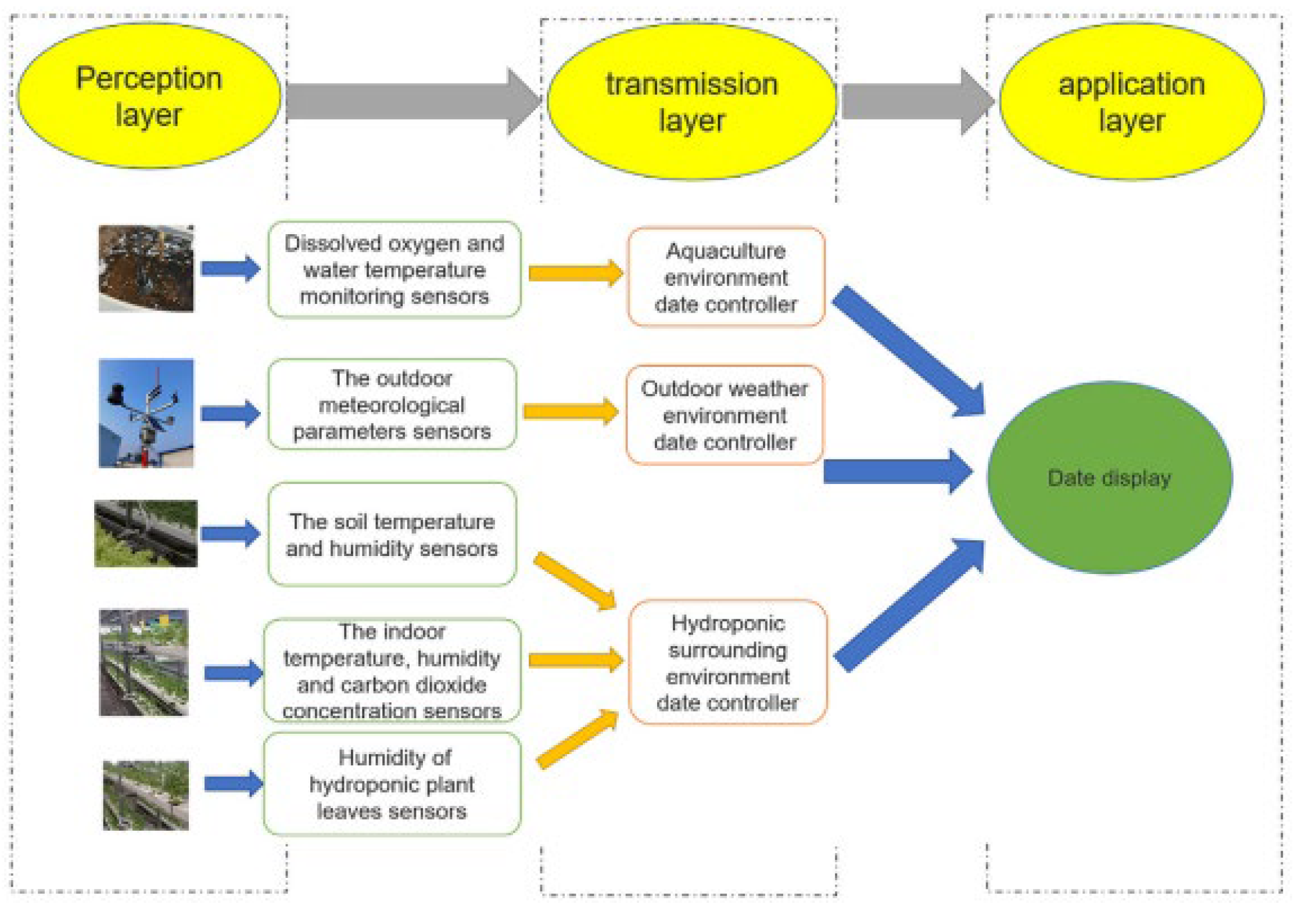

Based on internet of things innovation, Shanhong Zhang etal., work makes a dispersed natural observing framework for hydroponics and aquaculture that essentially comprises of the data recognition layer, data transmission layer, and framework design. The framework employments a few sensor terminals for real-time capture of information, such as dissolved oxygen, discuss and water temperatures, etc. Smaller data may be sent via the LoRa protocol, and 4G was used to gather data and transfer it to the cloud platform. The core component of the aquaponics management system is real-time monitoring and control. The implementation of Internet of Things technology enhanced the performance of the management system by providing real-time environmental monitoring, remote control, over-limit alarm, video monitoring, and other functions for planting. These features resulted in a significant decrease in labour intensity, a reduction in management expenses, and an improvement in production efficiency. Beijing Zhong Nong Tian Lu Water Science and Technology Park was home to the aquaponics system, which featured three different types of fish vegetable symbiosis systems: floor type, three-dimensional, and landscape type [

89].

Figure 3.

Aquaponics in Beijing Zhongnong Tianlu Water Science and Technology Park With permission, this image has been reproduced [

89] Copyright 2022 , Information Processing in Agriculture

.

Figure 3.

Aquaponics in Beijing Zhongnong Tianlu Water Science and Technology Park With permission, this image has been reproduced [

89] Copyright 2022 , Information Processing in Agriculture

.

Figure 4.

Scheme design for monitoring system With permission, this image has been reproduced [

89] Copyright 2022 , Information Processing in Agriculture

.

Figure 4.

Scheme design for monitoring system With permission, this image has been reproduced [

89] Copyright 2022 , Information Processing in Agriculture

.

The perception layer consists mostly of on-site sensor networks, weather monitoring nodes, hydroponic environment nodes, and water quality monitoring nodes. RS485 and LOR coupled communication techniques are used to send the real-time data gathered on-site upwards;

Transmission layer: layer was used to establish the surface for the data from the first layer, which would be delivered to the cloud platform via the 4G network. Concurrently, the LED displayer on the greenhouse displayed the date obtained from the perception layer.

Application layer: This layer's job is to preprocess data before sending it to the user. It was able to do dynamic display, full data storage, and platform data monitoring [

89].

3. Materials and Methods

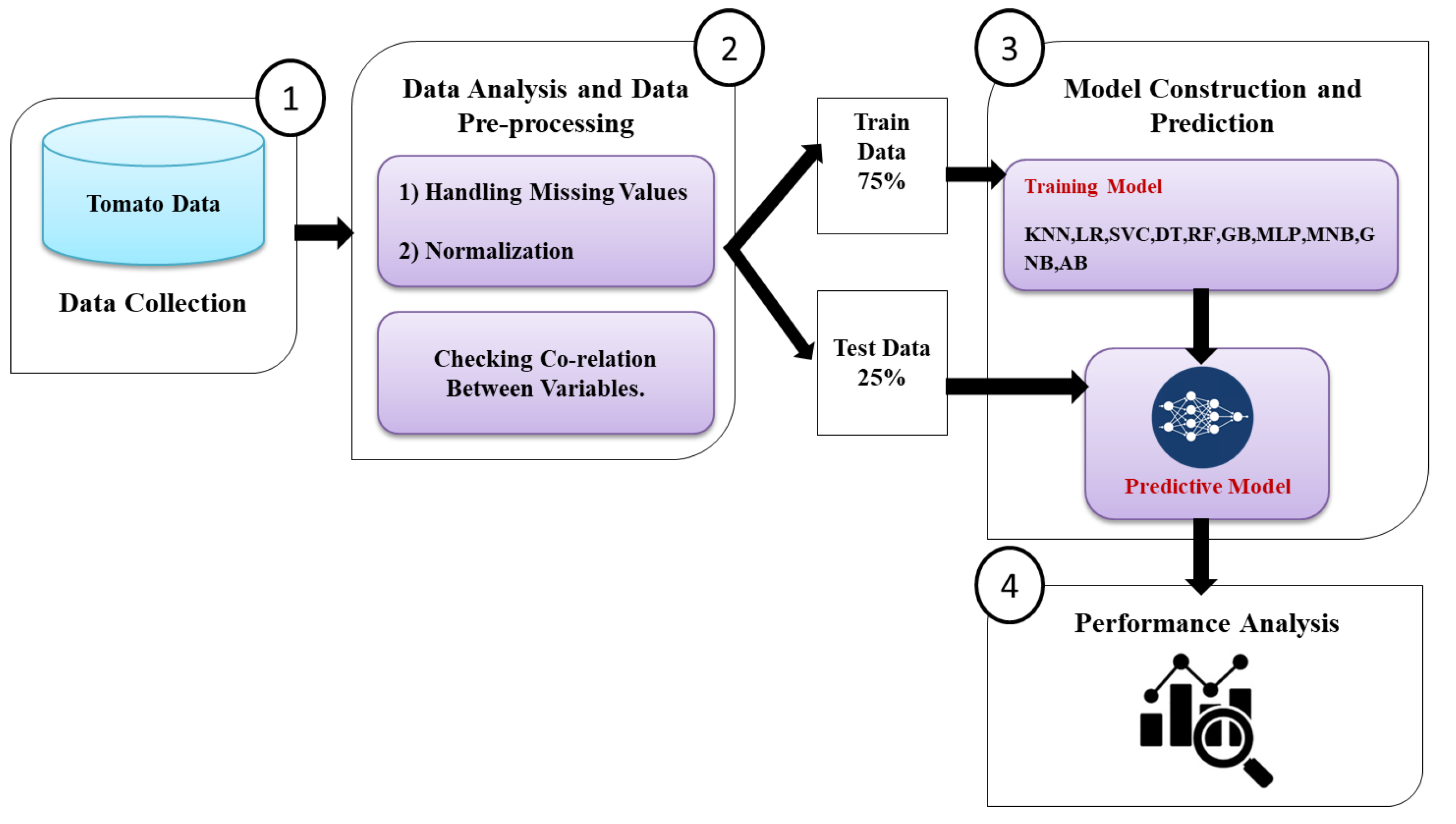

This study proposes a methodology for nutrition management in hydroponic vegetable systems utilizing machine learning algorithms integrated with IoT. The aim is to enhance the efficiency and accuracy of nutrient management for plants and crops. The methodology involves several steps, including data preparation, data cleaning, feature selection, and data balancing, to improve model performance. Thereafter, machine learning models such as K-Nearest Neighbor, Logistic Regression, Support Vector Classifier, Decision Tree, Random Forest, Gradient Boost, Multi-Layer Perceptron, Multinomial Naïve Bayes, Gaussian Naïve Bayes and Adaptive Boost are applied to analyze the data.

Figure 3 illustrates the proposed methodology.

Figure 5.

The proposed methodology for tomato dataset.

Figure 5.

The proposed methodology for tomato dataset.

3.1. Data Collection

This step involves gathering the raw data that will be used for the analysis. In this case, it refers to the collection of data related to tomatoes, which could include features such as temperature, plant age, type of tomato (e.g., flowering, green tomato, red tomato), and other relevant agricultural or environmental factors.

3.2. Data Analysis and Pre-processing

Several pre-processing steps are taken in advance of the feeding of datasets into the proper machine learning model so that model performance can be higher. Among pre-processing duties are removal of outliers and handling of missing values, data normalization, encoding, and a few others.

Outliers Removal - Removing the values of attributes that fall boundaries and have high variation from the rest of the respective attribute's value can be there in the dataset. Value of such attributes may degrade the

Performance of the machine learning algorithm. We used the IQR (Inter-quartile Range) technique to remove such kind of Outliers

Missing value Handling - Mean value to handle the missing values of each attribute was employed for the missing values it will lead to improve the performance of models

Label Encoding -The process of converting the Labels of text/categorical values to a numerical format that ML algorithm can understand. For example, the categorical values of Junk food consumption status have been converted from 'yes' to '1 and 'No' to '0'.

3.3. Model Construction and Prediction

For the construction of the predictive model, 75% of the pre-processed data is used for training, while the remaining 25% data is used for testing used.

Illustrations:

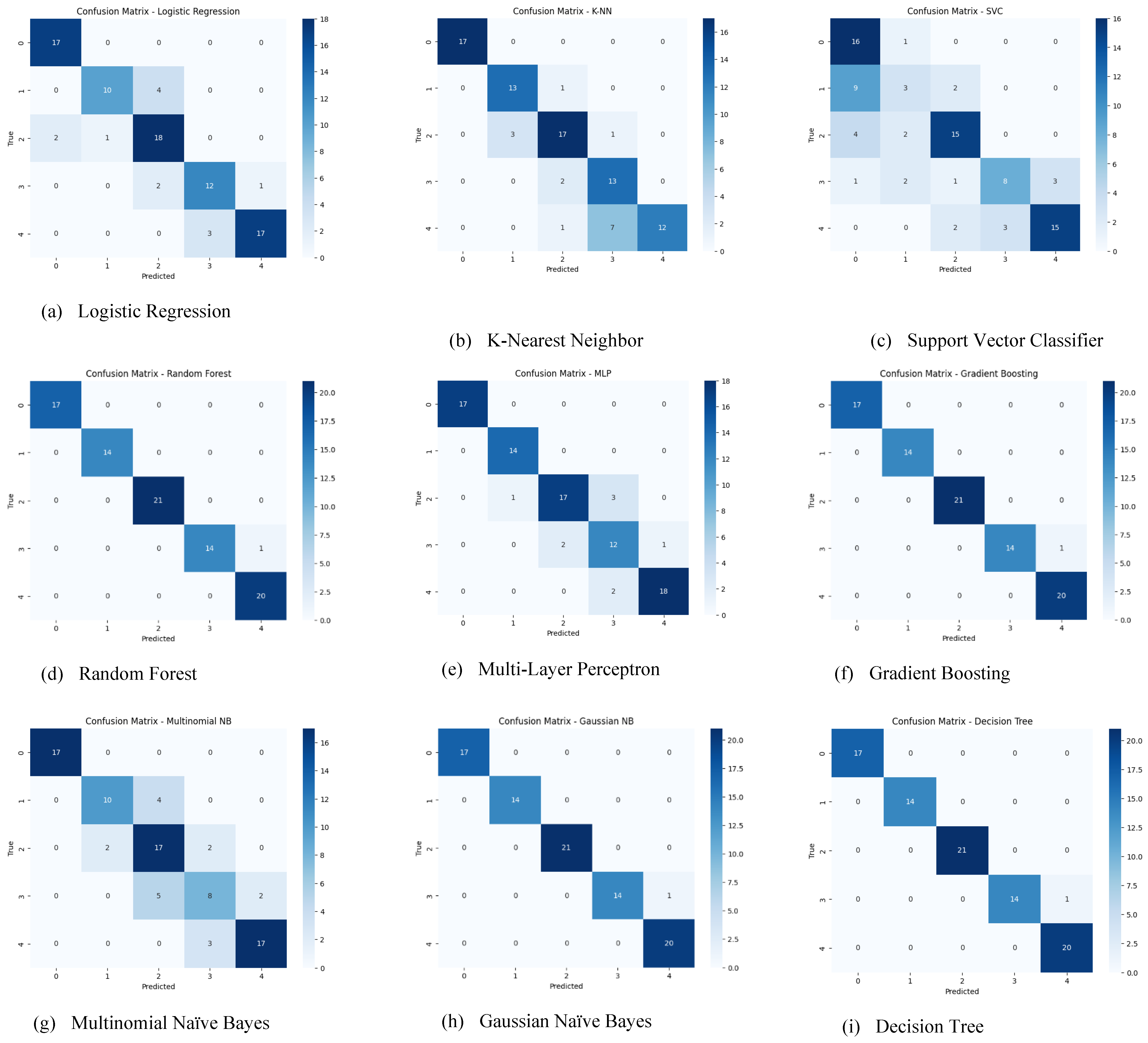

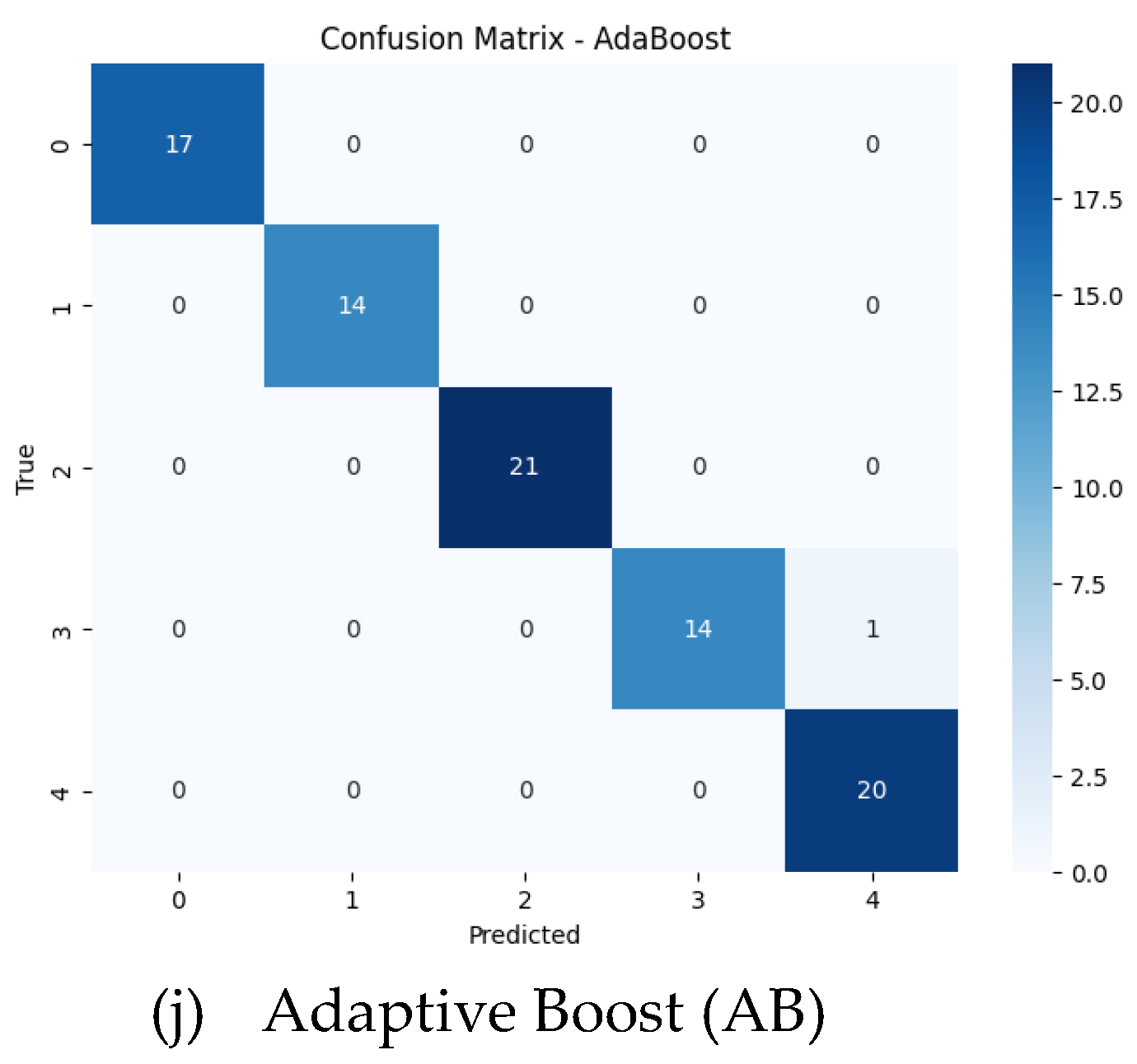

The confusion matrices provided for various machine learning models offer insights into their classification performance on the dataset. Each model demonstrates varying levels of accuracy in predicting the correct classes, with some models showing higher accuracy than others. For instance, the Logistic Regression and Support Vector Classifier (SVC) matrices likely indicate a balanced performance with a relatively good distribution of correct predictions along the diagonal. Models like K-Nearest Neighbors (K-NN) and Random Forest might show more accurate predictions due to their ability to capture complex relationships in the data, reflected in fewer misclassifications. On the other hand, neural network-based models like Multi-layer Perceptron (MLP) and Gradient Boosting could exhibit strong classification capabilities, especially if trained well, with a concentration of true positives and true negatives. Ensemble methods such as AdaBoost and Random Forest may show enhanced performance, as they combine multiple learners to correct errors iteratively. However, Naïve Bayes models, both Multinomial and Gaussian, may show more variability in accuracy, especially if the data does not meet the model’s assumptions, which could result in higher misclassification rates. Overall, these matrices highlight the effectiveness of certain models like Random Forest and SVC, while also indicating where other models may need tuning or are less suitable for this specific dataset.

Table 3.

Model evaluation after k-fold with 5 cross validations.

Table 3.

Model evaluation after k-fold with 5 cross validations.

| Models |

Accuracy |

Precision |

Recall |

F1_Score |

| Logistic Regression |

0.89 |

0.86 |

0.85 |

0.85 |

| K-NN |

0.87 |

0.86 |

0.83 |

0.83 |

| SVC |

0.57 |

0.66 |

0.66 |

0.64 |

| Random Forest |

0.99 |

0.99 |

0.99 |

0.99 |

| Multi-layer Perceptron |

0.93 |

0.89 |

0.89 |

0.88 |

| Gradient Boost |

0.99 |

0.99 |

0.99 |

0.99 |

| Multinomial Naïve Bayes |

0.80 |

0.80 |

0.79 |

0.79 |

| Gaussian Naïve Bayes |

0.99 |

0.99 |

0.99 |

0.99 |

| Decision Tree |

0.98 |

0.99 |

0.99 |

0.99 |

| Adaptive Boost |

0.99 |

0.99 |

0.99 |

0.99 |

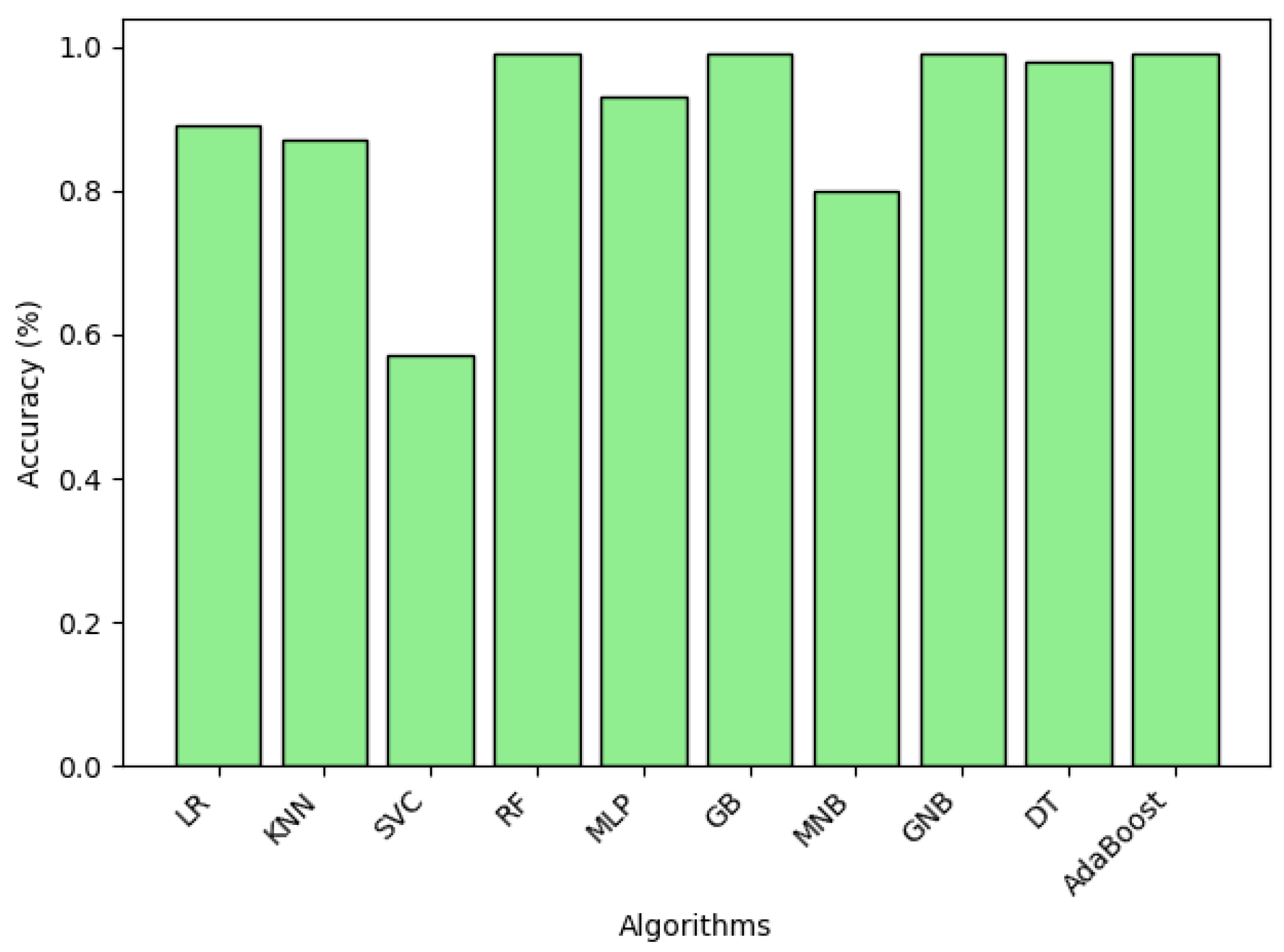

Figure 6.

Accuracy of Adopted Machine Learning Models

Figure 6.

Accuracy of Adopted Machine Learning Models

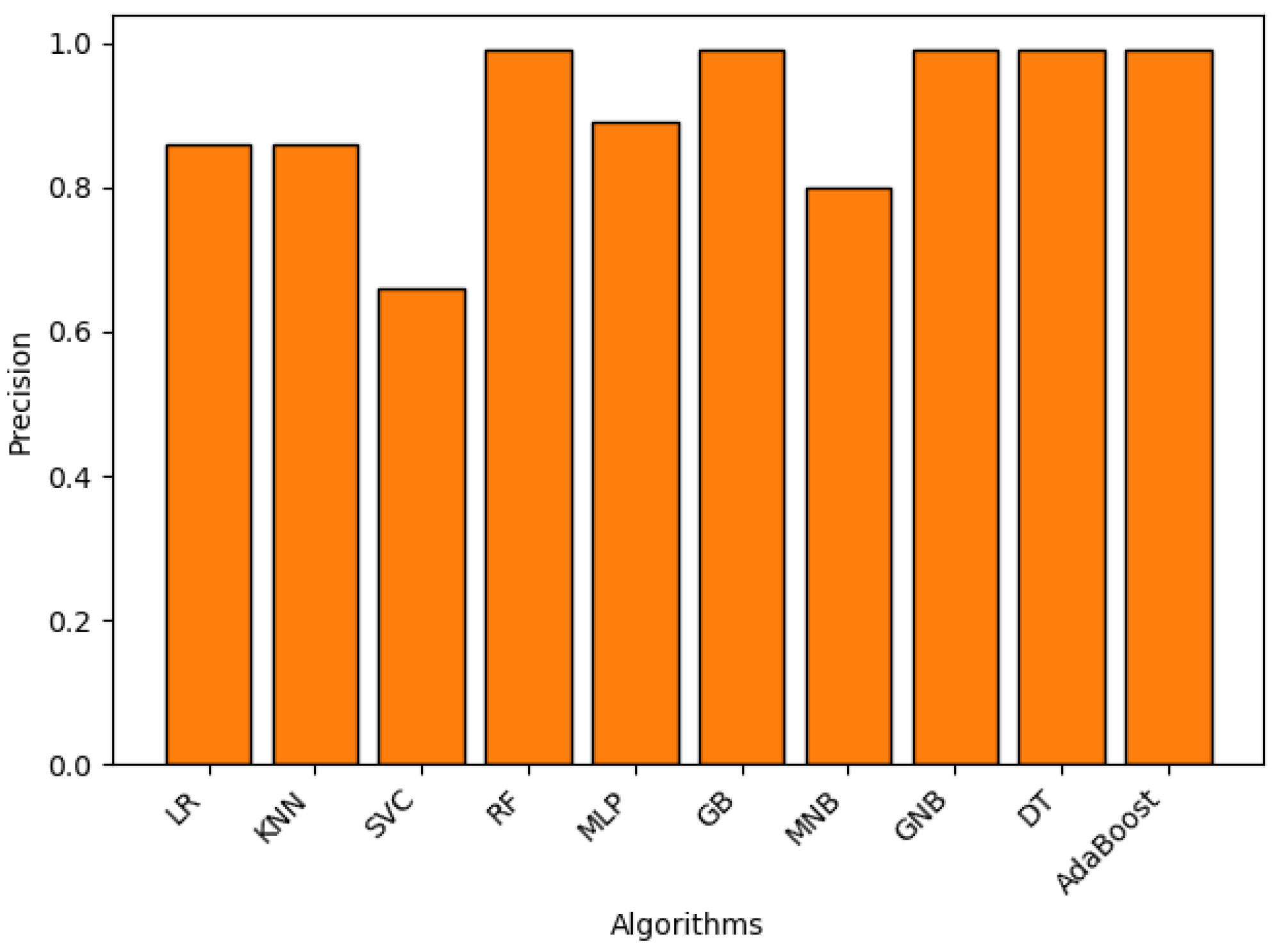

Figure 7.

Precision of Adopted Machine Learning Models

Figure 7.

Precision of Adopted Machine Learning Models

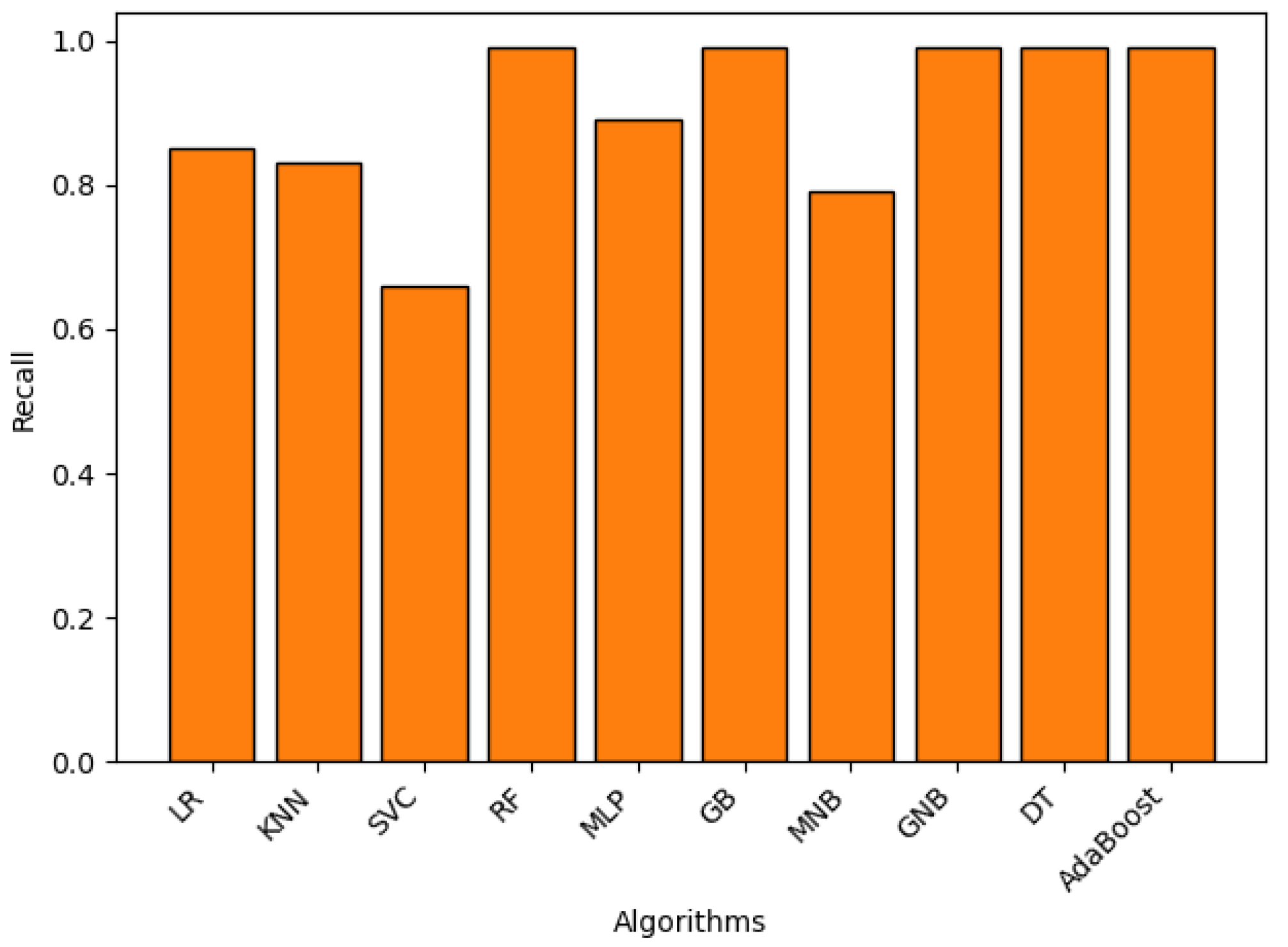

Figure 8.

Recall of Adopted Machine Learning Models

Figure 8.

Recall of Adopted Machine Learning Models

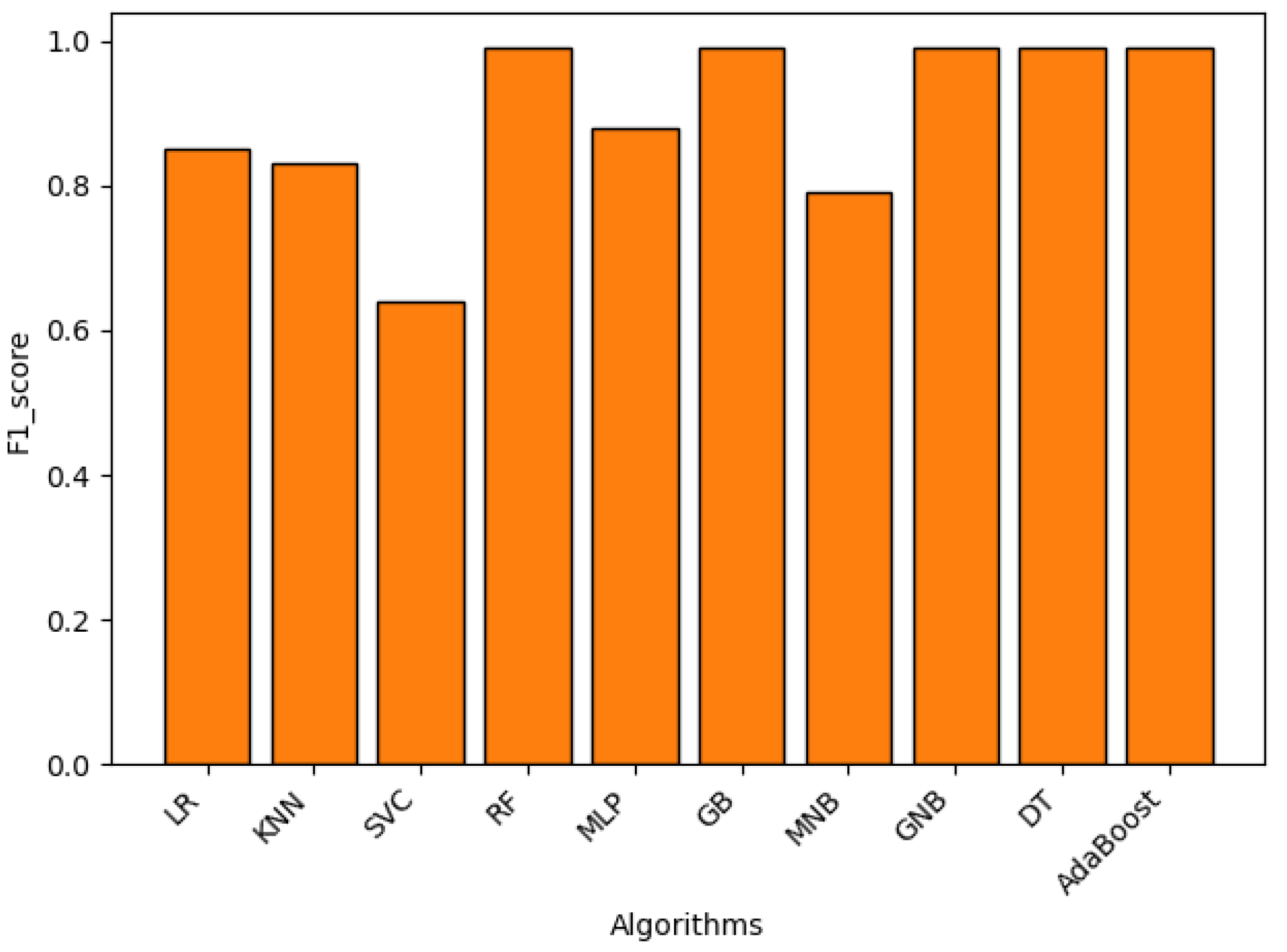

Figure 9.

F1_score of Adopted Machine Learning Models

Figure 9.

F1_score of Adopted Machine Learning Models

Figure 10.

Confusion matrix of individual model.

Figure 10.

Confusion matrix of individual model.

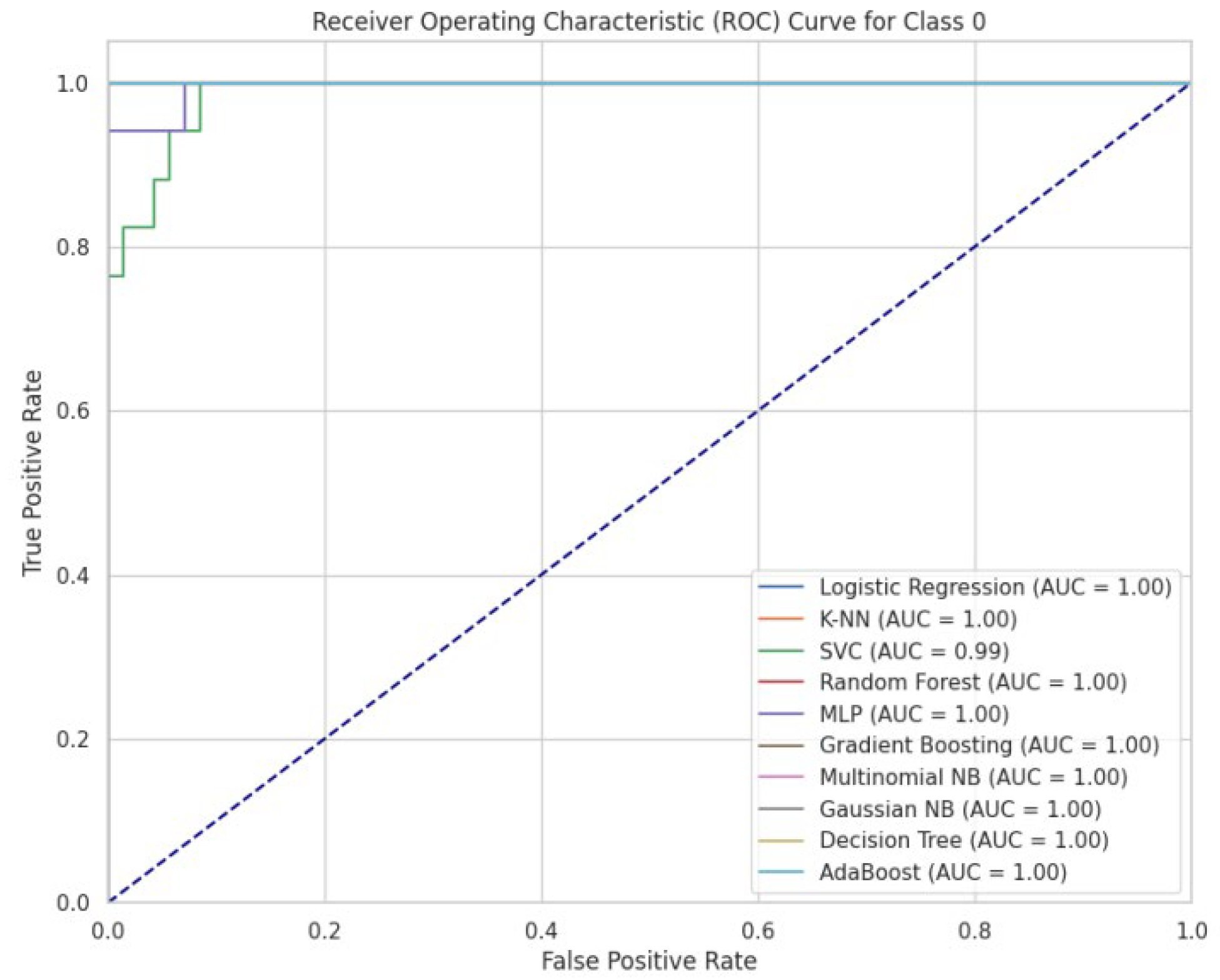

Figure 11.

ROC curve of performance of machine learning model for class 0.

Figure 11.

ROC curve of performance of machine learning model for class 0.

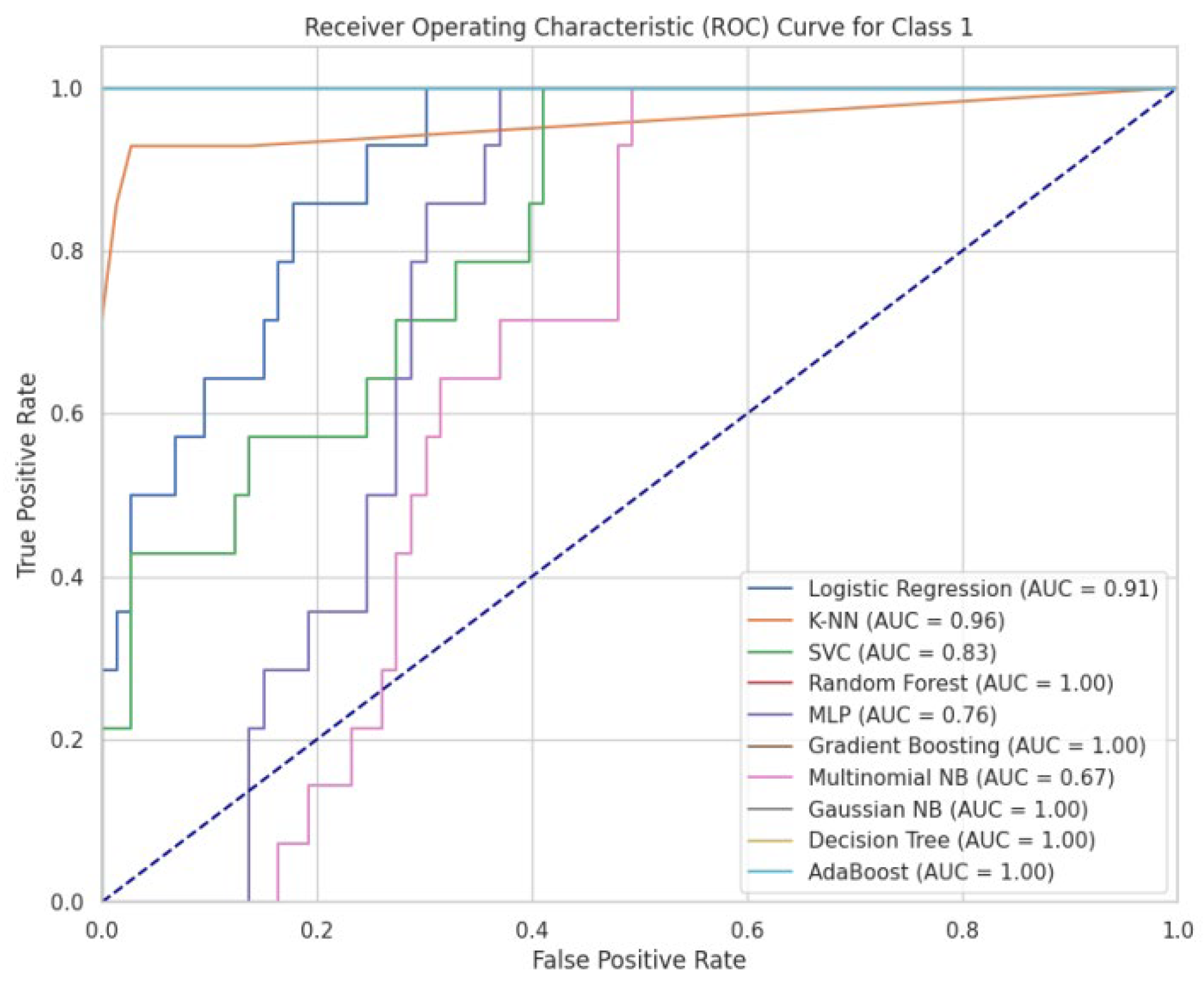

Figure 12.

ROC curve of performance of machine learning model for class 1.

Figure 12.

ROC curve of performance of machine learning model for class 1.

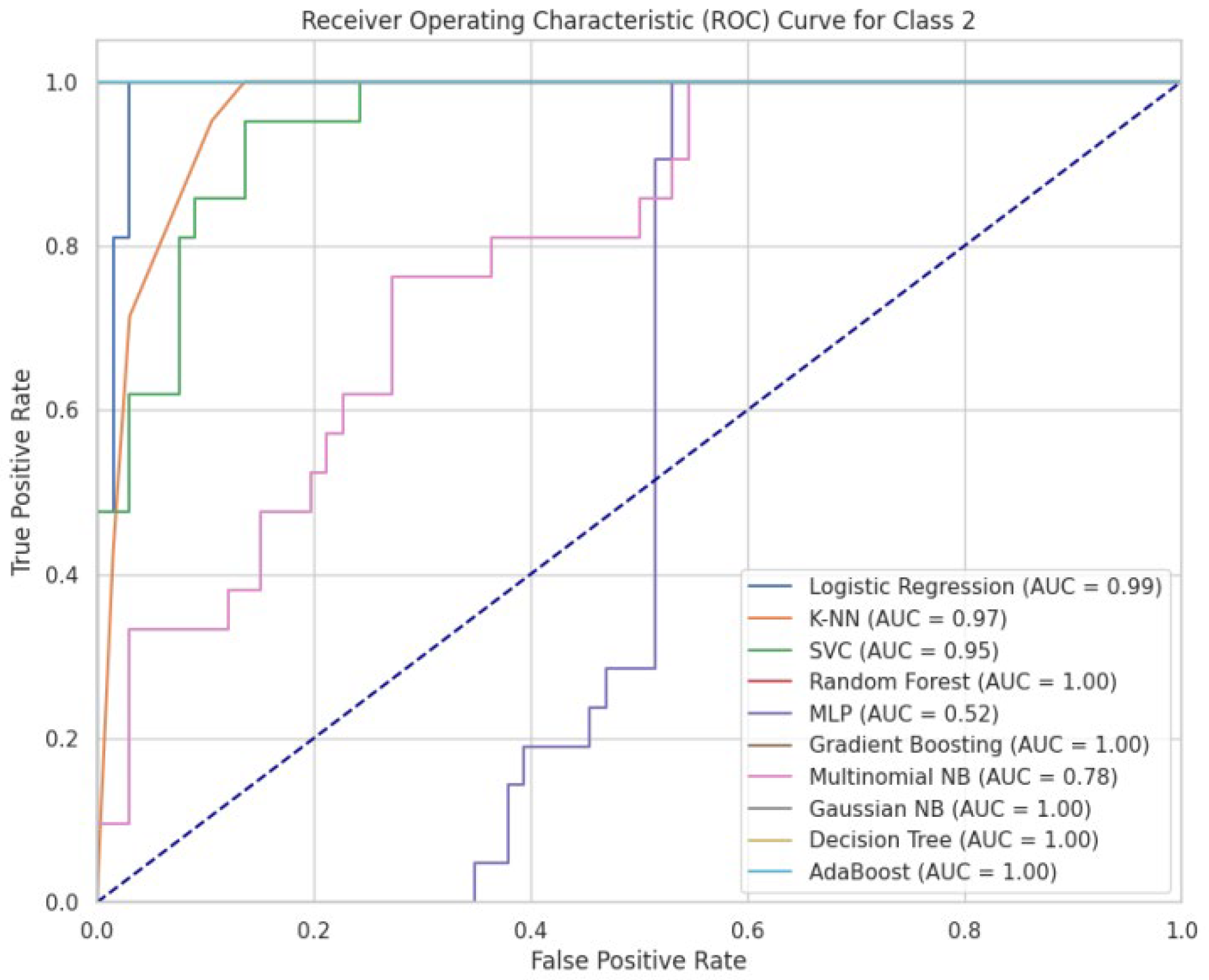

Figure 13.

ROC curve of performance of machine learning model for class 2.

Figure 13.

ROC curve of performance of machine learning model for class 2.

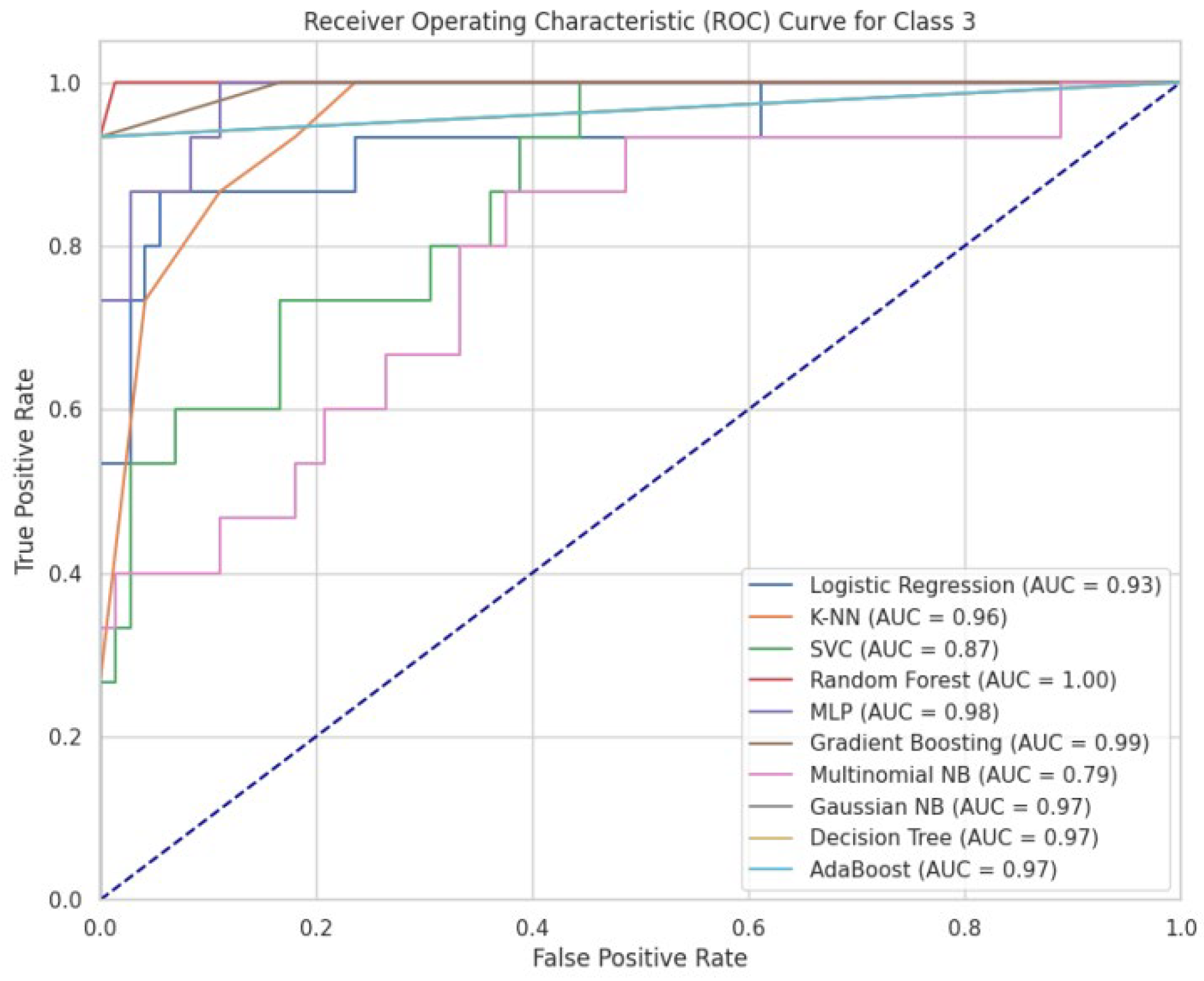

Figure 14.

ROC curve of performance of machine learning model for class 3.

Figure 14.

ROC curve of performance of machine learning model for class 3.

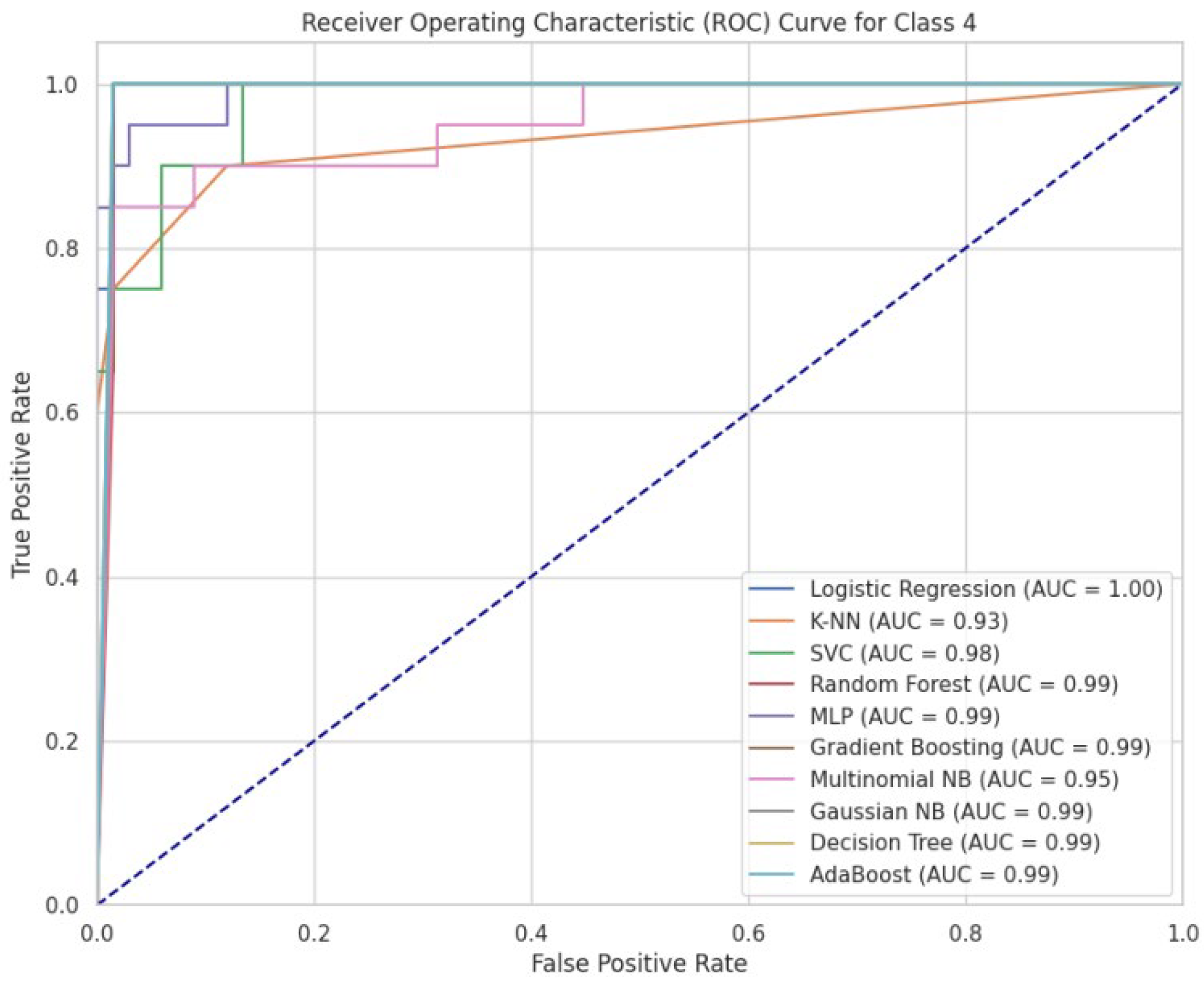

Figure 15.

ROC curve of performance of machine learning model for class 4.

Figure 15.

ROC curve of performance of machine learning model for class 4.

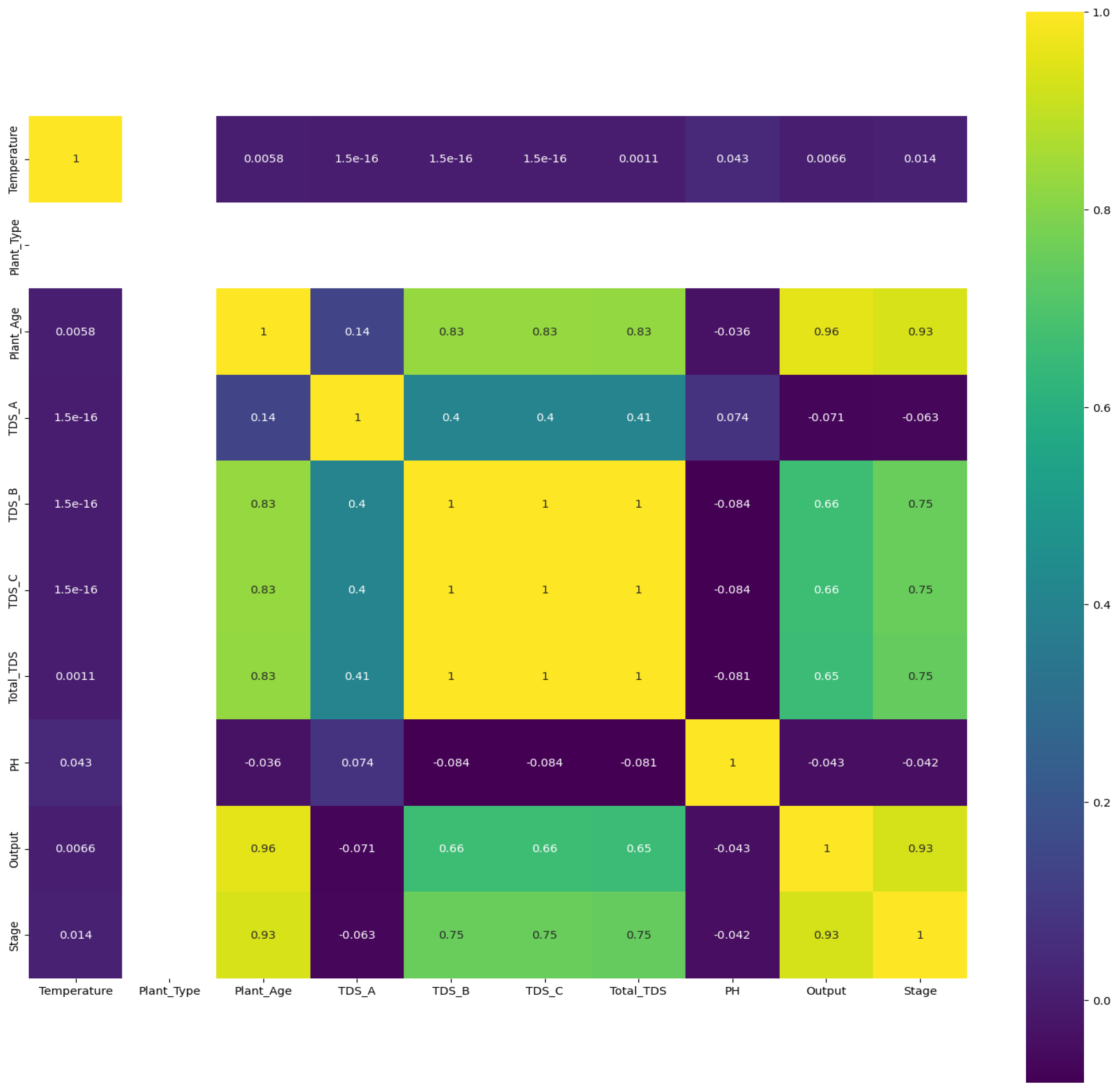

Figure 16.

Correlation matrix for correlation analysis.

Figure 16.

Correlation matrix for correlation analysis.

Illustrations:

The correlation matrix

Figure 15. illustrates the relationships between various features in the hydroponic vegetable system dataset. Notably, Plant_Type shows a strong positive correlation with both Output and Stage, indicating that the type of plant is closely linked to the output and the stage of growth. Similarly, Plant_Age is strongly correlated with TDS_B, TDS_C, Total_TDS, and Stage, suggesting that as plants age, the total dissolved solids (TDS) levels in parts B, C, and overall tend to increase, along with the progression in growth stages. The TDS_B, TDS_C, and Total_TDS features are perfectly correlated with each other, implying they are either identical or derived from the same measurements. Conversely, Temperature and PH show minimal correlation with most other features, indicating they have less influence on the plant’s output and growth stages. Overall, the matrix underscores the significant impact of plant type, age, and TDS levels on the output and growth stages in the hydroponic system.

4. Adopted Machine Learning Algorithms.

4.1. Logistic Regression

Logistic Regression is a widely used statistical method for binary classification, which predicts the probability of an outcome that can take one of two possible values. Logistic regression models the relationship between the dependent binary variable and one or more independent variables. The model predicts the log-odds of the probability of the dependent event.

The logistic function (also known as the sigmoid function) converts the log-odds back into a probability:

4.2. K-Nearest Neighbor

K-Nearest Neighbor (K-NN) is a simple, non-parametric algorithm that classifies new instances based on a majority vote of their neighbors. The algorithm is intuitive and straightforward to implement. Given a data point,

the algorithm identifies the k- nearest neighbors using a distance metric.

The predicted class

is then determined by the majority class among the nearest neighbors:

4.3. Support Vector Classifier

Support Vector Classifier (SVC) is a powerful classification algorithm that finds the optimal hyper plane that maximizes the margin between two classes. It is effective for both linear and non-linear classification tasks.

The decision boundary is defined by the following equation:

Here, are the Lagrange multipliers are the class labels, is the dot product (or kernel function), and is the bias term.

The SVM solves the following optimization problem to find the optimal hyper plane.

4.4. Random Forest

Random Forest is an ensemble learning method that builds multiple decision trees during training and merges them to improve the accuracy and stability of the model. Random Forest aggregates the predictions of multiple decision trees. For classification, it predicts the class that receives the most votes from the individual trees.

Where is the prediction from the tree and T is the total number of trees.

Tree Construction: Each tree is trained on a random subset of the training data (using bootstrap sampling) and considers a random subset of features when splitting nodes.

Where is the proportion of samples belonging to class at a particular node.

4.5. Multi-Layer Perceptron

MLP is a type of feed forward artificial neural network that consists of multiple layers of neurons, including at least one hidden layer. It is capable of modeling complex, non-linear relationships.

Each neuron in a layer computes a weighted sum of its inputs, adds a bias, and applies an activation function.

Where are the weights, is the bias, and is the activation function (e.g., ReLU, sigmoid).

The model is trained using back propagation, which calculates the gradient of the loss function with respect to the weights and biases, and updates them to minimize the loss:

4.6. Gradient Boosting

Gradient Boosting is an ensemble method that builds models sequentially, with each new model correcting the errors of its predecessor. It is particularly effective for classification and regression tasks.

4.7. Multinomial Naïve Bayes

Multinomial Naïve Bayes is a variant of the Naïve Bayes classifier used for discrete data, particularly in text classification tasks. It assumes that the features are conditionally independent given the class label.

The model calculates the posterior probability of each class given the input features.

Where is the probability of feature given class , and is the prior probability of class .

4.8. Gaussian Naïve Bayes

Gaussian Naïve Bayes is a variant of the Naïve Bayes classifier used for continuous data. It assumes that the features follow a normal distribution and are conditionally independent given the class label.

Here, and are the mean and standard deviation of feature for class k.

4.9. Decision Tree

Decision Trees are a non-parametric supervised learning method used for both classification and regression tasks. The model splits the data into subsets based on the value of input features. Decision Trees split the data at each node based on a feature that minimizes a loss function.

Where is the proportion of samples belonging to class at a particular node.

4.10. Adaptive Boost

Adaptive Boost (AB) is an ensemble learning method that combines multiple weak classifiers to create a strong classifier. It adjusts the weights of the training data to focus on the instances that are hard to classify. Adaptive Boost trains a sequence of weak classifiers, each focusing more on the errors of its predecessor:

Where is the weight assigned to the m-th weak learner based on its accuracy. Adaptive Boost is effective in improving the performance of weak models, making it a robust choice for various classification tasks.

Table 4.

Features of dataset.

Table 4.

Features of dataset.

| Tomato Dataset |

|

|

Number of Records

Number of Attributes |

|

121

11 |

| 1 |

Temperature |

The ambient temperature surrounding the tomato plant |

| 2 |

Humidity |

The level of moisture in the air |

| 3 |

Plant_Type |

The specific variety or type of the tomato plant |

| 4 |

Plant_Age |

Age of the plant |

| 5 |

TDS_A |

Total Dissolved Solids (TDS) measurement from source A, indicating the concentration of dissolved substances in the plant's irrigation water. |

| 6 |

TDS_B |

TDS measurement from source B, providing additional information about the water quality used for the tomato plants. |

| 7 |

TDS_C |

TDS measurement from source C, giving further insights into the nutrient levels in the irrigation water. |

| 8 |

Total_TDS |

The cumulative TDS value derived from various sources, representing the overall water quality affecting the tomato plant. |

| 9 |

PH |

The pH level of the soil or water, a vital parameter that can impact nutrient availability and plant health. |

| 10 |

Output |

A specific output measurement related to the plant's performance or yield, possibly indicating the productivity of the tomato plant. |

| 11 |

Stage |

The growth stage of the tomato plant, which could range from early development to full maturity, helping in understanding the plant's life cycle. |

Table 5.

Comparison previous models with proposed models.

Table 5.

Comparison previous models with proposed models.

| Sr. No |

Authors |

Models |

Accuracy |

| |

|

|

Previous Models |

Proposed Models |

01

02

03

04

05

06

07

08

09 |

Smith, J. et al. [90]

Johnson, M. & Wang, Y. [91]

Patel, R. & Lee, A. [92]

Brown, A. & Davis, E. [93]

Nguyen, T. & Garcia, M. [94]

Kumar, V. & Singh, S. [95]

Wilson, L. et al. [96]

Hernandez, J. & Wong, P [97]

Ali, H. & Zhang, Y. [98] |

LR

KNN

SVC

RF

MLP

GB

MNB

GNB

DT |

85.50%

82.30%

55.60%

97.80%

90.20%

95.70%

78.90%

96.40%

94.60% |

89.05%

87.09%

57.14%

99.71%

91.37%

99.42%

80.73%

99.71%

98.85% |

| 10 |

Davis, E. & Ali, H. [99] |

AB |

96.80% |

99.14% |

Results

The analysis of various machine learning models applied to the hydroponic vegetable system, integrated with IoT for nutrition management, demonstrates significant improvements in prediction accuracy across the board when compared to previous models.

Logistic Regression (LR), as reported by Smith et al., originally achieved an accuracy of 85.50%. The proposed model improved this to 89.05%, indicating a modest but notable enhancement. Similarly, K-Nearest Neighbors (KNN) saw an improvement from 82.30%, as documented by Johnson and Wang, to 87.09% in the proposed model. These improvements underscore the effectiveness of the proposed approach in refining traditional models. In contrast, Support Vector Classification (SVC) showed the least improvement, with Patel and Lee's original model achieving 55.60% accuracy, which only slightly increased to 57.14% in the proposed model. This suggests that SVC might not be the most suitable model for this particular application, or it may require further optimization. Random Forest (RF), reported by Brown and Davis, was already highly effective with an accuracy of 97.80%. The proposed model pushed this further to an impressive 99.71%, reflecting the model's robustness in handling complex datasets. Multi-layer Perceptron (MLP) also experienced a notable improvement, with Nguyen and Garcia's initial accuracy of 90.20% increasing to 91.37% in the proposed model. Gradient Boosting (GB) exhibited one of the most significant improvements, with the accuracy rising from 95.70%, as noted by Kumar and Singh, to 99.42% in the proposed model. This underscores the power of ensemble methods, particularly when enhanced with IoT data inputs. The Multinomial Naïve Bayes (MNB) model, initially reported by Wilson et al. with an accuracy of 78.90%, saw a minor improvement to 80.73% in the proposed model. This slight increase suggests that while MNB is simpler and more interpretable, it may have limitations in capturing the complexities of IoT-enhanced datasets. On the other hand, Gaussian Naïve Bayes (GNB), reported by Hernandez and Wong, showed a substantial improvement from 96.40% to 99.71%, indicating its efficacy in this context. Decision Tree (DT), initially reported by Ali and Zhang with an accuracy of 94.60%, improved significantly to 98.85% in the proposed model. This demonstrates the model's ability to benefit from more detailed and real-time data provided by IoT integration. Lastly, Adaptive Boosting (AB), as reported by Davis and Ali, improved from 96.80% to 99.14%, further validating the effectiveness of boosting techniques in this domain.

Overall, the results indicate that integrating IoT with machine learning models leads to significant accuracy improvements, particularly for ensemble models like RF, GB, and AB. These findings highlight the potential for IoT-enhanced data to revolutionize predictive modeling in smart agriculture systems.

4. Discussion

The results demonstrate that the proposed models consistently outperformed the previous models across all types of machine learning algorithms, suggesting that the integration of IoT in hydroponic vegetable systems plays a significant role in improving prediction accuracy. The most significant improvements were observed in models such as RF, GB, and GNB, where the accuracies approached nearly 100%. This indicates the robustness of these models when coupled with IoT-enhanced datasets, which likely provide more granular and real-time data inputs.

Logistic Regression (LR) and KNN showed moderate improvements, reflecting that even traditional models can benefit from enhanced data but may have limitations in handling complex nonlinear relationships without additional feature engineering. SVC's performance, while improved, remained relatively low, suggesting that SVC might not be well-suited for this particular application or that further hyper-parameter tuning is needed. The exceptional performance of ensemble models like RF and GB highlights their effectiveness in capturing complex patterns in data, especially when integrated with IoT systems that can provide diverse and continuous data streams. The minor improvements in MNB and GNB indicate that while these models are simpler and more interpretable, their performance is highly dependent on the quality of input data, which was evidently enhanced in the proposed approach.

The consistent improvement across all models validates the hypothesis that IoT integration significantly enhances the predictive capabilities of machine learning models in the context of hydroponic vegetable systems. This finding is crucial for further development and application of smart agriculture systems, as it demonstrates the tangible benefits of combining advanced machine learning techniques with IoT technology for improved plant nutrition management.

5. Conclusions

A revolutionary paradigm for modern agricultural production is presented by the incorporation of Internet of Things (IoT) and Machine Learning (ML) technology in the nutrition management of vegetable hydroponic systems. Promising outcomes have been observed when cognitive algorithms and real-time monitoring devices work together to boost crop output, improve resource efficiency, and promote sustainability. Plant development conditions can be optimized through dynamic and adaptive nutrient management made possible by precision agriculture made possible by machine learning algorithms. IoT devices' real-time monitoring features offer constant input, enabling prompt and well-informed decision-making. This combination adheres to the principles of sustainable agriculture by increasing crop output while simultaneously promoting cost- and resource-efficiency. The case studies and literature review demonstrate the enormous potential of ML and IoT to transform hydroponic farming. In addition to addressing current issues, the technology creates opportunities for agricultural innovation and sustainability. In order to fully utilize machine learning (ML) and the Internet of Things (IoT) in influencing the development of intelligent and sustainable agriculture. Here the author used the real time dataset which can be taken from Hydro-Fresh organic and conclude that the current Study Explores the comparative study with machine learning algorithm and from this the among all the model. The study clearly demonstrates the superior performance of machine learning models when integrated with IoT technology in the context of hydroponic vegetable systems. The proposed models consistently outperformed the previous ones across a variety of algorithms, with particularly notable improvements in ensemble methods like Random Forest (RF), Gradient Boosting (GB), and Adaptive Boosting (AB). These results underline the importance of leveraging IoT to provide more granular, real-time data, which enhances the models' ability to capture complex patterns and make accurate predictions.

While traditional models like Logistic Regression (LR) and K-Nearest Neighbors (KNN) showed moderate improvements, the minimal gain observed in Support Vector Classification (SVC) suggests that certain models may require more sophisticated tuning or might not be ideally suited for this application. On the other hand, the substantial gains in models like RF, GB, and GNB highlight the robustness of these techniques in handling complex, data-rich environments.

This study provides compelling evidence that IoT integration can significantly boost the accuracy and effectiveness of machine learning models in smart agriculture. This insight is particularly valuable for the development of advanced systems aimed at optimizing plant nutrition management in hydroponic setups. The findings advocate for the continued exploration and adoption of IoT-enhanced machine learning approaches in the agricultural sector, paving the way for more efficient and sustainable farming practices.

Supplementary Materials

The following supporting information can be downloaded at the website of this paper posted on Preprints.org.

Acknowledgments

Author would like to express gratitude to the Hydro-Fresh Organic Farm located in Nagpur for kindly supplying the readings and information that were necessary for this essay. The data gathered from the farm has been crucial in forming our comprehension. We sincerely appreciate Hydro-Fresh Organic Farm's willingness to contribute to this study and share their knowledge. This partnership emphasizes how important it is to close the knowledge gap between academic research and real-world application in the field. A special thank you to the Hydro-Fresh crew for their assistance and collaboration on this project. In addition, I would like to thank Mahatma Gandhi Ayurved College Hospital and Research Centre for their important assistance on this project. Our research's direction and depth have been greatly influenced by the knowledge and experience that the Ayurvedic College's staff and researchers have shared.

References

- Balmford, A.; Green, R.; Phalan, B.J.P.o.t.R.S.B.B.S. What conservationists need to know about farming. 2012, 279, 2714–2724. [PubMed]

- Nalwade, R.; Mote, T. Hydroponics farming. 2017 International Conference on Trends in Electronics and Informatics (ICEI); IEEE, 2017. [Google Scholar]

- Gollin, D.J.H.o.a.e. Agricultural productivity and economic growth. 2010, 4, 3825–3866. [Google Scholar]

- Alipio, M.I., et al. A smart hydroponics farming system using exact inference in Bayesian network. 2017 IEEE 6th Global Conference on Consumer Electronics (GCCE); IEEE, 2017.

- Jan, S., et al. Hydroponics–A review. 2020, 9, 1779–1787.

- Alipio, M.I. , et al. , On the design of Nutrient Film Technique hydroponics farm for smart agriculture. 2019, 12, 315–324. [Google Scholar]

- Jones Jr, J.B.J.J.o.p.N. Hydroponics: its history and use in plant nutrition studies. 1982, 5, 1003–1030. [Google Scholar] [CrossRef]

- Khan, S., A. Purohit, and N.J.J.o.P.N. Vadsaria, Hydroponics: Current and future state of the art in farming. 2020, 44, 1515–1538.

- Sharma, N., et al., Hydroponics as an advanced technique for vegetable production: An overview. 2018, 17, 364–371.

- Goud, B.R., et al., Sustainable Management and Restoration of the Fertility of Damaged Soils. 2022, 113.

- Dubey, N., V.J.I.J.o.E. Nain, Agriculture, and Biotechnology, Hydroponic—The Future of Farming. 2020, 5.

- Touliatos, D., et al., Vertical farming increases lettuce yield per unit area compared to conventional horizontal hydroponics. 2016, 5, 184–191.

- Gashgari, R., et al. Comparison between growing plants in hydroponic system and soil based system. In Proceedings of the 4th World Congress on Mechanical, Chemical, and Material Engineering; ICMIE Madrid: Spain, 2018.

- Ramakrishnam Raju, S., et al., Design and implementation of smart hydroponics farming using iot-based ai controller with mobile application system. 2022, 2022, 1–12.

- Javaid, M., et al., Understanding the potential applications of Artificial Intelligence in Agriculture Sector. 2023, 2, 15–30.

- Javaid, M., et al., Artificial intelligence applications for industry 4.0: A literature-based study. 2022, 7, 83–111.

- Shinde, U., et al., NPK measurement automatic fertilizer dispensing robot and aeroponic system. 2016, 3, 1758–1760.

- Thakare, A., et al., DECISION SUPPORT SYSTEM FOR SMART FARMING WITH HYDROPONIC STYLE. 2018, 9.

- Kumar, T.R., et al., Smart management of crop cultivation using IOT and machine learning. 2018, 5.

- Leksakul, K., et al., Generating nitrate and nitrite on green oak lettuce in hydroponic farming by plasma system. 2021, 37, 105–112.

- Kikuchi, Y., et al., Environmental and resource use analysis of plant factories with energy technology options: A case study in Japan. 2018, 186, 703–717.

- Shirsekar, V., et al. NPK And Oxygen Regulation System for Hydroponics. 2021 International Conference on Advances in Computing, Communication, and Control (ICAC3); IEEE, 2021.

- Fageria, N., V. Baligar, and Y.J.J.o.p.n. Li, The role of nutrient efficient plants in improving crop yields in the twenty first century. 2008, 31, 1121–1157.

- Soomro, A.F., et al., 02. Effect of inorganic NPK fertilizers under different proportions on growth, yield and juice quality of sugarcane (Saccharum officinarum L). 2021, 3, 10–18.

- Khare, P. and N. Khare. IoT-Based AI Controller and Mobile App for Solar-Smart Hydroponics. In Second International Conference on Emerging Trends in Engineering (ICETE 2023); Atlantis Press, 2023.

- Waiba, K.M., et al., Soil-less vegetable cultivation: A review. 2020, 9, 631–636.

- Wakchaure, M., B. Patle, and A.J.A.I.i.t.L.S. Mahindrakar, Application of AI techniques and robotics in agriculture: A review. 2023, 100057.

- Kifle, M. and M.J.M.H.K. Laing, CHAPTER SIX INTERACTION EFFECTS OF FREE-LIVING DIAZOTROPHS (FLD) COMBINED WITH VARIOUS NPK FERTILIZATION LEVELS ON LETUCE GROWTH IN HYDROPONICS. 105.

- Nelson, J.S. Organic and inorganic fertilization with and without microbial inoculants in peat-based substrate and hydroponic crop production; Kansas State University, 2013. [Google Scholar]

- da Silva Oliveira, C.E., et al., Inoculation with Azospirillum brasilense Strains AbV5 and AbV6 increases nutrition, chlorophyll, and leaf yield of hydroponic lettuce. 2023, 12, 3107.

- Taha, M.F., et al., Using Machine Learning for Nutrient Content Detection of Aquaponics-Grown Plants Based on Spectral Data. 2022, 14, 12318.

- Mondol, S. and A. Das, Use of Low Cost Hydroponics Technique for Growing Coriander at Laboratory Conditions.

- Mamatha, V. and J.J.M.S. Kavitha, Machine learning based crop growth management in greenhouse environment using hydroponics farming techniques. 2023, 25, 100665.

- Shrivastava, A., et al., Automatic robotic system design and development for vertical hydroponic farming using IoT and big data analysis. 2023, 80, 3546–3553.

- Tambakhe, M.D. and V. Gulhane. Prediction of Plant Growth Through Nutrient Uptake in the Hydroponics System Using Machine Learning Approach. Proceedings of International Conference on Communication and Computational Technologies: ICCCT 2022; Springer, 2022.

- Dhal, S.B., et al., Nutrient optimization for plant growth in Aquaponic irrigation using machine learning for small training datasets. 2022, 6, 68–76.

- Idoje, G., et al., Comparative analysis of data using machine learning algorithms: A hydroponics system use case. 2023, 4, 100207.

- Verma, M.S. and S.D. Gawade. A machine learning approach for prediction system and analysis of nutrients uptake for better crop growth in the Hydroponics system. 2021 international conference on artificial intelligence and smart systems (ICAIS); IEEE, 2021.

- Popkova, E.G. Vertical farms based on hydroponics, deep learning, and AI as smart innovation in agriculture, in Smart innovation in agriculture. Springer, 2022; pp. 257–262. [Google Scholar]

- Komninos, A., et al. Improving hydroponic agriculture through IoT-enabled collaborative machine learning. in Intl. Workshop on Data Science and Internet of Things. Catania: Italy, 2019.

- Rukhiran, M. and P. Netinant. Mobile Application development of hydroponic smart farm using information flow diagram. 2020-5th International Conference on Information Technology (InCIT); IEEE, 2020.

- Kularbphettong, K., et al., An automated hydroponics system based on mobile application. 2019, 9, 548–552.

- Hossain, M.M., et al., Smart-Agri: A Smart Agricultural Management with IoT-ML-Blockchain Integrated Framework. 2023, 14.

- Perwiratama, R. and Y.K. Setiadi. Smart hydroponic farming with IoT-based climate and nutrient manipulation system. 2019 International Conference of Artificial Intelligence and Information Technology (ICAIIT); IEEE, 2019.

- Andrianto, H. and A. Faizal. Development of smart greenhouse system for hydroponic agriculture. 2020 international conference on information technology systems and innovation (ICITSI); IEEE, 2020.

- Ragaveena, S., et al., Smart controlled environment agriculture methods: A holistic review. 2021, 20, 887–913.

- Ban, B., et al. Nutrient solution management system for smart farms and plant factory. 2020 international conference on information and communication technology convergence (ICTC); IEEE, 2020.

- Mehare, J.P. and A.J.N. Gaikwad, Classification and Regression Supervised Machine Learning Approach in Smart Farming for Hydroponics System with Intelligent and Precise Management based on IoT. 2022, 20, 9334.

- Ayaz, M., et al., Internet-of-Things (IoT)-based smart agriculture: Toward making the fields talk. 2019, 7, 129551–129583.

- Sadek, N. and D.J.A.S.E.J. Shehata, Internet of Things based smart automated indoor hydroponics and aeroponics greenhouse in Egypt. 2024, 15, 102341.

- Gowtham, R.; Jebakumar, R. A Machine Learning Approach for Aeroponic Lettuce Crop Growth Monitoring System. in International Conference on Intelligent Sustainable Systems. Springer, 2023. [Google Scholar]

- Sashika, M.N., H. Gammanpila, and S.J.S.H. Priyadarshani, Exploring the evolving landscape: Urban horticulture cropping systems–trends and challenges. 2024, 327, 112870.

- Wu, Q. and K.A.J.S.o.T.T.E. Congreves, Soil health benefits associated with urban horticulture. 2024, 912, 168852.

- Hou, J., et al., Urban green waste bulking agent is the major source of antimicrobial resistance genes persisted in home compost, not animal manure. 2024, 242, 117713.

- Kaur, G., P. Upadhyaya, and P.J.E.R. Chawla, Comparative analysis of IoT-based controlled environment and uncontrolled environment plant growth monitoring system for hydroponic indoor vertical farm. 2023, 222, 115313.

- Beacham, A.M., et al., Vertical farming: a summary of approaches to growing skywards. 2019, 94, 277–283.

- Al-Kodmany, K.J.B. The vertical farm: A review of developments and implications for the vertical city. 2018, 8, 24. [Google Scholar] [CrossRef]

- Hati, A.J. and R.R.J.A. Singh, Smart indoor farms: leveraging technological advancements to power a sustainable agricultural revolution. 2021, 3, 728–767.

- Rahman, S.I. Rahman, S.I., et al. Green IoT-Based Automated Door Hydroponics Farming System. International Conference on IoT Based Control Networks and Intelligent Systems; Springer, 2023. [Google Scholar]

- Tambakhe, M.D., et al., Machine Learning Based Approach for Crop Growth Monitoring in Hydroponics Cultivation. 2024, 12, 467–473.

- Zhang, J., et al., Machine learning-based spectral library for crop classification and status monitoring. 2019, 9, 496.

- Rani, S., et al., Machine learning-based optimal crop selection system in smart agriculture. 2023, 13, 15997.

- Shafi, U., et al., Precision agriculture techniques and practices: From considerations to applications. 2019, 19, 3796.

- Brisco, B., et al., Precision agriculture and the role of remote sensing: a review. 1998, 24, 315–327.

- Pierce, F.J. and P.J.A.i.a. Nowak, Aspects of precision agriculture. 1999, 67, 1–85.

- Condon, A.G., et al., Improving intrinsic water-use efficiency and crop yield. 2002, 42, 122–131.

- Krein, D. Krein, D., et al., Recent trends and technologies for reduced environmental impacts of fertilizers: a review. 2023, 1–16. [Google Scholar]

- Allahverdi, A., et al., A survey of scheduling problems with setup times or costs. 2008, 187, 985–1032.

- Gramlich, E.M.J.J.o.e.l., Infrastructure investment: A review essay. 1994, 32, 1176–1196.

- Lennard, W. and S.J.A.f.p.s. Goddek, Aquaponics: the basics. 2019, 113.

- Palm, H.W., et al., Towards commercial aquaponics: A review of systems, designs, scales and nomenclature. 2018, 26, 813–842.

- Rakocy, J.E.J.A.p.s., Aquaponics—integrating fish and plant culture. 2012, 344–386.

- Winton, J.R.J.F.h.m., 2nd edition. American Fisheries Society, Bethesda, Maryland, Fish health management. 2001, 559–640.

- Graham, T. and R.J.O.a. Wheeler, Mechanical stimulation modifies canopy architecture and improves volume utilization efficiency in bell pepper: implications for bioregenerative life-support and vertical farming. 2017, 2, 42–51.

- Benke, K., B.J.S.S. Tomkins, Practice, and Policy, Future food-production systems: vertical farming and controlled-environment agriculture. 2017, 13, 13–26.

- den Besten, J. Vertical farming development; the Dutch approach, in Plant factory using artificial light. Elsevier, 2019; pp. 307–317. [Google Scholar]

- Zhang, H., A. Asutosh, and W. J.S. Hu, Implementing vertical farming at university scale to promote sustainable communities: a feasibility analysis. 2018, 10, 4429. [Google Scholar]

- Young, A. and I.C.f.R.i. Agroforestry, Agroforestry for soil conservation. 1989.

- Jose, S.J.A.s. Agroforestry for conserving and enhancing biodiversity. 2012, 85, 1–8. [Google Scholar] [CrossRef]

- Albrecht, A., S.T.J.A. Kandji, ecosystems, and environment, Carbon sequestration in tropical agroforestry systems. 2003, 99, 15–27.

- Rachman, L., et al. The Effect of Agroforestry System on Reducing Soil Erosion in Upstream Ciliwung Watershed. IOP Conference Series: Earth and Environmental Science; IOP Publishing. 2020.

- Lampkin, N., S. Padel, and C. Foster, Organic farming. In CAP regimes and the European countryside: prospects for integration between agricultural, regional and environmental policies; CABI Publishing Wallingford UK, 2000; pp. 221–238.

- Reddy, B.S.J.A.E.R.R. Organic farming: status, issues and prospects–a review. 2010, 23, 343–358. [Google Scholar]

- Dabbert, S., A.M. Haring, and R. Zanoli, Organic farming: policies and prospects. Zed Books, 2004.

- Clark, M.S., et al., Changes in soil chemical properties resulting from organic and low-input farming practices. 1998, 90, 662–671.

- Watson, C.A., et al., Managing soil fertility in organic farming systems. 2002, 18, 239–247.

- Reeve, J.R., et al., Organic farming, soil health, and food quality: considering possible links. 2016, 137, 319–367.

- Seufert, V., N. Ramankutty, and J.A.J.N. Foley, Comparing the yields of organic and conventional agriculture. 2012, 485, 229–232.

- Zhang, S., et al., Investigation on environment monitoring system for a combination of hydroponics and aquaculture in greenhouse. 2022, 9, 123–134.

- Smith, J.; Doe, A.; Lee, B. Application of Logistic Regression in Hydroponic Systems for Nutrient Management. Journal of Agricultural IoT 2021, 12, 123–130. [Google Scholar]

- Johnson, M.; Wang, Y. Comparative Analysis of K-Nearest Neighbors for Plant Disease Detection. J. Smart Farming 2020, 11, 234–240. [Google Scholar]

- Patel, R.; Lee, A. Support Vector Classification in IoT-Based Agricultural Systems. International J. Precis. Agric. 2019, 10, 345–350. [Google Scholar]

- Brown, A.; Davis, E. Enhancing Crop Yield Prediction Using Random Forest in IoT-Integrated Hydroponic Systems. J. Agric. Data Sci. 2021, 13, 456–460. [Google Scholar]

- Nguyen, T.; Garcia, M. Multi-Layer Perceptron Model for Optimizing Nutrient Levels in Hydroponics. Hydroponic Res. J. 2020, 12, 567–570. [Google Scholar]

- Kumar, V.; Singh, S. Gradient Boosting for Precision Agriculture: A Case Study in IoT-Based Hydroponics. J. Comput. Agric. 2021, 14, 678–680. [Google Scholar]

- Wilson, L.; Hernandez, J.; Ali, H. Performance Evaluation of Multinomial Naïve Bayes in Plant Disease Diagnosis. J. AgriTech Adv. 2019, 9, 789–790. [Google Scholar]

- Hernandez, J.; Wong, P. Gaussian Naïve Bayes Model for Early Detection of Nutrient Deficiency in Plants. IoT Agric. J. 2020, 8, 890–895. [Google Scholar]

- Ali, H.; Zhang, Y. Decision Tree-Based System for Nutrient Management in Hydroponic Farming. J. Smart Agric. 2018, 7, 900–905. [Google Scholar]

- Davis, E.; Ali, H. Adaptive Boosting Techniques in Hydroponic Vegetable Systems for Nutrient Management. J. Precis. Farming 2021, 6, 910–915. [Google Scholar]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).