1. Introduction

Fiberglass is a common material widely used in many applications; generally, it is a thermoset composite with polyester matrix and continuous glass fibers (GFs) in different configurations, from fabrics to mats and unidirectional tapes. Recently, continuous glass fibers have been used into thermoplastic matrices, to take advantage from the behavior of this class of materials, in terms of toughness and processing. For this aim, low-density polyethylene (LDPE) has been also evaluated, due to its availability on the market and low cost. Processing LDPE in high production runs is easy, because of its low viscosity after molding and relatively low processing temperature, in comparison with other thermoplastics. In 2021 Ravichandran et al. have used carbon, Kevlar and glass fibers as reinforcements to create LDPE matrix composites through compression molding [

1]. Their study has examined the physical, mechanical and thermal characteristics of the molded composites to determine the influence of the different fibers on their properties. However, they have observed that the most noticeable effects were related to carbon fibers, for mechanical performances, whereas Kevlar fibers enhanced water absorption. Nevertheless, they concluded that these composites are viable to be used in various engineering sectors, like automotive and construction.

In 2012, Jahan et al. proposed a work in which there was a comparison between jute fiber reinforced and glass fiber reinforced LDPE composites [

2]. Both were made by using compression molding at the temperature of 120°C. Many physical and mechanical properties were compared, and results showed that glass reinforced composites had better mechanical stability compared to jute composites. This kind of studies, where LDPE is presented together with natural-base materials, is very typical as LDPE can be a sustainable material source as well, coming from recycling. In general, glass fibers and thermoplastic films are very common waste for industries (

Figure 1). However, jute is biodegradable but not the LDPE matrix, as well as glass fibers, and several waste management and recycling issues may arise. About this topic, in 2024, Soo et al. have proposed the use of bio-based PE, derived from renewable resources like corn and sugarcane, that represents an eco-friendly alternative [

3]. The production of bio-PE composites is growing, due to environmental issues and regulation pressures. Furthermore, the PE bio-composites employ agricultural waste as filler materials, representing a sustainable and environmentally friendly alternative to traditional plastics. They have interesting potential applications in automotive, furniture and building construction industries, if sufficient performances and durability would be reached.

In 2022, Karem et al. proposed a study for the mechanical characterization of LDPE as matrix in composite materials with glass fibers [

4]. In this work, composites were produced with different fractions of glass fibers (up to 22 wt%) by hand lay-up, and mechanical performances were tested under impact, tensile and bending tests. As expected, by increasing the glass fiber content, mechanical properties raise. Similar results had been already obtained by other researchers with discrete glass reinforcements. Chimeni et al. in 2018 used glass beads into LDPE [

5]. Smaller particle sizes had a greater impact on the composite behavior in several loading conditions because of their increased specific surface area. In general, a remarkable distinction was noted between virgin and recycled LDPE because of the contamination found in the recycled material. Falcone et al. in 2018 used hollow glass microspheres through melt blending [

6]. The improvement of the interaction between fillers and LDPE matrix was achieved by their surface modification with a proper organo-silane.

In 2021 Gulati et al. have discussed injection molding of hybrid composites with linear-LDPE (LLDPE) reinforced with date pit and glass fibers [

7]. The highest tensile strength achieved was 20.2±0.8 MPa with a reinforcement composed by 10% date pit and 20% glass fiber. Higher percentages of glass fiber were discovered to improve the water-resistant characteristics. These performances are typical for LDPE-matrix composites which are characterized by high ductility and toughness but low strength, in comparison with other thermoplastics. For this reason, hybrid composites are very often presented by researchers, mixing different typologies of fibers and particles. In 2017, Azizi et al. had studied an LDPE-matrix composites with graphene-like material prepared by using melt-intercalation compounding method [

8]. Composites were molded by compression molding, and a minimal decrease in both melting point and crystallinity compared to the pure polymer were found. Very recently, Krehula et al. have studied, in 2024, the incorporation of hematite particles into LDPE, and have discussed positive effects on the mechanical properties of the composites [

9].

The easiness of particle incorporation into LDPE melts has always pushed researchers to find new composite mixtures, mainly by using natural feedstocks. In 2022, Sakdapipanich et al. proposed a composite obtained incorporating macca carbon (MC) powder, a biomass derived from macadamia nut cultivation that emits far-infrared radiation, into a matrix of low-density polyethylene (LDPE) [

10]. It has a potential to be used for antimicrobial packaging applications. The results showed that 0.5% by weight MC powder in the LDPE/MC film composite caused the maximum percentage of microorganism decrease. In 2023 by Ferrandez et al. used LDPE waste as secondary raw material in the production of new eco-friendly gypsum composites. [

11]. In 2023, Melikoglu et al. have proposed innovative bio-composites for packaging films by inserting cellulose and cellulose nanocrystals, obtained from safflower head waste, into LDPE [

12]. In the same year, Rodriguez-Fabia et al. have used cellulose nanofibrils as fillers of LDPE bio-composites [

13], whereas Sharma et al. have produced nanocomposites by adding BiOCl nanoparticles for UV shielding applications [

14], and Yucesoy et al. have used magnesium hydroxide and magnesium carbonate at various weight ratios to create flame retardant LDPE composites [

15].

By studying LDPE composites, recycling is always an option and the best advantages for the environment are achieved when both matrices and fillers are recycled or recovered from waste. Gulser et al. in 2020 combined metal waste from the iron-steel industry with plastic waste from the plastic industry, with the goal of minimizing overall waste from industrial production processes and promoting sustainable waste management [

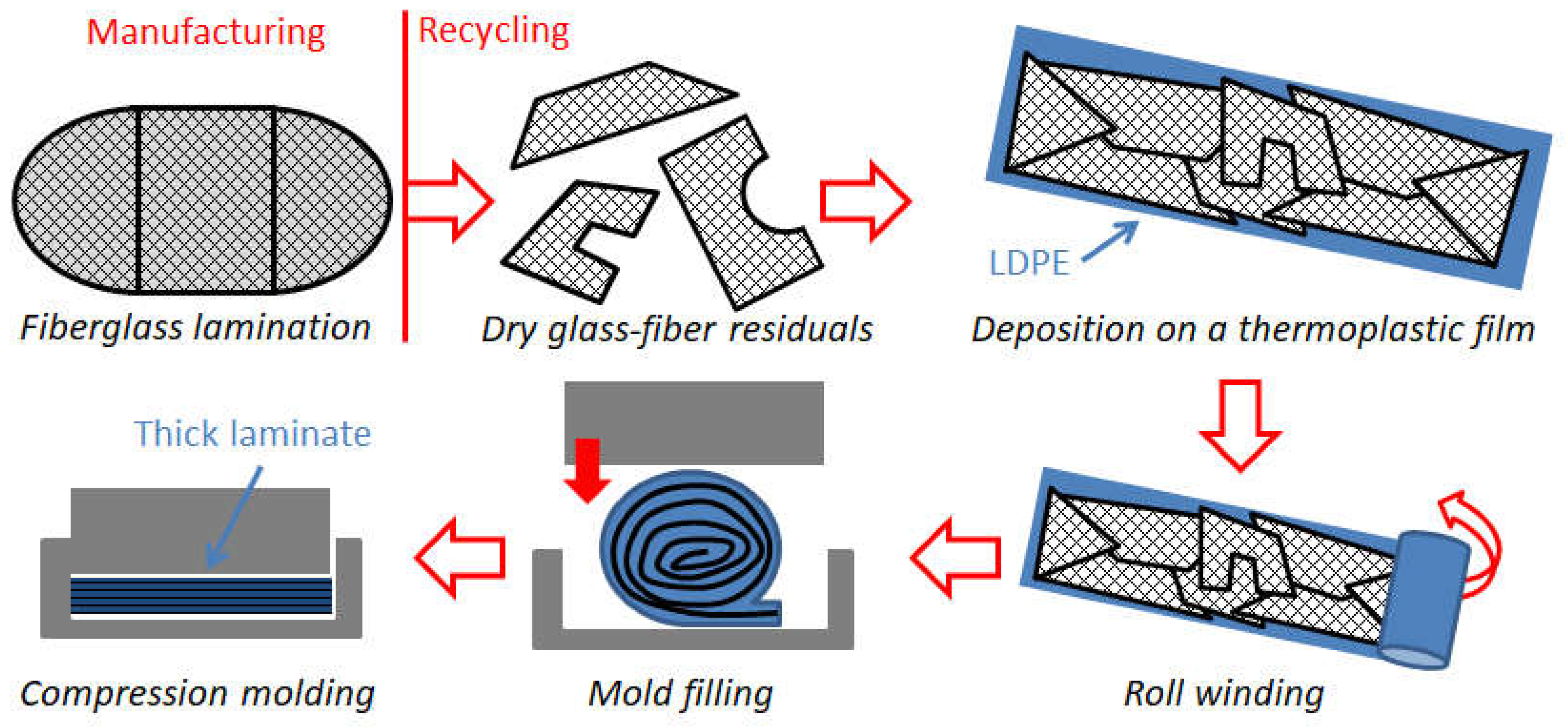

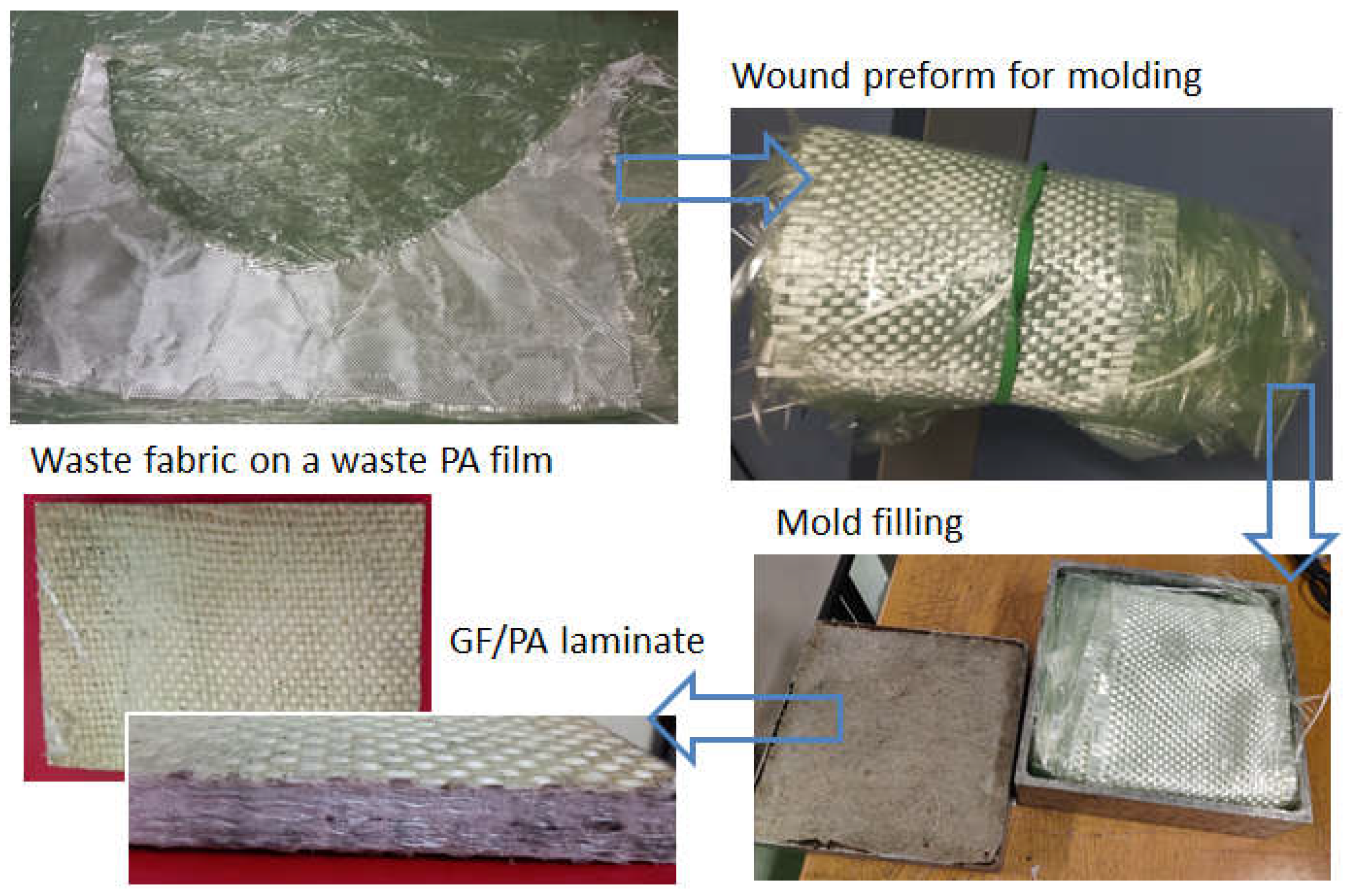

16]. Different quantities of blast furnace dust, that represents the major waste from iron-steel industry, was mixed with LDPE with the effect of enhancing the heat resistance, the thermal conductivity and the wear resistance of these composites. The idea at the basis of the current study is introducing a simple manufacturing process for LDPE composites by integrating different industrial waste streams. Process simplicity is a mandate to guarantee its success in industrial sphere. For this study, waste dry fabrics have been collected from factories that produce fiberglass products, and have been processed with LDPE films, used for packaging. In order to simplify its supply, the adopted LDPE film was virgin, but it is a typical material that, in future, could be recovered as waste. Thick thermoplastic laminates have been compression molded after a simplified lamination procedure (

Figure 2). The final composites have shown very good agglomeration and exhibit unique properties in terms of repairability.

2. Materials and Methods

Dry glass-fiber fabrics have been recovered from fiberglass manufactures in the shape of large residuals after fabric cutting. These materials have the same properties of virgin fabrics but are not usable because of the shape. For the matrix, an LDPE roll with a thickness of 60 μm and a width of 300 mm has been acquired. That is a typical packaging material and can be recovered by recycling streams as well as the glass-fiber fabrics. However, in this study, a virgin roll has been used to simplify the laboratory procedure, and to reduce possible uncertainties coming from t recycled LDPE. In following research activities, thanks to the outcomes of these studies, the manufacturing procedure has been successfully extended to 100% recycled composites and different thermoplastic matrices, as partially discussed in the conclusion section.

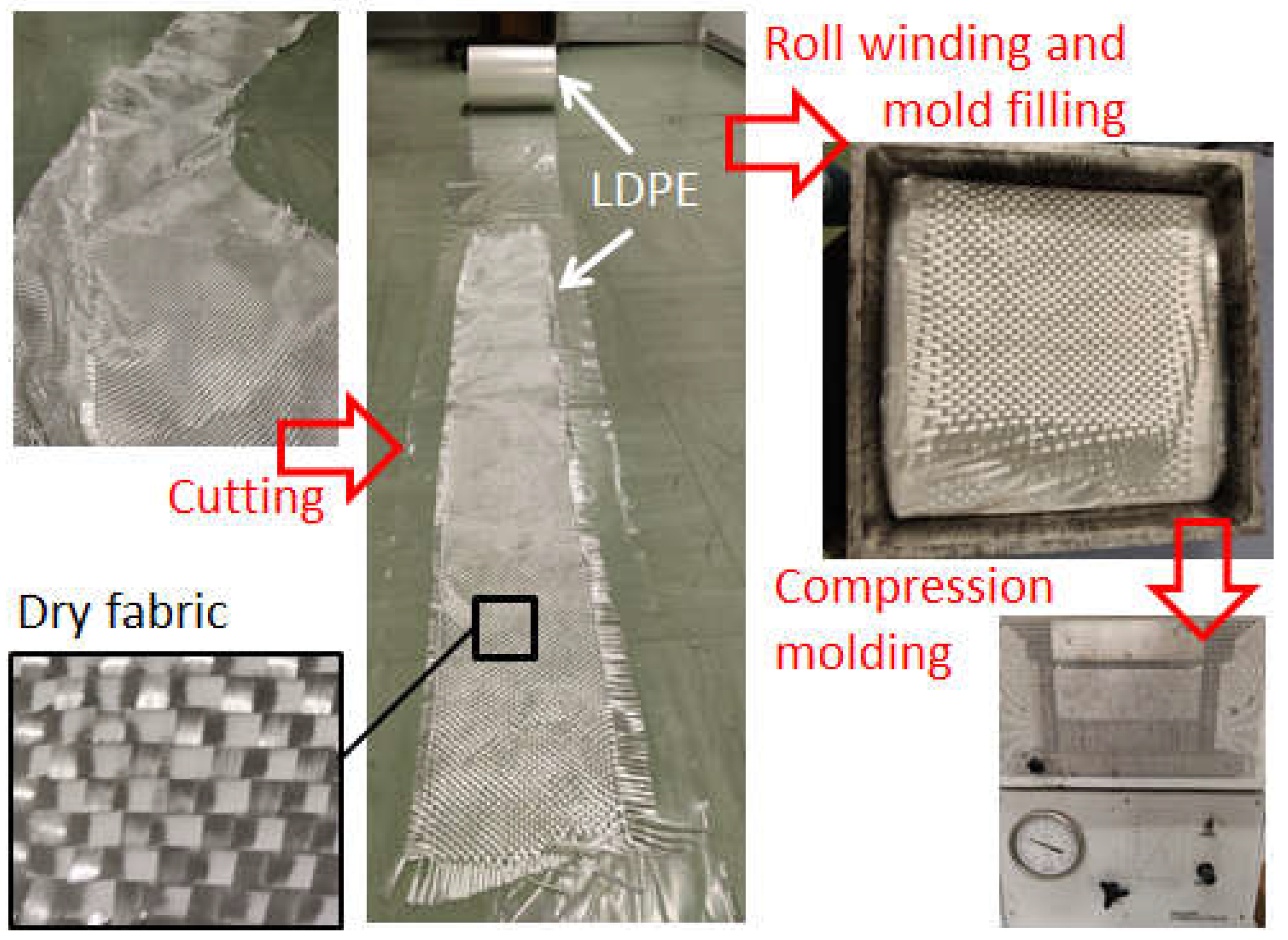

The first aspect to deal for the definition of a successful industrial process is the clarity and easiness of the fabrication steps, above all in the case of recycling processes. For composites, the main issues are related to the difficulty of managing very large raw materials (fabrics, sheets) and the need of implementing a reliable lamination procedure. Dealing with residuals from composite manufacturing (parts of fabrics and mats, waste packaging or vacuum bagging films), most of the time they are rapidly crumpled during manufacturing, and it is very difficult to re-use subsequently. Therefore, for recycling, an easy lamination procedure must be carried-out in parallel with the manufacturing of the composite part, to recycle residuals and waste materials without impacting on the main industrial process. The proposed process is shown in

Figure 2. Dry fabrics are deposited on thermoplastic sheets, and roll wounded to make molding preforms. These preforms are compression molded to make laminates. Because of the combined action of the mold temperature and punch pressure in the press, the thermoplastic film melts and the molten polymer infiltrates the dry fabrics. In this study, the procedure of

Figure 2 has been applied to make thick thermoplastic composite laminates in laboratory. In

Figure 3, some details of the production phase are shown.

Large residuals of glass-fiber fabrics, from fiberglass manufacturing, have been cut at the width of 250 mm, for an approximative length of about 3 m. These fabrics have been deposited on an LDPE film from the supplied roll. Subsequently, the GF-LDPE sheet has been wound and inserted into an aluminum mold with a 300x300 mm2 cavity. Compression molding has been carried out in hot press with at the temperature of 200°C and the pressure of 1.6 MPa for 30 min. The molding temperature has been selected based on the LDPE melting temperature, which is nominally in the range of 105-115°C. Over-heating is necessary because the mold is initially at room temperature. Furthermore, the long molding time has been set to allow mold-pre-heating and laminate consolidation. After molding, the mold was left to cool under pressure, which was released only when the mold reached a temperature about 50-60°C. The thick composite laminate was extracted by using the removable bottom plate of the mold.

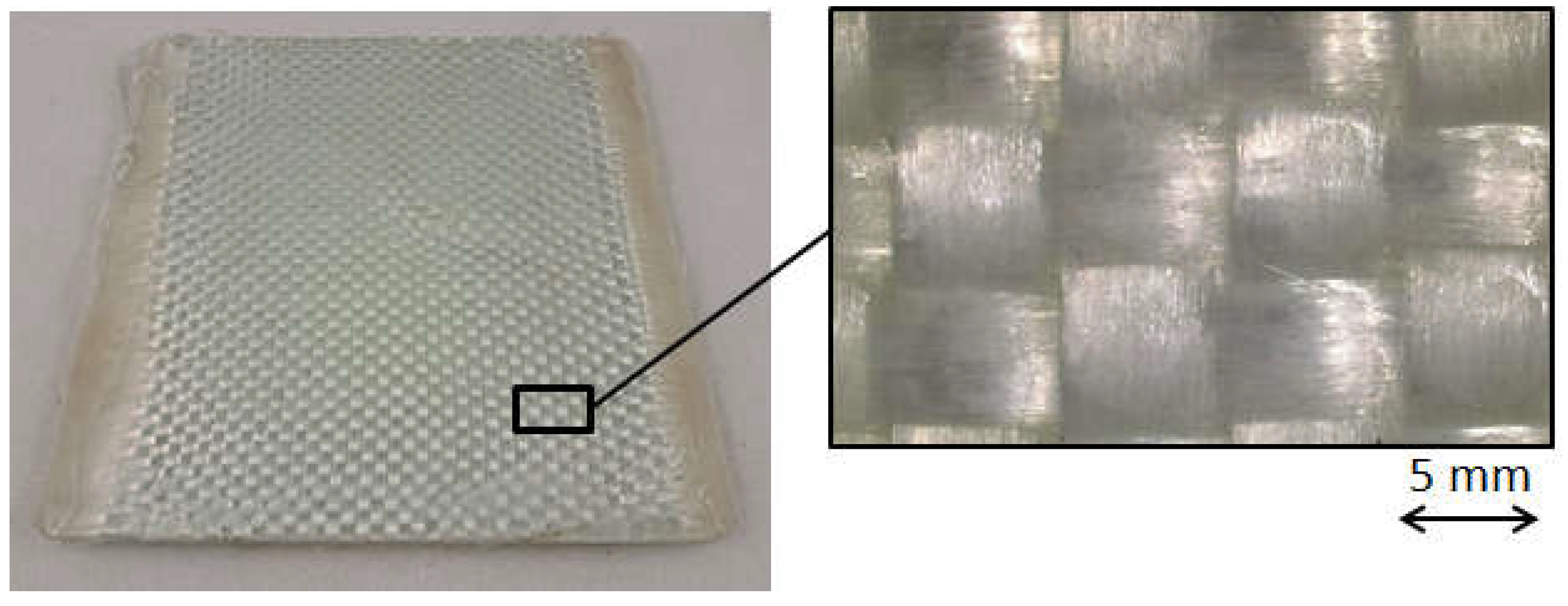

In

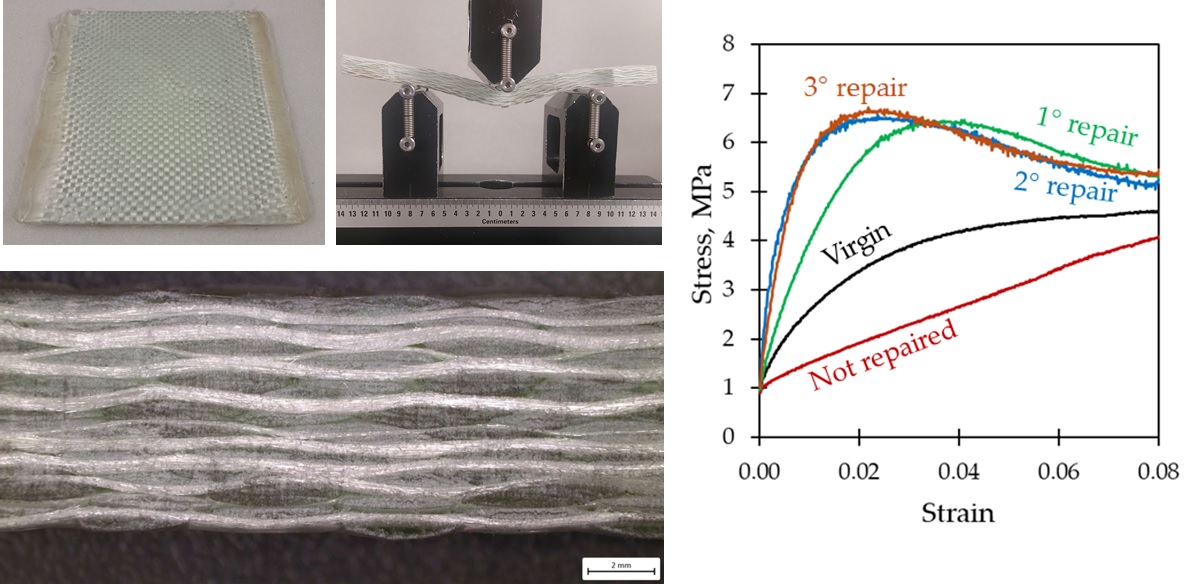

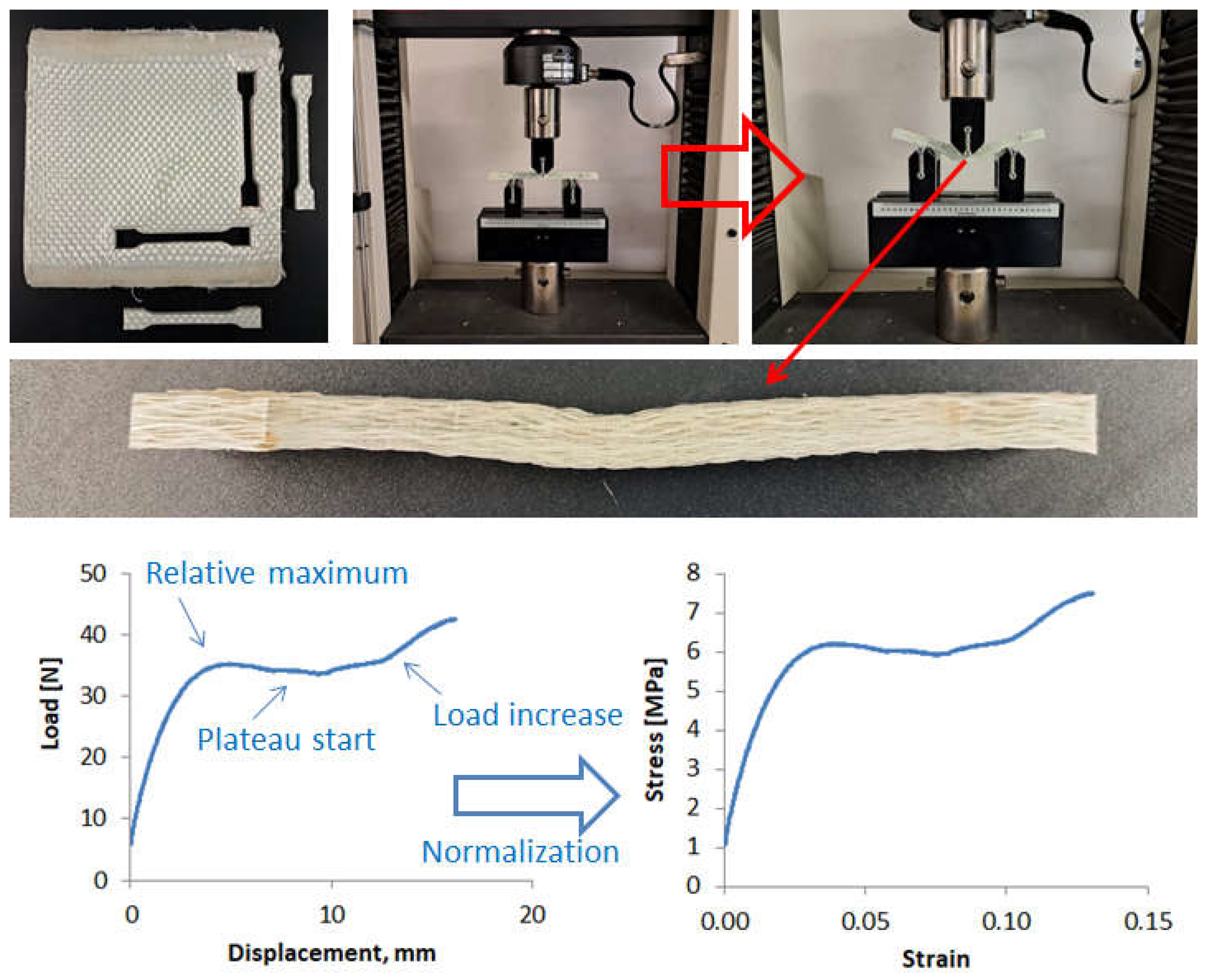

Figure 4, one molded thick laminate is shown together with a detail of its surface appearance. Some samples have been extracted by shearing for testing. Bending tests have been carried out at in a universal machine (MTS Insight 5), according to the ASTM D 6272-02 standard, at the rate of 10 mm/min with a span length of 80 mm. In

Figure 5, sheared samples are shown before and after testing, together with a typical tensile test curve.

The composite samples generally exhibited a tough behavior with low strength and rigidity, because of the LDPE matrix. An initial relative maximum of the loading curve was generally present with a following plateau start, as expected. Nevertheless, a load increase was observed after the plateau start because of the thickness of the sample and the contact with the bending supports. For this reason, tests were limited to maximum displacements of 10 mm. However, after load removal, the samples remained clearly deformed with the evidence of failure in the bending zone.

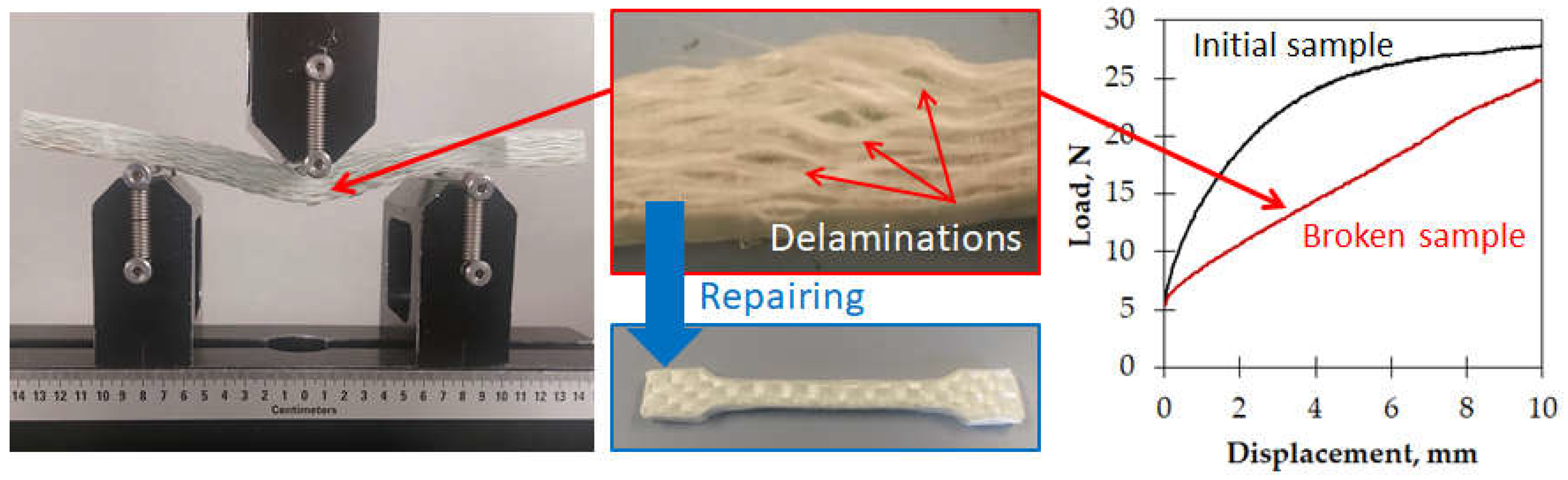

The thick laminate section has been observed by stereoscope (Leica S9i) on the sheared samples, and the distance between the plies has been estimated as well as the presence of cavities or other defects. In the end, tests have been carried out to estimate the repairing ability of this class of composites. Bending tests have been repeated on a sheared sample, in analogy with

Figure 5 but at the maximum displacement of 10 mm. Between 2 consecutive tests, a repairing procedure has been performed into the same hot press already used for compression molding. In comparison with the manufacturing conditions, the pressure was increase (up to 15 MPa) but the time was strongly reduced (down to 5 min) whereas the plate temperature was left to 200°C. In

Figure 6, the laminate sample is shown under the applied displacement of 10 mm together with its delamination, after unloading, and its appearance after the first repairing operation. To quantify the damage given by bending, the test was also repeated on the broken sample before the first repairing operation, and test curves are shown in the same

Figure 6.

3. Results

The thick thermoplastic composite has been agglomerated with a good aesthetics and minimal fiber distortion in most of the molded surfaces (

Figure 4). On the edges, an excess of polymer matrix is present because of the initial clearance between the molding preform and the mold cavity (

Figure 3). The final GF/LDPE laminate has a nominal thickness of 9 mm (8.6±0.1 mm, measured on the sheared samples). From bending tests (

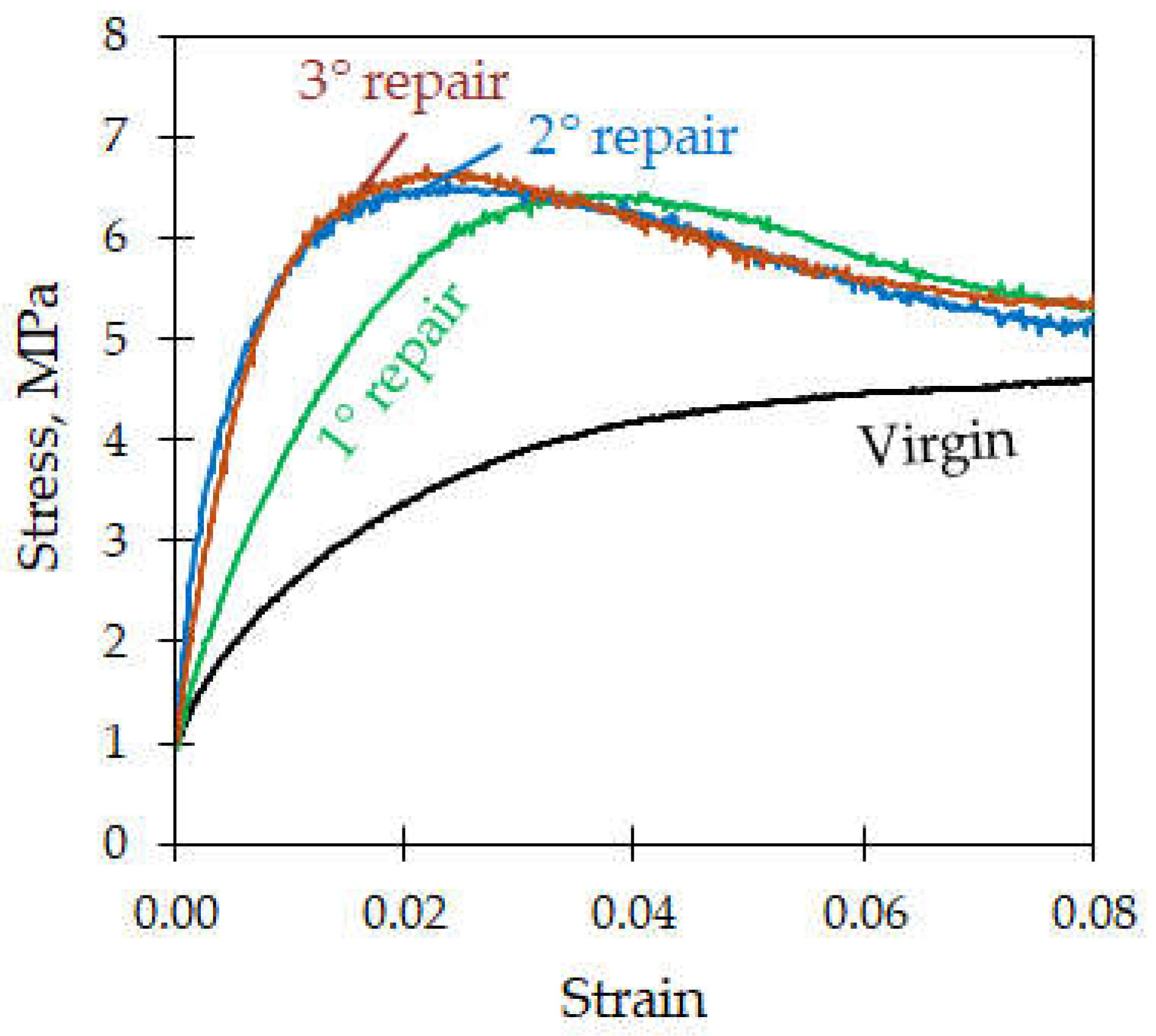

Figure 5), an average maximum strength of 6.2 MPa results at the strain of 3.70%, with an elastic modulus of 220 MPa. Tests on repaired samples are shown in

Figure 7 after normalization, in comparison with the virgin. After repairing, the sample performances improve, and the presence of the initial stress maximum becomes more evident.

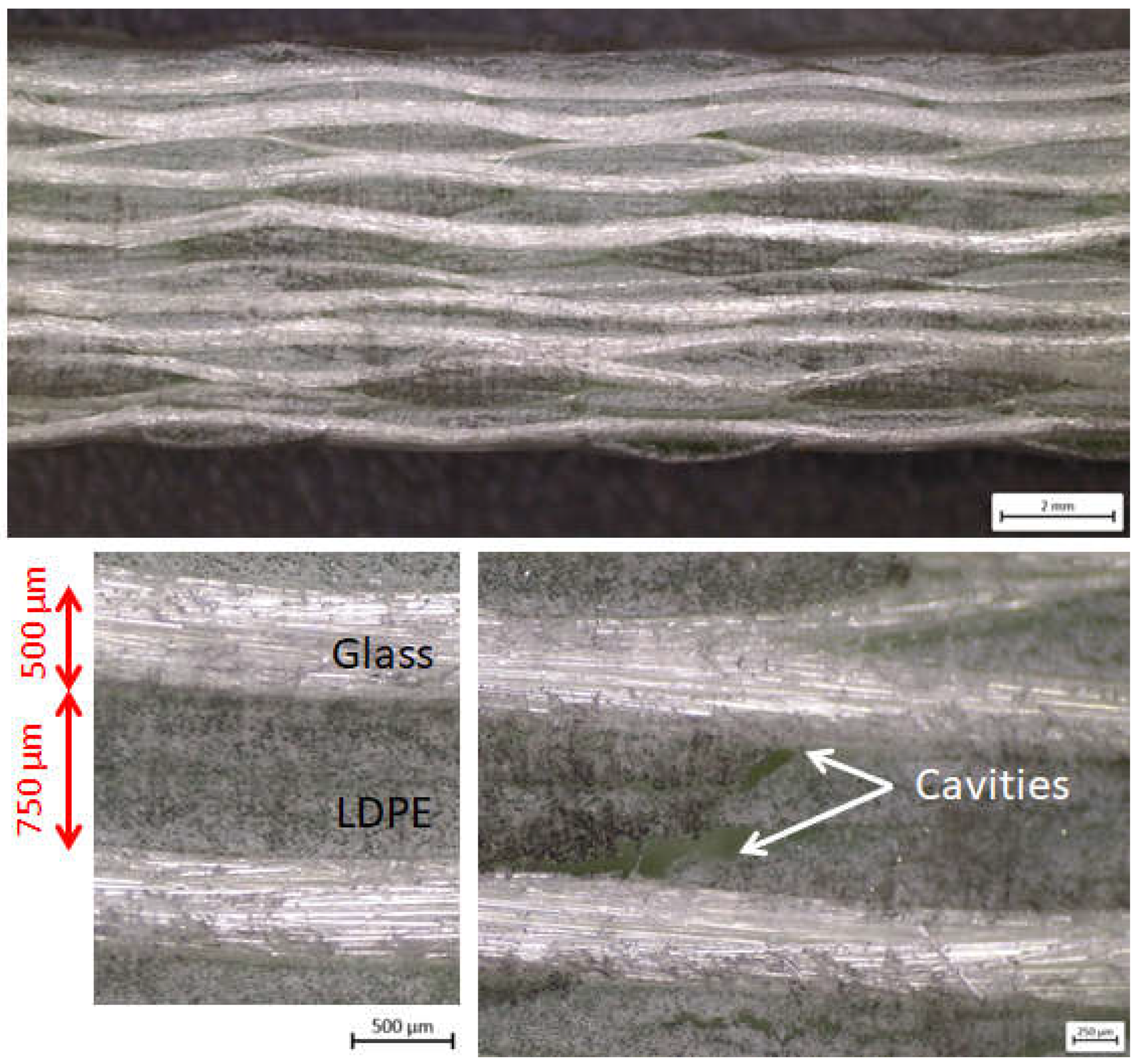

In

Figure 8, the images of the laminate section, from the sheared sample thickness, are shown: 10 glass-fiber plies can be observed with a thickness of 500 µm, whereas the distance between the plies is up to 750 µm. Some cavities are visible in the matrix between the plies, probably due to shrinking during solidification. In fact, their shape is irregular, and some strands are also visible across.

4. Discussion

The proposed impregnation procedure seems to be suitable for reaching good agglomeration of the thick composite. During compression molding, the LDPE film infiltrates through the dry fabrics thanks to its low fluidity but some cavities are visible in the laminate section because of the absence of the vacuum in the mold and shrinking under solidification (

Figure 8). These cavities partially affect mechanical performances as the maximum strength over 6 MPa is measured in absence of cavities. In samples where the maximum strength is observed, the maximum elastic modulus of 220 MPa is measured. This fact is not typical of traditional composites, where the strength is related to the presence of cavities and the elastic modulus can be poorly dependent, but it is typical of agglomerated materials. In presence of many cavities, the strength can reduce about 25% and the elastic modulus over 60%. However, these changes are not dramatic for the thick GF/LDPE composite which is not characterized by its strength and stiffness but its toughness, which is always very high. An example is given by the sample of

Figure 7, which shows mechanical performances lower than the sample of

Figure 5, but it recovers its performances during the repairing steps, and reaches in the end of the third repair a strength of 6.7 MPa and an elastic modulus of 630 MPa, higher than any virgin sample at the first bending test.

Figure 8 shows that 10 glass-fiber plies are visible in the section. The maximum distance between the plies is about 750 µm. Instead, the average distance between plies is about 400 µm, estimated by considering that the average thickness of the molded laminate is 8.6 mm, and the single reinforcement ply is 500 µm. Therefore, the final composites have a fiber volume content over 50 vol%.

Mechanical performances of the GF/LDPE composite are generally low as bending tests are strongly influenced from the matrix, much more than tensile tests, and the matrix is a very soft polymer, with an elastic modulus in the range of 200-300 MPa. In the best case, laminate samples reached an elastic modulus over 700 MPa, but not from the virgin panels. In fact, highest performances have been reached after the repairing steps. The reason is that the repairing procedure is able to fix damages occurred under bending, and also to reduce defects from manufacturing, such as low impregnation and cavities. Nevertheless, the damage which has been generate under bending is always very large, as it is possible to observe from the residual deformed shape of tested samples (

Figure 5) or the large delaminations before the repairing step (

Figure 6). Thanks to the thermoplastic behavior of the LDPE matrix and its low viscosity, delaminations are easily closed during repairing as well as cavities of

Figure 8.

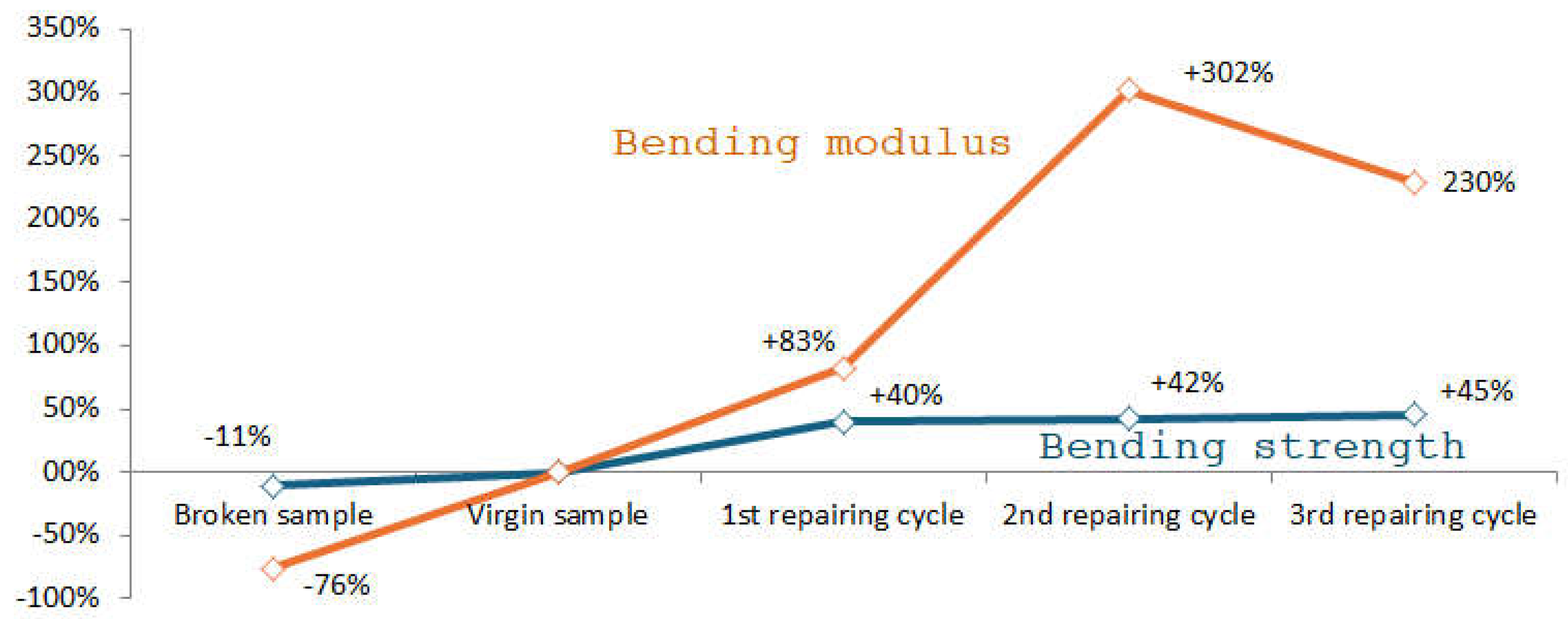

Figure 7 clearly shows the positive effect of the repairing procedure on the performances of GF/LDPE thick laminate as well as the strong damage after the first bending test. By repeating the breaking/repairing cycles, the stress-strain curves approach more and more the expected curve for a fully agglomerated sample, with a relative maximum at low displacements between 6-7 MPa. In the last 2 repairing steps, the bending curves are almost perfectly superimposed. Therefore, after an initial training, the repairing procedure allows reaching the nominal material behavior, without any evidence of the previous damage.

Figure 9 quantifies this effect, by comparing the sample strength and modulus during the different steps with the virgin condition. The bending strength increases after the first repairing step about 40%, from 4.6 MPa to 6.5 MPa, and this increase remains stable also in following repairing steps, with a maximum of 6.7 MPa in the end of the third repair. The elastic modulus increase is quite bigger than the strength, up to 300% and does not approach a plateau. Generally, the elastic modulus is more sensitive to damaging, as shown by the test of the broken sample where the strength reduces only 11% and the elastic modulus up to 80%. This difference can be related to the tough behavior of the LDPE matrix which is generally poorly influenced by the occurrence of delaminations and cavities into a large extent. Glass fibers do not contribute significantly under bending, and the general performances remain very low in comparison with traditional fiberglass. Instead, glass fiber orientation and buckling have a great influence on sample stiffness.

5. Conclusion

An easy lamination procedure has been designed to allow recycling of large residual of waste glass-fiber fabrics in fiberglass industry. Thick thermoplastic composites may be manufactured in parallel with the fiberglass production, also by recovering other waste materials such as packaging films or bags for autoclaves. In the current study, a virgin LDPE matrix has been chosen for simplicity and the final composite laminate has shown low mechanical properties but very high toughness. However, the main characteristic of this GF/LDPE laminate is its excellent repairability. In fact, the laminate can undergo several breaking/recycling steps without reducing its performances but increasing, as the repairing procedure allows reducing also defects by manufacturing. In the end, constant properties are reached in the last repairing step, with the perception of an infinite repairability from bending damages.

The proposed procedure can be extended to many other cases, by replacing the virgin LDPE film with other thermoplastics, also from recycling. Different fabrics can be selected as well. An example is given in

Figure 10, where the same residuals of glass-fiber fabrics are laminated with a waste bag from autoclave molding, made of polyamide (PA). A very good agglomeration has been achieved also for this filler/matrix combination by compression molding, but higher mechanical performances have been reached because of the PA matrix.

The proposed lamination procedure allows to insert each single reinforcement fabric between 2 sheets of thermoplastic matrix. Fiber impregnation is facilitated, and the amount of matrix can be tailored by selecting the thickness of the thermoplastic sheet or the number of sheets. Many combinations may be explored, and future works will focus on this new class of thick laminates. In general, producing thick thermoplastic composites by compression molding is a very complex task, because of the difficulty of fiber impregnation and the tendency of the molten matrix to flow away, between the reinforcement plies, instead of passing through the fabrics. The proposed lamination solution seems to be optimal, limiting polymer flow during agglomeration and forcing its penetration between the dry fibers. Some defects can occur such as cavities, for entrapped air or solidification shrinking, but proper process tuning could minimize them.

Acknowledgments

The authors want to acknowledge Dr. Fabrizio Betti for his technical support in all the activities of the research study.

References

- S. Ravichandran, S. Sagadevan, M.E. Hoque, Physical, Mechanical, and Thermal Properties of Fiber-Reinforced Hybrid Polymer Composites, Natural Fiber-Reinforced Composites: Thermal Properties and Applications (2021), Pages 309-320. [CrossRef]

- J. Arfin, R. Mahbubur, K. Humayun, M.A. Gafur, Comparative Study of Physical And Elastic Properties of Jute And Glass Fiber Reinforced LDPE Composites, International Journal of Scientific & Tec hnology Research (2012), Volume 1, Issue 10.

- X.Y.D. Soo, J.K. Muiruri, W. Wu, J.C.C. Yeo, S. Wang, N. Tomczak, W. Thitsartarn, B.H. Tan, P. Wang, F. Wei, A. Suwardi, J. Xu, Bio- Polyethylene and Polyethylene Biocomposites: An Alternative toward a Sustainable Future, Macromolecular Rapid Communications (2024). [CrossRef]

- H.M. Kareem, F.A. Abdulla, Improvement the mechanical behavior of recycled low-density polyethylene as a composite material, AIP Conference Proceedings (2023), Volume 2787, Issue 1, Article Number 090002. [CrossRef]

- D.Y. Chimeni, E. Vallèe, L. Sorelli, D. Rodrigue, Effect of glass bead size and content on the thermomechanical properties of polyethylene composites, Polymer Engineering and Science (2018), Volume 58, Issue 10, Pages 1826-1836. [CrossRef]

- G. Falcone, A. Vignali, R. Utzeri, G. Porta, F. Bertini, P. Stagnaro, S. Iannace, Light weight LDPE composites with surface modified hollow glass microspheres, AIP Conference Proceedings (2018), Volume 1981, Article Number 020131. [CrossRef]

- K. Gulati, S. Lal, S. Kumar, S. Arora, Effect of gamma irradiation on thermal, mechanical and water absorption behavior of LLDPE hybrid composites reinforced with date pit (Phoenix dactylifera) and glass fiber, Polymer Bulletin (2021), Volume 78,Issue 12, Pages 7019-7038. [CrossRef]

- S. Azizi, C. Ouellet-Plamondon, E. David, M.F. Frechette, Electrical and thermal properties of low-density polyethylene/graphene-like composite, Annual Report-Conference on Electrical Insulation and Dielectric Phenomena, CEIDP (2017), Volume 2017-October, Pages 517-520. [CrossRef]

- L.K. Krehula, A. Persic, N. Popov, S. Krehula, Polymer Composites of Low-Density Polyethylene (LDPE) with Elongated Hematite (α-Fe2O3) Particles of Different Shapes, Journal of Composites Science (2024). [CrossRef]

- J. Sakdapipanich, P. Rodgerd, N. Sakdapipanich, A Low-Density Polyethylene (LDPE)/Macca Carbon Advanced Composite Film with Functional Properties for Packaging Materials, Polymers(2022). [CrossRef]

- D. Ferrandez, A. Zaragoza-Benzal, P. Santos, L. Duraes, Characterisation of new sustainable gypsum composites with low-density polyethylene waste from single-use bags, Journal of Building Engineering (2023), Volume 80, Article number 108103. [CrossRef]

- A.Y. Melikoglu, I. Tekin, N. Hayatioglu, S. Ersus, Development of environmentally friendly composite packaging films from safflower (Carthamus tinctorius L.) plant wastes, Food bioscience (2023), Volume 55, Article n. 102991. [CrossRef]

- S. Rodriguez-Fabia, C. Zarna, G. Chinga-Carrasco, A comparative study of kraft pulp fibres and the corresponding fibrillated materials as reinforcement of LDPE and HDPE-biocomposites, Composites Part A: Applied Science and Manufacturing (2023), Volume 173, Article number 107678. [CrossRef]

- S. Sharma, A.D. Acharya, Bhawna, Y.S. Thakur, S. Bisoyi, Optimizing BiOCl concentration for enhanced LDPE performance: Investigation of structure, thermal stability, and optical characteristics, Journal of Molecular Structure (2023), Volume 1294, Article number 136382. [CrossRef]

- A. Yucesoy, Y. Balcik Tamer, H. Berber, Improvement of flame retardancy and thermal stability of highly loaded low density polyethylene/magnesium hydroxide composites, Journal of Applied Polymer Science (2023), Volume 140, Issue 30, Article number 54107. [CrossRef]

- C. Gulser, T.K. Merve, Environmental properties of environmentally friendly construction materials: Recycled LDPE composites filled by blast furnace dust, Journal of Green Building (2021), Volume 16, Issue 3, Pages 135-153. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).