Submitted:

06 September 2024

Posted:

06 September 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Material and Methods

2.1. Sample Collection

2.2. Analytical Reagents

2.3. Extraction, Quantification, and Identification of Trace Components

2.3.1. Extraction of Trace Components by VASE [4]

2.3.2. Analytical Conditions for GC-MS

2.3.3. Isolation of Trace Components by Liquid-Liquid Extraction (LLE)

2.3.4. Screening of Trace Components by GC-O-MS

2.3.5. Odor Specific Magnitude Estimation (Osme)

2.3.6. Identification of Trace Components

2.4. Quantification and Odor Active Values/Taste Active Values (OAVs/TAVs) Calculation of Trace Components

2.5. Sensory Quantitative Descriptive Analysis (SQDA)

2.6. Flavor Addition Experiments

2.7. Statistical Analysis and Statistical Methods

3. Results and Discussion

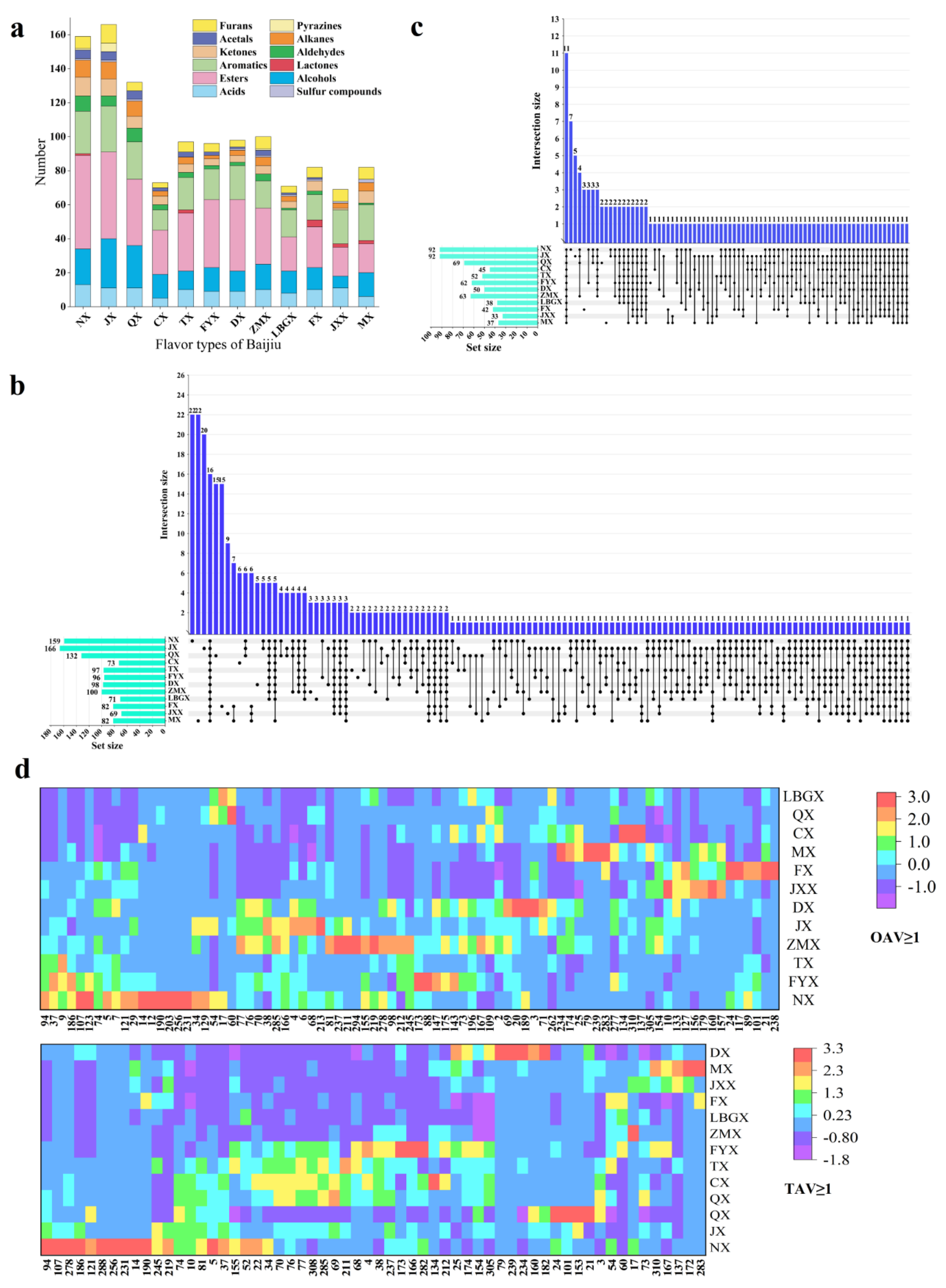

3.1. Analysis of Distribution Characteristics on Trace Components

3.2. Aroma Expression Evaluation of Trace Components

3.3. Quantification of Trace Components

3.4. OAVs and TAVs of Trace Components

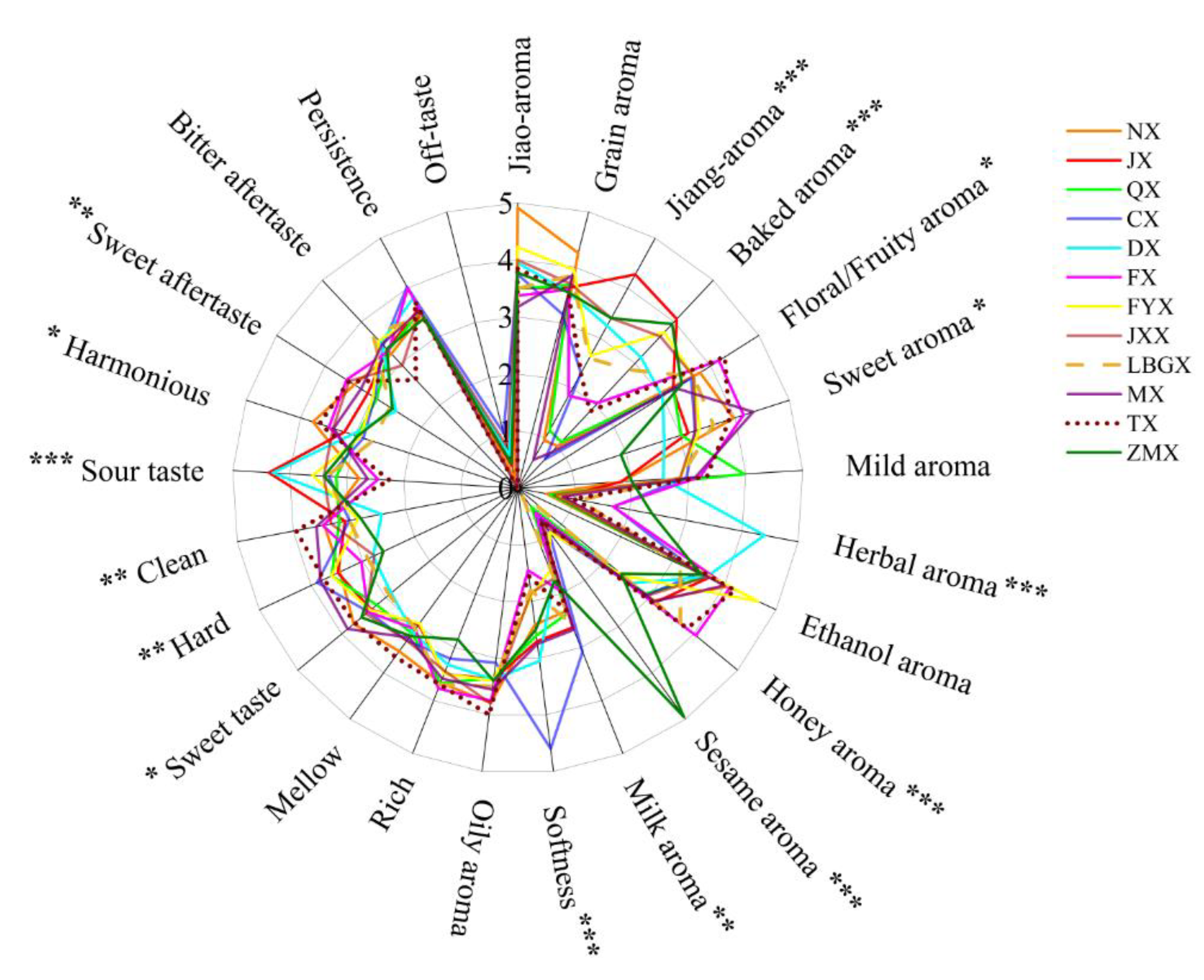

3.5. SQDA on 12 Flavor Types of Baijiu

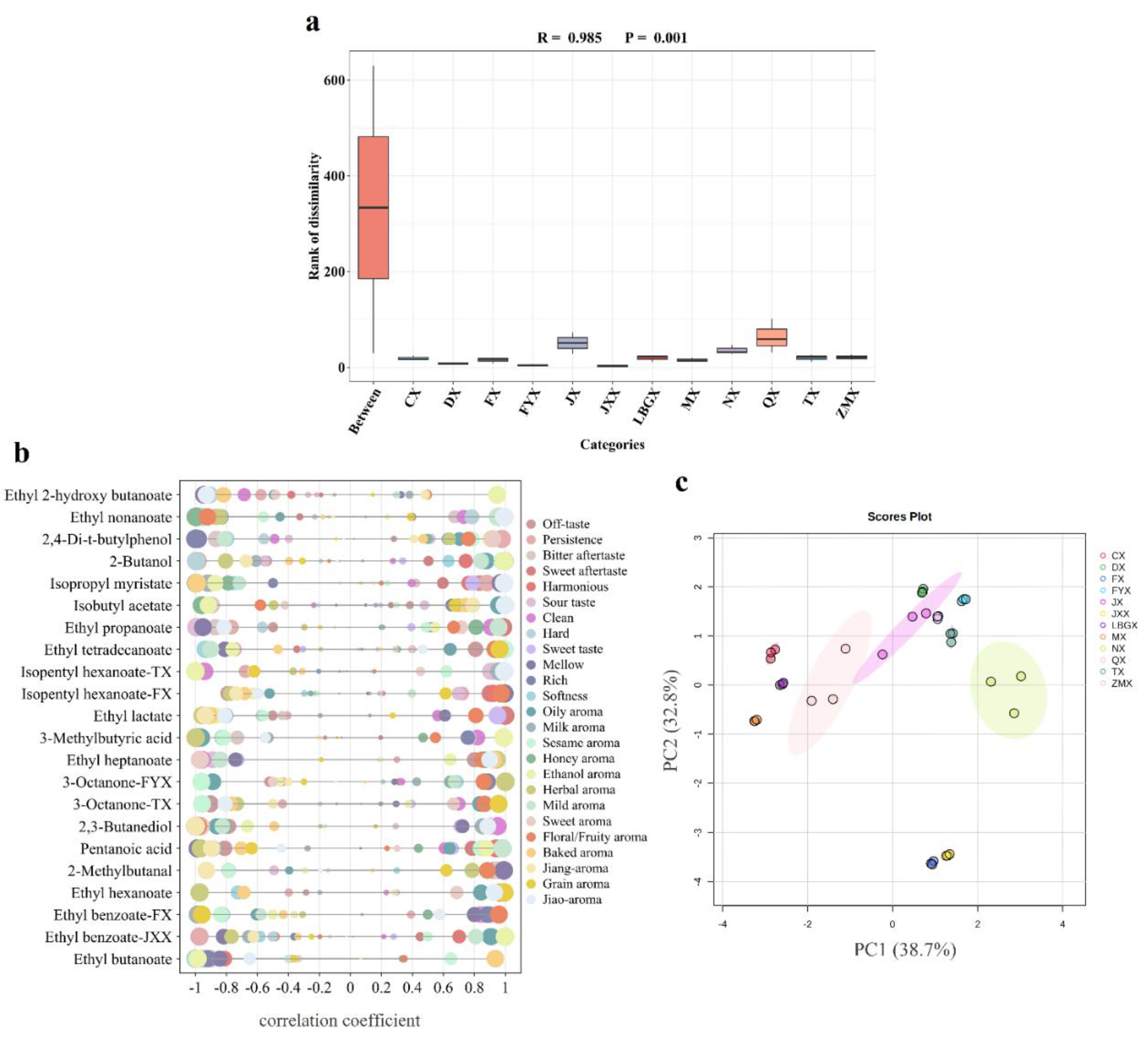

3.6. Correspondence Analysis on the Evolution of Baijiu Flavor Types

3.6.1. Analysis of Similarities (ANOSIM) on Baijiu of 12 Flavor Types

3.6.2. Differential Analysis on the Evolution of Baijiu Flavor Types through Machine Learning

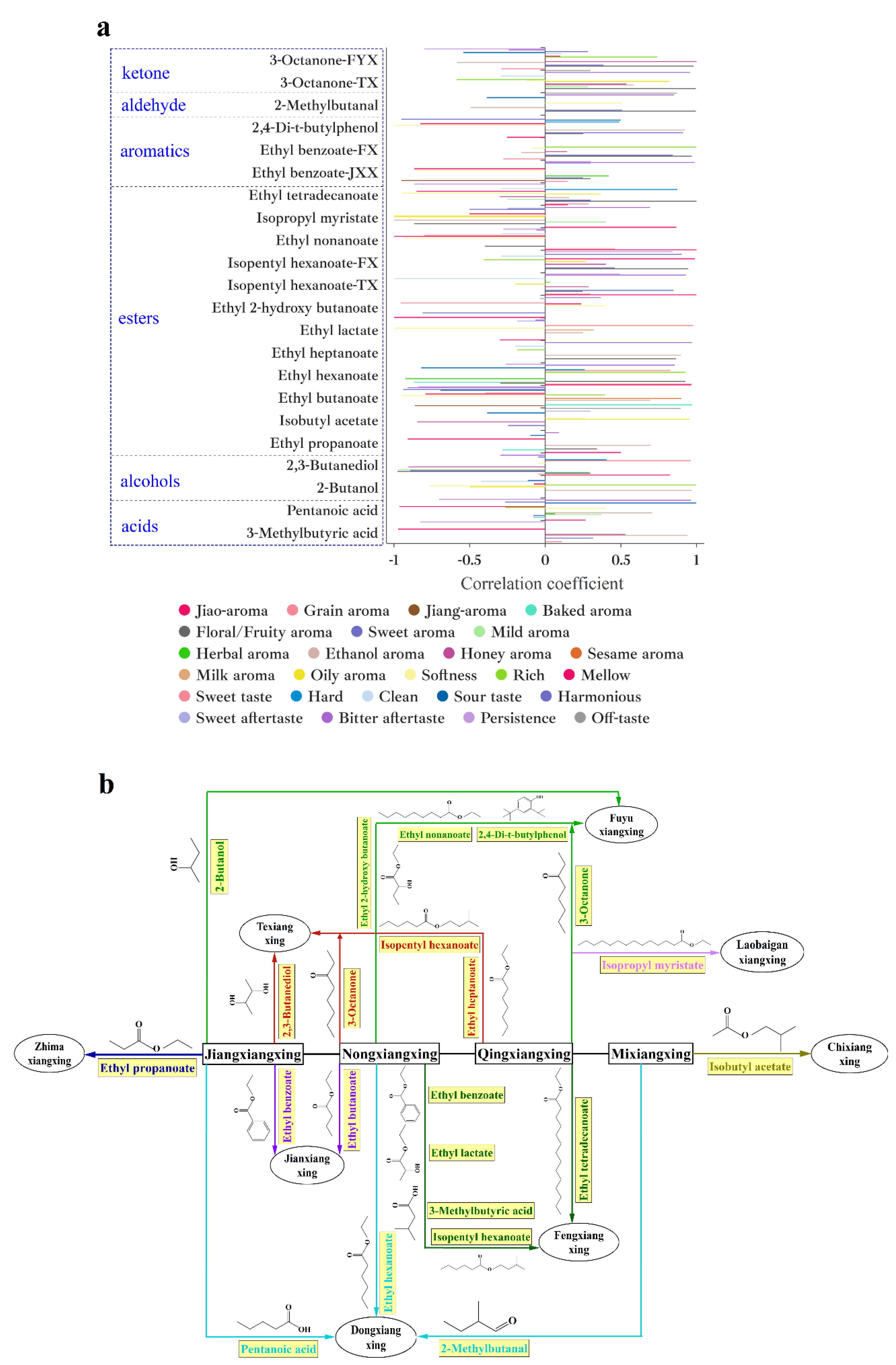

3.7. Correlation Analysis Based on Flavor Addition Experiments

4. Conclusion

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Declaration of Competing Interest

Abbreviation

References

- Zheng, X. W. and B. Z. Han. "Baijiu (白酒), chinese liquor: History, classification and manufacture." Journal of Ethnic Foods 3 (2016): 19-25. https://www.sciencedirect.com/science/article/pii/S2352618116300087. [CrossRef]

- Zou, F., L. Ye, L. Feng, X. W. Zheng, B. Huang, B. Xia, W. J. Zhang, X. Y. Chen, Z. G. Fang and Y. T. Sun. "Research progress on microbial diversity, evaluation and maintenance of baijiu pit mud." Food Science 45 (2024): 320-28. https://kns.cnki.net/kcms2/article/abstract?v=MBTPQIn9ZKFNrtSxfJtvtZ91bJIfikyTA-sMaWGky85VNwENCAApCjEPXqDPsczsc4R4WyUTh2P301GaDfA5k0GV3CcnIOxF8r9XOZV7Fw9A5YS2N9q-UADGoa1sH18AV9jpLd-tWbniNV94oQ7SMPWnPIsdoUA2yiU-x9jh39vjuZomU3OgfDvclg9KO0QN&uniplatform=NZKPT&language=CHS.

- Hou, X. B., X. X. Lu and H. Huang. "Five sessions of baijiu appraisal fuelled chinese baijiu flavor type with continuous growth." Liquor Making 50 (2023): 152-53. https://kns.cnki.net/kcms2/article/abstract?v=7P8mTOHD94Fq9cxE4vSrNZYZyaylnAx8ydufyh7lavH0-ZgPevr_rLrd6THdOEOML4o2EAZiBxsW4feoQVBZZ3MgJ92LcCeKMllh17G4bD3usiSTJR60RhKX7TpBqyWJiaLcfaEEQ3LIPq1yN7TOFg==&uniplatform=NZKPT&language=CHS. https://kns.cnki.net/kcms2/article/abstract?v=7P8mTOHD94Fq9cxE4vSrNZYZyaylnAx8ydufyh7lavH0-ZgPevr_rLrd6THdOEOML4o2EAZiBxsW4feoQVBZZ3MgJ92LcCeKMllh17G4bD3usiSTJR60RhKX7TpBqyWJiaLcfaEEQ3LIPq1yN7TOFg==&uniplatform=NZKPT&language=CHS.

- Hou, Y. X., Y. C. Ma, H. Huang, Y. S. Wu, H. Chen, D. R. Zhao, R. Ao, Z. G. Zhao, C. S. Zhang, J. Y. Sun, et al. "Anchoring for the quality difference factor of strong-flavor baijiu based on sensory quantitative descriptive analysis and sorbent pen-gas chromatography-mass spectrometry." Food and Fermentation Industries 49 (2023): 255-67. https://kns.cnki.net/kcms/detail/11.1802.ts.20230302.1435.004.html. [CrossRef]

- Zhang, X. J., L. J. Meng, Z. M. Lu, L. J. Chai, S. T. Wang, J. S. Shi, C. H. Shen and Z. H. Xu. "Identification of age-markers based on profiling of baijiu volatiles over a two-year maturation period: Case study of lu-flavor baijiu." Lwt-Food Science and Technology 141 (2021): <Go to ISI>://WOS:000636138600057. [CrossRef]

- Huang, H., Y. S. Wu, H. Chen, Y. X. Hou, J. S. Wang, J. X. Hong, D. R. Zhao, J. Y. Sun, M. Q. Huang and B. G. Sun. "Identification of regionalmarkers based on the flavor molecular matrix analysis of sauce-aroma style baijiu." J Sci Food Agric 103 (2023): 7434-44. <Go to ISI>://WOS:001034066100001. [CrossRef]

- Somerfield, P. J., K. R. Clarke and R. N. Gorley. "A generalised analysis of similarities (anosim) statistic for designs with ordered factors." Austral Ecology 46 (2021): 901-10. <Go to ISI>://WOS:000657172200001. [CrossRef]

- Niu, Y. W., Q. Zhu and Z. B. Xiao. "Characterization of perceptual interactions among ester aroma compounds found in chinese moutai baijiu by gas chromatography-olfactometry, odor intensity, olfactory threshold and odor activity value." Food Research International 131 (2020): 108986. https://www.sciencedirect.com/science/article/pii/S0963996920300119. [CrossRef]

- Niu, Y., Q. Zhu and Z. Xiao. "Characterization of perceptual interactions among ester aroma compounds found in chinese moutai baijiu by gas chromatography-olfactometry, odor intensity, olfactory threshold and odor activity value." Food Research International 131 (2020): <Go to ISI>://WOS:000528252800011. [CrossRef]

- He, Y., Z. Liu, M. Qian, X. Yu, Y. Xu and S. Chen. "Unraveling the chemosensory characteristics of strong-aroma type baijiu from different regions using comprehensive two-dimensional gas chromatography–time-of-flight mass spectrometry and descriptive sensory analysis." Food Chemistry 331 (2020): 127335. https://www.sciencedirect.com/science/article/pii/S0308814620311973. [CrossRef]

- Lytra, G., S. Tempere, S. Marchand, G. de Revel and J.-C. Barbe. "How do esters and dimethyl sulphide concentrations affect fruity aroma perception of red wine? Demonstration by dynamic sensory profile evaluation." Food Chem 194 (2016): 196-200. <Go to ISI>://WOS:000364248900026. [CrossRef]

- Liu, L., H. Yang, X. Jin, Y. Zhang, Z. Yan, Y. Qi and C. Xu. "Effect of different liquor storage containers on flavor substances of feng flavor baijiu." Food Science 43 (2022): 285-93. https://kns.cnki.net/kcms2/article/abstract?v=j14_WWxyq7LJQacnNVZ4zZJq4CVS1P8VpPdqzyYUFeLgDldk_hZemUWHBF3LdKj-dVwaipmJed-LktRueuLcKbhs67838UyIxWYLS98CS3sYCBYAz7XcskK8N2kcQ9Ur&uniplatform=NZKPT&language=CHS. [CrossRef]

- Hong, J. X., H. Huang, D. R. Zhao, J. Y. Sun, M. Q. Huang, X. T. Sun and B. G. Sun. "Investigation on the key factors associated with flavor quality in northern strong aroma type of baijiu by flavor matrix." Food Chem 426 (2023): 136576-86. <Go to ISI>://WOS:001020227000001. [CrossRef]

- Yan, Y., S. Chen, Y. Nie and Y. Xu. "Characterization of volatile sulfur compounds in soy sauce aroma type baijiu and changes during fermentation by gc × gc-tofms, organoleptic impact evaluation, and multivariate data analysis." Food Res Int 131 (2020): 109043. https://www.sciencedirect.com/science/article/pii/S0963996920300685. [CrossRef]

- Wang, Z., Y. Wang, T. T. Zhu, J. Wang, M. Q. Huang, J. W. Wei, H. Ye, J. H. Wu, J. L. Zhang and N. Meng. "Characterization of the key odorants and their content variation in niulanshan baijiu with different storage years using flavor sensory omics analysis." Food Chem 376 (2022): 131851. https://www.sciencedirect.com/science/article/pii/S0308814621028570. [CrossRef]

- Wang, P. P., Q. X. Kan, L. X. Yang, W. T. Huang, L. F. Wen, J. Y. Fu, Z. Liu, Y. Q. Lan, Q. R. Huang, C.-T. Ho, et al. "Characterization of the key aroma compounds in soy sauce by gas chromatography-mass spectrometry-olfactometry, headspace-gas chromatography-ion mobility spectrometry, odor activity value, and aroma recombination and omission analysis." Food Chem 419 (2023): 135995. <Go to ISI>://WOS:000970030000001. [CrossRef]

- Wang, L. H., L. Zhu, F. P. Zheng, F. G. Zhang, C. H. Shen, X. J. Gao, B. G. Sun, M. Q. Huang, H. H. Li and F. Chen. "Determination and comparison of flavor (retronasal) threshold values of 19 flavor compounds in baijiu." J Food Sci 86 (2021): 2061-74. <Go to ISI>://WOS:000641954500001. [CrossRef]

- Huang, H., H. Chen, Y. S. Wu, J. X. Hong, Y. Y. Chen, S. Wang, Y. Sun and D. R. Zhao. "Non-targeted identification of age markers of north category strong flavor baijiu." Journal of Food Safety & Quality 14 (2023): 171-82. [CrossRef]

- Gemert, L. J. v. Compilation of compound flavour threshold values (second enlarged and revised edition). Science Press., 2015,.

- Niu, Y. W., W. H. Li and Z. B. Xiao. "Research progress on analysis of flavor compounds in baijiu." Journal of Food Science and Technology 39 (2021): 23-31+90. https://kns.cnki.net/kcms2/article/abstract?v=6TwuVQQ8bf_UJMFzt5BcirQdlwhph5tKU90dJciXInj3JxrC4X3CxiOa_mhlatYSLsbeAHJms31lnMs1Z1EPCmfnN8QDx4l4AnN56BgBAJEstYMzFNQI2JfMDYGLf5oZ5_iqm8kVGUlOamjre66Necowh1F-DUj_fGQmwSXJeAdUILKMNacvIBCUGZ01U4IBPjIq02TEQrk=&uniplatform=NZKPT&language=CHS.

- Xiao, Z., D. Yu, Y. Niu, N. Ma, J. J. F. Zhu and F. Journal. "Characterization of different aroma-types of chinese liquors based on their aroma profile by gas chromatography–mass spectrometry and sensory evaluation." 31 (2016): 217-27. [CrossRef]

- Wang, Z., W. J. Hao, J. W. Wei, M. Q. Huang, X. A. Zeng, Y. Wang, J. H. Wu and B. R. Chen. "Unveiling innovation in aroma attribute evaluation of niulanshan baijiu: An advanced exploration of two different processing methods via food sensory omics and penalty analysis." Food Chem X 19 (2023): 100852. <Go to ISI>://WOS:001106569900001. [CrossRef]

- Ding, L. J., Y. Tang, Y. X. Zhao, D. Xun, T. Wang, L. Guo and R. Wang. "Research status of important esters in baijiu and their sources." Liquor-Making Science & Technology (2024): 91-100+07. https://link.cnki.net/doi/10.13746/j.njkj.2023104. [CrossRef]

- Xu, Y., Q. Wu, W. L. Fan and B. F. Zhu. "The discovery & verification of the production pathway of tetramethylpyrazine(ttmp) in chiese liquor." Liquor-Making Science & Technology (2011): 37-40. https://kns.cnki.net/kcms/detail/52.1051.TS.20110611.0752.001.html. [CrossRef]

- Zhang, M., Z. Tian, J. P. Wei and T. L. Yue. "Analysis of volatile flavor compounds in 6 flavor types of baijiu based on gas chromatography-ion mobility spectrometry and solid phase microextraction-gas chromatography-mass spectrometry." Journal of Food Safety & Quality 14 (2023): 226-35. [CrossRef]

- Yu, J. Y., G. L. Liu, W. D. Bai, Y. T. Fei, L. Z. Ai, J. S. Yu and L. C. Wang. "Research progress on rice-flavor baijiu." China Brewing 40 (2021): 29-32. https://kns.cnki.net/kcms2/article/abstract?v=MBTPQIn9ZKE6rjLmVTnx0wlwls9B1aXqTGZl79g0z-Dn73V7K7iZYojn_HtU1J2Hvh5c0ssyjM1TecwAWw_th01HnerT7TtK5r7SboJzleOYLNGKXFYzLAb1GrItVsZOHRmsewUICpt1vIlEzkGoo0Yrli6mTdtp7xxgSjQyAh4EuppdftJL1pcjQFSc5hCdrF1EaWyL_ZI=&uniplatform=NZKPT&language=CHS.

- Tang, P., G. M. Shan Qi, L. Wang, F. Wang, C. W. Li and J. Lu. "A review of research methods in baijiu flavor chemistry and recent progress in the flavor chemistry of maotai-flavored baijiu." Food Science 41 (2020): 315-24. https://link.cnki.net/urlid/11.2206.TS.20191115.1342.012.

- Miao, K. C., M. M. Zhang, Q. Z. Zhao, Z. Y. Lv, X. F. Lv and G. H. Ren. "Influence of mixed application of functional fuqu on the production of zhimaxiang baijiu." Liquor-Making Science & Technology (2024): 74-82. https://link.cnki.net/doi/10.13746/j.njkj.2024403. [CrossRef]

- Yang, S., Y. H. Luo, J. Zhang and R. Hou. "Simultaneous determination of 12 kinds of pyrazine compounds in different vintages of maotai-flavor baijiu by high performance liquid chromatography." Journal of Food Safety & Quality 15 (2024): 220-29. https://link.cnki.net/doi/10.19812/j.cnki.jfsq11-5956/ts.20240328003. [CrossRef]

- Chen, H., Y. X. Hou, H. Huang, Y. Sun, Y. S. Wu, J. X. Hong, D. R. Zhao, J. Y. Sun, M. Q. Huang and B. G. Sun. "Anchoring of quality variance factors and uncovering its influence on the flavor quality of bcsgb during aging process of sun-exposure." Int. J. Food Prop 26 (2023): 3445-64. <Go to ISI>://WOS:001128305600003. [CrossRef]

- Yu, Y., Y. Nie, S. Chen and Y. Xu. "Characterization of the dynamic retronasal aroma perception and oral aroma release of baijiu by progressive profiling and an intra-oral spme combined with gc * gc-tofms method." Food Chemistry 405 (2023): 134854-54. <Go to ISI>://FSTA:2023-04-Hl3406. [CrossRef]

- Wang, N. X. X., X. Li, Y. L. Huang, Y. L. Wang, H. M. Lai, M. L. Yang, C. W. Tang, L. H. Ge and N. Zhao. "Advances in the application of machine learning to microbial structure and quality control of traditional fermented foods." Science and Technology of Food Industry (2023): 1-13. https://kns.cnki.net/kcms/detail/11.1759.TS.20231110.1123.002.html. [CrossRef]

- Wang, Y. T., H. B. Ren, W. Y. Liang, X. Jin, Q. Yuan, Z. R. Liu, D. M. Chen and Y. H. Zhang. "A novel approach to temperature-dependent thermal processing authentication for milk by infrared spectroscopy coupled with machine learning." J Food Eng 311 (2021): 1-9. <Go to ISI>://WOS:000687724700015. [CrossRef]

- Guo, X. L., X. G. Gao, J. Jia and X. L. He. "Identification of coffee flavor by gc-ims." Analytical Instrumentation (2021): 16-21. https://kns.cnki.net/kcms2/article/abstract?v=b4E8SuETvlLlk5-Dlhq7r0i-5Irm-gJxwoGUvAZnyKc5MPROhJnYCBYxTeQHpEKRDv0H1xjP-npaB7GKLuIT6W04Gre4-I9lKhYf5zIK5oHxlFDy-rdZelARBYMjjbiKefPR_T4r3u4=&uniplatform=NZKPT&language=CHS.

- Zhou, R., Q. Yuan, X. Y. Jin, Y. Zhang, M. B. Chen and S. L. Fang. "Analysis of aroma components of strong-sauce-flavor aged baijiu." China Brewing 39 (2020): 137-43. https://kns.cnki.net/kcms2/article/abstract?v=6TwuVQQ8bf-CO6olU84NNrlIYbCFeemWMkboMHkFV-uf7Fu0c7fSKC7jLAYyN0agFkMOyYK-BHhMU5OH62qHuDP19OPTCO8xyMoSD4fcXw0fnGsD72MMvnGvvPb0grX0qqTPIyn6hOt4k5iuNNVCs6ITjqHcSgDtsO0wAmcIy-JeZNj2bbmL24ClsW0bvs5xjO_w2isqSvc=&uniplatform=NZKPT&language=CHS. [CrossRef]

- Zhou, R., Q. Yuan, Y. Xia, Y. L. Zheng and S. L. Fang. "Application of electronic nose technology in distinguishing the strong-sauce-flavor aged baijiu." China Brewing 39 (2020): 65-69. https://kns.cnki.net/kcms2/article/abstract?v=6TwuVQQ8bf8GlyqfG2nPJGspFDxoXw-zFNjw5mgvMYcBJder5jc0YYP0NiXoFSFSGtFB9kjlgzbGuHL_h2X4SCM3arxjZGiTJs0HWfXGXLeqYFfOEO85gf13scor4BDYCsNNCiC5Kc02Xtk1He_Wqo8Iu5nbG8CgMY6RLBOm36u7omNQdVd8WlrtR6g75uQbeUU79sJpFyc=&uniplatform=NZKPT&language=CHS.

- Li, T., J. Wang, B. Z. Xu, H. B. Sun, H. Q. Liu, D. Q. Wang, Y. Shen, J. H. Wu, J. L. Zhang, M. Q. Huang, et al. "Comparative analysis of the differences among langya flavor baijiu and strong and soy sauce flavor baijiu by targeted flavor analysis." J Food Compost Anal 122 (2023): 105479. https://www.sciencedirect.com/science/article/pii/S0889157523003538. [CrossRef]

- Li, Q. S. and H. Y. Fan. "Discussion on the origin of flavoring substances and healthcare substances in dongjiu." Liquor-Making Science & Technology (2020): 125-30. [CrossRef]

- Li, T. Y., W. P. Li, L. X. Tian, Z. J. Liu, Z. Guo and Q. C. Hou. "Quality difference of twelve flavor types baijiu of china based on bionics technology." China Brewing 41 (2022): 39-44. https://kns.cnki.net/kcms2/article/abstract?v=b4E8SuETvlIYQhIfFOx0EpG11f1E-rzxNvQ_3ZGYZ315xrnO57lr2_CEfMp1v2OOTtxrZkAYHouJ6iUd6pefYyWeSy8r-Tu2APTBdOSFLceFNMZGw22WONGielHFJtMITXlpRGZdcYA=&uniplatform=NZKPT&language=CHS.

- Wu, S. W., P. Lin, Z. H. Ye, S. Cai and Q. H. Li. "Construction of flavor wheel of te-flavor baijiu and description of typical sensory characteristics." China Brewing 40 (2021): 148-53. https://kns.cnki.net/kcms2/article/abstract?v=b4E8SuETvlKbdz9rFlVTJYo3XSSo7KoU0njg5XbJFNL9mmptYMXn0MunA-1lWmIEozGBpuc3W9J2sma245t1RXIYK0x8UKcuQp3VqOUyMUm4mN9k_krp6kik-Ec1Oc7oSq1oY6z-StY=&uniplatform=NZKPT&language=CHS. [CrossRef]

- Hu, J. H., J. X. Hu, Y. Q. Chen, J. Xia, M. C. He, J. J. Zhang, Z. P. Xu and X. L. Han. "Summary of the development of feng-flavor baijiu." Liquor Making 50 (2023): 11-18. https://kns.cnki.net/kcms2/article/abstract?v=b4E8SuETvlKiKgTtJD4HwjGtEFBU0JEfUqirkjLCSj68-QhScz-mCSFYBKh1P2e3EI8-tYbXHSz4iB-kwNBbf5T1WHckiOuFEoMuTXg7PVvaElTYVM-Kn7o4NyKCVzhxdmUiFQUI0tk=&uniplatform=NZKPT&language=CHS.

- Fu, G. C. "Studies on relationship between content of micro components and quality of feng-flavor liquou." Liquor Making (2008): 113-16. https://kns.cnki.net/kcms2/article/abstract?v=b4E8SuETvlJC0UOqnfVu82jHPcZJrQ5UVXoiJASE6hvapxswgHtrKRkTrXyNDwiO0MP9aD4dWs2vX5AE0t71JBNK2dv5bzd485qg5mr1pWcLwg9j9KElw7Ev57poPHyk&uniplatform=NZKPT&language=CHS.

- Gao, C. Q. "Typical technological characteristics of sesame flavor baijiu: A review." Liquor Making 49 (2022): 3-15. https://kns.cnki.net/kcms2/article/abstract?v=6TwuVQQ8bf9hKLkdUlv4yRaDu69GGVAvlQSgdgKQYxufnoBv_4cwOVb-1yhEh0JDTMRE7bnk_-bFj8k7NT2rKkEeFmNG5BanQlWNJxW5nvRktOKuihTDrnpvraw518Ol614sjJoRi5vuBB5KjazX9C8v3bU42ubkwnZBgAQVP15r2Fo3VeydeZ7xrQyvdS2kGs6JiSndIBw=&uniplatform=NZKPT&language=CHS.

- Fan, H. Y., W. L. Fan and Y. Xu. "Characetrization of volatile aroma components in chinese chixiang aroma type liquor by gc-o and gc-ms." Food and Fermentation Industries 41 (2015): 147-52. https://kns.cnki.net/kcms/detail/11.1802.ts.20150302.0301.011.html. [CrossRef]

- Zeng, X. A., B. S. Zhang and S. J. Yu. "A study on the typical fragrane components of chi-xiang style rice wine." Journal of South China University of Technology(Natural Science Edition) (2001): 93-95. https://kns.cnki.net/kcms2/article/abstract?v=7P8mTOHD94HTABLRbQxNYNnGPGNKAbDjCyxuwVGOYiGDkKJYakyH1Du7WSnuX9TA665e5yiLjk9Fix281zdYv-_mvruqn_QLL_SsH7MgTkt2RvTrrpPK43oxEIMH2JSC&uniplatform=NZKPT&language=CHS.

- Shen, Y. F. Complete book of baijiu production technology. China Light Industry Press Ltd., 1998,.

- Chang, Y. T., Y. J. Luo, C. J. Qian, Y. T. Yang and X. M. Shi. "Analysis of relationship between flavor and quality of fuyu flavor baijiu by two comprehensive dimensional gas chromatography-mass spectrometry." Journal of Food Science and Technology, China 37 (2019): 64-93. <Go to ISI>://FSTA:2020-06-Hl4341. [CrossRef]

- Chen, Y. C., J. Mao, Z. L. Zhou, S. Q. Zhan and W. M. Wang. "Research progress on brewing technology and flavor of fuyu-flavor baijiu." China Brewing 43 (2024): 1-6. https://kns.cnki.net/kcms2/article/abstract?v=6TwuVQQ8bf-Iulk_iB_NE7dpb9nSzz8u877jrmMaxAqpcawPsnLJuOnOm6Ee0BJyK-GQqpYpssfNePHIUs9vNGf7Zo4j4qjiV0VtSWFveXasczq7471JBlIZAwxUNfb2xtuns7PJuMlKuJN8DBXlWjv00FmhN7Y5oYMtusFZwwX_ljevd2m7jXm3_Ag9Q_1J&uniplatform=NZKPT&language=CHS. [CrossRef]

- Zhang, W., F. Y. Mou, M. Chen, X. Y. Dong, X. Chang, S. L. Fang and M. B. Chen. "Research progress on propionic acid bacteria and application in baijiu brewing." China Brewing 43 (2024): 1-6. https://kns.cnki.net/kcms2/article/abstract?v=_dQyPpHgqRv77x_FMVNqqT_XjaII7RW19HnNke_6kvTiox1pTPO9uOshMt_ah_7dBZApdSOR9XPER_KVArJpgVEE8ify-nDvgoa4C6PNOWKNDHgIhCYDlw1LUt43igrMkpl45ThDr5lc4focpLnGLqbfpANw-LanCgDq3BSYj8iBpWMFifkF1zeMK2VeZT0Fxliwn1I9sGE=&uniplatform=NZKPT&language=CHS. [CrossRef]

- Yu, H. Y., T. Xie, J. R. Xie, L. Z. Ai and H. X. Tian. "Characterization of key aroma compounds in chinese rice wine using gas chromatography-mass spectrometry and gas chromatography-olfactometry." Food Chem 293 (2019): 8-14. <Go to ISI>://WOS:000469331900002. [CrossRef]

- Ye, L., S. Q. Chen, H. Yin, Z. Y. Ding, X. W. Zheng, H. Zhao, B. Yu and X. Q. Jin. "Relationship between flavor and quality of fuyu flavor baijiu and its flavor source." China Brewing 42 (2023): 1-6. https://kns.cnki.net/kcms2/article/abstract?v=_dQyPpHgqRtUJ3e0VHtMvDooVhcgeQa9deY5F2lAYkZWvy3fPMX6VRgWKxa9OV9p8_uE3KaZlc2UZnmFQdaRodf-ZwdxfJZn4yB48h1uAvsVN9P3ayw-A2PzZ2hN-dNkdTag4Ca6v4VrExfoh7HMy3ejPVn68tM99HUbASv1NbIhXPXQDR77M8pSIrN8hgYqawH4LiUWE64=&uniplatform=NZKPT&language=CHS. [CrossRef]

- Chen, P. P., Y. Liu, J. H. Wu, B. Yu, H. Zhao, M. Q. Huang and F. P. Zheng. "Sensory-directed decoding of key aroma compounds from jiugui-series baijiu, the representative of fuyu-flavor-type baijiu (fftb)." J Food Compost Anal 114 (2022): 104799. https://www.sciencedirect.com/science/article/pii/S0889157522004173. [CrossRef]

- Zhen., S. X., D. J. Wei., Z. Fan. and H. Pan. "Analysis of volatile aroma components of tianlongquan rice-flavor liquors by headspace solid phase microextraction-gas chromatography mass spectrometry." Liquor Making 48 (2021): https://kns.cnki.net/kcms2/article/abstract?v=WOgJpqC0z4aLmhkY_WOO2qxyDGaGJxrtO_r9GUDKc5RoPw6rfnBwDguzrrNSLB1xG7_7eZJschC8A2A1sn6dRFTEhJEqUqKZH4VHJ6TTxNfYi12fkpGt2NIogzwaVrsaUlw_gsfTyoqQQIpnjWL7Y1NKYJJ8Zaai&uniplatform=NZKPT&language=CHS. https://kns.cnki.net/kcms2/article/abstract?v=WOgJpqC0z4aLmhkY_WOO2qxyDGaGJxrtO_r9GUDKc5RoPw6rfnBwDguzrrNSLB1xG7_7eZJschC8A2A1sn6dRFTEhJEqUqKZH4VHJ6TTxNfYi12fkpGt2NIogzwaVrsaUlw_gsfTyoqQQIpnjWL7Y1NKYJJ8Zaai&uniplatform=NZKPT&language=CHS. [CrossRef]

| No. | Abbreviation | Flavor types | Ethanol concentration/ %v/v |

|---|---|---|---|

| 1 | NX | nongxiangxing | 52 |

| 2 | NX | nongxiangxing | 39 |

| 3 | NX | nongxiangxing | 52 |

| 4 | NX | nongxiangxing | 52 |

| 5 | NX | nongxiangxing | 42 |

| 6 | JX | jiangxiangxing | 53 |

| 7 | JX | jiangxiangxing | 53 |

| 8 | JX | jiangxiangxing | 53 |

| 9 | JX | jiangxiangxing | 53 |

| 10 | JX | jiangxiangxing | 46 |

| 11 | QX | qingxiangxing | 53 |

| 12 | QX | qingxiangxing | 53 |

| 13 | QX | qingxiangxing | 52 |

| 14 | CX | chixiangxing | 53 |

| 15 | TX | texiangxing | 52 |

| 16 | FYX | fuyuxiangxing | 54 |

| 17 | DX | dongxiangxing | 54 |

| 18 | ZMX | zhimaxiangxing | 53 |

| 19 | LBGX | laobaiganxiangxing | 67 |

| 20 | FX | fengxiangxing | 52 |

| 21 | JXX | jianxiangxing | 42 |

| 22 | MX | mixiangxing | 52 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).