Introduction

Producing enough food to feed an estimated global population of 9.5 billion people by 2050 is the greatest challenge of our time and implies that production must increase by 70% above the current level (Godfray et al., 2010). Rapid population growth [Garnett etal., 2013), decreasing agricultural productivity (FAO,2016), climate change (Baldos et al., 2014), natural resource scarcity (Tilman et al 2011), and biofuel production (Godfray et al., 2010) collectively undermine the current and future capacity of global food production systems. Sub Saharan Africa whose population is projected to reach 2.5 billion people by 2050 and with the highest food hunger prevalence will be extremely vulnerable (Alexandratos and Bruinsma , 2012). One way of availing more food without investing in additional production resources is addressing post harvest losses (PHL) in the agri-food value chains. Postharvest technologies can contribute to food security in numerous ways. They can reduce PHL, thereby increasing the amount of food available for consumption by farmers and poor rural and urban consumers. For example, the control of the Larger Grain Borer (LGB) or Prostephanus truncanus greatly reduced the loss of maize in on-farm storage among smallholders in a number of African countries, thus improving their food security (Golleti 2003). Post-harvest loss in the food chain is a significant problem globally (Hodges et al., 2011). Approximately one-third of food produced is wasted globally before it reaches the final consumer and this loss is estimated to be 1.3 billion tons per year (Gustavsson et al., 2011). Thus reducing PHL offers an important option to increasing food available for human consumption and hence enhance food security. Over the past decades significant resources and focus have been devoted to increasing productivity especially in Sub Saharan Africa (SSA), yet these efforts are not sufficient since agricultural productivity is increasingly being challenged by climate variability, unsupportive biophysical, institutional and business environment (World Bank, 2011).

PHL in SSA for grains alone is estimated to be USD 4 billion, while about 50% of the budget required to reduce hunger in SSA by 2050 will be focused on reducing PHL (Ndaka et al., 2012).

In order to sustainably increase the goal of food security (UN, 2016) food availability needs to be increased through reductions in post harvest losses at different nodes of the value chain.. Previous studies have mainly focused on the storage node of the value chain while ignoring other stages such as bulking, transportation, processing, retailing and consumption (Aulakh and Regmi, 2013).

PHL is defined as a measurable quantitative and qualitative food loss starting from the time of harvest till consumption (FAO, 2011; Hodges et al., 2011). It comprises of interconnected activities from the time of harvest through processing, marketing and consumption. Quality losses include those that affect the nutritional composition, acceptability, and edibility of a product. PHL can occur as a result of food waste or due to losses along the value chain. Aulakh and Regmi (2013) define food waste as the loss of edible food due to human action or inaction such as food appropriate for human consumption being discarded, not consuming food before its expiry date or serving large portions of food beyond one’s ability to consume. Food waste occurs at the retail and final consumption and relates to consumers behaviour. On the other hand they define food loss as the losses occurring along the chain due to constraints or limitation within a particular value chain. Hence total PHL is the sum of food wastage and food losses. Food losses have a direct or negative impact on food security, incomes and economic well-being of farmers, processors, traders and consumers along the chain. It also represents a waste in the physical and financial resources used in production such as land, water, farm inputs, finances and labour. Given that majority of smallholder farmers are poor, a reduction in food losses would significantly impact on their livelihoods.

Food security is more a question of access rather than supply and therefore reducing PHL could bring down the cost of food to consumers by making it more accessible. In Kenya, 25% of the population suffer from chronic food shortages while USD 1.3 billion is used to import food annually. In a recent review of twelve common staple commodities for postharvest losses in Kenya (maize, rice, banana, mango, Irish potato, cassava, beans, groundnuts, cabbage, tomato, milk and meat), Ndaka et al. (2012) found Postharvest losses to be case-specific, varying largely along the value chain. The losses were in the range of 0-50% within the value chain, but there was little or no information on postharvest losses at each step of the value chain.

PHL in milk and dairy products in East Africa have been estimated at more than USD 90 million annually (FAO, 2004) and these losses are attributed to milk rejection, spoilages and spillages.

The dairy industry in Kenya accounts for about 6 % of Gross Domestic Product (GDP) and is a major source of livelihood for more than 2 million people in the sub sector (FAO, 2011). The country produces more than 5 billion litres annually. Out of the total milk production, 70% comes from dairy cattle and of this 65% is marketed while 35% is for home and calf consumption (Omore et al., 2004). Milk marketing in Kenya is carried out through two main channels: The formal channel consisting of cooperatives and processors which accounts for about 25% while 75% of the milk reaches the final consumer through the informal channel consisting of transporters, traders or milk bars (Omore,et al., 2005).

Despite the impressive performance of the dairy sector in Kenya, challenges associated with milk losses have not been given much attention. Lore et al (2005) estimated the total value of post- harvest milk losses in Kenya at USD 17.8 million annually. The Kenya Dairy Board estimated milk losses at the national level in 2008 to be 95 million kg per year which translates to KES 2.8 billion at the processor price of KES 30 per litre. However, this loss is only attributed to rejection in the formal channel in which milk passes through the cooperatives and processors. Given that the informal channel handles 80% of all the marketed milk the losses are much higher. A recent study by Ndungu et al (2016) found high prevalence of antibiotic residues, total bacterial counts and adulteration in milk delivered at collection centres in Central Kenya, indicating potential economic losses that farmers may experience as a result of rejection due to low quality.

Despite the reported losses, empirical data on stages and sources of milk losses, associated factors, losses in quantity, actual socio economic impact and intervention strategies along the value chain remain scanty. The overall objective of the study was to identify stages along the value chain where PHL occur, quantify losses at different stages, identify factors influencing PHL and determine potential solutions to minimize PHL losses.

Methodology

The study was carried out in Nandi in Chesumei Sub County - ecological zone Upper medium (UM) where dairy farming is a major economic activity and Kakamega in Ikolomani Sub County- ecological zone Lower medium (LM2), (Nandi CIDP, 2014, Kakamega CIDP, 2017)

Although are classified as high rainfall areas with high productivity, these Counties have incidences of food and nutritional insecurity, widespread poverty and high prevalence of malnourished mothers and stunted children (USAID, 2016).

Framework for estimating post-harvest food losses (Aulakh and regmi, 2013)

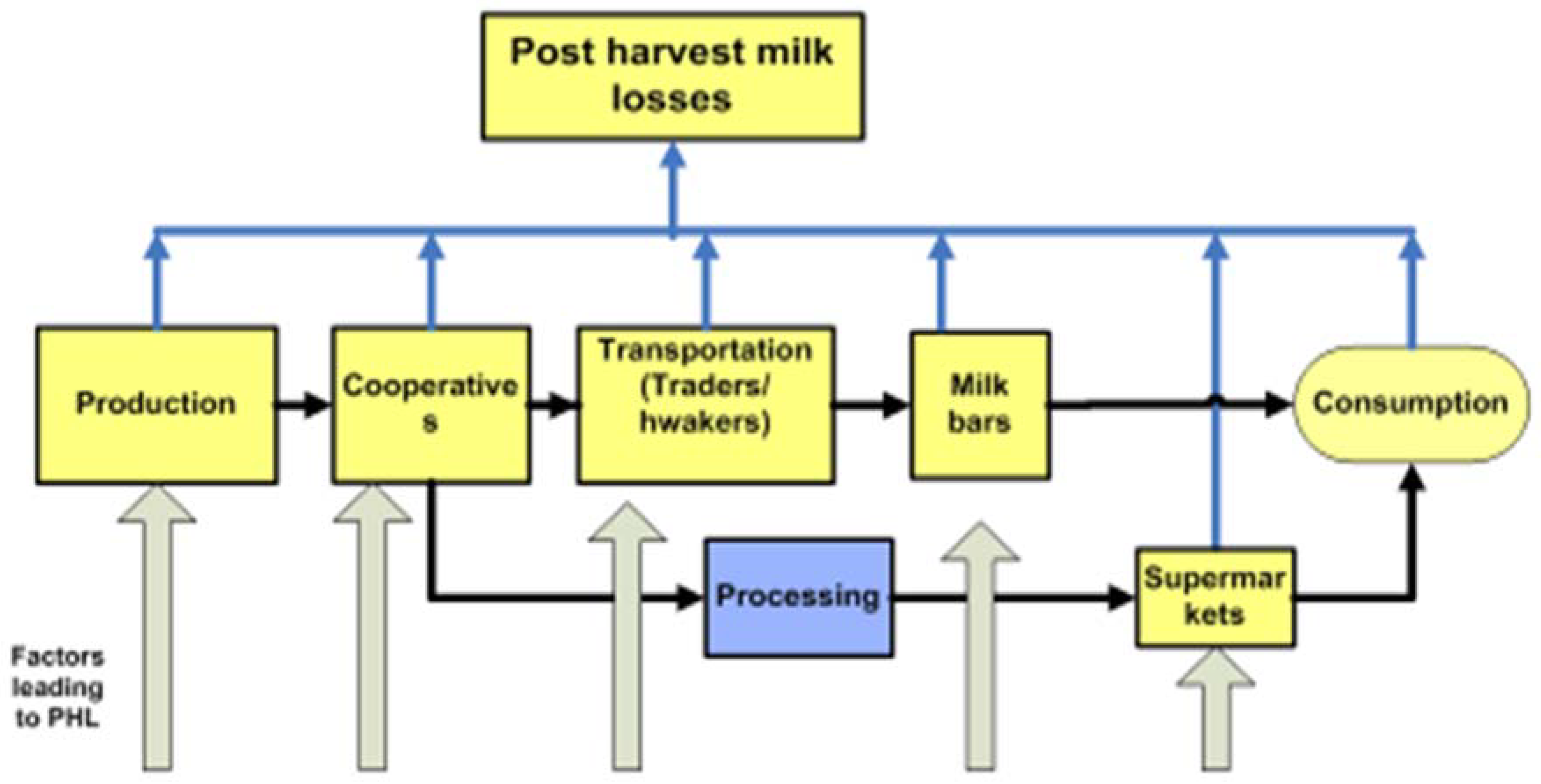

Milk flows along the value chain from after milking on farm through different nodes and actors to consumption. The loss at each node is driven by different factors (

Figure 1).

Total PHL= sum of PHL at each node of the value chain

Total PHL = ∑PHL1 + ∑PHL2+∑PHL3 + ∑PHL4------------------------------------------(1)

Where: 1, 2, 3 and 4 are different stages of the value chain.

Total PHL = ∑ Si = ∑ f(Xj)-----------------------------------------------------------------------(2)

Si = ∑ f(Xj) ------------------------------------------------------------------------------------------(3)

Where Si stands for losses in each node; Xj stands for the factors affecting each node and I represents critical nodes from milking to retailing (Milk bar/supermarket)

Research Design and Study Variables

The study adopted an exploratory design (Shields and Rangavajan, 2013) which aimed at understanding the phenomenon of post-harvest loses at different stages of the value chain by interviewing various actors. The study variables were: quantity of milk lost at each node of the value chain, economic value of PHL, factors responsible for PHL and causes of PHL.

Data Collection and Analysis

The target population, sample size and sampling technique for different target actors of the value chain are shown in

Table 1.

Data for this study was collected through a formal survey using a structured questionnaire administered to 400 dairy farmers selected proportionally from Chesumei (225) and Ikolomani (175), milk cooperatives, milk traders/transporters, milk bars and supermarkets. Additionally, six focus group discussions (FGDs) from each region were carried out with farmer groups to gain a deeper understanding of sources, causes and potential solutions to address the PHL problem . Each FGD comprised 12 participants stratified in each group and randomly selected. The participants per FGD were male, female and youth in the ratio of 5:5:2 respectively. During discussions, participants talked among themselves on every key topic or question before a consensus was reached. They also ranked important issues through pair-wise ranking method (Morgan, 2002). All combinations were done and responses were recorded and visualized on flipcharts. Key informant interviews were also conducted with extension staff to triangulate information from FGDs. There was no processor in Nandi and Kakamega and therefore no data was collected at this node. The exploratory research approach was more suitable for this study for identifying the real nature of the PHL phenomenon.

Quantitative data was analysed using descriptive statistics and presented in tables while factors influencing post-harvest losses at the farm level were analysed using multiple regression analysis (Nathans et al., 2012) to determine the relationship between individual factors (independent variables) and milk losses (dependent variables). Factors found to be significant were used to make recommendations for minimizing the losses. Assessment of economic value of PHL along the value chain was calculated using the quantity lost multiplied by the mean buying price at each node of the value chain.

Qualitative data from other actors was analysed using thematic approach (Saunders et al., 2009).

RESULTS

Quantity of Milk Lost

The quantities of milk lost at different stages of the value chain are shown in

Table 2 indicate that in Nandi county most losses occurred at the cooperative (52.6%), collection centres (36.2%) and milk bars (7%), while in Kakamega most milk was lost in supermarkets (47.1%), cooperative (25.2%) and milk bars (13.9%)

Economic Value of PHL

The total economic value of PHL per annum in both Chesumei (Nandi) and Ikolomani (Kakamega) was about KES 13 million.

Table 3.

Estimated economic value of losses in the study area.

Table 3.

Estimated economic value of losses in the study area.

| Actors |

Quantity (l) loss per year |

Price (KES) |

| Mean |

SD |

Minimum |

Maximum |

Value loss (KES) |

| Production |

4,613 |

37 |

5.9 |

25 |

62 |

170,681 |

| Cooperative |

141,576 |

45 |

8.4 |

38 |

60 |

6,370,920 |

| Collection |

944,28 |

38 |

4.7 |

30 |

45 |

3,588,264 |

| Trader |

7,596 |

47 |

8.3 |

30 |

60 |

357,012 |

| Milk bars |

21,000 |

57 |

6.6 |

38 |

60 |

1,197,000 |

| Supermarket |

10,680 |

128 |

32 |

57 |

184 |

1,367,040 |

| Total |

279,893 |

|

|

|

|

13,050,917 |

Factors Influencing PHL

Production

The results of regression model in

Table 4 show that the model was adequate and significant (F

(5,49) , P<0.001) in explaining the variation in milk losses at production in the study area. Further, 79.9% of the this variation was explained by the model (adjusted R

2 = 0.799). The remaining variance (21.1%) could be due to other factors beyond the scope of this study. All the five factors (type of cow housing, level of training of milkers, mixing morning and evening milk, type of containers and lack of cooling facilities) were highly significant.

Factors Contributing to Milk Losses

Cooperatives

Table 5 indicates that poor road network mainly influenced milk losses in Nandi County (78%) compared to Kakamega County (40%). About 11% losses in Nandi and 40% in Kakamega were attributed to poor preservation of milk, while mastitis incidences contributed to more milk losses in Kakamega (40%) than Nandi (11%) county.

Traders/milk transporters

Fifty percent of traders in Nandi and 63% in Kakamega mentioned poor storage as the most important factor influencing milk losses. Bad road infrastructure was the second most identified factor in Nandi (33%) compared to Kakamega County (13%).A higher proportion of traders in Kakamega (25%) reported milk adulteration to have influence on milk losses compared to Nandi (17%) (

Table 5).

Milk bars

In the study, lack of storage facilities and poor milk handling practices were identified as main factors contributing to milk losses. About (80%) and (56%) of milk bars in Nandi and Kakamega counties respectively, attributed milk losses to lack of storage facilities. The proportion was lower for poor milk handling practices Nandi (20%) and Kakamega (44%) (

Table 5).

Supermarkets

A high proportion (50%) and (57%) of supermarkets from Nandi and Kakamega counties respectively, reported major losses due to inadequate storage facilities. This is relatively higher compared to losses influenced by poor packaging materials in Nandi (40%) and Kakamega (29%). The least effect was attributed to milk short shelf life Nandi (10%) and 14% in Kakamega (

Table 5).

Causes of Post-Harvest Losses

Milk spillage was the most common cause of losses in supermarkets, while spoilage was experienced by all actors in the value chain with most affected players being milk bars and producers, adulteration and physical dirt were the most common cause of losses in cooperatives.

Table 6.

Causes of post-harvest milk losses among actors in the value chain (% Response).

Table 6.

Causes of post-harvest milk losses among actors in the value chain (% Response).

| Cause |

Producers (n= 400) |

Cooperatives (n=15) |

Traders (n=40) |

Milk bar (n= 20) |

Supermarkets (n= 17) |

| Spillage |

2 |

5 |

22 |

4 |

55 |

| Spoilage |

70 |

44 |

64 |

78 |

45 |

| Adulteration |

23 |

41 |

13 |

14 |

0 |

| Physical dirt |

5 |

10 |

1 |

0 |

0 |

Discussion

Quantity and Value of PHL

The results obtained showed that about 260,000 litres of milk valued at KES 10 million are lost in Nandi annually with the highest losses in Cooperatives and collection centres representing 89% of the total loss. Milk bars in Nandi loose 18,000 litres (7%). In Kakamega County, an estimated 20,000 litres valued at KES 1.8 million are lost annually in the value chain with Supermarkets, cooperatives and milk bars loosing 9567 (47%), 5136 (25%) and 2820 (14%) litres respectively. Based on interviews, the high losses in Supermarkets in Kakamega was attributed to spoilages and spillages associated with products overstaying on shelves without being purchased and poor packaging materials. Compared to Nandi, Kakamega is a milk deficit region and Supermarkets order large quantities of milk from processors hence the large volumes losses. Overall, the total combined losses in Nandi and Kakamega counties were about 280000 litres per annum valued at KES 13 million (USD 100 000). If these losses are extrapolated taking into account the entire population of dairy farmers in Nandi County (120,000) and Kakamega County (18,000), annual PHL at farm level alone would be KES 51 and 10 million respectively. At the national level, with an estimated population of 1.8 million smallholder dairy farmers (ILRI, 2006), PHL at production level alone would be more than 22 million litres annually worth KES 813 million (USD 6.3 Million). Cooperatives in Nandi bulk more quantities than Kakamega and this is also reflected in the losses. The high milk losses in cooperatives and collection centres was attributed to rejections due to adulteration, physical dirt and spoilage as reported during interviews with cooperative officials. Cooperatives and collection centres perform quality tests before buying and bulking raw milk, while on the other hand the informal channel of traders and milk bars rarely carry out quality checks or keeps records. Considering that 70% of all milk marketed in the country flows through the informal channel (Omore et al., 2004), volumes and value lost at trader/ transportation and milk bar levels could be much higher. An earlier study by Lore et al (2005) reported a loss in value of USD 17.8 million (KES 1.78 billion) in the dairy sector. Compared to previous studies (Lore et al., 2005; FAO, 2011) which have estimated farm level losses as 6% of volume produced, the findings of this study suggest that the annual milk loss on smallholder dairy farms is estimated to be 94 litres. This means on average smallholder farms loose 0.25 litres per day, representing 4% of total milk produced. Thus these findings suggest the need for interventions to minimize losses at all levels of the value chain especially in collection centres, cooperatives and Milk bars.

Factors Influencing Losses

The study findings indicated that most of the milk losses occurring at cooperative level are attributed to poor road infrastructure. Dairy value chains link the actors and the activities involved in delivering milk and milk products from production to the final consumer Ndungu et al. 2016). The actors within the value chain are normally scattered leading to longer periods sometimes up to 3.5 hours before milk is delivered to the cooperative. Poor milk preservation by farmers and mastitis were also identified to influence milk losses. Basically the cooperative cited milk preservation to mean storage of milk overnight at farm level to avoid spoilage before delivery in the morning. Mastitis incidences were reported as a major factor contributing to milk losses by cooperatives that have extension programs with their farmers. Poor milk storage, bad roads and adulteration of milk were important at traders/transporters stage. Inadequate storage facilities for farmers to maintaining the cold chain constrain marketability of raw milk (GoK, 2010; Orregard, 2013). In this study, mixing evening and morning milk was found to be a significant factor that caused milk losses at farm level. Foster et al (2015) reported that evening milk which comprises 40% of the daily cow production mostly goes to waste due to lack of on farm refrigeration facilities. In some circumstances, it is only possible to market the morning milk as mixing it with the evening milk leads to rejection. Long distances covered to markets and high tropical temperatures could lead to milk spoilage during transportation. Adulteration of milk by either farmers or traders/transporters is aimed at increasing volumes to in order to earn more revenue. Milk bars in the study area identified lack of appropriate storage facilities and poor milk handling practices as key factors influencing losses. The results of this study are similar to findings reported by Melesse et al.(2014). Inadequate storage facilities, short milk shelf life and poor packaging materials were identified by supermarkets as important factors influencing post-harvest milk losses. Super markets received milk and milk products from processors outside Nandi and Kakamega. However, poor packaging causes spillage, while in some cases lack of refrigeration or disruption of power supply can adversely affect milk shelf life. In order to reduce post-harvest losses along the dairy chain, key technologies to provide the much-needed cold chain are necessary. One such option could be technologies providing clean energy such as solar-driven coolers for the dairy chain could be deployed. Overall, enhancing the quality of milk in order to reduce PHL may require adoption of milk based payment system by all actors in the sector. This approach is currently being piloted by Happy Cow ltd, a private processor in Nakuru, Kenya with milk cooperatives (Ndungu et al (2016).

Socio Economic Impact

Dairy is the most important sector in Nandi County (CIDP, 2013) while in Kakamega County it is one of the priority commodities. Hence post-harvest milk losses impact negatively on household food security due to loss of incomes and loss of protein nutrition. Milk losses at household level therefore may impact on health of infants and maternal health. Unemployment is another potential impact of reduction in milk through losses since many people earn their wages in the sector.

Based on interviews and focus group discussions with farmers and cooperative officials, milk losses as a result of rejections has a direct impact on relations between cooperatives and its membership. While loss of income is the immediate economic impact to both partners, loss of trust leads to farmer apathy which manifests itself through diversion of milk to informal markets and high numbers of inactive members (Wanjala et al., 2015). Thus post-harvest milk losses affects market actors along the chain but with varying socio economic impacts.

Critical Control Points in Milk PHL

A greater proportion of PHL was recorded at Cooperative and collection centers (84%) while milk that passes through the informal sector milk bars and traders/transporters lost 26% of the total milk marketed. The same trend was recorded in Nandi County where cooperative and collection centers lost 89% and milk bar/traders combined had PHL of 9%. Kakamega County lost huge quantities of milk at super markets and cooperatives with milk bars and traders reporting relatively low quantities. Based on these findings critical control points for PHL are cooperatives, collection centres, traders/transporters and milk bars.

Interventions for Reducing Milk PHL

The findings of this study show that milk spoilages, adulteration, spillages and physical dirt are the main causes of PHL along the value. Critical cross cutting interventions based on the study findings include:

Improvement of road infrastructure which connects rural producers with market agents to reduce milk spoilages and spillages. This could be done within the framework of public private partnership between the County and National Governments. Training of market actors (Producers, traders, transporters, milk bars) on milk handling from farm to consumer level is necessary to improve on the quality of milk marketed and minimize losses. This could be done partnership between cooperatives and their members, Kenya Dairy Board, County departments of Livestock, Milk Traders associations and private sector actors in the sector. Potential modules for intervention in milk handling practices may include: Clean milk production- cow housing, hygiene, containers, physical dirt and storage facilities and milk testing. The results of this study identified these factors as having the greatest influence on PHL.

Conclusion and Recommendations

The results show that post harvest loses occurred at all stages of the value chain in Nandi and Kakamega Coutnties with the highest losses at Cooperative (50.6%) collection centres (33.7%) and milk bars (7.5%).

Annual milk loss was estimated to be 260,000 litres and 20,000 litres in Nandi and Kakamega counties respectively. The economic value of PHL per year was estimated at KES 13 million.

Significant factors (P<0.001) influencing PHL at farm level were: type of cow housing, level of training of milker, mixing morning and evening milk and Lack of cooling facilities. Collectively these factors explained 79.9% of PHl at farm level. At the cooperatives poor roads, poor preservation of milk and mastitis influenced milk PHL causing milk rejection due to spoilages; while at transporters/traders attributed PHL to storage during transportation and adulteration. Inadequate storage facilities and milk handling practices influenced PHL in milk bars while supermarkets attributed PHL to poor packaging materials and short shelf life. The most important causes of milk PHL were at farm level: spoilages; cooperative level: spoilages, adulteration and physical dirt; traders/transporters: spoilage and spillages; Milk bars: spoilages; and supermarkets: spillages. Key interventions to minimize PHL should hence be targeted at improving rural road infrastructure connecting farmers to markets; Milk storage/ preservation facilities at farm level and milk bars and for transportation of milk by traders and capacity building on milk handling practices for all actors.

In order to enhance and sustain quality of milk in the value chain to reduce PHL, the following policy recommendations are necessary: payment of milk based on quality rather than quantity to enhance production and trade in clean and safe milk for national consumption and for export; adoption of good dairy farming practices and accreditation of all farmers and market agents supplying milk for trade; public awareness on the importance of buying milk from accredited market agents; processors encouraged to improve on milk packaging to minimize losses attributed to spillages and spoilages. Future research to enhance reduction of milk PHL should evaluate the effect of these recommendations on minimizing spoilages, spillages, adulteration and physical dirt in milk along the value chain.

Funding

This study was funded by USAID through the KALRO-USAID FtF IARD project.

Acknowledgement

The authors are grateful to the following stakeholders for the support and collaboration in the study: County Directors of Livestock in Nandi and Kakamega, sub-County Livestock Officers in Chesumei and Ikolomani, dairy farmers, milk Cooperatives, traders and supermarkets in Nandi and Kakamega. The support by enumerators who administered the questionnaire and KALRO ICT staff who provided the assistance in electronic data collection is appreciated. We are grateful to the Director General KALRO for facilitating the study.

Conflict of interest

The authors declare no conflict of interests

References

- Alexandratos N. and Bruinsma J. (2012). World agriculture towards 2030/2050: the saving water. From Field to Fork-Curbing Losses and Wastage in the Food Chain 2012 revision. Working paper: FAO: ESA No. 12-03, p.4.

- Aulakh J. Regmi A. (2013). Post-harvest Food Losses Estimation- Development of Consistent Methodology. FAO.

- Baldos U.L.C.and Hertel T.W. (2014). Global food security in 2050: The role of agricultural productivity and climate change. Australian Journal of Agriculture and Resource Economics, 58, 554–570. [CrossRef]

- CIDP. (2013).County Integrated Development Plan. Republic of Kenya, County Government of Kakamega.

- CIDP. (2013). County Integrated Development Plan. Republic of Kenya, County Government of Nandi.

- FAO (2004). Action programme for the prevention of food losses; milk and dairy products, postharvest losses and food safety in sub-Saharan Africa and the near east: types, levels and causes of postharvest milk and dairy losses in sub-Saharan Africa and the Near East.

- FAO (2011). Global food losses and waste: Extent, Causes and Prevention.

- Foster R., Jensen B., Dugdilli B., Knight B., Faraj A., Mwove M. and Hadley W (2015). Solar milk cooling: Smallholder dairy farmers experience in Kenya. Proceedings Solar World Congress Daegu, Korea 08-12 November 2015.

- Garnett T, Appleby M.C., Balmford A., Bateman I.J., Benton T.G., Bloomer P., Burlingame B., Dawkins, M., Dolan L. and Fraser D. (2013). Sustainable intensification in agriculture: Premises and policies. Science, 2013, 341. FAO. The State of Food and Agriculture; Food and Agriculture Organisation of the United Nations: Rome, Italy, 2016. [CrossRef]

- Godfray H.C., Beddington J.R., Crute I.R., Haddad L., Lawrence D., Muir J.F., Pretty, J., Robinson S., Thomas, S.M. and Toulmin C. (2010). Food security: The challenge of feeding 9 billion people. Science 327, 812–818. [CrossRef]

- Goletti F (2003). Current status and future challenges for the post harvest sector in developing countries. Acta hoticulturae. [CrossRef]

- Gustavsson J., Cederberg C., Sonesson U., van Otterdijk R. and Meybeck A. (2011). Global Food Losses and Food Waste: Extent Causes and Prevention. Rome: Food and Agriculture Organization (FAO) of the United Nations.

- Hodges R.J., Birby J.C. and Bennet B. (2011). Postharvest losses and waste in developed and developing countries: Opportunities to improve resource use. Journal of Agricultural Science, 149, 37-45. [CrossRef]

- ILRI. (2006) Informal Traders lock Horns with the Formal Milk Industry: The role of research in pro-poor Dairy.

- Lore J., Omore A. and Stall S. (2005). Types, level of causes of post-harvest milk and dairy losses in Sub-Saharan and the Near East. ILRI-FAO Programme for Prevention of Food Loss.

- Nathans L.L., Oswald F.L. and Nimon K. (2012). Interpreting Multiple Linear Regression: A Guidebook of Variable Importance. Practical Assessment Research & Evaluation, 17:9.

- Ndaka D., Macharia I., Mutungi C. and Affognon H. (2012). Postharvest losses in Africa – Analytical review and synthesis: the case of Kenya. Available online: https://www.researchgate.net/publication/285594327 (accessed on October 2017).

- Ndungu W.T., Muliro P.S., Omwamba M., Oosterwijk G. and Jansen A. (2016). Quality control of raw milk in the smallholder collection and bulking centres in Nakuru and Nyandarua counties in Kenya. African Journal of Food Science Vol. 10 (5): 70:78.

- Mellesse K., Agza B. and and Melesse A. (2014). Milk Marketing and Post-harvest loss problem in Adaa and Lume districts of as Shoa Zone, Central Ethiopia. Sky Journal of Food Science, Vol 3 (4) 027-033.

- Morgan D.L. (2002). Focus Group Interviewing. In: Gubrium J.F. and Holstein J.S (Eds.), and Book of Interview Research: Context and method. Thousand Oaks, CA: Sage Publications.

- Omore A., Muriuki H.G.M., Kenyanjui M., Owango, M. and Staal S. (2004). The Kenyan dairy sub sector: a rapid appraisal. SDP research and development report. Smallholder Dairy Project (SDP), Nairobi, Kenya. Available online: http://www.smallholderdairy.org.

- Omore A., Lore T., Staal S., Kutwa J., Ouma R., Arimi S. and Kang’ethe, E. (2005). Addressing the public health and quality concerns towards marketed milk in Kenya. SDP Research and Development Report No. 3. Nairobi (Kenya): Smallholder Dairy (R & D) Project.

- Orregård M. (2013). Quality analysis of raw milk along the value chain of the informal milk market in Kiambu County , Kenya. Master Thesis. Swedish University of Agricultural Sciences. https://doi.org/ISSN: 1101-8151.

- Saunders M, Lewis P.and Thornhill A. (2009). Research Methods for Business Students, 5th Edition, Harlow, England: FT Prentice Hall-Pearson Education Limited.

- Shields P.M. and Rangavajan, N.A. (2013). A playbook for Research Methods: Integrating conceptual frameworks and Project Management, New Forning Press: Stillwater, OK, USA.

- Tilman D., Balzer, C., Hill, J. and Befort, B.L. (2011). Global food demand and the sustainable intensification of agriculture. Proceedings of National Academy of Sciences, USA 2011, 108, 20260–20264. [CrossRef]

- United Nations. (2016). The Sustainable Development Goals Report 2016. United Nations, New York.

- Wanjala S.P.O., Njehia B.K. and Murithi F.M. 2015. Is the traditional role of milk cooperatives still relevant? Evidence from Western Kenya. Asian Journal of Agricultural Extension Economics and Sociology, 6 (4): 202-268.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).